Patents

Literature

238results about How to "Guaranteed process requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machining process of thin-wall groove milling stainless steel part

The invention discloses a machining process of a thin-wall groove milling stainless steel part. The machining process of the thin-wall groove milling stainless steel part mainly comprises the following steps of heat treatment of a rough casting, rough machining, natural aging processing, subsequent rough groove milling, finish machining and finish groove milling. Through the design of a machining route, the machining process of the thin-wall groove milling stainless steel part reduces production of stress as much as possible, and effectively avoids deformation caused by stress concentration, thereby improving machining precision and the accuracy degree.

Owner:ANHUI YINGLIU ELECTROMECHANICAL

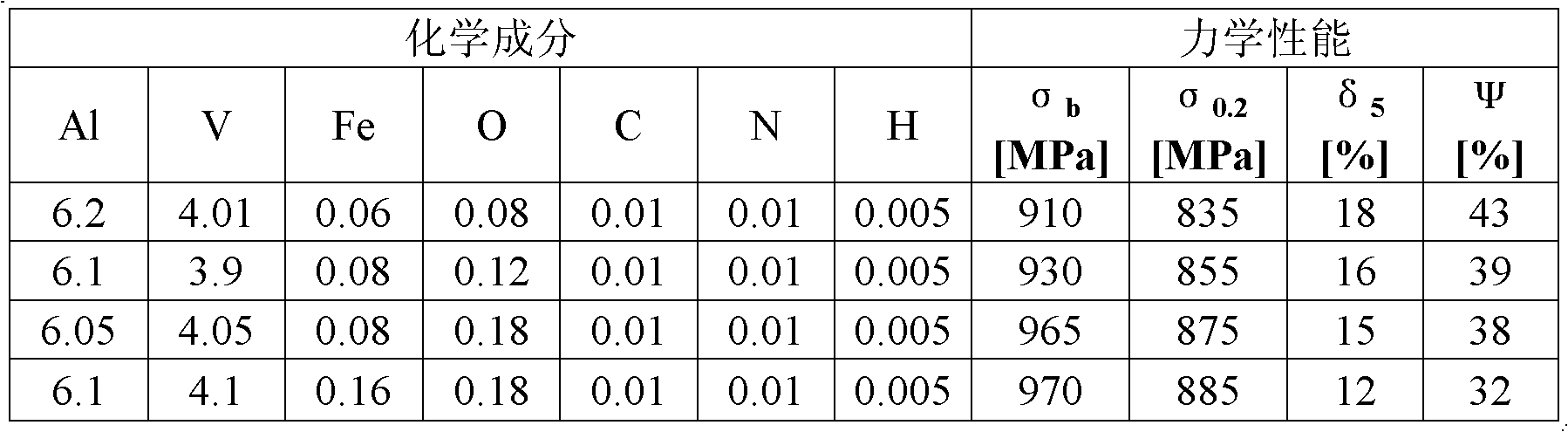

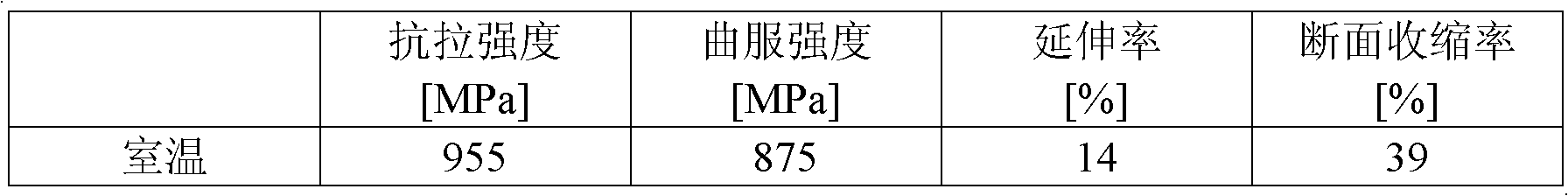

Method for processing TC4 titanium alloy into forged rings

InactiveCN101927312AGuaranteed process requirementsMeet the use requirementsHeating/cooling devicesHollow articlesElectrical resistance and conductancePunching

The invention relates to a method for processing TC4 titanium alloy into forged rings, comprising the following steps of: (1) raising the temperature of a titanium cast ingot to 1150-1200 DEG C in a natural gas heating furnace, and keeping the temperature for more than 180 minutes to ensure that the inner temperature and the outer temperature of the whole titanium cast ingot are consistent and uniform; (2) directly processing the titanium cast ingot into a square blank at the deformation rate of 70%-80% by utilizing an oil press; (3) sawing the square blank into small blanks by using a band saw; (4) heating and forging the small blanks for three times by utilizing a resistance heating furnace to form cakes; (5) punching in the centers of the cakes by using a puncher; (6) heating the hollow blanks to 950 DEG C, keeping the temperature for more than120 minutes, and then broaching by using a saddle; and (7) completely annealing at the temperature of 120-200 DEG C by adopting the alpha+beta / beta phase transformation point temperature of 985 DEG C, placing the blanks in the resistance heating furnace at the temperature below 500 DEG C, keeping the temperature of 785 DEG C for 90 minutes, and then cooling in the air. The titanium cast ingot is forged into qualified forged rings by using a reasonable forging process.

Owner:宝鸡市金盛伟业稀有金属有限公司

Processing process of automobile engine crank shaft

The invention provides a processing process of an automobile engine crank shaft. The process comprises the following processing steps of (1) blank forging; (2) coarse tuning: coarse turning of a main shaft neck and a connecting rod neck is carried out; (3) coarse drilling: coarse drilling of a main oil hole is carried out; (4) annealing heat treatment; (5) semi-finish turning: semi-finish turning is carried out on the main shaft neck and the connecting rod neck; (6) tempering; (7) fine turning: fine turning is carried out on the main shaft neck and the connecting neck; (8) coarse and fine grinding: coarse and fine grinding is carried out on the main shaft neck and the connecting rod neck; (9) hole drilling: coarse drilling, expanding and reaming of balance block installing holes and inclined oil holes are carried out; (10) compounding reinforcing; (11) rolling processing: each processed hole is subjected to rolling pressing processing; (12): the main shaft neck and the connecting rod neck are subjected to polishing processing; (13) anti-rust processing; (14) inspection and packaging. The process solves three problems of low rigidity intensity, poor wear resistance and good lubrication performance in the existing automobile engine crank shaft production process, so that the finally produced crank shaft has the sufficient rigidity and intensity, good impact load bearing capability and good abrasion resistance and lubrication performance.

Owner:ANHUI JINQINGLONG MACHINERY

Precision shaping molds separating group processing method

InactiveCN101214530AGuaranteed process requirementsImprove processing pass rateFoundry mouldsFoundry coresEngineeringMechanical engineering

The invention relates to a splitting and assembling processing method for a fine forming die which leads about 30mm of a movable mould core blank and utilizes a linear cutting processing to divide into a plurality of equal parts, codes running numbers according to sequence and carries through plane furbishing and polishing processing on a cutting parting surface; then utilizes the radial actions of an anchor ear and trip bolt to fix the movable mould core; clamps and turns the locating devices at two ends and then utilizes a fine jig mill to process a datum hole; then utilizes a self-turning mode and adopts the modes that a floral disc and a mandrel are tightly cooperated and the mandrel is cooperated with the datum hole of the movable mould core in small clearance to carry through fine forming processing on the inner shape and outer taper of a product. The die forming product processed by the method has the advantages of large extent improving on the surface quality and dimension precision, completely qualified quality, no security hidden troubles, convenient processing. The processing equipment used has the advantages of simple structure and lower cost.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

Application of waterproof type emulsified olefin in use for production of fiberboard

A method to apply waterproof emulsified paraffin wax in fibreboard production includes emulsifying paraffin wax in water with emulsification additive to let paraffin wax solid content up to 40-50 % of being used as waterproofing agent, applying it in fibreboard production and drying all hydrophilic contents in emulsification agent off at drying process of 100-180 deg.C for achieving purpose of waterproof for fibre.

Owner:曾宪平

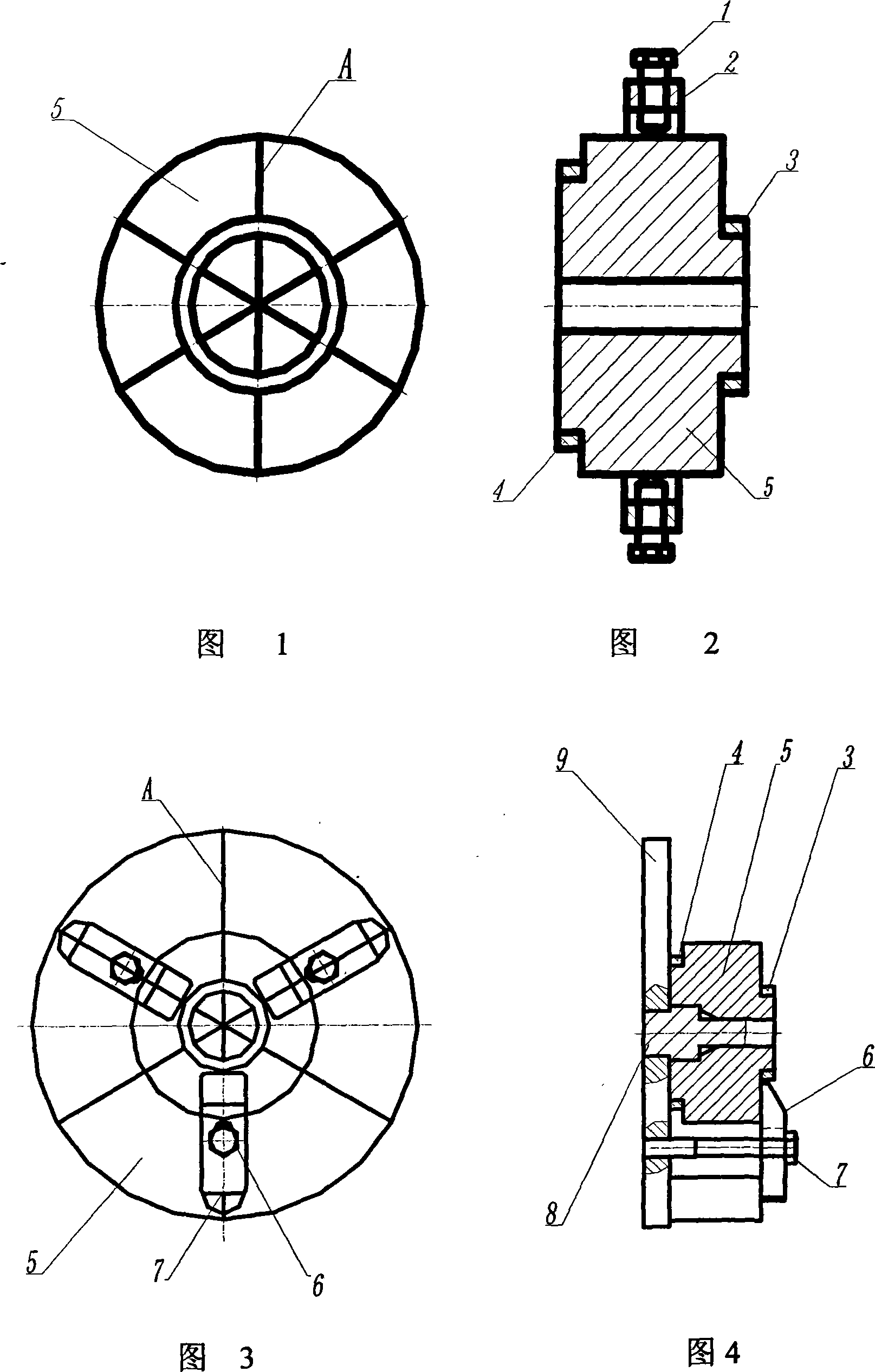

Anti-vibration strip component of steam generator of AP1000 nuclear power unit

ActiveCN102794608ASimple structureQuality assuranceNuclear energy generationNuclear power plant detailsNuclear engineeringRadiochemistry

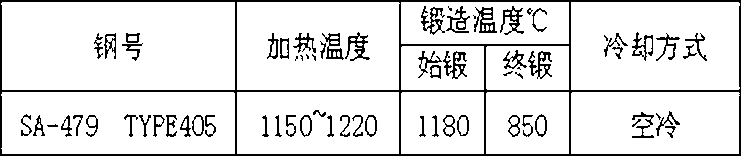

The invention discloses an anti-vibration strip component of a steam generator of an AP1000 nuclear power unit. The anti-vibration strip component comprises a V-shaped anti-vibration strip and two end caps respectively arranged on both ends of the anti-vibration strip, wherein the anti-vibration strip is made of a 405 stainless steel material, and the end caps are made from a 609 nickel-based alloy material. A preparation method for preparing the anti-vibration strip component comprises the following steps of: preparing the anti-vibration strip, preparing the end caps, bending, assembly the end caps, heading, checking, cleaning and packaging. According to the anti-vibration strip component of the steam generator of the AP1000 nuclear power unit provided by the invention, the structure is simple, the product quality conforms to precision requirements of the steam generator in a nuclear power plant about the anti-vibration strip, and the anti-vibration strip component is safer to use. According to the preparation method of the anti-vibration strip, through strict preparation steps, the technique requirements about the anti-vibration strip component of the steam generator in the nuclear power plant are ensured, the quality is ensured, and safety is improved.

Owner:丹阳市龙鑫合金有限公司

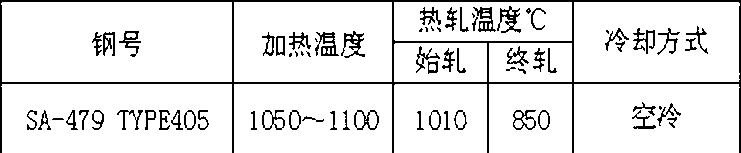

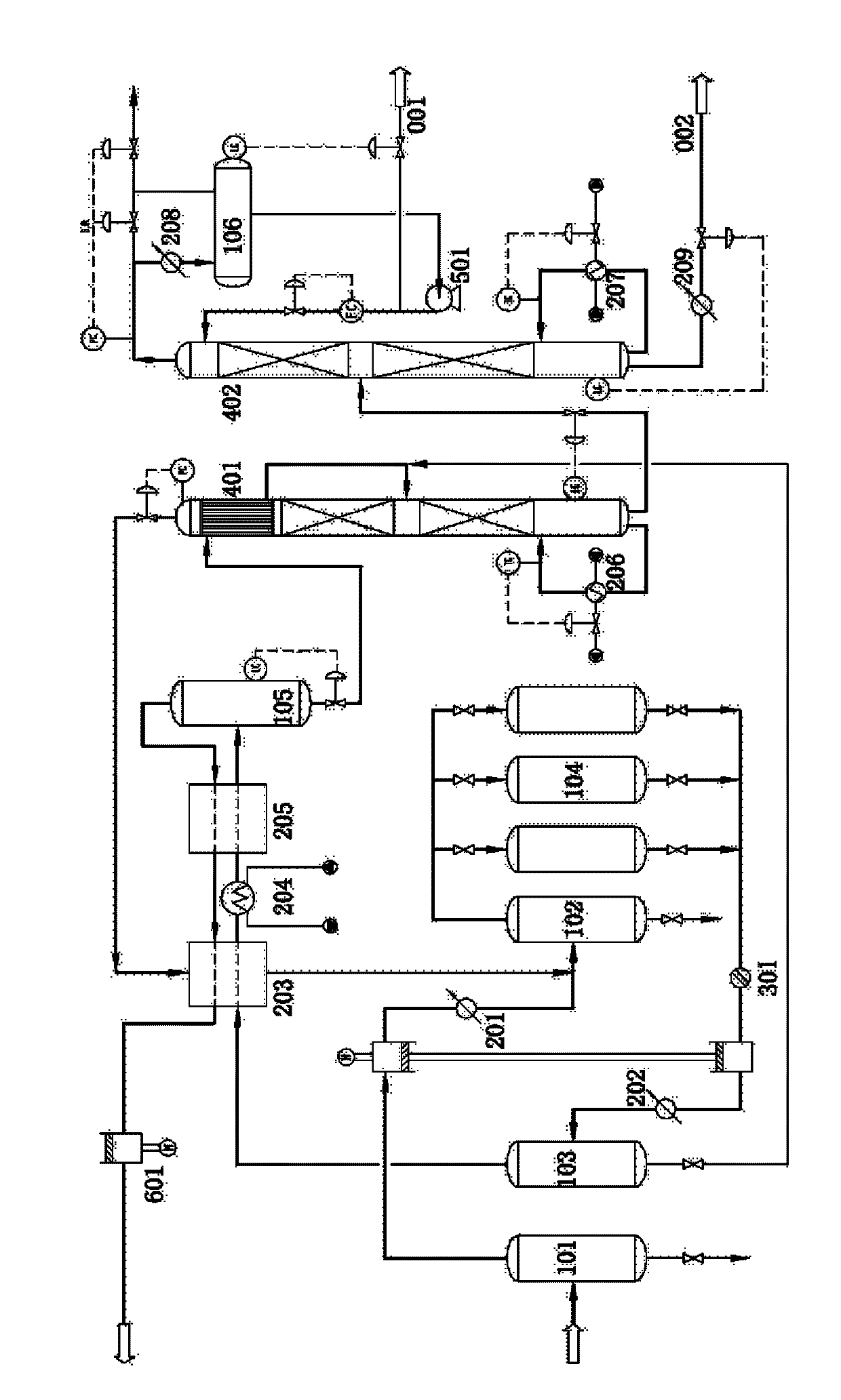

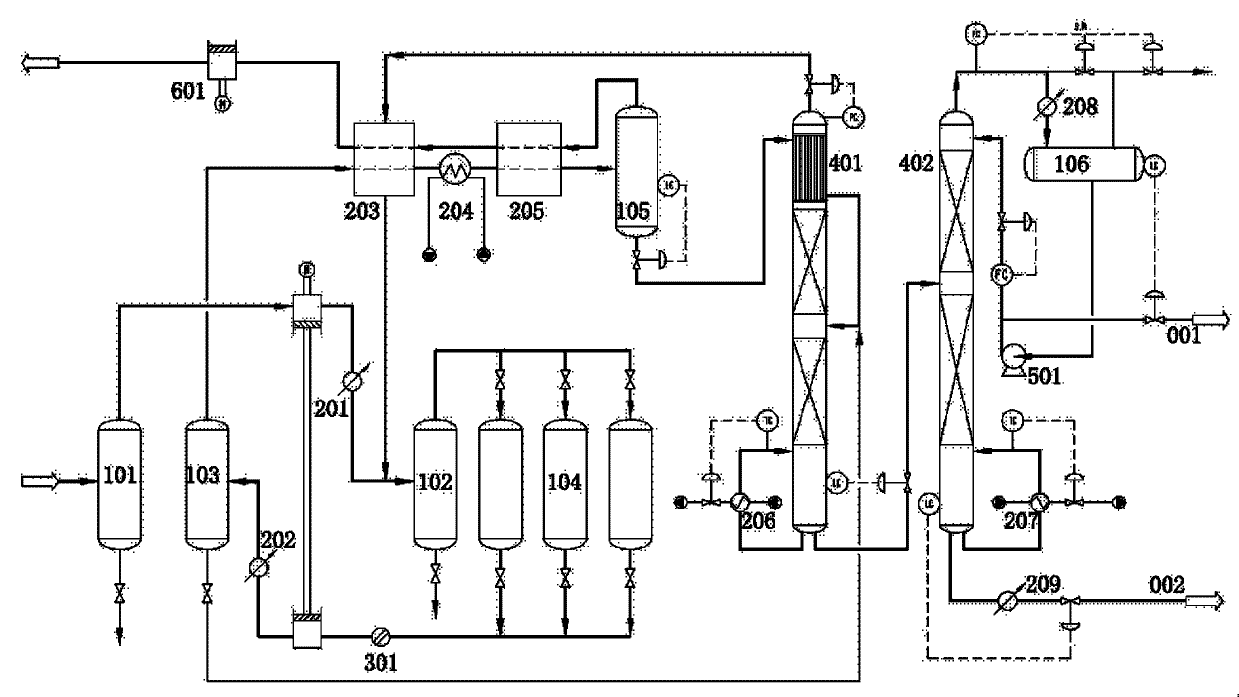

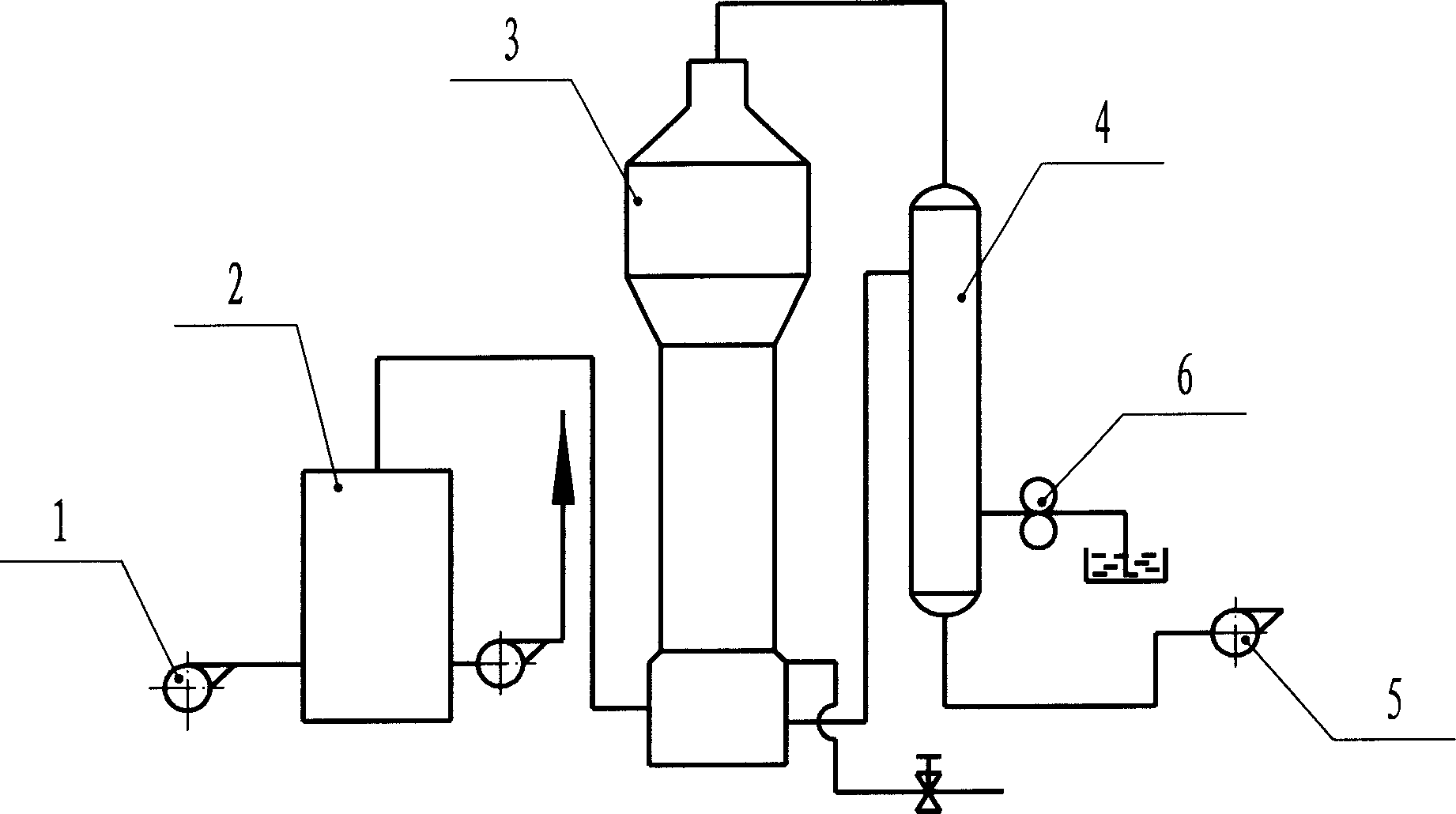

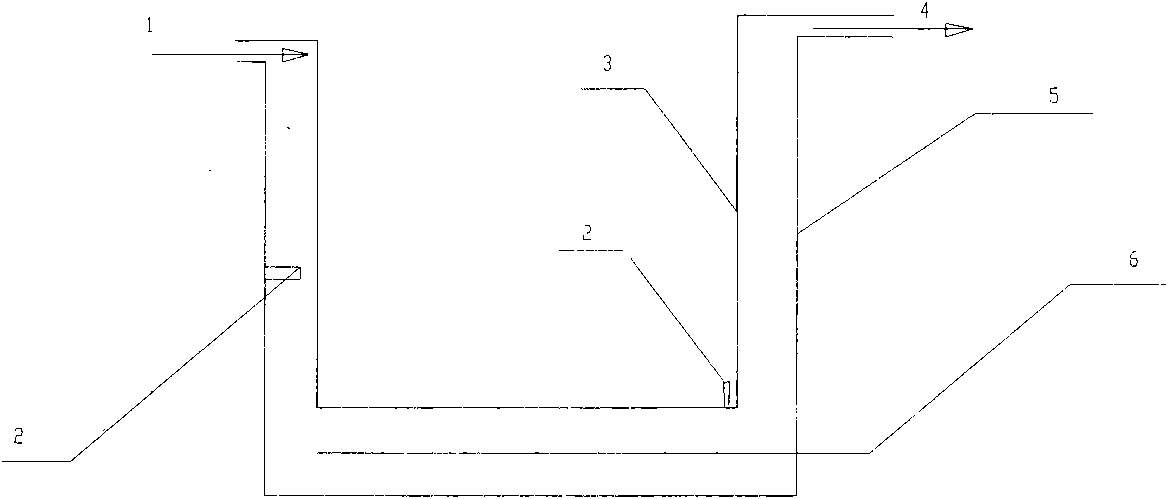

Feed gas processing device for natural gas

InactiveCN102168905ALarge operating rangeGreat operating flexibilitySolidificationLiquefactionSocial benefitsOperating energy

The invention provides a feed gas processing device for natural gases, which comprises a feed gas preseparator, a compressor, a refrigerating separator and a fractionating device which are connected in sequence. The feed gas processing device also comprises a CNG (compressed natural gas) compressor; the refrigerating separator and the fractionating device are respectively provided with a dry gas exhausting pipe; and the CNG (compressed natural gas) compressor is connected with the dry gas exhausting pipe of the refrigerating separator and the dry gas exhausting pipe of the fractionating device. The feed gas processing device is particularly suitable for processing the natural gas incapable of being fed into a gathering pipe network of far oil-gas fields or sporadic oil-gas wells, can greatly reduce investment, and can simultaneously reduce the operating energy consumption during the production process. The liquefied gas and stabilized light dydrocarbon produced by the feed gas processing device can be used as chemical raw materials and industrial or civil fuels; the compressed natural gas can be conveyed to cities and used as fuel for natural gas automobiles to replace gasoline and diesel used by urban automobiles; and the feed gas processing device greatly cleans urban environment, and has excellent economic benefits and social benefits.

Owner:北京中油联自动化技术开发有限公司

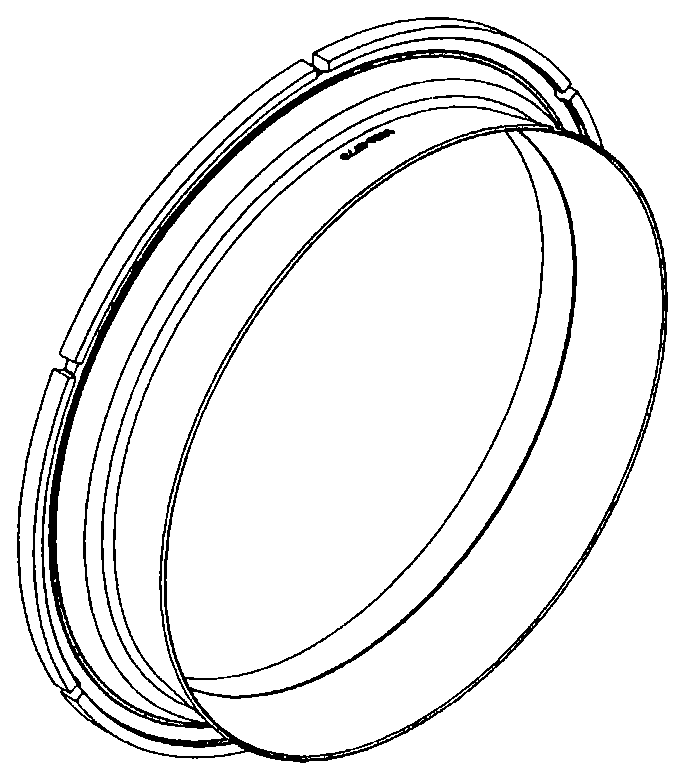

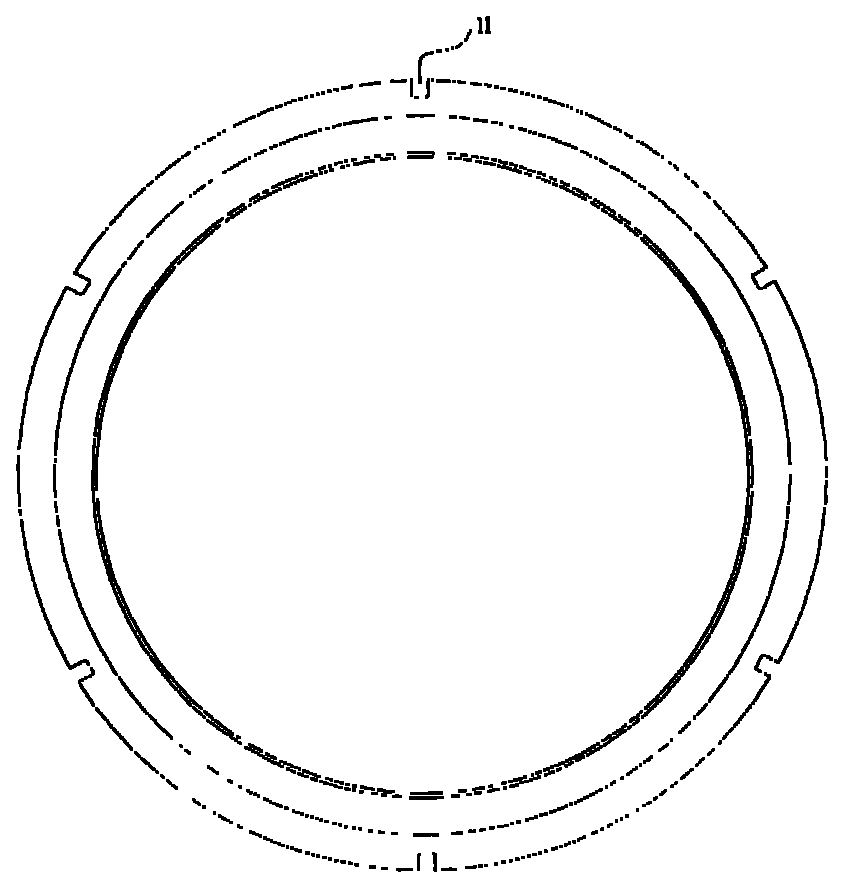

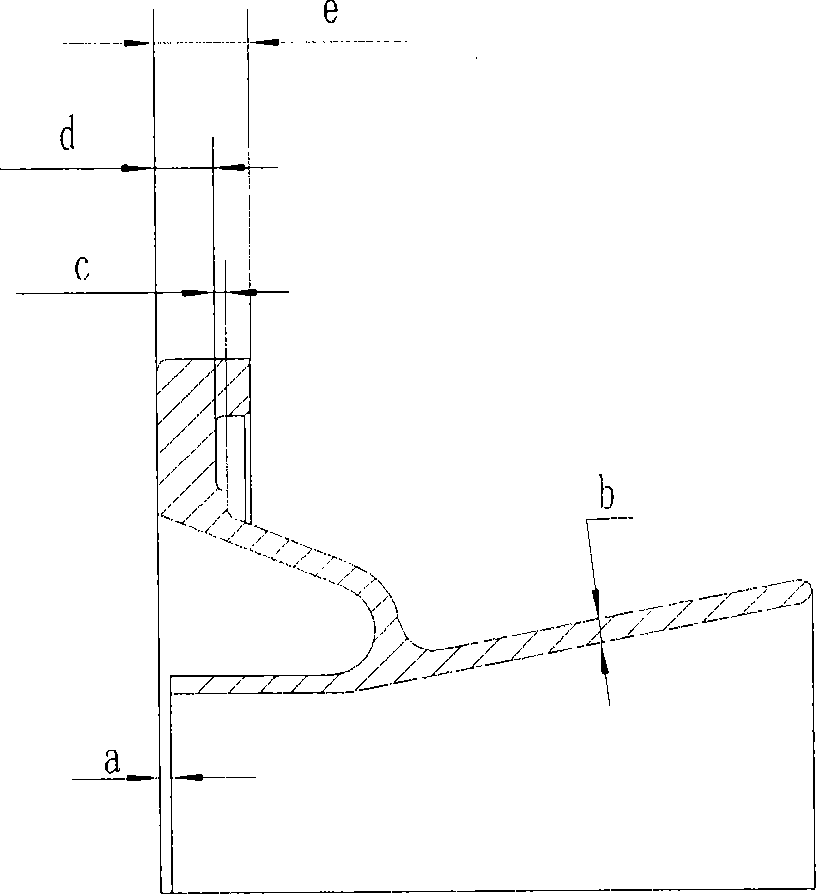

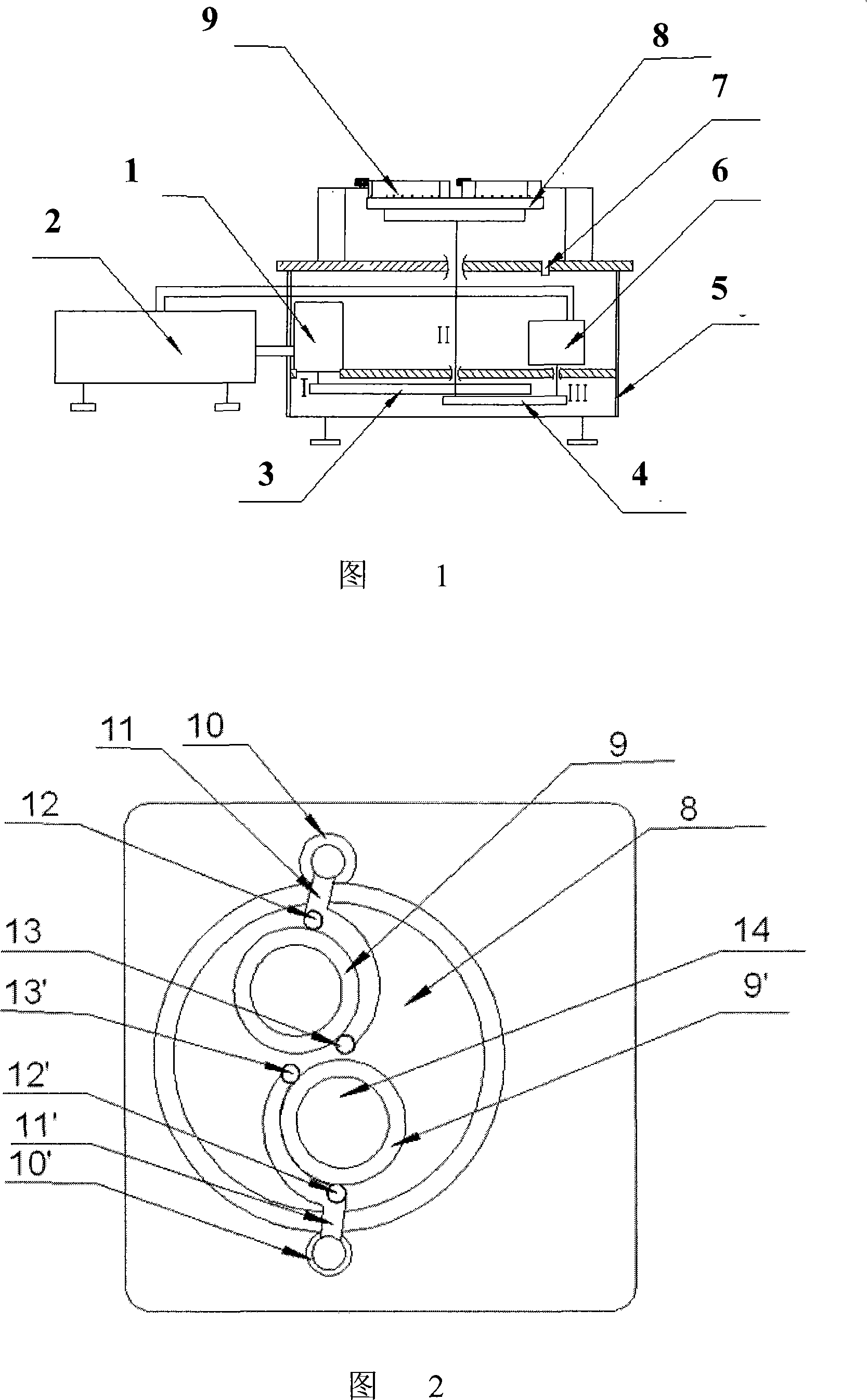

Trimming ring type intelligent super precision polishing machine

InactiveCN101148026AShorten the processing cycleHigh plane machining accuracyPolishing machinesGrinding drivesDrive motorIntelligent control

The intelligent precise polishing machine with one finishing ring consists of one frame, one polishing disc mounted on the frame through one spindle, one driving motor with output shaft connected to the spindle, one speed measuring mechanism connected to the spindle, and one intelligent control platform connected to the driving motor and the speed measuring mechanism. The intelligent precise polishing machine has also one finishing ring and one finishing ring holder, the finishing ring with one base disc for holding the workpiece is located over the polishing disc, and the finishing ring holder mounted on the frame has one middle arc segment not less 90 deg and two friction wheels in two ends for the finishing ring to be connected to. The present invention realizes the on-line trimming of the planar precision of the polishing disc to result in ver high planar processing precision and short processing period.

Owner:ZHEJIANG UNIV OF TECH +1

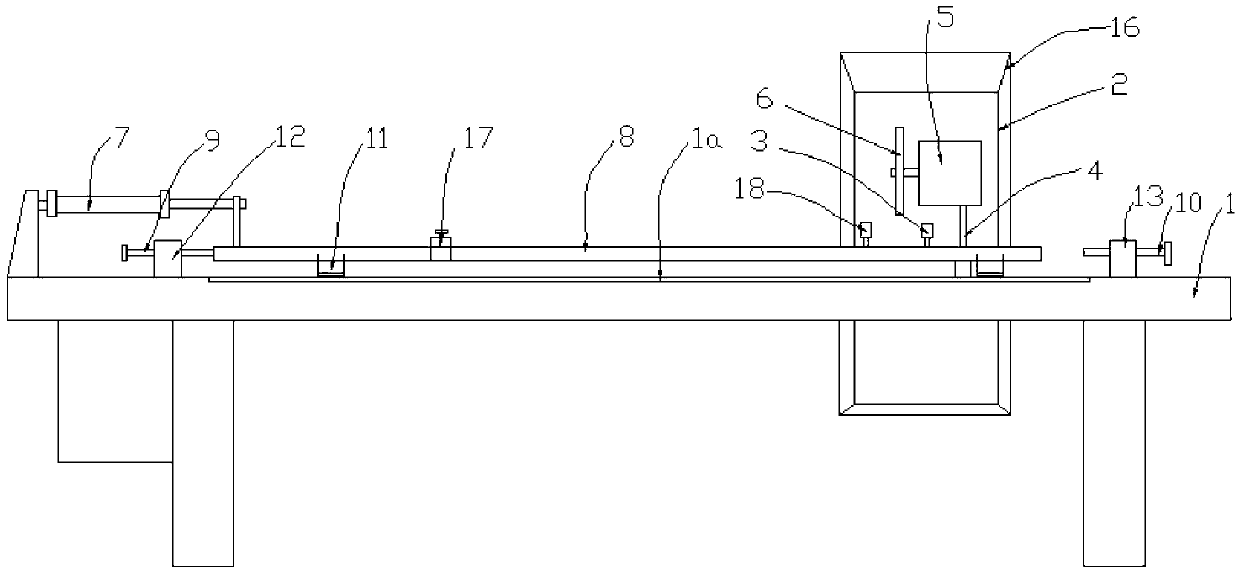

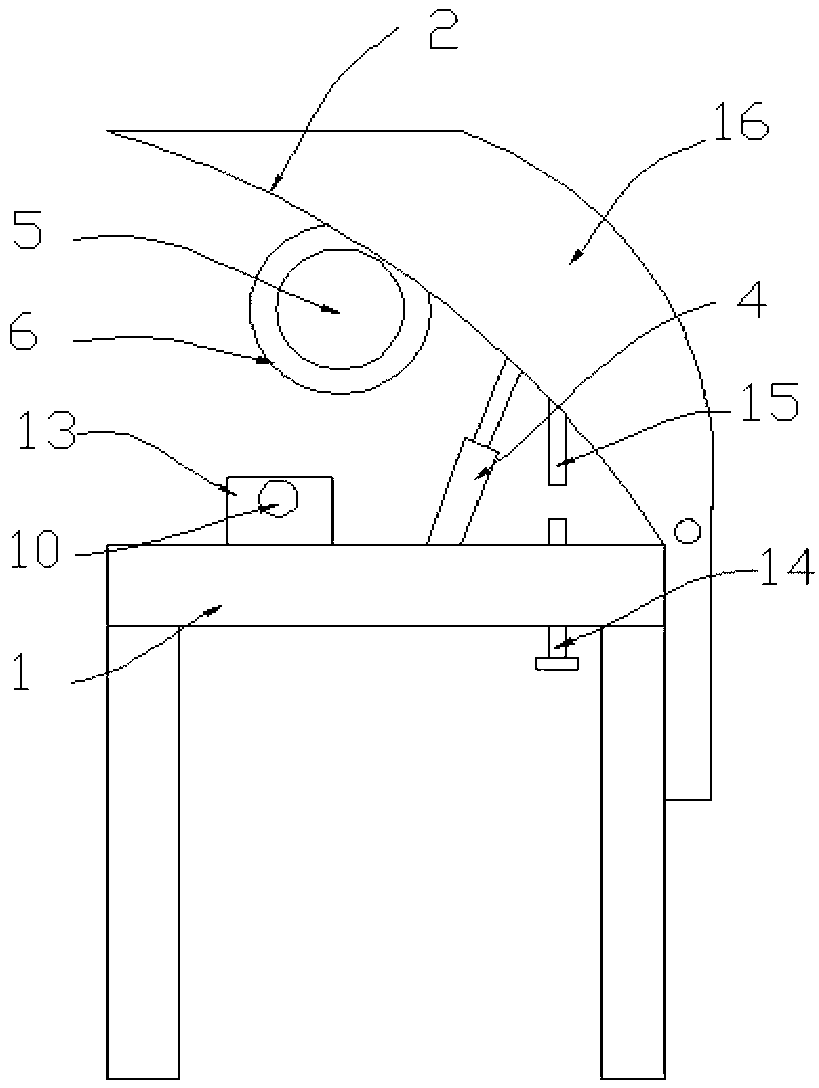

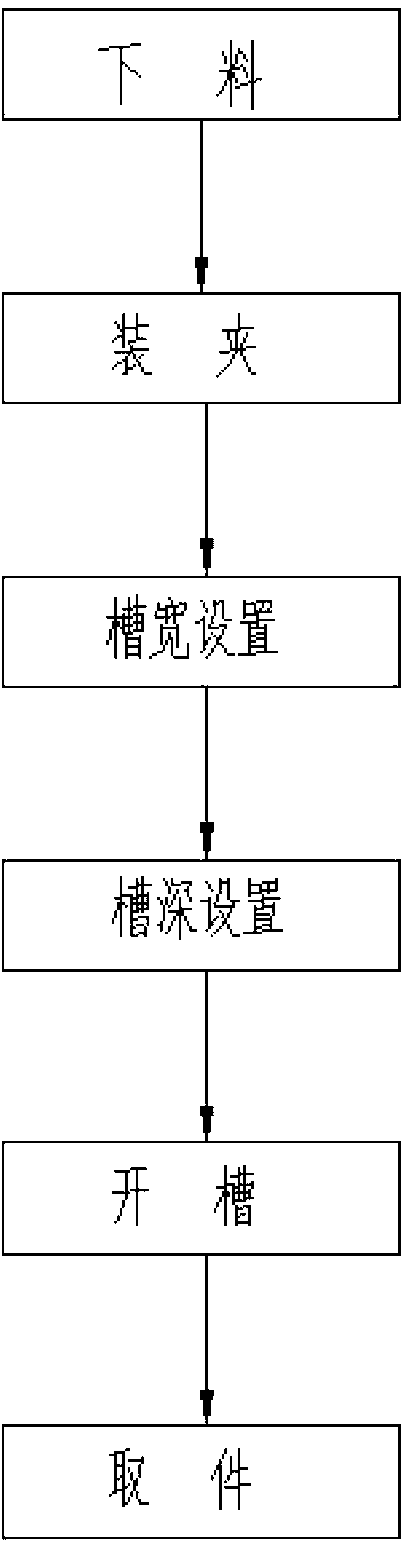

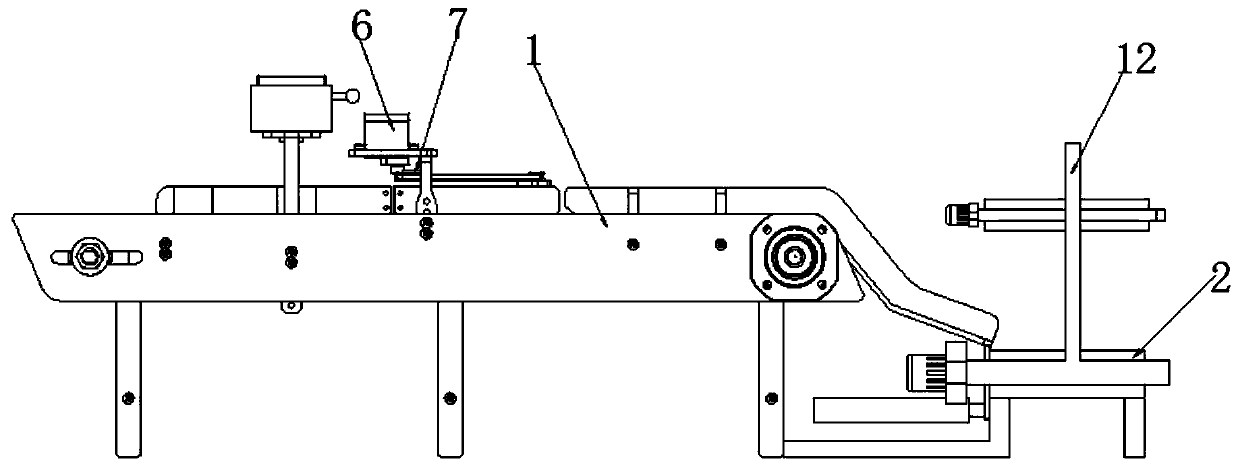

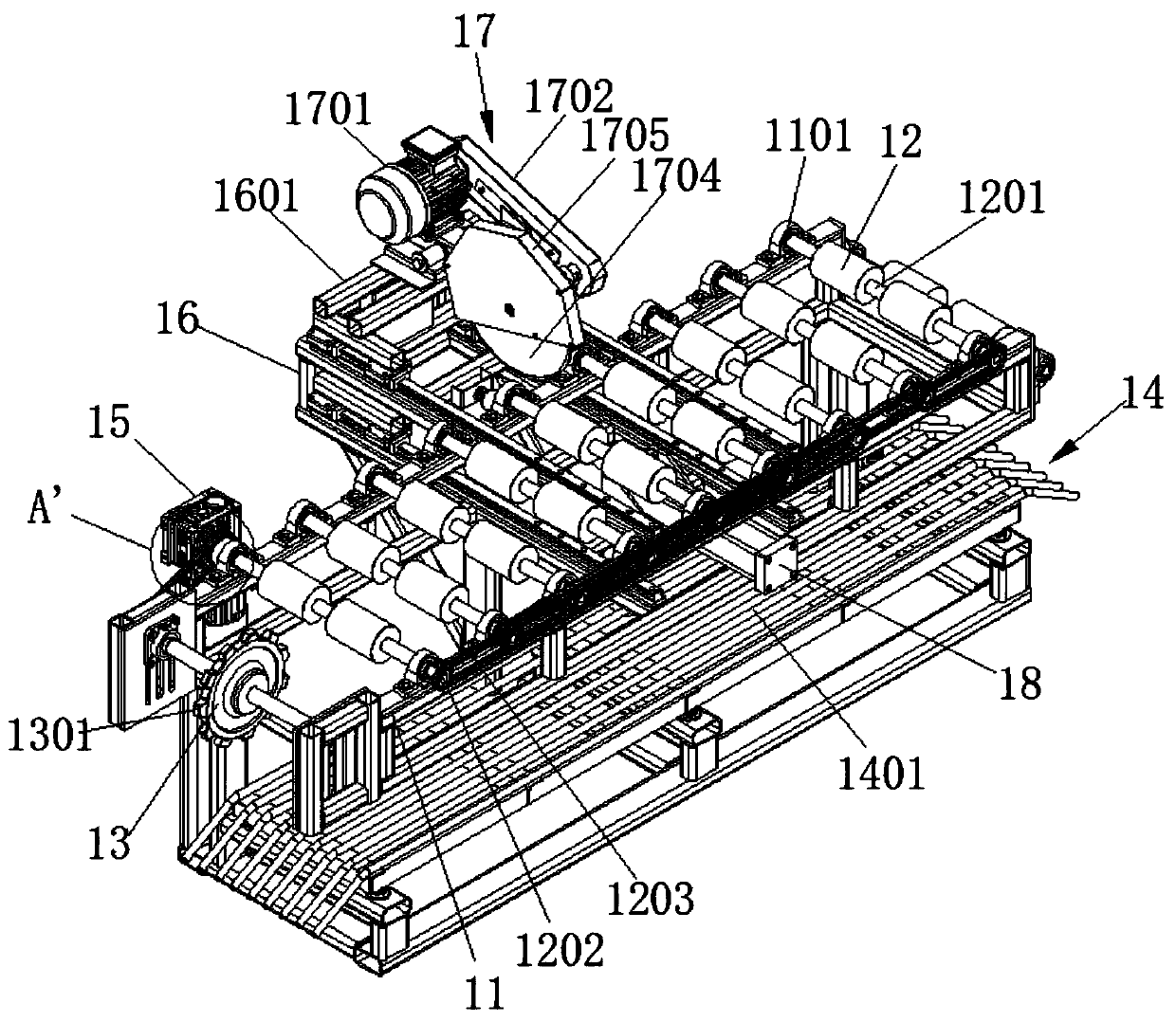

Decorating strip caulking groove automatic groove cutting machine and processing technology

The invention discloses a decorating strip caulking groove automatic groove cutting machine. The decorating strip caulking groove automatic groove cutting machine comprises a working table, and is characterized in that, a cutting machine frame is hinged on one side of the working table, a sawing air cylinder is installed between the cutting machine frame and the working table, a cylinder body of the sawing air cylinder is fixed on the working table, a piston rod of the sawing air cylinder is connected with the cutting machine frame, a cutting motor is fixed on the cutting machine frame, a cutting saw is fixedly sleeved on an output shaft of the cutting motor, a feed regulating mechanism is fixed on the working table, and the feed regulating mechanism is located below the cutting saw. The invention further discloses a decorating strip caulking groove processing technology. The decorating strip caulking groove processing technology is characterized by including the following steps: blanking; clamping; setting groove width; setting groove depth; opening a groove and fetching pieces. The decorating strip caulking groove automatic groove cutting machine and the decorating strip caulking groove processing technology have the advantages of being high in machining precision, ensuring satisfying technological requirements, improving production capacity, improving work efficiency by 10 times compared with the prior handcrafted art, reducing rejection rate, saving raw materials, and being low in cost, high in automaticity, easy to achieve and the like.

Owner:CHONGQING HANGXING GLASS TECH

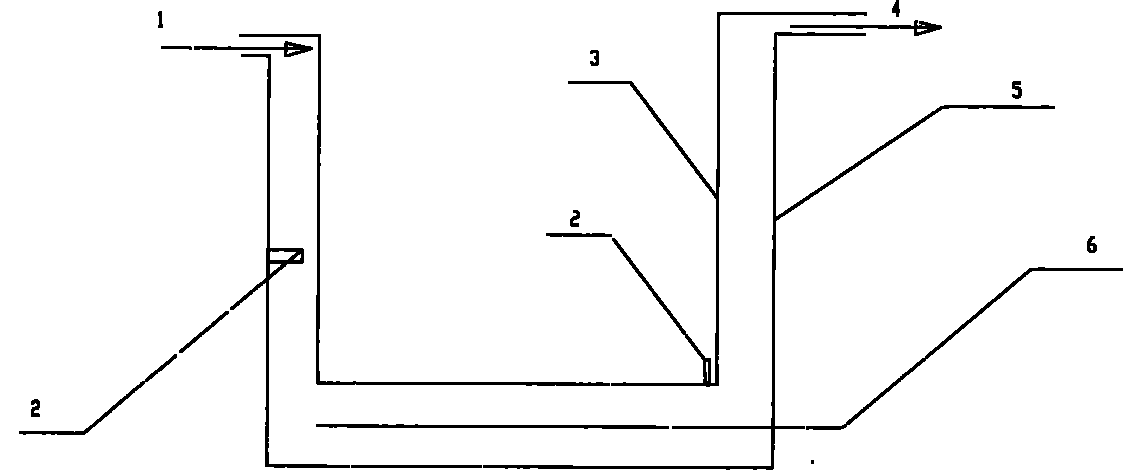

Hot-air mediated evaporation and concentration method

InactiveCN1522779AExtend continuous running timeVisible energy-saving effectEvaporationAgricultural engineeringEvaporation

The present invention relates to the field of concentration by evaporation technology. Said equipment is mainly composed of hot-air indirectly-heating hot-blast furnace, evaporator, condenser and hot-air transferring equipment. The hot-air outlet of indirectly heat-exchanged hot-blast furnace is connected with evaporator by pipeline, the outlet of evaporator is connected with condensation heat-exchanger, and the air outlet of condenser is connected with blower fan by pipeline, so that they are formed into the connected evaporation and condensation system.

Owner:辽宁东大粉体工程技术有限公司

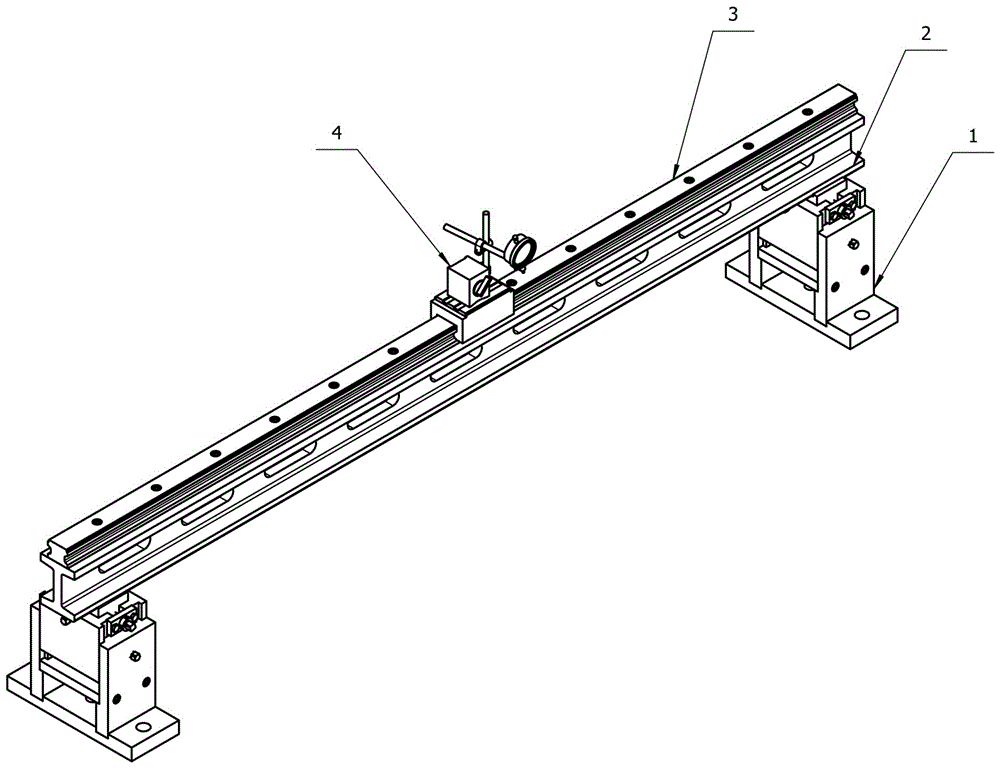

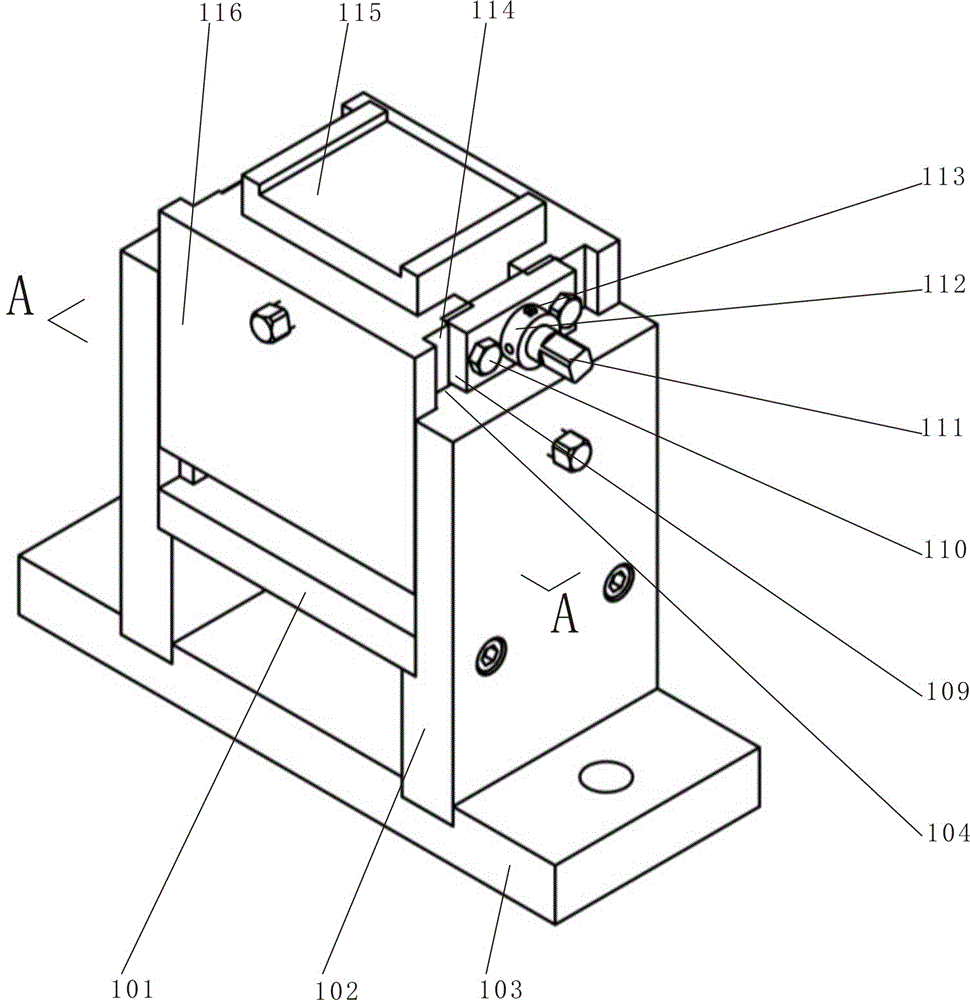

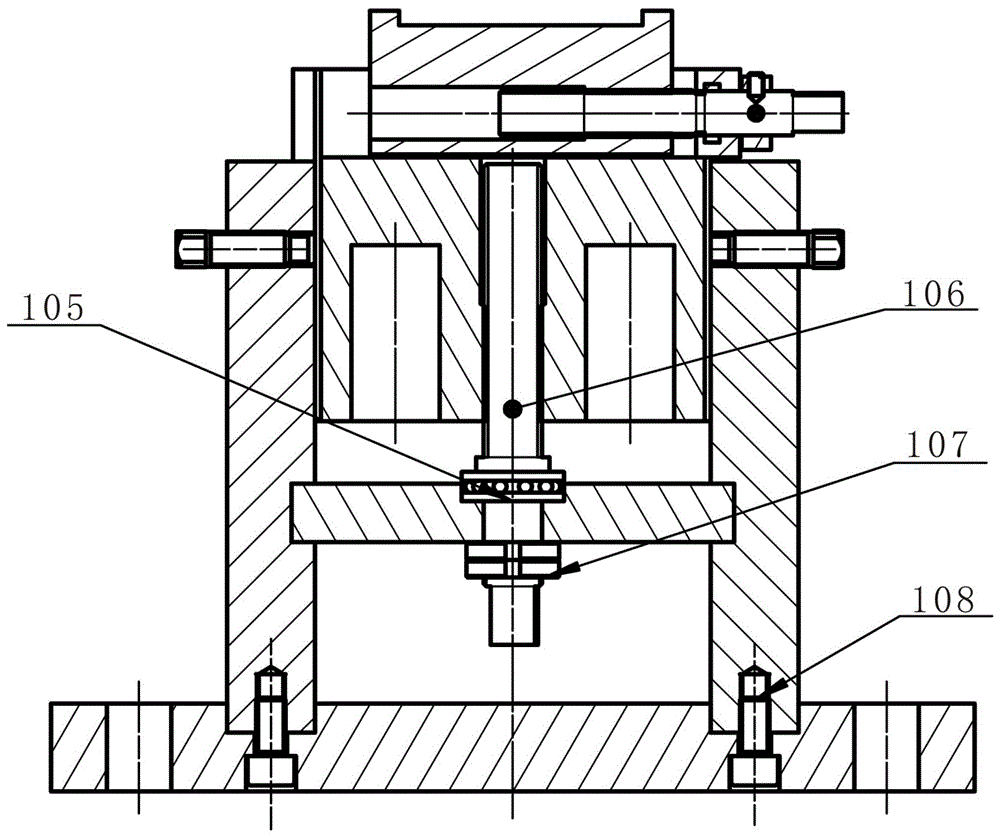

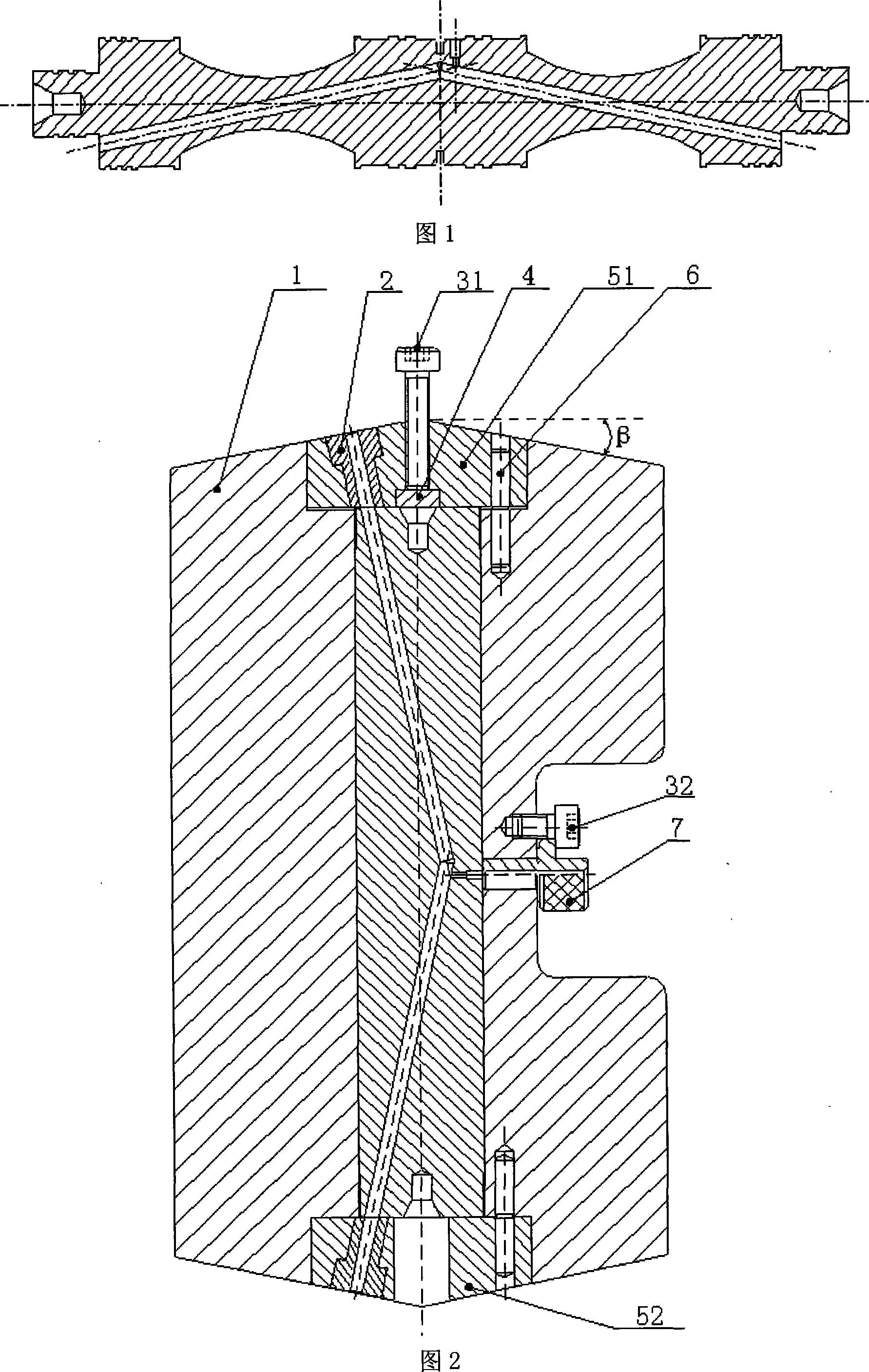

Straightness detection device for inner hole of spindle storing drum

ActiveCN105783678AAccurate measurementIn the deep hole of the measurement, the measurement through the dial gauge is accurateAngles/taper measurementsEngineeringDeep hole

The invention relates to a straightness detection device for an inner hole of a spindle storing drum. The straightness detection device comprises two adjusting bases, a leveling ruler guide rail, a linear slide block and a dial gage, wherein the two ends of the leveling ruler guide rail are arranged on the two adjusting bases, respectively; the linear slide block with the length identical to that of the leveling ruler guide rail is arranged at the upper end of the leveling ruler guide rail; the dial gage is arranged on the linear slide block; slide chutes matched with the linear slide block are formed in the upper and lower ends of the dial gage; a vertical adjusting mechanism and a horizontal adjusting mechanism are also arranged on the adjusting bases. According to the straightness detection device provided by the invention, the leveling ruler guide rail is adjusted to a required angle through the adjusting bases, is located in a horizontal straight line and passes through a to-be-measured deep hole; the straightness of the deep hole can be accurately measured through the dial gage; the straightness detection device can be excellently applied to measurement for the straightness of deep holes.

Owner:LUOYANG CHANGLI MACHINERY CO LTD

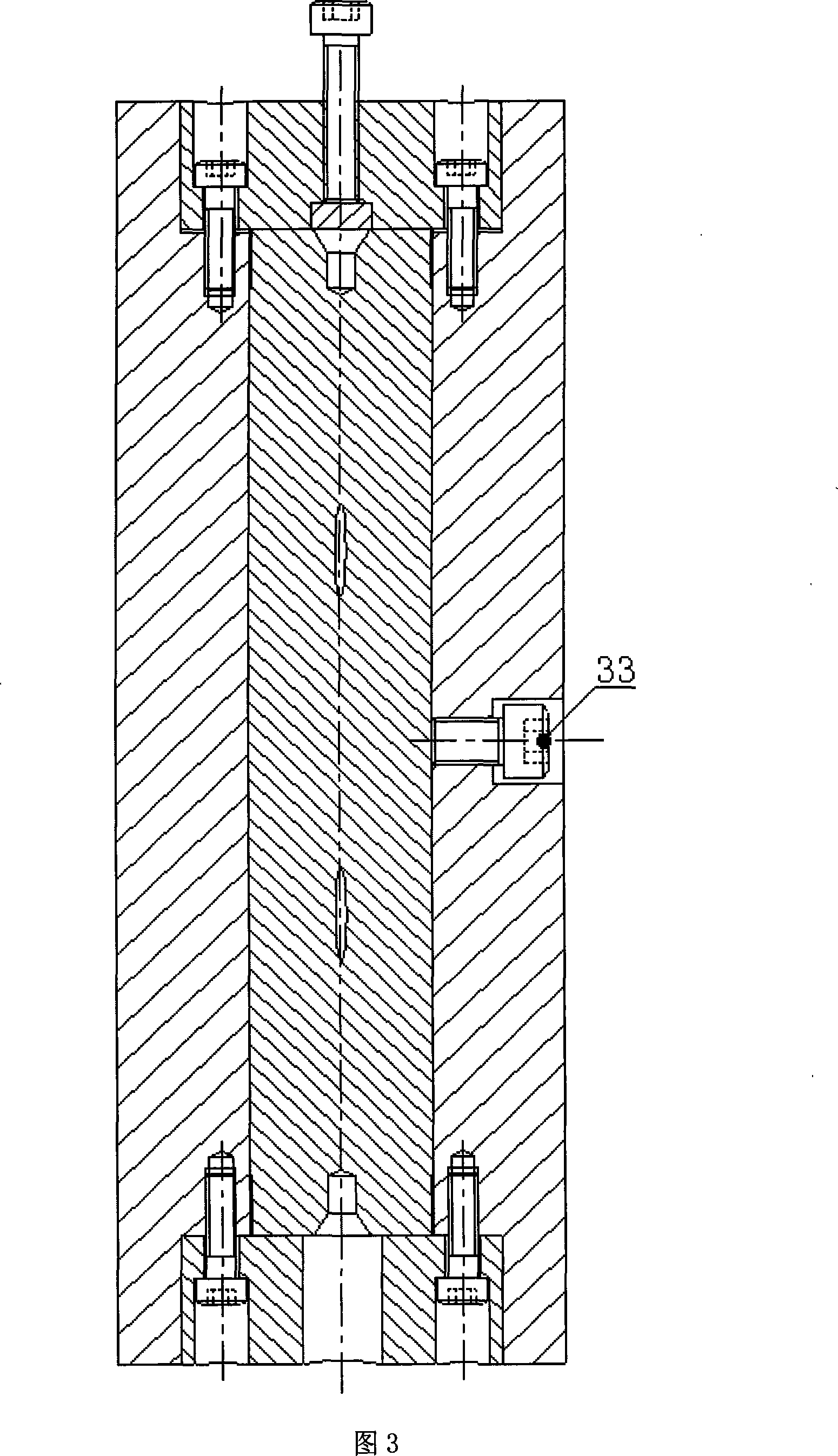

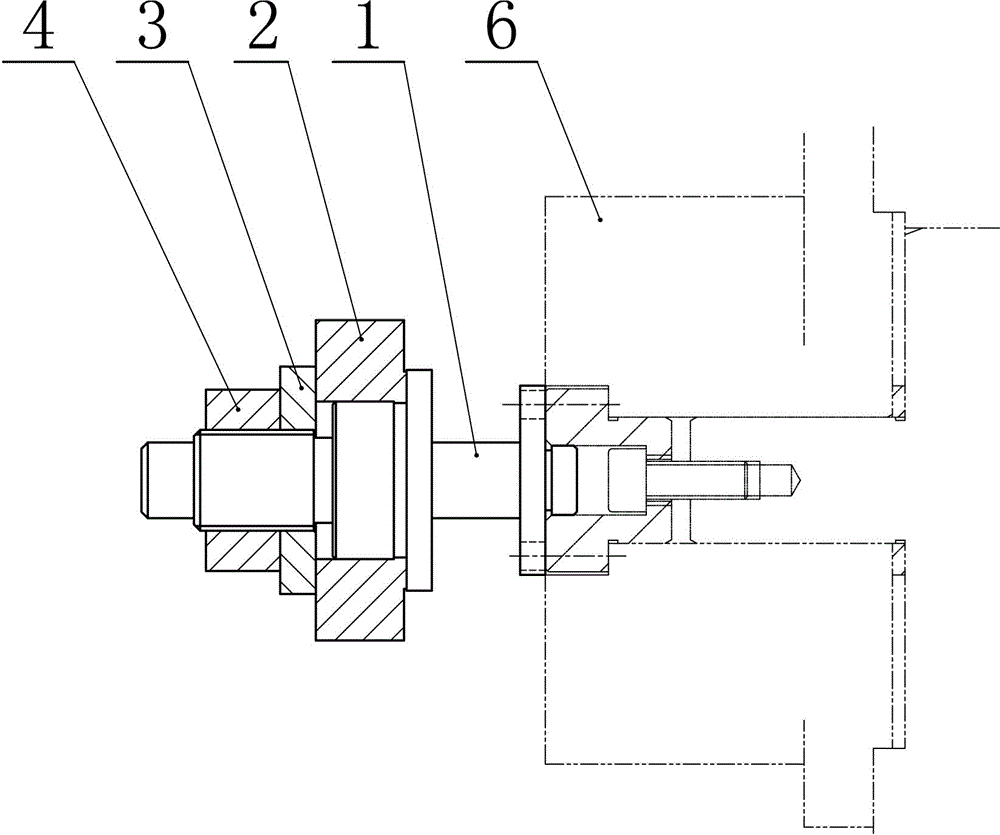

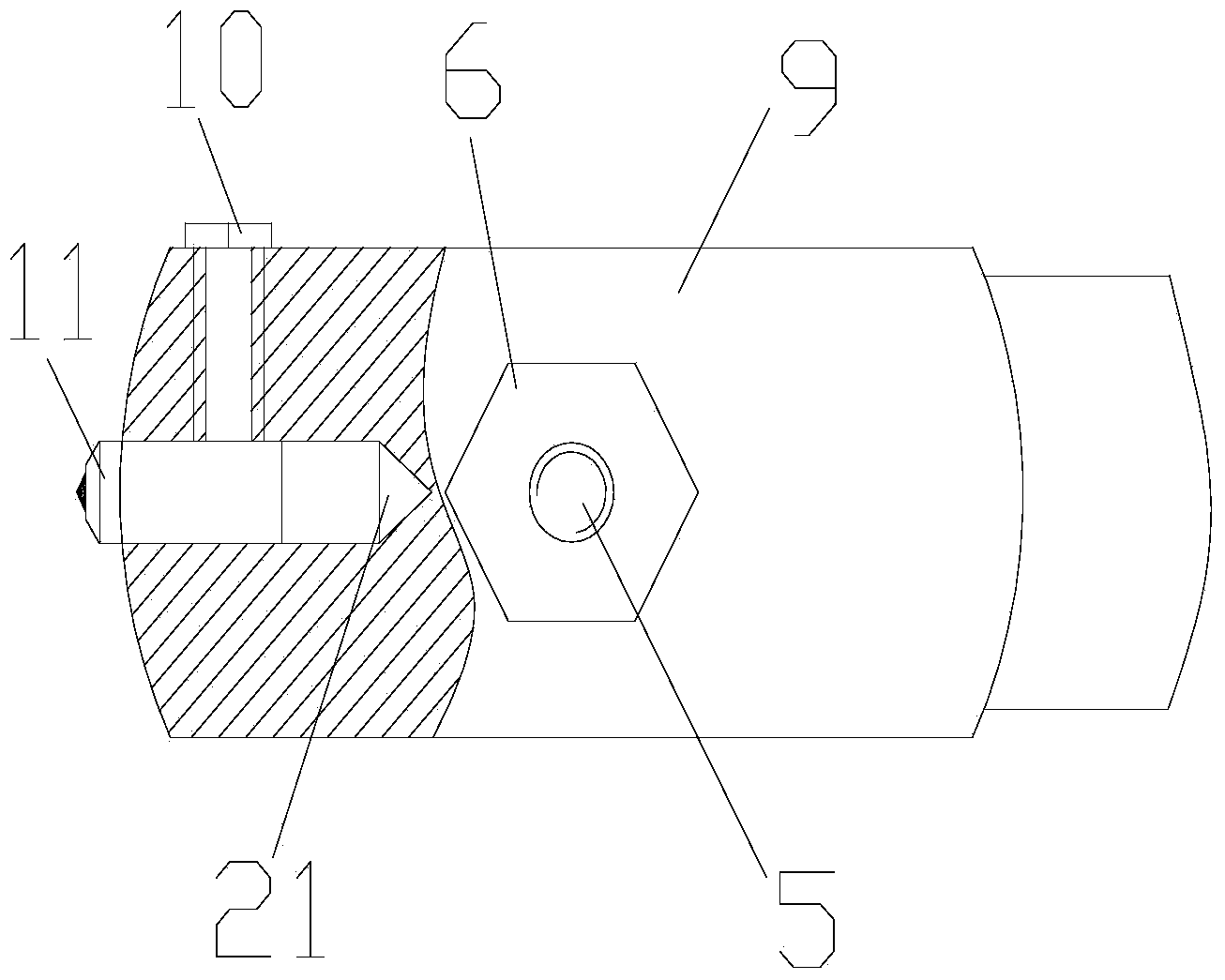

Inclined hole of electro-hydraulic servo valve core drill and clipper for countersunk head ascopore

InactiveCN101176927AReduce hardness requirementsEasy to processDrill jigsElectro hydraulicEngineering

The invention relates to a jig used for drilling incline hole and the countersunk keyhole on the valve core of electro-hydraulic servo valves, comprising a jigs body (1), a drill bush (2), a padding block (4), two drill bush seats (51) and (52), a straight pin (6) and two quick-changing drill bushes (7). The invention is characterized in that: jigs body (1) is vertically-faced on the left and right sides, front side and the back side and the lateral faces; two end faces are bilaterally symmetric and take an included angle Beta with the horizontal plane; the intracavity is a hollow cylinder coordinating with the valve core clearance; the drill bush erection holes, countersunk threaded hole are arranged at both ends of the cylinder, and the gap for the installation of the quick-changing drill bush and bolts are arranged on the lateral face of the cylinder. The invention has the advantages of convenient clamping of the valve core on the driller vice and processing two inclined holes and the countersunk keyholes on the driller. Meanwhile, on the premise of guaranteeing the processing requirements, the frequent clamping of the jig is consistent with the positioning precision, the work efficiency is increased and the requirement of the technical level of workers is lowered.

Owner:SHANGHAI NUOMA HYDRAULIC SYST

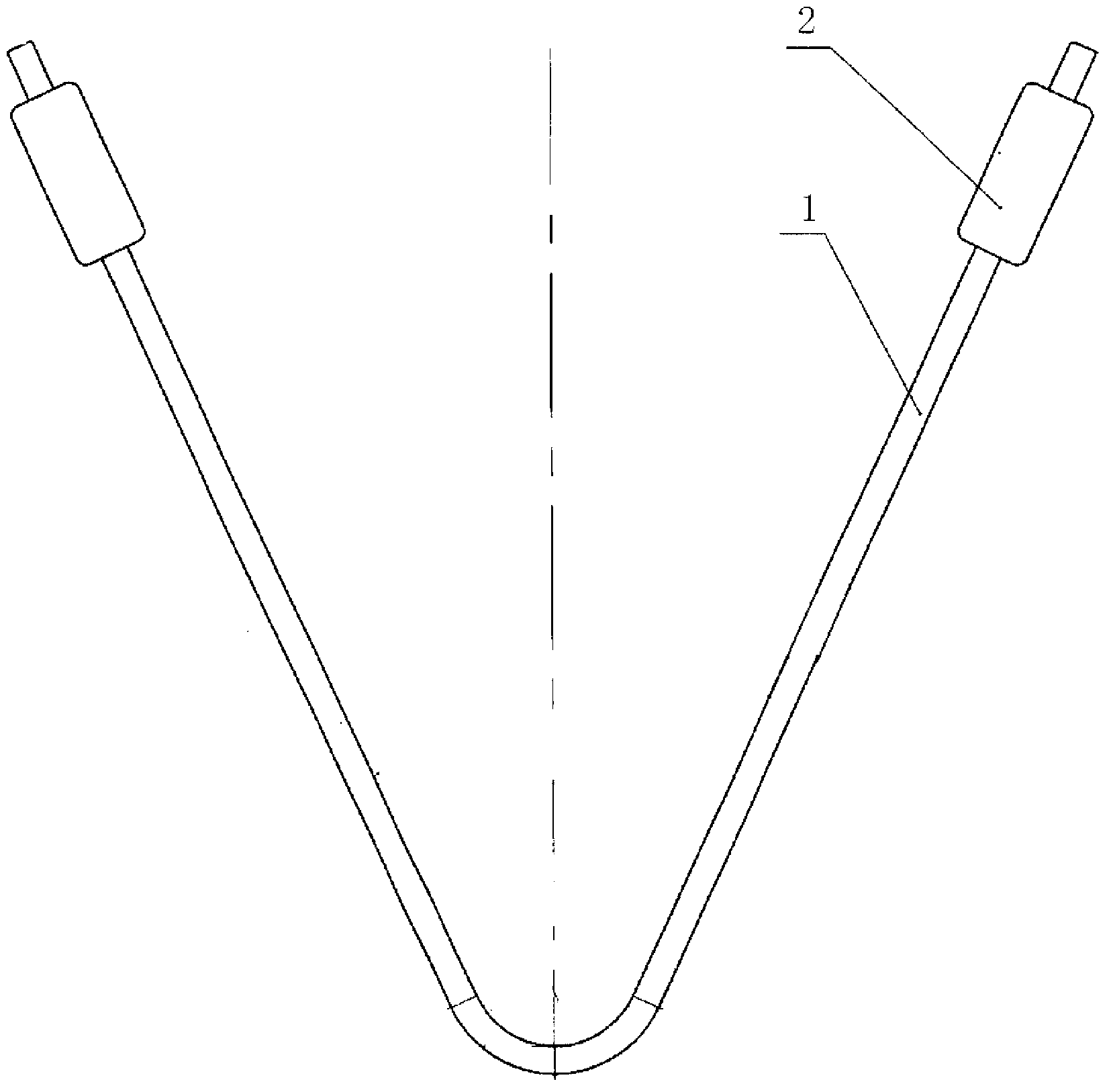

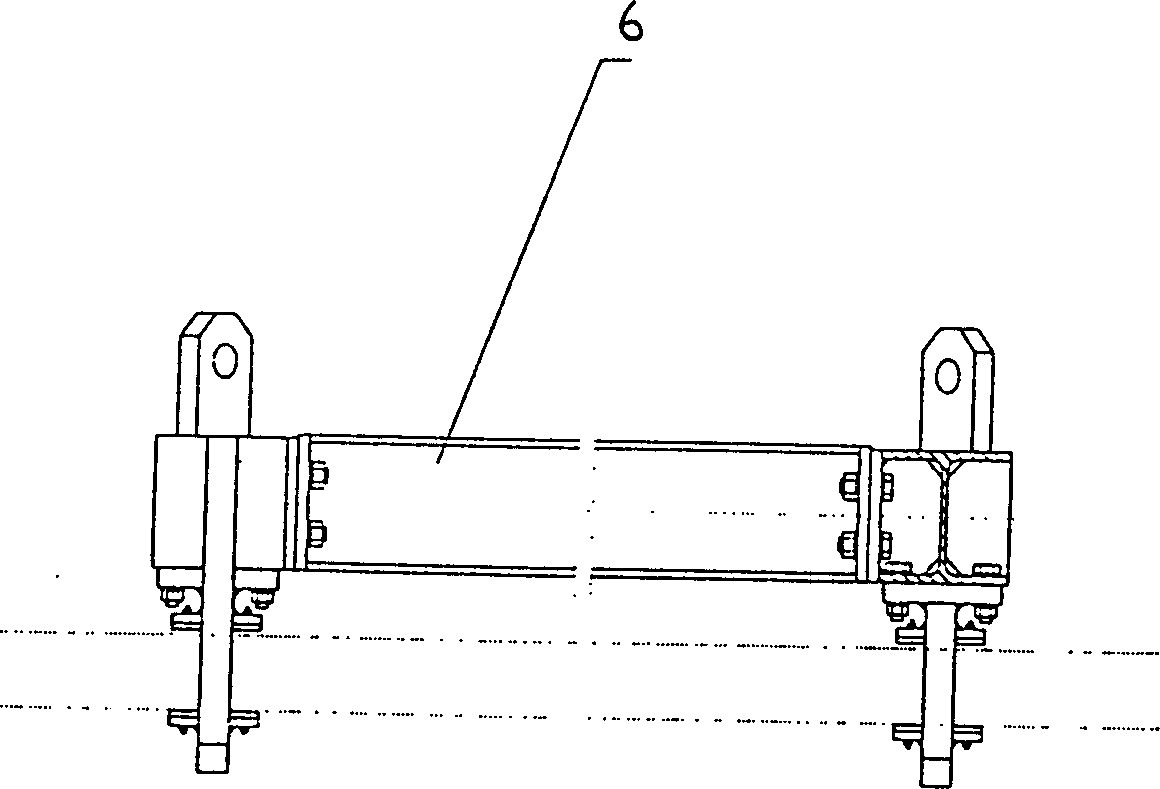

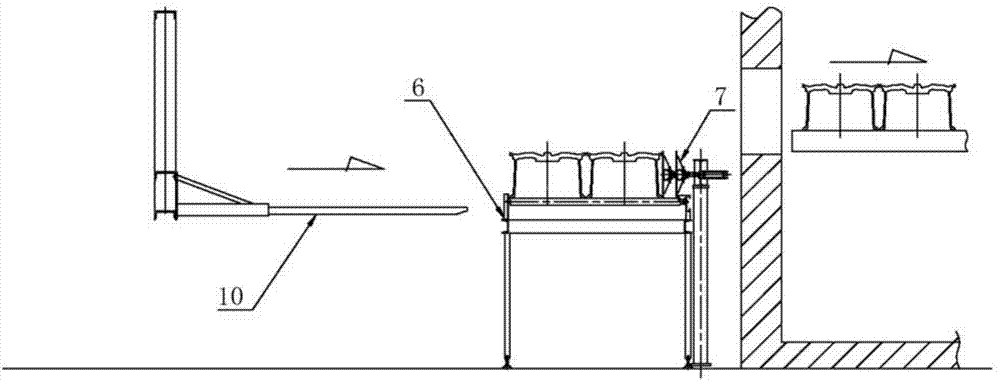

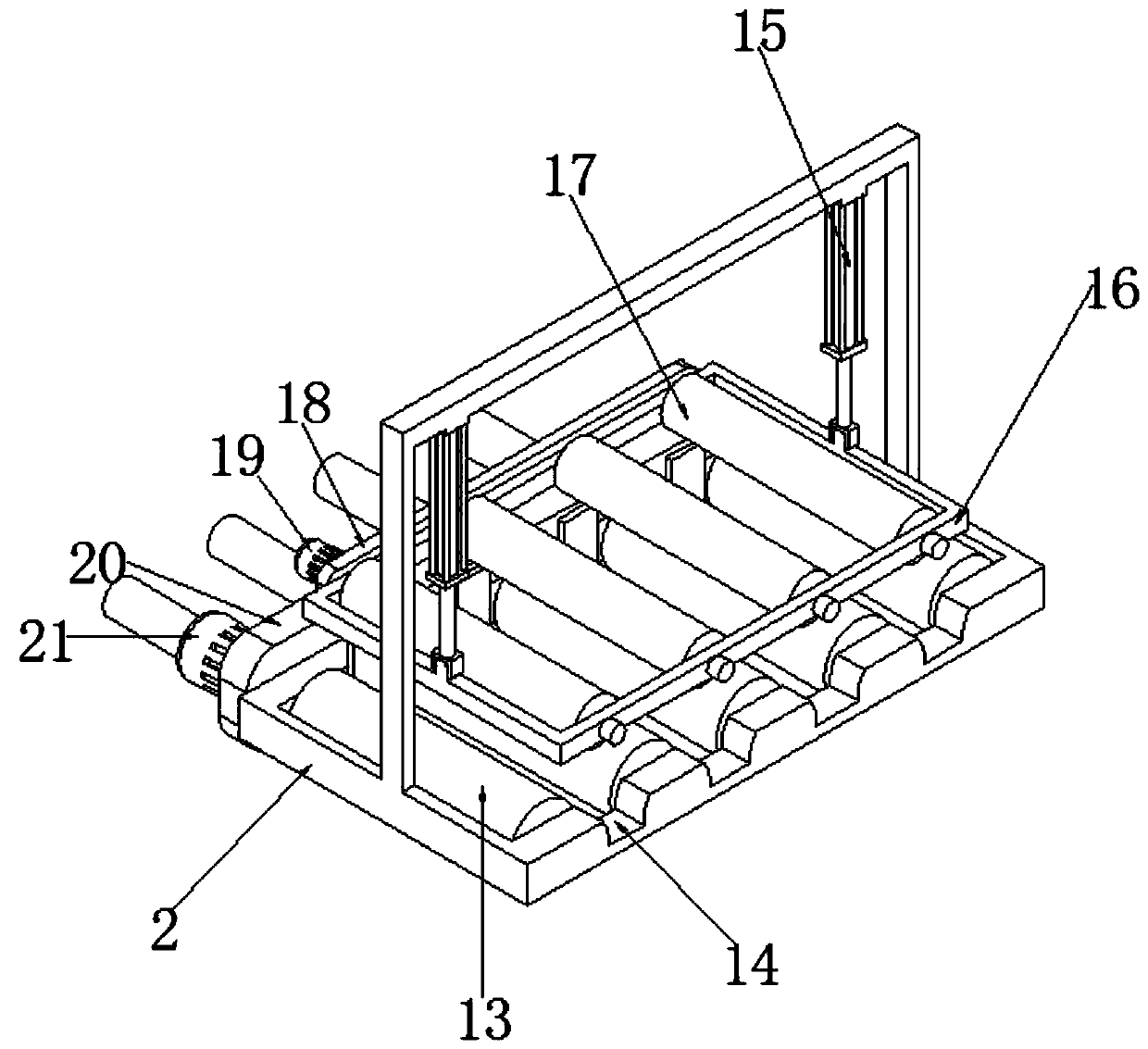

Composite sling for hot press plate translation lifting and turn over and its use method

InactiveCN1785778AAvoid compression deformationGuaranteed process requirementsLoad-engaging elementsRigid frameHot press

The present invention relates to a plates hoisting equipment, in particular, it relates to combined hoisting equipment for horizontally-hoisting and turning hot-pressed plate and its application method. Said invention is characterized by changing the original flexible steel wire rope hoisting method into the invented rigid frame structure hoisting method. The invented hoisting equipment mainly includes the following several portions: curved board, cross-beam, horizontal hoisting plate, hoisting hooks, turning-hoisting plate and channel steel. Besides, said invention also provides the concrete steps of its application method.

Owner:SHANGHAI WOOD-BASED PANEL MASCH CO LTD

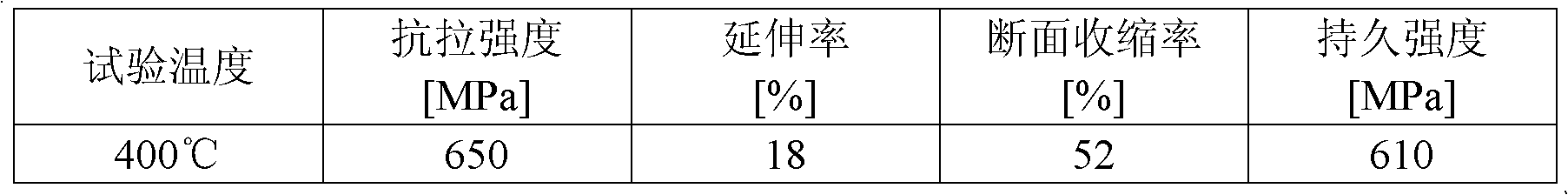

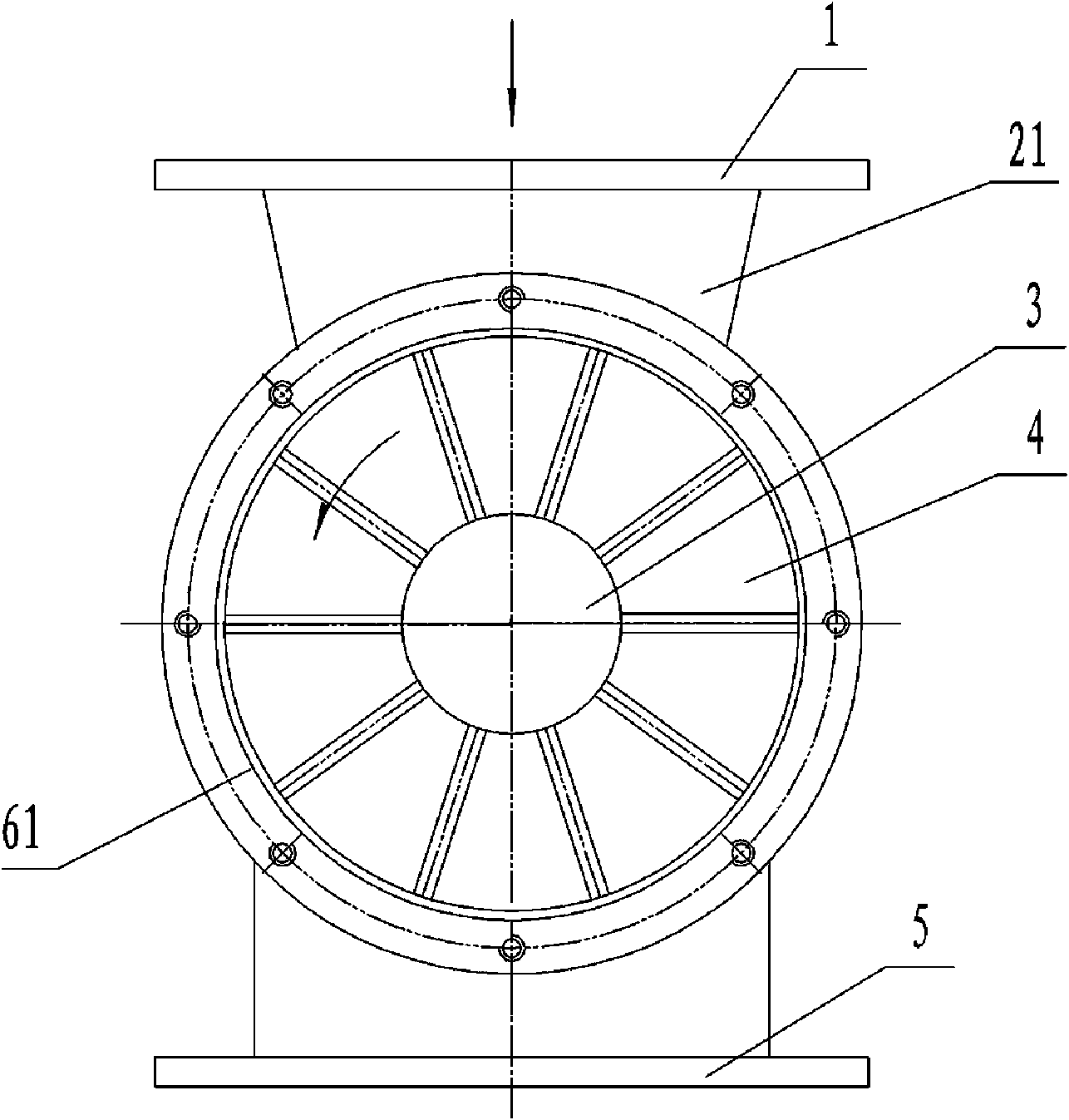

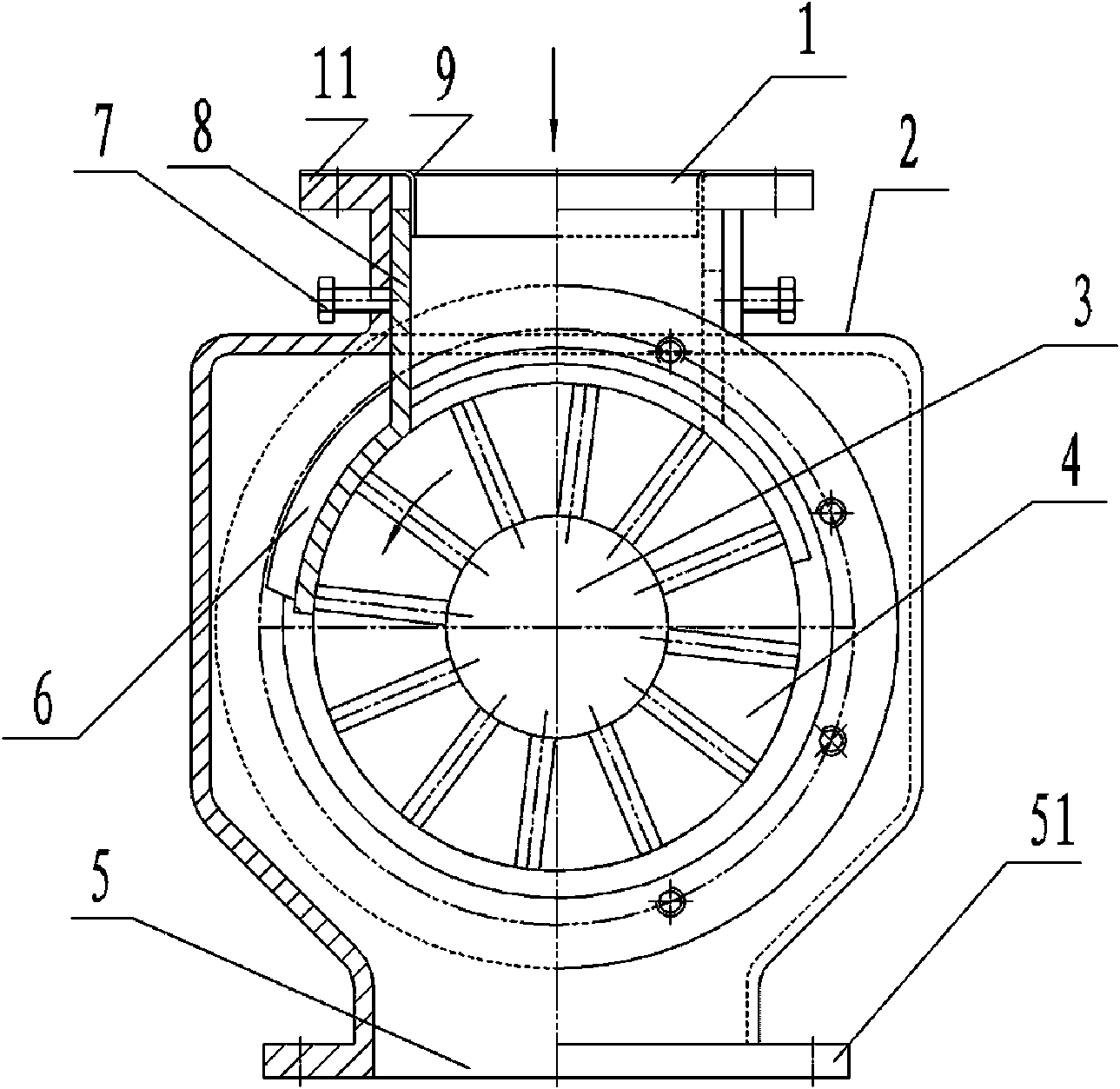

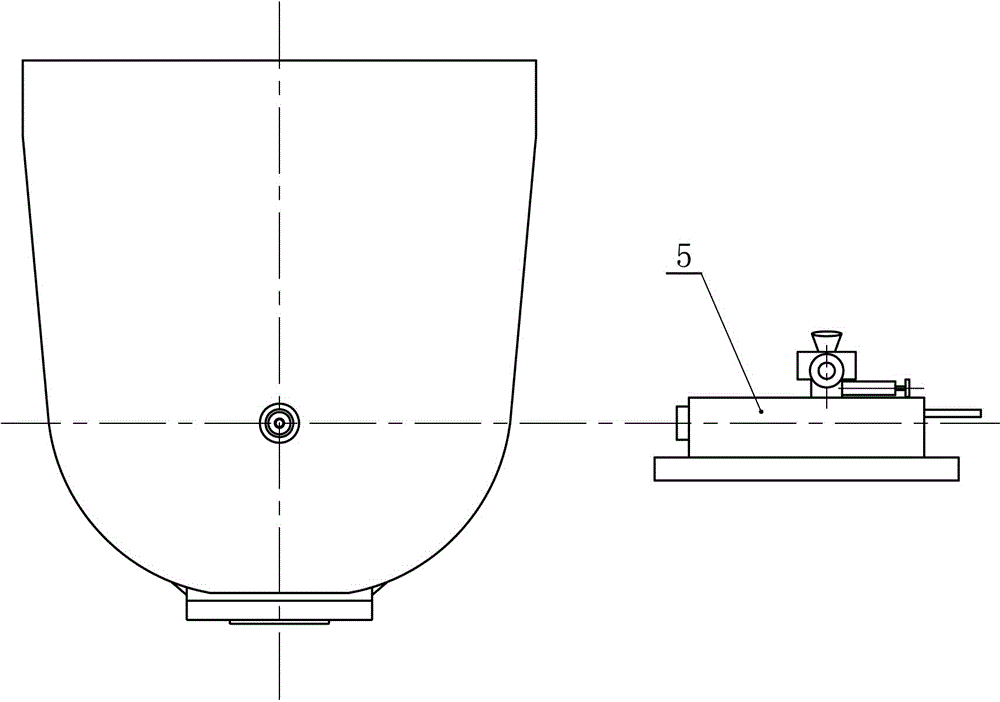

Adjustable sealing rotary valve

InactiveCN101670937AReduce processing technologyGuaranteed process requirementsRotary conveyorsMaintenance managementRotary valve

An adjustable sealing rotary valve mainly solves technical problems that the traditional rotary valve has short service life, heavy maintenance management workload, bad gas tightness, and when the rotary valve is used in the high temperature work conditions, equipment accidents easily happen, and the like. The adjustable sealing rotary valve has the technical solution that the rotary valve is formed by the combination of a rotary valve shell and a rotor (3), wherein the rotor (3) is provided with a rotor slot (4); the rotary valve shell is provided with a feeding hole (1) and a discharge hole(5); a feeding hole connecting piece (11) and a discharge hole connecting piece (51) are arranged on the feeding hole (1) and the discharge hole (5); the rotary valve shell (2) is internally sheathedwith a seal housing which is of a non-circular structure; the feeding hole (1) on the upper part of the rotary valve shell (2) is internally provided with a sliding sleeve (8) which is movably matched; the lower part of the sliding sleeve (8) is arc-shaped and sheathed between a sealing housing (6) and the rotor (3) in a matching way; by changing the structural style that the valve body of the traditional rotary valve directly contains the rotor, the valve body and a containing component of the rotor are separated, thus prolonging the service life thereof and increasing the gas tightness. Theadjustable sealing rotary valve is mainly used for powder or granule conveying devices.

Owner:XIANGXIANG MACHINERY FACTORY

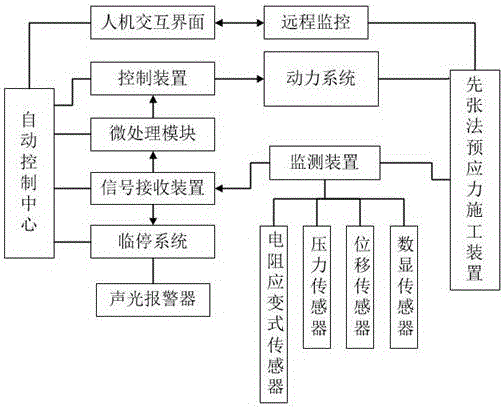

Automatic control system and method of pre-tensioning prestress construction

ActiveCN106049880AGuaranteed Quality StandardsEnsure quality stabilityBridge erection/assemblyBuilding material handlingAutomatic controlAutomatic train control

The invention relates to the technical field of prefabricated beam construction, in particular to an automatic control system and method of pre-tensioning prestress construction. The automatic control system comprises an automatic control center and a power system. The automatic control center is connected with a monitoring device and a control device. The monitoring device comprises a component used for monitoring the steel strand tensioning parameters and the pressure of the power system. The automatic control center is further provided with a signal receiving device and a micro processing module. An original data signal is received by the signal receiving device, analyzed and processed by the micro processing module, converted into a control signal and transmitted to the control device. The tensioning process is completed through control of the control device to the power system. By the adoption of the automatic control system, the problems that according to manual control, numerical reading is inaccurate, and the tensioning stress is difficult to control accurately are solved, the tensioning stress is well controlled, the tensioning process of steel strands meets the technological requirements, the quality of a prefabricated beam is improved, and standard production of products is also promoted.

Owner:CHINA RAILWAY 23RD BUREAU GRP RAILTRANSIT ENG CO LTD +1

Double-tilt-angle universal milling head rotating shaft locating precision measuring device

ActiveCN104476325AAccurate detectionGuaranteed process requirementsMeasurement/indication equipmentsNumerical controlMotor drive

The invention discloses a double-tilt-angle universal milling head rotating shaft locating precision measuring device, and discloses a device and detection method suitable for the rotary precision detection of an A / B, C axis moment motor driven and machinery driven numerical control double-tilt-angle universal milling head. The device comprises a 12-surface or 36-surface prism and an autocollimator, wherein the 12-surface or 36-surface prism is arranged on a locating shaft, the 12-surface or 36-surface prism is located by a shaft neck and an end face on the locating shaft, the other side is provided with a gland and a nut, and the 12-surface or 36-surface prism is fixed on the locating shaft by the gland and the nut. The device provided by the invention is compact in structure and easy and convenient to operate, can adjust the location fast and effectively, guarantees that the connection detection center of detection elements such as a 36-surface prism and a 36-surface prism is overlapped with the centre of the A / B, C axis, guarantees the veracity and effectiveness of detection results, and further guarantees the positioning precision of the double-tilt-angle universal milling head, thereby meeting the high-precision machining requirements; the fixture is low in cost and has high precision and high stability.

Owner:JIER MACHINE TOOL GROUP

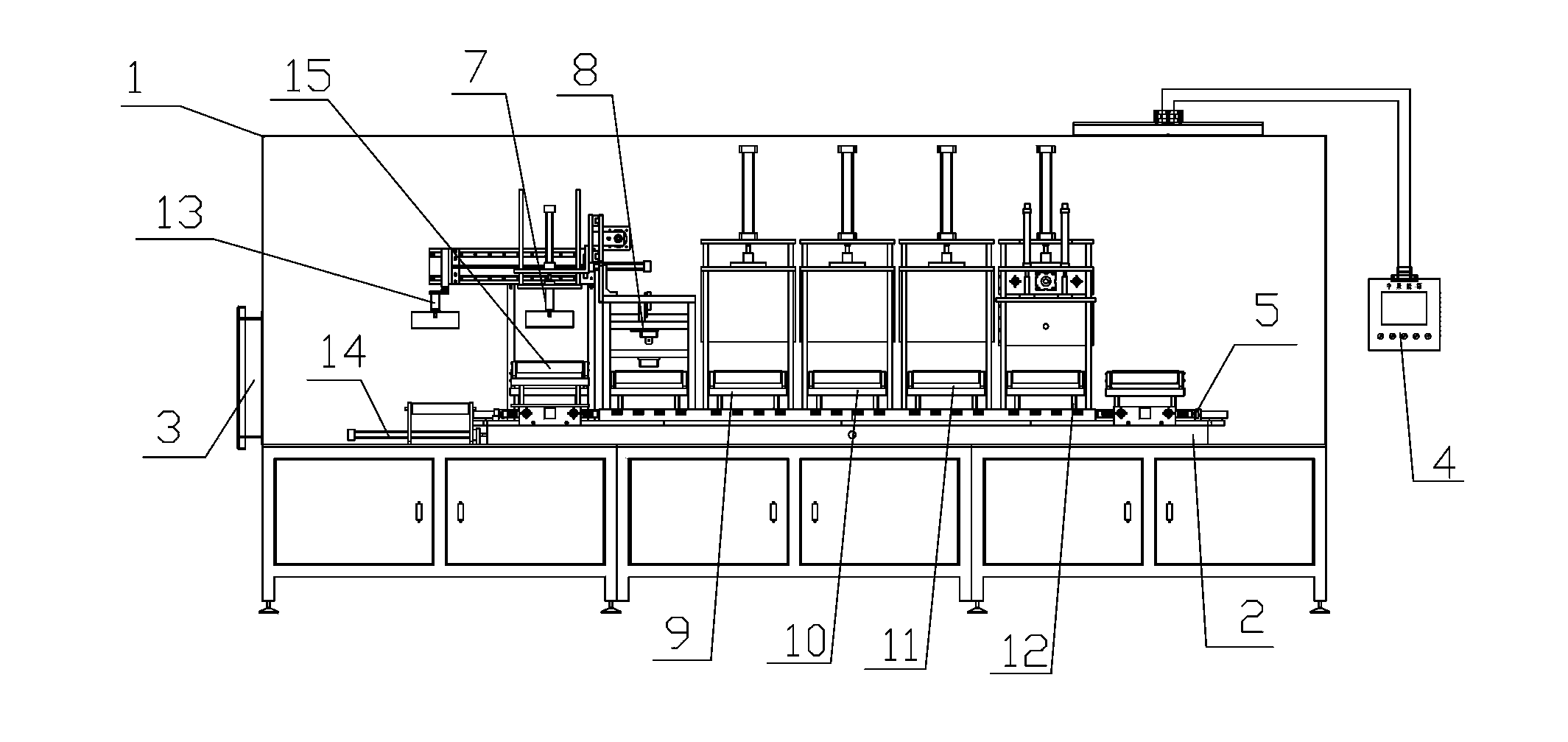

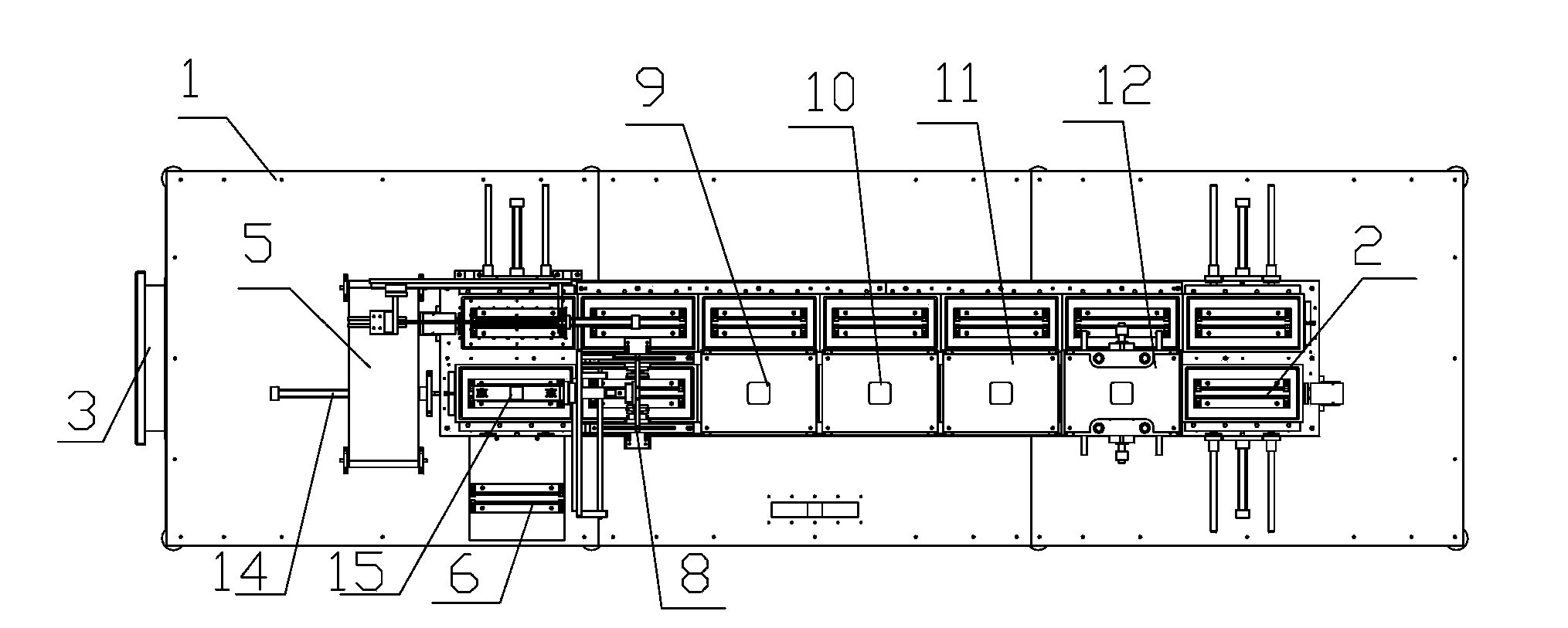

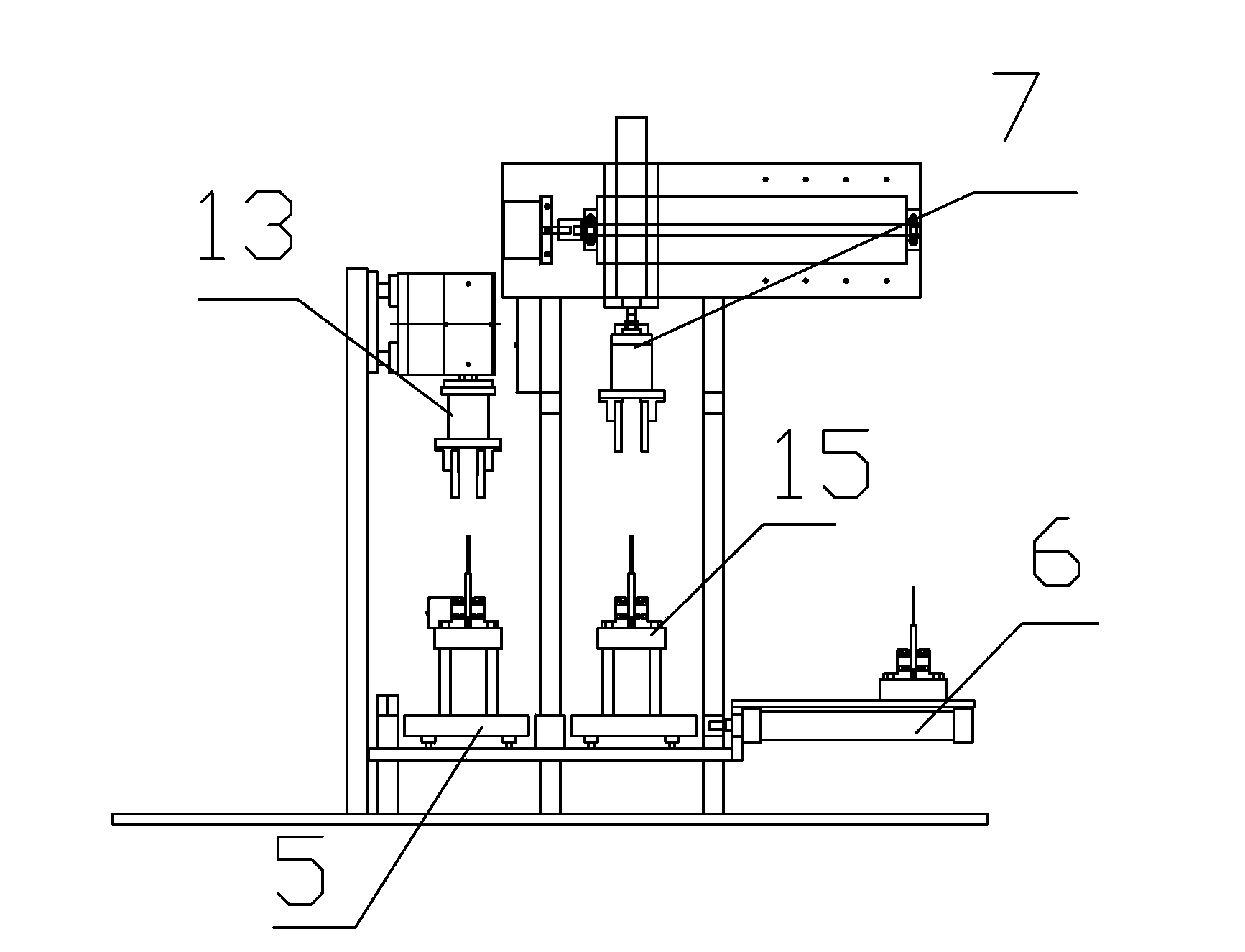

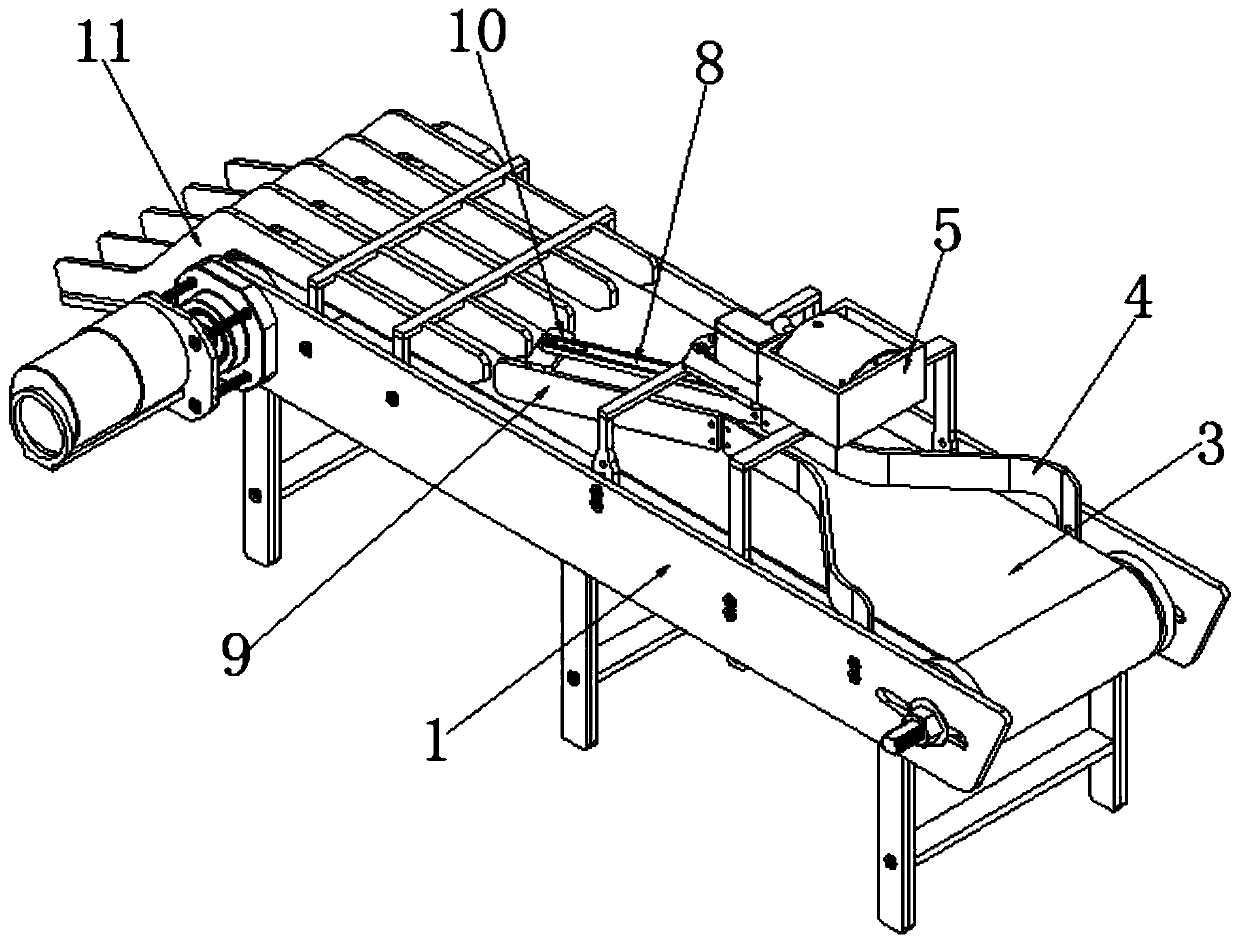

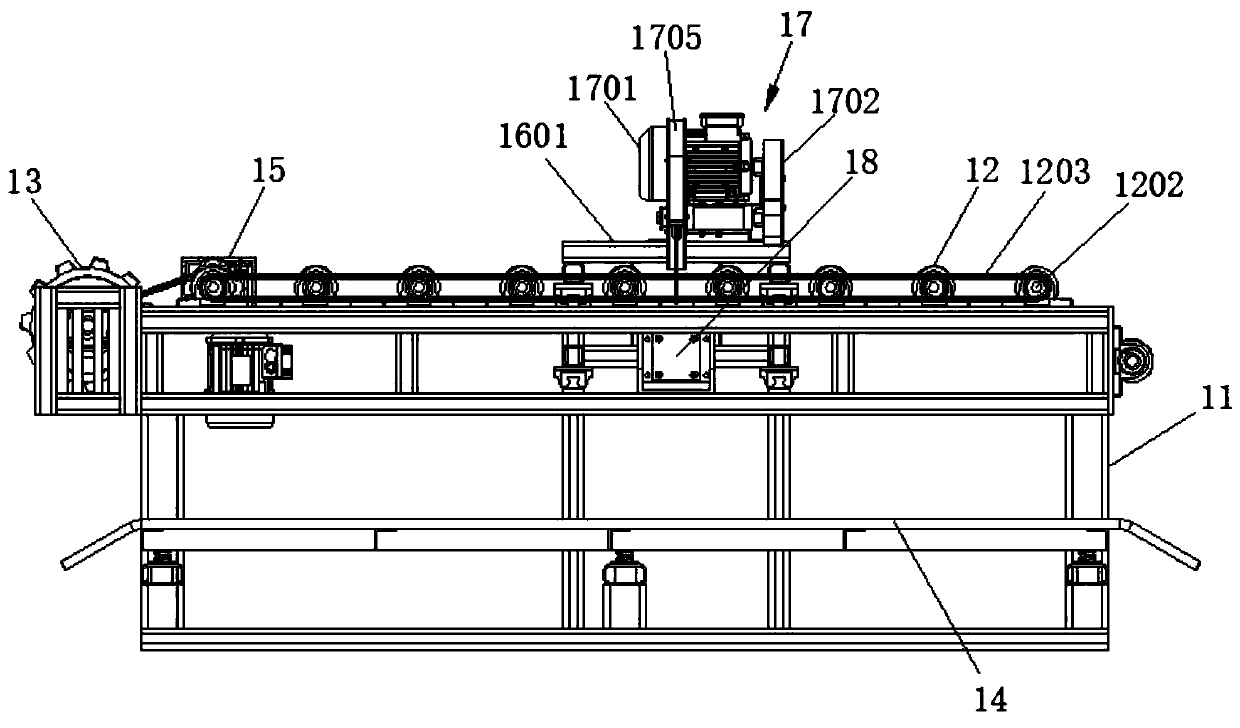

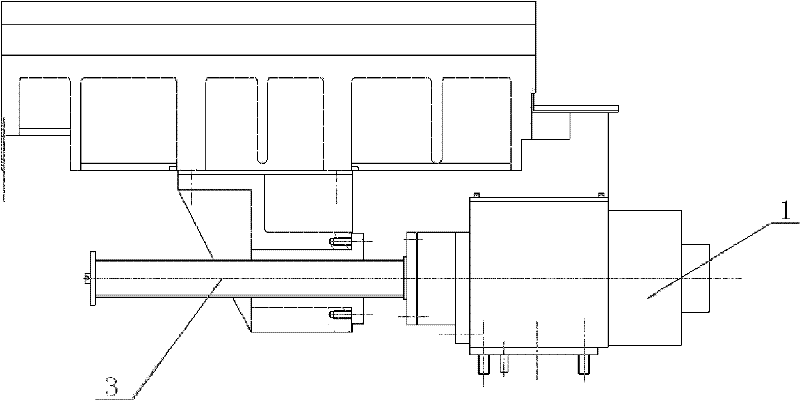

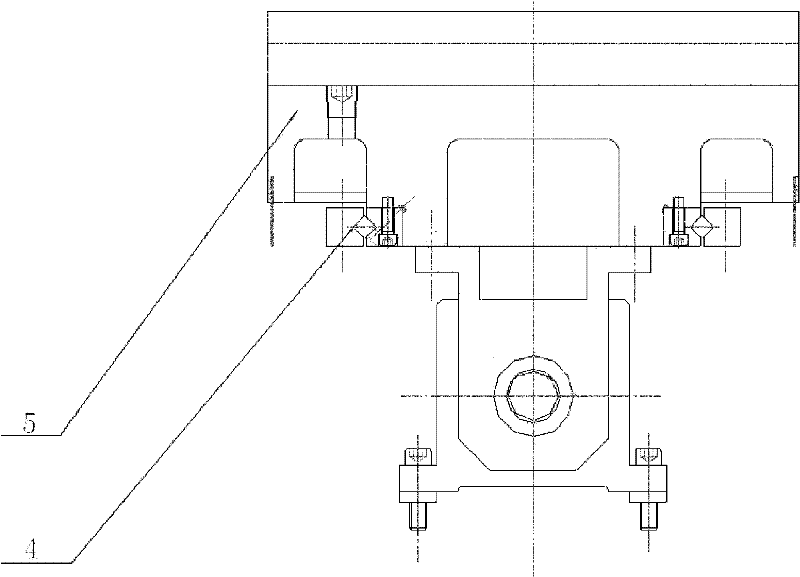

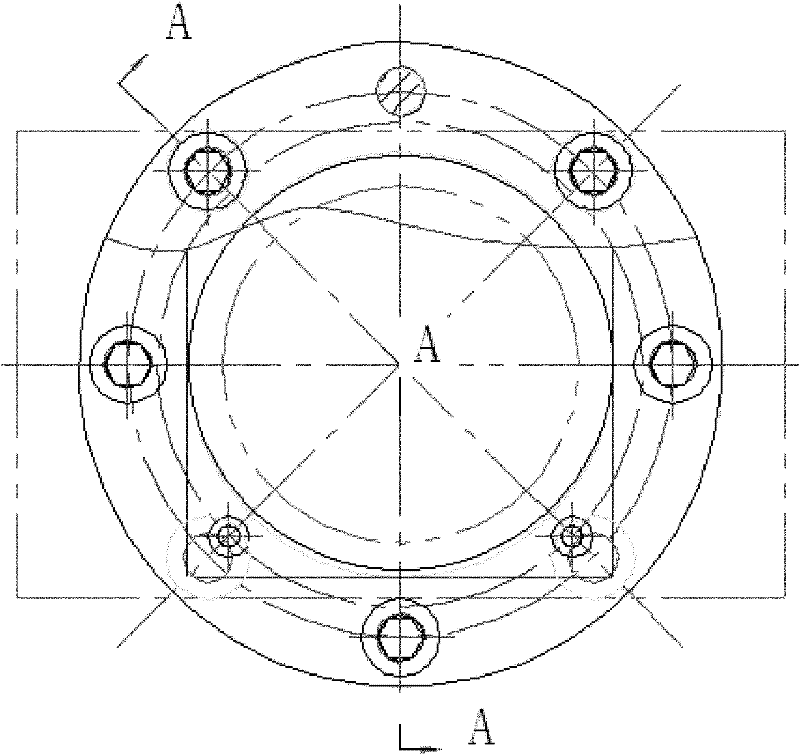

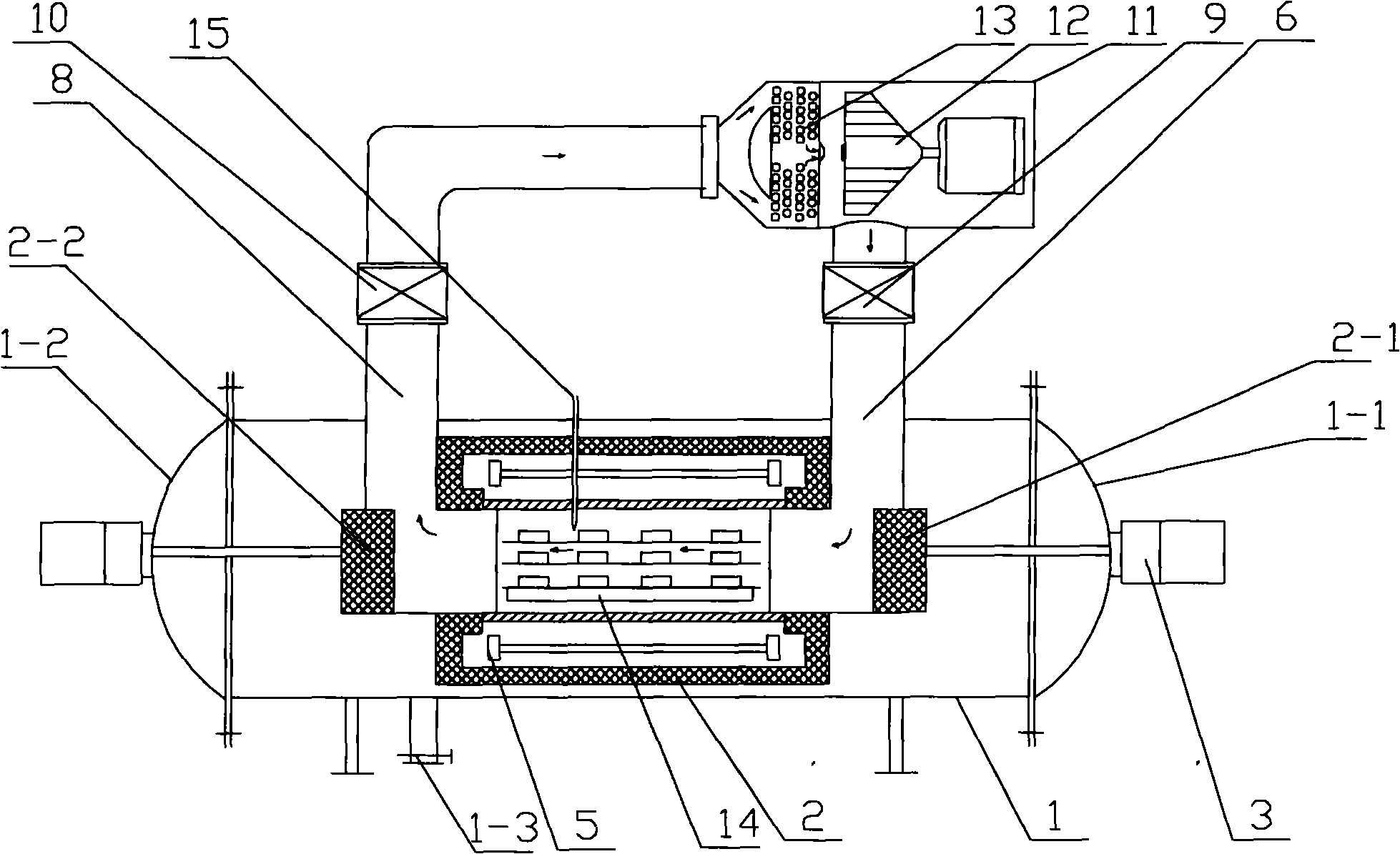

Power-and-free material-loading and transporting apparatus used for material-basket-free thermal-treatment furnace of aluminum alloy product

ActiveCN104328263ASpeed up the loading processIncrease delivery speedFurnace typesHeat treatment process controlUtilization rateHeat treating

A power-and-free material-loading and transporting apparatus used for a material-basket-free thermal-treatment furnace of an aluminum alloy product belongs to the technical filed of thermal treatment devices of the aluminum alloy product. By means of parts, including a transporting roller track, a pre-assembling roller track, a material pushing machine, a material-feeding detection photoelectric tube, a material-full detection photoelectric tube, a power-and-free roller track, a removing roller cylinder, a removing motor, a material-loading fork and the like, the power-and-free material-loading and transporting apparatus enables workpieces arranged in a material-loading zone on the power-and-free roller track to be changed from one row into two or more rows, wherein the workpieces are pre-arranged by a material baffle. Redundant workpieces are removed from the roller cylinder and from the material-loading zone. The pieces in the material-loading zone are sent to the thermal-treatment furnace by the material-loading fork in one step for thermal treatment. By means of the power-and-free material-loading and transporting apparatus, automatic level of the device is improved and time period during material loading is effectively prolonged. In addition, the power-and-free material-loading and transporting apparatus can increase effective space in the thermal-treatment furnace by 20%, can reduce a production cost and can increase energy resource utilization rate.

Owner:SHENYANG NEU-SANKEN IND FURNACE MFG CO LTD

Automatic liquid injection type vacuum edge bonding machine

InactiveCN103855429AHigh degree of automationEnsure low temperature and low humidity environmentAssembling battery machinesFinal product manufactureProcess engineeringConveyor belt

The invention provides an automatic liquid injection type vacuum edge bonding machine, comprising a cylinder, a work chamber and a worktable arranged in the work chamber, wherein a transition bin is arranged on one end of the work chamber, a rotary operating panel is arranged on the other end of the work chamber, and a conveyor belt and a feeding platform are arranged on the table top of the worktable. The automatic liquid injection type vacuum edge bonding machine further comprises a feeding mechanical arm, a liquid injection mechanism, a first degassing standing box, a second degassing standing box, a third degassing standing box and a vacuumizing edge bonding mechanism, which are arranged right above the conveyor belt and are connected in sequence. The automatic liquid injection type vacuum edge bonding machine provided by the invention is completely sealed by a high-performance sealing pad, and an inlet dehumidifying device is further arranged, thus the low temperature and low humidity environment in the machine and the process requirements in the liquid injection process are ensured, the operation automation degree is high, the machine operation is simple, only one operator is needed in the whole production process to manually feed and discharge materials, and the intermediate processes are all automatically finished by machines, therefore, the production efficiency is improved and influence of the complicated intermediate processes to the product quality is reduced.

Owner:武汉中聚能源科技有限公司

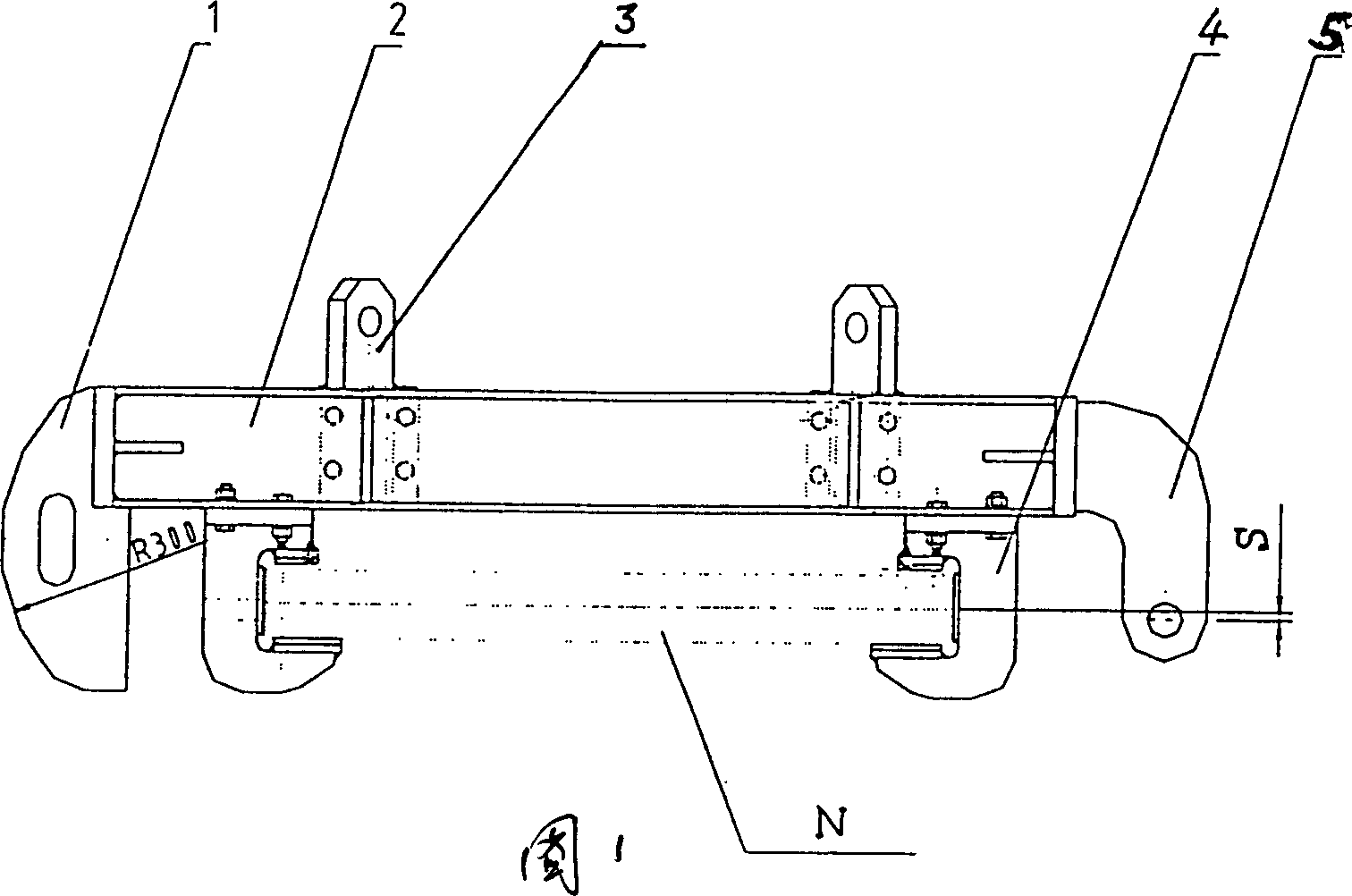

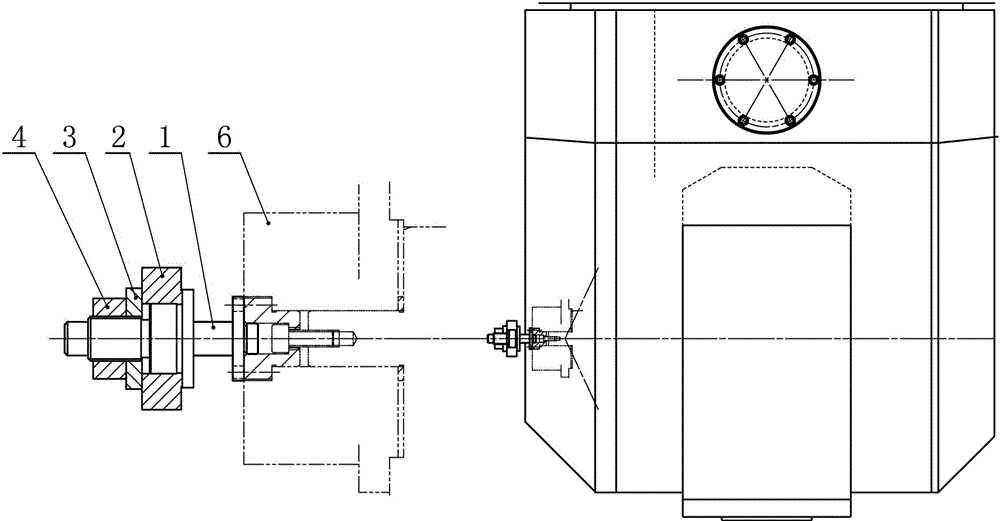

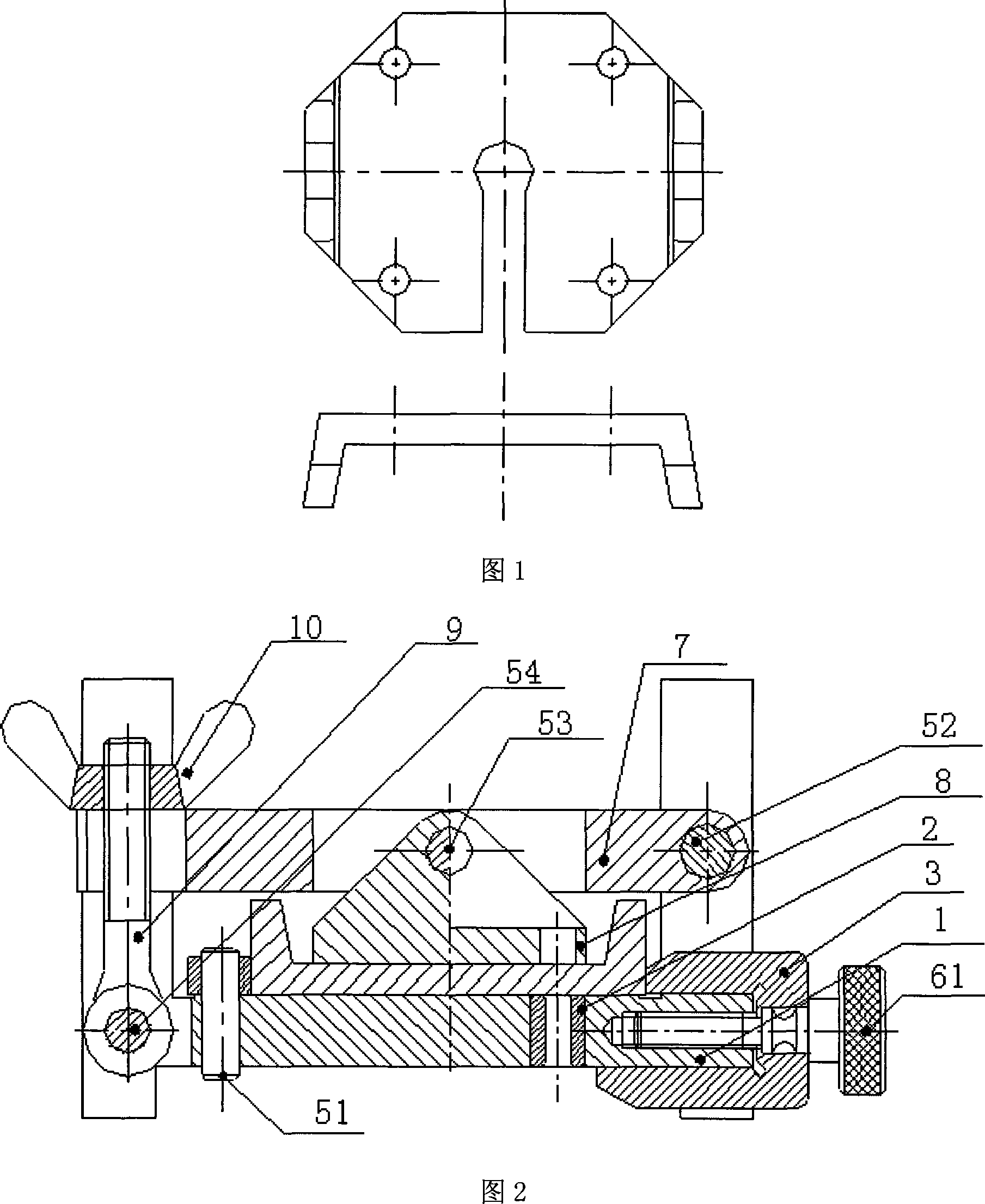

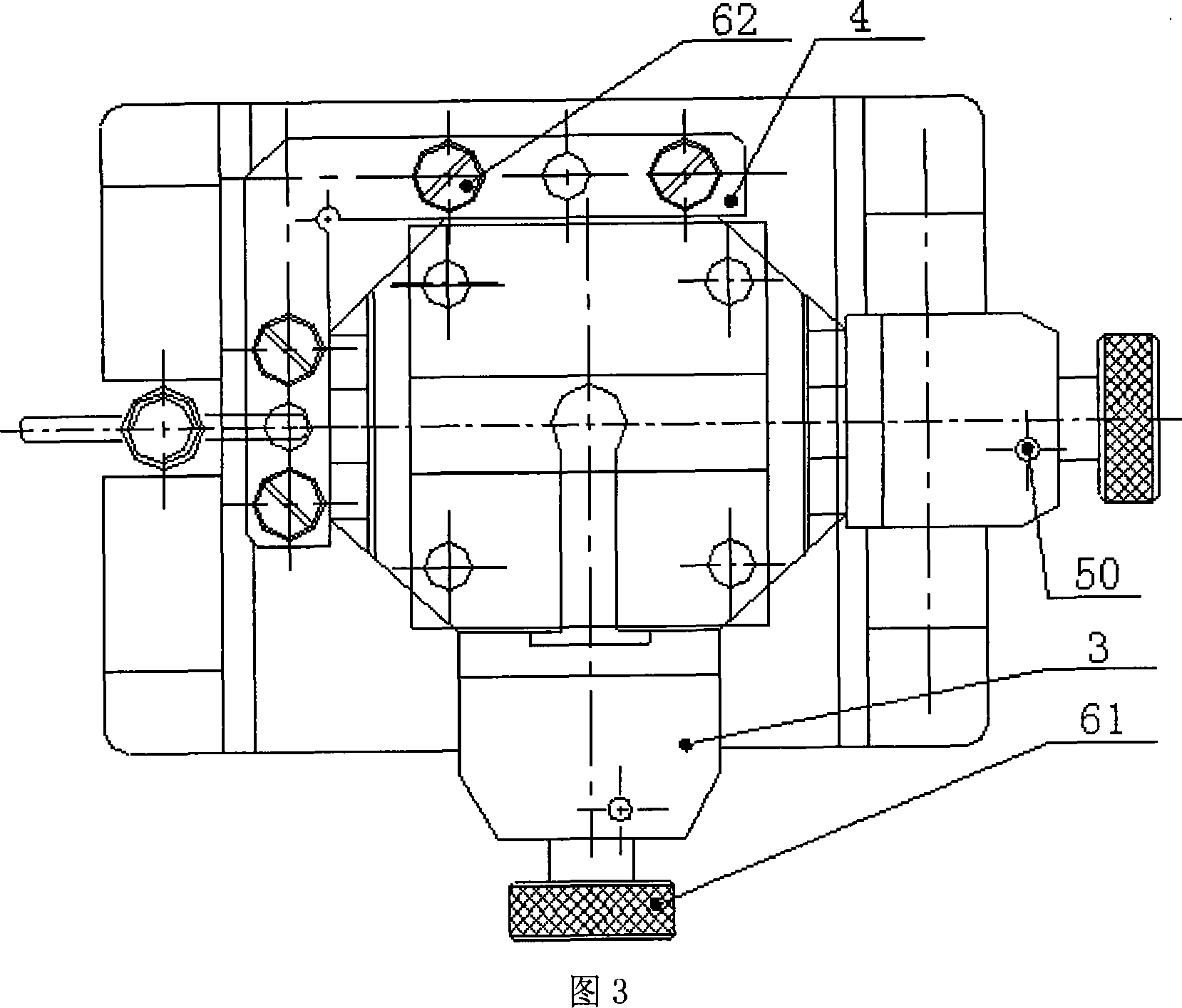

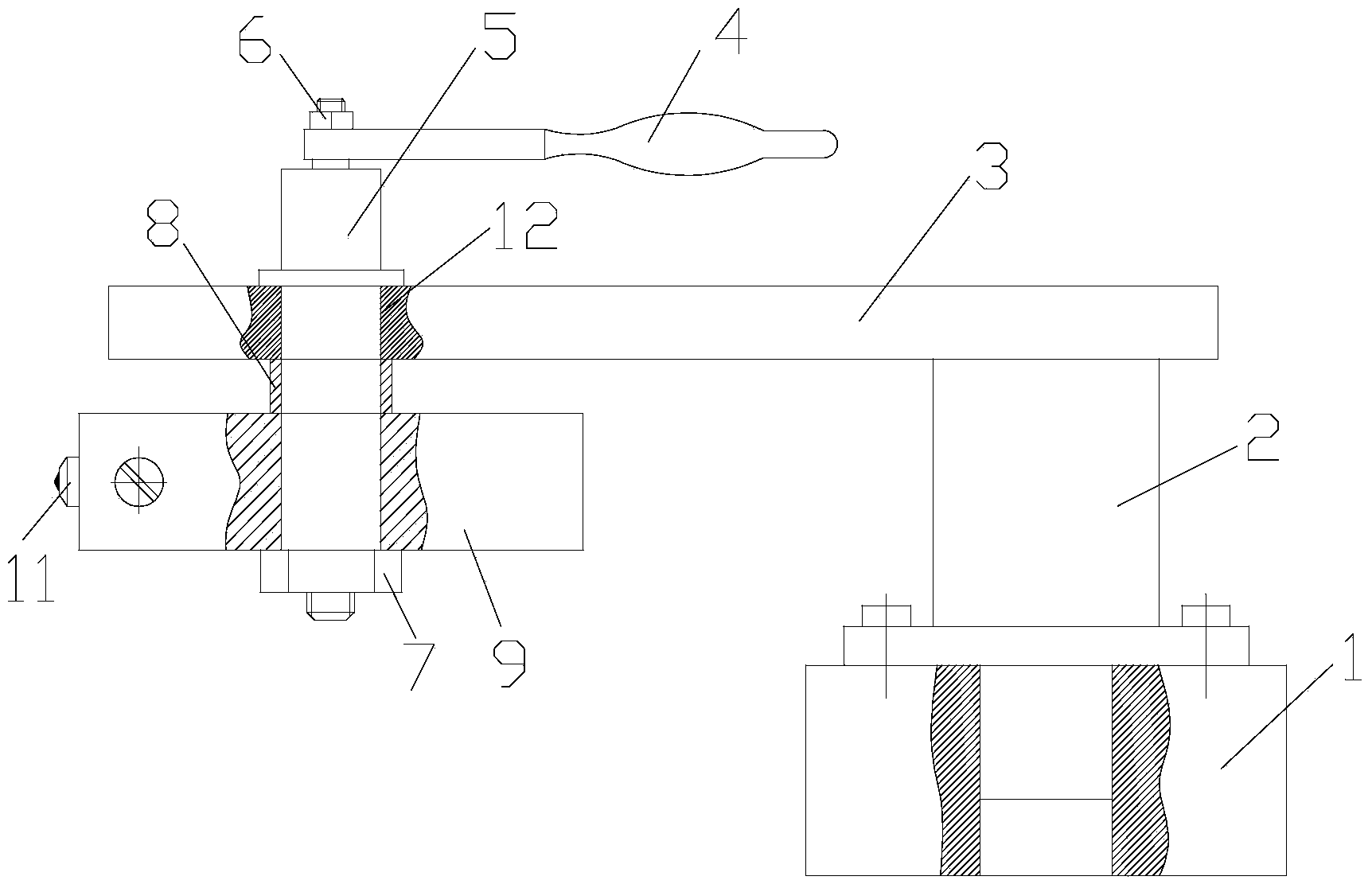

Magnetizer drilling jig gripper for electro-hydraulic servo valve

The invention relates to a drilling die and clamp for an electro-hydraulic servo valve magnetizer, comprising a jig body (1), a drill sleeve (2), a horizontal positioning mechanism, and a compaction mechanism. The invention is characterized in that: the drill sleeve (2) is tightly matched in a mounting hole of the jig body; the horizontal positioning mechanism comprises an L-shape positioning plate (4) and two U-shape slide positioning plates (3); wherein, the L-shape positioning plate is arranged on an installation position on the jig body and is fixed on the jig body through a Straight pin (51) and a screw (62); a through hole is arranged at the bottom of the U-shape slot of the slide positioning plate, and a magnetizer is positioned through one end of the U-shape slot. The invention has the advantages of convenient magnetizer positioning, convenient manufacturing of locating holes on the magnetizer, assurance of consistency of positioning precision for repetitious installation of jigs, improvement of work efficiency, and less requirements to the technological levels of workers while assuring demands of manufacturing.

Owner:SHANGHAI NUOMA HYDRAULIC SYST

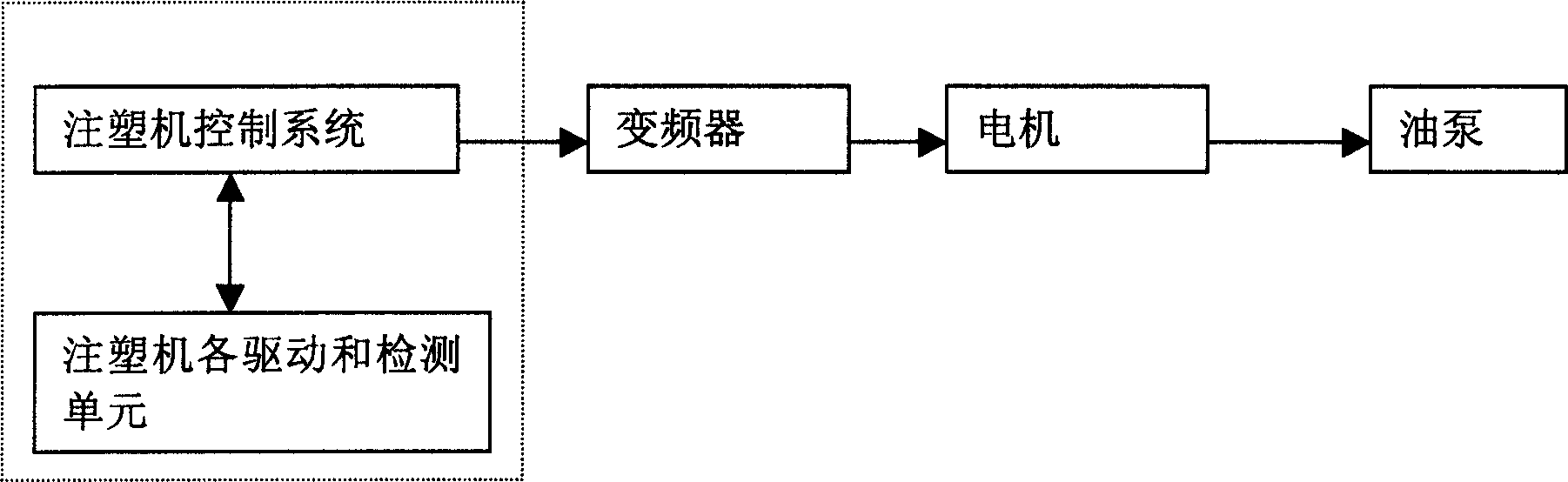

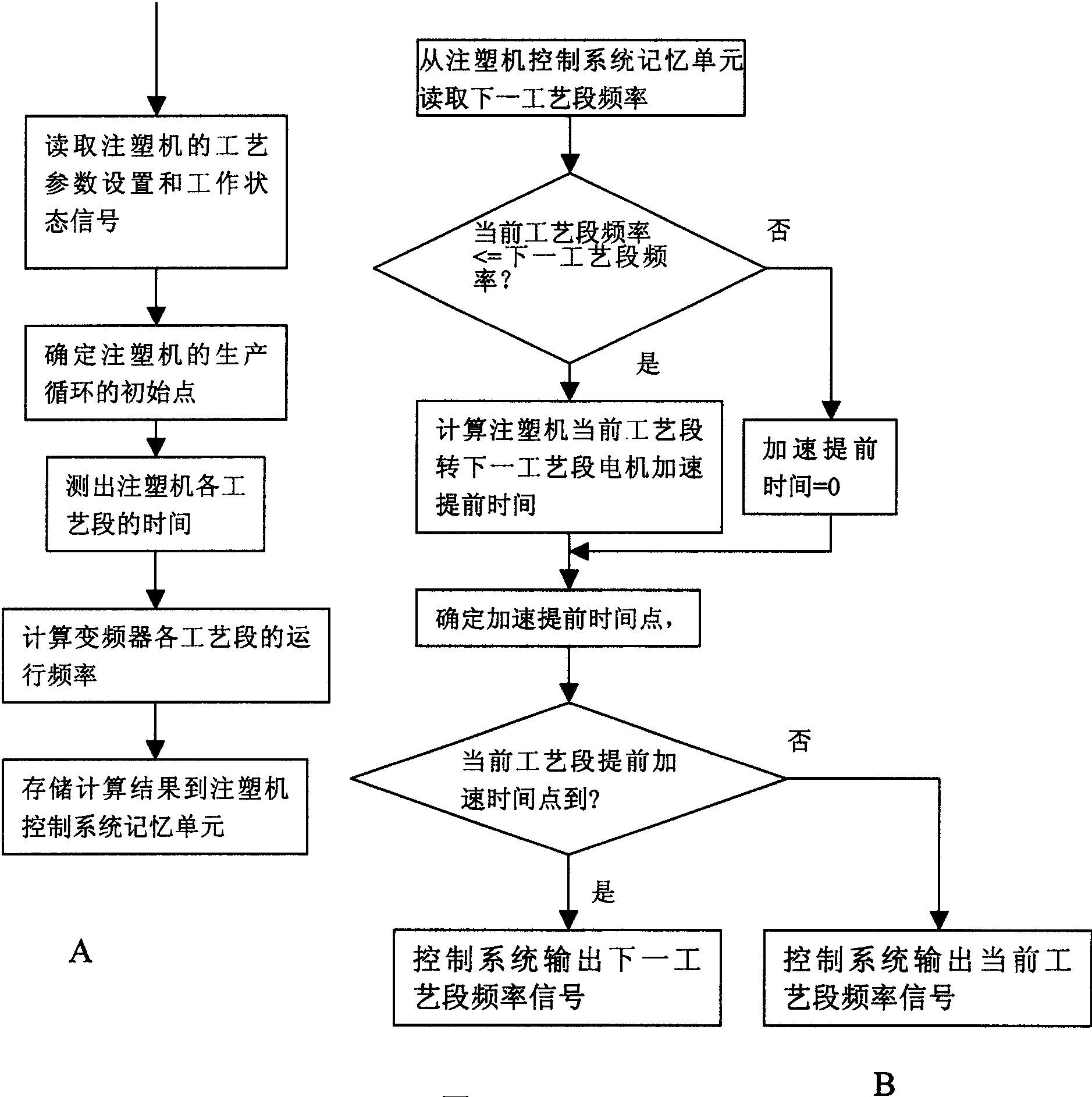

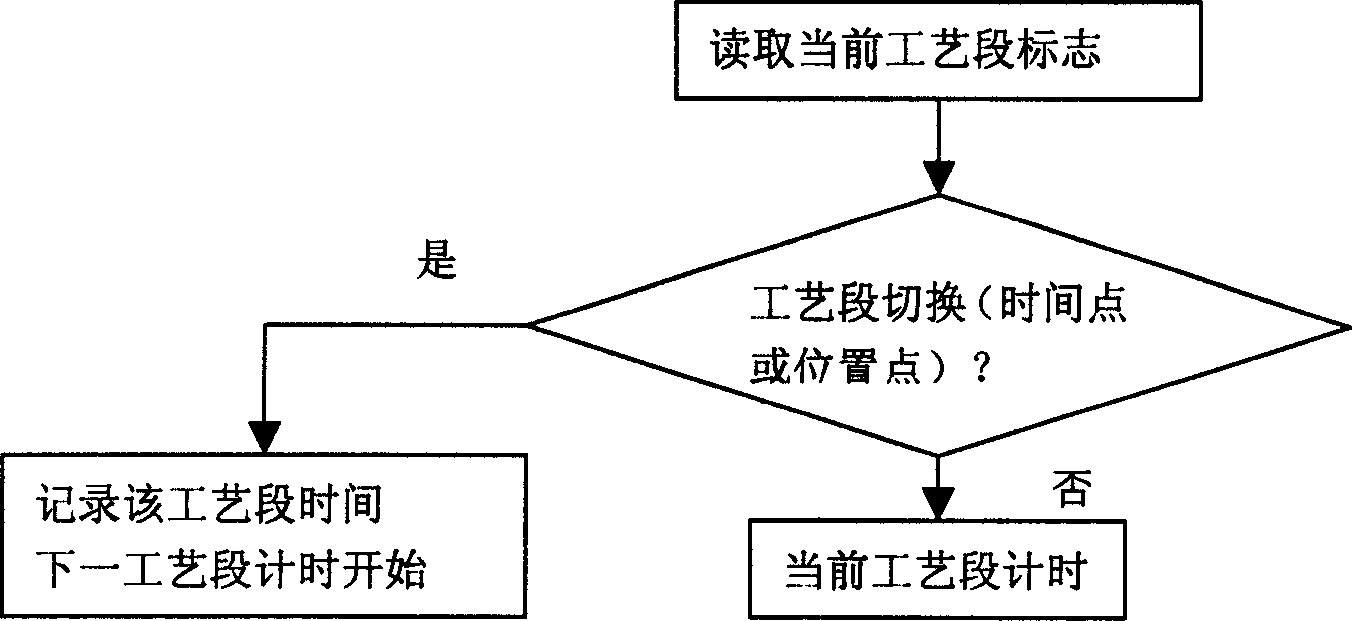

Control device and method for raising injection moulding machine production efficiency using application frequency changer

InactiveCN1597298AAchieving early accelerationQuick responseDC motor speed/torque controlFrequency changerControl signal

A control device and method for increasing the productivity of injection moulding machine by use of frequency variator to increase the switching speed between technological steps features that the technological parameters and working state signals are set up, the preset time from one step to next step is calculated out, and a frequency control signal for next step is output to the frequency variator when the preset time is reached.

Owner:深圳市珊星电脑有限公司

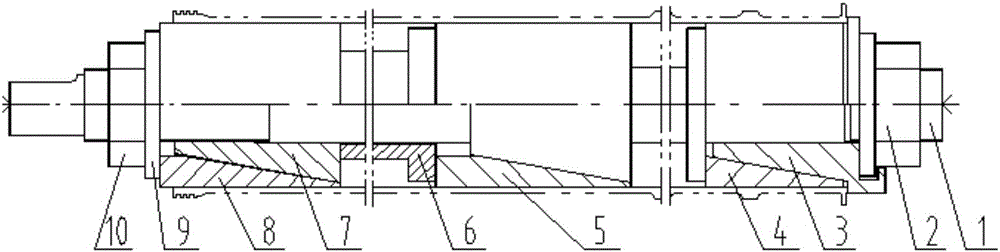

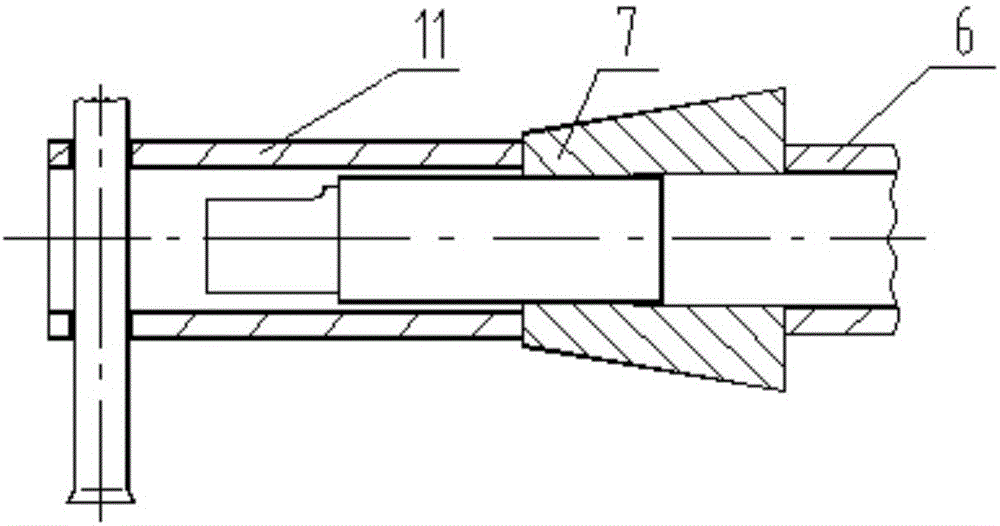

Core expansion type positioning mandrel

ActiveCN106270600AEliminate positioning gapsSolve the problem of difficult processing guaranteeExpansion mandrelsEngineeringRight-to-left

The invention discloses a core expansion type positioning mandrel, and belongs to the technical field of machining. The core expansion type positioning mandrel is a multi-section core expansion type positioning mandrel. A front end nut, a pressing ring, a front end elastic piece, a middle elastic piece, a pressing sleeve, a conical block, a rear end elastic piece, a gland and a rear end nut are sequentially connected through a shaft from right to left. The shaft is a rotary body and is composed of multiple cylindrical sections. The two ends of the shaft are provided with central holes and used for being connected with a machine tool. The core expansion type positioning mandrel is used for machining an outer profile of a hollow thin-walled thin and long shaft; according to a conical body core expansion and elastic deformation principle, by embedding the core expansion type positioning mandrel in the hollow thin-walled thin and long shaft, the positioning gap is eliminated when the outer profile of the hollow thin-walled thin and long shaft is machined, the problem that the outer profile of the hollow thin-walled thin and long shaft can not be easily turned and ground is solved, the core expansion type positioning mandrel is convenient to operate, reliable in positioning and novel in structure, and the machining requirement of the thin-walled thin and long shaft is met.

Owner:AECC AVIATION POWER CO LTD

Fresh vegetable processing technology

InactiveCN111034959AGuaranteed processing requirementsEasy to cleanFood treatmentProcess engineeringVegetable processing

The invention discloses a fresh vegetable processing technology. The processing technology comprises the following steps: selecting vegetable varieties with rich meat quality, removing parts with diseases and pests, rotten parts and wizened parts, cleaning the vegetables through a cleaning device, and drying the vegetables in a shade place; respectively slitting the cleaned vegetables, putting thevegetables into boiling water to finish precooking and blanching for 2-4 minutes, fishing out the vegetables, draining the vegetables, and cooling the vegetables to normal temperature; and uniformlyspreading the vegetables in a tray, putting the tray on a preset drying rack, putting the drying rack into a drying box, and keeping the temperature of the drying box to be 50-85 DEG C and the dryingtime to be 4.5-5.5 hours. A rotating plate cover is driven to rotate through rotation of a rotating rod, then vegetables with different sizes and diameters are conveyed to the positions between different flow distribution plates and conveyed to the positions between rotating cylinders with different intervals along the flow distribution plates, and the vegetables with different sizes are distinguished and cleaned through the rotating cylinders with different intervals while the vegetables are screened.

Owner:ANHUI METTLE FOODS CO LTD

Energy-saving printing and coating machine and energy-saving method

InactiveCN101850324AHigh solid contentReduce energy consumptionLiquid surface applicatorsCoatingsTemperature controlEngineering

The invention relates to an energy-saving printing and coating machine and an energy-saving method. In the technical scheme, a glue and ink supply system (an ink tank, a glue tank, an ink storage tank and a glue storage tank) is additionally provided with functions of heating and constant-temperature control to reduce the viscosity and to improve the solid content of the glue or ink, thereby achieving the energy-saving purpose. The invention belongs to the field of energy conservation and emission reduction.

Owner:杨峥雄

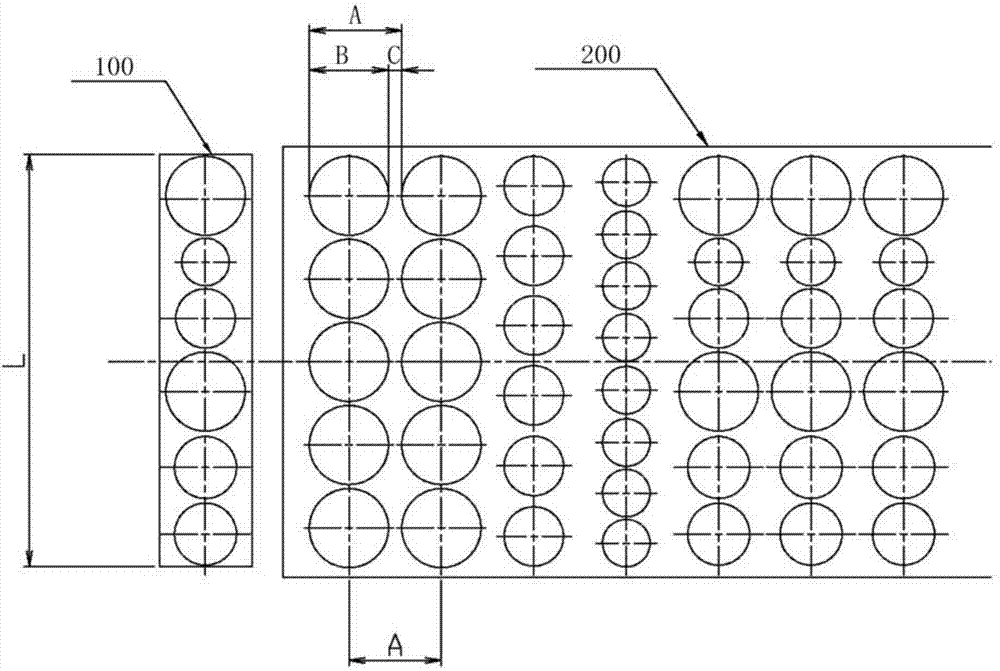

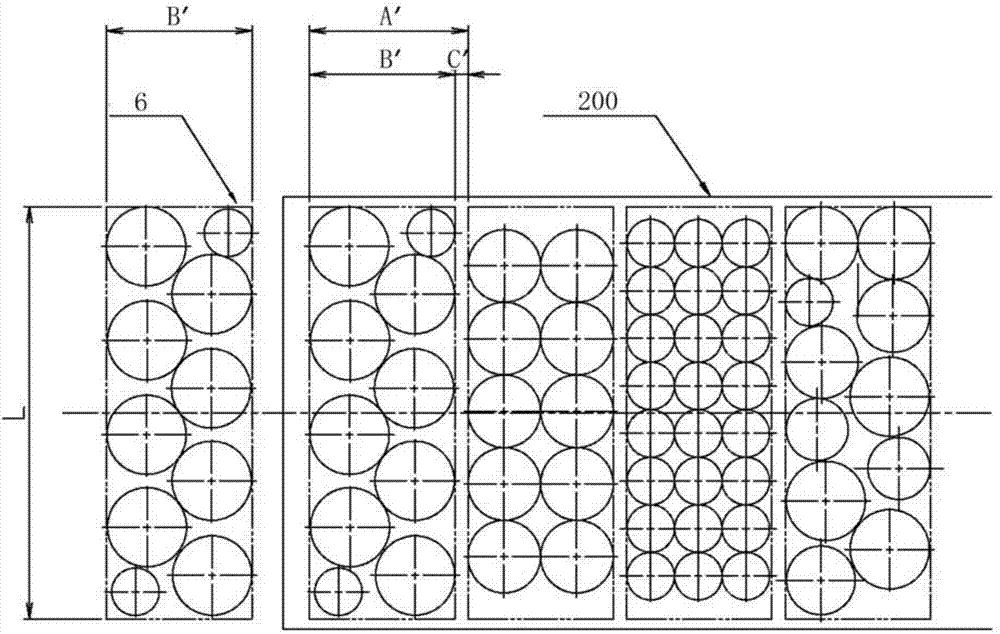

Engineering meridian tyre body cord fabric/belt bundle layer combining type cutting technique

ActiveCN101254660AGuaranteed accuracy requirementsGuaranteed process requirementsTyresManufacturing technologyTransmission belt

The invention relates to a combined body ply / belt layer cutting process for engineering radial tire, which belongs to the field of tire manufacture technology. The process comprises the following steps: guiding a guide roller, feeding cloth at fixed length by a traction device, cutting by a cutting machine, transferring to a belt layer jointing device by a conveying belt to carry out automatic jointing, storing the jointed belt layer and transferring to an automatic rubber sheet bonding device by a conveying belt to bond a rubber sheet and wrap the edges, and transferring to a coiling device to coil the belt layer; and guiding a guide roller, feeding cloth at fixed length by a traction device, cutting by the same cutting machine, transferring to a body ply jointing device by a conveying belt to carry out automatic jointing, storing the jointed body ply and transferring to an automatic rubber sheet bonding device by a conveying belt to bond a rubber sheet and wrap the edges, and transferring to a coiling device to coil the body ply. The process has the advantages of reduced equipment investment and ensured cutting accuracy and process requirement of the body ply and the belt layer.

Owner:TRIANGLE TIRE

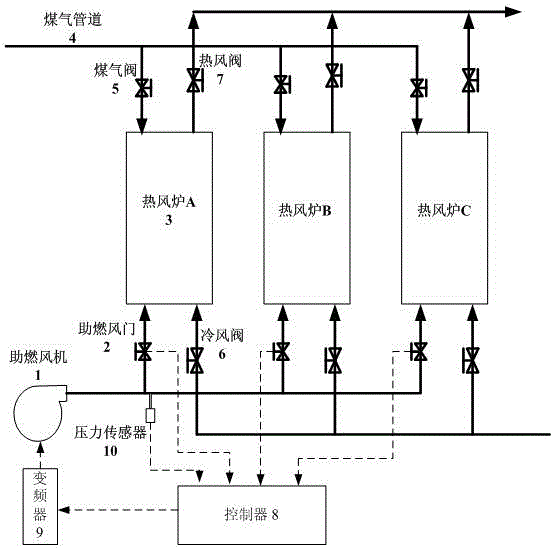

Energy-saving regulating and controlling method for combustion fan of blast furnace hot blast stove

ActiveCN104805247ARealize energy saving and consumption reductionGuaranteed process requirementsBlast furnace detailsHeating stovesFrequency changerAir volume

The invention relates to an energy-saving regulating and controlling method for a combustion fan of a blast furnace hot blast stove. A traditional combustion fan is designed according to needs of maximum working stations of multiple hot blast stoves, operates at power frequency and is constant in power supply pressure; air supply amounts of each hot blast stove at different working conditions are regulated by a corresponding combustion air door of each hot blast stove; as open degrees of the combustion air doors at the most of time are small, and the air supply pressure is higher, the waste of mass power energy is caused. According to the energy-saving regulating and controlling method disclosed by the invention, under the condition that operation working conditions of the combustion fan of the original blast furnace hot blast stove are unchanged, a frequency converter is added on the blast furnace hot blast stove, and a pressure sensor is arranged on an outlet pipeline of the combustion fan; a control signal of the frequency converter, a pressure signal of the pressure sensor and an open degree signal of the combustion air door are connected to an energy-saving controller; the energy-saving regulation and control over the combustion fan of the blast furnace hot blast stove are realized by adopting a technical method of linking the air door with pressure regulation, so that proper air supply pressure is dynamically regulated and controlled according to the maximum open degree of the air door, and the aims of greatly saving energy and reducing consumption are achieved.

Owner:上海联达节能科技股份有限公司

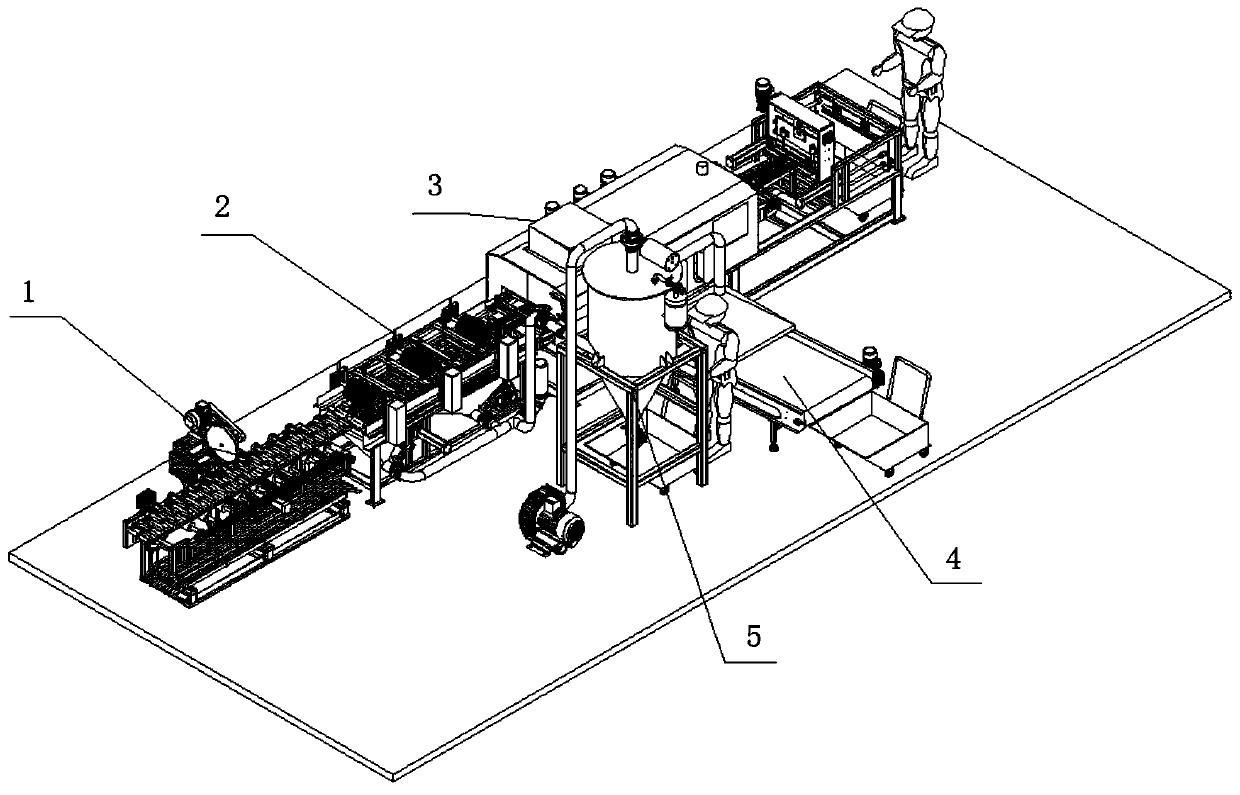

Waste rubber crawler belt material recycling production line

PendingCN110435048AImprove cutting recovery efficiencyNo displacementPlastic recyclingMetal working apparatusProduction lineSurface layer

The invention discloses a waste rubber crawler belt material recycling production line. The waste rubber crawler belt material recycling production line comprises a segmenting and cutting-off tool, asurface rough cutting tool, a surface treatment and separation device, a reclaimed material conveying structure and a vacuum recycling device; the segmenting and cutting-off tool is used for segmenting and cutting off a crawler belt; the surface rough cutting tool is used for carrying out rough cutting treatment on cut-off long-strip-shaped crawler belt surface rubber; the surface treatment and separation device is used for carrying out cutting treatment, embedded part separation, steel wire separation and steel wire shearing short and recycling on the roughly cut crawler belt remaining surface layer rubber; the reclaimed material conveying structure is used for conveying the cut surface rubber and an embedded part; and the vacuum recycling device is used for carrying out vacuum collectionand recycling on rubber particles left by the rough cutting treatment. According to the waste rubber crawler belt material recycling production line, residual rubber scraping, embedded part separation and steel wire shearing short and collection of the waste rubber crawler belt can be realized, the functions of the equipment are various, the classification and collection of all components in thewaste rubber crawler belt are effectively realized, the working synergy of all the mechanisms in the equipment is high, and the working efficiency is high.

Owner:ZHENJIANG SHEN WARD MACHINERY CO LTD

Traverse feeding device of external groove plungecut grinder

InactiveCN102172890AReduce frictional resistanceImprove stabilityGrinding drivesReduction driveReducer

The invention provides a traverse feeding device of an external groove plungecut grinder. The traverse feeding device comprises a roller cross guide rail pair, a traverse feed table and a drive unit, wherein the roller cross guide rail pair comprises guide rails, a roller retainer and a cylindrical roller, and the cylindrical roller is arranged on the guide rails through the roller retainer; the drive unit comprises a stepping motor, a harmonic speed reducer and a ballscrew, wherein the stepping motor drives the harmonic speed reducer to connect the ballscrew, an output shaft of the harmonic speed reducer is fixedly connected with a shaft end of a screw of the ballscrew, a nut of the ballscrew is connected with the transverse feed table, and the nut of the ballscrew can move forth and back on the screw of the ballscrew. By means of the transverse feeding device, the deceleration with large rotation ratio can be carried out through the harmonic speed reducer so that the transverse feeding is more stable, and the transverse feeding precision is improved by controlling the stepping motor through electric programs, thus accurate feeding and reversing are realized, and the machining precision of a bearing ring is accurate; and simultaneously, the stroke of the transverse feeding is also enlarged, the purchase cost of new equipment is reduced, and the purpose of a machine tool is widened.

Owner:HARBIN BEARING GROUP CORP

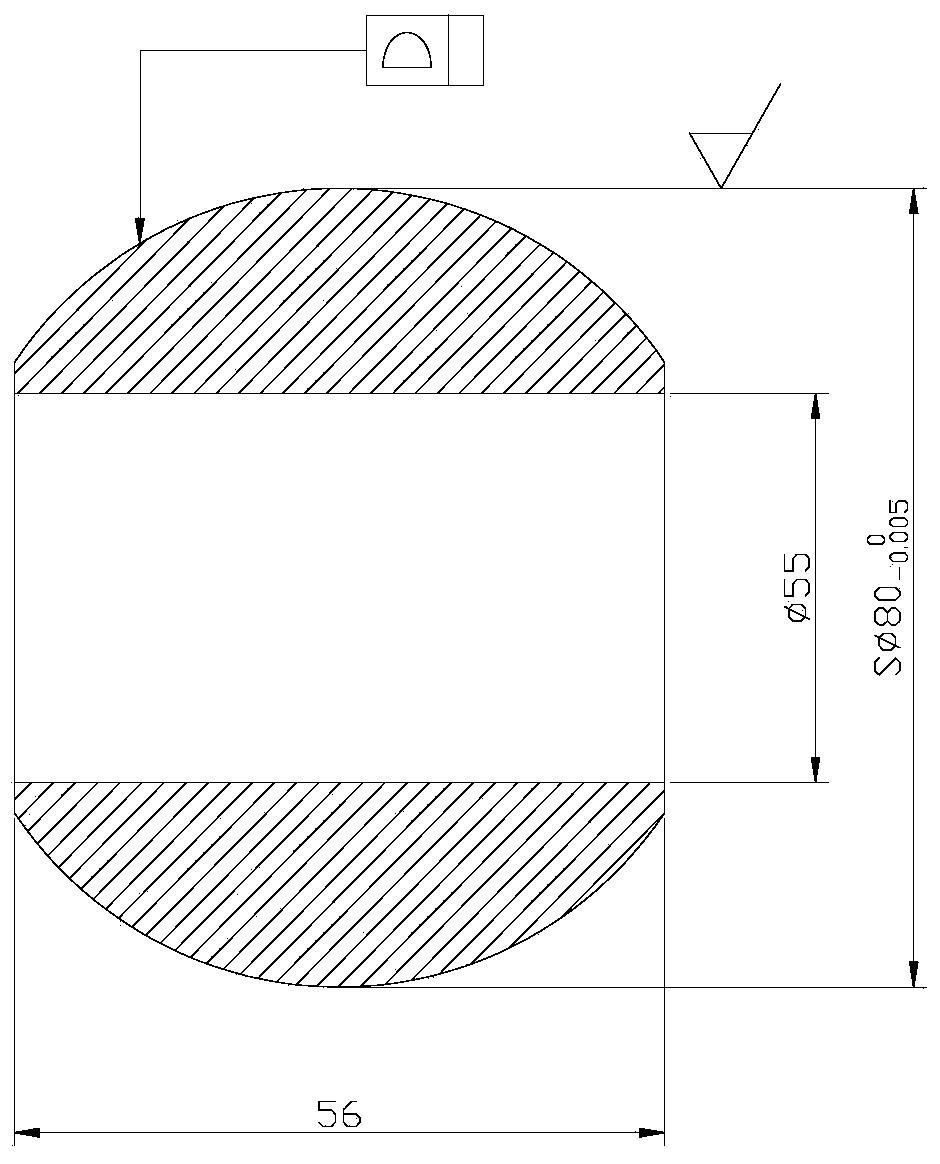

Grinding method for machining high-precision outer spherical surface through ordinary cylindrical grinding machine

ActiveCN103659519AGuaranteed process requirementsLess investmentSpherical surface grinding machinesAbrasive surface conditioning devicesEngineeringCylindrical grinding

The invention provides a grinding method for machining a high-precision outer spherical surface through an ordinary cylindrical grinding machine. The grinding method comprises the steps that firstly, a grinding wheel is selected, wherein the width of the grinding wheel is 14-16mm larger than that of a finished spherical part, the diameter of the grinding wheel is large enough so that a spherical surface of a part can be formed through grinding, and namely the distance between the outer side of the grinding wheel and an installation hole must be larger than the depth of the spherical surface; secondly, a special dressing clamp for grinding wheel dressing is manufactured, wherein a grinding machine end face grinding wheel dressing device is installed on the grinding machine, and the special dressing clamp is made to be well fixedly connected with the grinding machine end face grinding wheel dressing device; the grinding wheel is dressed until the size requirement is met by the grinding wheel; a part to be machined is fixed to the grinding machine and the dressed grinding wheel are aligned; grinding is conducted until the finished spherical part is obtained. By the adoption of the grinding method for machining the high-precision outer spherical surface through the ordinary cylindrical grinding machine, under the condition that the equipment investment is not increased, the existing ordinary cylindrical grinding machine is used for machining the outer spherical surface which has high size precision and good surface quality, and high practical value is obtained.

Owner:TIANJIN SAIXIANG M&E ENG CO LTD

Compression sintering and quenching integrated production process for cemented carbides

The invention relates to a pressure sintering and quenching integrated manufacturing process for the hard alloy. The manufacturing process is characterized in that the manufacturing process comprises the process steps that product charge into furnace, vacuum pumping (0.1 to 350Pa), temperature elevation, compression sintering (the temperature is kept at 1350 to 1600DEG C and the product is sintered for 30 to 100 minutes, and the pressure is up to 1 to 10 MPa), cooling down, heat preservation (1000 to 1300 DEG C, for 0 to 100 minutes), decompression (0.10 to 0.65MPa), quenching, cooling down, pressure relief and furnace tapping. The manufacturing process has the advantages that because the two working procedures of pressure sintering and quenching of the hard alloy are integrated into one working procedure and integrated on one device, the equipment investment can be saved on premise that the product quality is not influenced, thus the energy consumption can be reduced by above one time, the production cycle is shortened by above 4.5 times, the production efficiency is improved by above 4.5 times, the production cost is reduced by above one time, the man power is saved by one time, and the worksite is saved by about one time.

Owner:荆门金钻硬质合金有限责任公司

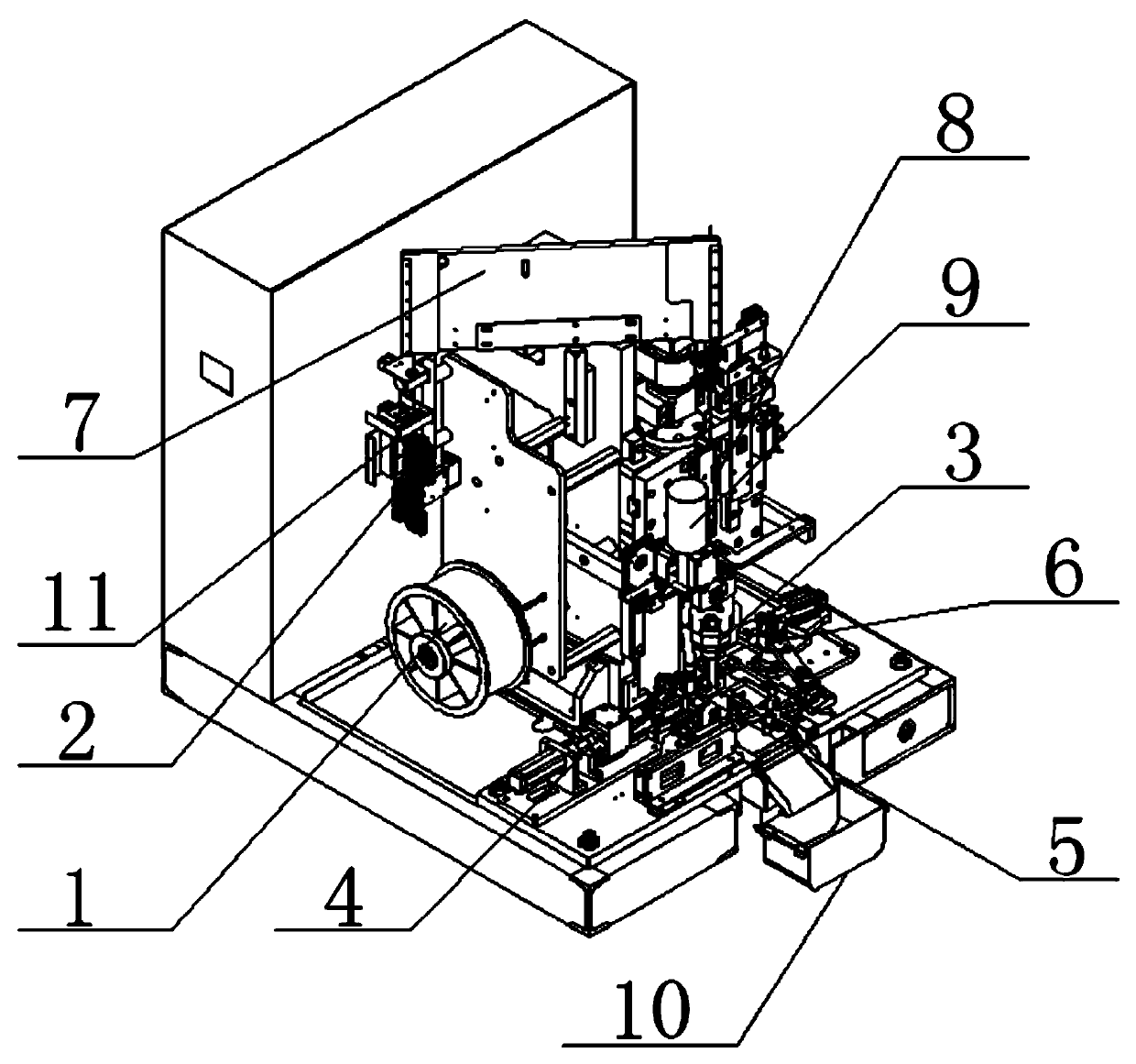

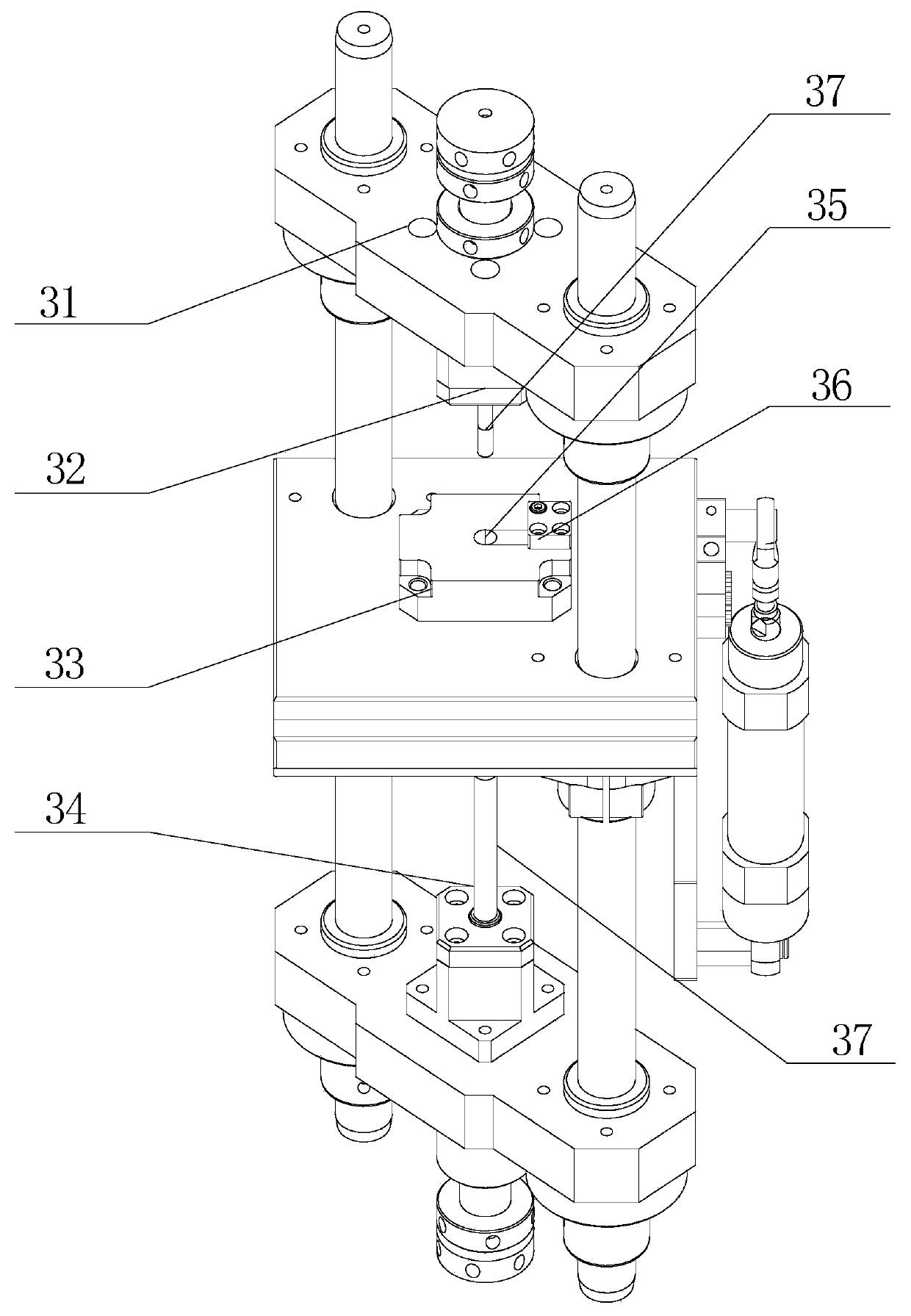

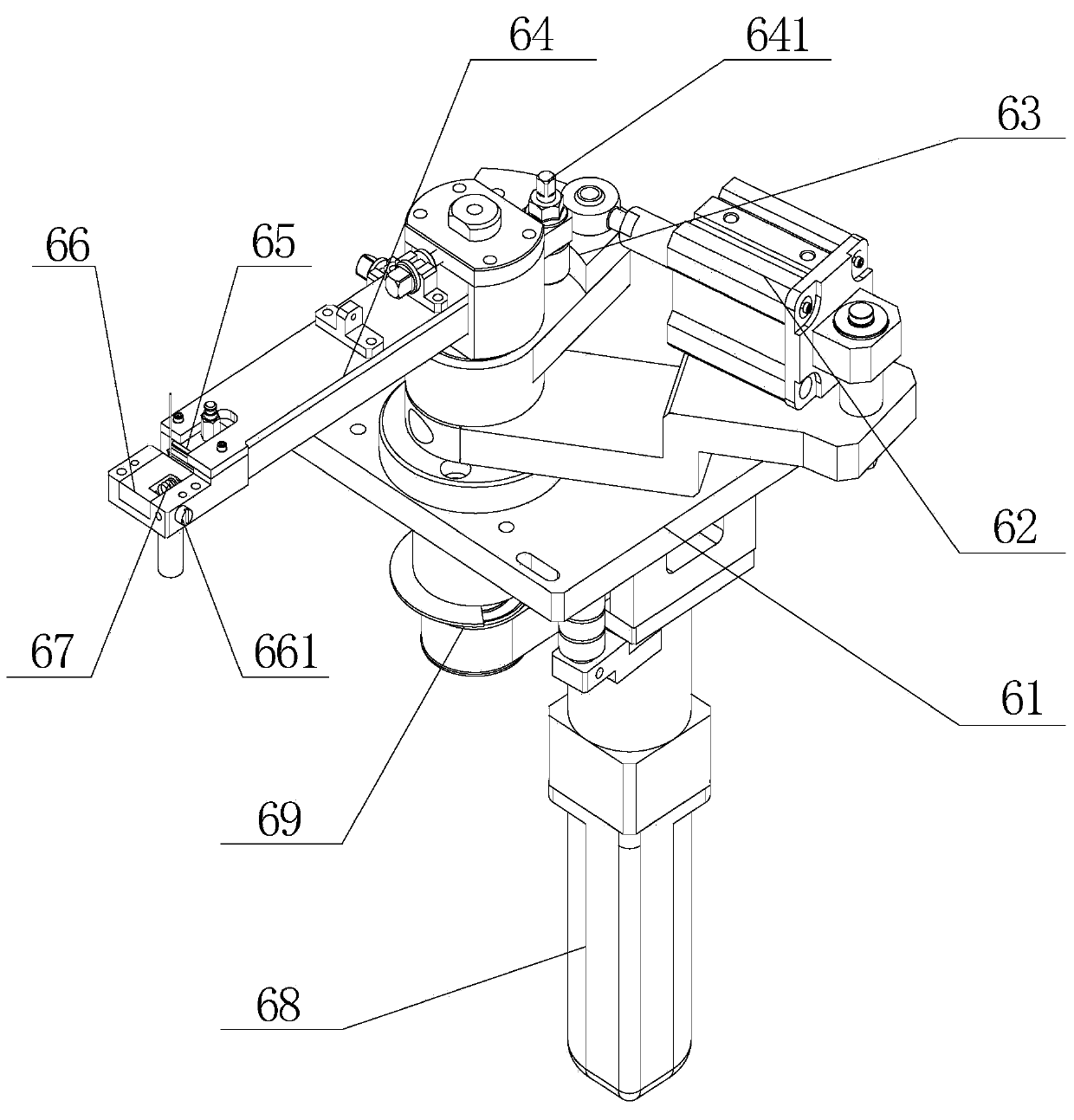

Automatic vertical forming machine

ActiveCN104259457AAvoid situations where tantalum powder is not embeddedEasy weightMolding machineStructural engineering

The invention discloses an automatic vertical forming machine. The machine comprises a rolled tantalum wire disc which is arranged at the position, on the side face of a vertical mounting frame, above a rack; a tantalum wire is led out of the rolled tantalum wire disc to penetrate into a one-time straightening mechanism above the rolled tantalum wire disc, then penetrate into a tantalum wire supply mechanism above the one-time straightening mechanism, and finally stretch into a mould cavity of a mould in the middle of a horizontal mounting plate in the middle of the rack; a powder shaking mechanism on the left side of the horizontal mounting plate feeds tantalum powder into the mould cavity from a powder shaking box, the tantalum powder allowing the tantalum wire to be inserted is formed through the mould, the tantalum is cut off through a cutting-off flattening mechanism on the right side of the horizontal mounting plate, the head end of the tantalum wire is flattened, and a finished product after compression moulding is fed out. According to the machine, digital control automatic machining is achieved, the machining efficiency is high, the weight and the size of a tantalum block are easy to regulate and control, the quality is better, the mass deviation is not large, one person can control multiple devices to work, manual input is reduced, the machining cost is reduced, and the good use value and economical value are achieved.

Owner:贵阳立特精密机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com