A novel polysilicate green fluorescent powder doped with rare earth ions for near-ultraviolet excitation white light LED and its preparation method

A technology of green fluorescent powder and rare earth ions, which is applied in the direction of luminescent materials, chemical instruments and methods, can solve the problems of low color rendering index of devices, lack of red light components, unfavorable indoor lighting, etc., and achieve high luminance of green light, suitable for Mass production, good effect of color purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

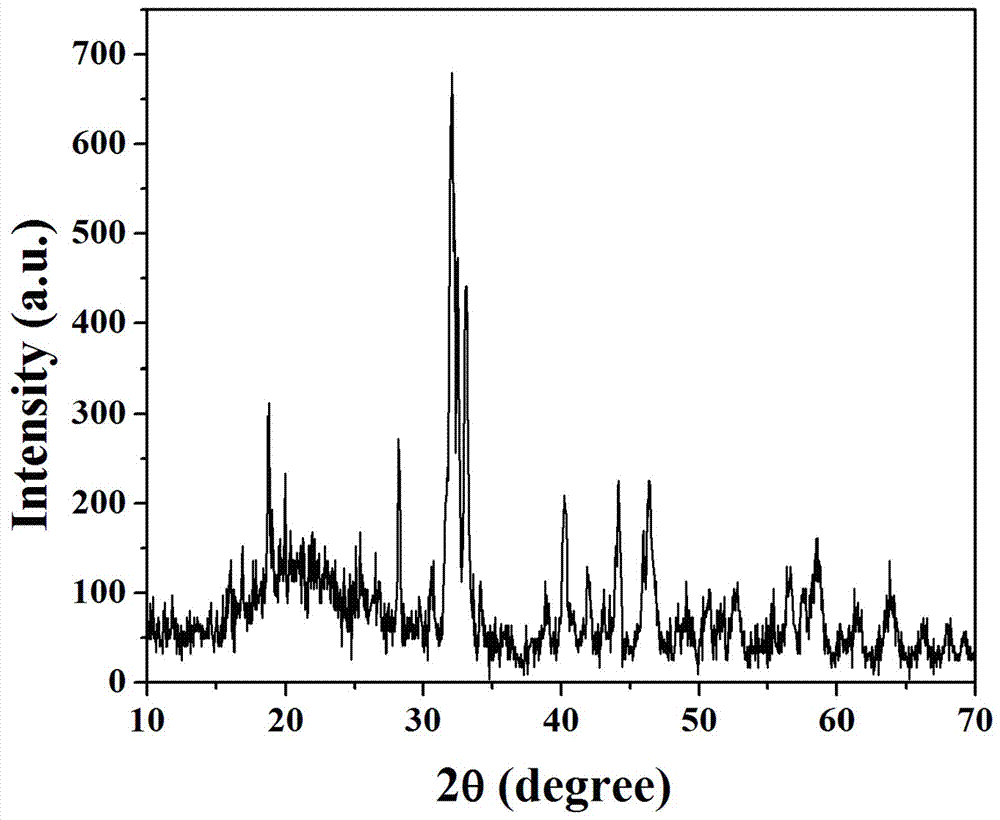

Embodiment 1

[0028] (1) According to the stoichiometric ratio, weigh 0.4312g Na 2 CO 3 , 0.4517g Y 2 o 3 , 0.4807g SiO 2 and 0.5995gSrCO 3 , and put them in a medium agate mortar accordingly;

[0029] (2) adding dehydrated ethanol whose quality is 2 times of the raw material quality to the above mixture, then grinding for 2 hours to make the reactants mix uniformly;

[0030] (3) Place the uniformly ground mixture in an oven and dry it at 80±5°C for 5 hours, then grind the obtained mixture again and put it into an alumina crucible;

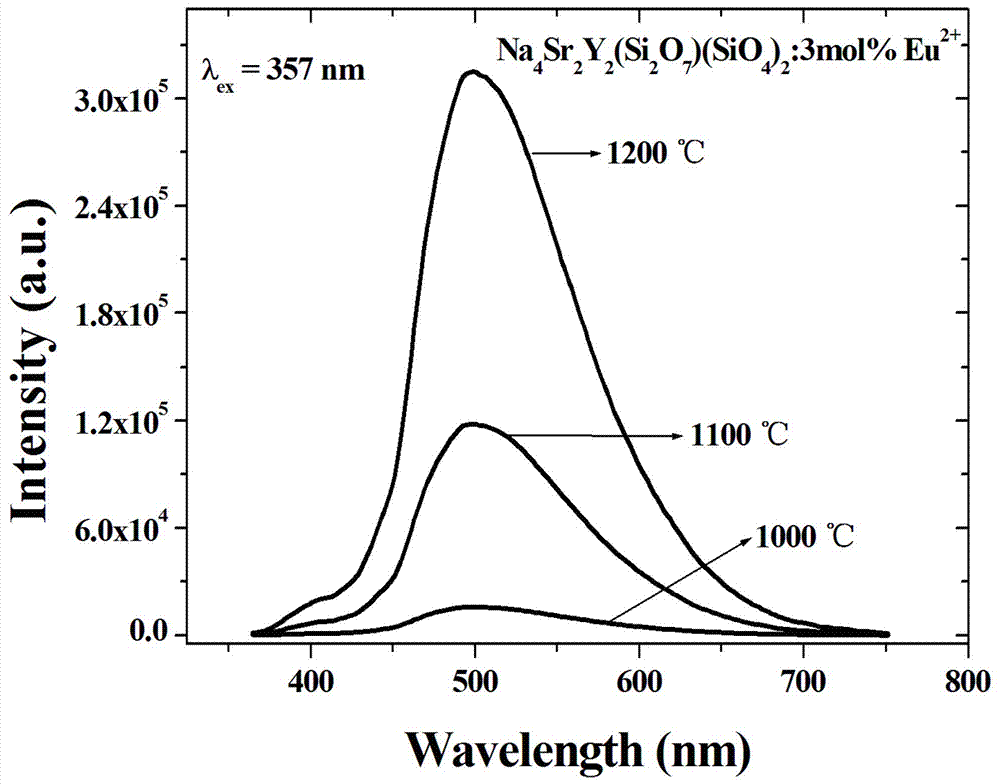

[0031] (4) Put the above-mentioned alumina crucible loaded with raw materials into the constant temperature zone of the high-temperature sintering furnace. The high-temperature sintering furnace is first raised to 800±10°C (preferably 800°C) for sintering, and the temperature is kept constant for 5 hours. After the high-temperature furnace is cooled to room temperature, Take out the reaction raw materials and grind them again for 30 minutes. Finally, put ...

Embodiment 2

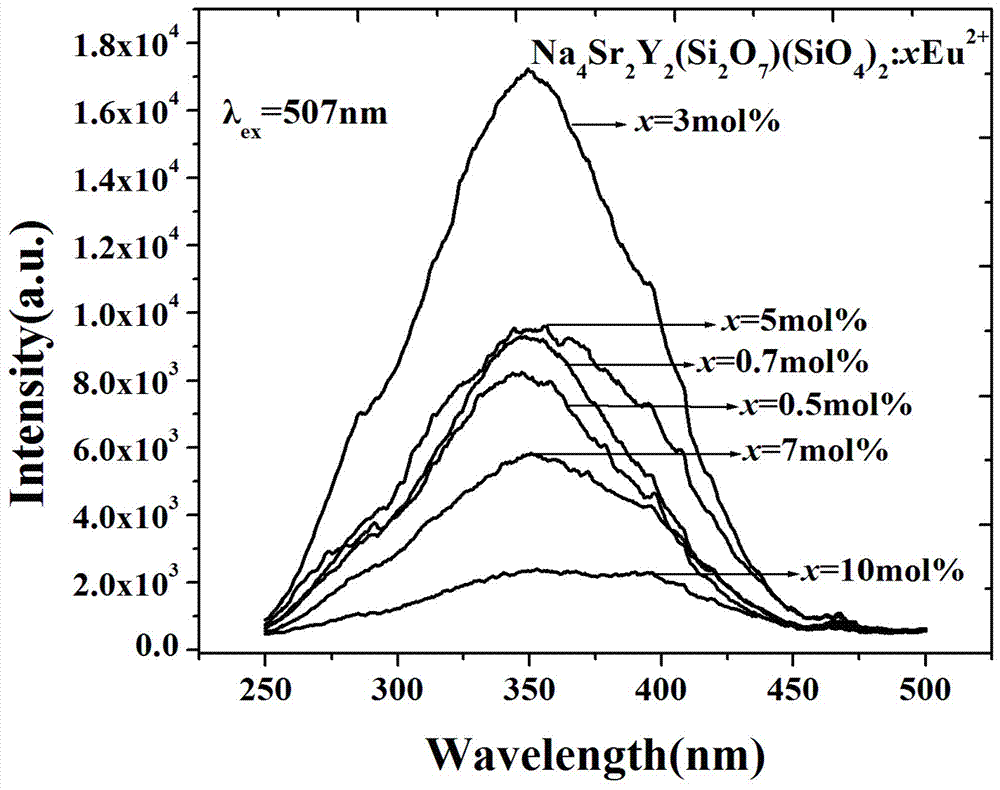

[0033] According to the stoichiometric ratio, weigh 0.4312g Na 2 CO 3 , 0.4517g Y 2 o 3 , 0.4807g SiO 2 , 0.5956gSrCO 3 and 0.0011g Eu 2 o 3 , and put into the medium agate mortar accordingly, all the other conditions are the same as embodiment 1, obtain the Na of the present invention after testing 4 Sr 2 Y 2 (Si 2 o 7 ) (SiO 4 ) 2 :0.3mol%Eu 2+ Phosphor.

Embodiment 3

[0035] According to the stoichiometric ratio, weigh 0.4312g Na 2 CO 3 , 0.4517g Y 2 o 3 , 0.4807g SiO 2 , 0.5950gSrCO 3 and 0.0018g Eu 2 o 3 , and put into the medium agate mortar accordingly, and all the other conditions are the same as embodiment 1, and the Na of the present invention is obtained after testing. 4 Sr 2 Y 2 (Si 2 o 7 ) (SiO 4 ) 2 :0.5mol%Eu 2+ Phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com