Energy-saving printing and coating machine and energy-saving method

A coating machine and coating technology, which is applied to devices and coatings for coating liquid on the surface, can solve problems such as waste of resources, large emissions, and impact on human health, and achieve the effect of reducing emissions and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

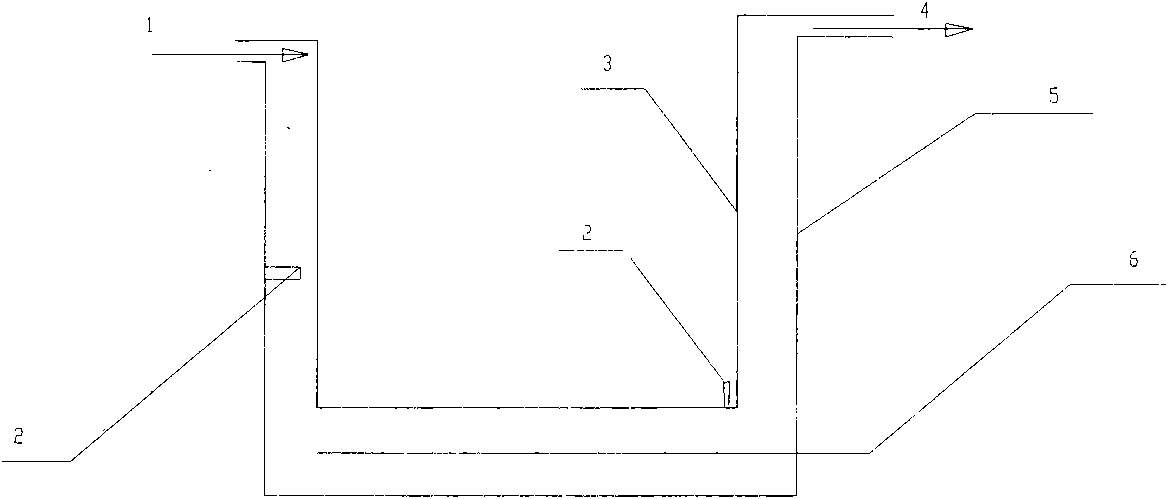

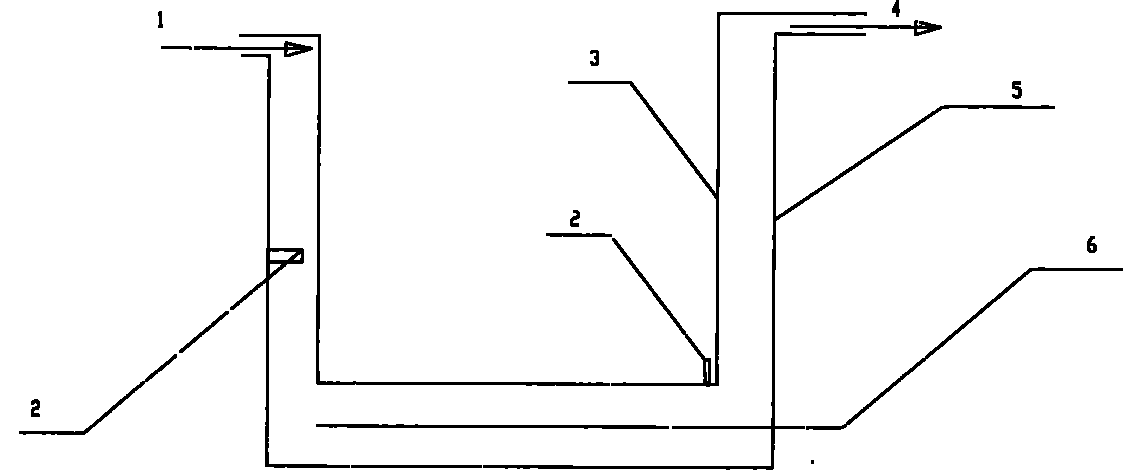

[0008] According to the general existence of ink and glue that the viscosity decreases when heated and the leveling property improves, the ink tank (or glue tank, ink storage barrel (or glue storage barrel)) is added with heating and constant temperature control functions, which can make the ink , glue, and paint are kept at a suitable temperature higher than room temperature, so as to ensure the leveling property, increase the solid content of ink, glue, and paint, thereby reducing the energy consumption of the drying box. For solvent-based inks , glue, paint, which not only saves energy, but also reduces the emission of organic solvents.

[0009] For water-based inks, glues, and paints, because water has a large latent heat of evaporation and is difficult to volatilize, in order to achieve the purpose of drying, the previous method is to increase the drying power and reduce the production speed, which affects the production efficiency and increases the cost. According to dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com