Patents

Literature

60results about How to "Reduce production speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

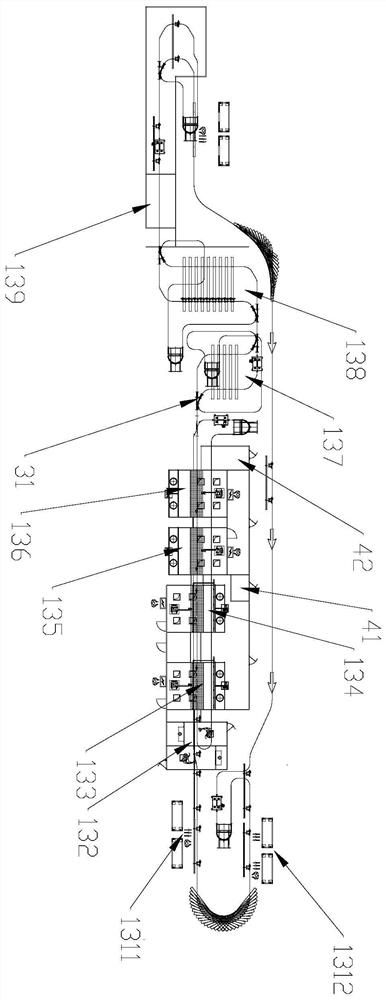

Linear eye drop bottle washing, filling, plugging and cap screwing integrated machine and method

InactiveCN103738903AAvoid insufficient debugging and maintenance spaceShortened line lengthBottle-handling machinesProcess engineeringWash bottle

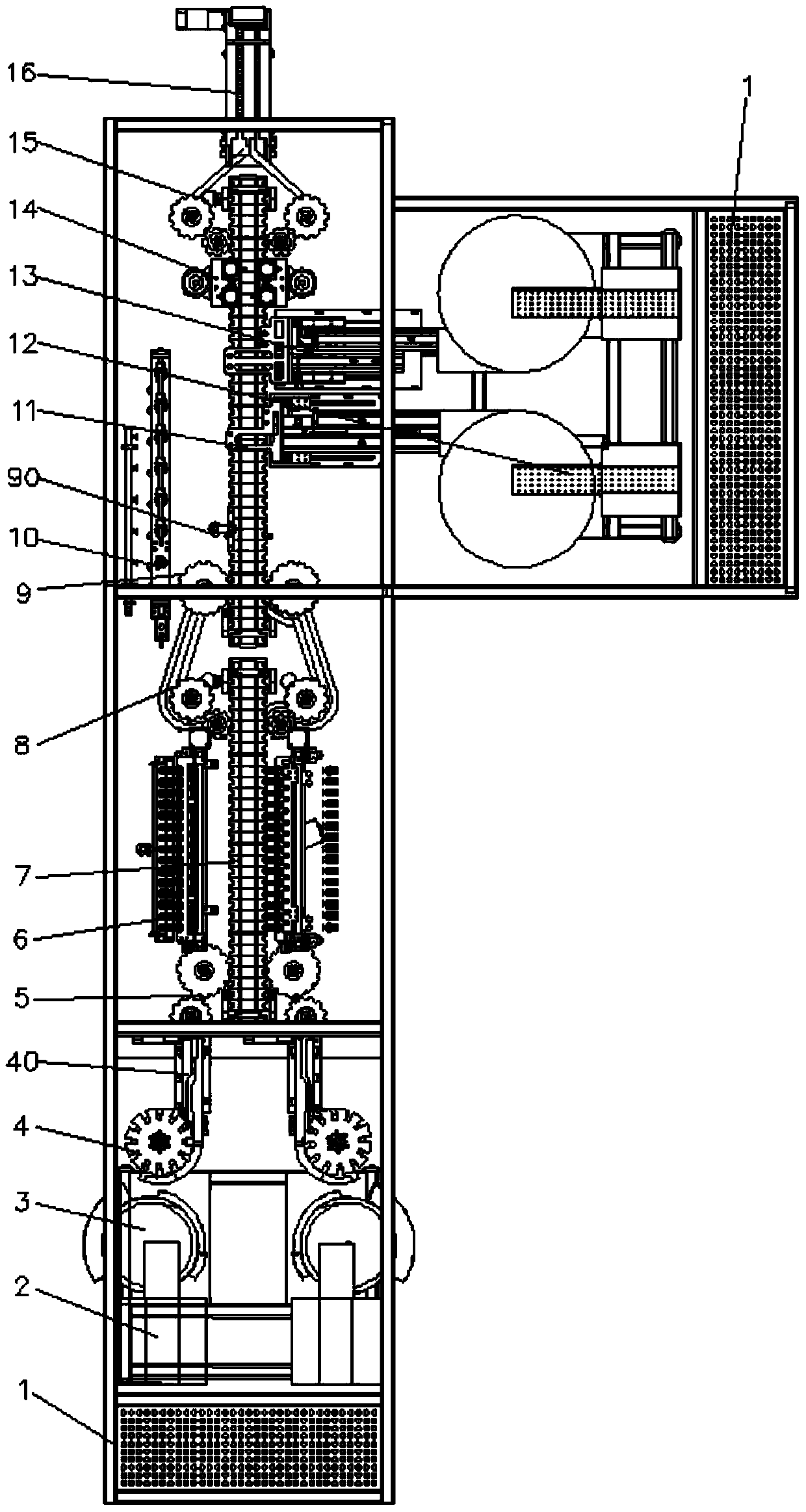

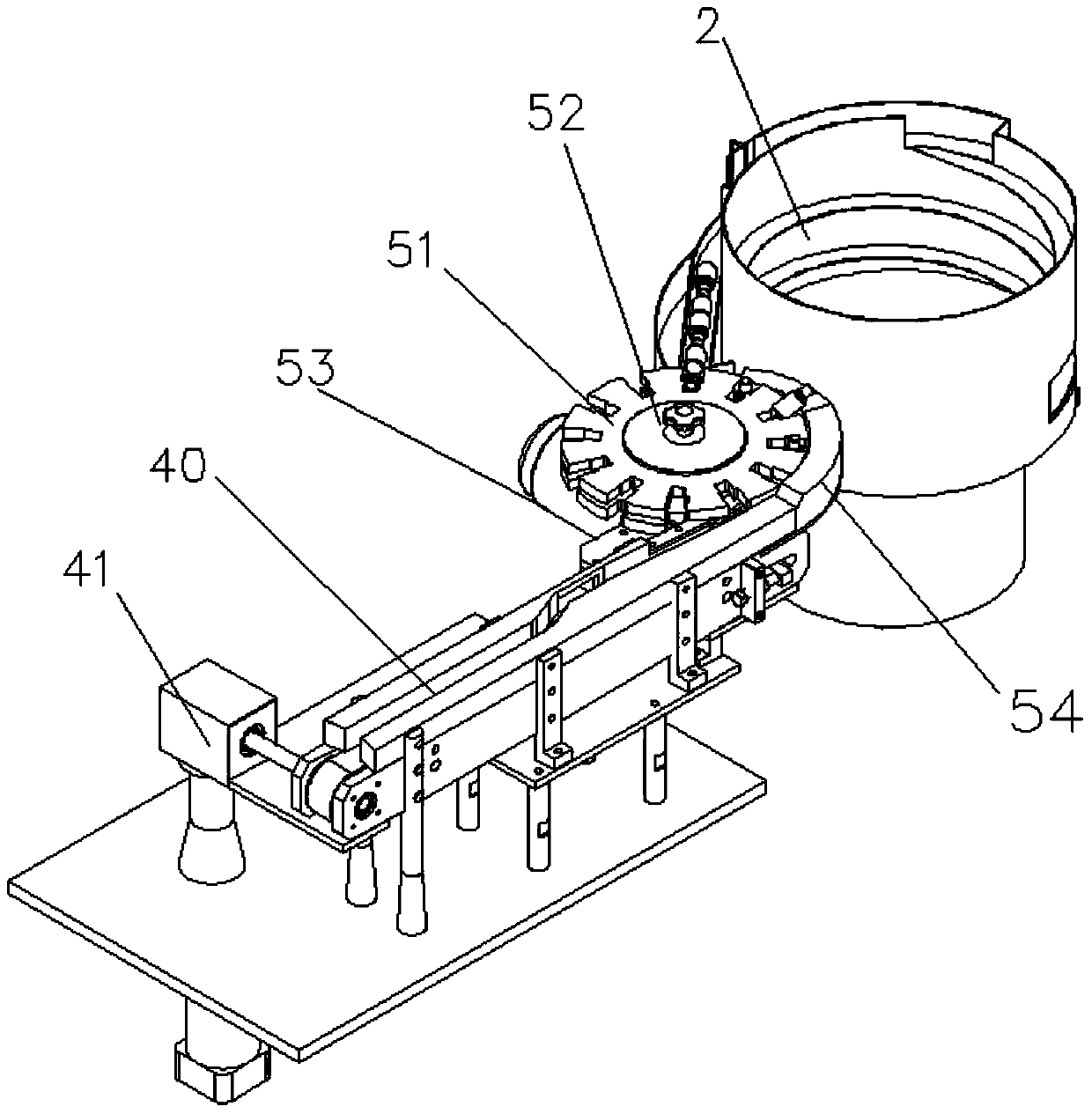

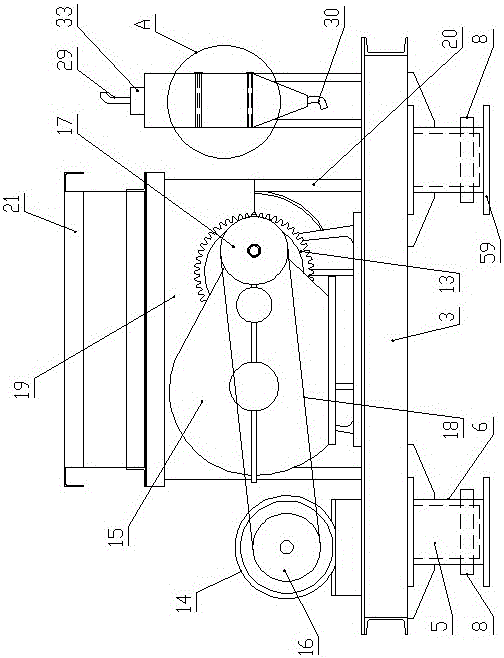

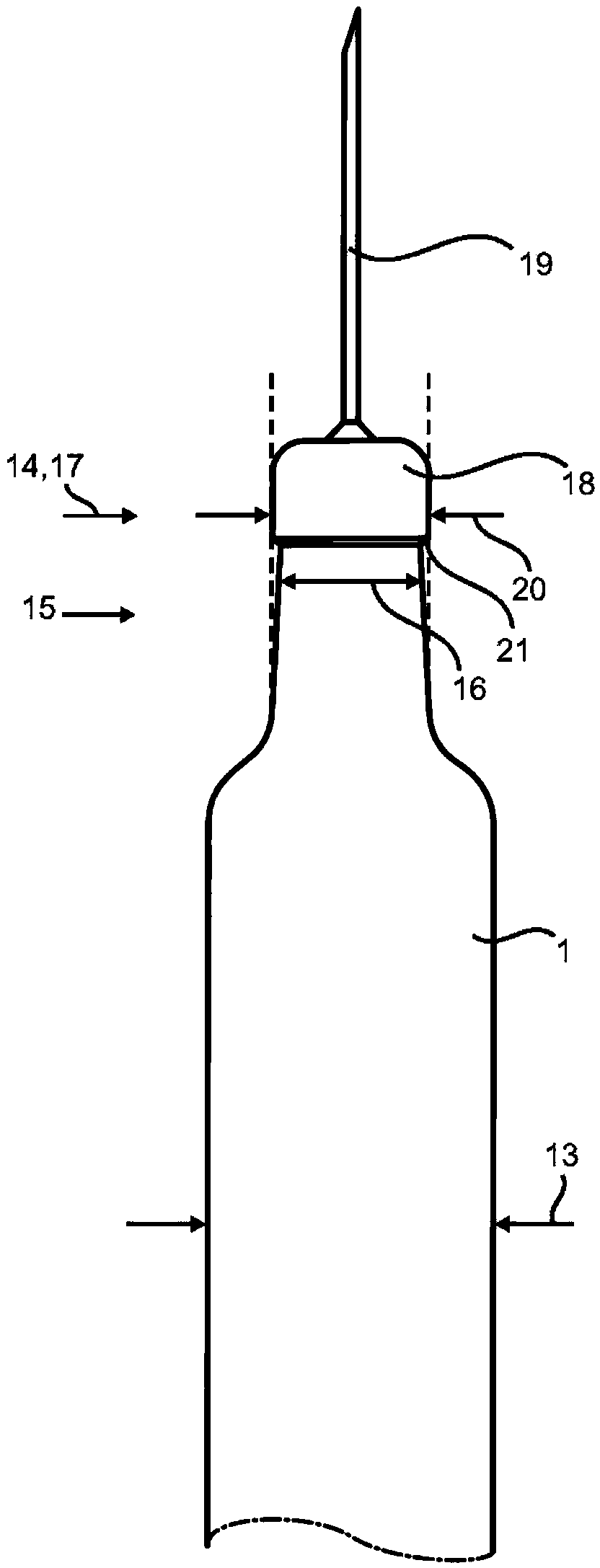

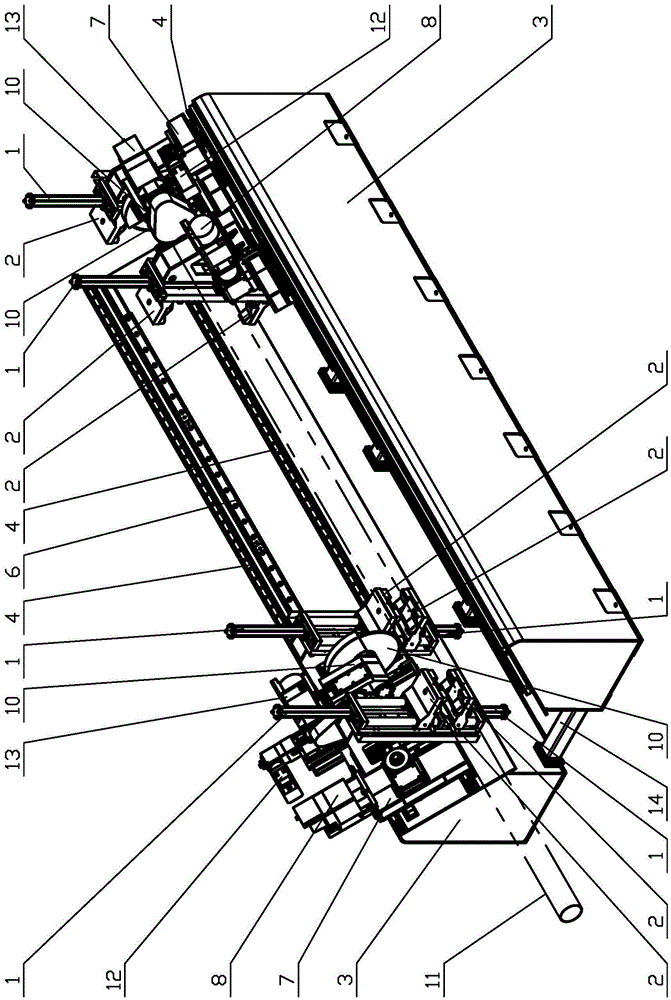

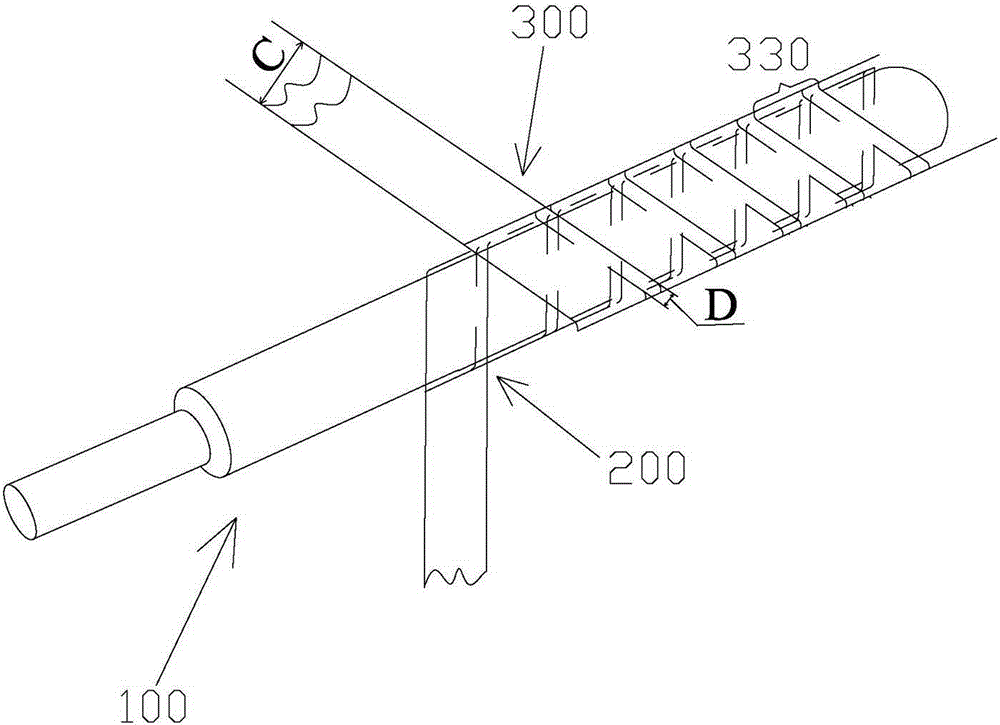

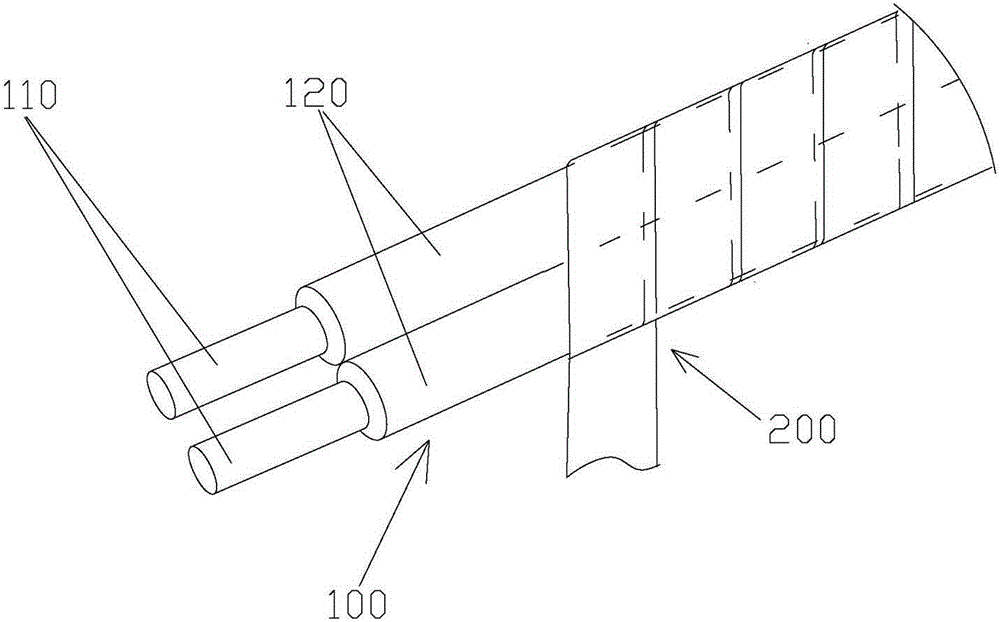

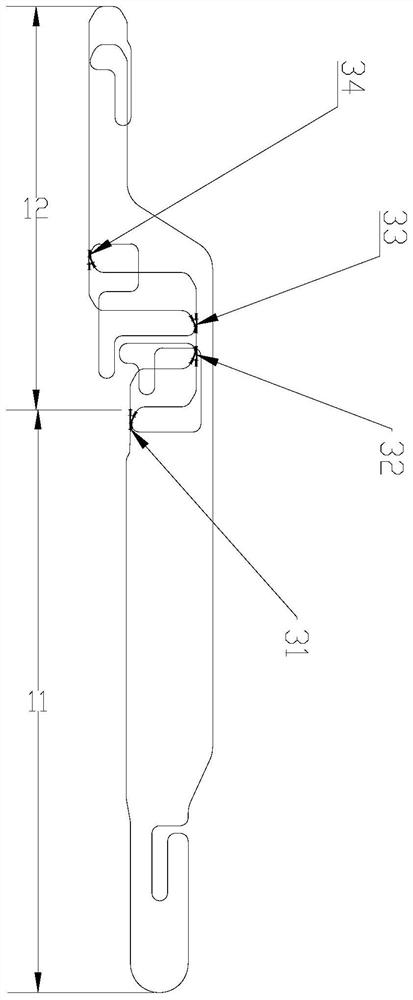

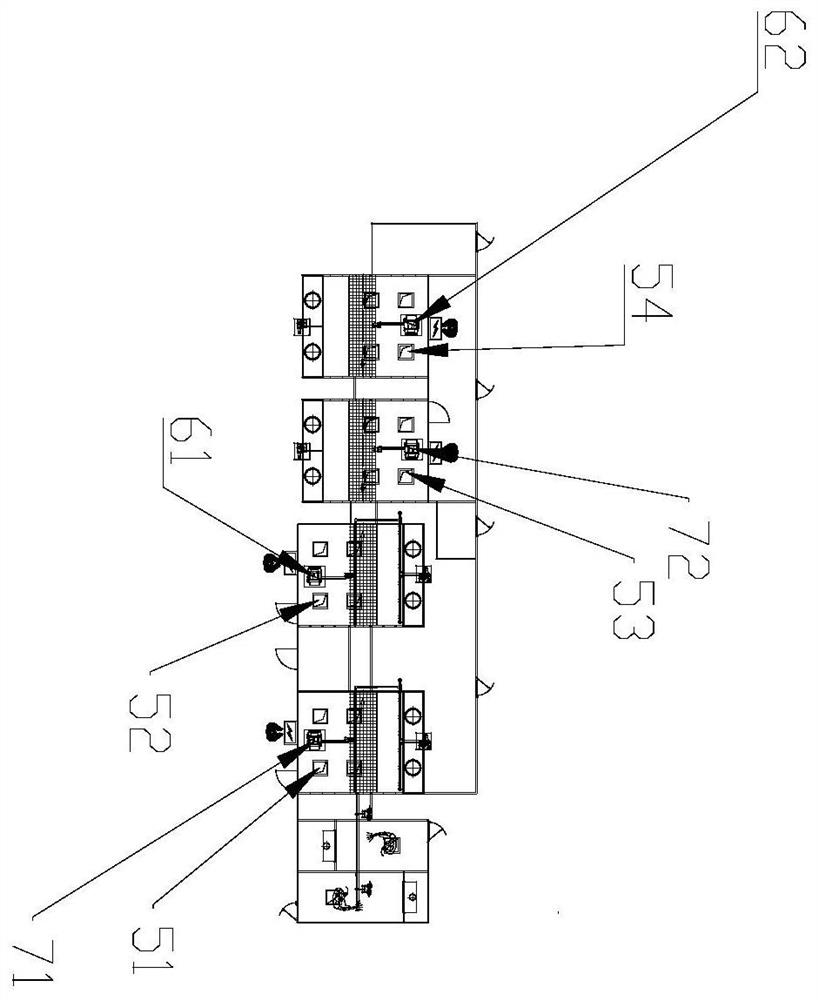

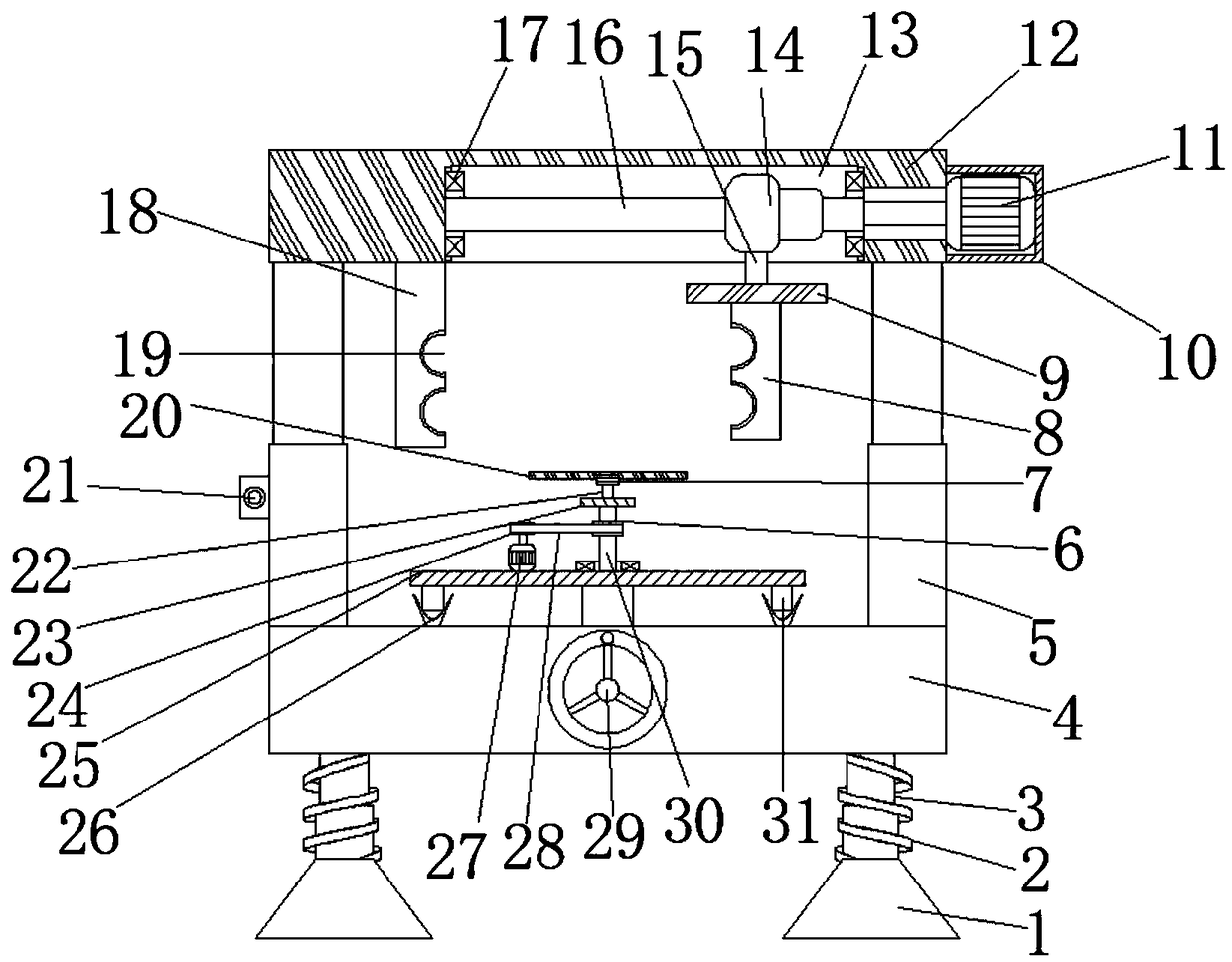

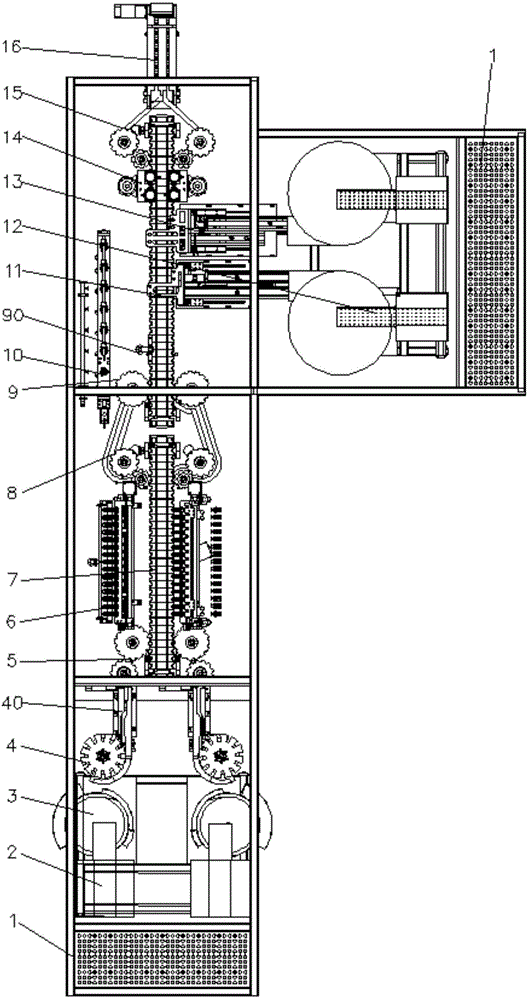

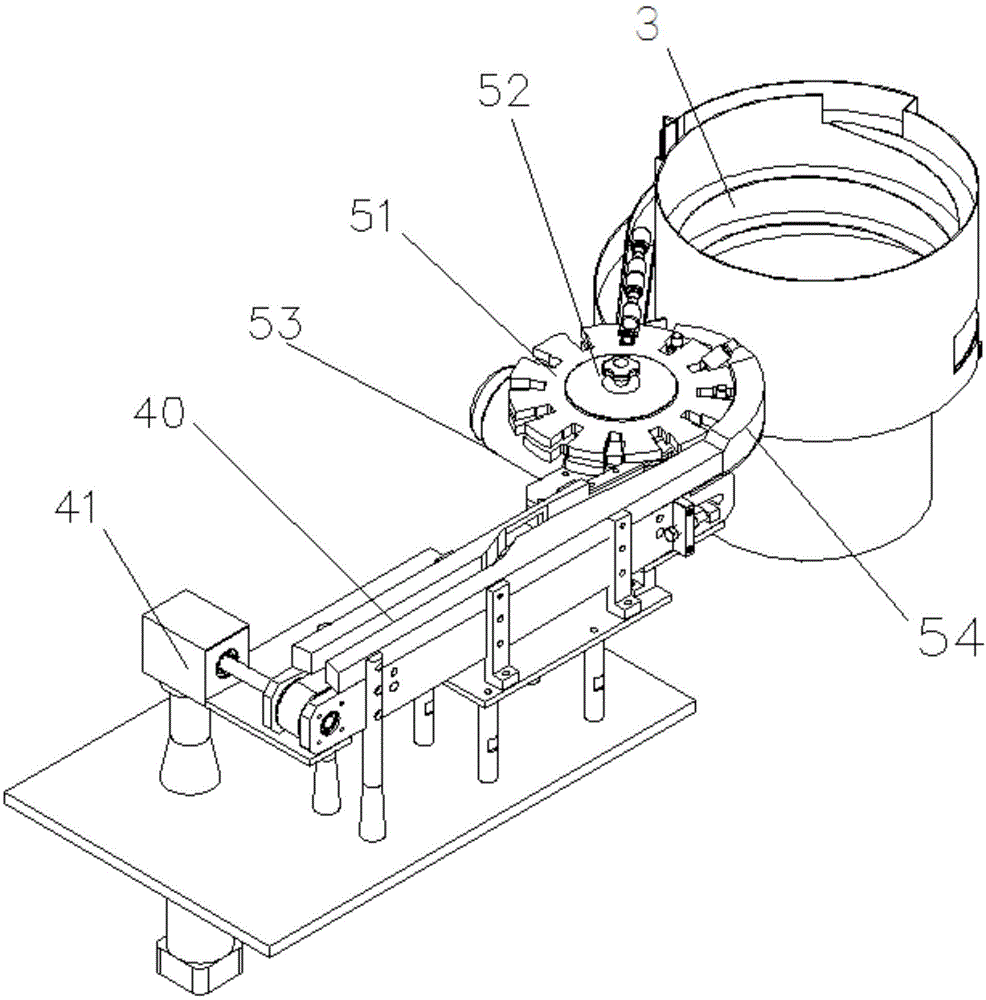

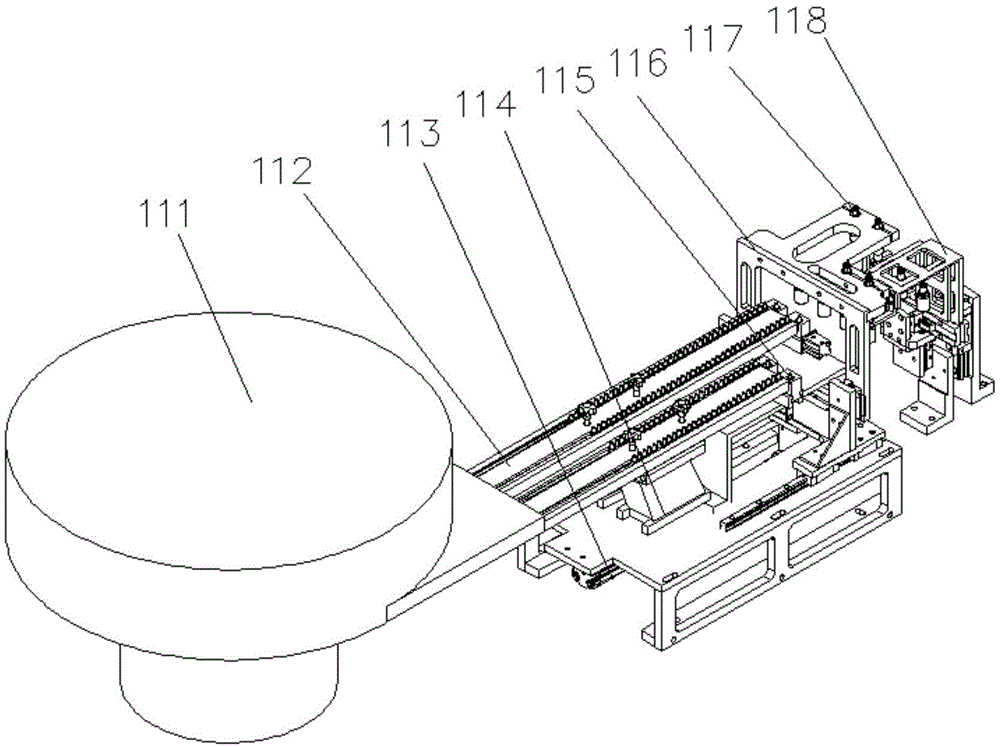

The invention discloses a linear eye drop bottle washing, filling, plugging and cap screwing integrated machine and a method. The linear eye drop bottle washing, filling, plugging and cap screwing integrated machine comprises a bottle washing and conveying synchronous belt and a filling, plugging, cap screwing and bottle conveying synchronous belt which are arranged back and forth in parallel; under the state of laminar flow protection and online monitoring sterile control state, the sterile production process of each function of bottle washing, filling, plugging, capping and cap screwing in the linear intermittent motion process of eye drops is realized; not only can insufficient debugging and maintaining space be prevented, but also the length of the production line can be shortened; the sterile control cost can be reduced; the device running and connection stability can be improved; the number of operators can be reduced; the production speed can be improved; each component is arranged in a linear mode, and a shifting wheel guides and turns over sterile eye drop bottles to arrange; a gantry structure is adopted for plugging and capping, so that the space for debugging, maintenance and artificial intervene can be settled effectively; the length of the whole line is shortened by the shifting wheel; the gantry plugging and capping structure is stable and reliable, facilitating to increasing the quantity of cap and plug conveying channels and improving the production stability.

Owner:CHANGSHA ZHONGYI PHARMA MACHINERY

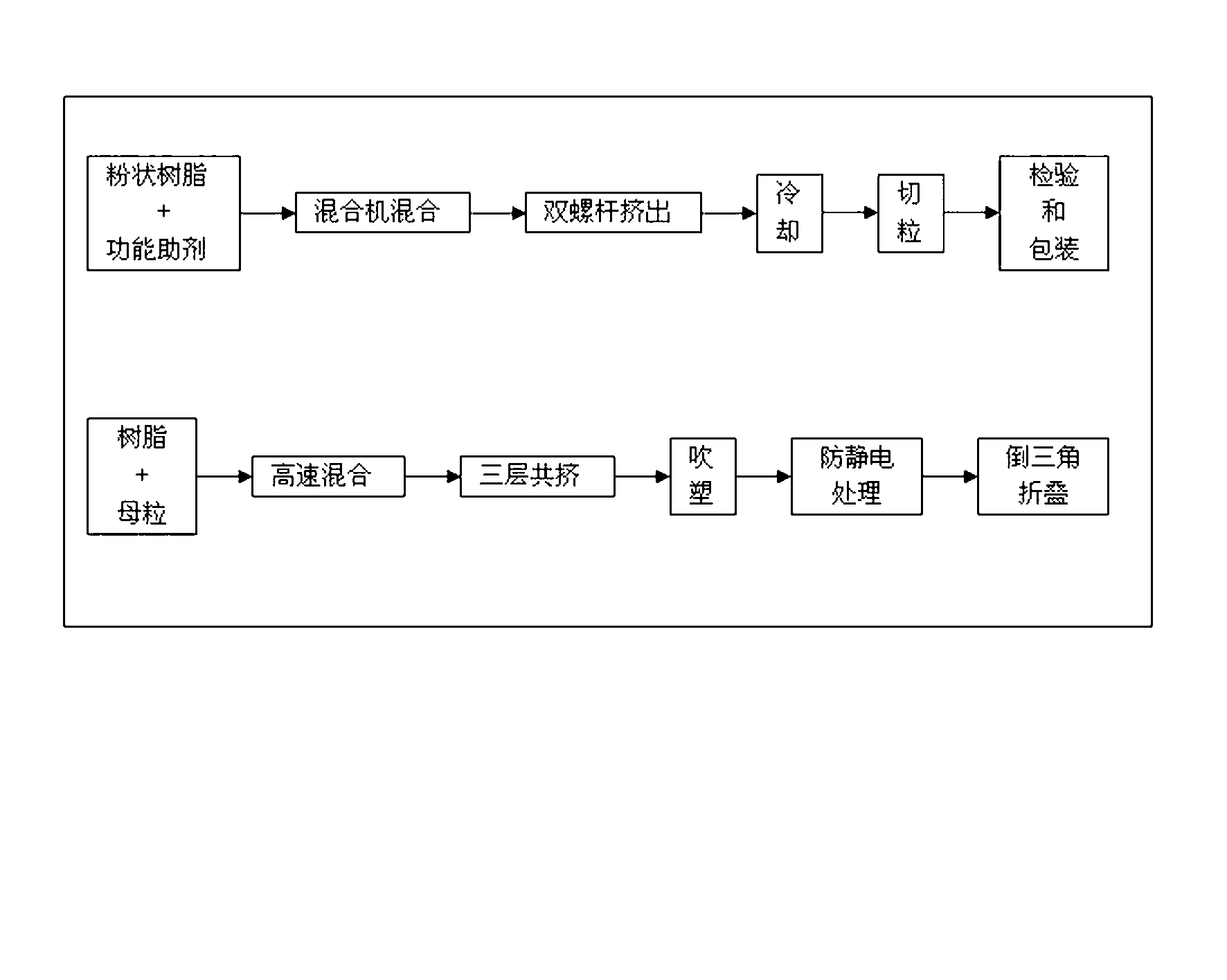

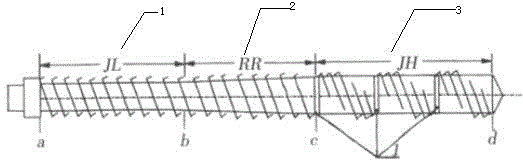

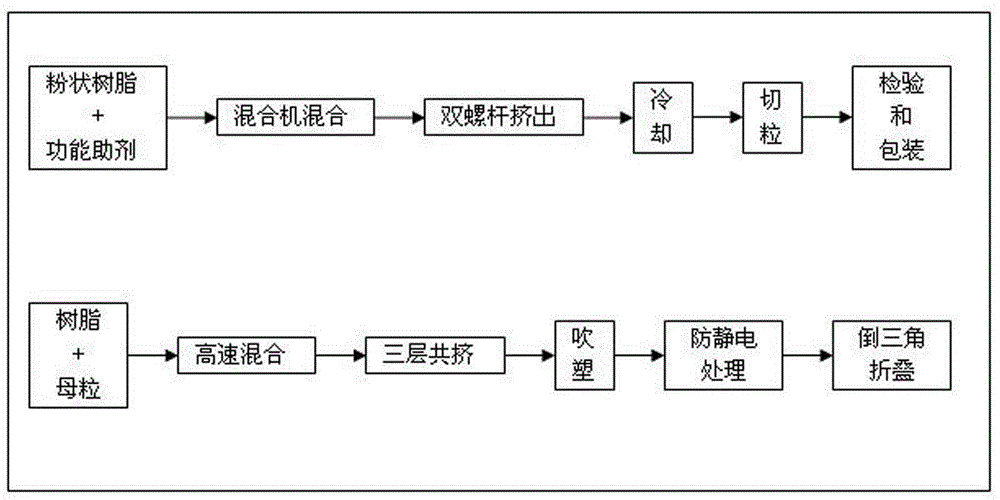

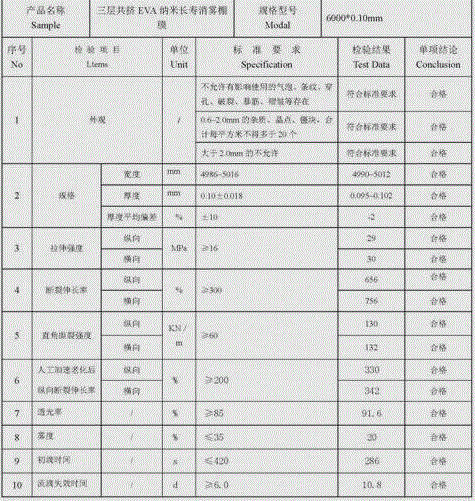

Three-layer co-extruded EVA (ethylene-vinyl acetate copolymer) long-life fog-dissipation environment-friendly multifunctional greenhouse film

ActiveCN103264563AGood colorEasy to processClimate change adaptationSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a nano fog-dissipation multifunctional greenhouse agricultural film, and in particular relates to a three-layer co-extruded EVA (ethylene-vinyl acetate copolymer) long-life fog-dissipation environment-friendly multifunctional greenhouse film, belonging to the field of agricultural mulching films. The raw material formula of an outer layer comprises the following components in percentage by weight: 20-50% of linear low-density polyethylene (LLDPE), 20-50% of low-density polyethylene (LDPE), 10-20% of metallocene polyethylene (mPE) and 5-10% of double-prevention masterbatch; the raw material formula of a middle layer comprises the following components in percentage by weight: 30-40% of ethylene-vinyl acetate copolymer (EVA), 20-40% of linear low-density polyethylene (LLDPE), 20-40% of low-density polyethylene (LDPE) and 5-10% of three-prevention masterbatch; the raw material formula of an inner layer comprises the following components in percentage by weight: 30-40% of ethylene-vinyl acetate copolymer (EVA), 10-20% of linear low-density polyethylene (LLDPE), 20-50% of low-density polyethylene (LDPE) and 5-10% of three-prevention masterbatch; and the formulas of the outer layer, the middle layer and the inner layer are uniformly mixed respectively, master batches are prepared by using a double-head thread screw double-screw extruding machine, a three-layer film is formed through a co-extrusion die head and is extruded out to prepare the multifunctional agricultural greenhouse film. Every quality technical index of the film reaches or exceeds a national standard, and a small part of the indexes is more than 2 times better than the national standard, so that the film is excellent in antiaging performance and cannot generate fog drops, and the service life of the film reaches more than 3 years.

Owner:HENAN YINFENG PLASTIC

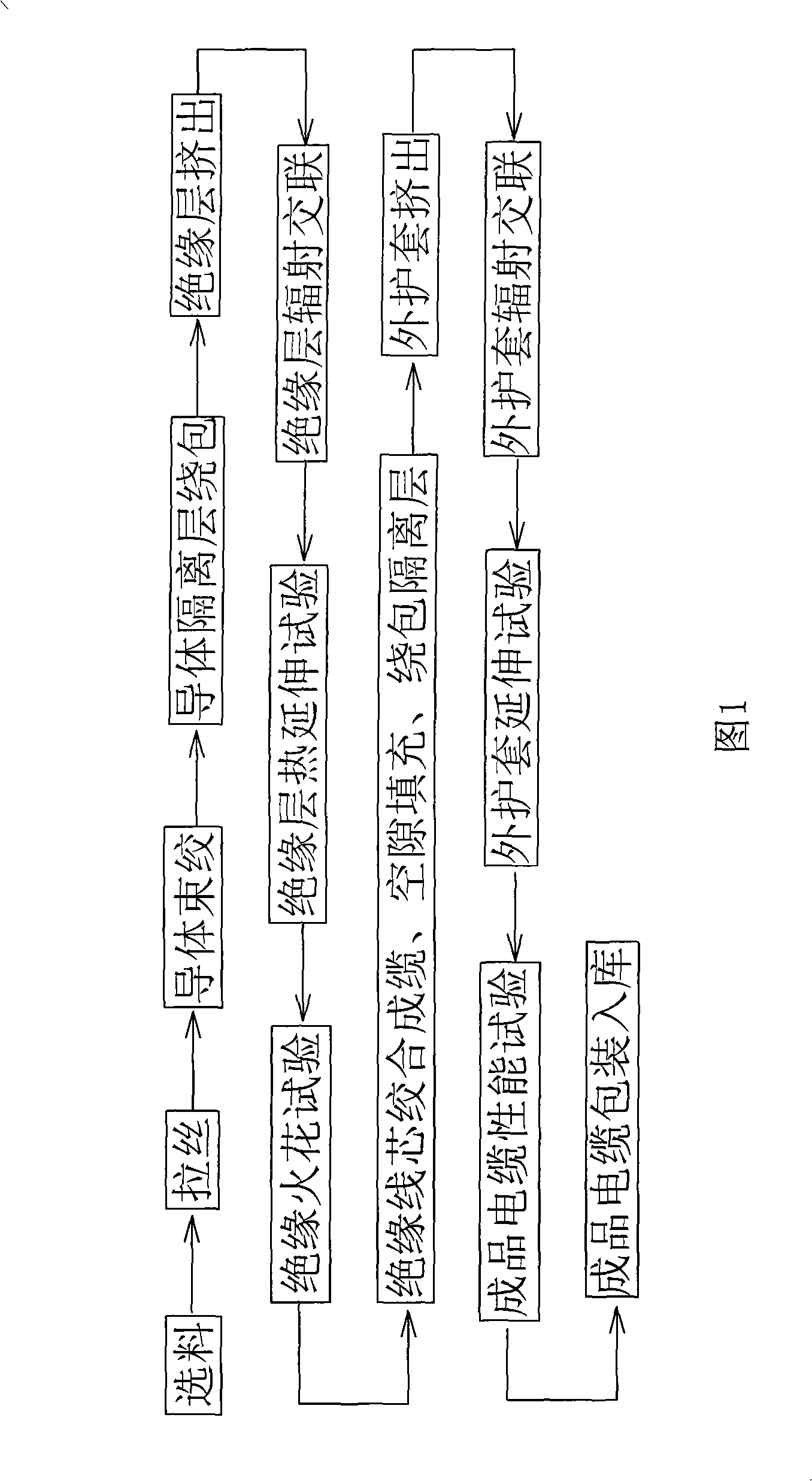

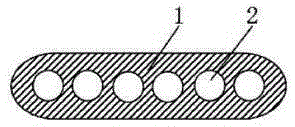

Method for manufacturing special cable of wind power plant

ActiveCN101494105AReduce production speedHigh energy consumptionInsulating conductors/cablesBunchesCorrosion

The invention relates to a manufacturing method of a special cable for wind-power generating equipment; the manufacturing method comprises the following steps of: selecting materials-drawing wires-stranding conductor bunches-lapping an isolating layer-extruding an insulating layer-radiation cross-linking the insulating layer-twisting insulating cores into cables, filling gaps and lapping the insulating layer-extruding an outer sheath-radiation cross-linking the outer sheath-checking finished products-packaging and storing finished cables. The cable produced by the manufacturing method has low-temperature resistance, twist resistance, ozone-corrosion resistance, light aging resistance, oil resistance, sea water resistance and mechanical and physical performances better than the performances of EPR-insulating chlorinated polyethylene-sheath wind energy cable.

Owner:安徽华能电缆股份有限公司

Building garbage crusher

InactiveCN106040362AAchieve recyclingIncrease profitUsing liquid separation agentGrain treatmentsDrive shaftLitter

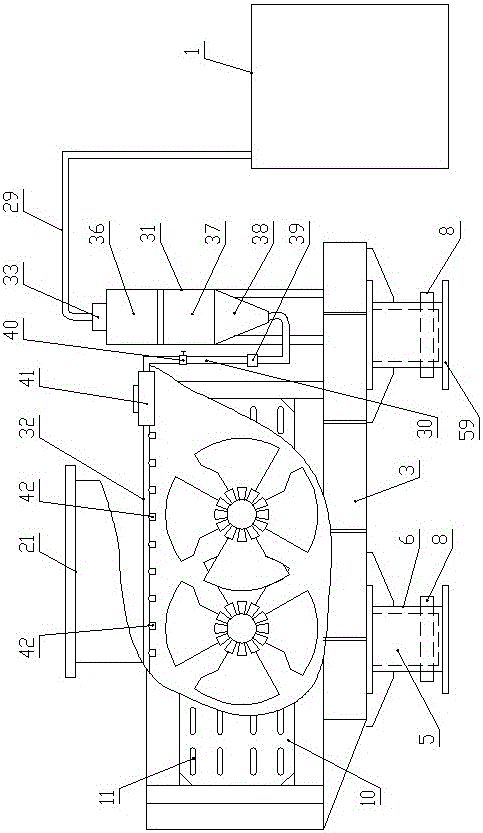

The invention discloses a building garbage crusher which comprises a rack, wherein the left end part of the rack is provided with a power drive system; the power output end of the power drive system is in transmission connection to a material crushing system positioned at the right side of the power drive system; the material crushing system is fixed to the rack; an automatic spraying and dust-reducing system in front of a charging part of the material crushing system is arranged on the rack; a spraying part of the automatic spraying and dust-reducing system is positioned in the material crushing system; and one side of the rack is provided with a settling tank. According to the building garbage crusher disclosed by the invention, synchronous drive of a primary transmission shaft and a secondary transmission shaft is realized through the power drive system, dust generated in a crushing process is effectively reduced through the automatic spraying and dust-reducing system, cyclic utilization of water flow is realized, and material crushing is realized through the material crushing system, so that building garbage is recycled; and the building garbage crusher is simple to operate, is stable in work, is good in crushing effect, increases a waste utilization rate, reduces production cost, and is energy-saving and environmentally friendly.

Owner:HUANGHE S & T COLLEGE

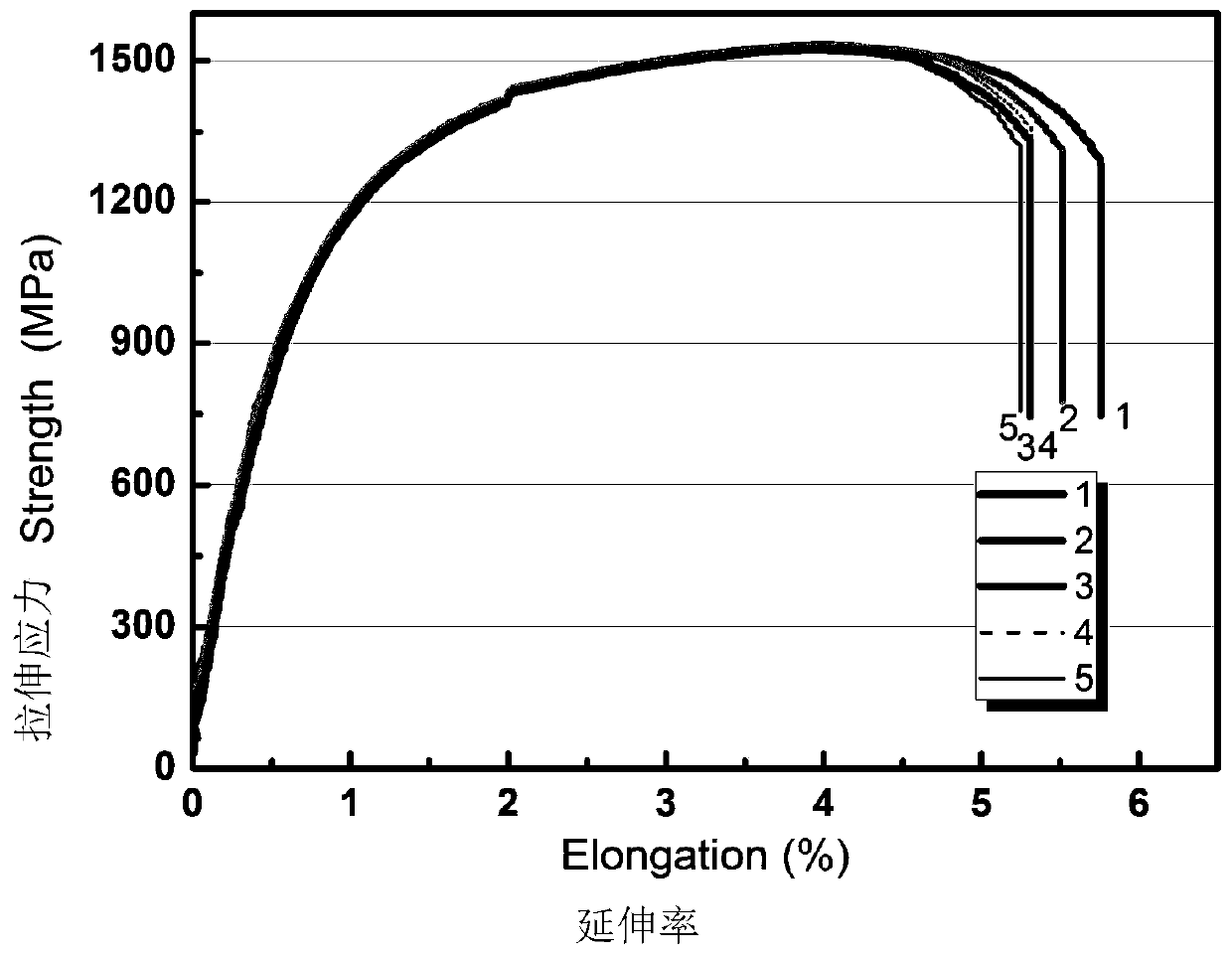

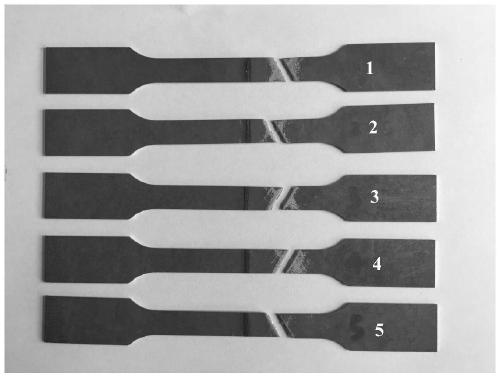

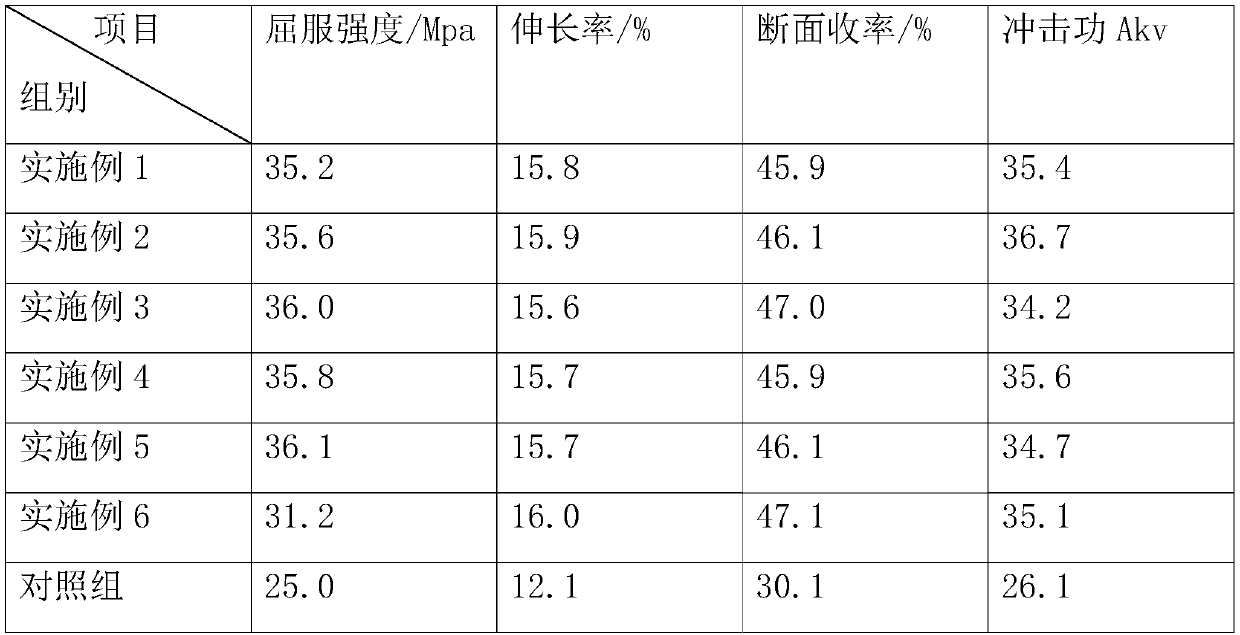

Method for manufacturing steel thin-wall welding equal-strength components with aluminum or aluminum alloy coatings

ActiveCN111230301APromote homogenizationImprove hardenabilityArc welding apparatusWelding/cutting media/materialsHot stampingMetal alloy

Provided is a method for manufacturing steel thin-wall welding equal-strength components with aluminum or aluminum alloy coatings. A steel plate to be welded comprises a base body and at least one coating on the surface of the base body. Each coating comprises an intermetallic compound alloy layer in contact with the base body and a metal alloy layer on the intermetallic compound alloy layer. Thecoatings do not need to be removed or thinned before welding or in the welding process; by presetting the welding gap and using a carbon manganese steel welding wire, a welding process and protectivegas for welding, after a welding component is subjected to hot stamping treatment, the tensile strength of a weld joint is greater than the tensile strength of a base material, the extension rate of the weld joint is greater than 4%, and the application requirement of the equal-strength welding components in the hot stamping field is met.

Owner:BAOSHAN IRON & STEEL CO LTD

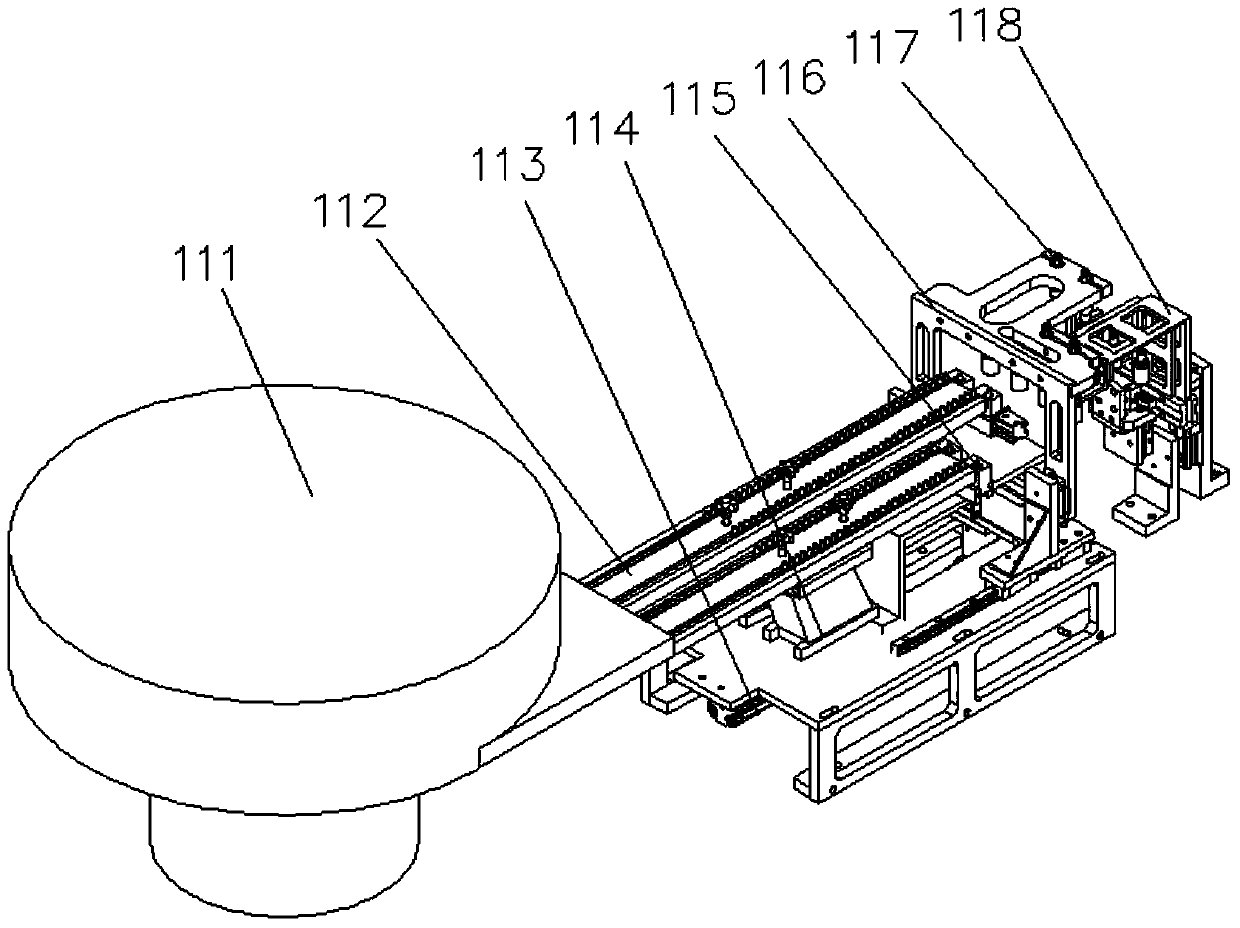

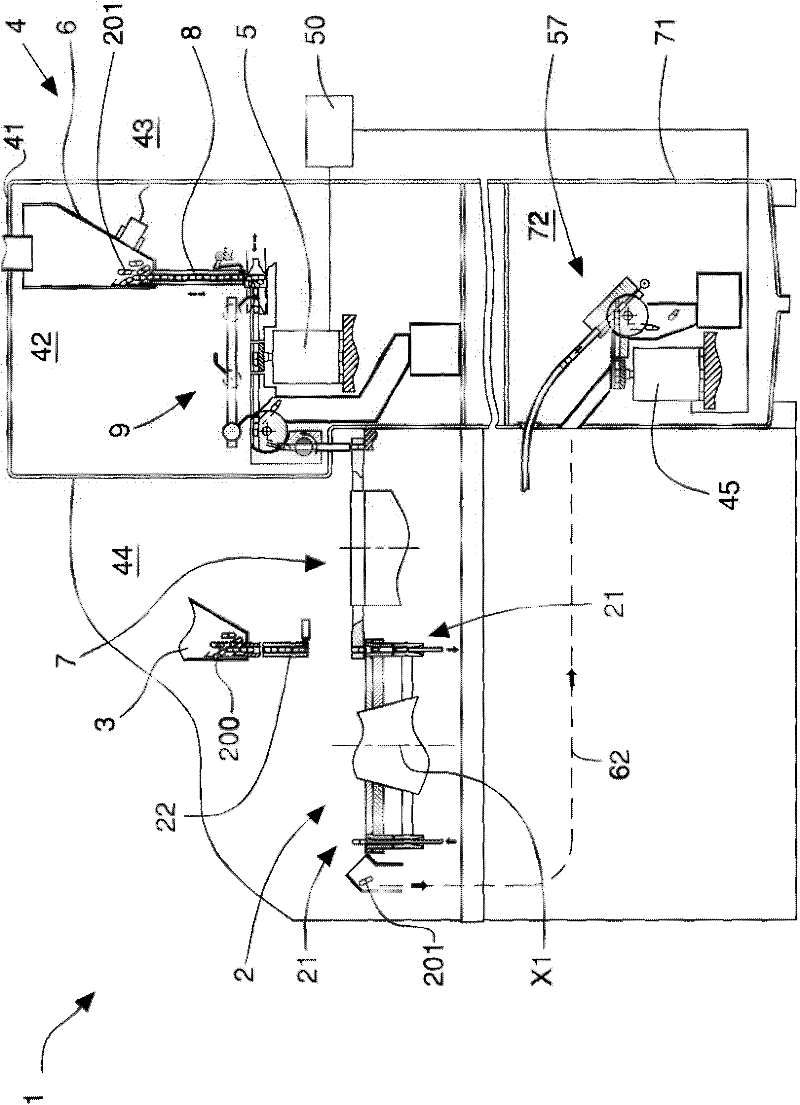

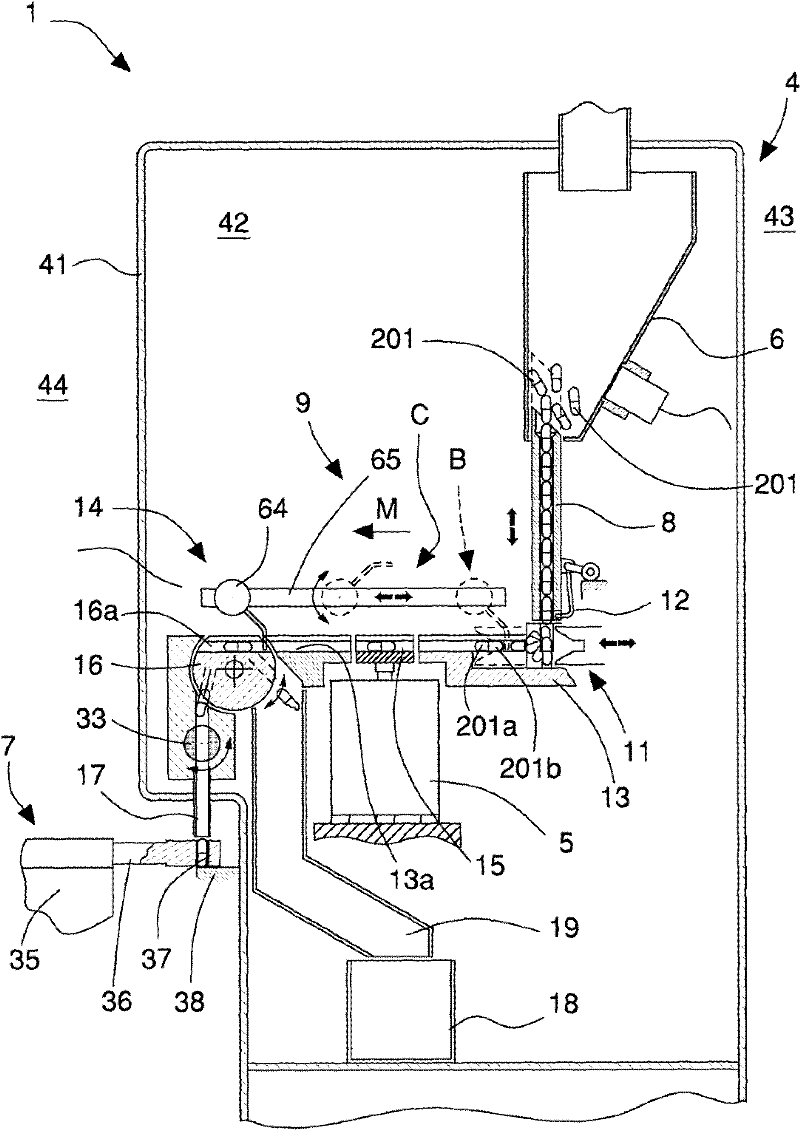

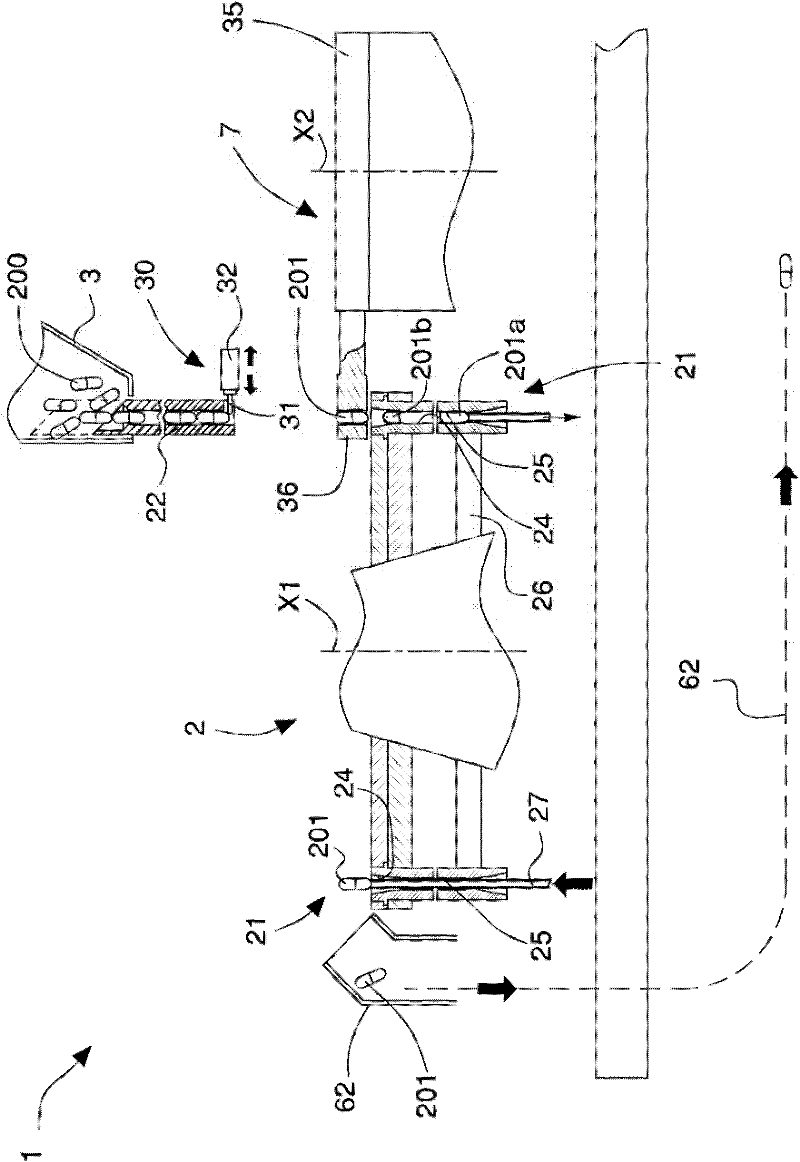

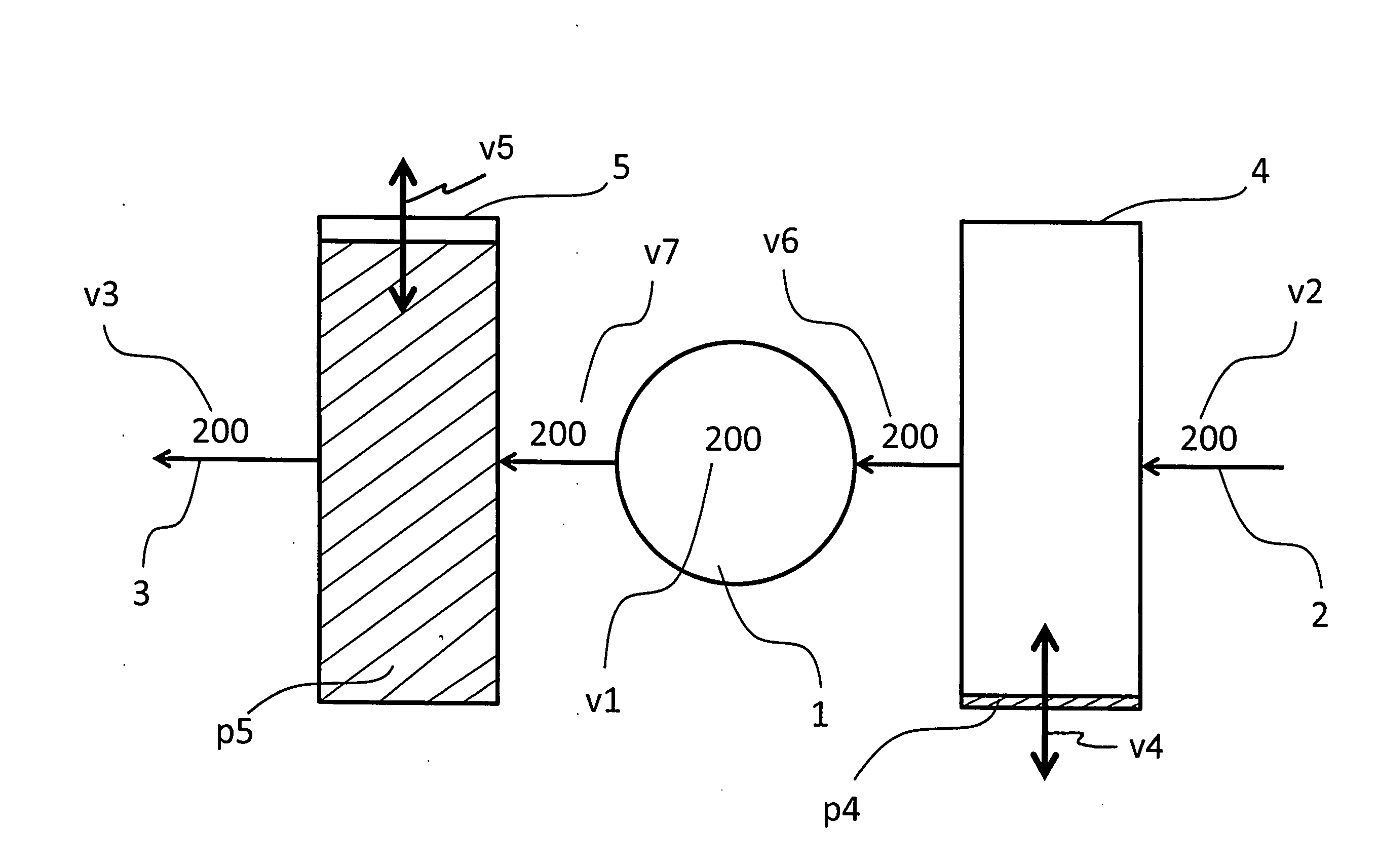

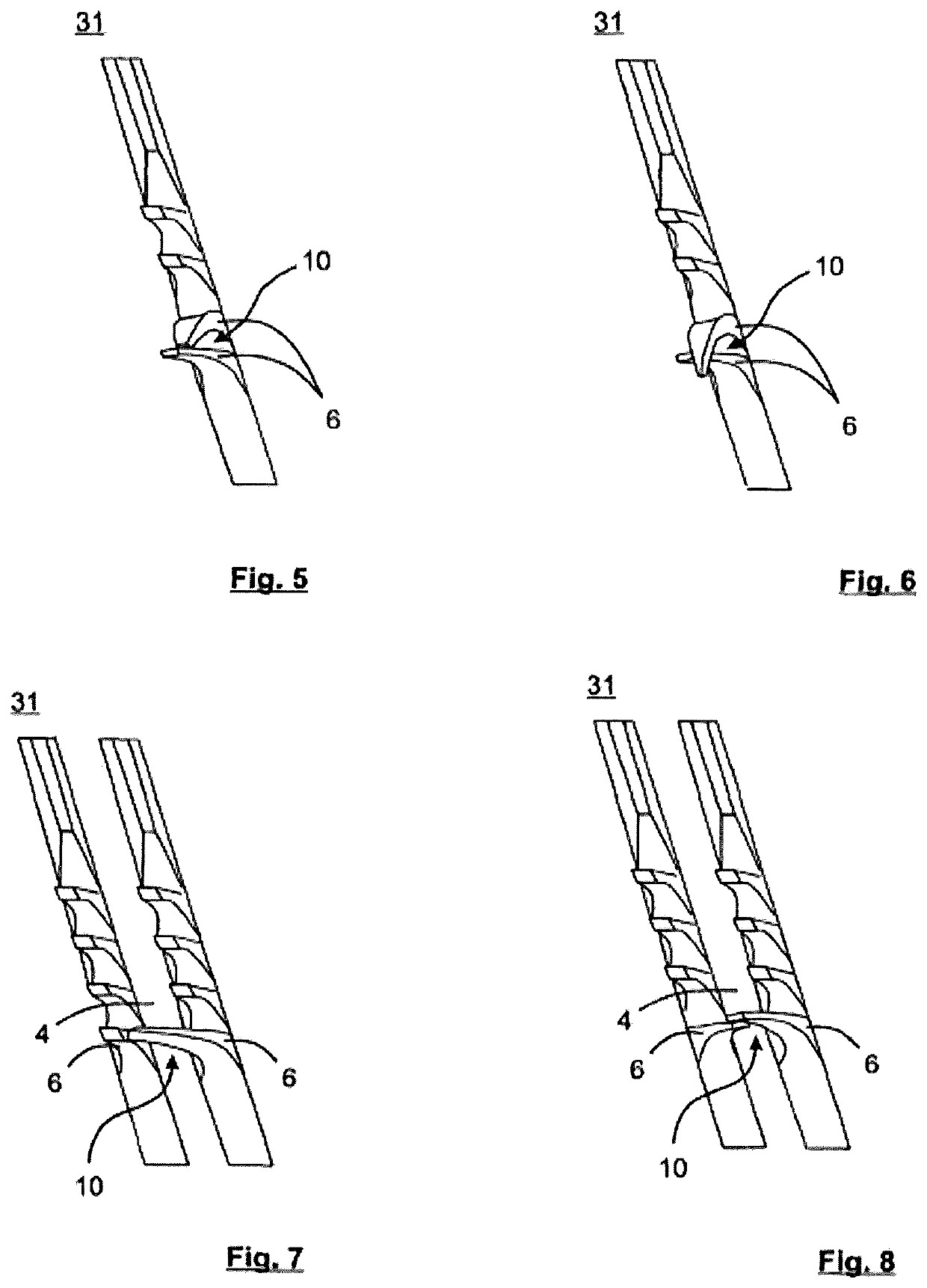

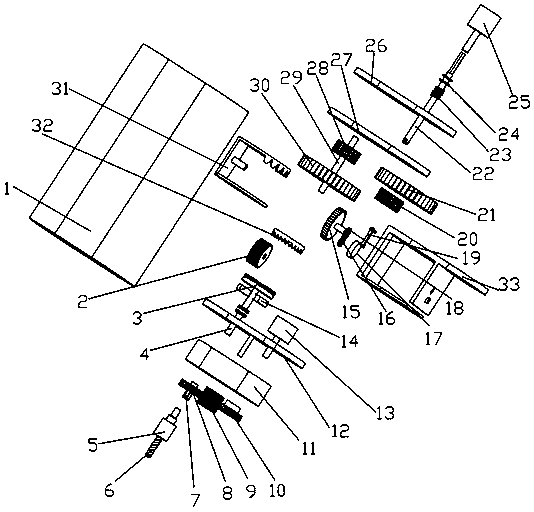

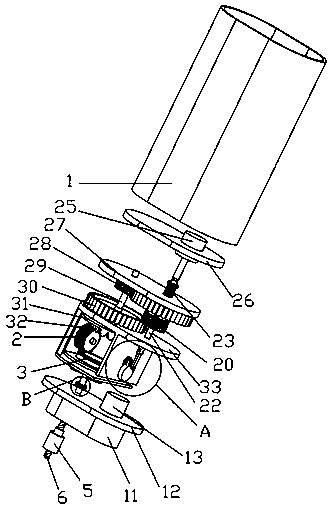

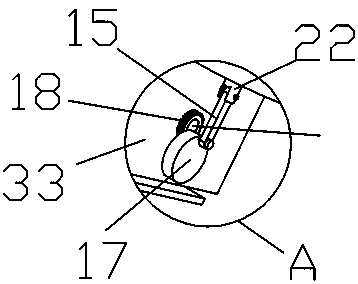

Machine and method for filling and weighing capsules

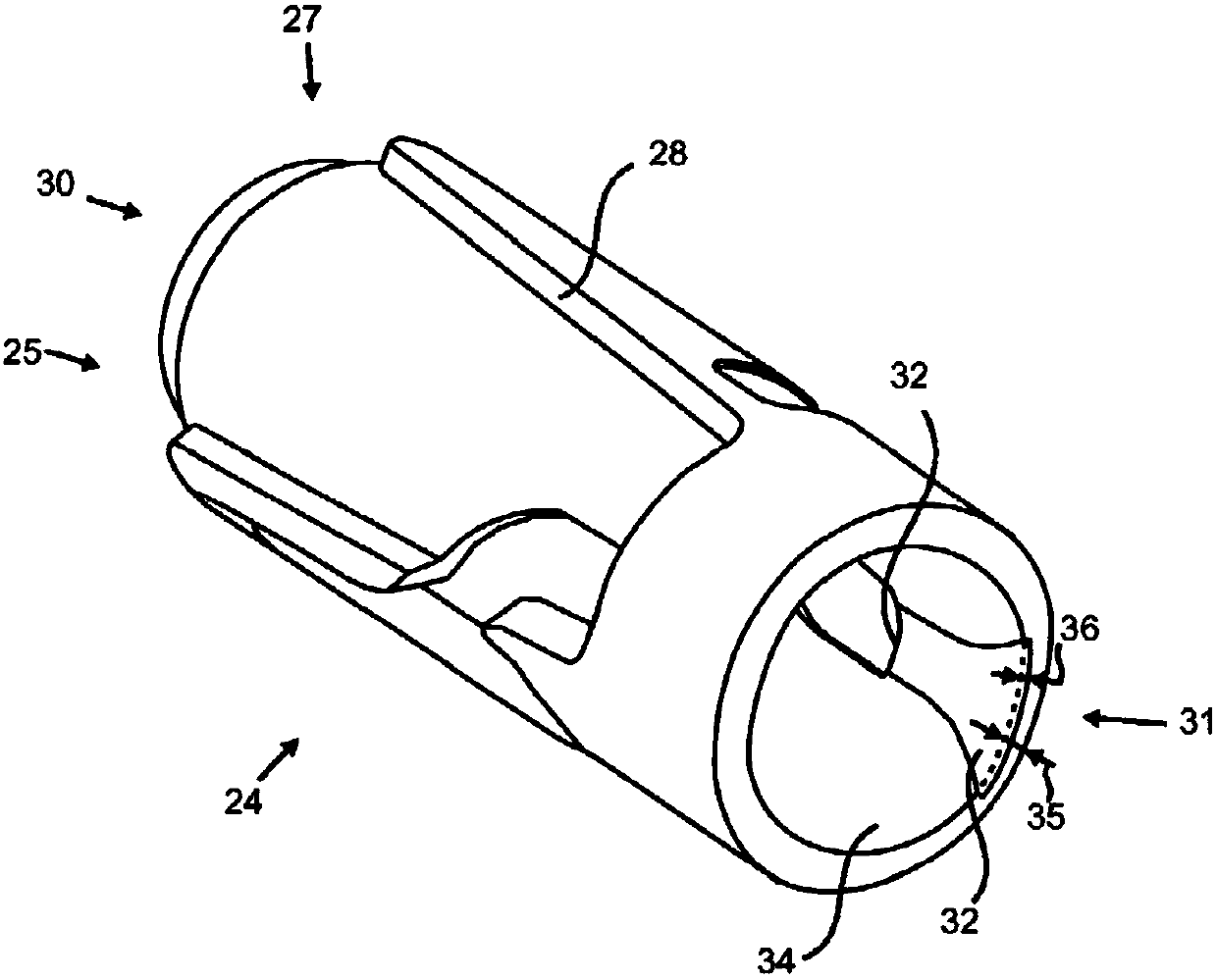

InactiveCN102227201AReduce production speedCapsule deliveryDomestic articlesEngineeringWeight measure

A machine for dosing a product in capsules (200, 201), or similar elements, comprises the steps of rotating turret means (2; 102) which have seats (24; 124) suitable for receiving capsules (200) drawn empty from a first store (3; 103) and dosing means for dosing the product in the capsules (200), the machine further comprising: a feeding unit (4) having first weighing means (5), for weighing further capsules (201) drawn empty from a second store (6); transfer means (7; 107) for transferring the further capsules (201), when weighed, to predetermined seats (24; 124) of the turret means (2; 102) for being filled with the product; second weighing means (45) for weighing the further capsules (201) filled with the product and taken out from the turret means (2; 102); and processing means (50) connected to the first weighing means (5) and to the second weighing means (45) for receiving data relative to weights measured by means of the first and second weighing means (5, 45) and for calculating for each further capsule (201) a difference between a weight measured before and a weight measured after filling, in such manner as to calculate a respective quantity of dosed product.

Owner:IMA IND MASCH AUTOMATICHE SPA

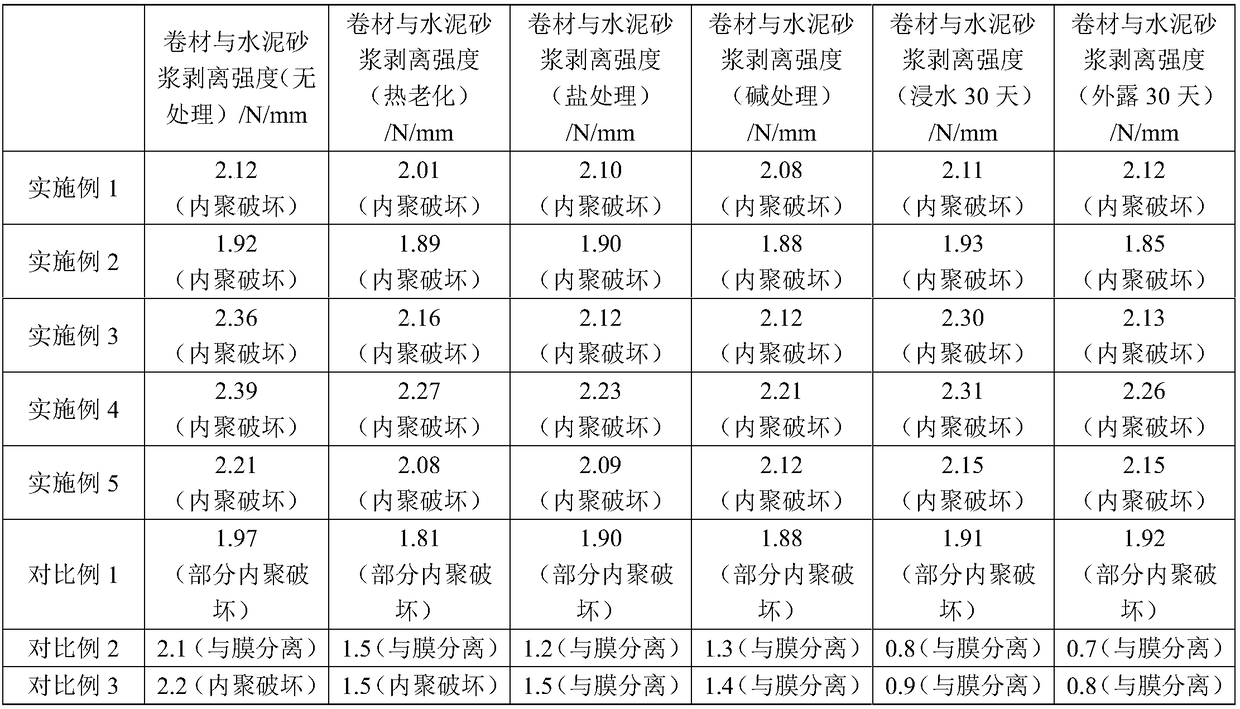

Novel non-asphalt-based self-adhesive waterproofing coiled material and preparation method thereof

InactiveCN108587509AReduce tensionReduce production speedMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer scienceUltimate tensile strength

The invention discloses a novel non-asphalt-based self-adhesive waterproofing coiled material and a preparation method thereof. The coiled material comprises a main base, non-asphalt self-adhesive glue coating the main base and an isolating membrane. The non-asphalt self-adhesive glue comprises, by weight, 10-25% of a C5 / C9 copolymer resin, 3-4% of polyisobutylene, 10-25% of cycloalkyl rubber oil,3-12% of SIS rubber, 4-14% of styrene-butadiene rubber, 15-35% of a filler, 0.5-2.5% of a pigment and 4-6% of an auxiliary agent. Compared with the prior art, the novel non-asphalt-based self-adhesive waterproofing coiled material has high peeling strength, and the main base and the non-asphalt self-adhesive glue are not easily separated.

Owner:KUNSHAN KESHUN WATERPROOF MATERIAL

Absorbent structures with high strength and low md stretch

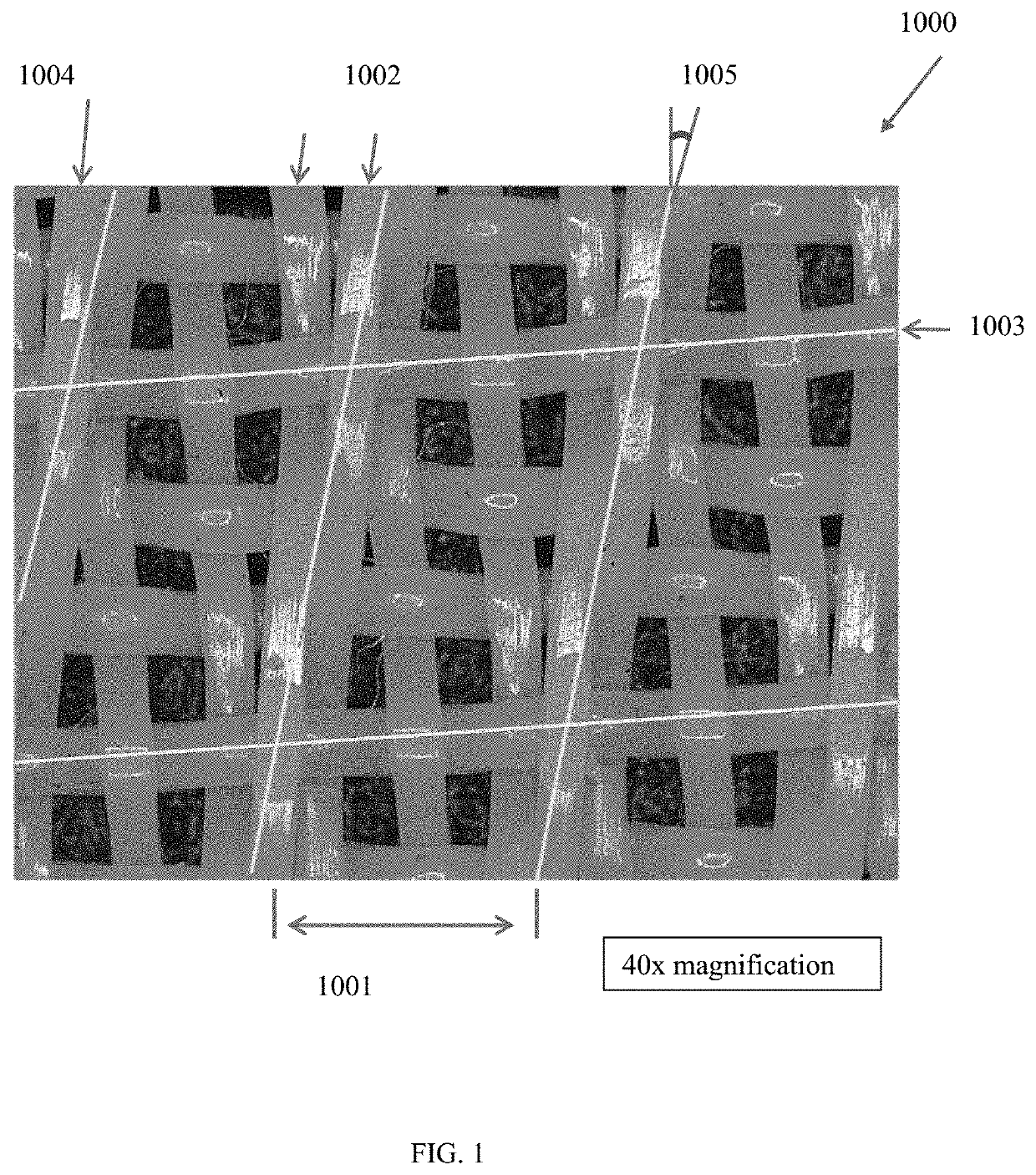

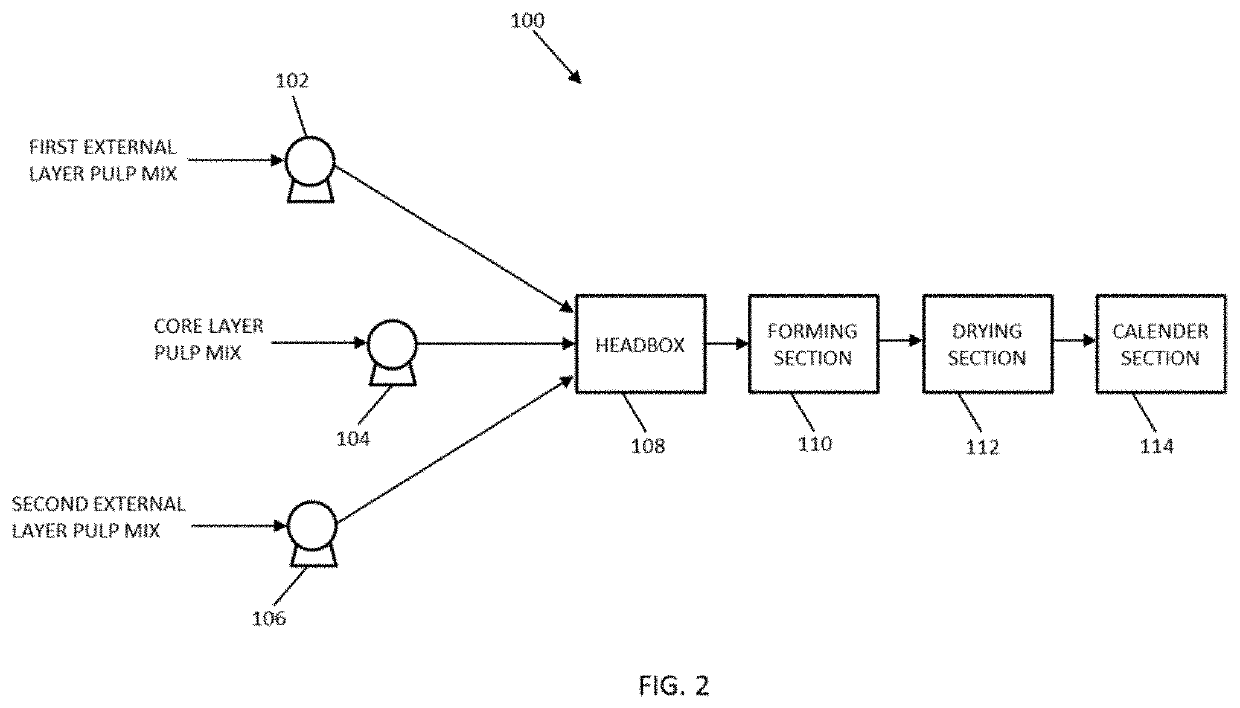

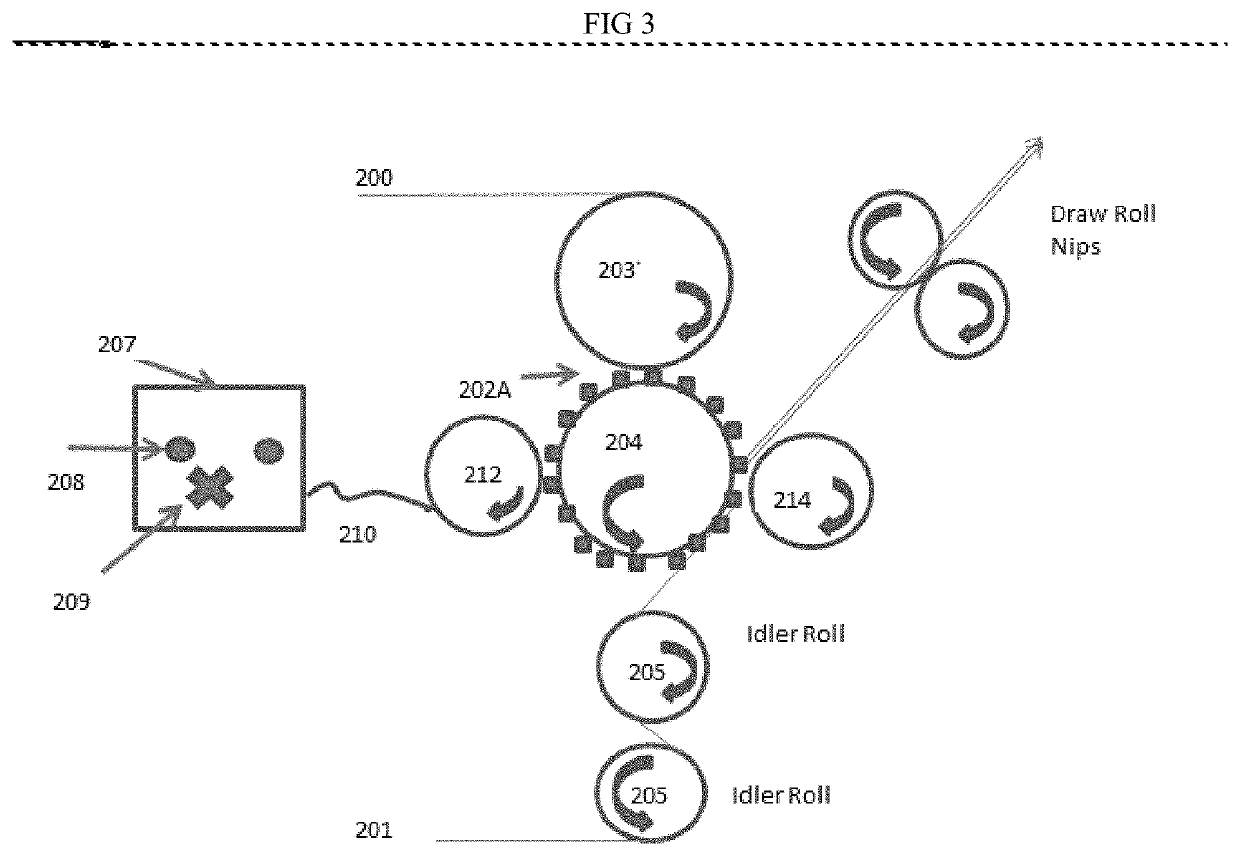

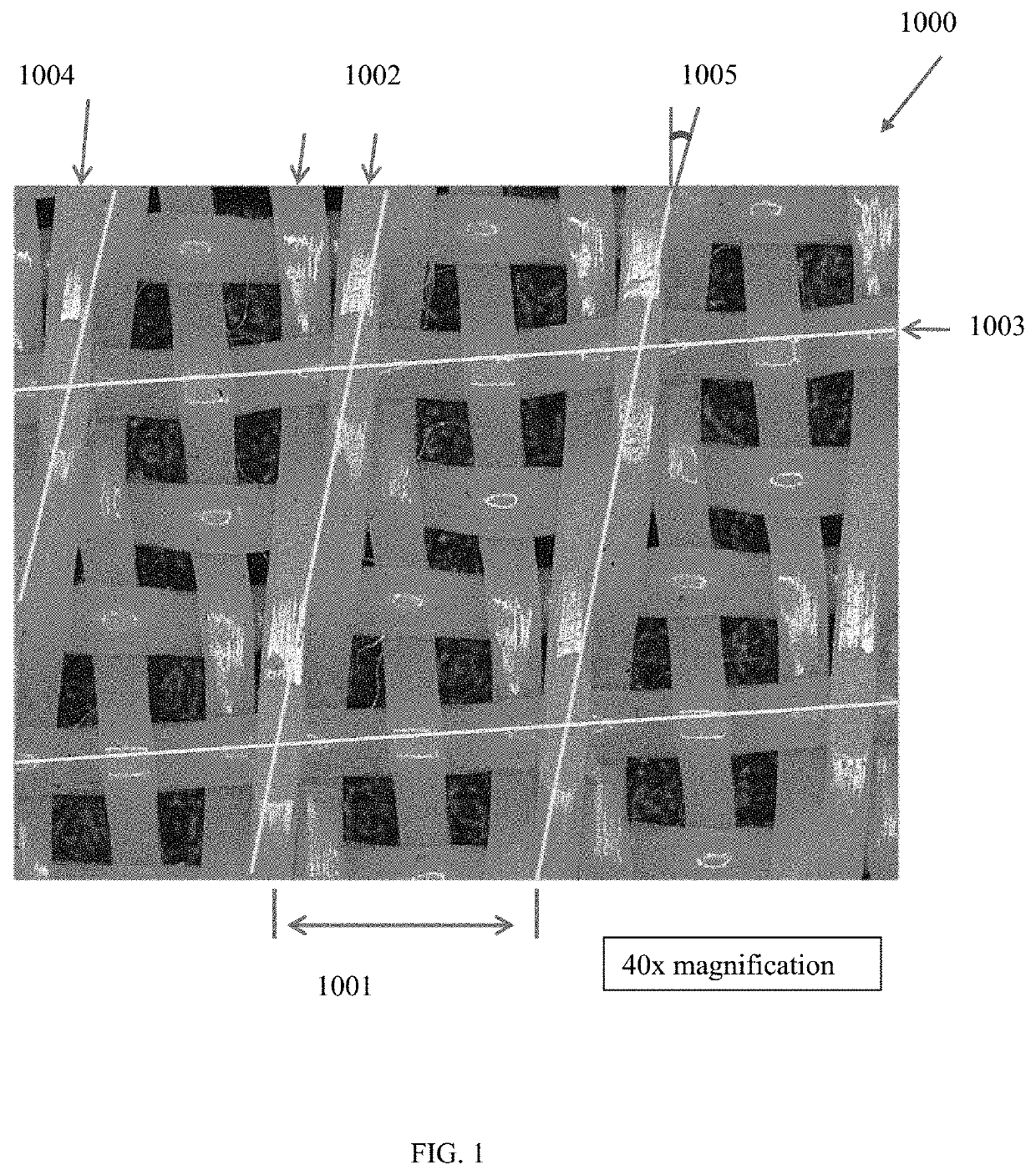

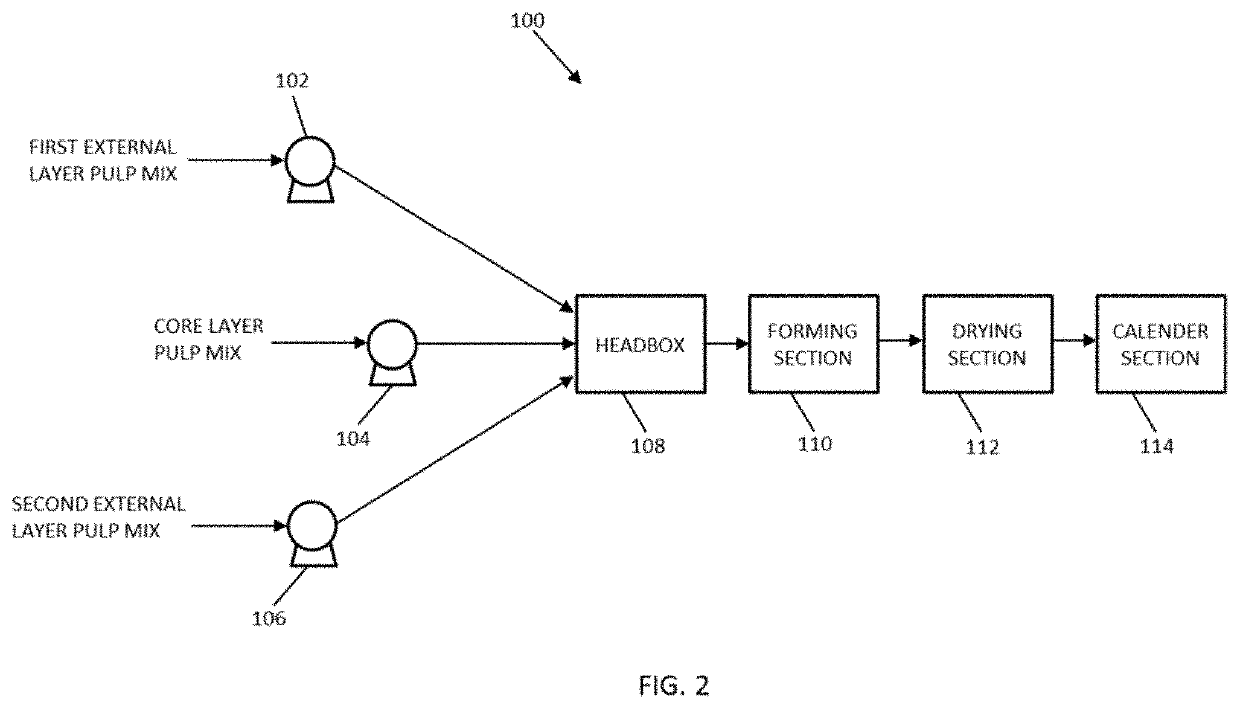

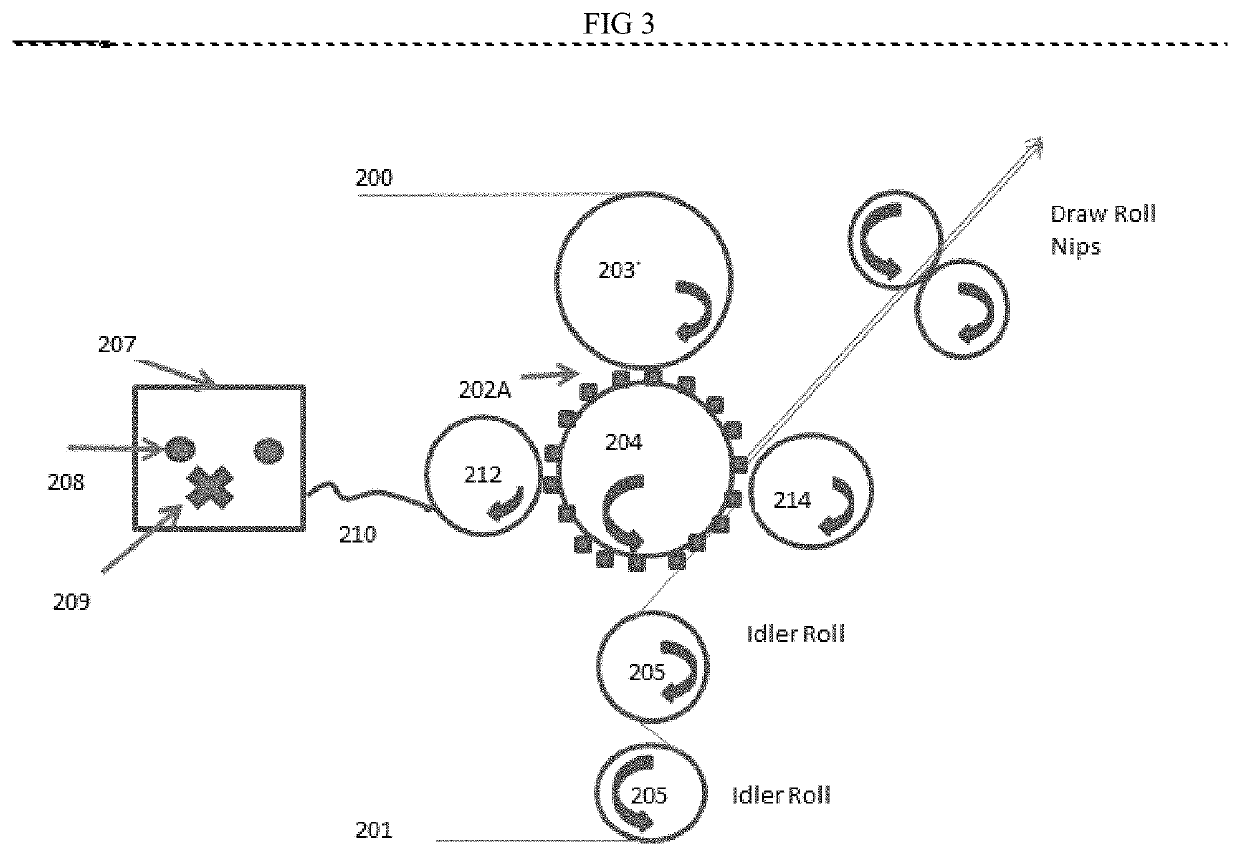

PendingUS20200347556A1High ball burst strengthLow MD stretchNon-fibrous pulp additionCleaning equipmentMachineComposite material

Absorbent product including a laminate of at least two plies, wherein the absorbent product has a measured Y-Connected Area parameter greater than 20 and a Surface Channel Spacing of less than 2.5 mm. The absorbent product has high strength and low machine direction stretch.

Owner:FIRST QUALITY TISSUE

Absorbent structures with high strength and low md stretch

PendingUS20200347555A1High ball burst strengthLow MD stretchNon-fibrous pulp additionCleaning equipmentComposite materialManufacturing engineering

Absorbent product including a laminate of at least two plies, wherein the absorbent product has a measured Y-Connected Area parameter greater than 20 and a Surface Channel Spacing of less than 2.5 mm. The absorbent product has high strength and low machine direction stretch.

Owner:FIRST QUALITY TISSUE

Energy-saving printing and coating machine and energy-saving method

InactiveCN101850324AHigh solid contentReduce energy consumptionLiquid surface applicatorsCoatingsTemperature controlEngineering

The invention relates to an energy-saving printing and coating machine and an energy-saving method. In the technical scheme, a glue and ink supply system (an ink tank, a glue tank, an ink storage tank and a glue storage tank) is additionally provided with functions of heating and constant-temperature control to reduce the viscosity and to improve the solid content of the glue or ink, thereby achieving the energy-saving purpose. The invention belongs to the field of energy conservation and emission reduction.

Owner:杨峥雄

Safety device for prefilled syringes, comprising Anti-triggering mechanism

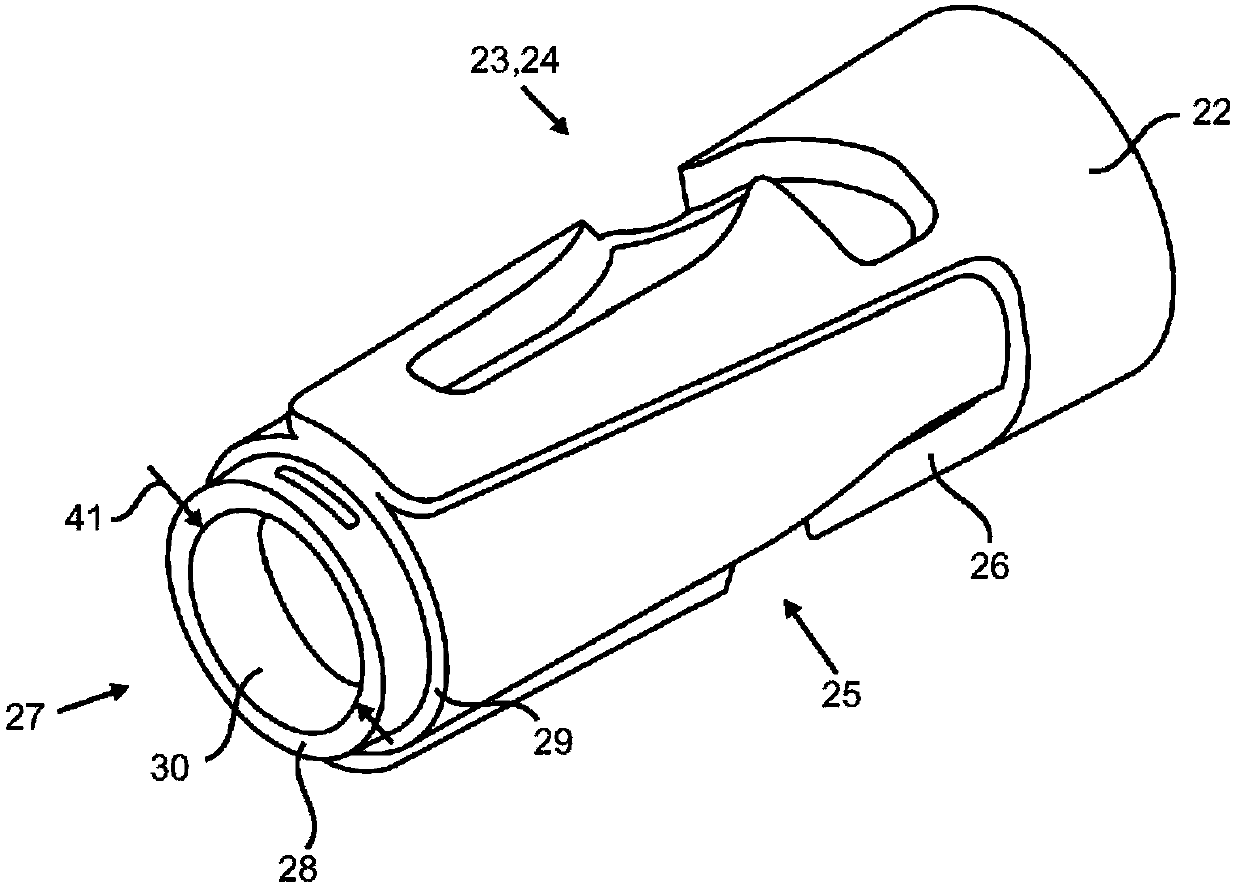

ActiveCN107635607AEasy to installQuick installationInfusion syringesInfusion needlesEngineeringPhysics

Disclosed is a method for assembling a safety device and mounting the safety device on a syringe member before the syringe member is filled, said method comprising the steps of: providing a sleeve, aspring element and a mounting element; introducing the spring element into the sleeve along a mounting direction; introducing the mounting element into the sleeve along the mounting direction; obtaining the safety device; before the syringe member is filled, mounting the safety device on the syringe member by connecting the mounting element to the syringe member.

Owner:GERRESHEIMER REGENSBURG GMBH +1

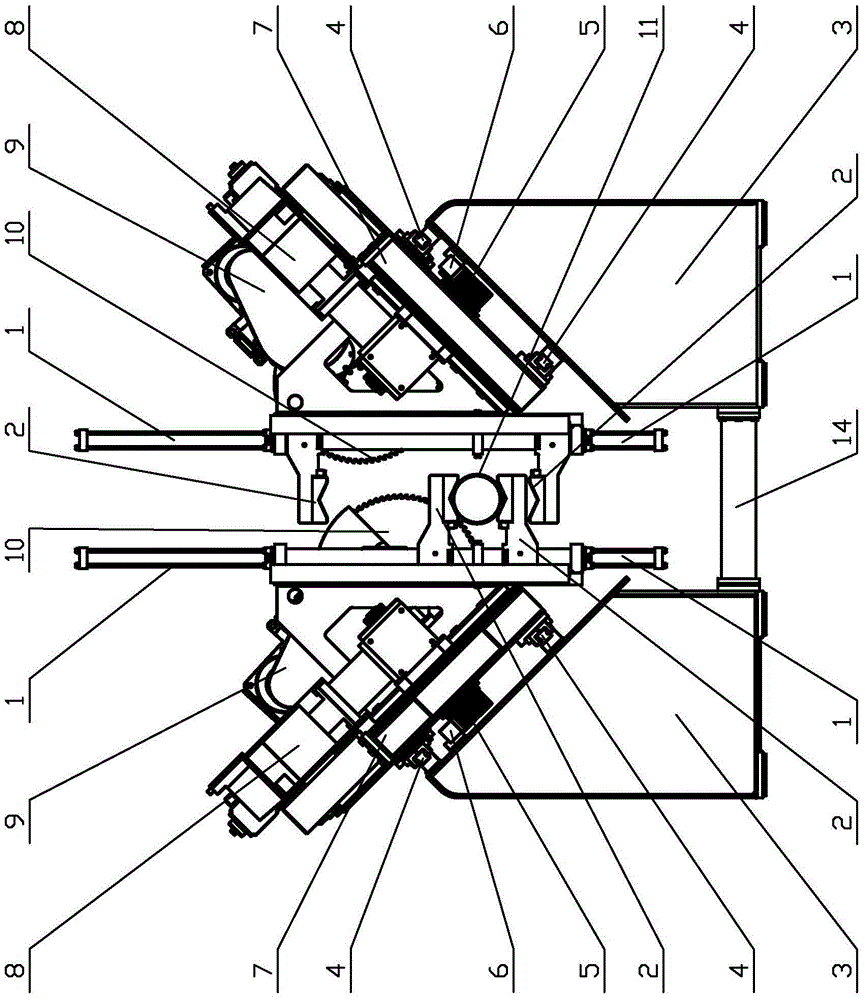

Double-vehicle type size-fixed flying saw machine

The invention discloses a double-vehicle type size-fixed flying saw machine which comprises two size-fixed cutting devices, wherein the two size-fixed cutting devices are symmetrically arranged at the left side and the right side of a to-be-cut workpiece, and comprise saw vehicles, machine bases, workpiece clamping mechanisms arranged on the saw vehicles, cutting feeding mechanisms arranged on the saw vehicles, and cutting mechanisms arranged at feeding ends of the cutting feeding mechanisms; walking table tops for the saw vehicles to travel are arranged at the upper ends of the machine bases; walking mechanisms for driving the saw vehicles to travel on the walking table tops are arranged between the saw vehicles and the walking table tops; and the workpiece clamping mechanisms are cantilever type clamping mechanisms. With the adoption of the technical scheme, the two size-fixed cutting devices are symmetrically arranged to form series connection; through flexible arrangement of the various mechanisms, the coordination work of the two size-fixed cutting devices are ensured; and the two size-fixed cutting devices alternately and circularly cut the workpiece, so that the cutting efficiency is increased to be twice of that of the conventional single saw vehicle flying saw, and the requirements of a high-speed cold rolled section steel unit are met.

Owner:大连三高科技发展有限公司

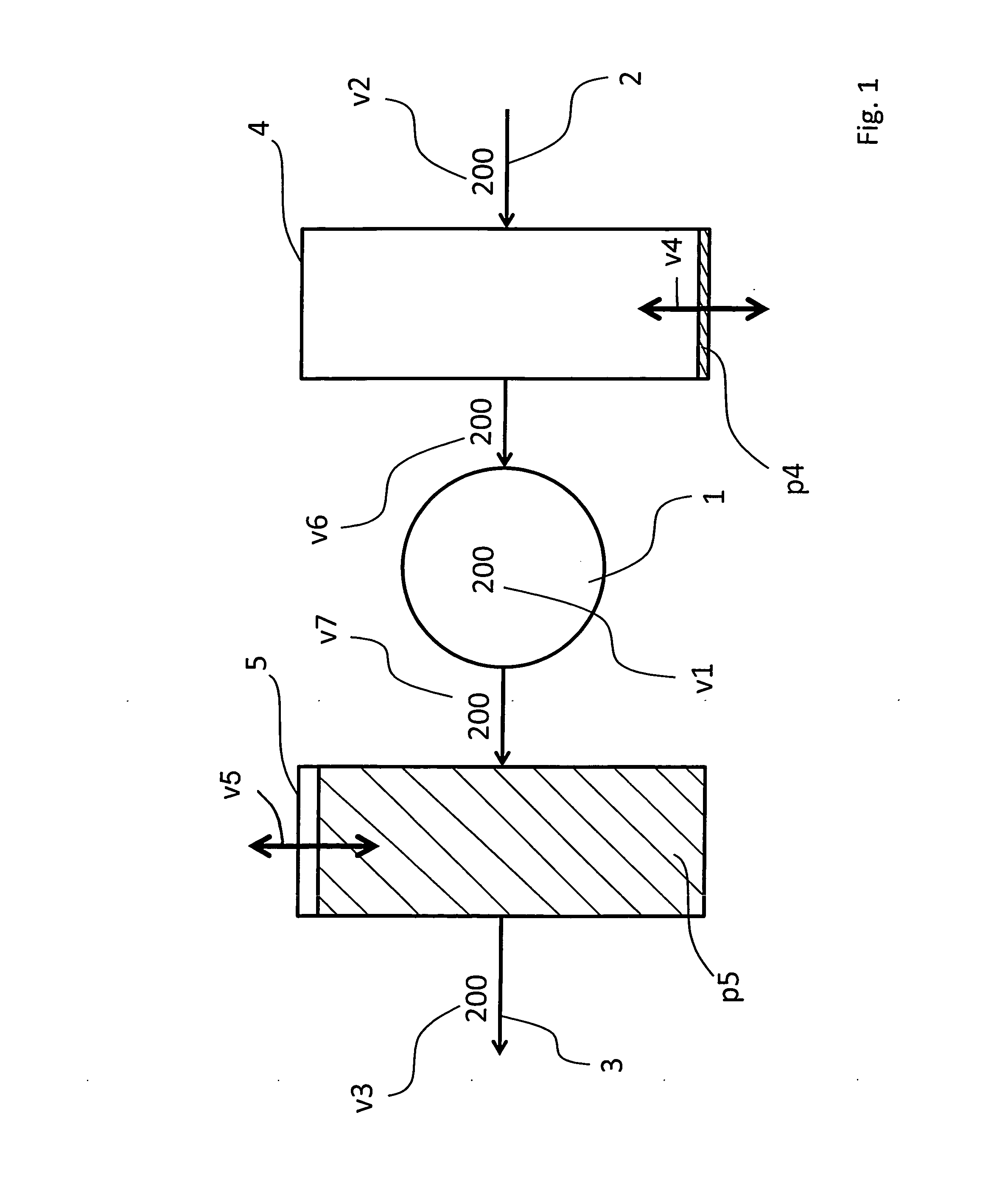

Press machine and method of controlling press machine

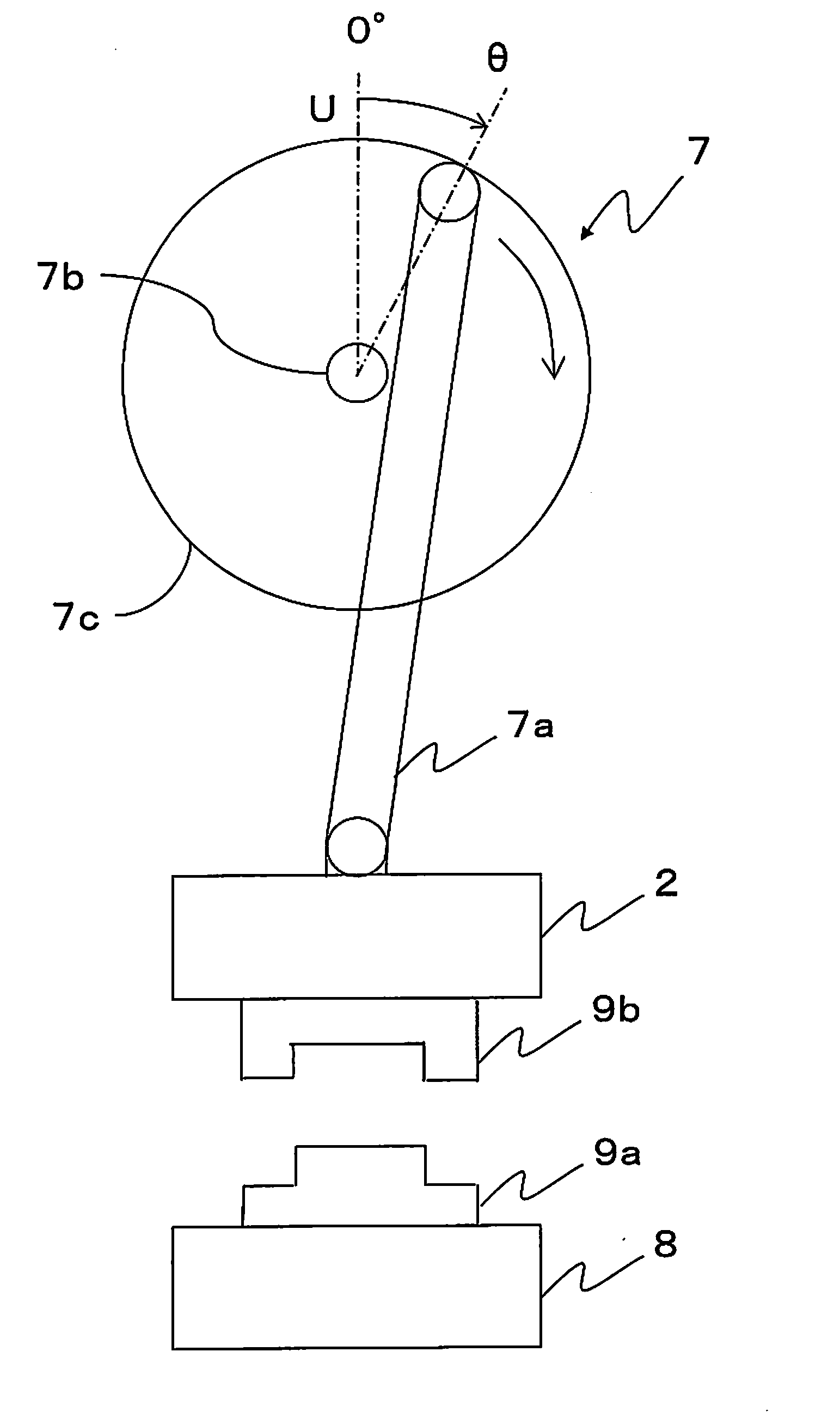

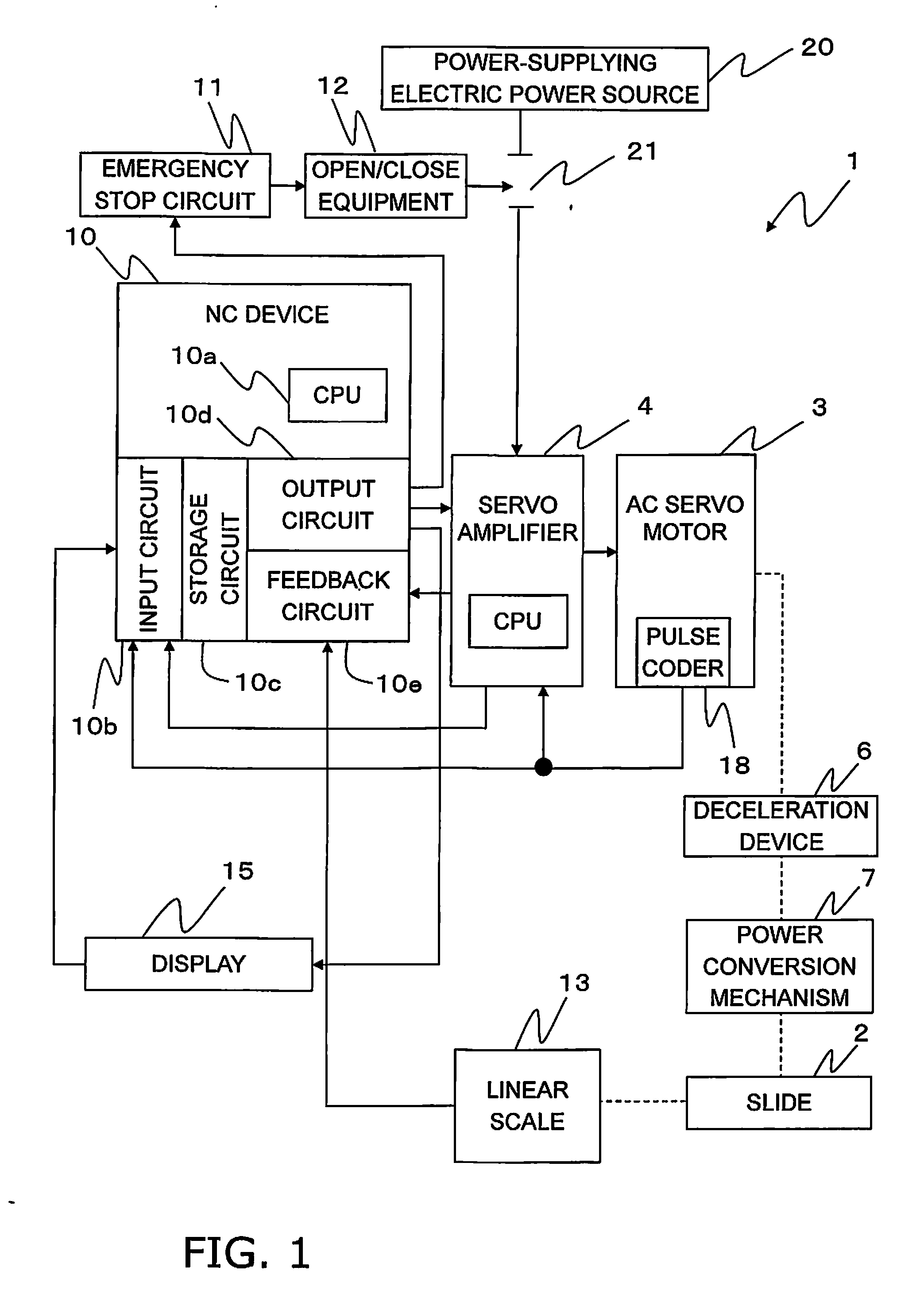

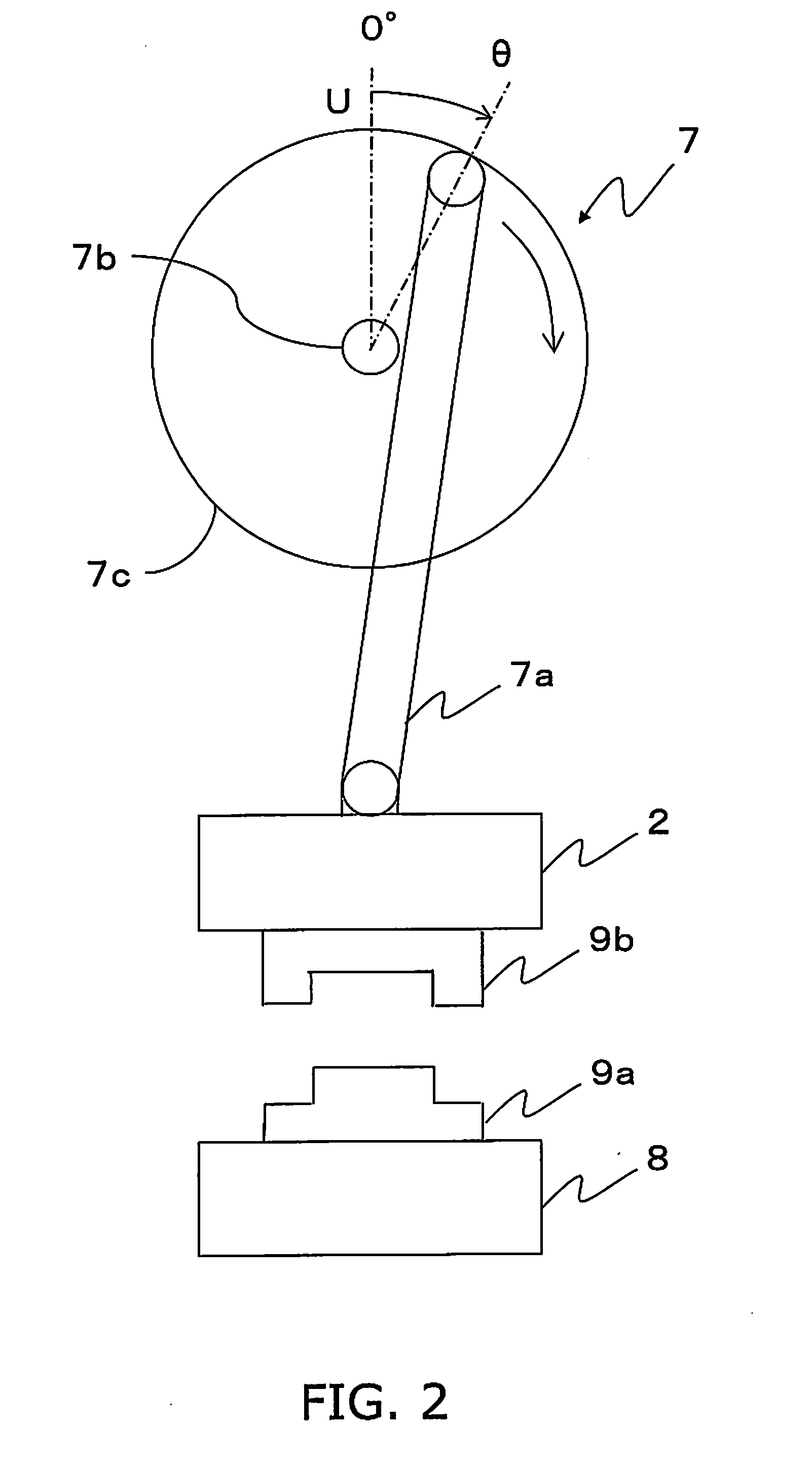

InactiveUS20150352799A1Reduce drive currentReduce production speedAC motor controlElectric motor controlDriving currentPower flow

A press machine includes a servo amplifier configured to supply a drive current to a servo motor, current detecting means for detecting the drive current, rotational angle detecting means for detecting a rotational angle of a rotary motion, speed setting means, determination means and speed changing means. The speed setting means is configured to set a press production speed by setting a correspondence between rotational angles and rotational speeds at the rotational angles, which defines the rotary motion. The determination means is configured to determine whether or not the drive current detected by the current detecting means is greater than or equal to a first threshold. The speed changing means is configured to reduce all the rotational speeds set by the speed setting means by an equal ratio when the drive current detected by the current detecting means is greater than or equal to the first threshold.

Owner:KOMATSU IND CORP

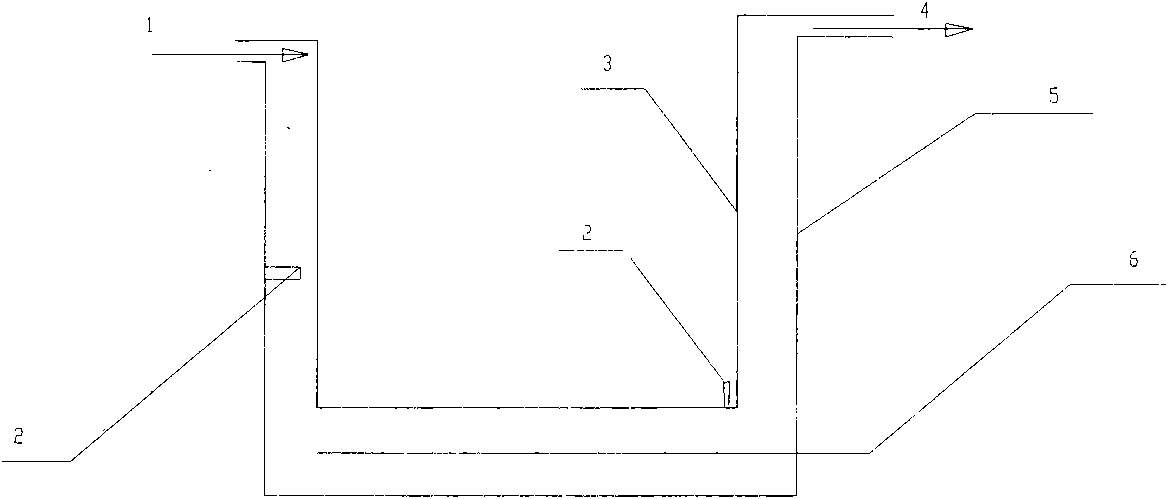

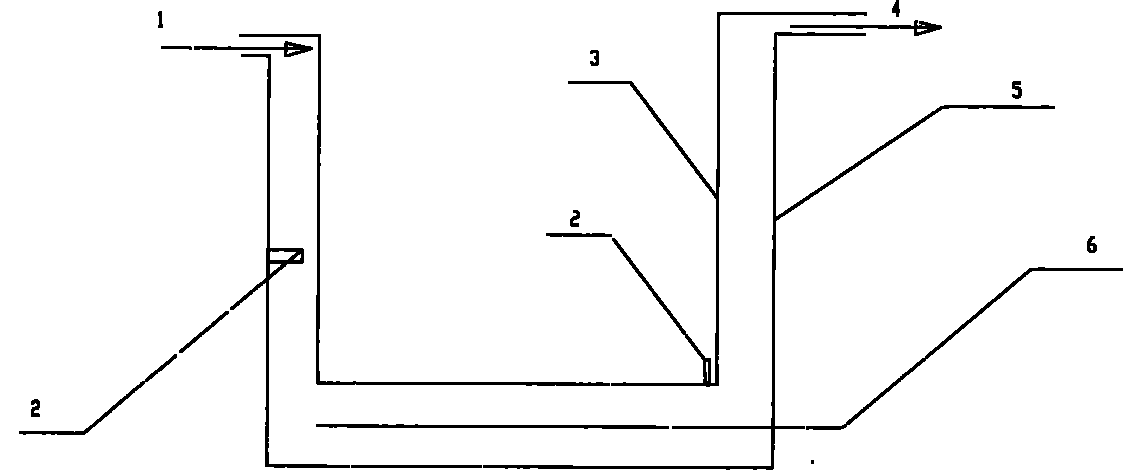

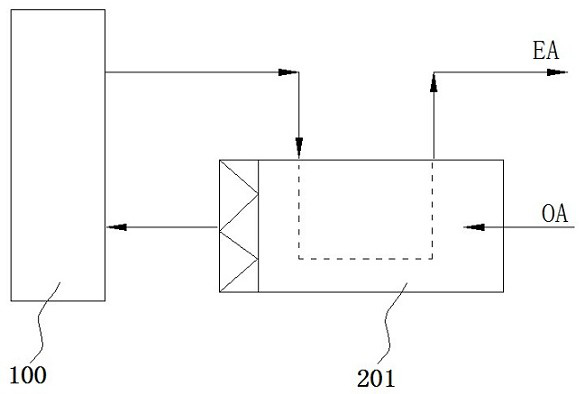

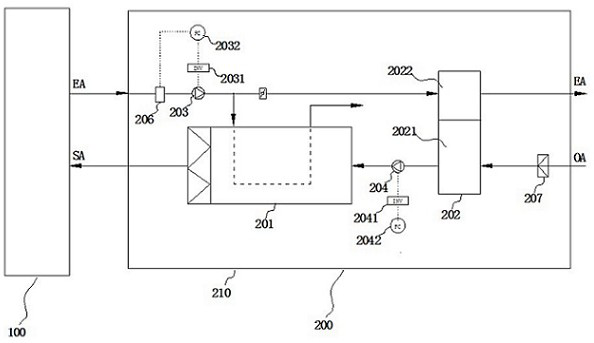

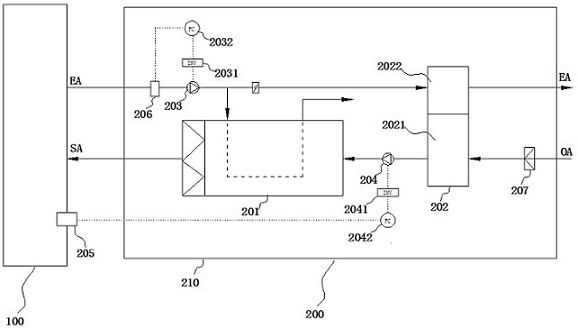

Production equipment heat recovery humidity control module and heat recovery humidity control system using same

ActiveCN114146879AReduce production speedReduce energy consumptionDispersed particle separationDrying gas arrangementsWater vaporControl system

The invention relates to a production equipment heat recovery humidity control module and a heat recovery humidity control system applying the module, the heat recovery humidity control module is provided with an adsorption dehumidification rotating wheel at a fresh air inlet, moisture in outdoor fresh air in an adsorption area of the adsorption dehumidification rotating wheel is used for adsorption, moisture in the outdoor fresh air can be removed to a large extent, and the moisture in the outdoor fresh air can be removed to a large extent. The influence of air humidity changes caused by seasonal changes on the coating production speed and the product quality is reduced, the adsorption dehumidification rotating wheel is not provided with an additional regeneration heater, and part of high-temperature gas exhausted into the drying oven directly acts on a regeneration area of the adsorption dehumidification rotating wheel so that water vapor adsorbed on the rotating wheel can be desorbed and regenerated to the outside air. The system energy consumption is further reduced; in addition, heat exchange is carried out on external low-temperature fresh air and high-temperature gas in the production equipment through the heat exchanger, the external low-temperature fresh air is heated to be close to be guided into the drying oven, and therefore the system does not need to be provided with a fresh air heater, and energy consumption of the system is greatly reduced.

Owner:SUZHOU ZHAOHE ENVIRONMENT & ENERGY TECH CO LTD

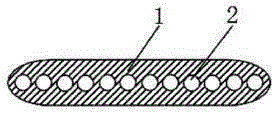

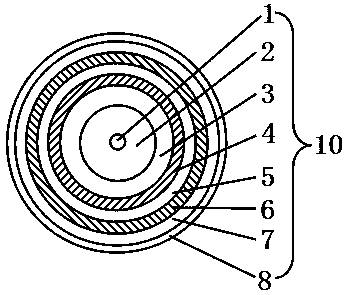

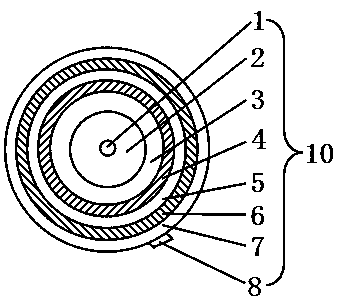

Novel shielding cable

InactiveCN105225738ATightly boundGuaranteed continuityInsulated cablesCommunication cablesCapacitanceShielded cable

Provided is a novel shielding cable comprising at least one signal line and two metallic conductive shielding tapes covering the periphery of the signal line. The metallic conductive shielding tape is formed by a metallic foil covering a side of a plasticity base material. The metallic foil of the first metallic conductive shielding tape faces outwardly, is spirally wound around the signal line, and defines a plurality of first spiral coils. The metallic foil of the second metallic conductive shielding tape faces inwardly, reversely spirally wound around the first metallic conductive shielding tape, and defines a plurality of second spiral coils. Continuous electrical contact is formed between the first metallic conductive shielding tape and the second metallic conductive shielding tape. The two metallic conductive shielding tapes are wound in a crossed manner such that the metallic foils of the two metallic conductive shielding tapes can be completely and tightly combined and cannot generate periodic breakpoints, thereby guaranteeing continuity of a conductive surface. Thus, a resonance problem generated by periodic fluctuation of shielding conductive surface capacitance is solved and an effect of solving a high-frequency point abrupt attenuation.

Owner:通盈电业(深圳)有限公司

Aluminum section bar surface brightening method

InactiveCN109913925AWith cleanReduce production speedAnodisationElectrophoretic coatingsPhosphoric acidColor changes

The invention discloses an aluminum section bar surface brightening method. The aluminum section bar surface brightening method comprises the steps of sand blasting, oil removing, water washing, polishing, oxidizing, coloring, medium-temperature hole sealing and electrophoresis curing, wherein the polishing is performed inside a three-acid polishing tank, the three-acid polishing tank contains theingredients of, in percentage by weight, 65-85% of phosphoric acid, 14-22% of sulfuric acid and 6-8% of nitric acid, the polishing is performed for 20-25 min under the condition of the polishing temperature being 100-110 DEG C, and by means of reduction of the oxidizing temperature and the oxidizing tank sulfuric acid concentration, the oxide film production speed can be reduced, a more uniform and compact oxide film is obtained, and appearance of flow marks in aluminum materials is reduced; and the aluminum materials are not prone to fading when being subjected to the water washing and electrophoresis after being subjected to the coloring and the hole sealing and high adhesion can be obtained when the electrophoresis is performed in a half hole sealing state, and when combination with the electrophoresis is performed, suitable voltage can slow down the paint film coating speed, in addition of an appropriate curing method, dye color changing and coating surface roughness and excessivebrittleness can be prevented, and the coating adhesion is improved.

Owner:佛山市南海区和顺超强铝型材有限公司

Weaving technology of 20D/7F nylon high-elastic skin windbreaker fabric

ActiveCN104695097ASolve the weft fileSolve serious warp reed marksLoomsWoven fabricsLongitudeEngineering

The invention discloses a weaving technology of 20D / 7F nylon high-elastic skin windbreaker fabric. The weaving technology comprises the following steps: white body preparation loom fittings are set, and parameters of a loom are regulated. According to the invention, the problems that warps are easy to break and form stripes, weft bars are generated on fabric cover, and warp-direction reed marks are serious are solved, the effect of the fabric cover in latitude and longitude directions is greatly improved, enough preparation is provided for the smoothness of the fabric cover after deep-processing of the subsequent fabric, and the demands for markets are sufficiently satisfied.

Owner:WUJIANG FUHUA WEAVING

Efficient production line for aerosol cans

InactiveUS20130084148A1Reduce productionImprove productivityProgramme controlPackaging automatic controlManufacturing lineAerosol

A production line with processing stations processing products with a production speed in products per unit time, the production line comprising a temporarily discontinuously operating processing station; a production line section connected upstream of the temporarily discontinuously operating processing station; a production line section connected downstream from the temporarily discontinuously operating processing station; a first product buffer arranged between the upstream production line section and the temporarily discontinuously operating processing station; and a second product buffer arranged between the temporarily discontinuously operating processing station and the downstream production line section.

Owner:MALL & HERLAND

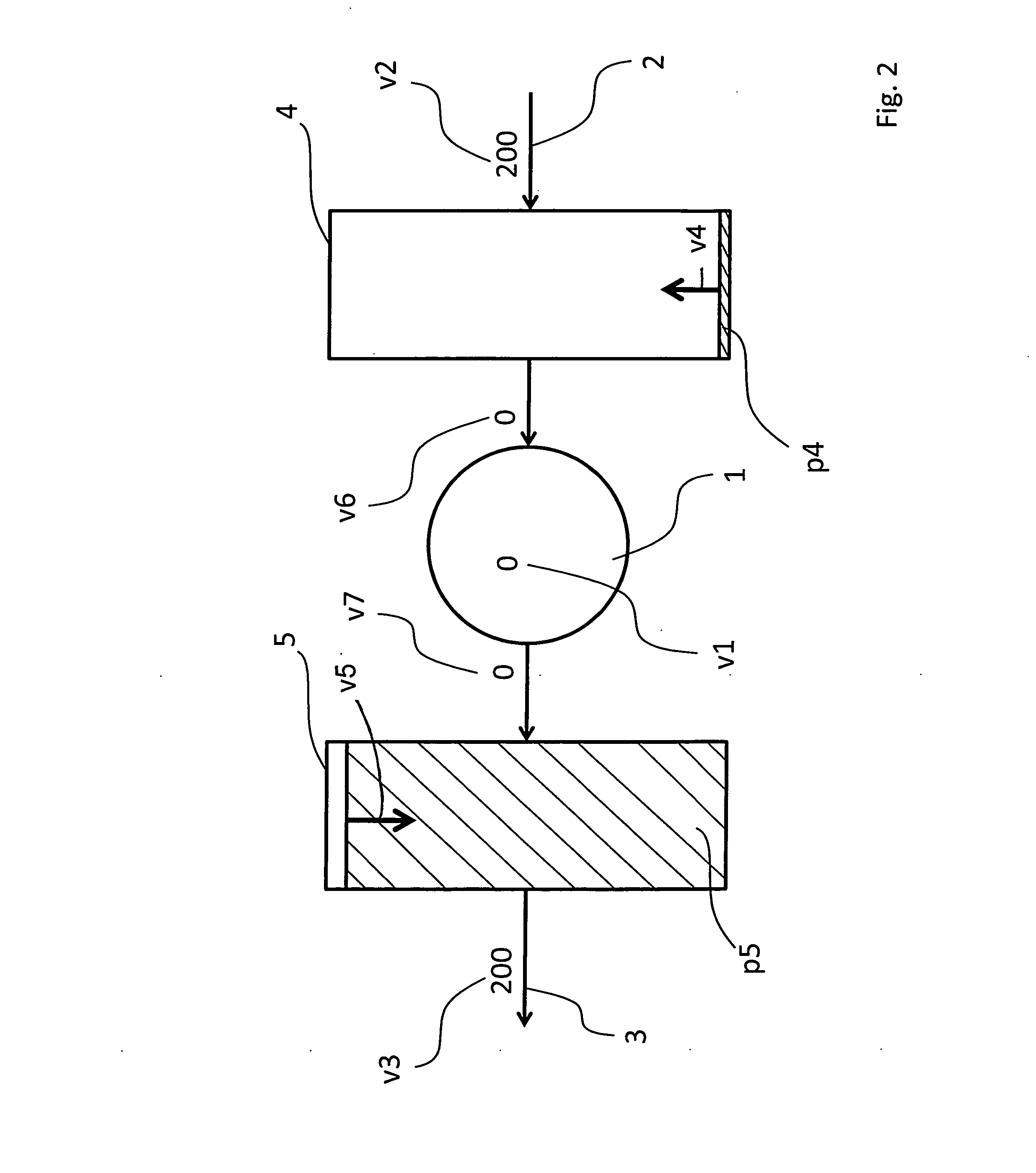

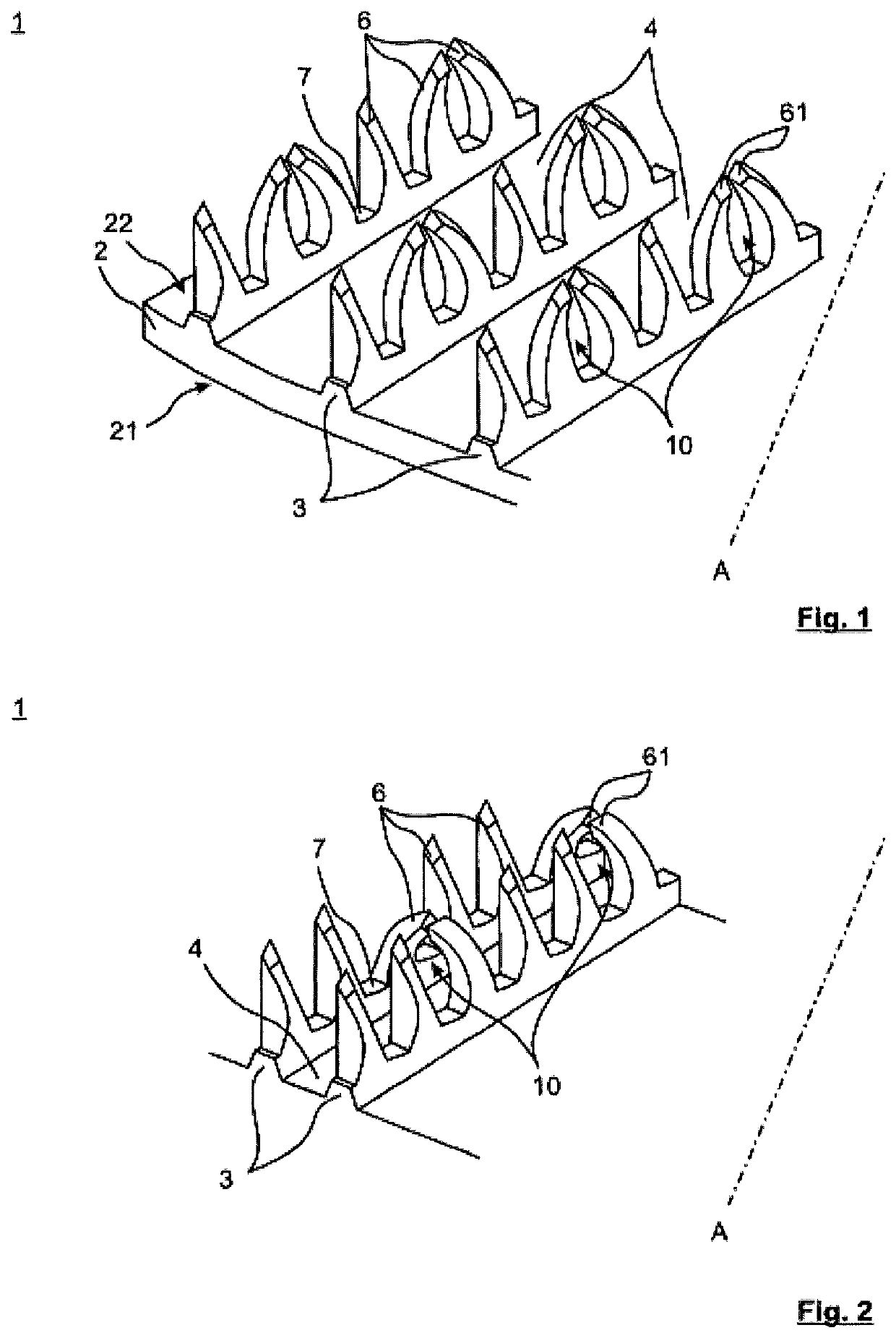

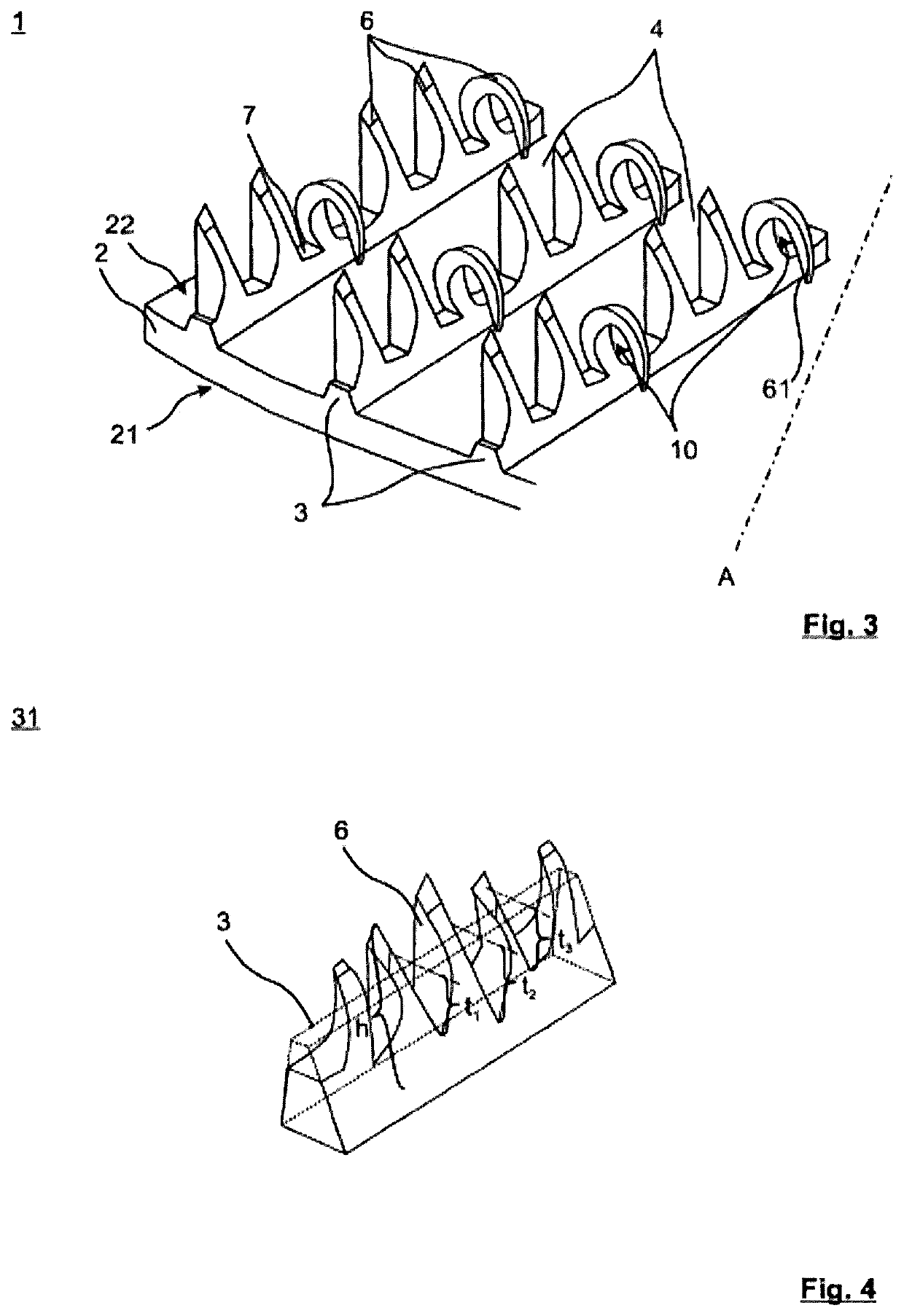

Heat exchanger tube

ActiveUS10996005B2Increase temperature differenceExcessive transferTubular elementsMechanical engineeringPhysics

The invention relates to a heat exchanger tube having a tube longitudinal axis, wherein fins extend continuously from the tube wall on the tube outer face and / or the tube inner face, or extend axially parallel thereto or in the form of a helix. Continuously extending primary grooves are formed between adjacent fins, said fins have at least one structured area on the tube outer face and / or tube inner face, and the structured area has a plurality of projections of a projection height projecting from the surface, the projections being separated by notches. According to the invention, a plurality of projections are deformed relative one another in pairs to such an extent that cavities are formed between adjacent projections. Furthermore, according to the invention, a plurality of projections are deformed in the direction of the tube wall such that cavities are formed between a respective projection and the tube wall.

Owner:WIELAND WERKE AG

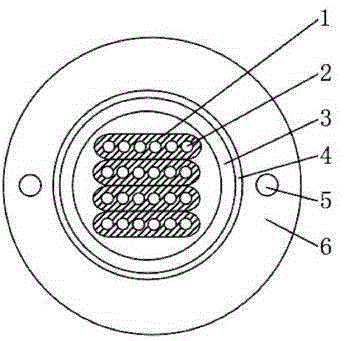

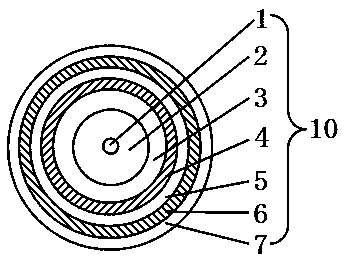

Layer-stranded ribbon fiber cable for electric power or communication

The invention belongs to the field of fiber cable technology, in particular to a layer-stranded ribbon fiber cable for electric power or communication. The ribbon fiber cable comprises multiple loose tubes outside a reinforcing piece and a small filling rope in an outer gap of every two adjacent loose tubes. The loose tubes and the small filling ropes are provided with a protection layer outside. The exterior of the protection layer is coated by a sheath layer in an extrusion molding manner. The fiber cable is characterized in that multiple fiber cable ribbons are arranged in each of the loose tubes; each of the fiber cable ribbons is provided with multiple optical fibers and multiple fiber cable ribbon resin coating the whole optical fibers; there is no other visible filling matter except for the fiber cable ribbons in gaps of the loose tubes; and there is no visible filling material in gaps formed by the loose tubes, the reinforcing piece, the small filling ropes and the protection layer. The beneficial effects are that the fiber cable ribbons have quite high water resisting performance; cost of the fiber cable is quite low; the fiber cable is quite environmentally-friendly and light; detection and construction are quite convenient to perform; and production environment is quite clean.

Owner:孙海东

Three-layer co-extruded EVA (ethylene-vinyl acetate copolymer) long-life fog-dissipation environment-friendly multifunctional greenhouse film

ActiveCN103264563BGood colorEasy to processClimate change adaptationSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a nano fog-dissipation multifunctional greenhouse agricultural film, and in particular relates to a three-layer co-extruded EVA (ethylene-vinyl acetate copolymer) long-life fog-dissipation environment-friendly multifunctional greenhouse film, belonging to the field of agricultural mulching films. The raw material formula of an outer layer comprises the following components in percentage by weight: 20-50% of linear low-density polyethylene (LLDPE), 20-50% of low-density polyethylene (LDPE), 10-20% of metallocene polyethylene (mPE) and 5-10% of double-prevention masterbatch; the raw material formula of a middle layer comprises the following components in percentage by weight: 30-40% of ethylene-vinyl acetate copolymer (EVA), 20-40% of linear low-density polyethylene (LLDPE), 20-40% of low-density polyethylene (LDPE) and 5-10% of three-prevention masterbatch; the raw material formula of an inner layer comprises the following components in percentage by weight: 30-40% of ethylene-vinyl acetate copolymer (EVA), 10-20% of linear low-density polyethylene (LLDPE), 20-50% of low-density polyethylene (LDPE) and 5-10% of three-prevention masterbatch; and the formulas of the outer layer, the middle layer and the inner layer are uniformly mixed respectively, master batches are prepared by using a double-head thread screw double-screw extruding machine, a three-layer film is formed through a co-extrusion die head and is extruded out to prepare the multifunctional agricultural greenhouse film. Every quality technical index of the film reaches or exceeds a national standard, and a small part of the indexes is more than 2 times better than the national standard, so that the film is excellent in antiaging performance and cannot generate fog drops, and the service life of the film reaches more than 3 years.

Owner:HENAN YINFENG PLASTIC

Accumulation type intelligent conveying and spraying production line and spraying process for billiard table

PendingCN112354761AImprove surface smoothnessReduce manual operationsPretreated surfacesCoatingsConvertersProduction line

The invention discloses an accumulation type intelligent conveying and spraying production line for a billiard table. The accumulation type intelligent conveying and spraying production line for the billiard table comprises a billiard table circulating conveying line, wherein the billiard table circulating conveying line comprises a paint spraying conveying chain section and a drying conveying chain section; a workpiece loading area, a billiard table dust blowing station, a reverse-side automatic paint spraying room, a reverse-side supplementary spraying room, a front-side automatic paint spraying room, a front-side supplementary spraying room, a micro-air leveling area, a drying area, an illumination area and a workpiece unloading area are sequentially arranged in the machining directionof the billiard table circulating conveying line to form the production line; dust blowing devices which are aligned with one another to remove dust from workpieces in advance are arranged in the billiard table dust blowing station, and the plurality of workpieces vertically stay and are accumulated on the drying conveying chain section through a rail converter; and the workpiece loading area, thebilliard table dust blowing station, the reverse-side automatic paint spraying room, the reverse-side supplementary spraying room, the front-side automatic paint spraying room and the front-side supplementary spraying room are arranged on the paint spraying conveying chain section, and the micro-air leveling area, the drying area, the illumination area and the workpiece unloading area are arranged on the drying conveying chain section.

Owner:广东创智智能装备有限公司

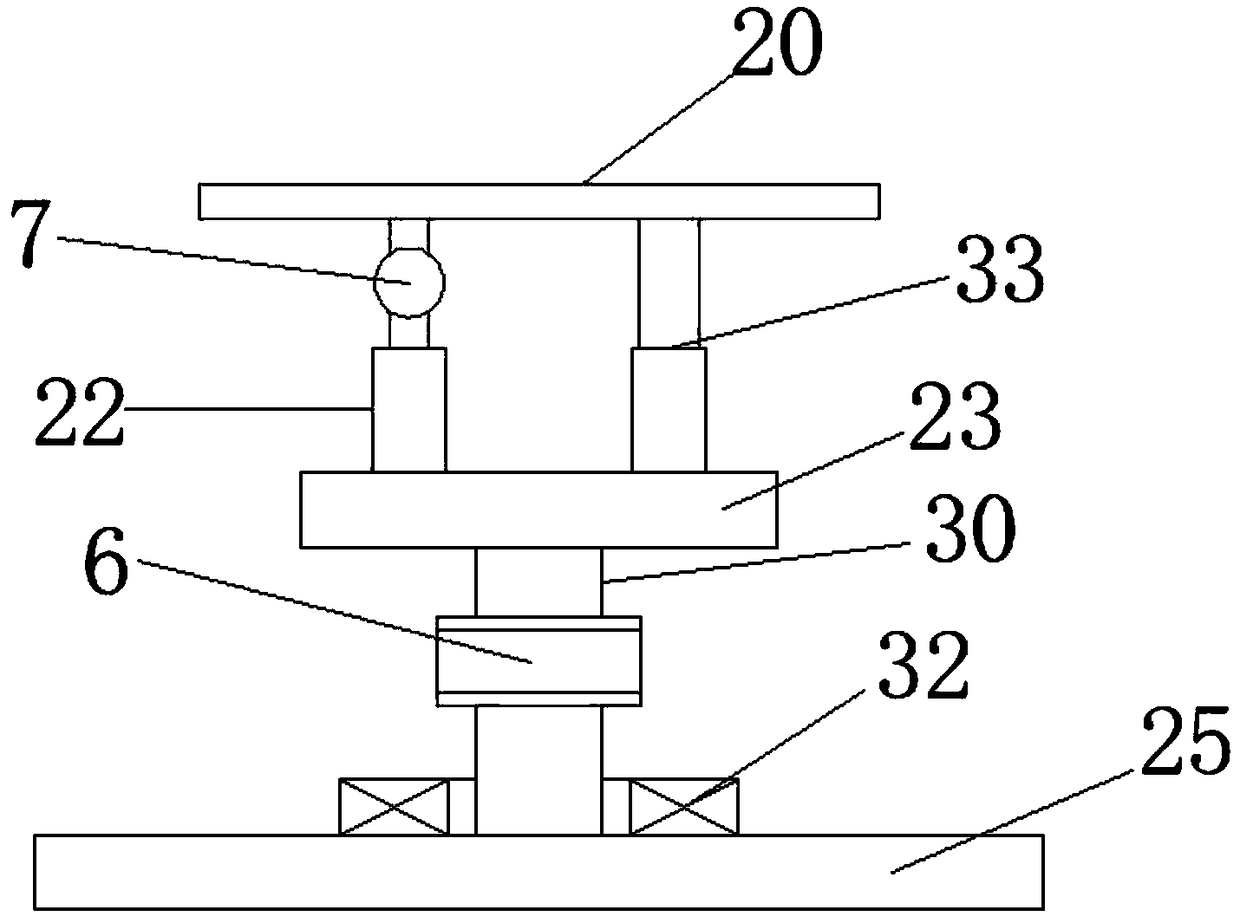

Work table convenient to adjust height for computer hardware production

PendingCN108994794AReduce production speedImprove work efficiencyWork benchesWorkbenchComputer engineering

The invention belongs to the technical field of computer hardware production, in particular to a work table convenient to adjust height for the computer hardware production. The following scheme is provided basing on the problems that the height of the work table can not be adjusted, the computer hardware production can not be facilitated, angle can not be adjusted by the work table, and a production part can not be fixed by the work table. The work table comprises bases, wherein telescopic rods are welded to the top of the corresponding base; a damping spring sleeves the outer wall of the corresponding telescopic rod; one end, away from the corresponding base, of each telescopic rod is connected with a work table body through a bolt; and the two sides of the top of the work table body areconnected with four telescopic air cylinders through bolts. According to the work table, the height adjustment can be carried out according to requirements, the problem that a computer hardware can not be normally produced due to the height problem of the work table is avoided; the front and back positions of an operation board can be adjusted, so that the production position of a computer is conveniently adjusted; and the computer hardware can be clamped, so that the computer hardware is prevented from falling off due to the fact that fixation is not firm.

Owner:郭锦明

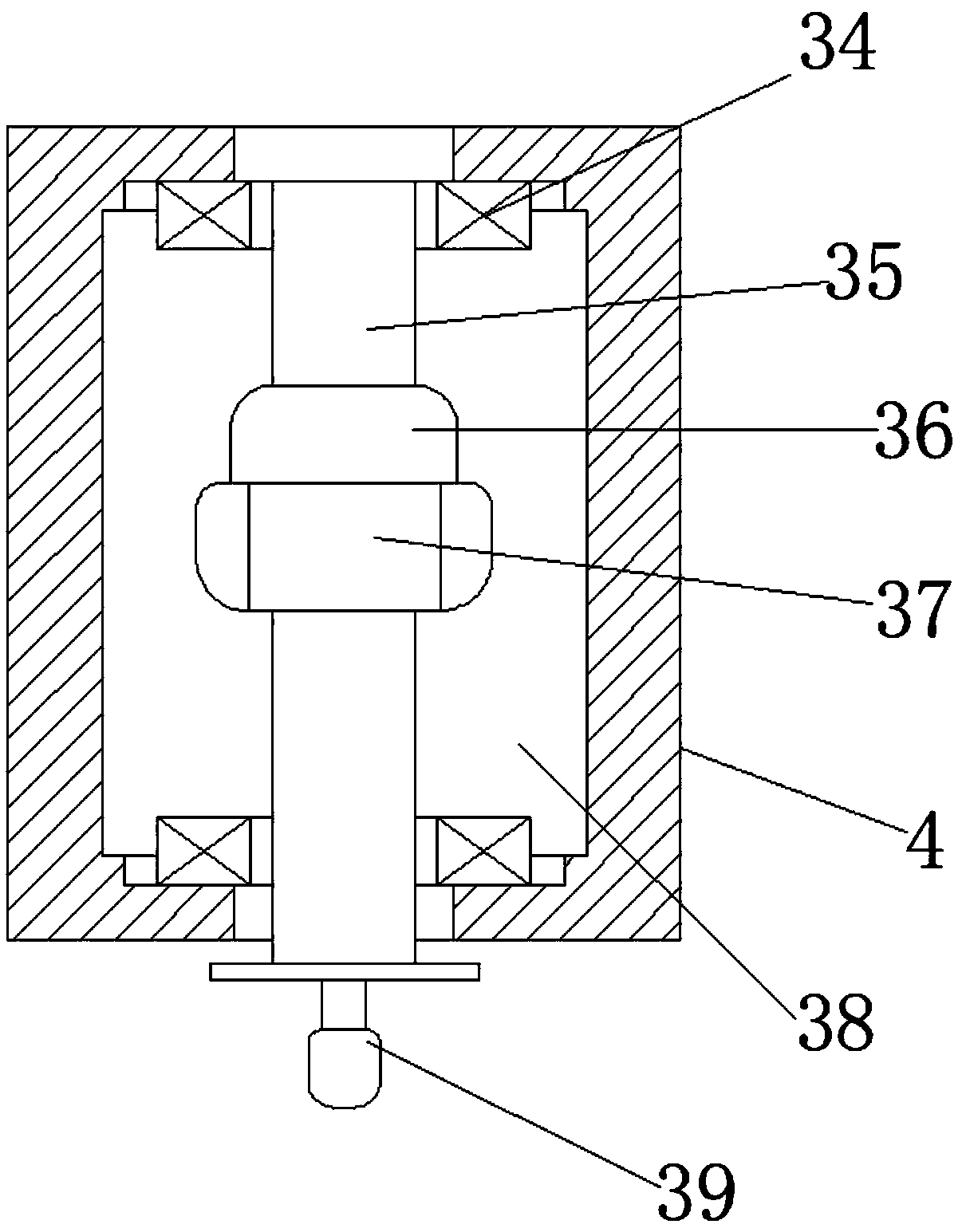

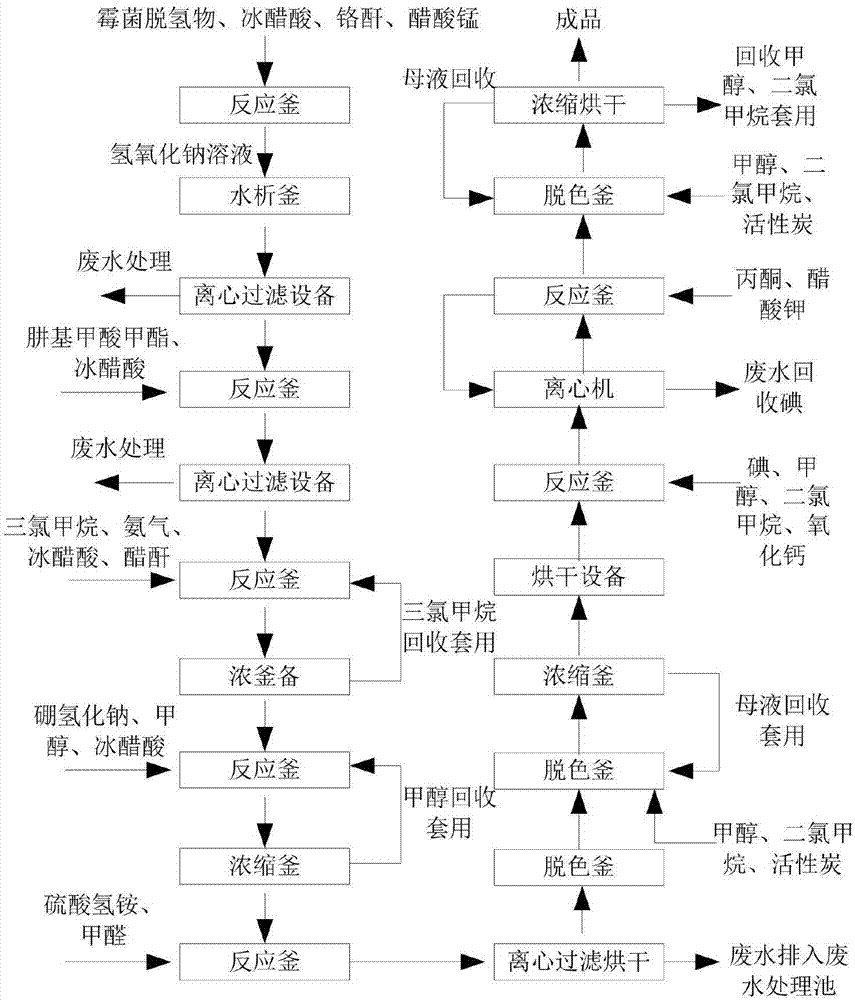

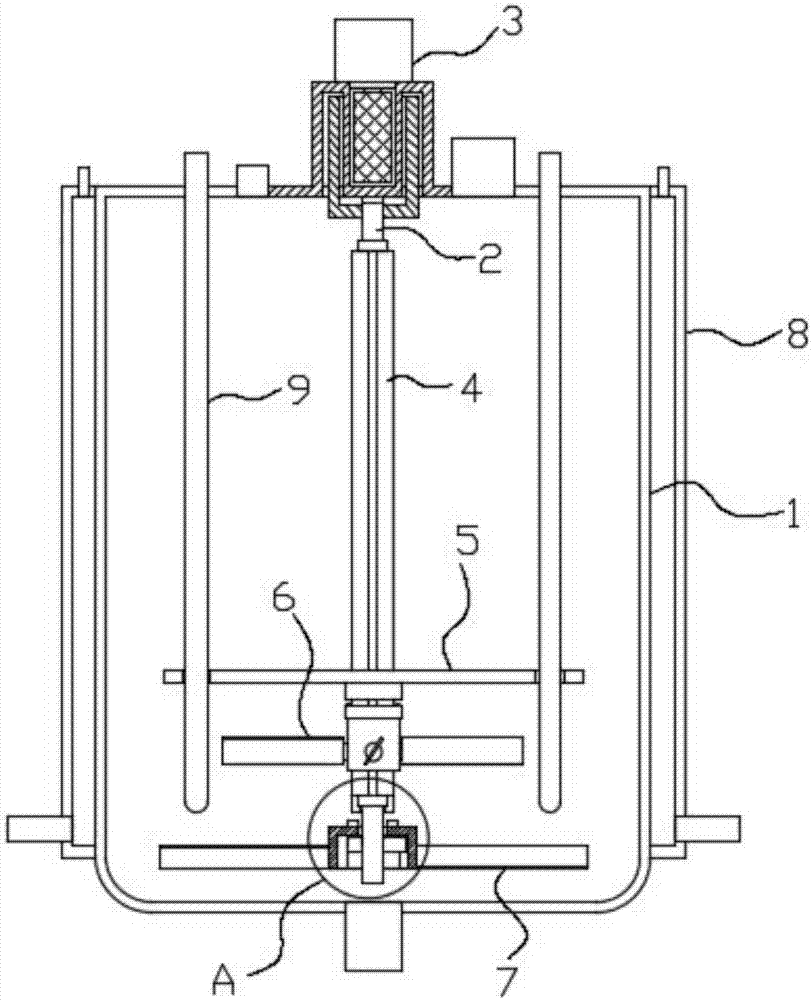

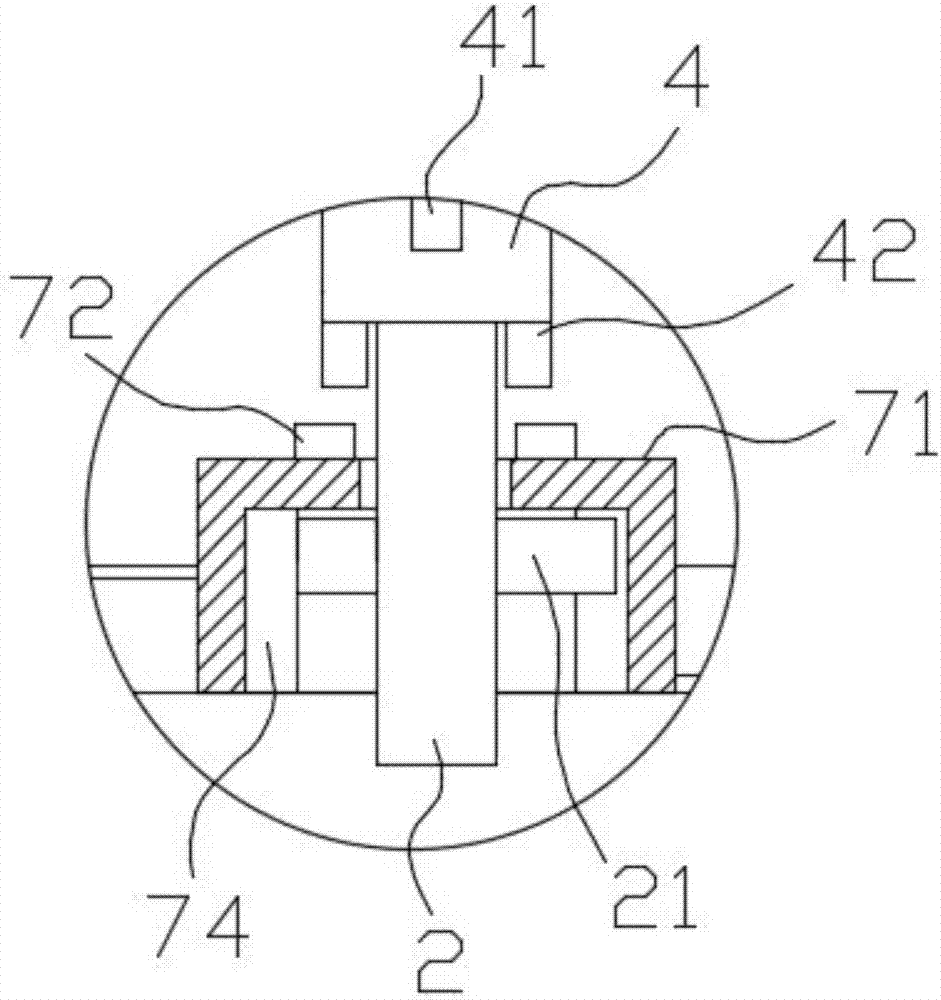

Quick reaction technology and production system for deflazacort

The invention discloses a quick reaction technology and a production system for deflazacort. The production system comprises a reaction kettle, an elutriation kettle, centrifugal filtering equipment, a concentration kettle, drying equipment and a discoloring kettle which are mutually connected according to procedures, wherein the reaction kettle comprises a tank body, and an interlayer cavity is arranged at the outer wall of the tank body; a temperature adjusting tube is arranged in the tank body; a stirring shaft is arranged at the center of the interior of the tank body; the upper end of the stirring shaft is connected with a magnetic coupling rotary device, and a stirring impeller is arranged at the lower end of the stirring shaft; a rotary cylinder is arranged on the stirring shaft; a buoyancy impeller is arranged on the rotary cylinder; a lifting tray is arranged at the upper end of the buoyancy impeller; a circular hole is formed in the lifting tray; water filtering holes are uniformly distributed in the lifting tray; a vertical slide groove is arranged in the outer wall of the rotary cylinder; a rolling shaft is arranged at the inner wall of a base of the buoyancy impeller; an upper key board is arranged at the upper end of a rotary cover of the stirring impeller; a lower key board is arranged at the lower end of the rotary cylinder. The production system and the technology have the advantages that the multi-azimuth flowing of reaction liquid is realized, the reaction time of the deflazacort in each step is shortened, and the quick production of the deflazacort is realized.

Owner:YUEYANG HUANYU PHARMA

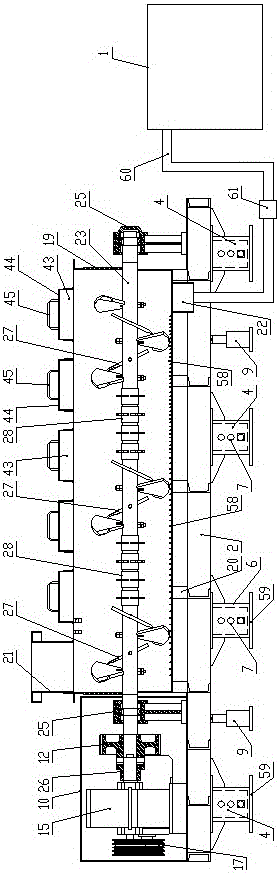

A linear eye drop bottle washing, filling, stoppering and capping integrated machine and method

InactiveCN103738903BReduce in quantityIncrease the number of channelsBottle-handling machinesControl engineeringProcess engineering

The invention discloses a linear eye drop bottle washing, filling, plugging and cap screwing integrated machine and a method. The linear eye drop bottle washing, filling, plugging and cap screwing integrated machine comprises a bottle washing and conveying synchronous belt and a filling, plugging, cap screwing and bottle conveying synchronous belt which are arranged back and forth in parallel; under the state of laminar flow protection and online monitoring sterile control state, the sterile production process of each function of bottle washing, filling, plugging, capping and cap screwing in the linear intermittent motion process of eye drops is realized; not only can insufficient debugging and maintaining space be prevented, but also the length of the production line can be shortened; the sterile control cost can be reduced; the device running and connection stability can be improved; the number of operators can be reduced; the production speed can be improved; each component is arranged in a linear mode, and a shifting wheel guides and turns over sterile eye drop bottles to arrange; a gantry structure is adopted for plugging and capping, so that the space for debugging, maintenance and artificial intervene can be settled effectively; the length of the whole line is shortened by the shifting wheel; the gantry plugging and capping structure is stable and reliable, facilitating to increasing the quantity of cap and plug conveying channels and improving the production stability.

Owner:CHANGSHA ZHONGYI PHARMA MACHINERY

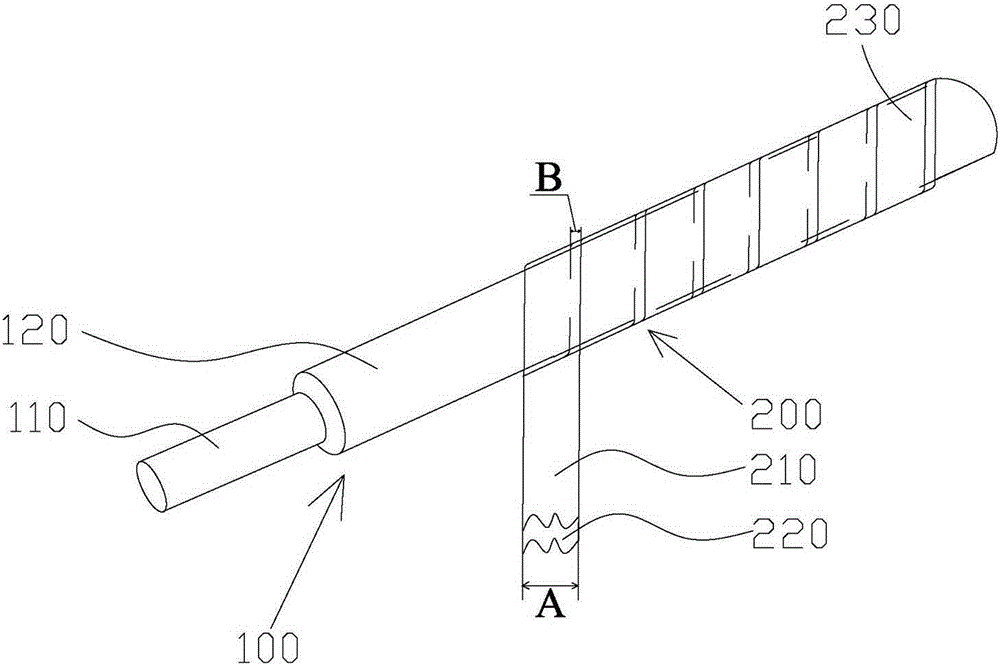

Water-blocking optical fiber and optical cable using the optical fiber

InactiveCN104238005BImprove tensile propertiesLow costOptical fibre with multilayer core/claddingFibre mechanical structuresFiberEngineering

The invention belongs to the technical field of wires and cables, and particularly relates to a waterproof optical fiber. The waterproof optical fiber comprises a core in the center, a lapping layer outside the core, and an internal coating layer outside the lapping layer. The waterproof optical fiber is characterized in that a first waterproof layer covers the coating layer, a damp-proof layer covers the first waterproof layer, a second waterproof layer covers the damp-proof layer, an external coating layer covers the second waterproof layer, and a color layer covers the external coating layer. The invention further discloses an optical cable utilizing the optical fibers. The waterproof optical fiber has good effect and high tension resistance; the optical cable utilizing the optical fibers is convenient to produce, low in cost and much popular with producers, proofers and users.

Owner:浙江劳兰信息技术有限公司

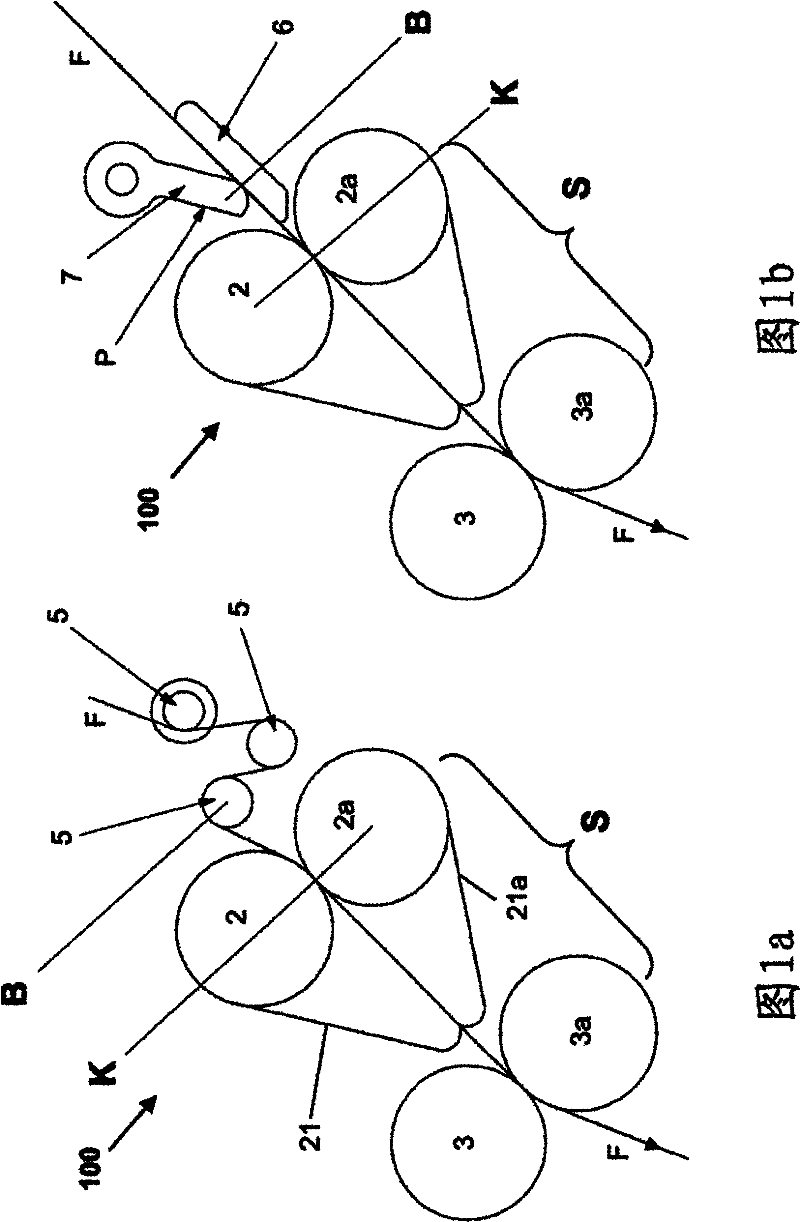

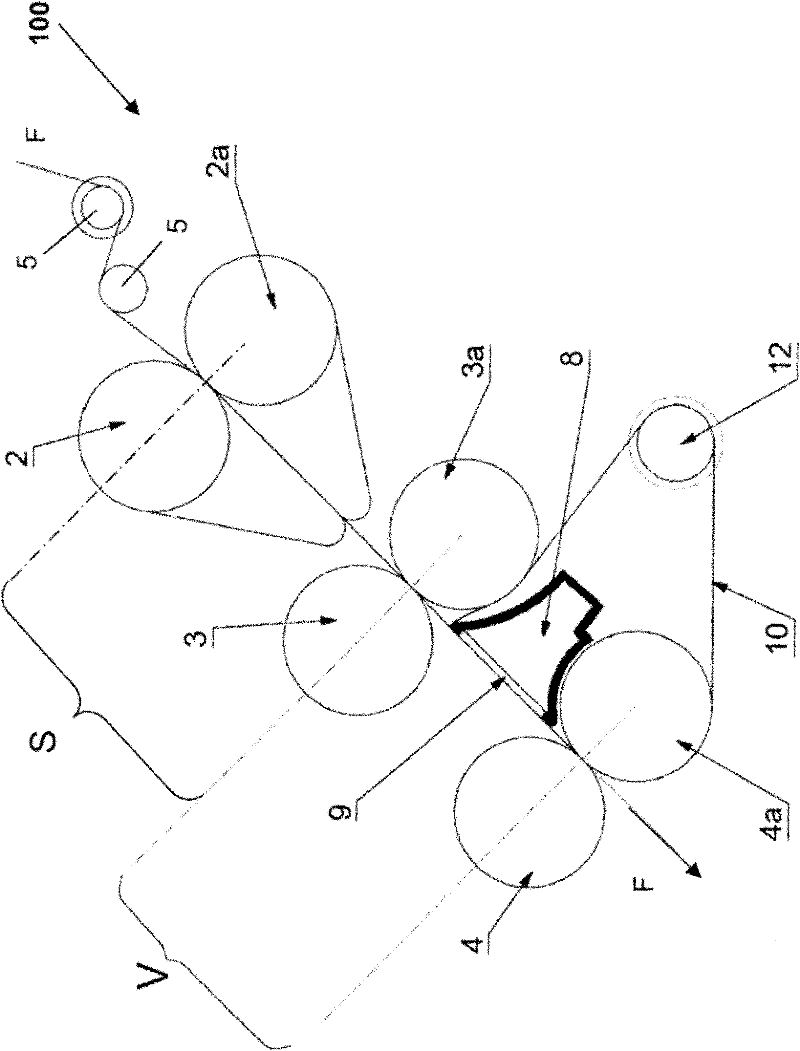

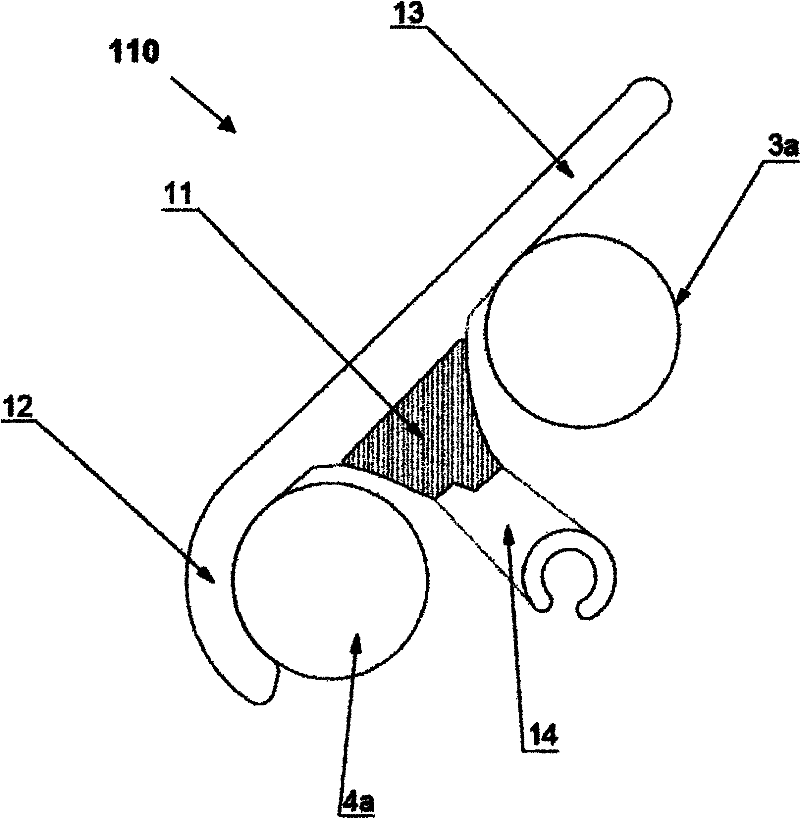

Compact roller drawing frame and spinning machine including same

InactiveCN102199818ANot suitable for high loadsGuaranteed finenessDrafting machinesFiberMechanical engineering

A compact roller drawing frame and a spinning machine including the same. The invention provides a roller drawing frame 100 for drawing at least a short fiber strip (F), characterized in that a drawing region (S) on which the strip (F) is wholly drawn is only composed of two pairs of rollers (2 / 2a, 3 / 3a) and the strip is wholly drawn between two pairs of rollers (2 / 2a, 3 / 3a).

Owner:ROTORCRAFT SA (PTY) LTD

Manufacture method for a projection capacitive touch screen

InactiveUS20180101257A1Easy to produceFast productionInput/output processes for data processingPet substrateEngineering

The present invention discloses a manufacture method for a projection capacitive touch screen, comprising following steps: (1) placing a clean PET substrate on a 3D printing platform, (2) the 3D printing platform outputing movement of x, y and z directions through control software, (3) aligning tail-throwing leads on the PET-X film, (4) tearing off the protective release film on one side of the PET-Y film, (5) bonding the PET-Y film and the PET-X film, (6) cutting off the redundant areas around the PET-XY film completed in the step (5), (7) drying the PET-XY film, and (8) laser welding the dried PET-XY film to obtain a projection capacitive touch screen. Through above approaches, the manufacture method for a projection capacitive touch screen according to the present invention is mainly used for large-size capacitive touch film and has advantages of simple production process, fast production speed, high yield and low cost.

Owner:SUZHOU TOUCH PLANET CO LTD

Drill gun capable of automatically changing torque

ActiveCN110666217AHigh torqueReduce torquePortable power-driven toolsDriving apparatusGear wheelDrive shaft

The invention discloses a drill gun capable of automatically changing torque. The drill gun comprises a shell, wherein a fourth baffle, a third baffle, a second baffle gear bracket and a first baffleare fixedly connected to the interior of the shell from top to bottom in sequence. According to the drill gun capable of automatically changing the torque, an eighth gear, a ninth gear, a sixth gear and a seventh gear are arranged, so that a small transmission ratio can be converted when a drill bit is subjected to resistance, therefore, the effect of increasing the torque is achieved; a pull rod, a transmission shaft a and a spring are arranged, so that the positions of the sixth gear and the seventh gear can be restored when the drill bit is subjected to small resistance, therefore the torque of the drill bit is reduced; and through the integral structural arrangement, the problems that a current drill gun is inconvenient to use and not conducive to popularization and use due to wastedprecious time and reduced production speed of an enterprise in the assembly process caused by the fact that the common drill gun in the current market requires manual adjustment when adjusting the torque are solved.

Owner:南通东科工具有限公司

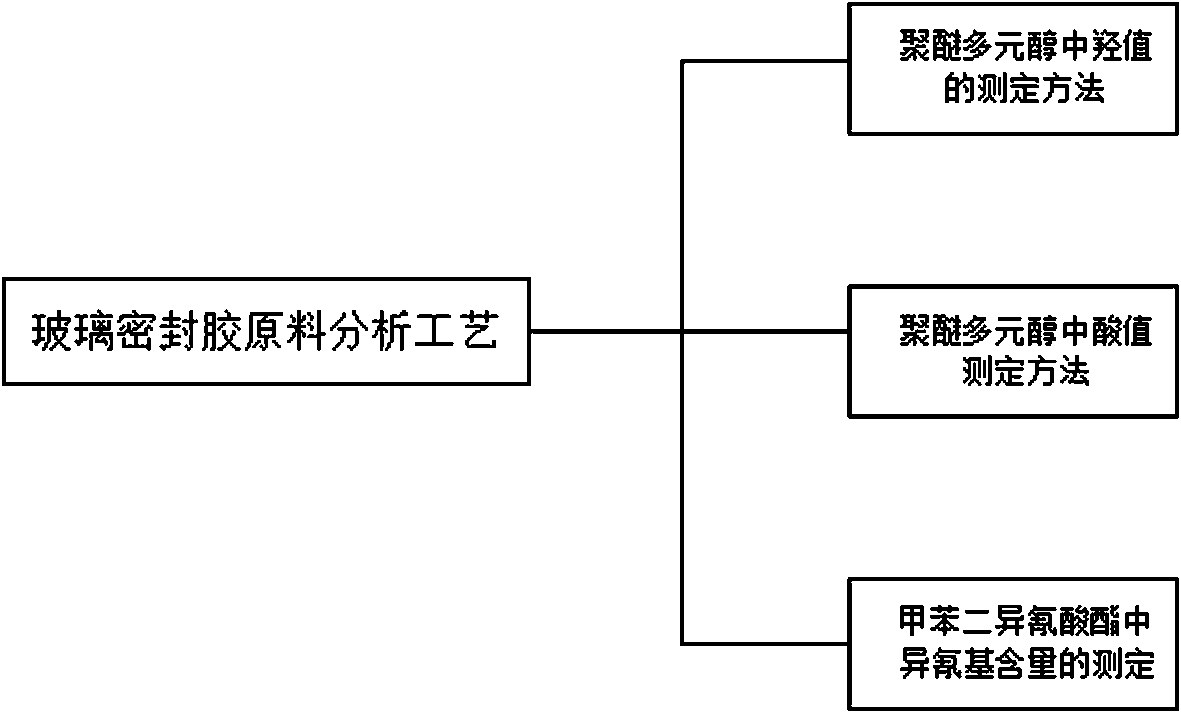

Glazing compound raw material analysis process

InactiveCN108508139AEasy to analyzeQuality improvementChemical analysis using titrationMaterial resourcesBottle

The invention discloses a glazing compound raw material analysis process, comprising a determination method of a hydroxyl value in polyether polyol. The method comprises the following steps: step S1,weighing 116g of phthalic anhydride and putting into a 1L brown bottle, adding 700mL of pyridino and shaking fiercely until pyridino is dissolved, adding 16g of imidazole and shaking carefully until imidazole is dissolved, wherein the solution needs to stand to stay overnight before use to prevent absorption of moisture by exposure in air for a long time; and S2, abandoning the reagent when the color is deepened. In blank titration, 25ml of such reagent needs to consume 95ml-100ml of 0.5mol / L sodium hydroxide standard titration solution, and the production rate is saved by 2-3 hours; furthermore, the accuracy is improved, calibration is not needed, manpower and material resources are saved, the calculated result is the actual measurement result, great convenience is brought for productionand analysis, a certain value is achieved in actual analysis and production, the material is analyzed more reasonably, the quality of the glazing compound in later period is improved, and the problemof untight sealing of the glazing compound in the later period is prevented.

Owner:武汉锦程华兴密封材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com