Patents

Literature

62 results about "Walking table" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

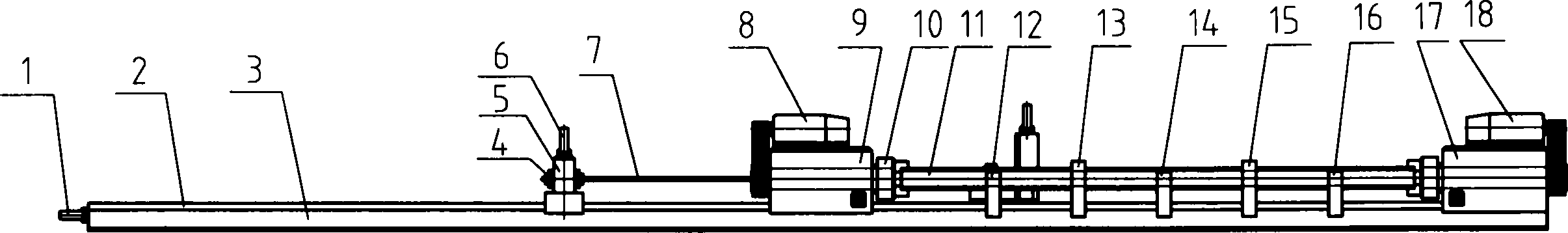

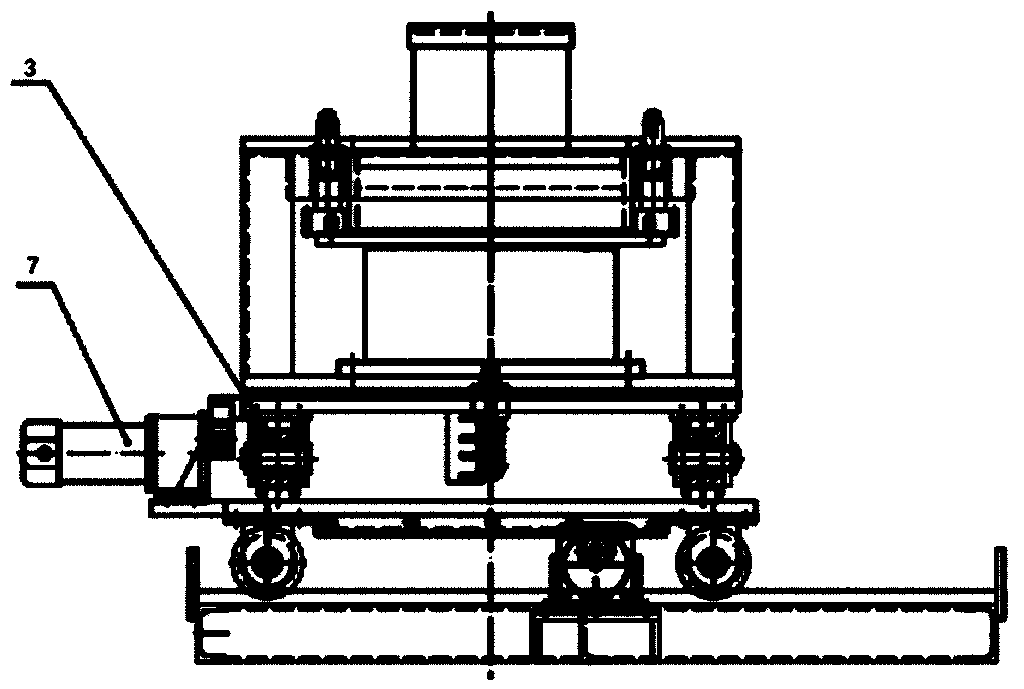

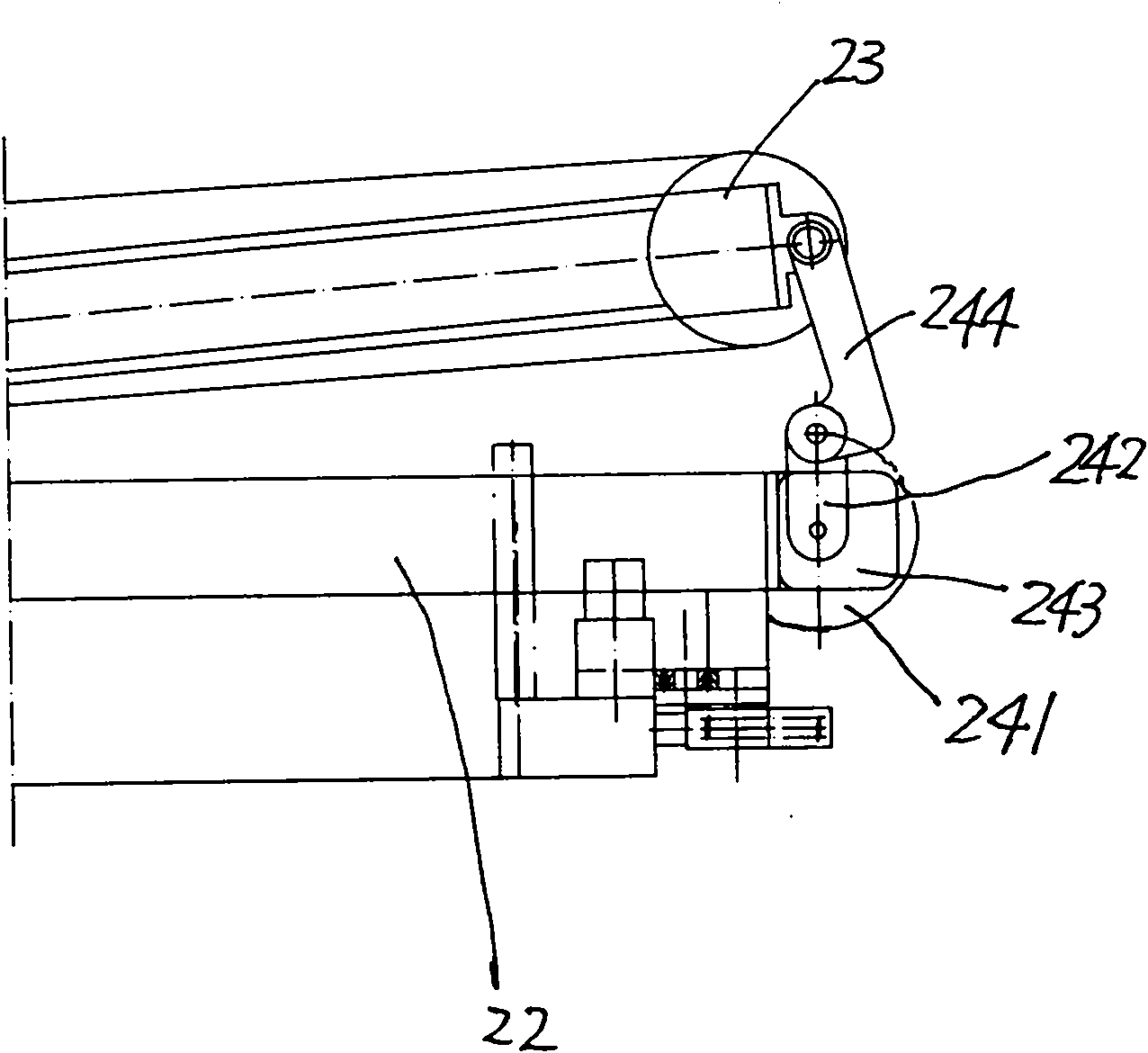

Machine tool for processing super long workpiece

InactiveCN1880012ARequirements to ensure design accuracyImprove processing efficiencyOther manufacturing equipments/toolsMetal working apparatusMotor driveSlide plate

The invention relates to a machine tool for machining overlong workpiece, which comprises a workpiece machine bed and walking machine bed, which are parallel arranged, wherein the workpiece machine bed has head box and tail box, while the head box is arranged with power cutter, and the head box and the tail box are independently mounted with head box driving motor and tail box driving motor, while the main axle is the hollow axle; the hollow axle is rotated by the main axle motor; the head box driving motor and the tail box driving motor drive the head box and the tail box moves on the track quickly; the walking bed is arranged with one walking table whose two sides are mounted with blade support slide plate and the grinding slide plate with grinder. The invention can complete the processes as grinding, milling, drilling, and drawing at one time, without adjusting workpiece. And the coaxial accuracy between outer round of workpiece and the central axle of inner hole are confirmed.

Owner:刘星海

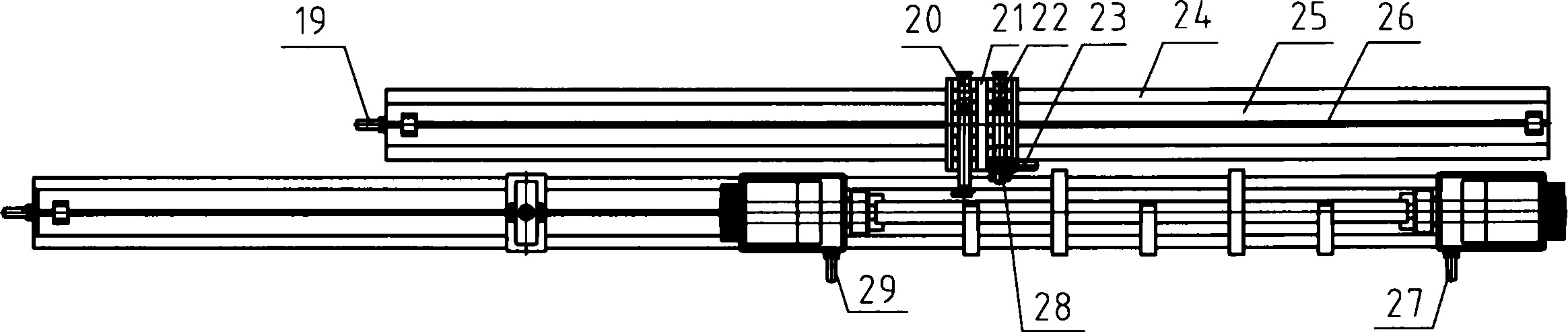

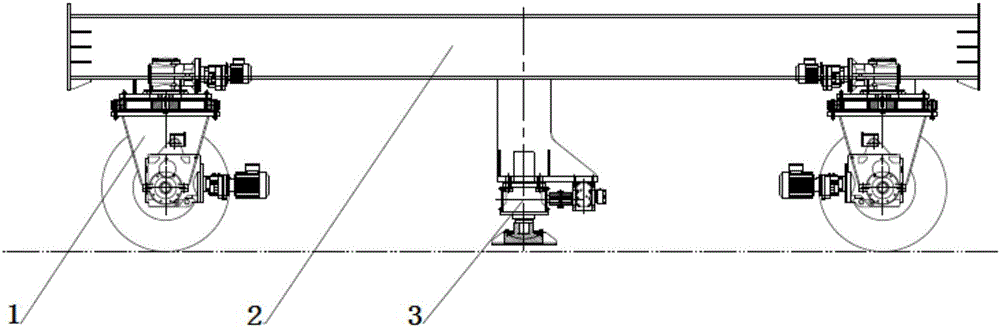

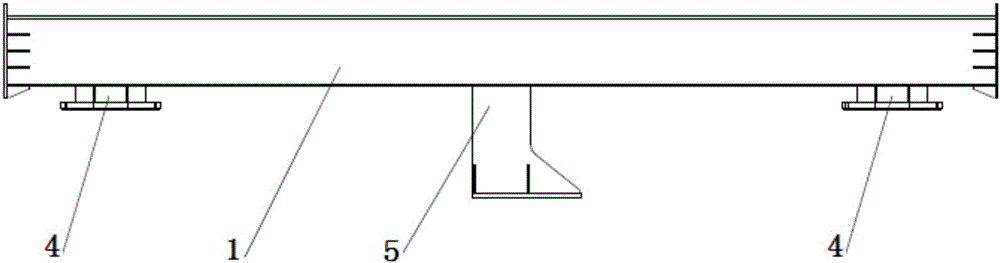

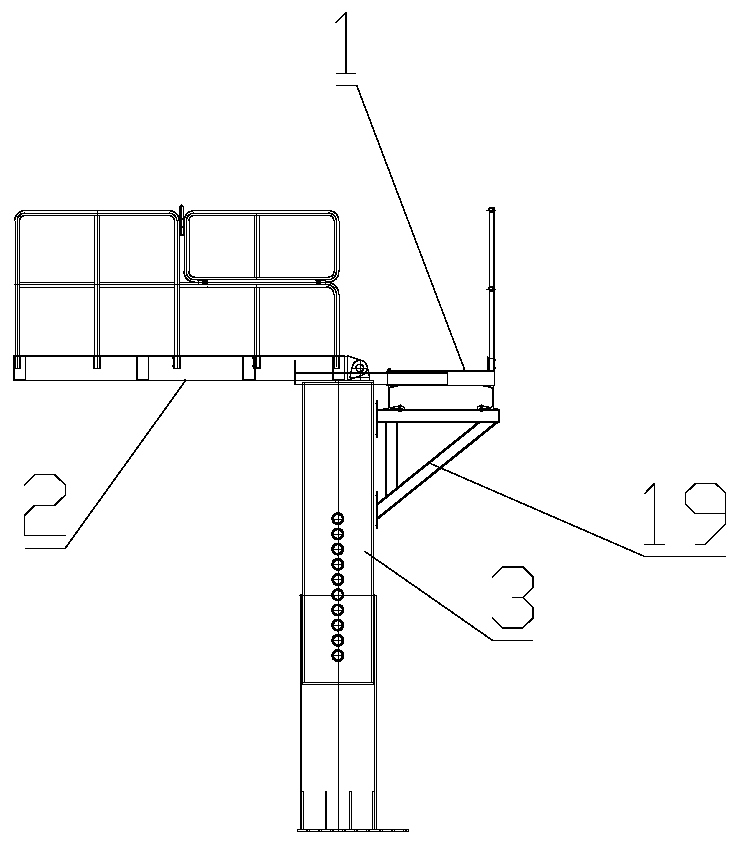

Gantry crane all-dimensional steering device and method

InactiveCN106429830AAccurate control of movement directionHigh precisionTravelling gearCranesEngineeringSlewing bearing

The invention discloses a gantry crane all-dimensional steering device and method. The device comprises walking beams arranged at the lower ends of gantry crane supporting legs, a walking steering mechanism arranged at the two ends of the walking beams, and a jacking mechanism arranged between the walking beams; and the walking steering mechanism comprises a walking wheel train, a walking table frame and a rotating mechanism. By means of the jacking mechanism, the walking beams can be jacked up or lowered, so that the walking wheel train can be suspended; and by means of the rotating mechanism, the movement direction of the walking wheel train can be changed, so that a gantry crane on the walking beams can achieve all-dimensional steering, and therefore the using range of the operation environment of a hoisting device is widened. In addition, the rotating mechanism comprises a rotating bearing, a rotating driving motor and a gear; and the rotating bearing is driven by the rotating driving motor and the gear to rotate, the movement direction of the walking wheel train can be accurately controlled, and the hoisting operation precision is improved. According to the gantry crane all-dimensional steering device and method, all-dimensional steering can be achieved, the operation accuracy and the operation precision are high, the application range is wide, and cost is low.

Owner:BEIJING INST OF ENVIRONMENTAL FEATURES

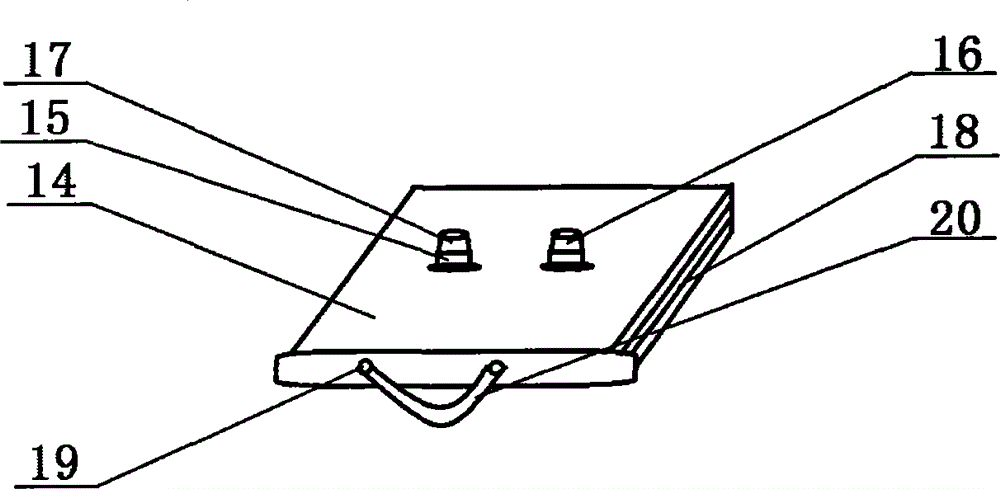

Rehabilitation device for lower limb paralysis caused by nervous centralis

InactiveCN104434490ASimple structureSimple and fast operationVibration massageRadiation therapyEngineeringWalking table

A rehabilitation device for lower limb paralysis caused by the nervous centralis comprises a walking table and a main support and is characterized in that a walking support is arranged on the lower side of the walking table, supporting legs are arranged on the lower side of the walking support, the supporting legs and the walking support are connected together through supporting leg fixing connectors, hydraulic damping buffers are arranged on the lower sides of the supporting legs, fixed supporting feet are arranged on the lower sides of the hydraulic damping buffers, and damping anti-slide mats are arranged on the lower sides of the fixed supporting feet. The rehabilitation device for lower limb paralysis caused by the nervous centralis has the advantages of being simple in structure, easy and convenient to operate and capable of enabling a patient to do lower limb rehabilitation exercises by himself according to a made rehabilitation plan, reducing the pain of the patient, improving the rehabilitation effect and relieving the workload of medical staff.

Owner:巩法桃

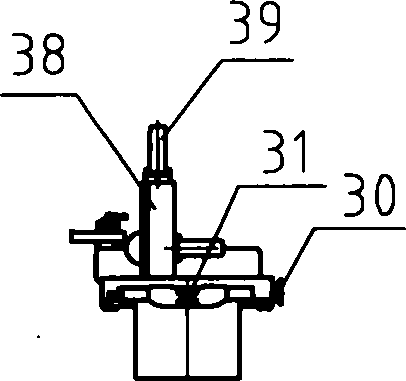

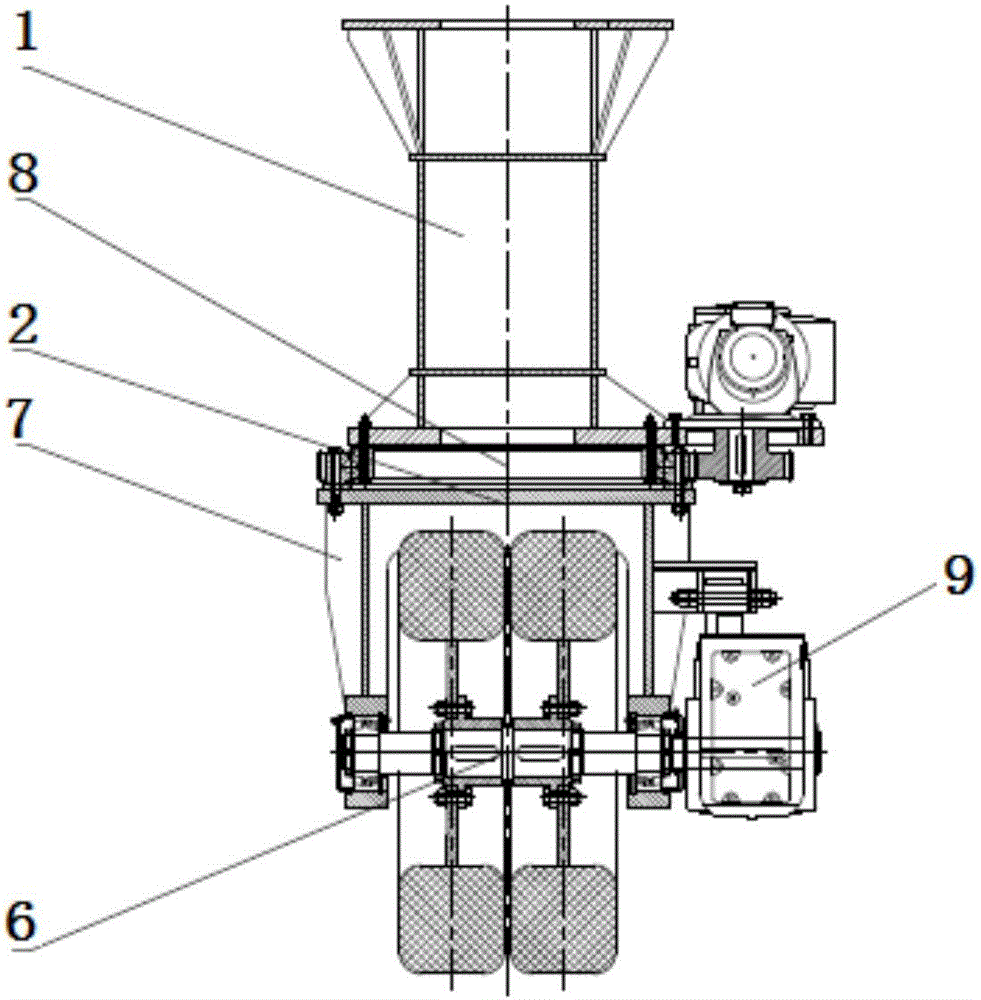

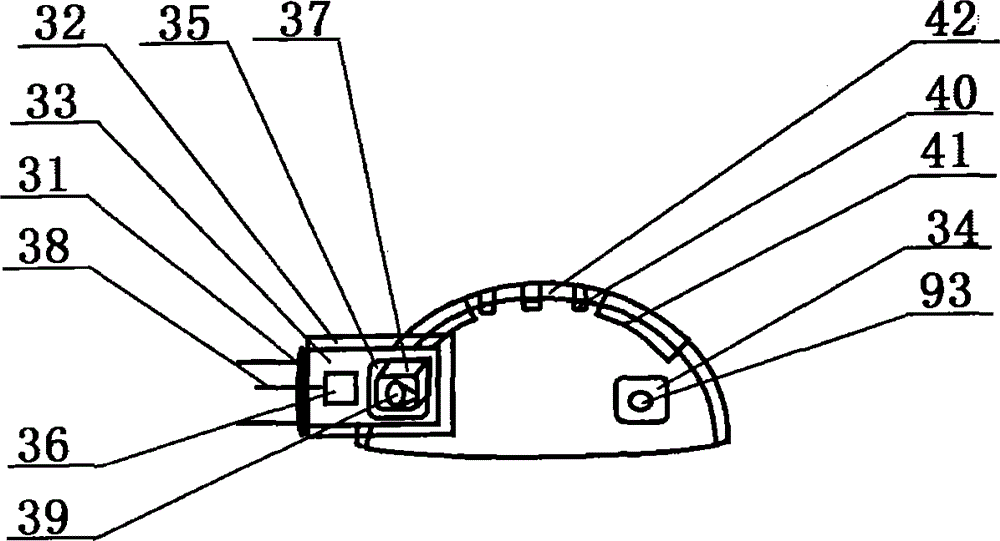

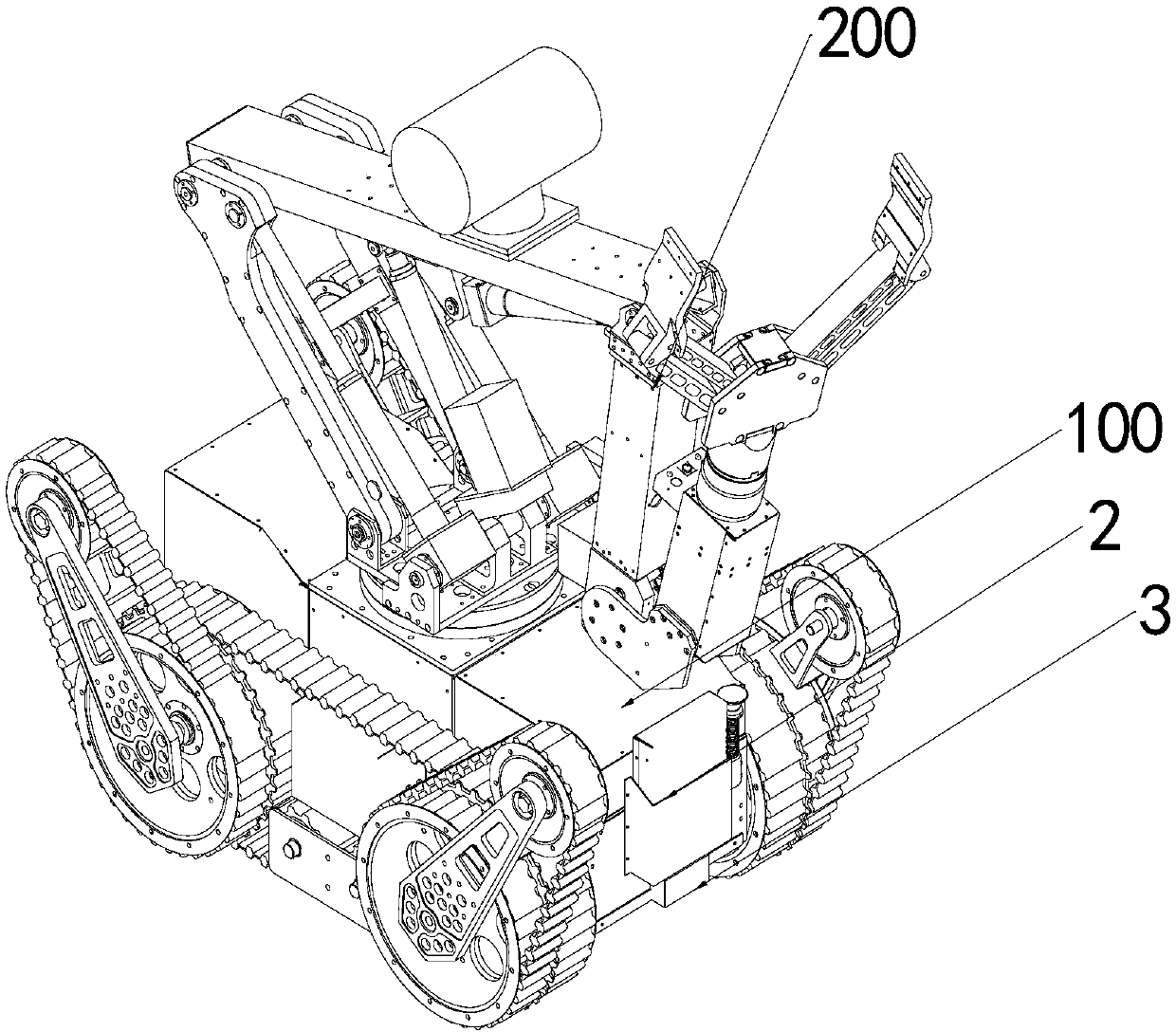

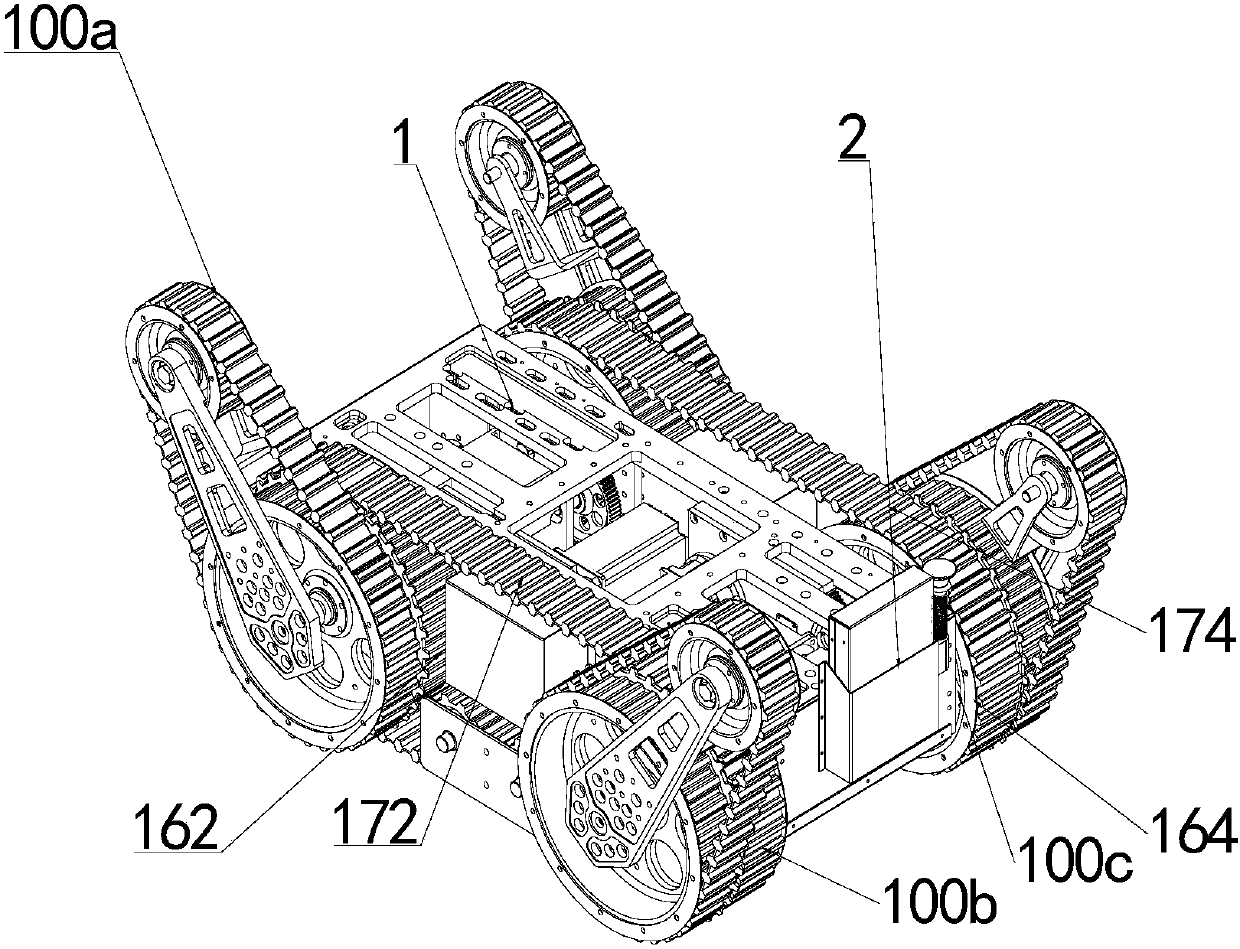

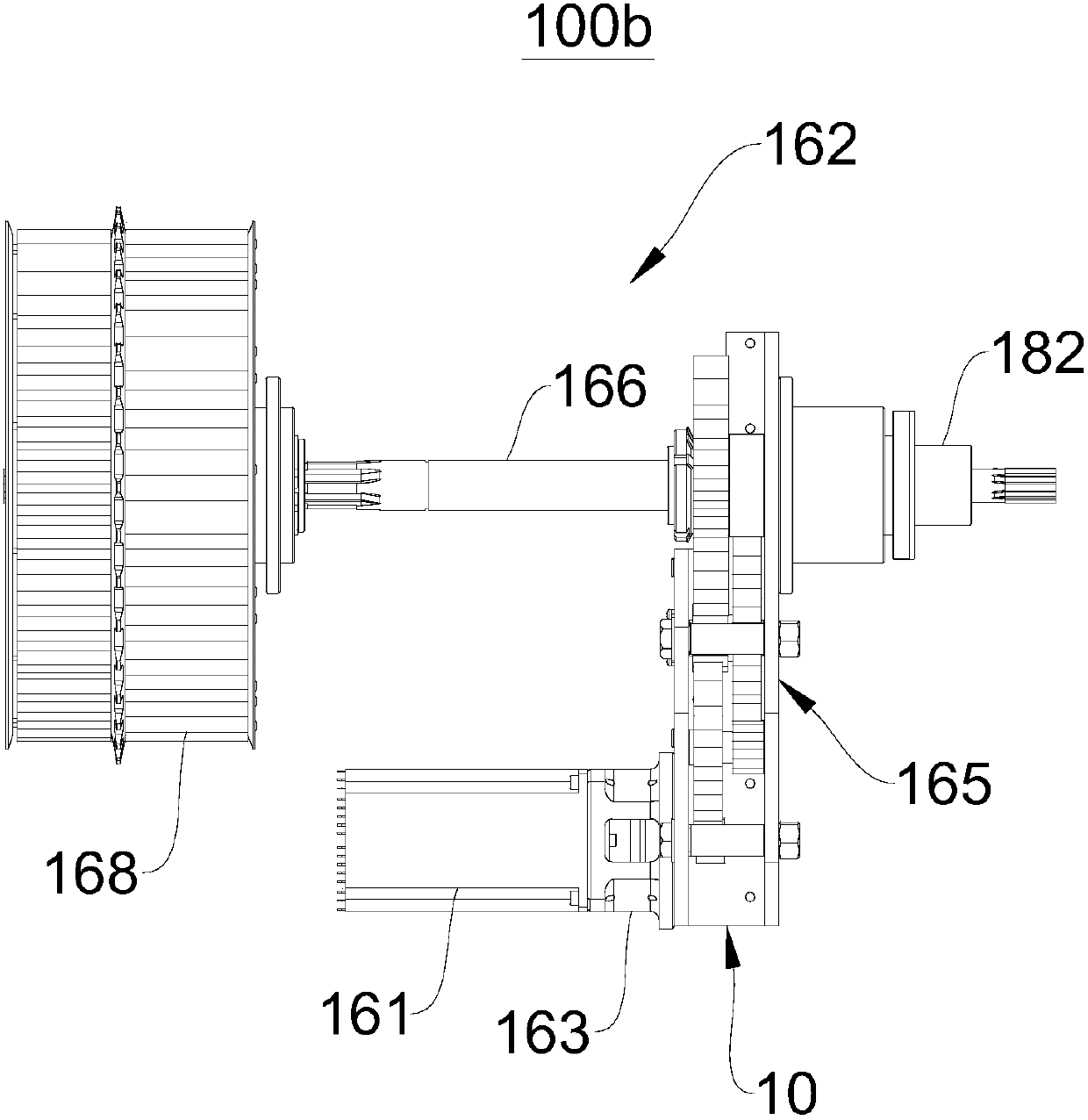

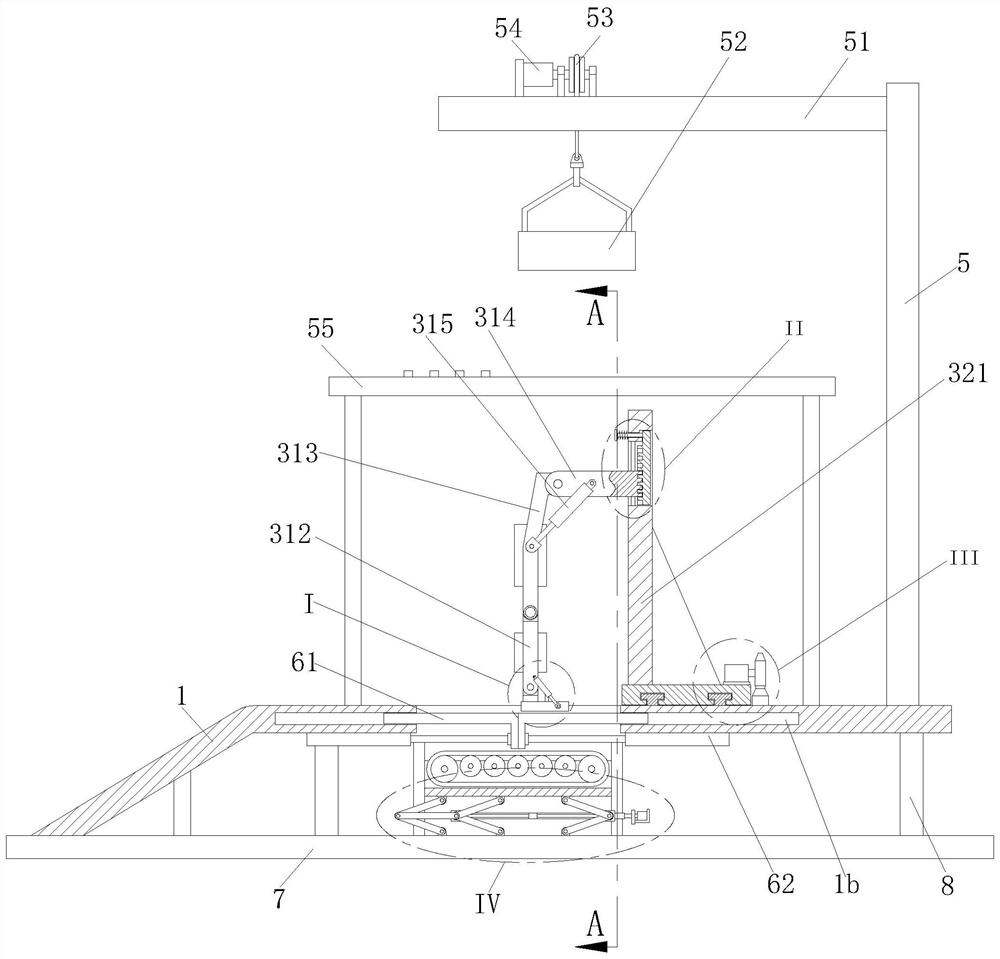

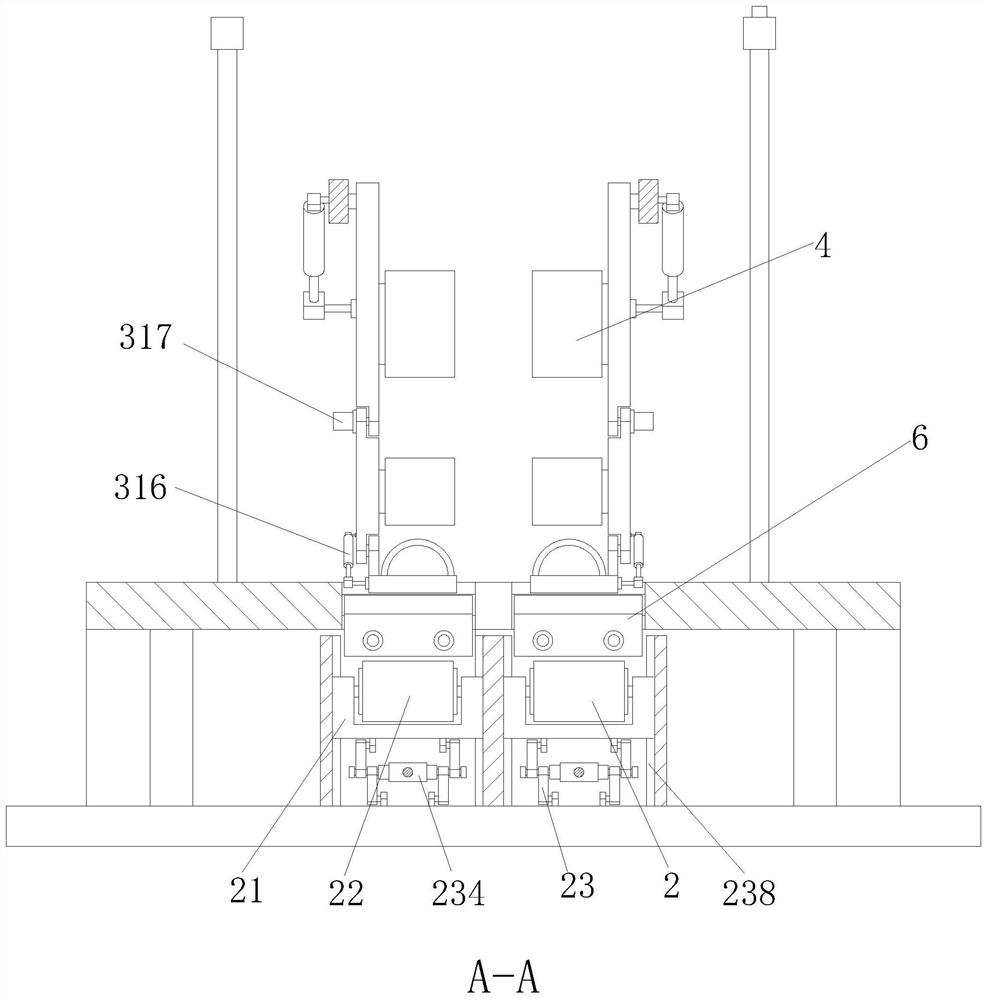

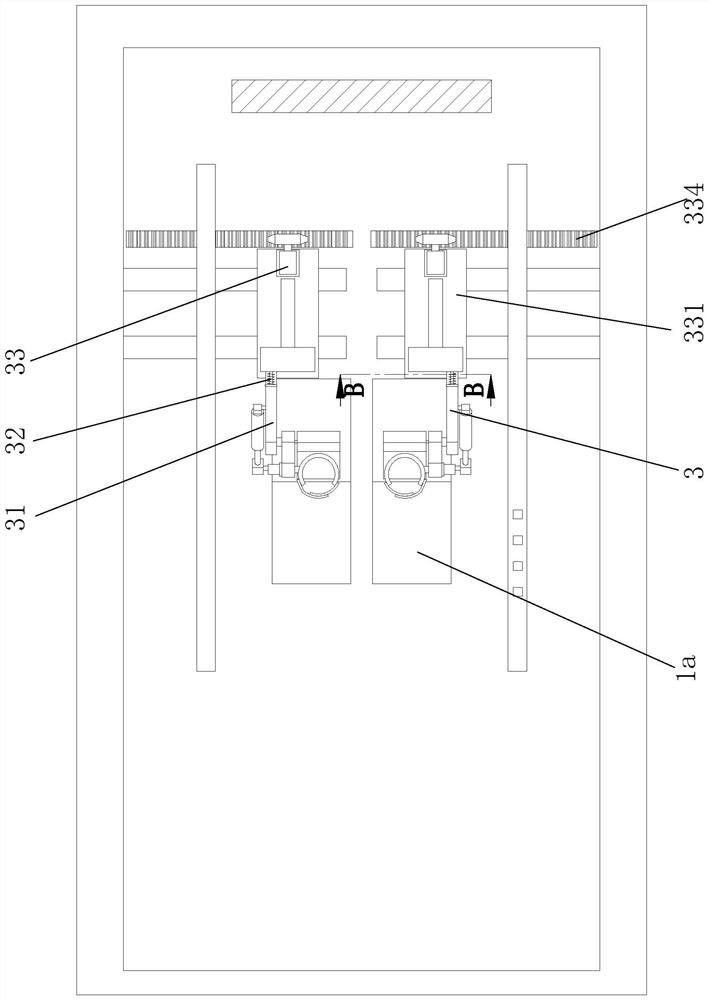

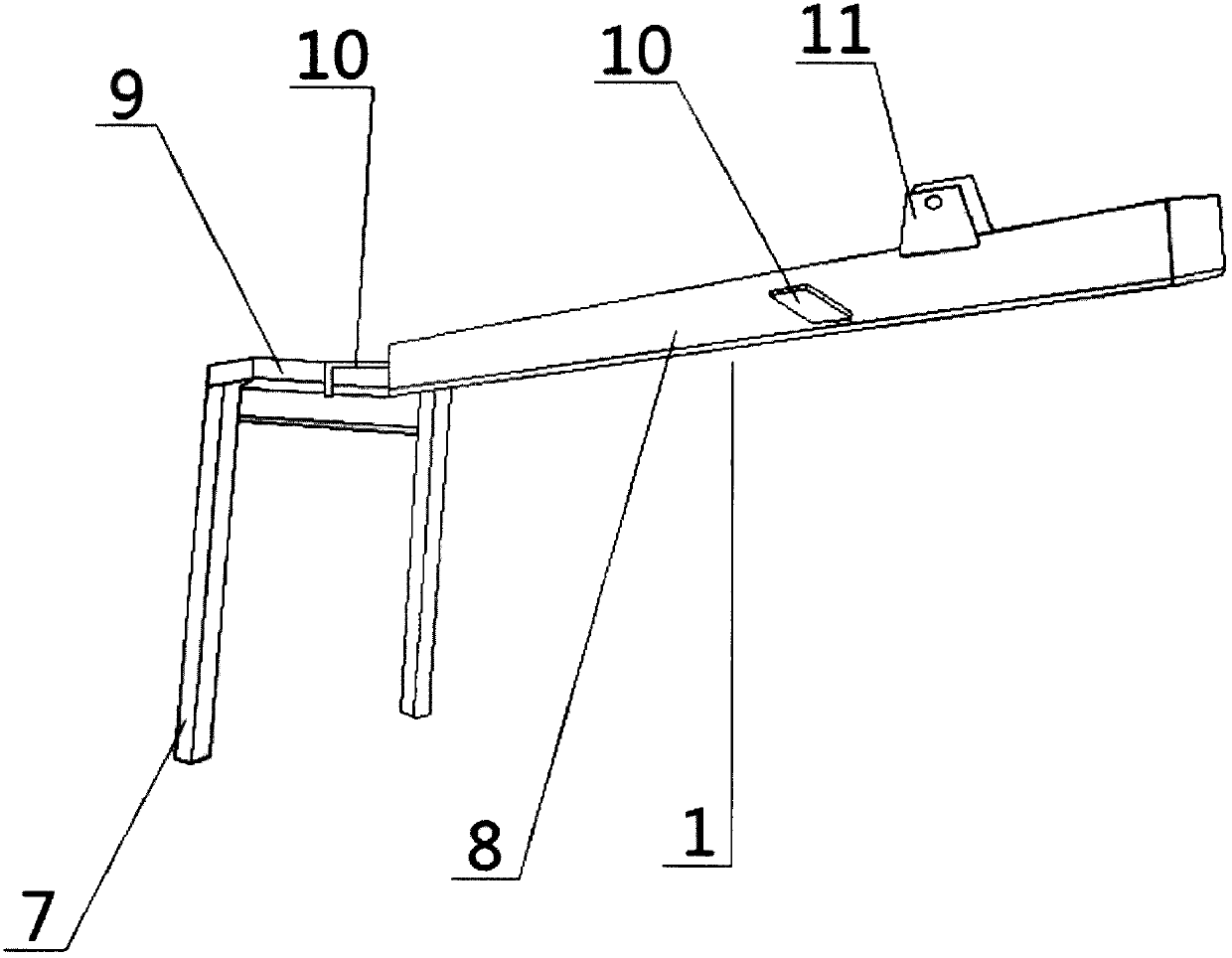

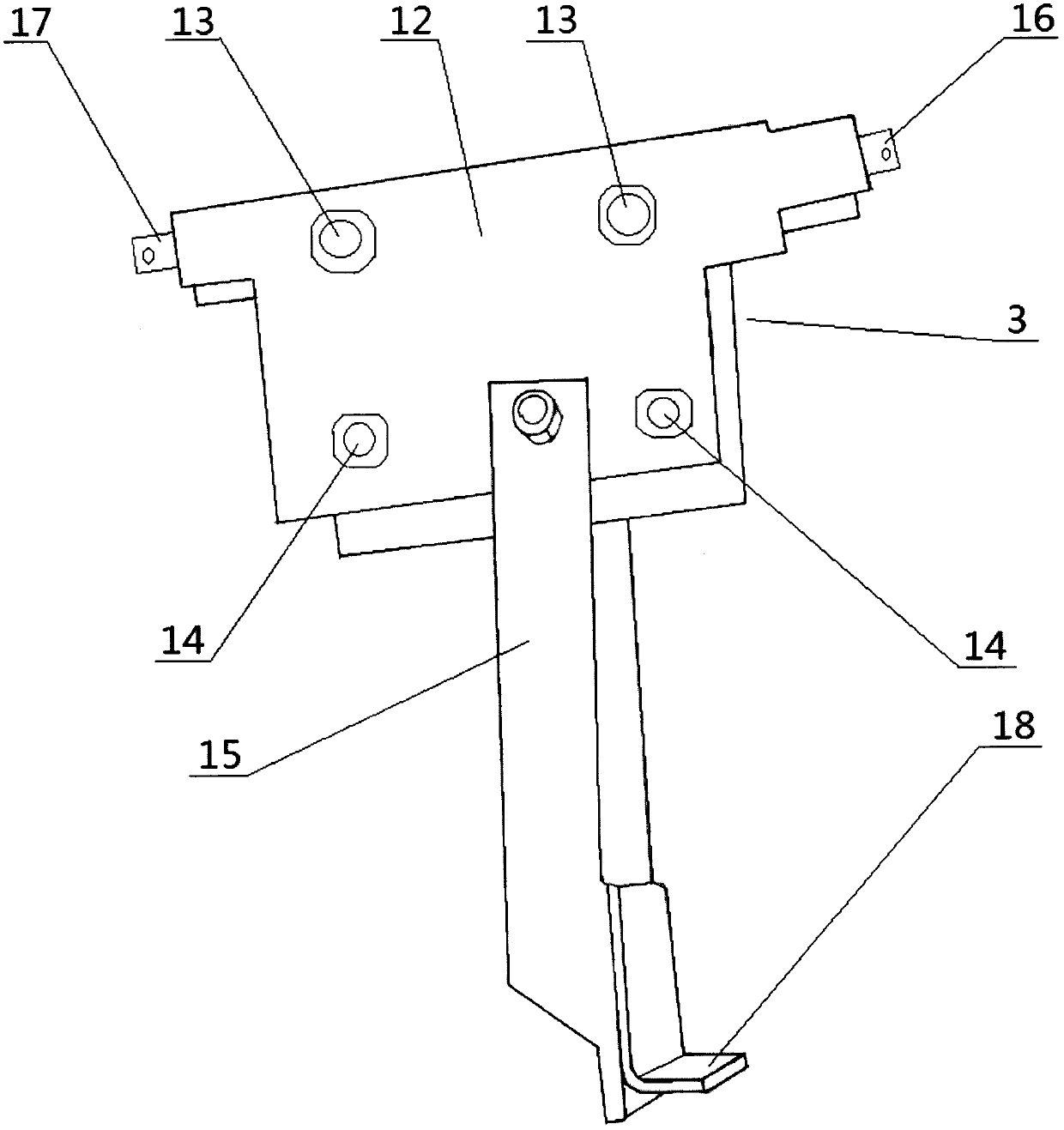

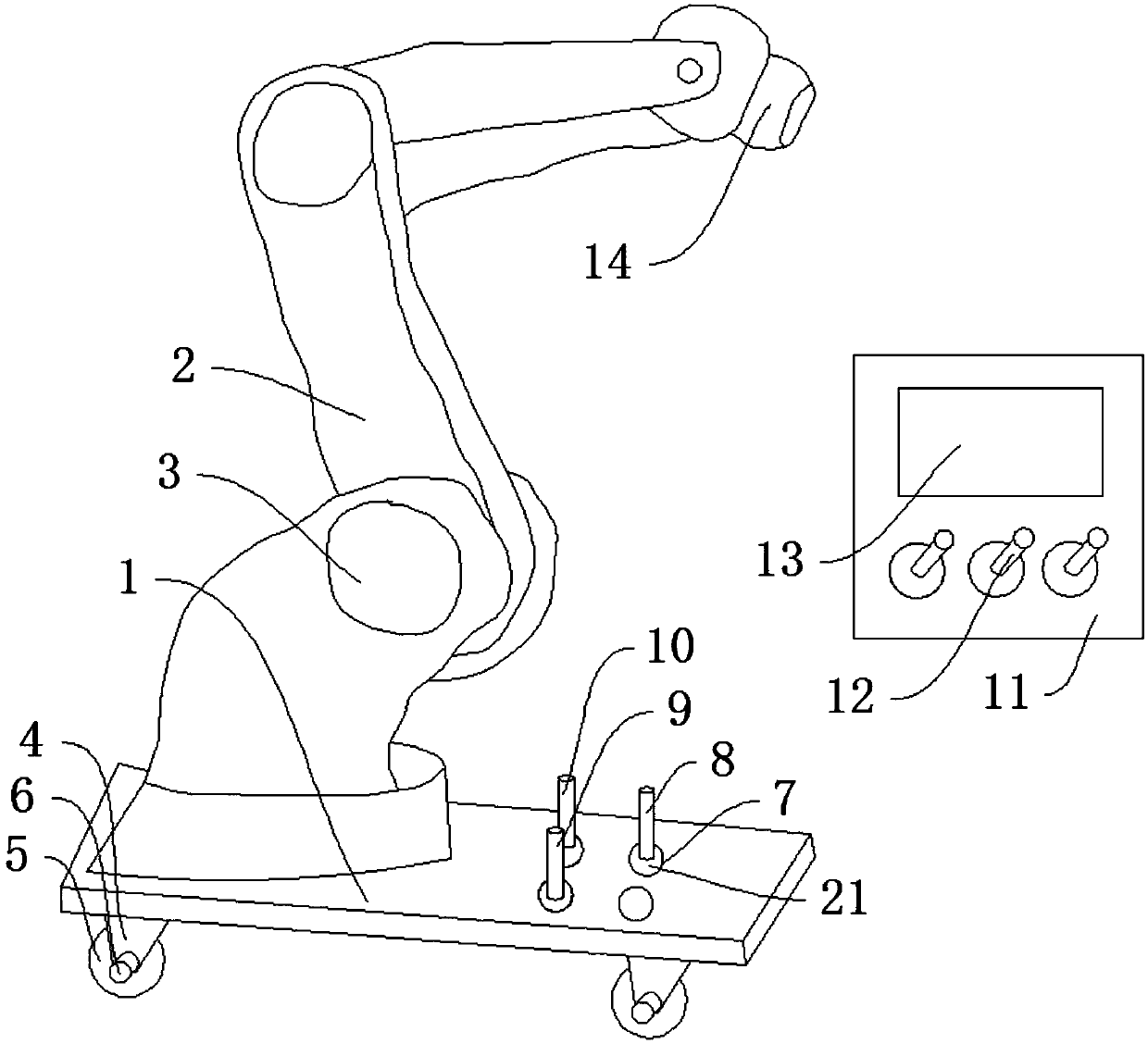

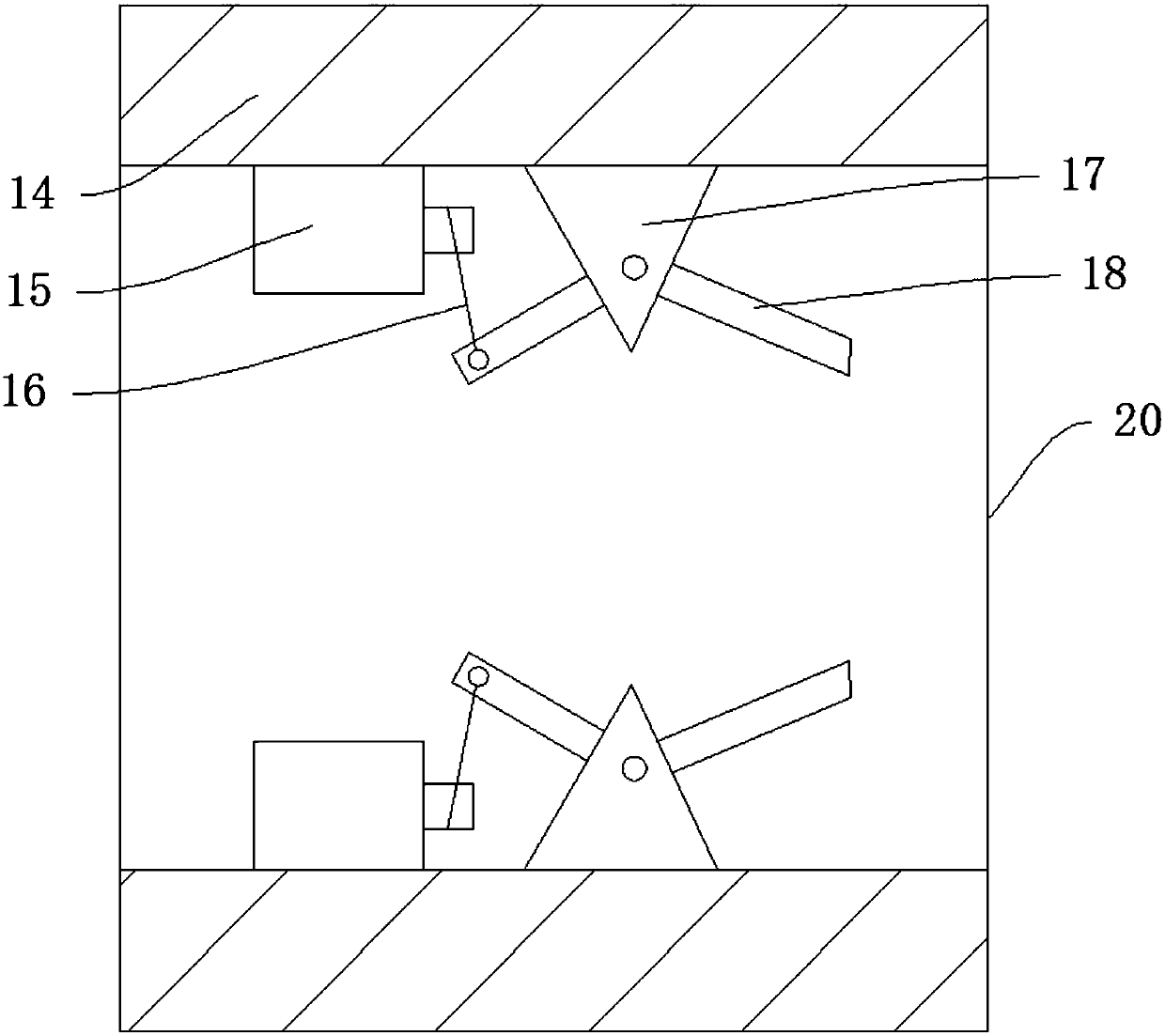

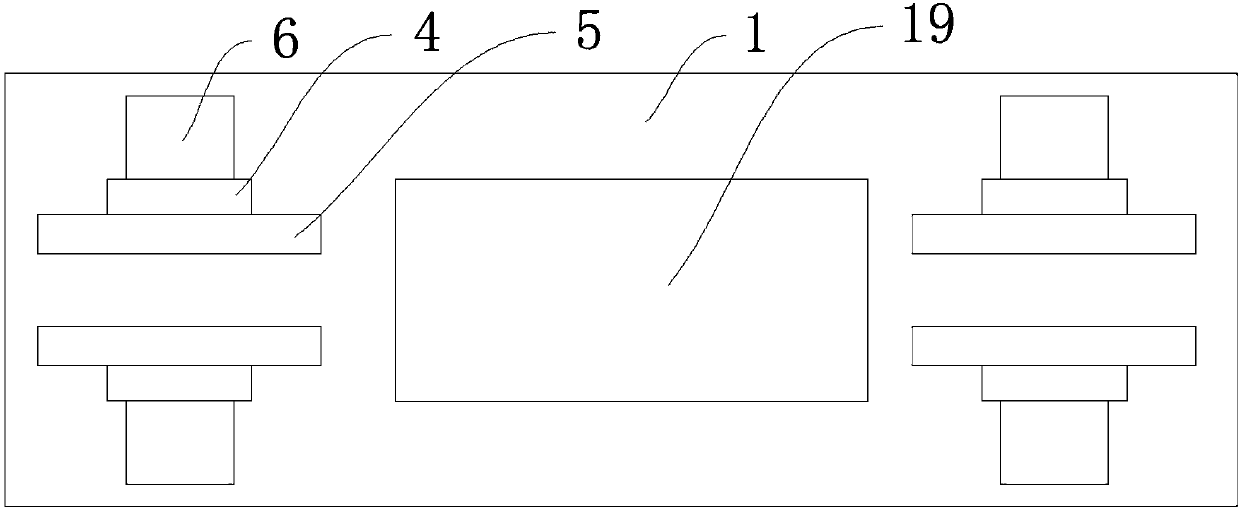

Explosive-handling robot and remote-control robot

The invention provides an explosive-handling robot and a remote-control robot, and relates to the technical field of robots. The explosive-handling robot comprises a walking table and a mechanical arm; the walking table comprises a carframe, walking mechanisms, leg swinging mechanisms and bearing mechanisms; the robot walks and climbs over a barrier through the walking mechanisms and the leg swinging mechanisms; the mechanical arm comprises a rotary assembly mechanism and a manipulator structure; and explosive handling is finished through rotation of the rotary assembly mechanism and telescopic grabbing of the manipulator structure. The remote-control robot comprises the explosive-handling robot, and further comprises a control box; the control box comprises a box body and a box cover; acontrol panel is arranged in the box body; a flow-up operation model is arranged on the control panel and is used for controlling a rotary table, first leg-swinging components, second leg-swinging components, a big arm, a secondary arm and a forearm; and a display is arranged in the box cover. By adopting the explosive-handling robot and the remote-control robot, the technical purpose that the explosive-handling robot climbs over the barrier is achieved.

Owner:BEIJING JINGJINWU HIGH TECH

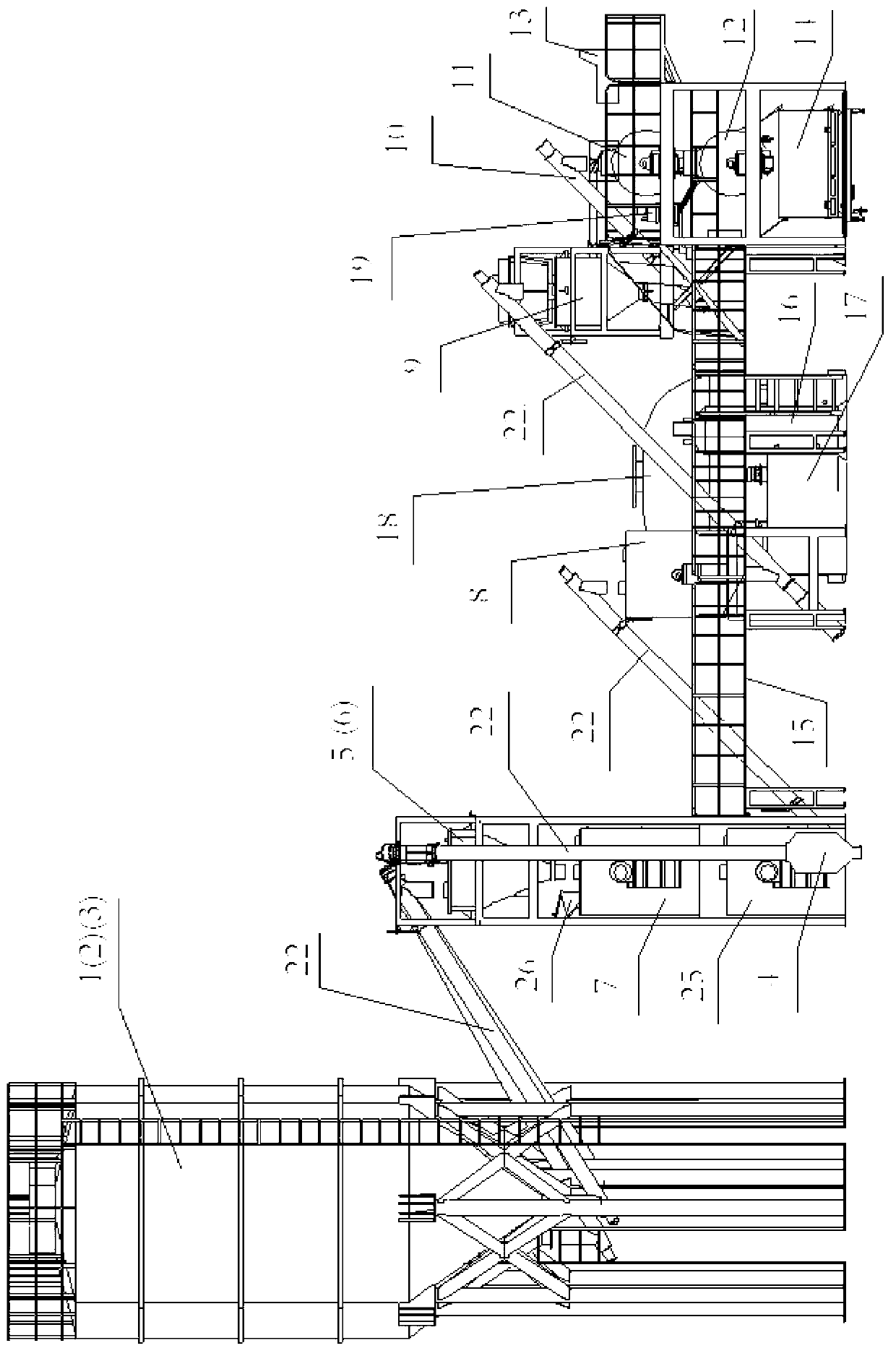

Installation method of coke dry-quenching loading device

ActiveCN101928578AEasy to operateImprove work efficiencyCoke quenchingCharging devicesDesign standardWalking table

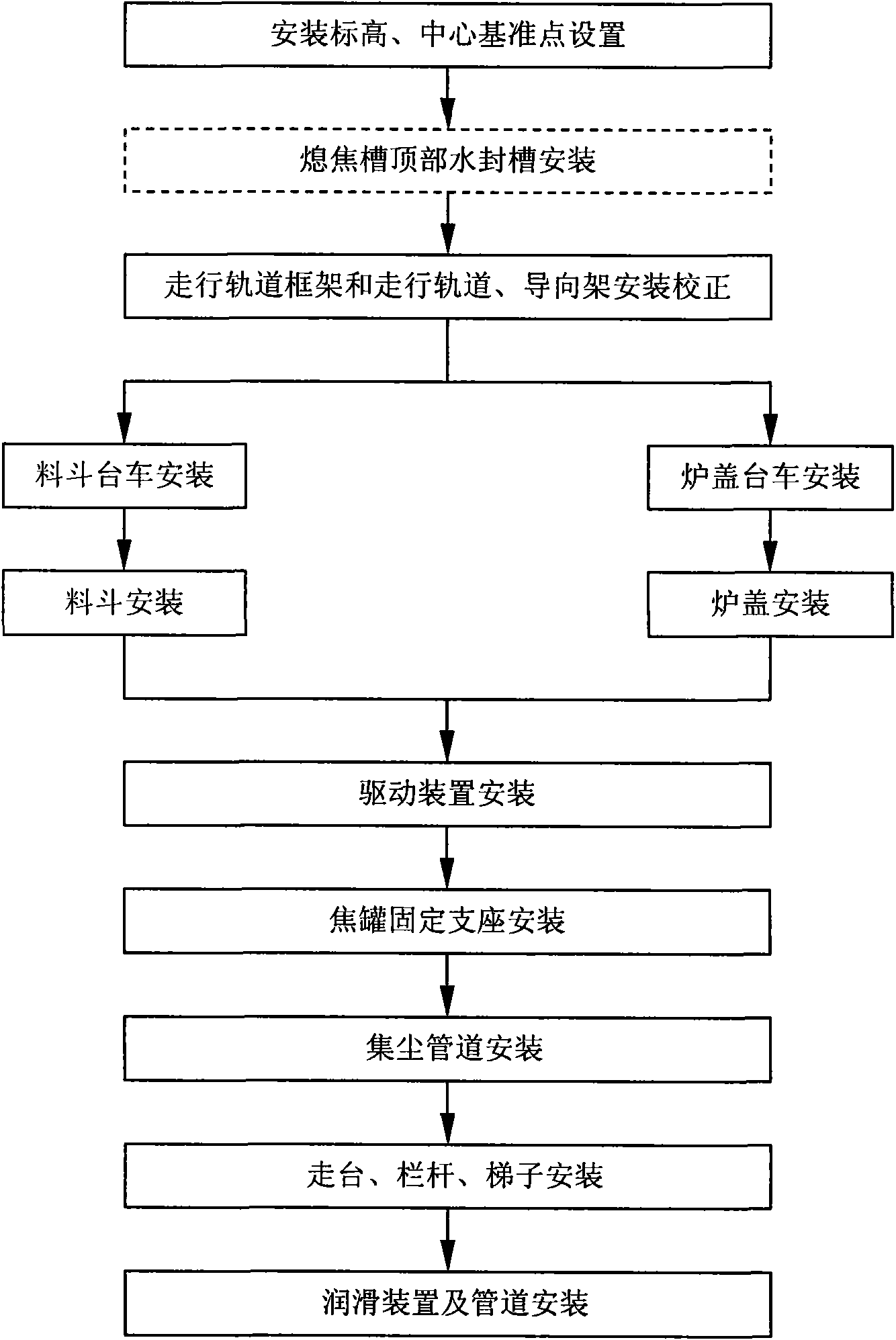

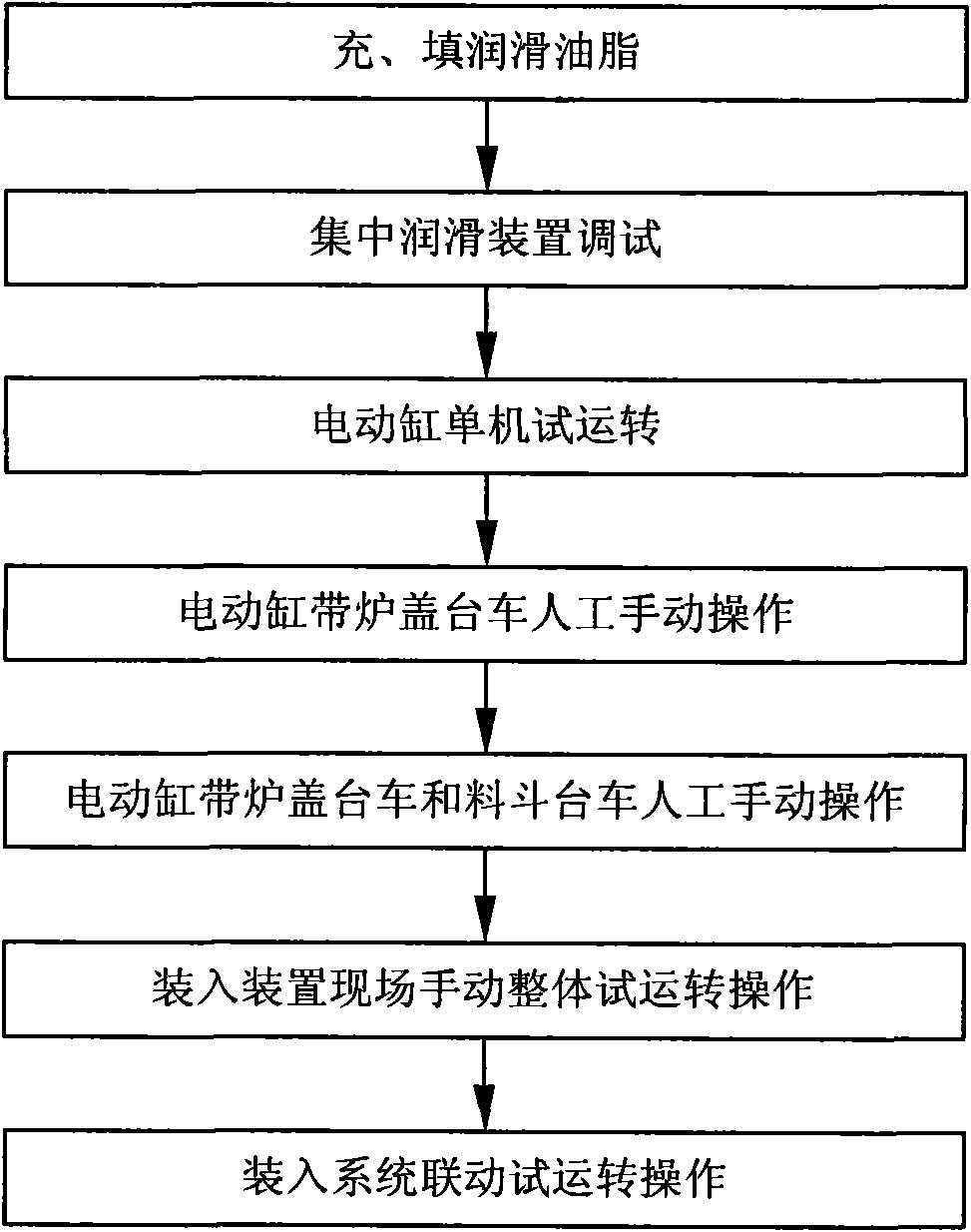

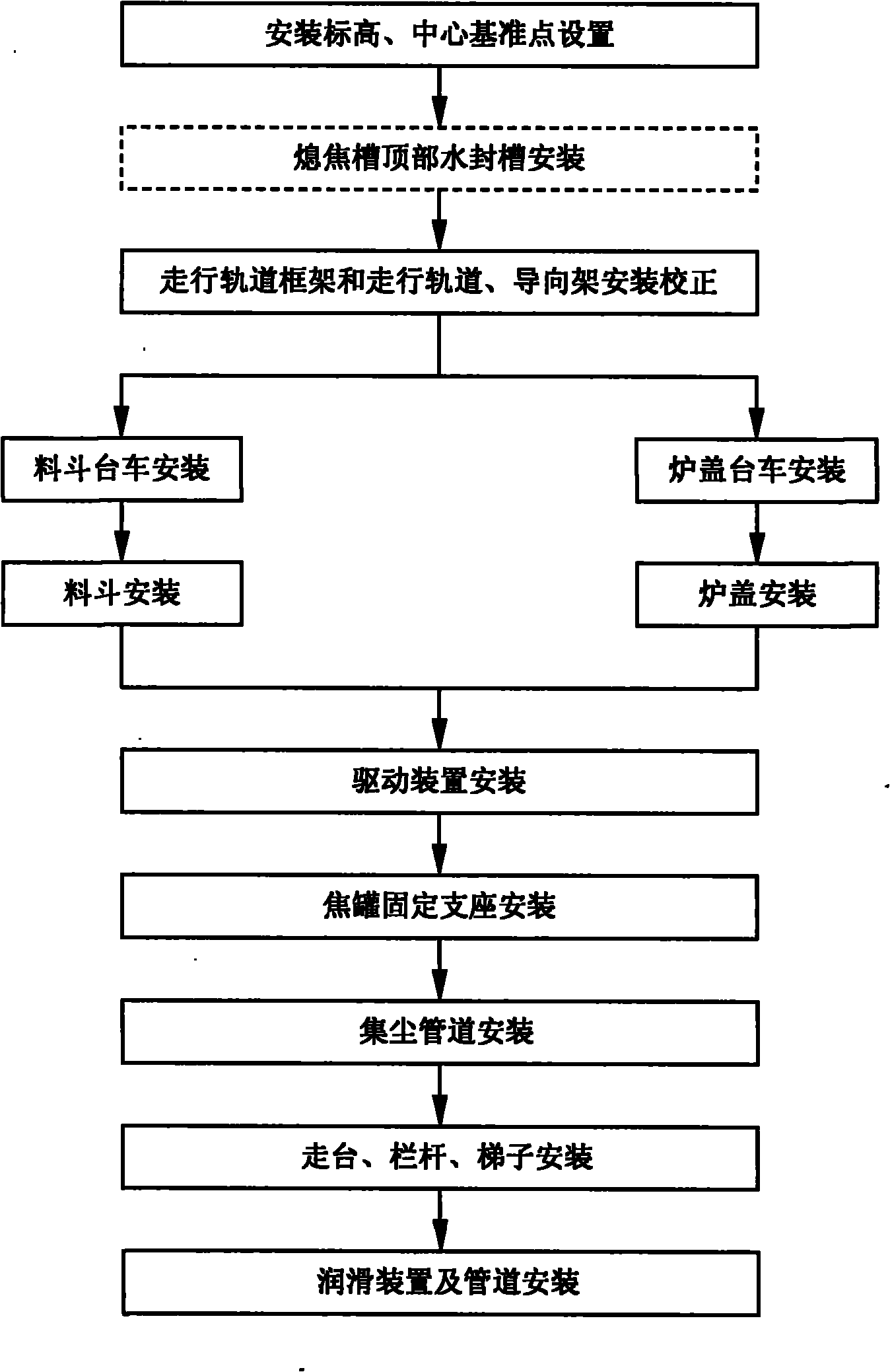

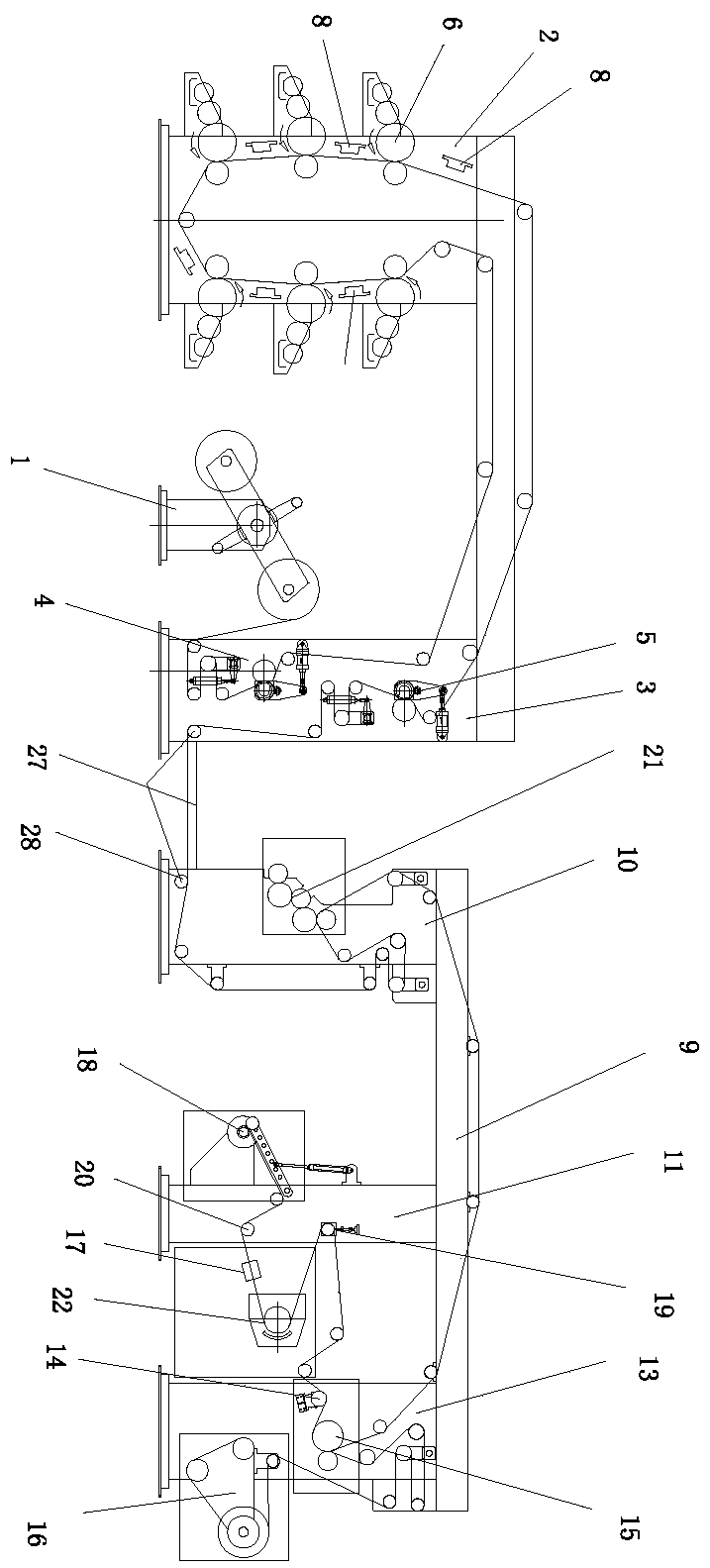

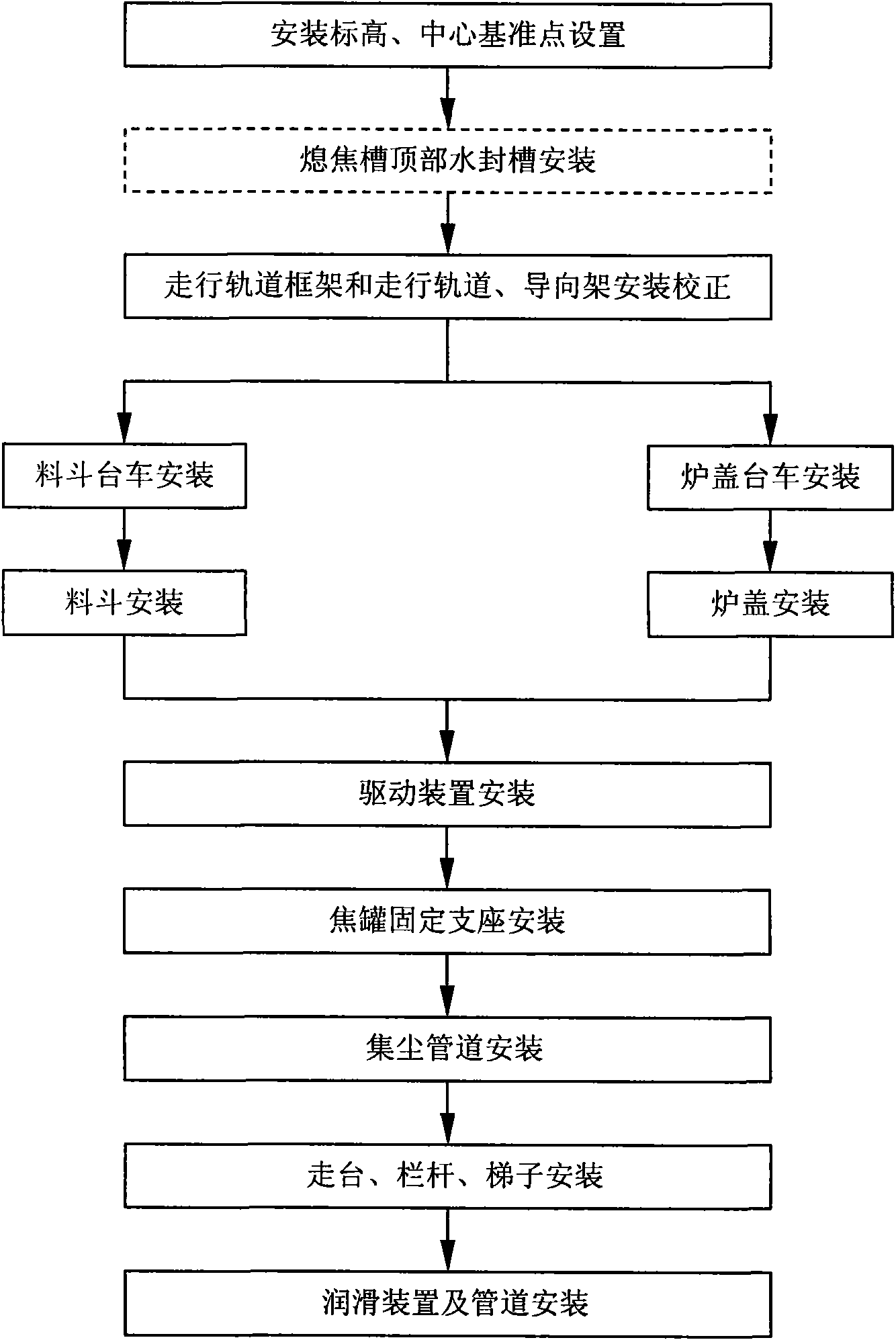

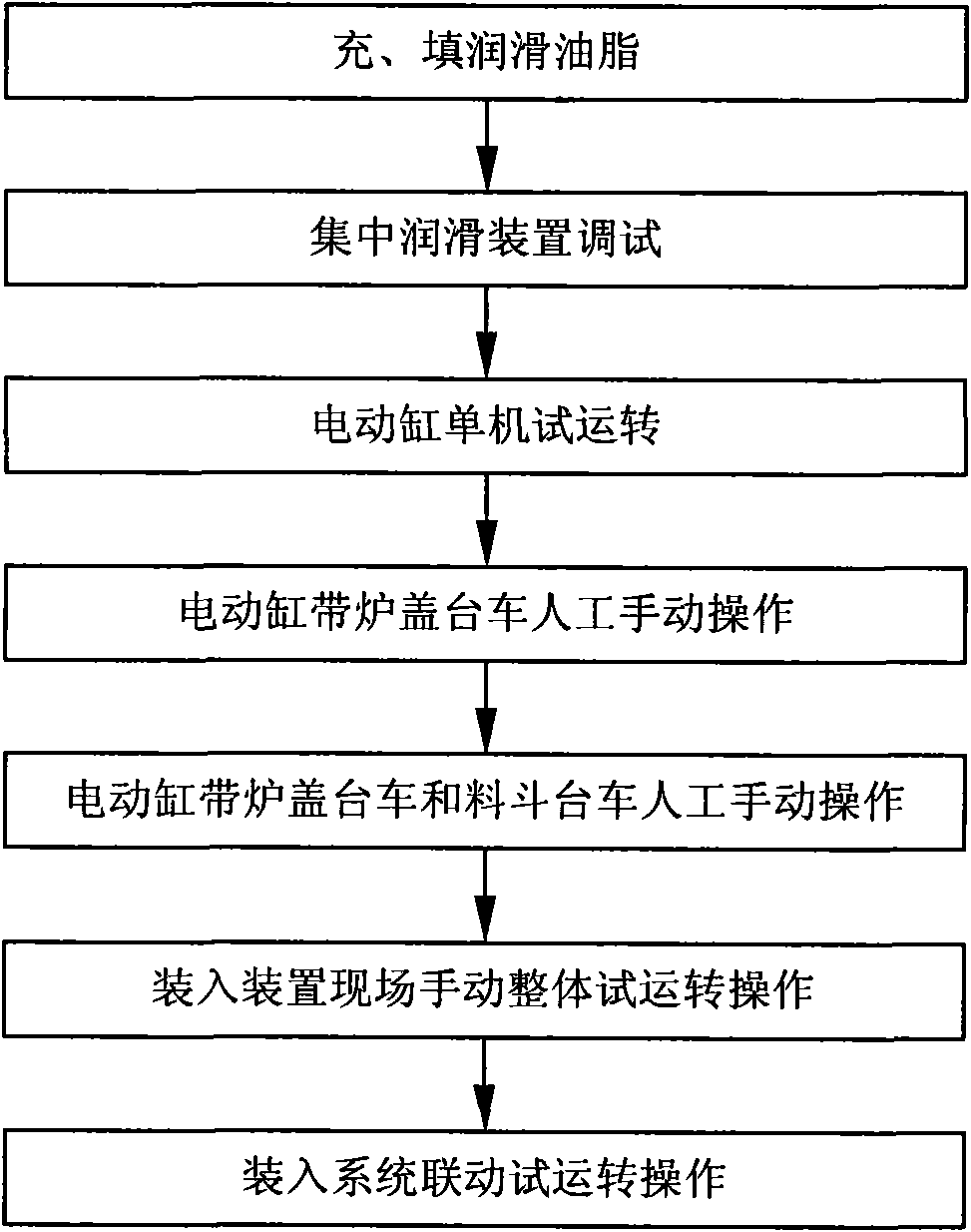

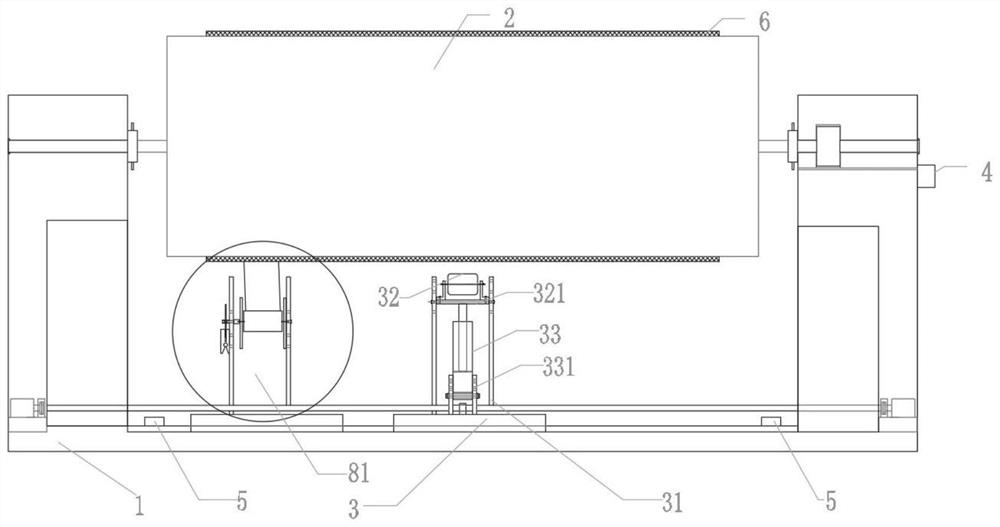

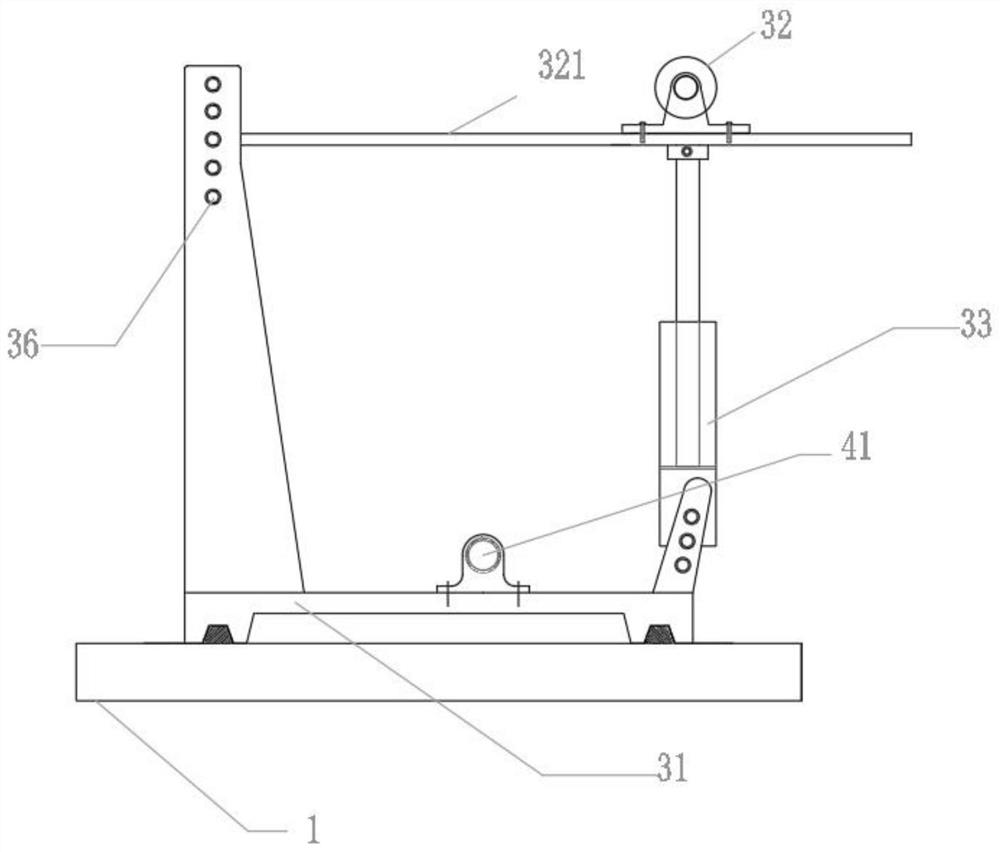

The invention relates to the field of metallurgy equipment installation, in particular to an installation method of a coke dry-quenching loading device. The installation method of the coke dry-quenching loading device comprises the following steps: a, installation of elevation and setting of central reference point; b, installation of a water sealed tank on the top of a quenching groove; c, installation and correction of a walking track frame, a walking track and a guiding frame; d, installation of a hopper trolley; e, installation of a hopper; f, installation of a furnace cover trolley; g, installation of a furnace cover; h, installation of a drive device; i, installation of a coke pot fixed support; j, installation of dust-collecting pipeline; k, installation of a walking table, a railing and a ladder; and l, installation of a lubricant device and a pipeline. In the invention, through the strictly-designed standard installation and detection reference, the installation method is simple, safe and reliable and has high work efficiency.

Owner:MCC5 GROUP CORP SHANGHAI

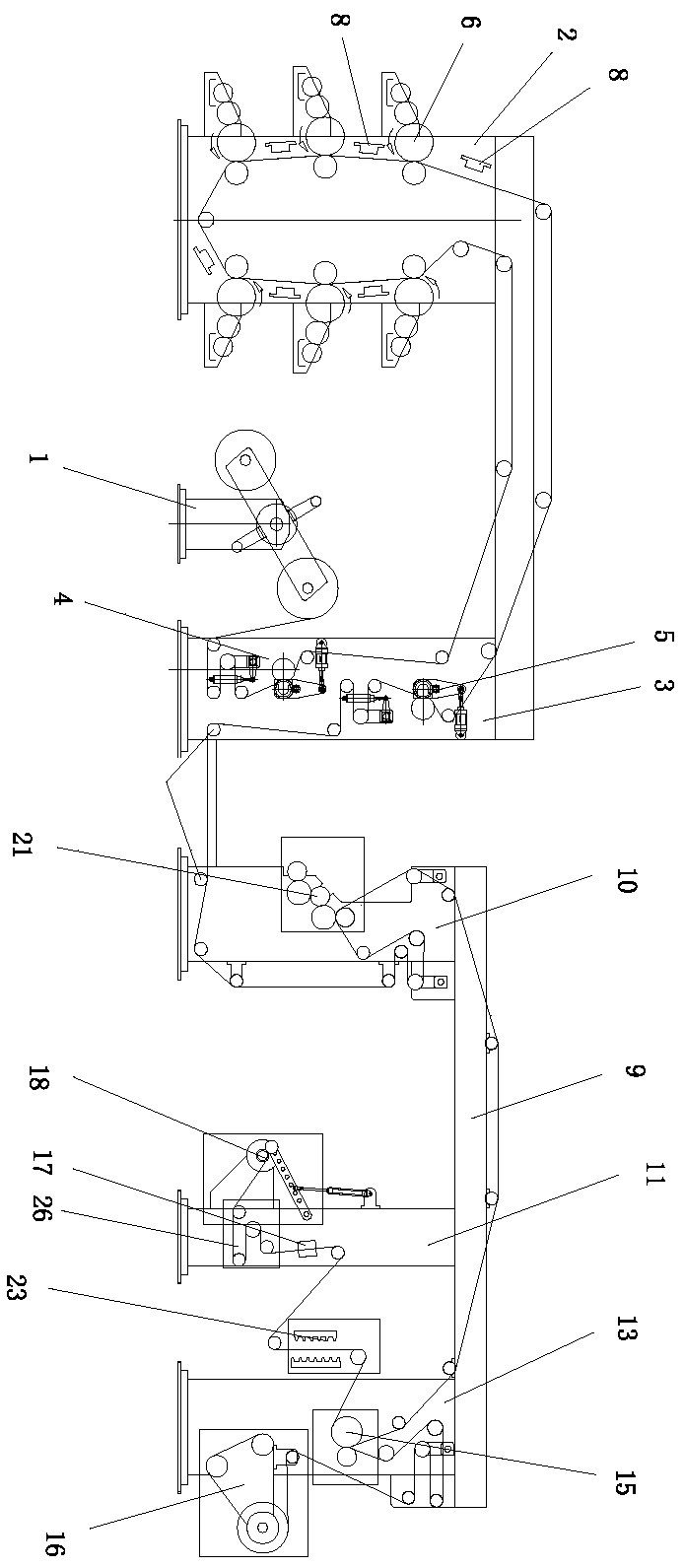

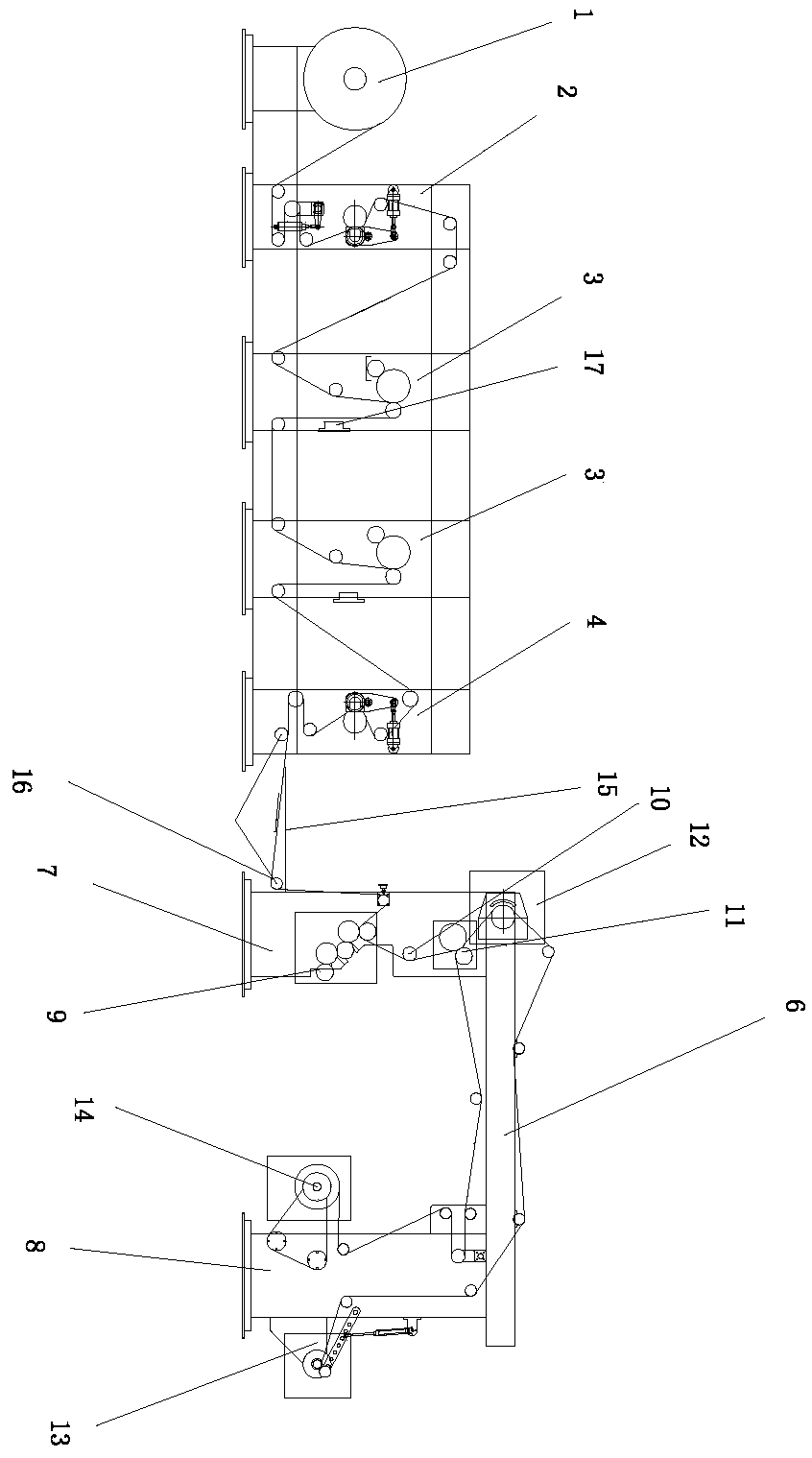

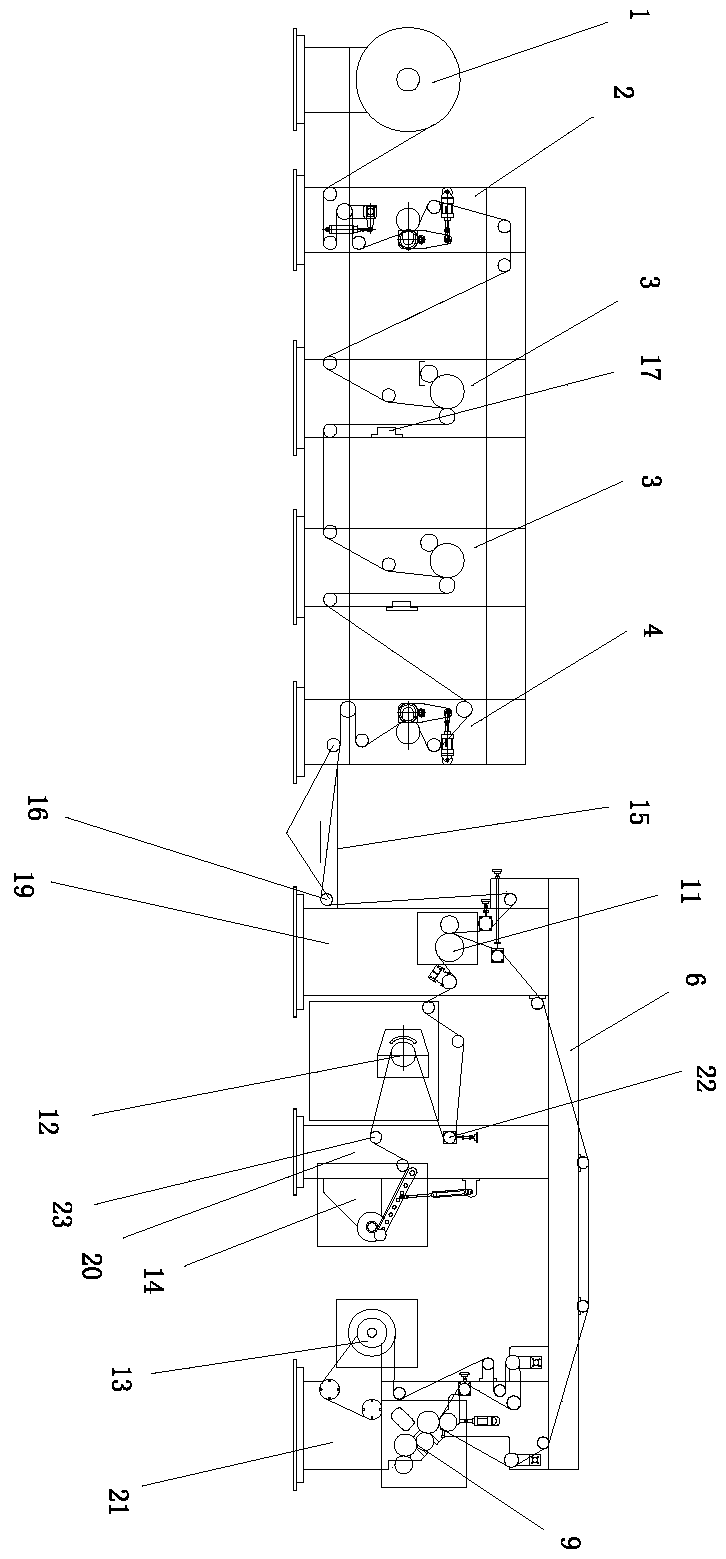

Stacked flexile printing machine connecting line EB radiation instant curing compound machine

InactiveCN108481897ARun fastIncrease productivityPretreated surfacesCoatingsPulp and paper industryPrinting press

The invention discloses a stacked flexile printing machine connecting line EB radiation instant curing compound machine. The machine comprises a printing uncoiling unit, a printing unit and a compoundcuring device; the printing unit comprises a printing board, a printing uncoiling traction unit and a printing coiling traction unit; multiple flexible printing color sets are arranged on the left and right sides of the printing plate up and down; a color drying device is arranged between the upper and lower adjacent flexible printing color sets; the compound curing device comprises a coating unit, a compound unit, an EB radiation device, a coiling unit and a second uncoiling unit; a walking table is arranged between the printing unit and the compound curing device; a connecting line film walking roller is arranged below the walking table; as the EB radiation device is adopted, substrates are coated and printed by adopting EB glue and EB ink; compared with traditional general glue and ink, the ink drying and the glue curing are performed without additional arrangement of an oven, so that the occupied size is small, the drying and curing speed is high, meanwhile, harmful gas cannot begenerated, and higher environmental protection in the production process is achieved. The machine synergistic operation speed is greatly increased; the production period is shortened; and quick delivery is facilitated.

Owner:SINOMECH CORP

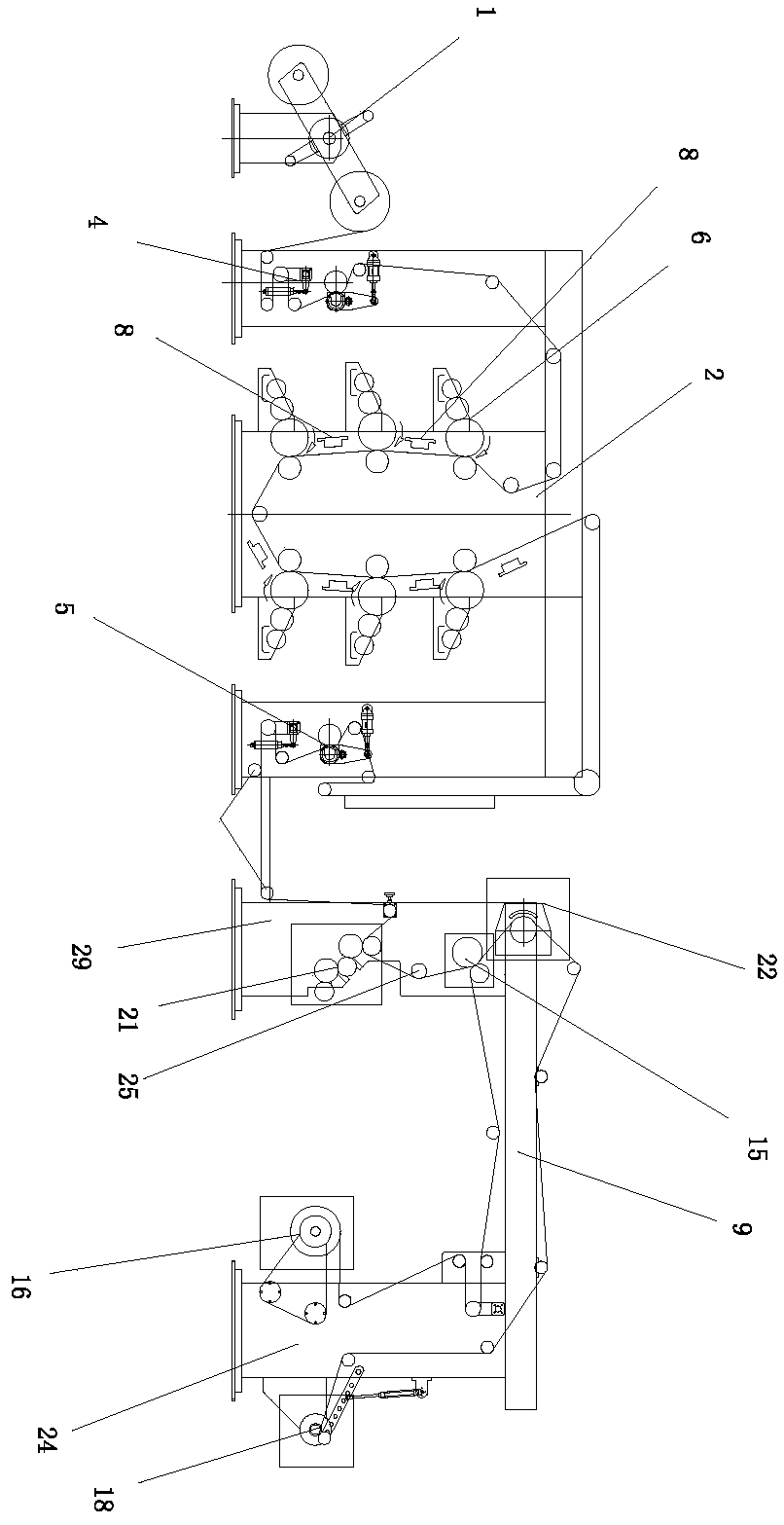

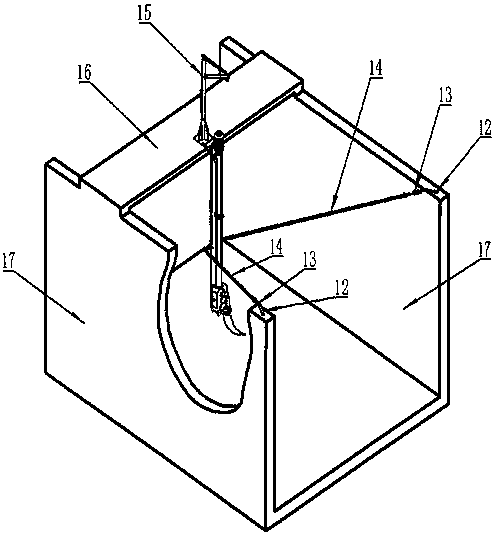

Automated production line and automated production method of light-weight wall material

ActiveCN103341908AGuaranteed stabilityImprove accuracyMixing operation control apparatusCeramic shaping plantsProduction lineFoaming agent

The invention relates to a production line and production method of building wall material, in particular to an automated production line and automated production method of light-weight wall material. According to the specific technical scheme, the automated production line of the light-weight wall material comprises a raw material rationing system, a compound material mixing system, a constant temperature water supplying system, a foaming agent supplying system, a stirring reacting system, an electric control system, a mold box conveying device and an equipment connecting walking table. The automated production method of the light-weight wall material includes the steps of raw material rationing, compound material mixing, mixed material supplying, constant temperature water supplying, stirring, foaming agent supplying, reacting and mold box forming. According to the automated production line and automated production method of the light-weight wall material, quality stability of the light-weight wall material can be ensured, production efficiency is improved, and industrial production of the light-weight wall material is achieved.

Owner:丹东市兄弟建材有限公司

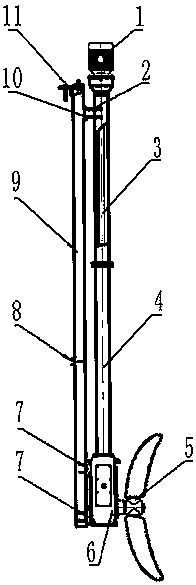

Overwater driving type underwater water impeller

InactiveCN105948237AEasy to handleSimple structureSustainable biological treatmentBiological water/sewage treatmentImpellerUnderwater

The invention discloses an overwater driving type underwater water impeller. A motor is fixed to the upper end of a supporting cylinder. The tail end of the supporting cylinder is submerged underwater and fixed to the upper face of a reversing reduction gearbox. A transmission vertical shaft is arranged in an inner cavity of the supporting cylinder. One end of the transmission vertical shaft is connected with an output shaft of the motor. The other end of the transmission vertical shaft is connected with an input shaft on the reversing reduction gearbox submerged underwater. A supporting rod is arranged at the adjacent position of the supporting cylinder side by side. The supporting rod and the supporting cylinder are connected through a fixing frame and fixed through a connecting plate. A stainless steel wire rope fixing frame is arranged on the supporting rod. An impeller body is installed on the input shaft of the reversing reduction gearbox. A supporting frame at the upper end of the supporting rod is fixed to a walking table through expansion bolts. A hoisting rack is fixed to the supporting frame through expansion bolts. One end of a stainless steel wire rope is fixed to the stainless steel wire rope fixing frame on the supporting rod. The other end of the stainless steel wire rope is connected with one end of a basket bolt. A basket bolt connecting frame is fixed to a wall of an oxidation ditch through expansion bolts.

Owner:新乡市蓝海环境科技有限公司

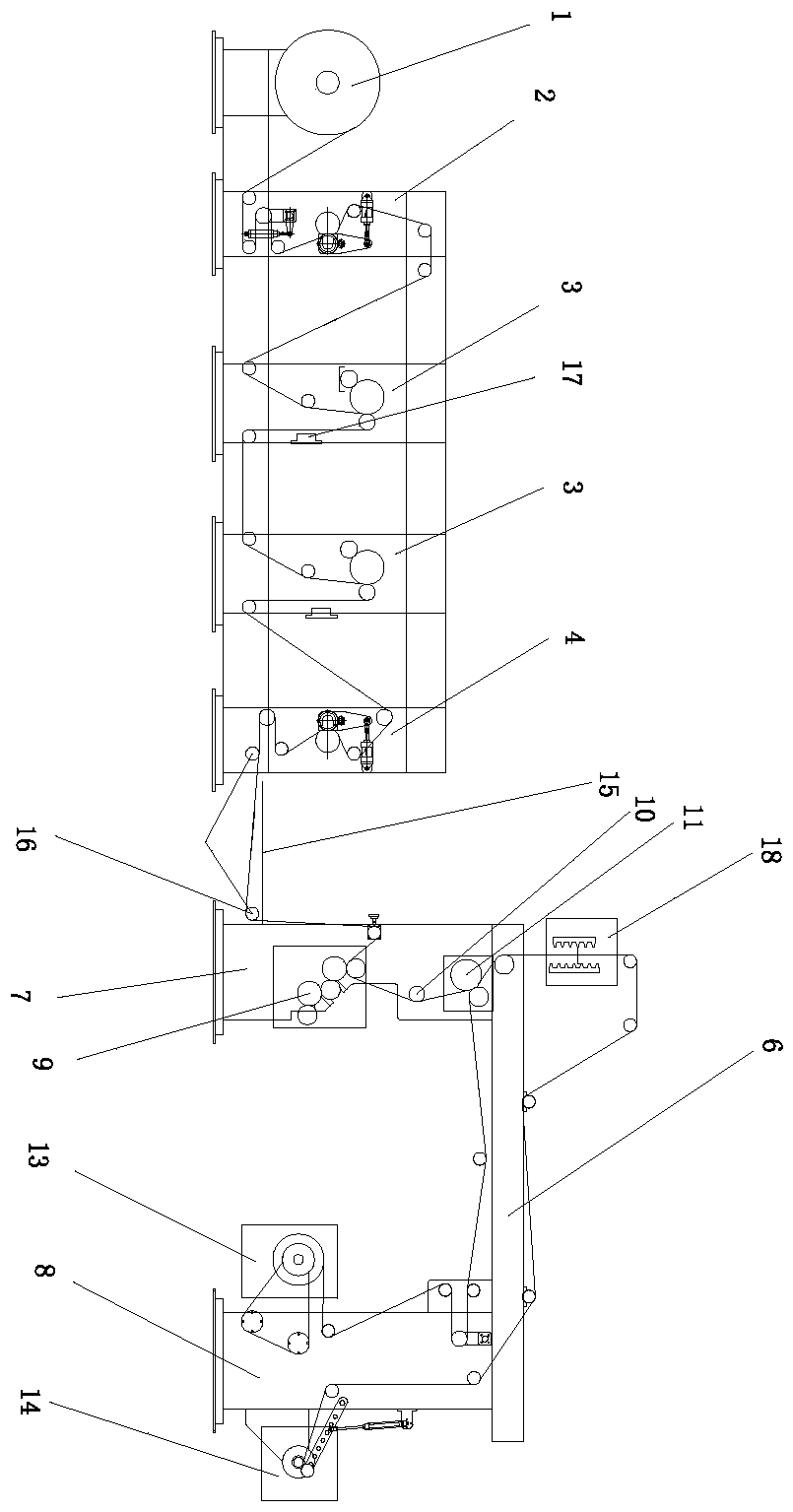

Unit-type flexo printing machine connecting EB irradiation real-time curing type compound machine

InactiveCN108357189ARun fastIncrease productivityRotary letterpress machinesPrinting press partsPulp and paper industryPrinting ink

The invention provides a unit-type flexo printing machine connecting EB irradiation real-time curing type compound machine. The compound machine comprises a printing pay-off unit, a printing pay-off traction unit, multiple flexo printing color cells, a printing take-up traction unit and a compound curing device, all of which are sequentially arranged from left to right. The compound curing devicecomprises a coating unit, a compound unit, an EB irradiation device, a take-up unit and a second pay-off unit. A walking board is arranged between the printing take-up traction unit and the compound curing device, and a connecting film walking roller is arranged below the walking table. As the EB irradiation device is adopted, EB glue and EB printing ink are adopted during coating and printing ofbase materials, compared with existing common glue and printing ink, an oven does not need to be additionally arranged for drying glue for curing, the overall structure is lighter, the occupied volumeis small, the drying and curing speed is high, meanwhile, no harmful gas is generated, and the production process is more environmentally friendly. The machine synergistic operating speed is greatlyincreased, the production period is shortened, and rapid delivery is promoted.

Owner:SINOMECH CORP

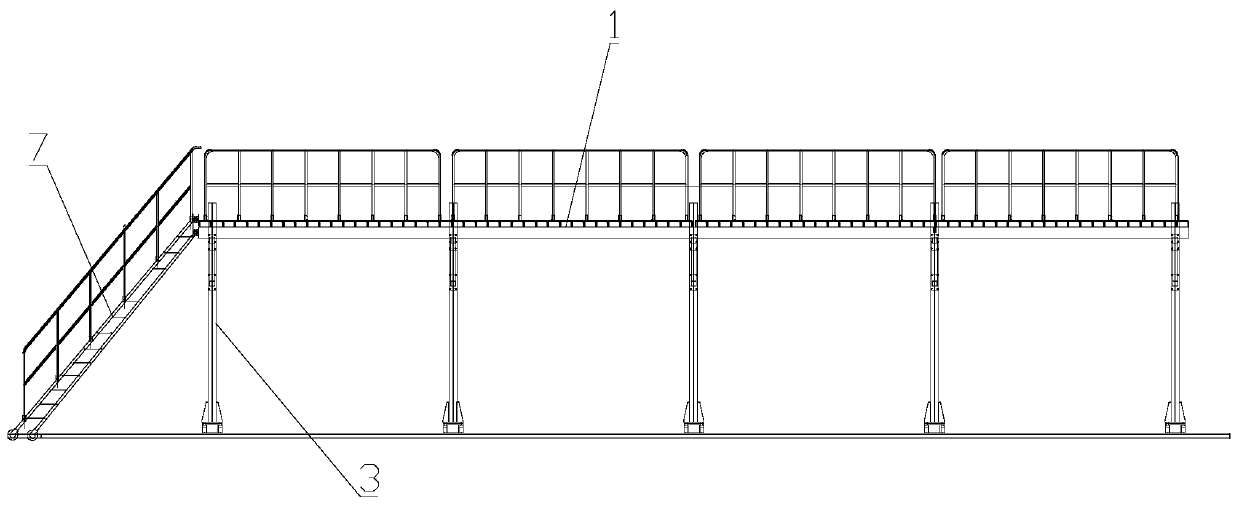

Vehicle body flexible assembly operation device

InactiveCN110936124ASatisfy the needs of water transportMeet assembly requirementsMetal working apparatusMetal-working hand toolsControl theoryWalking table

The invention relates to a vehicle body flexible assembly operation device. The device comprises supporting frames, side walking tables and end walking tables, wherein the supporting frames are oppositely arranged in the first direction and have two; the side walking tables and the supporting frames are arranged in a one-to-one correspondence manner, the side walking tables can ascend and descendrelative to the working ground, the distance between the side walking tables on the two supporting frames is adjustable, the lengths of the side walking tables in the second direction are adjustable,and the second direction and the first direction are vertically arranged; the two ends of each supporting frame in the second direction are correspondingly provided with one end walking table, the endwalking tables can ascend and descend relative to the working ground, the ends of the end walking tables are rotatably arranged on the end parts of the supporting frames in the second direction, andthe other ends of the end walking tables extends between the two supporting frames in the first direction. According to the vehicle body flexible assembly operation device, the flexible adjustment inthree directions of XYZ can be carried out, the assembly requirements of different vehicle types can be met, the required transfer space can be provided for the turnover of a vehicle body to meet thedemand of vehicle body water transmission, and good practicability is achieved.

Owner:CRRC YANGTZE CO LTD

Auxiliary walking rehabilitation device for lower limb

ActiveCN111658439APrevent fallingNo rate adjustment requiredChiropractic devicesHydraulic cylinderPhysical medicine and rehabilitation

The invention relates to an auxiliary walking rehabilitation device for the lower limb. The auxiliary walking rehabilitation device comprises a walking table, wherein the middle of the walking table is provided with walking areas which are symmetrically distributed along a width direction of the walking table; unpowered running equipment capable of lifting and lowering is independently distributedbelow each walking area; a walking device capable of driving diseased legs to carry out bionic movement is evenly distributed above each walking area; an opening and closing mechanism for opening andclosing each walking area is independently arranged in each walking area; the walking table is also provided with a suspension device for preventing a patient from accidently falling. The auxiliary walking rehabilitation device can meet the patients of different diseases in different sickening periods, has a simple structure, is quick to lift and lower, does not need to regulate the speed of a running machine, and is completely controlled by a patient. A No.1 hydraulic cylinder and a sealing plate are cooperated to open and close the walking areas so as to avoid a phenomenon that under a situation that the patient without a walking ability does not stably hold, the patient falls when the unpowered running machine lowers or rises. Pushing rods, positioning plates and spacing plates are cooperated to regulate the height of food boards so as to prevent from generating motion interference in a movement table sliding process.

Owner:焦磊

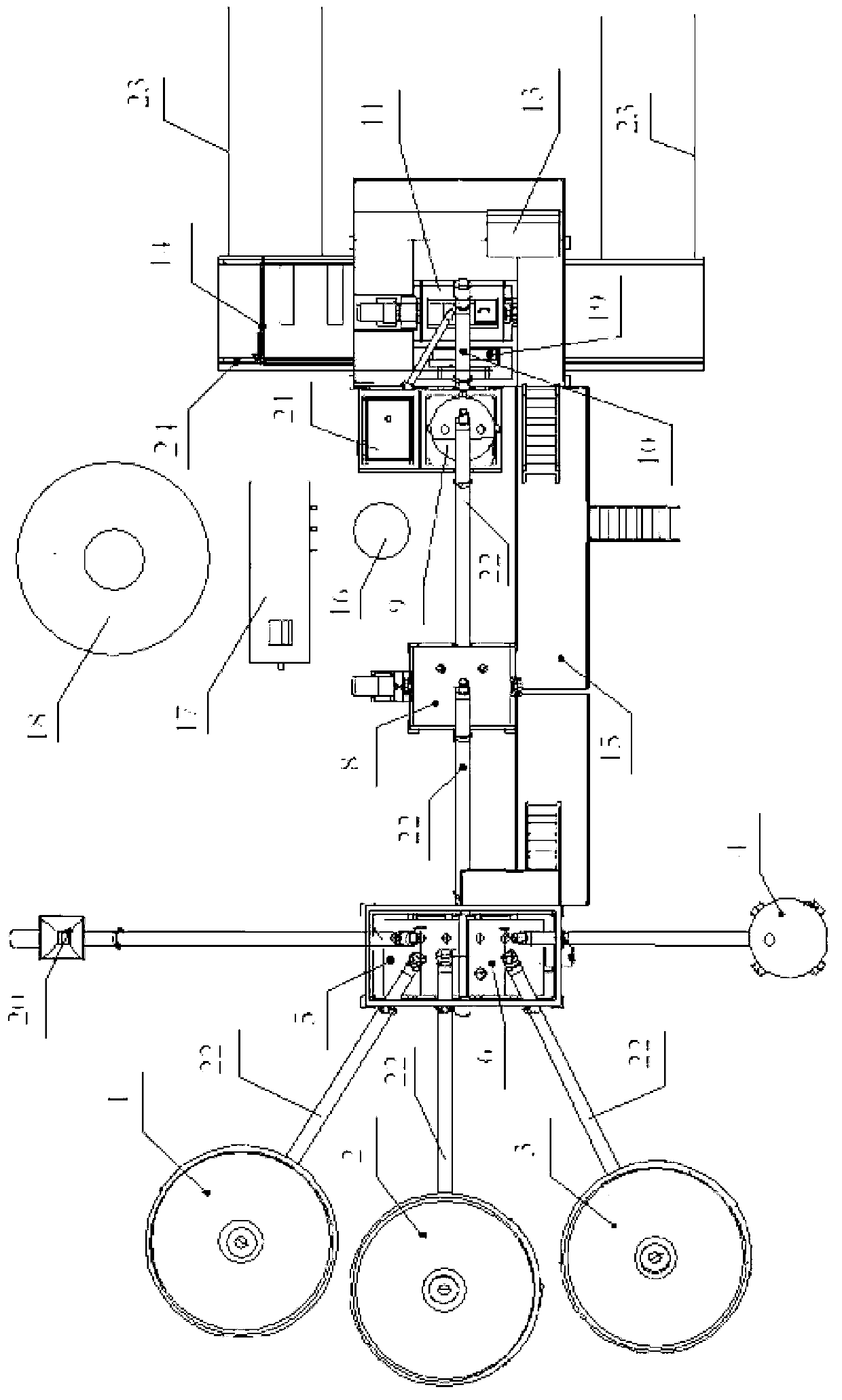

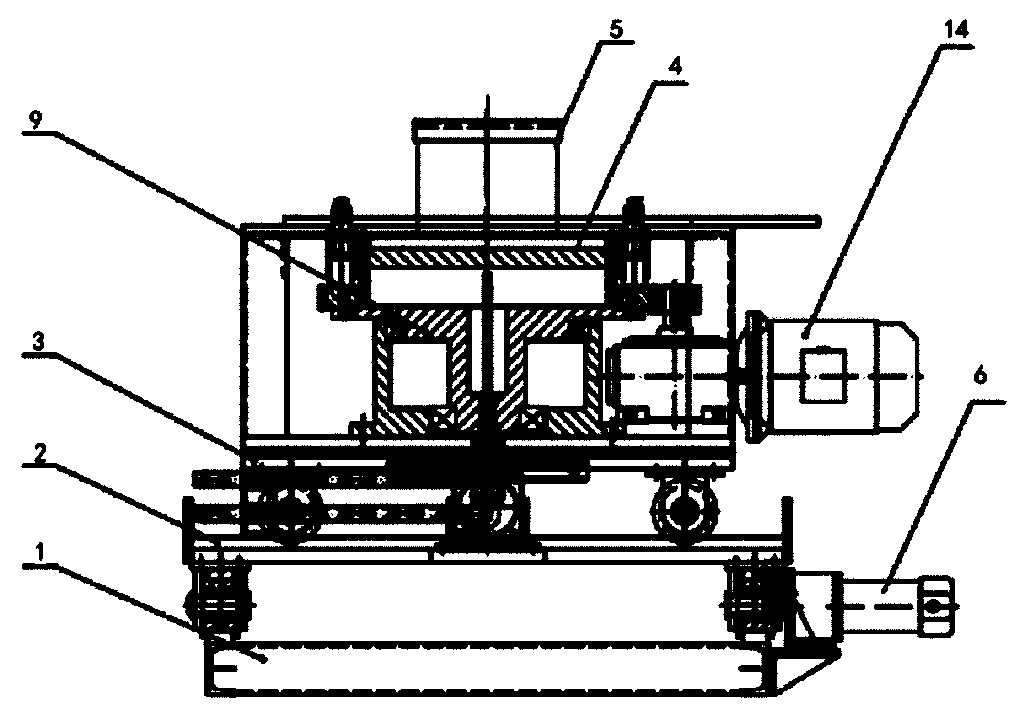

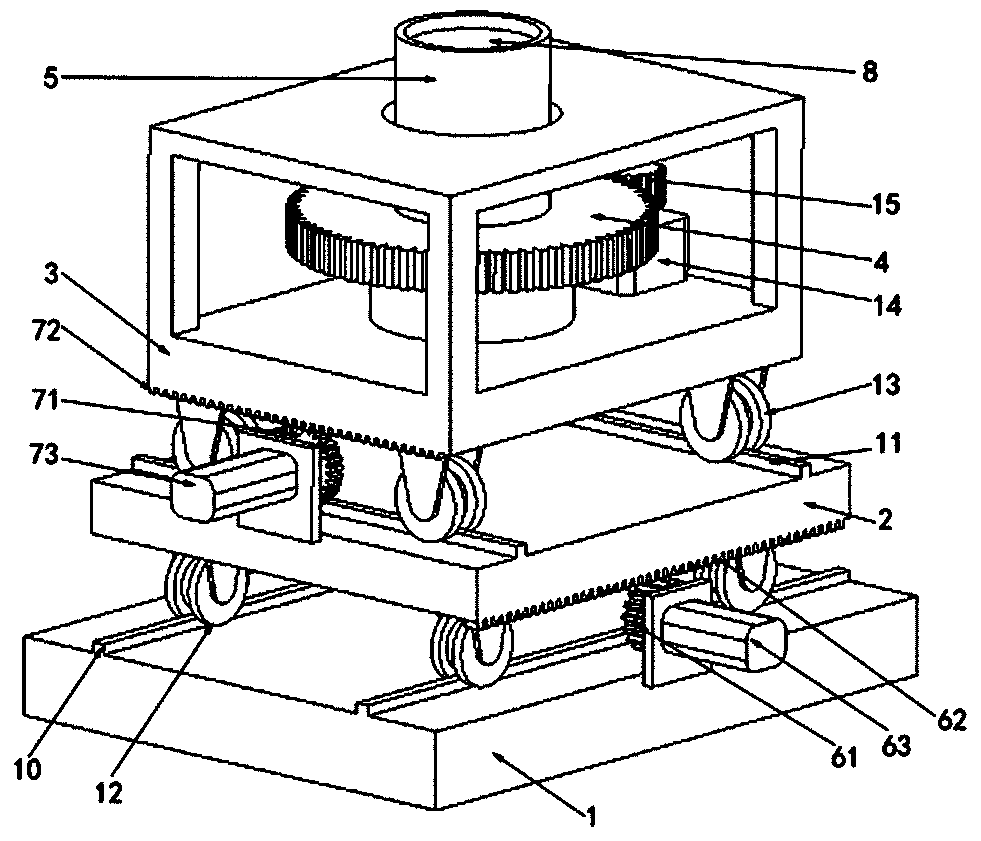

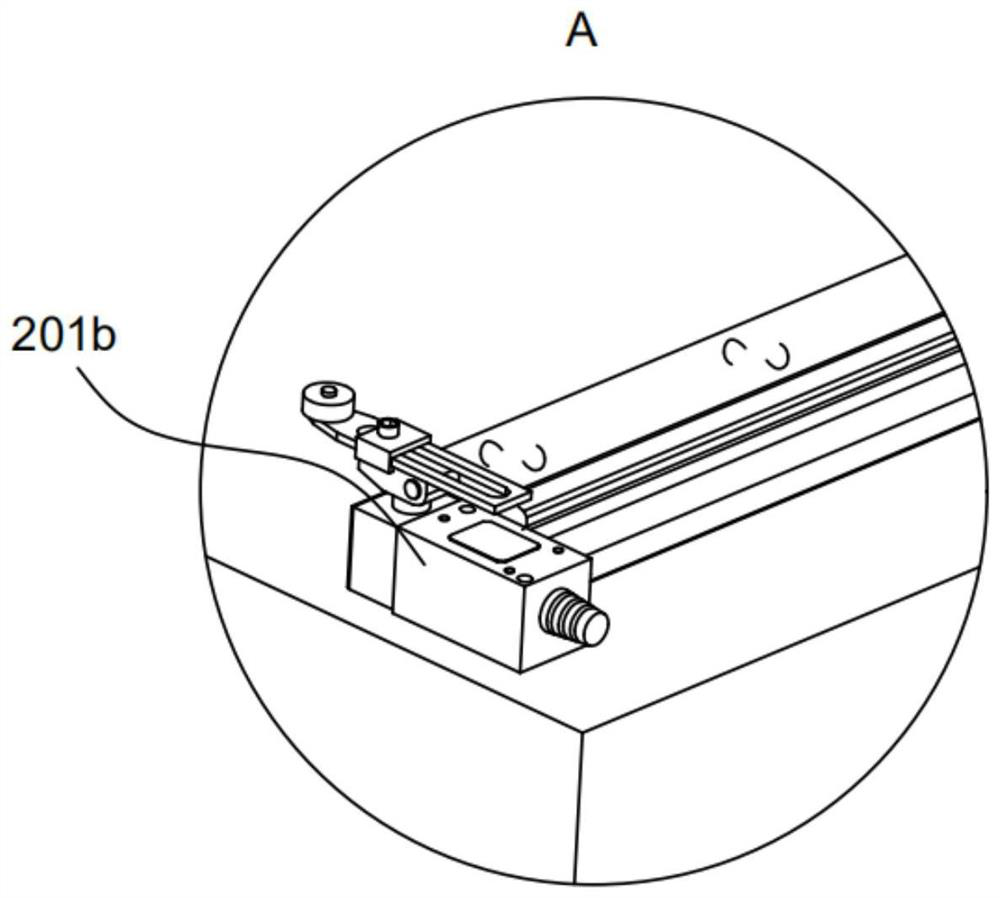

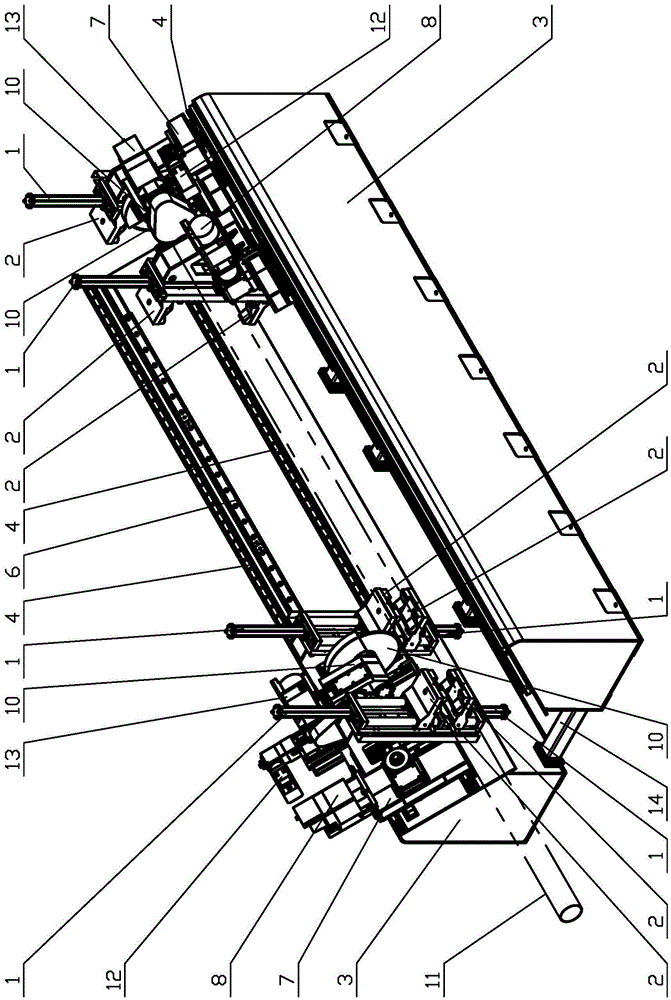

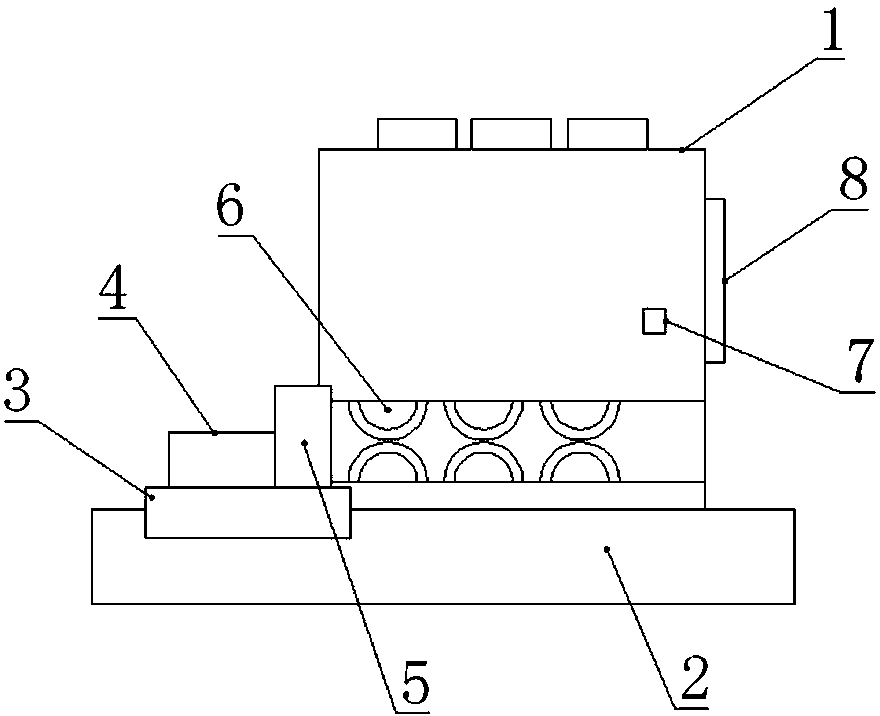

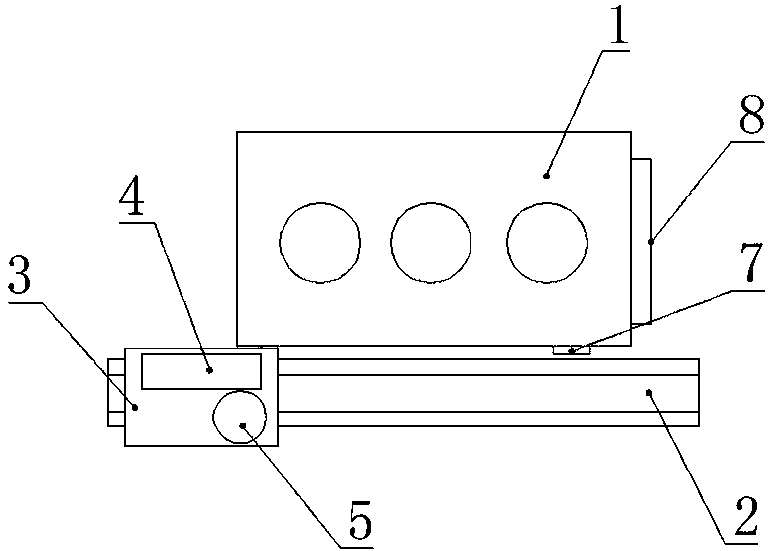

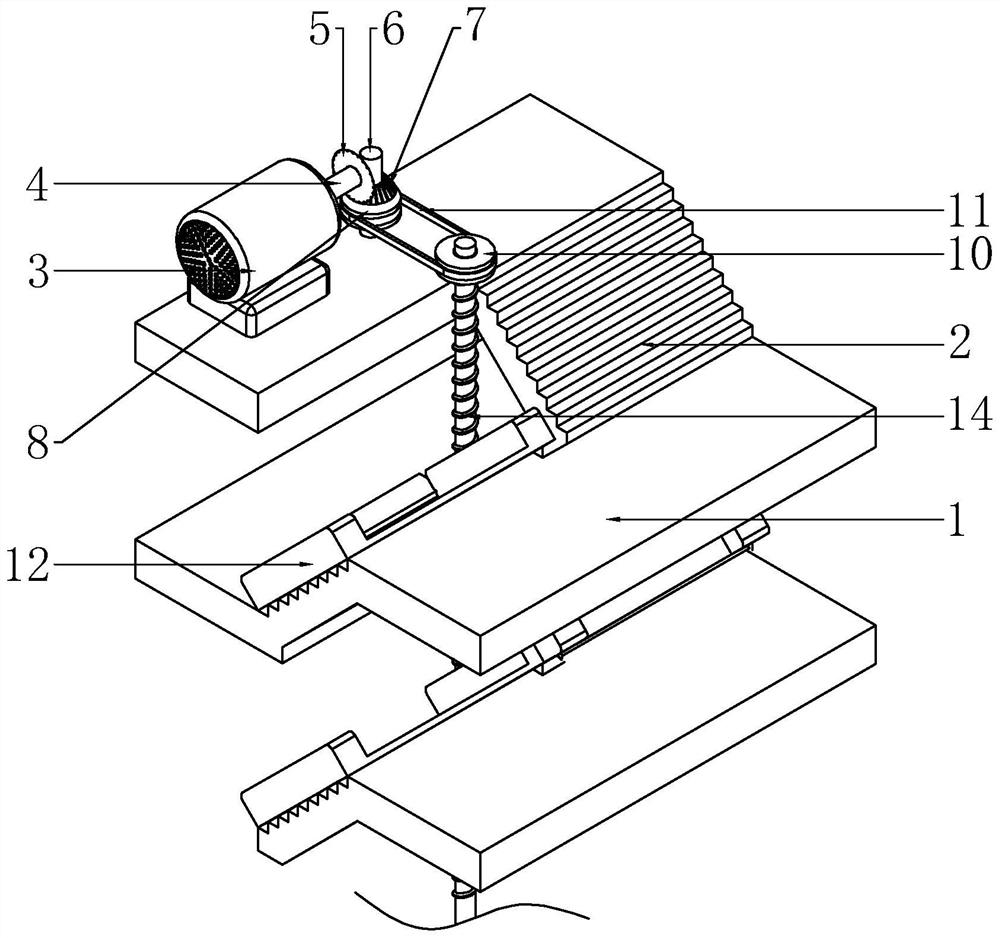

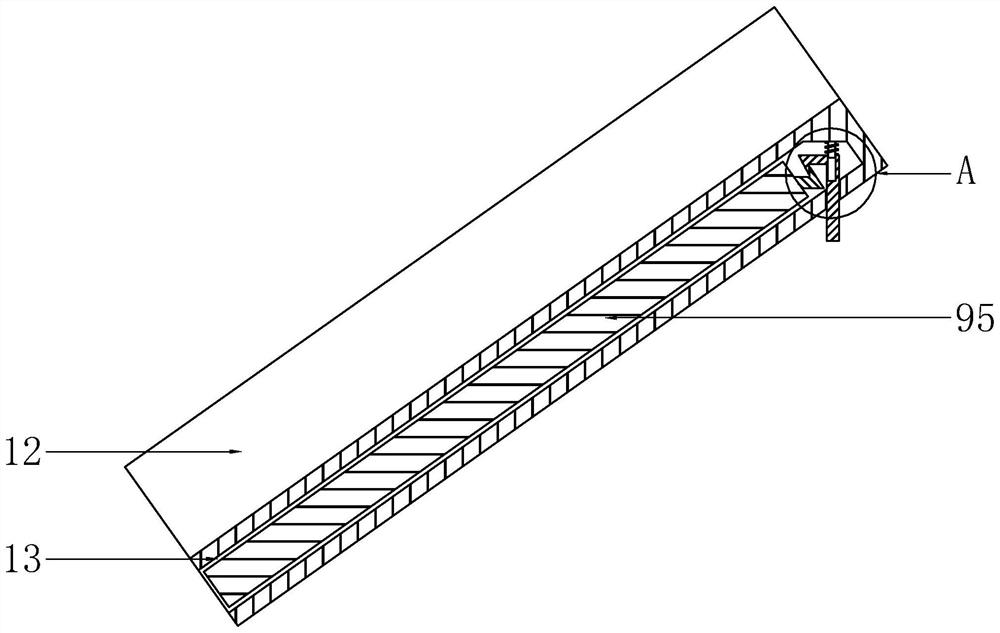

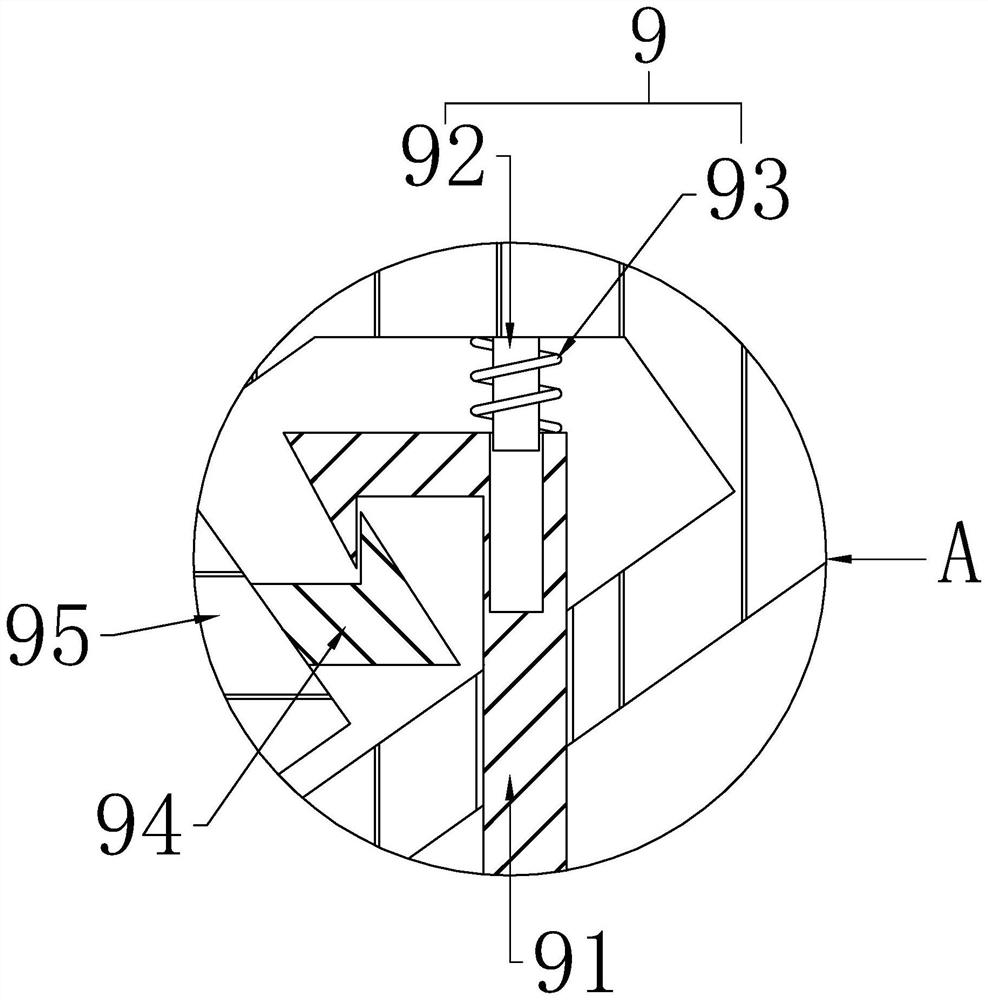

Rotating device for bimetallic metallurgy combined composite seamless pipe billet

The invention belongs to the technical field of seamless pipe production auxiliary devices, and particularly relates to a rotating device for a bimetallic metallurgy combined composite seamless pipe billet. The rotating device comprises a base, a transverse walking table and a longitudinal walking table; the transverse walking table is arranged on the base and can move transversely relative to thebase, the longitudinal walking table is arranged on the transverse walking table and can move longitudinally relative to the transverse walking table, the longitudinal walking table is provided witha rotating disc capable of rotating, and the rotating disc is provided with a supporting seat; and the transverse walking table can move transversely relative to the base, the longitudinal walking table is arranged on the transverse walking table and can move longitudinally relative to the transverse walking table, and the rotating disc is arranged on the longitudinal walking table. During operation, an outer layer hollow material is arranged on the supporting seat of the rotating disc, rotating of the outer layer hollow material and the supporting seat is achieved through rotating of the rotating disc, and thus even heating is ensured; and transverse and longitudinal fine-adjusting can be achieved through moving of the transverse walking table and the longitudinal walking table, and the coaxiality of the outer layer hollow material and core bars is ensured.

Owner:山西凯通源管业有限公司

Multi-color three-dimensional laminated foaming printing method for textile fabric

InactiveCN107227637ARich color variationStrong concave and convexDyeing processColor printingPulp and paper industry

The invention discloses a multi-color three-dimensional laminated foaming printing method for a textile fabric. Foaming pulp and elastic white glue pulp are added in printing pulp; water and thickening agents are added for regulating the pulp to the proper concentration and thickness; an automatic walking table plate printing machine and multi-color printing are used; after the printing of one color, the cloth is subjected to primary baking by a medium-temperature baking oven; then, the next color is printed; after the printing, the proper-temperature baking is performed by a high-temperature baking oven, so that foaming pulp foams; the patterns left on the cloth surface can show the three-dimensional laminated raised effect; the multi-color three-dimensional laminated printing is used; the concave-convex effect is strong; the pattern color change is rich; the strong three-dimensional laminated raised effect is shown; the color of the multi-color foaming slurry can be freely regulated; mutual combination can be realized; the pattern design is richer; in addition, the attaching degree with the cloth is good; falling cannot easily occur through scratching.

Owner:绍兴柯桥立桐布业有限公司

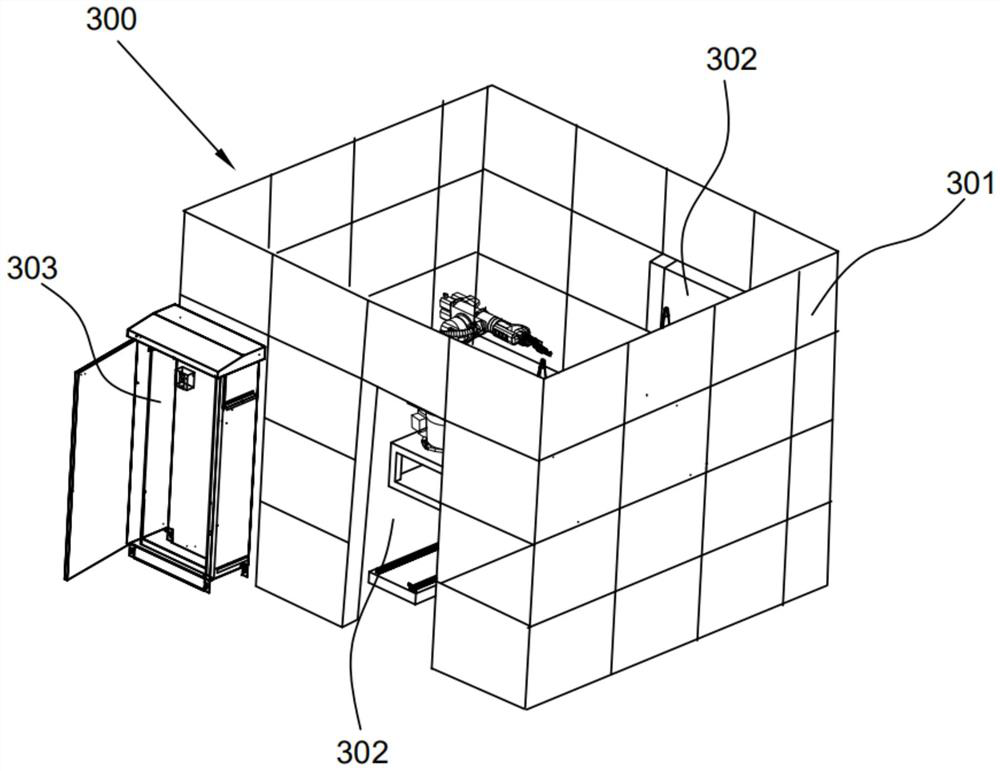

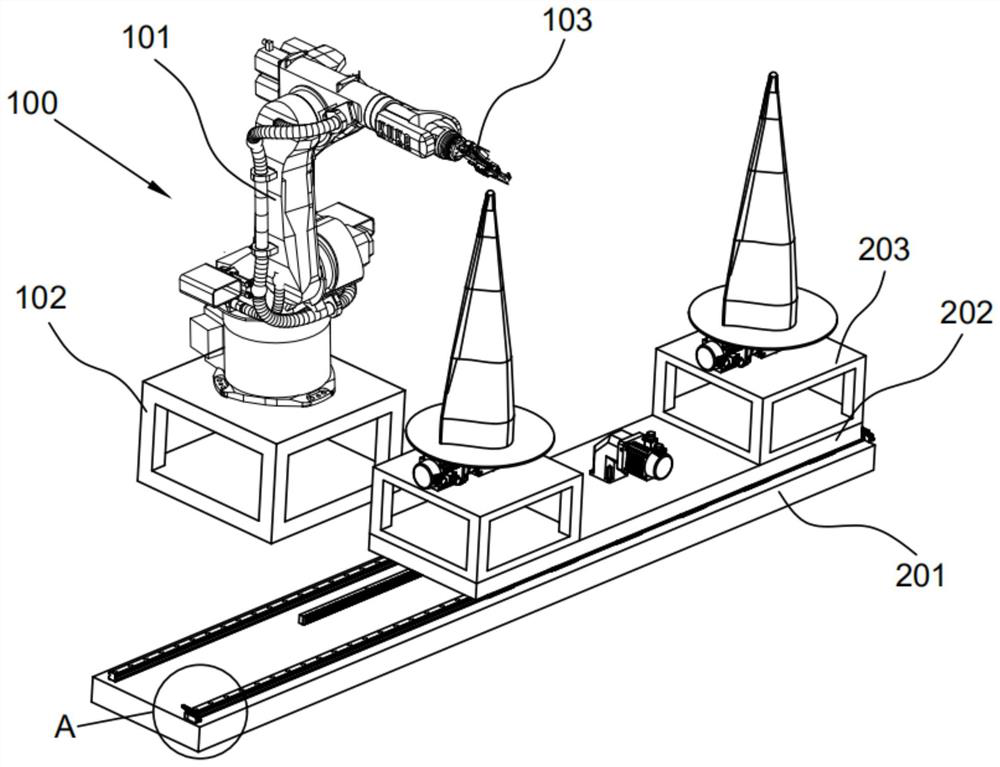

Double-station needling robot equipment

Owner:XI'AN POLYTECHNIC UNIVERSITY +1

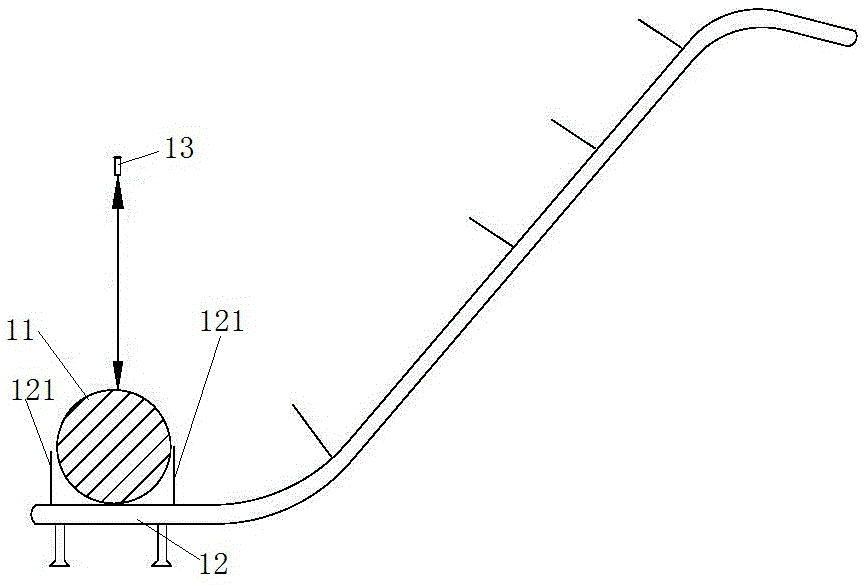

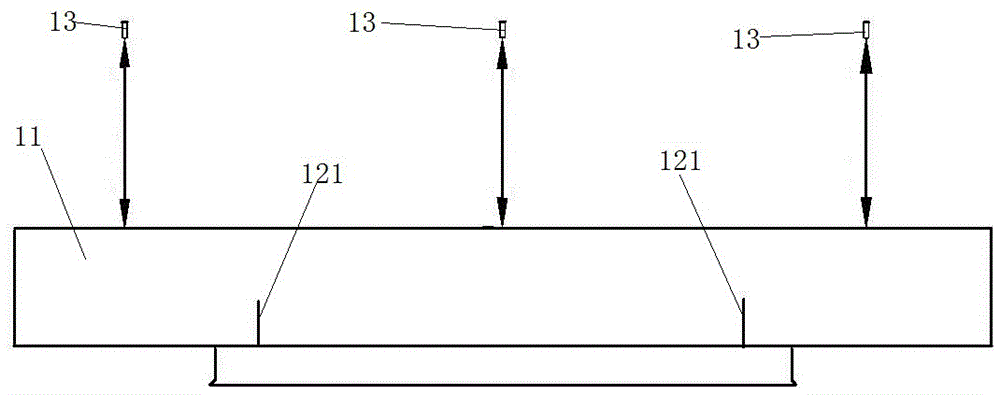

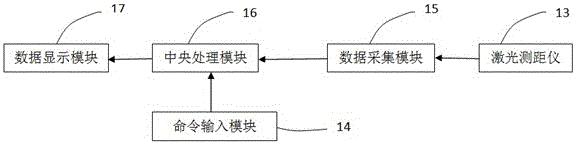

Round log diameter detection device and method

InactiveCN106382893AOvercoming time-consuming and laboriousOvercome errorUsing optical meansLaser rangingAutomatic control

The invention discloses a round log diameter detection device and method. The round log detection device comprises a support for placing a round log, a laser range finder arranged on one side of the support, an order input module, a data collection module and a central processing module; the size of the diameter of the round log can be determined through collecting signal data of an infrared sensor; and the size of the diameter of the round log can be analyzed and calculated through detecting a distance from the laser range finder to the surface of the round log and combining with the distance between the laser range finder and the support for placing the round log. In the round log diameter detection device, the central processing module is connected to a control system of a rotary cutting machine. The round log diameter detection device and method are applied in the round log rotary cuter, can realize automatic control on a moving distance of a moving cutter table, overcomes a defect of controlling a walking distance of a walking table through artificial observation wastes time and energy, and improves working efficiency.

Owner:佛山市海科知识产权交易有限公司 +1

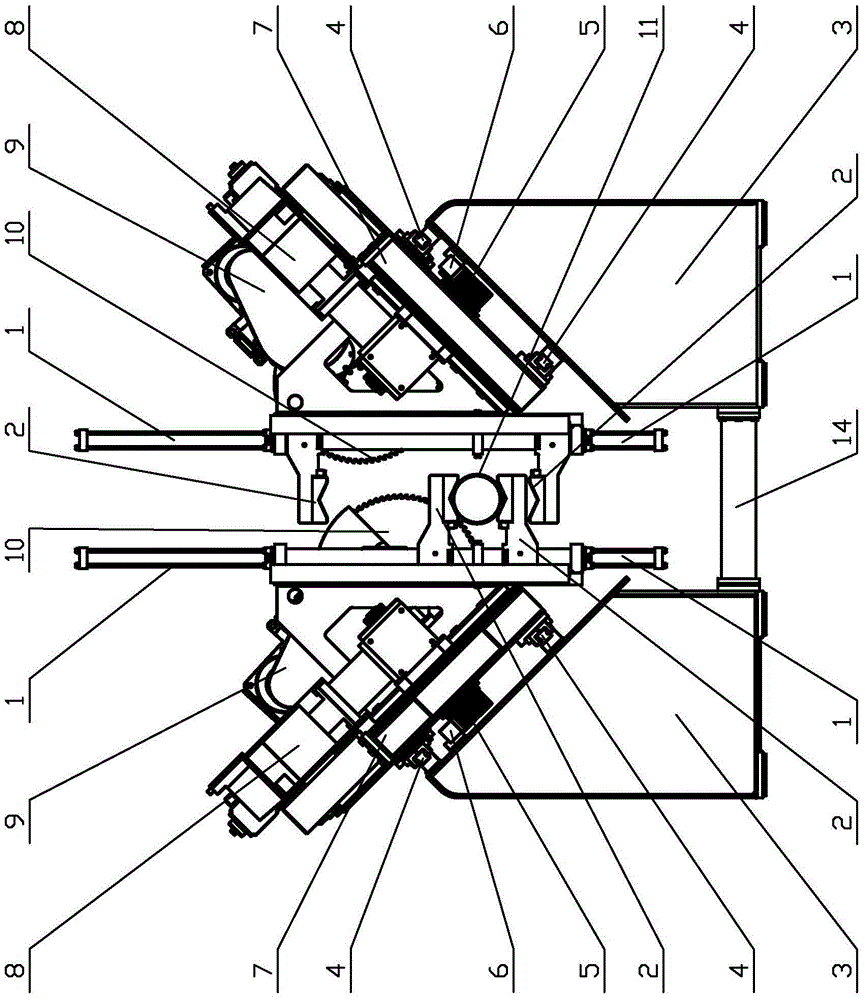

Double-vehicle type size-fixed flying saw machine

The invention discloses a double-vehicle type size-fixed flying saw machine which comprises two size-fixed cutting devices, wherein the two size-fixed cutting devices are symmetrically arranged at the left side and the right side of a to-be-cut workpiece, and comprise saw vehicles, machine bases, workpiece clamping mechanisms arranged on the saw vehicles, cutting feeding mechanisms arranged on the saw vehicles, and cutting mechanisms arranged at feeding ends of the cutting feeding mechanisms; walking table tops for the saw vehicles to travel are arranged at the upper ends of the machine bases; walking mechanisms for driving the saw vehicles to travel on the walking table tops are arranged between the saw vehicles and the walking table tops; and the workpiece clamping mechanisms are cantilever type clamping mechanisms. With the adoption of the technical scheme, the two size-fixed cutting devices are symmetrically arranged to form series connection; through flexible arrangement of the various mechanisms, the coordination work of the two size-fixed cutting devices are ensured; and the two size-fixed cutting devices alternately and circularly cut the workpiece, so that the cutting efficiency is increased to be twice of that of the conventional single saw vehicle flying saw, and the requirements of a high-speed cold rolled section steel unit are met.

Owner:大连三高科技发展有限公司

Dust collecting box for sweeping robot

InactiveCN108451444AEasy to integrateReasonable structural designCarpet cleanersFloor cleanersEngineeringDrive motor

The invention discloses a dust collecting box for a sweeping robot. The sweeping robot includes a dust collecting box, an air inlet, an air outlet, a gear rack, a recycling port, a tighten hole, a walking motor, a driving gear, a walking table, an upper bonding plate, a rear sliding block, a front sliding block, a lower bonding plate, a baffler, a lifting slide rail, a horizontal slide rail, a storage box, a dust collecting bag, a connection bag tail, a bag mouth, a wire outlet hole, a lacing wire, a traction wire, a placing plate, an electric push rod and a telescopic rod. According to the invention, the structural design is reasonable. No more structure is added to the outside of the dust collecting box, namely, the structure of the original dust collecting box is not required to be changed while achieving some effect. The research and development cost is reduced. The traditional cleaning operation to the dust collecting box inside the sweeping robot is changed. A special dust collecting bag is used for collecting the sucked dust, so that the cleaning of the dust collecting box is facilitated. Mechanical replacement of the dust collecting bag is realized. Only the electric push rod and the driving motor needs to be supplied with energy. No more additional energy is consumed.

Owner:黄瑾

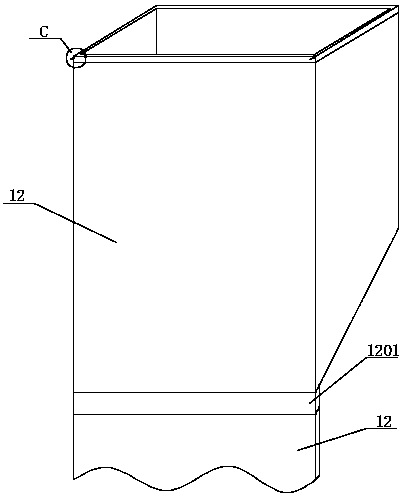

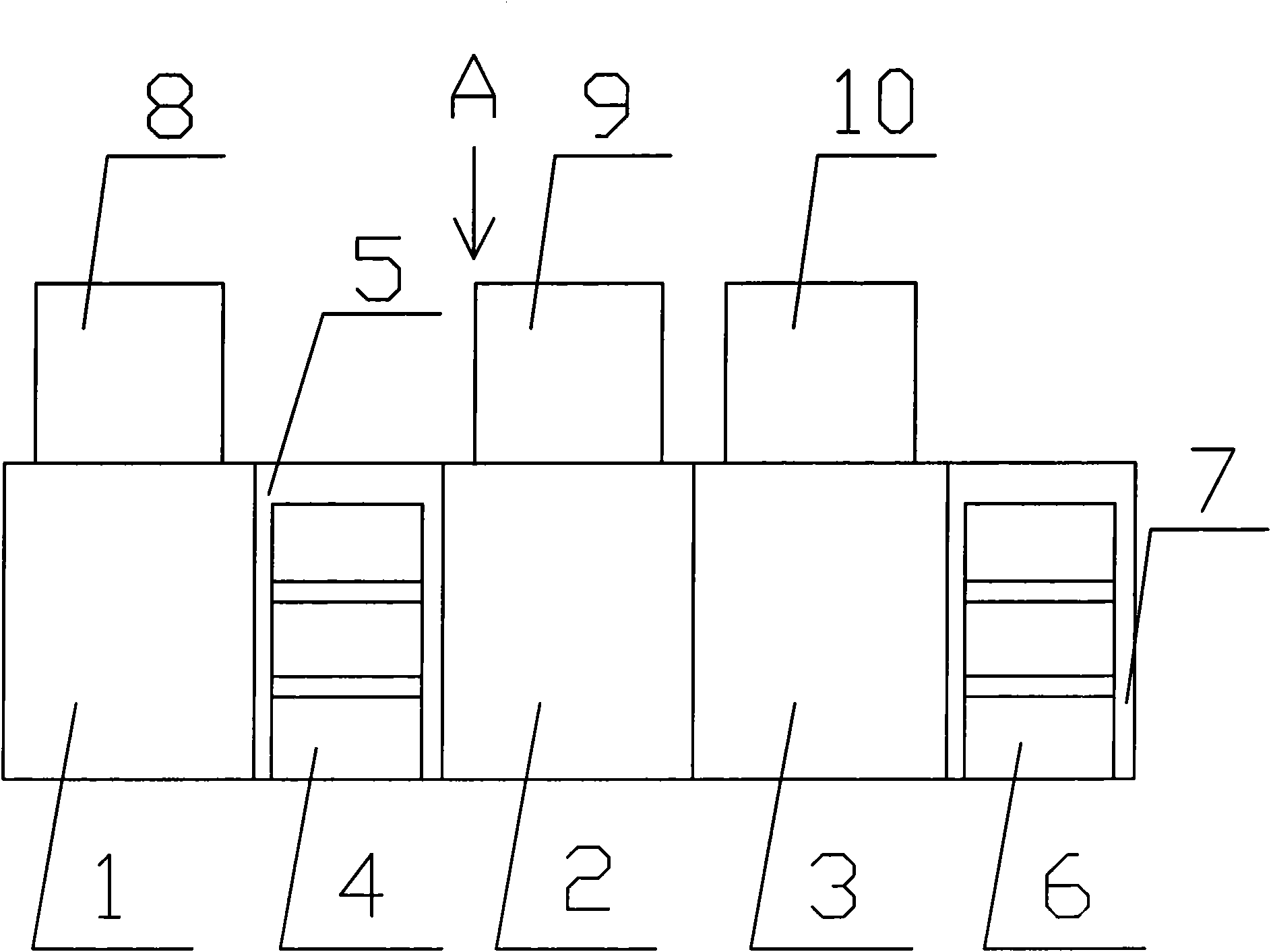

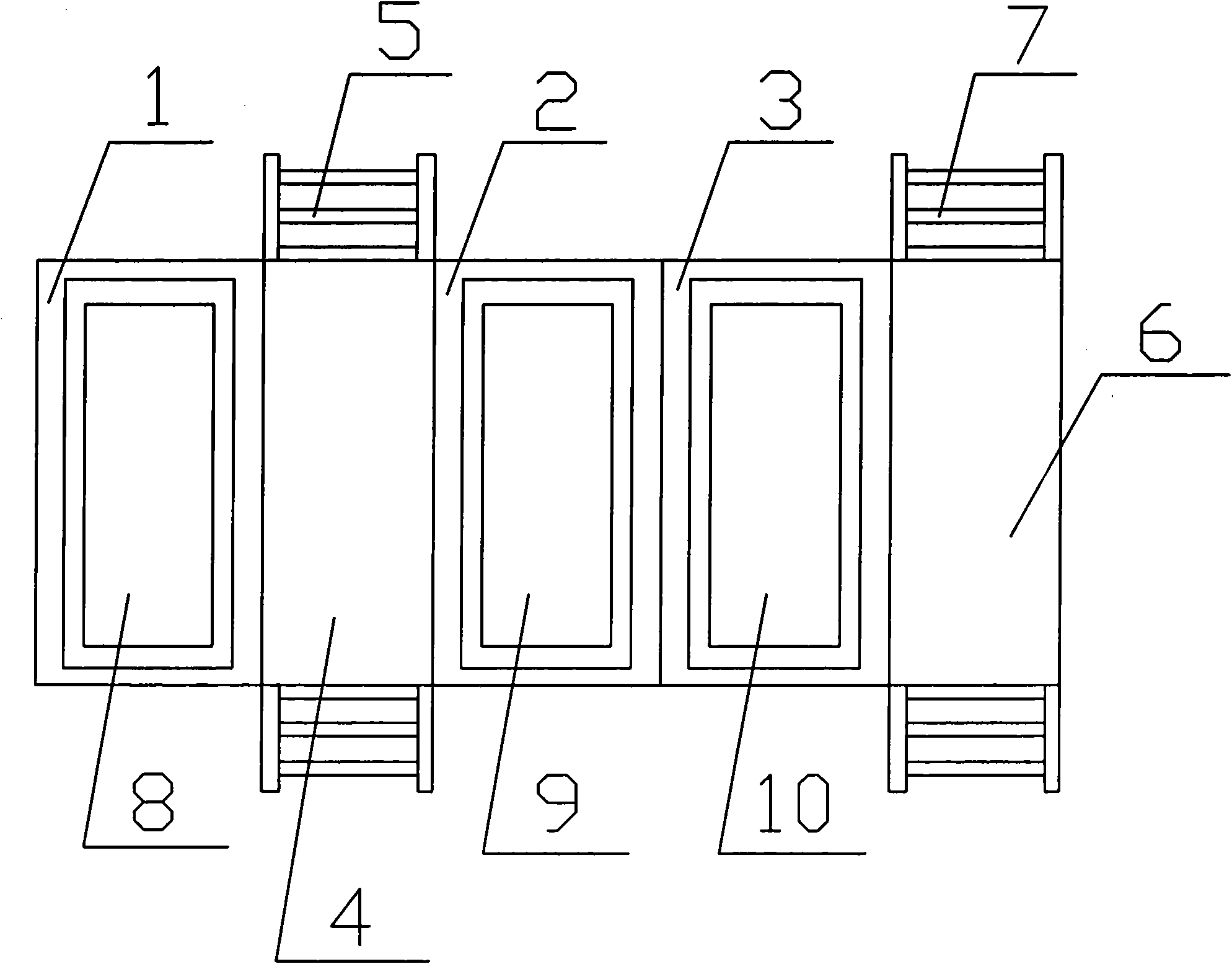

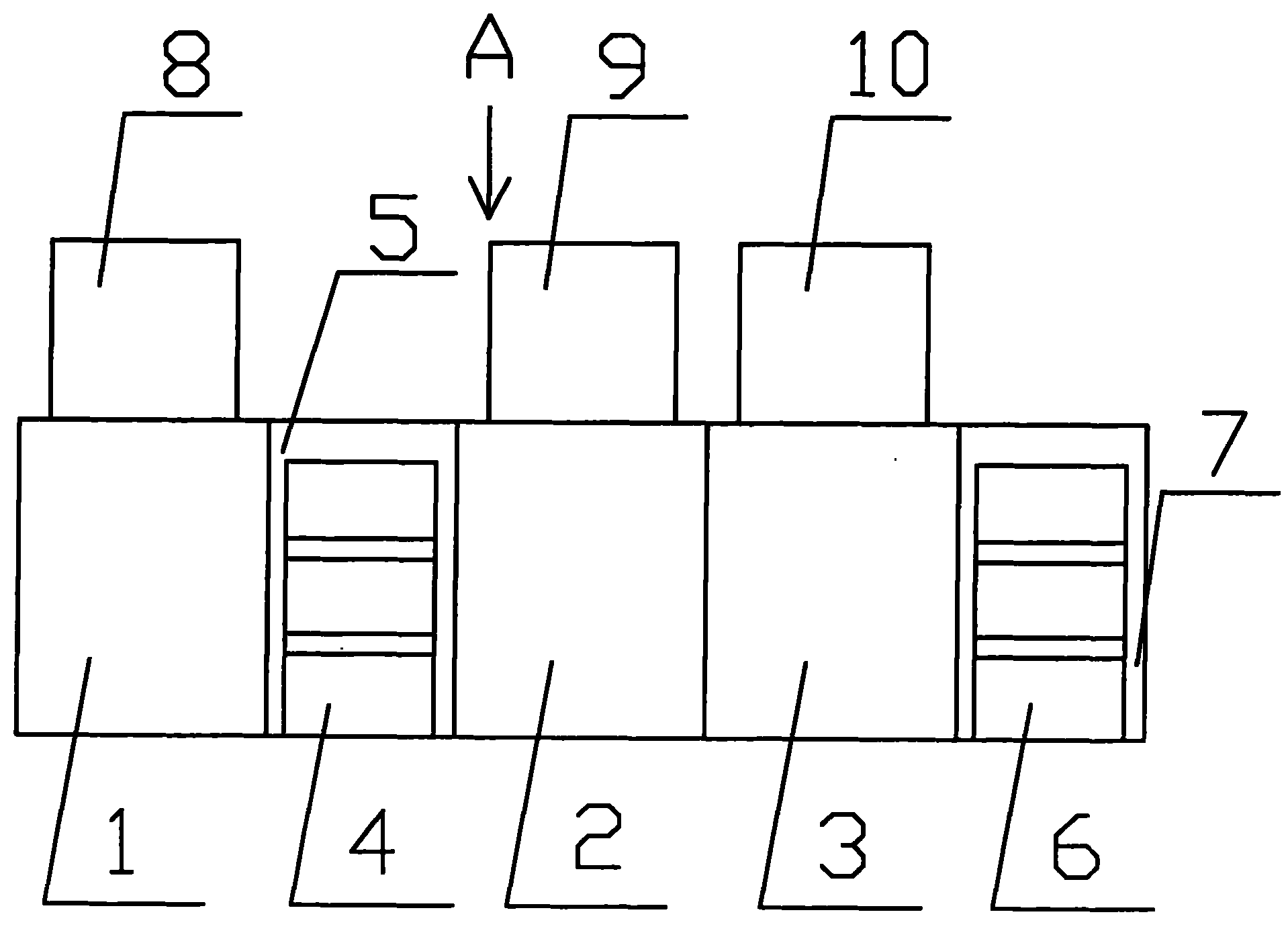

Antirust treating pond system

The invention discloses an antirust treating pond system used for the rust prevention treatment of iron pipes. The system comprise a first work table, a second work table and a third work table, wherein the three work tables are arranged in parallel, a first walking table is arranged between the first work table and the second work table, and the front part and the rear part of the first walking table are respectively provided with a first inclined ladder; the outer side of the third work table is provided with a second walking table, and the front part and the rear part of the second walking table are respectively provided with a second inclined ladder; and a first antirust pond is arranged on the first work table, a second rust removing pond is arranged on the second work table, and a neutralization pond is arranged on the third work table. The invention has the advantages of simple structure, convenient use and high working quality.

Owner:NANTONG ZHONGLIAN S&T SERVICE

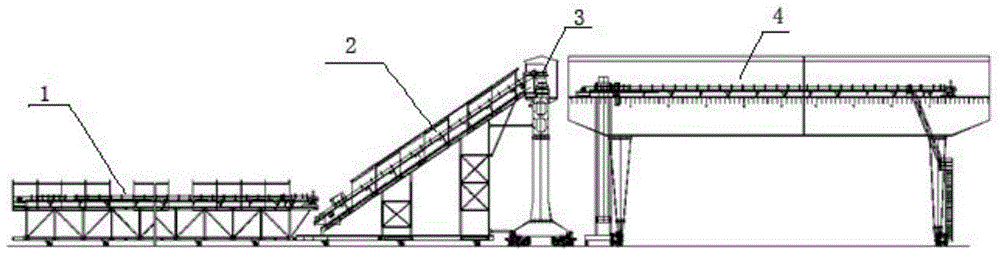

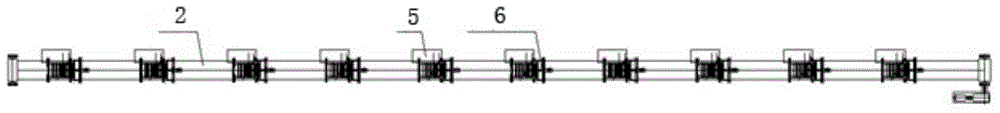

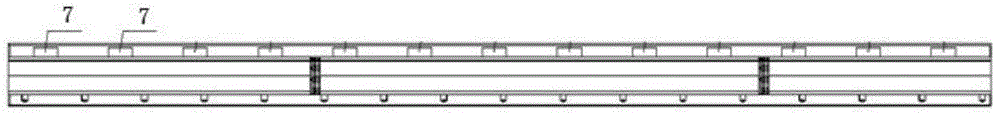

Novel distributing machine

InactiveCN104590871ARealize fast delivery operationImprove work efficiencySupporting framesEngineeringMaterial transfer

The invention provides a novel distributing machine. The novel distributing machine comprises a horizontal conveying belt, and a loading conveying belt connected with the distributing machine. Multiple unloading apparatuses are additionally mounted on a conveying belt of a bearing portal beam mechanism; materials are separated into material boxes through the unloading apparatuses; the material boxes are arranged at the upper part of a walking table of the distributing machine; a leaking hole is formed in the bottom of each material box; reserved openings are formed in the walking table corresponding to the material boxes; and the materials become material stacks through the leaking holes and the reserved openings. The bearing portal beam mechanism of the distributing machine can realize quick material transfer without being limited by the floor space through the combination of the conveying belt of the distributing machine with such related devices as the unloading apparatuses, so that the span is free, the working efficiency is improved, and the operation cost is reduced.

Owner:HENAN DAFANG HEAVY MACHINERY

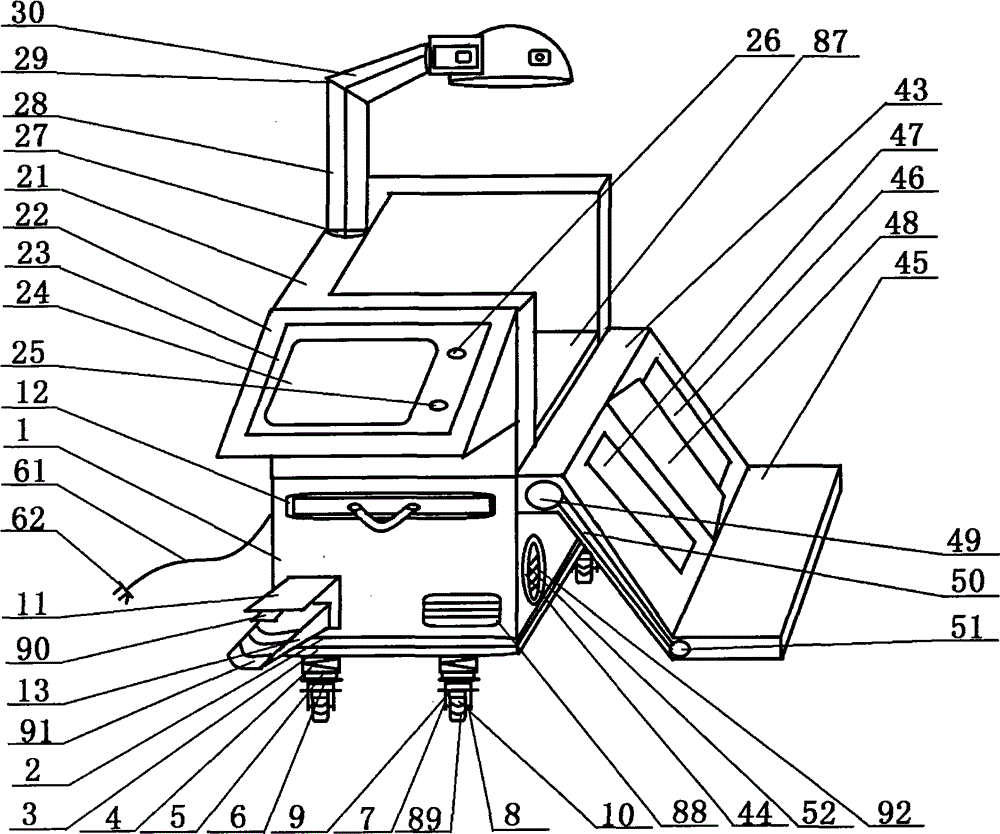

Solder paste dispensing device

InactiveCN108544049AEasy to carryAvoid damagePrinted circuit assemblingSolder feeding devicesDisplay deviceSolder paste

The invention discloses a solder paste dispensing device. The solder paste dispensing device comprises a tin dispensing device body, a tin dispensing cabin, a rotary shaft, a tin dispensing cabin cover, a walking table, a walking frame, a spraying valve, a storage rack and a displayer. The tin dispensing cabin communicating with the outside is arranged on the inner side of the upper portion of thetin dispensing device body, and the rotary shaft mounted on the surface of the tin dispensing device body is arranged at the top of the tin dispensing cabin. A tin dispensing cabin cover matched withthe tin dispensing cabin is mounted on the surface of the rotary shaft. The walking frame fixed to the surface of the inner wall of the tin dispensing device body is mounted in the middle in the tindispensing cabin. According to the solder paste dispensing device, the displayer is connected with the surface of the inner side of the tin dispensing device body through a hinge, and when the solderpaste dispensing device is not used, the displayer can be stored in the tin dispensing cabin by rotating the hinge; and at this moment, an input keyboard can be stored in the tin dispensing cabin at the same time, it is avoided that when an existing solder paste dispensing device is transported, the displayer and the input keyboard are exposed, and consequently the displayer and the input keyboardare damaged.

Owner:昆山振顺电子科技有限公司

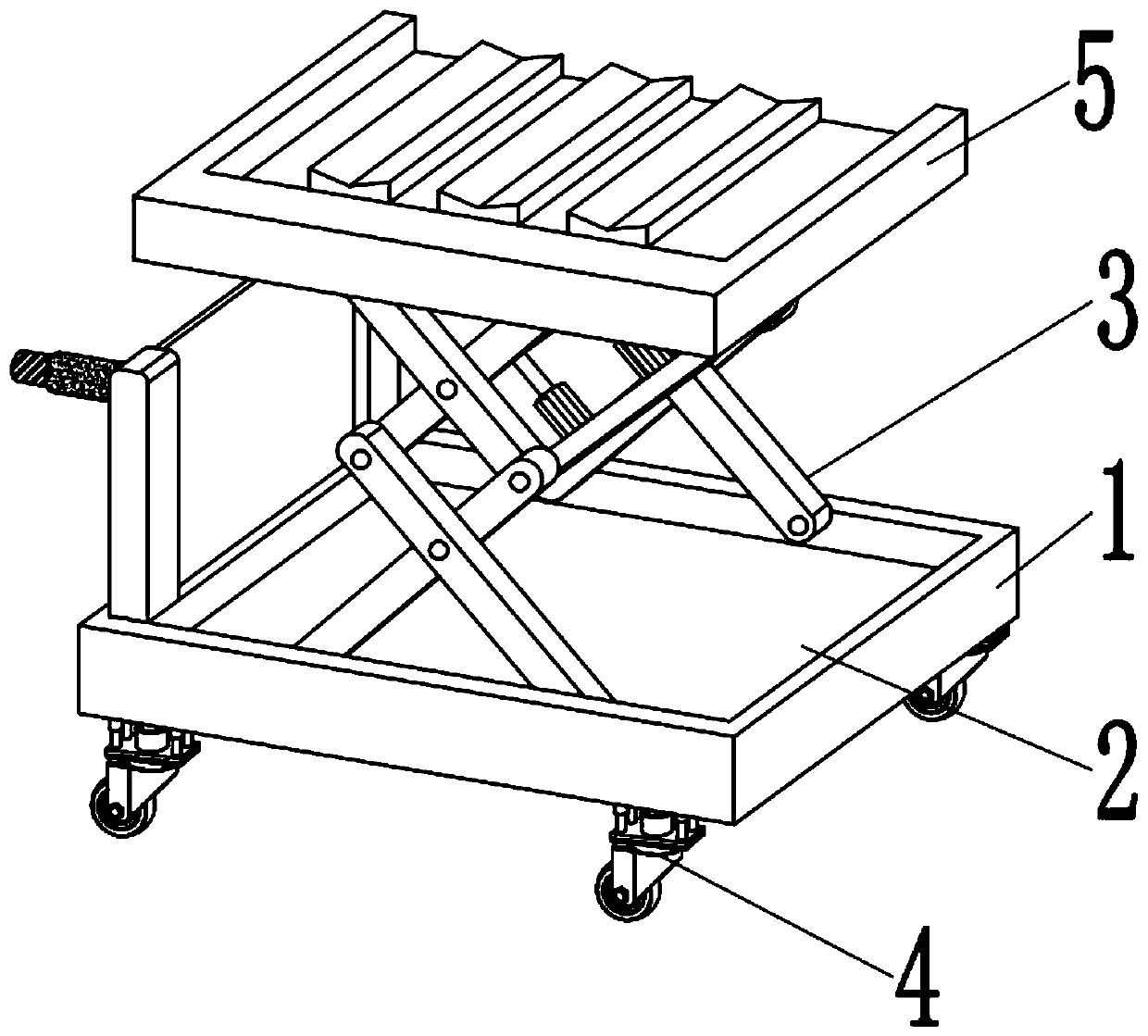

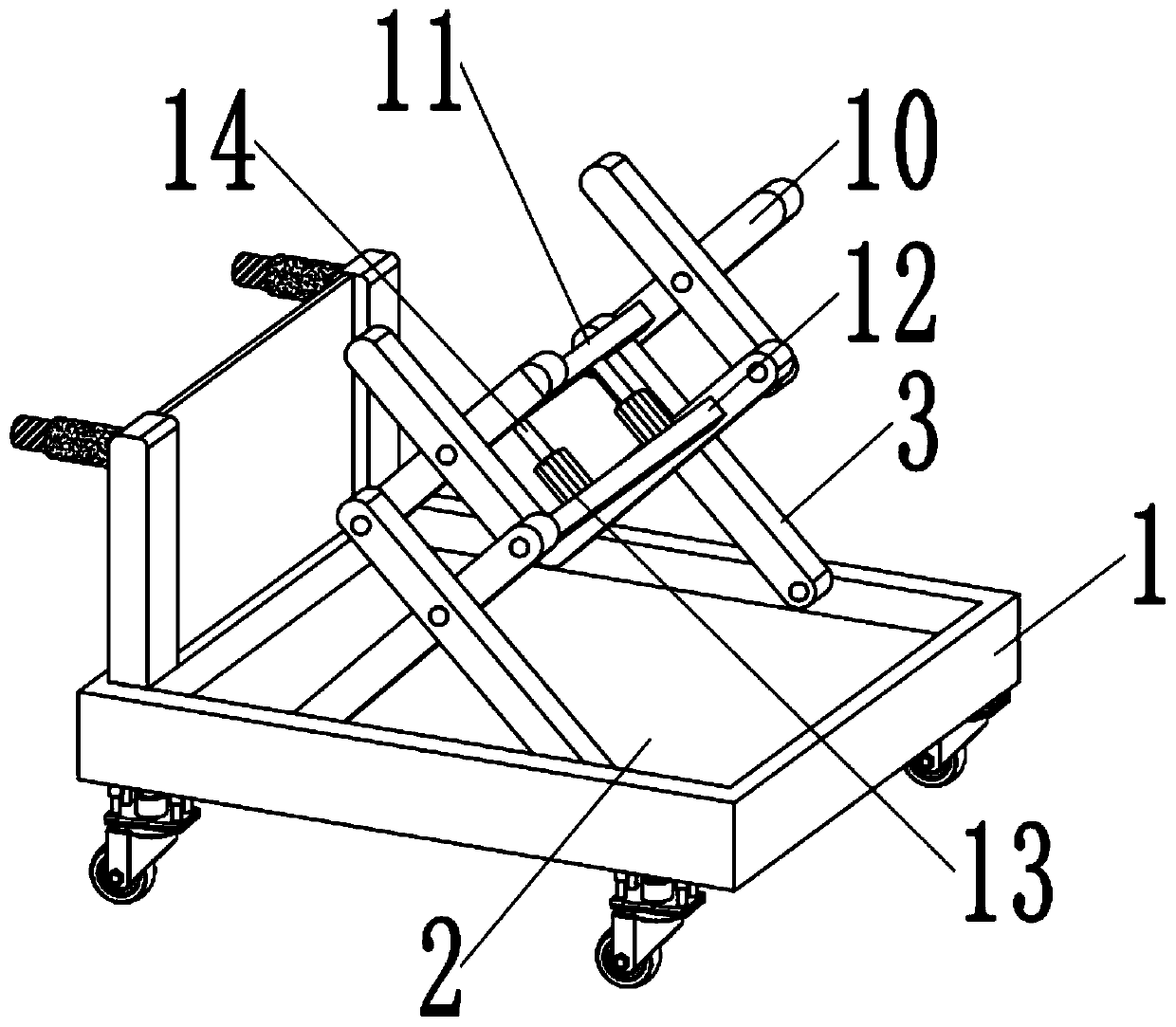

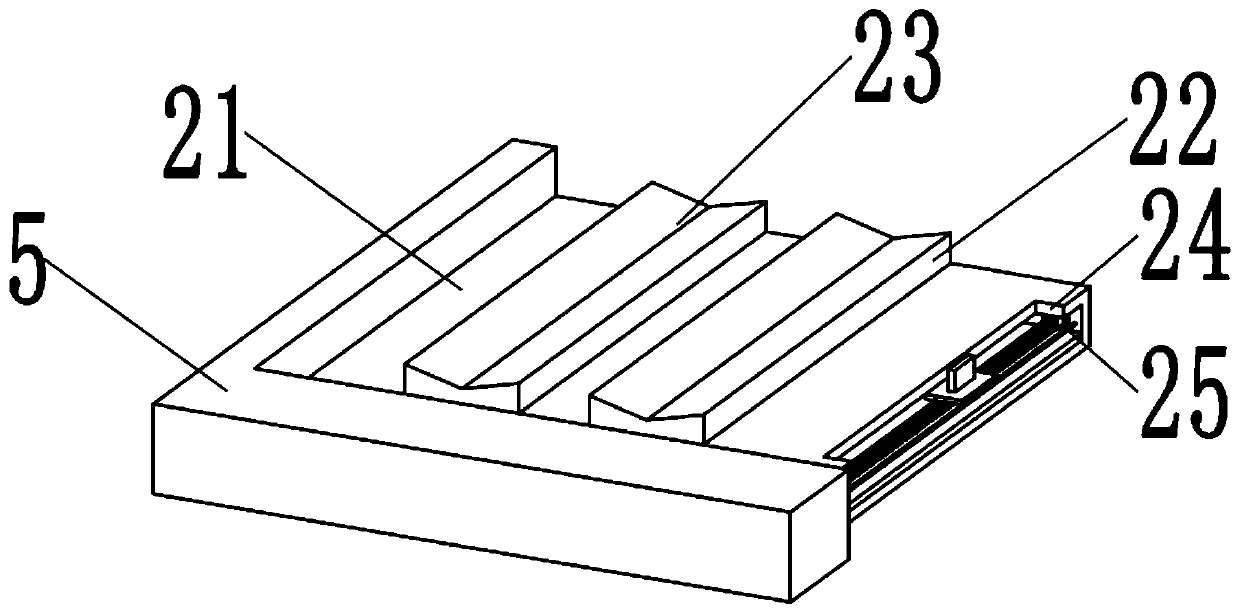

Pushing device for refrigerator stamping part

InactiveCN111482485APrevent slidingPlace stableHand carts with multiple axesHand cart accessoriesHydraulic cylinderIcebox

The invention relates to the technical field of refrigerator stamping, in particular to a pushing device for a refrigerator stamping part. The pushing device comprises a base, wherein an accommodatinggroove is formed in the outer wall of the top of the base; main crossed lifting rods are movably connected to the inner walls of the two sides of the accommodating groove through rotating shafts; theother ends, away from the base, of the main crossed lifting rods are connected with auxiliary crossed lifting rods through the rotating shafts; a second cross beam is welded to the tops of the outerwalls on the adjacent sides of the main crossed lifting rods; a first cross beam is welded to the bottoms of the adjacent sides of the auxiliary crossed lifting rods; the first cross beam and the second cross beam are parallel to each other; and hydraulic cylinders are arranged at the two ends of the outer walls on the adjacent sides of the first cross beam and the second cross beam through bolts.The pushing device for the refrigerator stamping part has the beneficial effects that material rollers with different diameters can be placed, so that materials are placed more steadily; and a walking table drives storing plates to move, and then rolled raw materials are transferred to the position of the rotating shafts, so that time is saved, and efficiency is effectively improved.

Owner:CHUZHOU XINKANGDA METAL PROD

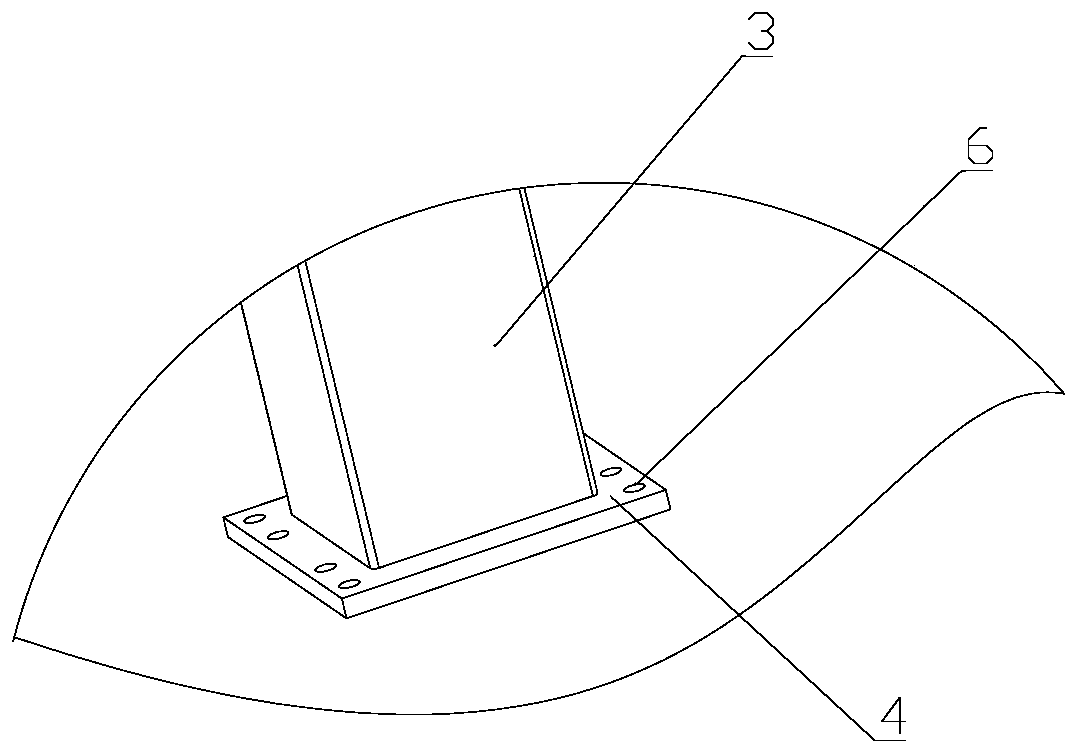

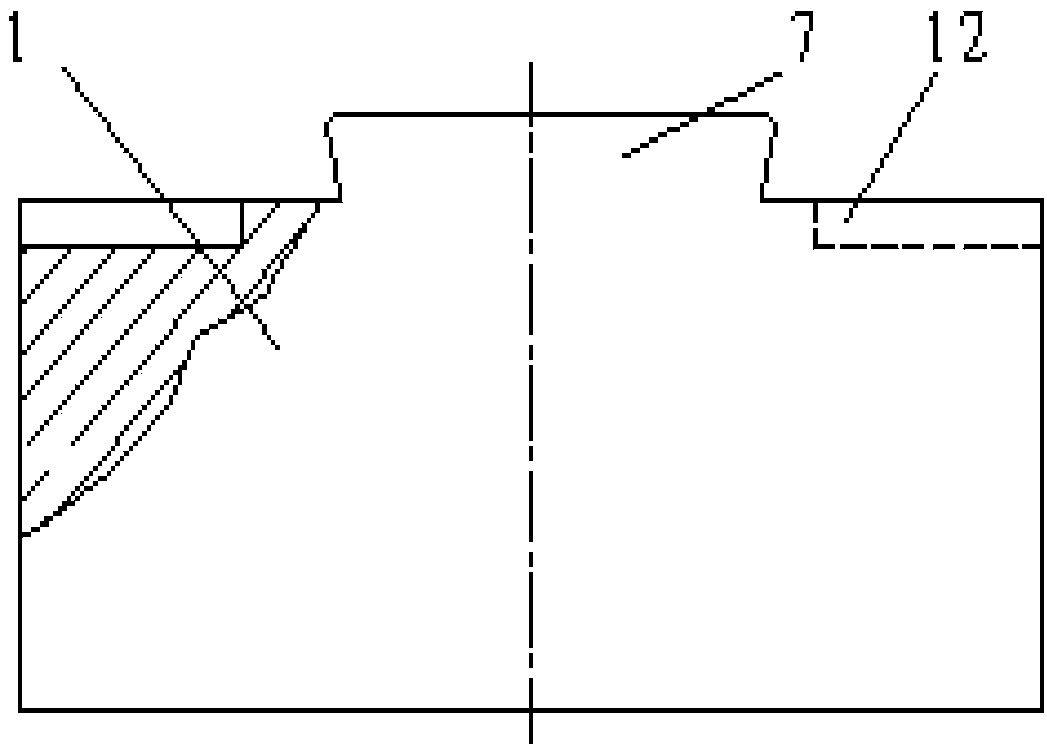

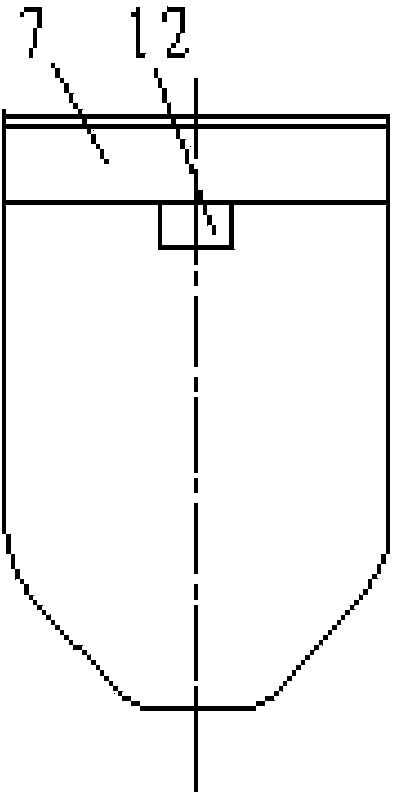

Inclined plane anvil forging connecting rod transition conical face and transition conical face machining method thereof

InactiveCN104368742AIncrease profitGood streamlineForging/hammering/pressing machinesEngineeringModel Number

The invention relates to an inclined plane anvil forging a connecting rod transition conical face and a transition conical face machining method thereof. An upper anvil portion is composed of an upper anvil and an upper anvil base, and a lower anvil portion is composed of a lower anvil and a lower anvil base. The lower portion shape of the upper anvil and the upper portion shape of the lower anvil are the same as the shape of a connecting rod machined conical face. A forked tail of the upper anvil of the upper anvil portion is clamped into a forked tail groove in the upper anvil base. The protruding narrow edge of the side face of the lower anvil of the lower anvil portion is arranged in a key groove in the lower anvil base. During machining, the upper anvil base is connected to a pressing machine connecting plate, the lower anvil and the lower anvil base are placed on a pressing machine walking table, a pressing machine is operated, a jaw of a blank operating machine clamps a blank, the blank is rotated, the lower plane of the upper anvil and the upper plane of the lower anvil form a connecting rod middle rod portion and a transition inclined plane, finishing is carried out by an upper flat anvil and a lower flat anvil, log marking and coining are carried out in sequence, and therefore the connecting rod middle transition conical face is formed. A connecting rod forged by the inclined plane anvil is regular in outline, simple in production procedures, high in material utilization rate, good in metal streamline performance, short in machining period and low in production cost. By means of the inclined plane anvil, connecting rods of marine diesel engines of the model number being 50 or larger than 50 can be produced.

Owner:武汉重工铸锻有限责任公司

Cocooning frame grooving machine achieving dust removal and sound insulation conveniently

ActiveCN107379148AEasy to collectEasy to oilGear lubrication/coolingWood mortising machinesFuel tankPulp and paper industry

The invention discloses a cocooning frame grooving machine achieving dust removal and sound insulation conveniently. The grooving machine comprises a working table, a baffle, a sound insulation bin, a belt pulley, chain gears, a spray head, an oil storage tank, a pressing rod, a duct collection groove, a funnel and a protective cover; the baffle is installed on the top of the working table, the sound insulation bin is installed at the upper end of the baffle, the oil storage tank is installed on one side of the working table, the funnel is arranged on the side, close to supporting legs, of the bottom of the walking table, the dust collection groove is installed at the lower end of the funnel, and the spray head is installed on the side, close to the chain gears, of the other end of a hose. The grooving machine is scientific and reasonable in structure and safe and convenient to use; by arranging the duct collection groove and the funnel, chippings generated in the grooving process are collected conveniently; by arranging the oil storage tank and the spray head, oiling of the chain gears is conducted conveniently; by arranging a partition plate and the pressing rod, lubricating oil in the oil storage tank is used conveniently; by arranging the sound insulation bin and sound-absorbing cotton, noise generated by the grooving machine can be reduced; by arranging a magnet, assembling and disassembling of the sound-absorbing cotton are conducted conveniently.

Owner:MENGSHAN TIANYU REARING INSTR PROD CO LTD

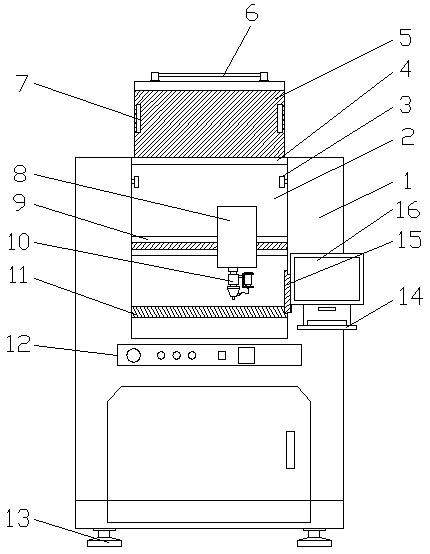

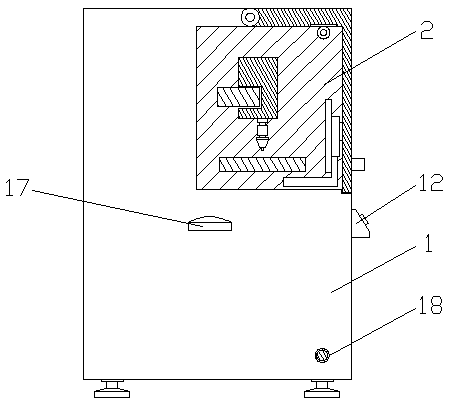

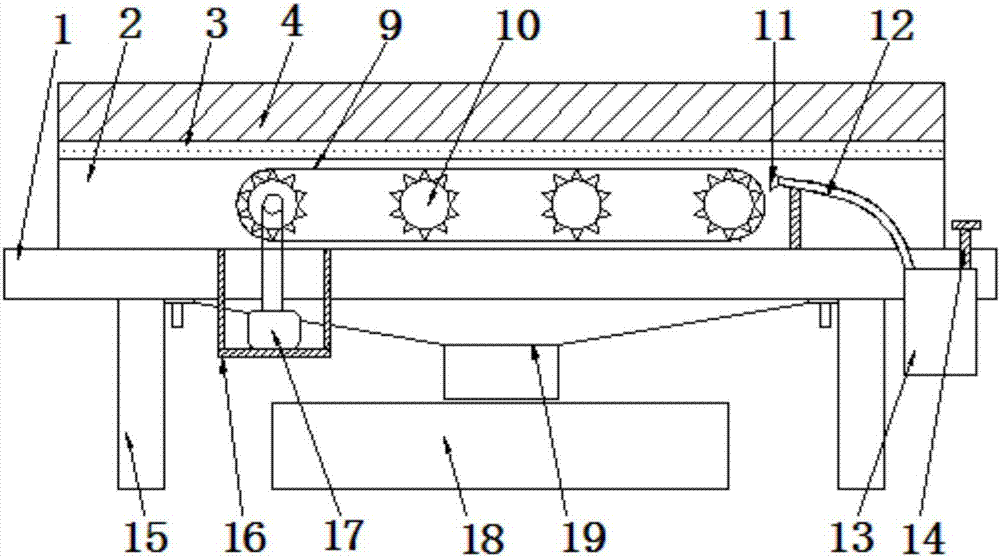

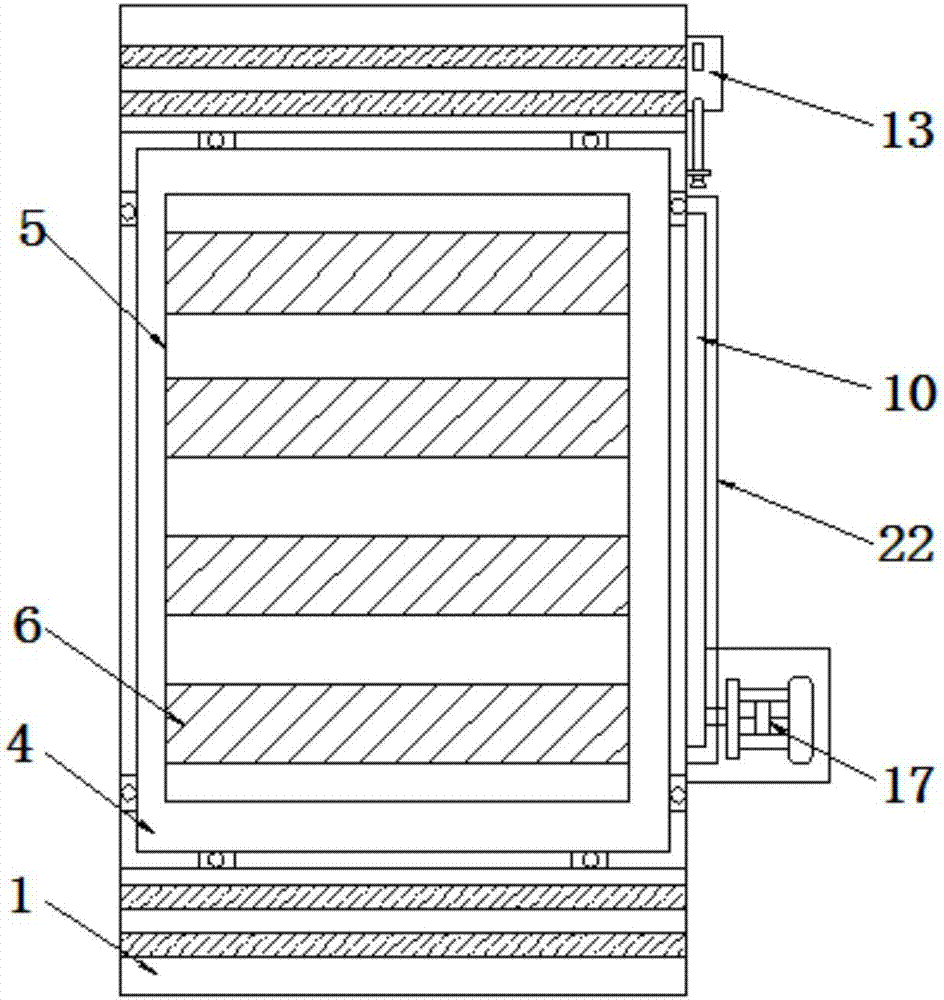

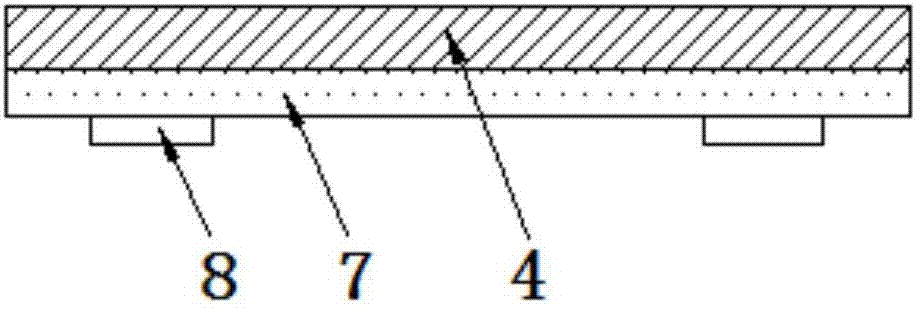

High-precision polishing machine

InactiveCN108466161ASimple structureEasy to useGrinding carriagesPolishing machinesElectric machineryDrive motor

The invention discloses a high-precision polishing machine which comprises a polishing machine body, a sliding rail and polishing wheels; the polishing wheels are arranged at the lower part of the polishing machine body; a servo motor is connected to the polishing machine body; the lower shell of the polishing machine body is in an opening mode; the sliding rail and the polishing machine body arearranged in parallel; a shell of the polishing machine is provided with a polishing wheel regulator; the polishing machine also comprises a clamp walking table, a clamp and a walking table drive motor; the clamp walking table is arranged on the sliding rail and is matched with the sliding rail through a screw rod; the clamp is installed on the clamp walking table through a clamp fixing piece and is arranged on the clamp walking table close to one side of the polishing machine body; the walking table drive motor is arranged on the clamp walking table and on the opposite side of the clamp; and the polishing machine also comprises a control device. The high-precision polishing machine has the beneficial effects that a part can be polished for many times, the sliding rail can perform operations on the part on a preset rail for many times, fine polishing operation can be finished with one person only, simultaneous polishing of multiple parts can be realized, and the polishing efficiency ishigh.

Owner:成都亚沃航空科技有限公司

High-rise stair escape device

InactiveCN113069695AEasy to coverSpeed up the time to go downstairsBuilding rescueCross connectionGear wheel

The invention discloses a high-rise stair escape device. The high-rise stair escape device comprises slow walking tables, stairs, a motor, a connecting rod, a driving bevel gear, a rotating rod, a driven bevel gear and a driving belt wheel, wherein the plurality of slow walking tables are arranged, the plurality of stairs are arranged, and the plurality of slow walking tables and stairs are sequentially connected in a cross mode; the motor is connected to the front side of the top end of the slow walking table located at the topmost end through screws, the front end of the connecting rod is locked to the output end of the motor through a coupler, and the driving bevel gear is connected to the rear side of the outer wall of the connecting rod in a sleeving mode and locked through the coupler; the bottom end of the rotating rod is arranged in the middle portion of the left side of the top end of the slow walking table located at the topmost end through bearings, the driven bevel gear is connected to the middle portion of the outer wall of the rotating rod in a sleeved mode and locked through jackscrews, and the driving bevel gear is meshed with the driven bevel gear; and the driving belt wheel is connected to the bottom of the outer wall of the rotating rod in a sleeved mode and locked. According to the device, the escape efficiency can be improved, the escape time of escape personnel is shortened, and fire losses are reduced.

Owner:温州砼程维禹科技有限公司

Semi-automatic board pushing machine

The invention discloses a semi-automatic board pushing machine. The semi-automatic plate pushing machine is composed of a frame body, a motor, a sliding pushing handle, chain wheels, a chain and a travel switch. According to the machine, the automation degree is high, and the travel switch and the motor are used for driving the sliding pushing handle to automatically push boards to a board connecting walking table one by one and finally the boards are conveyed to related equipment through the board connecting walking table so that the semi-automatic board conveying can be realized, and the requirement for uninterrupted production can be met; automatic and accurate board pushing can also be carried out on the boards with the board surface being uneven and provided with grooves and burr hooks; and the machine is simple in structure, has the remarkable effects of saving energy, saving labor saving and no noise, and is worthy of wide popularization.

Owner:GUANGXI NANNING QIAOSHENG WOOD

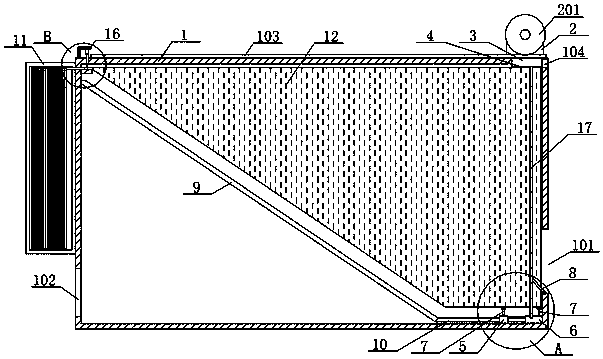

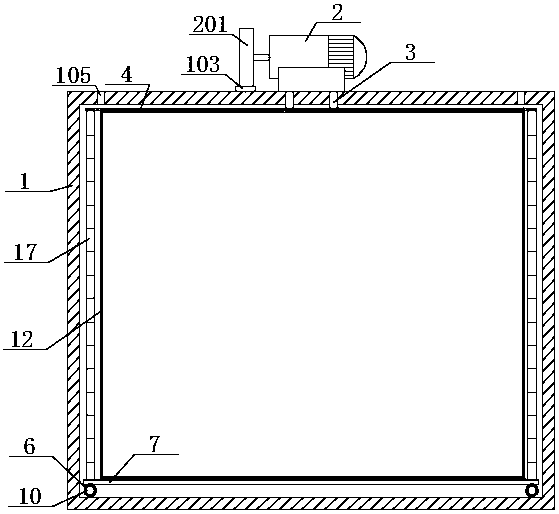

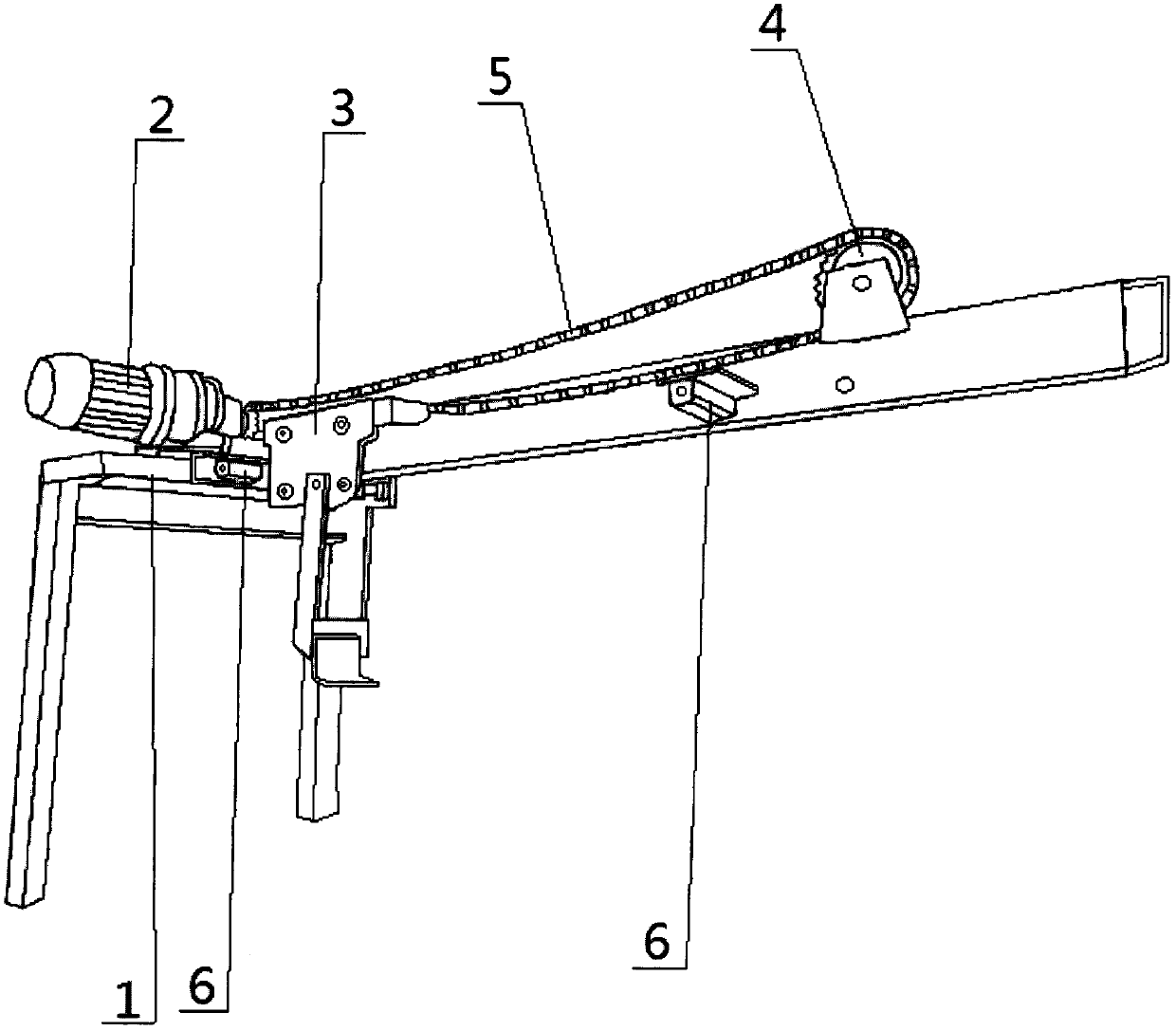

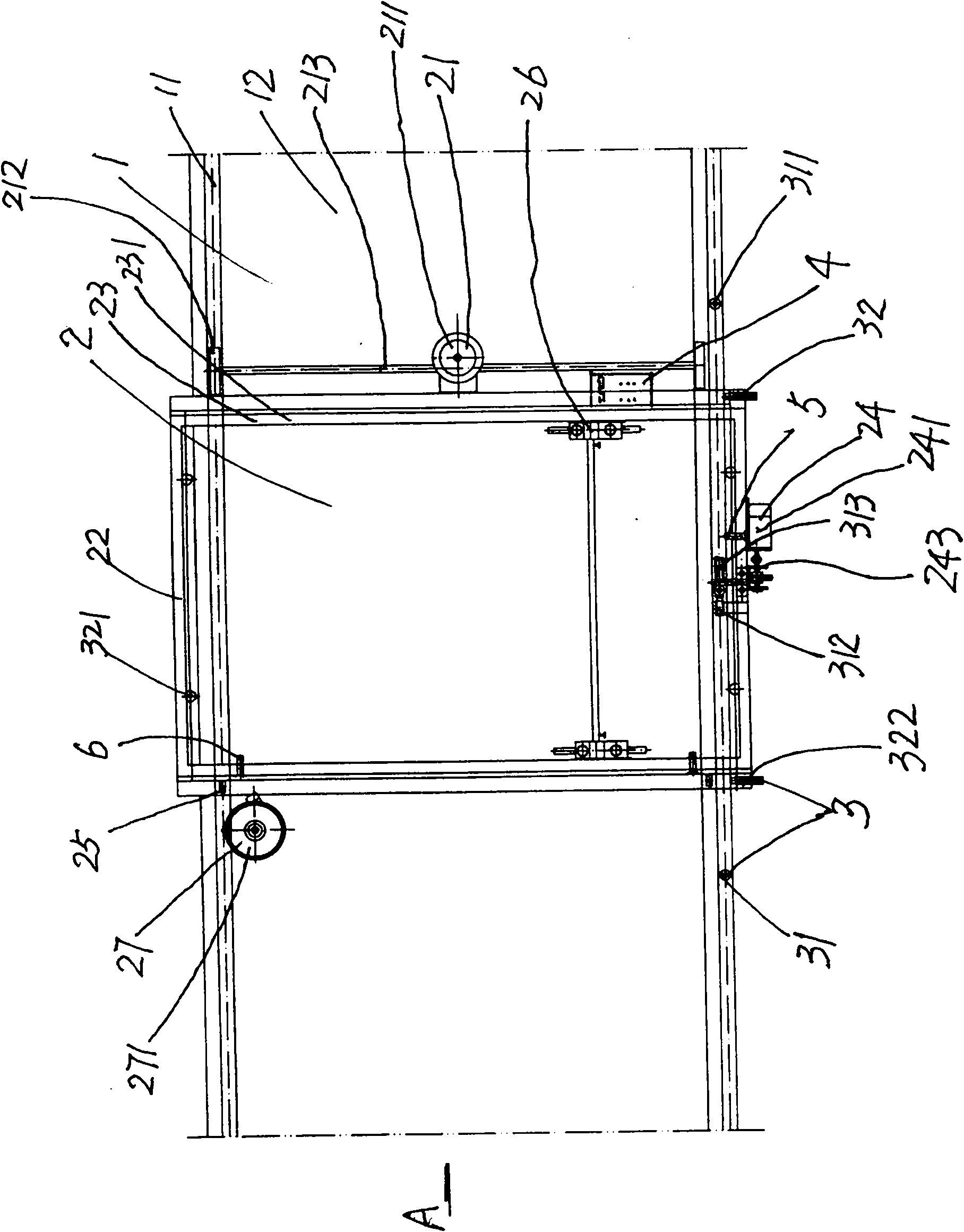

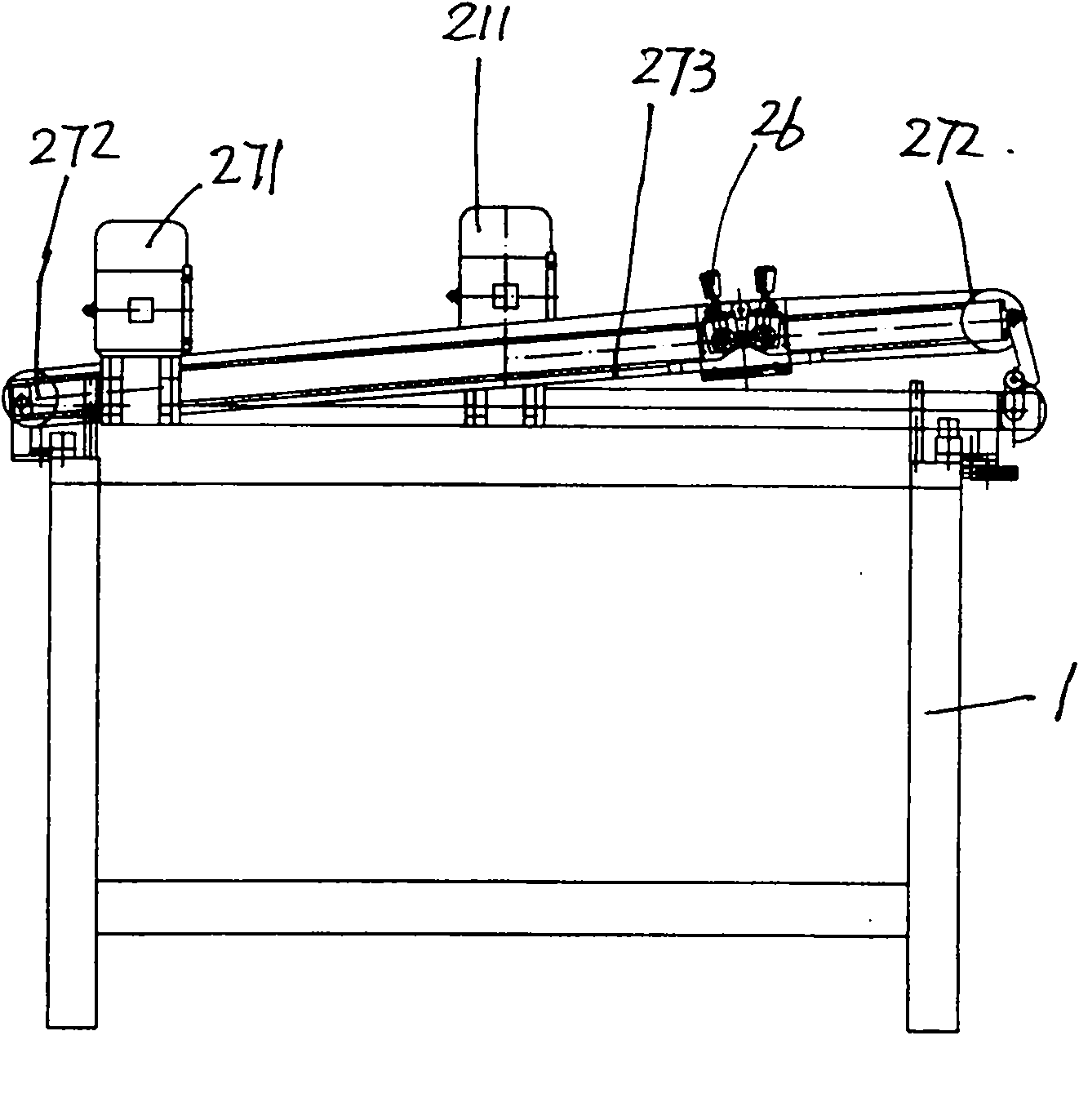

Movable walking board automatic printing machine

ActiveCN102431280BEasy to adjustAvoid obstaclesScreen printersPrinting press partsEngineeringWalking table

The invention relates to a movable walking board automatic printing machine, which consists of a guide rail walking board, a movable printing machine, positioning devices, an electric apparatus control part, a longitudinal sensor and a squeegee sensor, wherein the guide rail walking table is provided with the movable printing machine; the positioning devices are arranged on the guide rail walking board and the movable printing machine respectively; the movable printing machine is provided with the electric apparatus control part; the longitudinal sensor is arranged on the movable printing machine; since the movable printing machine is an automatic printing device which can automatically walk and can be automatically positioned and printed, automation of the overall printing is realized; due to the arrangement of the longitudinal sensing device, when the movable printing machine walks to a printing position, a pre-signal can be obtained and positioning and printing can be performed; since longitudinal and transverse positioning devices, accurate positioning can be realized; since an inner frame can be lifted by an inner frame lifting device, the obstruction of a positioning block can be avoided; and since computer control is adopted and is combined with photoelectric sensing, each work step is coordinate in action and accurate in positioning.

Owner:如皋市天元服饰印业有限公司

Multifunctional decoration mechanical arm device

The invention discloses a multifunctional decoration mechanical arm device. The multifunctional decoration mechanical arm device comprises a walking table, a working head and a mechanical arm, whereina controller is arranged in the middle of the walking table. Supporting legs are arranged at the four corners of the walking table, walking wheels are arranged on the supporting legs, walking motorsare arranged on the walking wheels, the mechanical arm is arranged on the walking table, a rotating arm motor is arranged on the mechanical arm, the top of the mechanical arm is provided with an operating head, an inlet and an outlet are formed in front of the operating head, a supporting frame is arranged in the operating head, a clamping rod is arranged on the supporting frame, a steel wire ropeis arranged behind the clamping rod, and a clamping motor is arranged behind the steel wire rope. The invention has the beneficial effects that the mechanical arm is flexibly rotated, so that the operating head can automatically replace different tools on the walking table, and multiple different decoration operations can be carried out, and meanwhile a handheld control box is arranged, so that the mechanical arm is convenient to operate and control, and the use convenience of the decoration mechanical arm is improved.

Owner:江苏阿尔博装饰工程有限公司

Installation method of coke dry-quenching loading device

ActiveCN101928578BEasy to operateImprove work efficiencyCoke quenchingCharging devicesDesign standardQuenching

The invention relates to the field of metallurgy equipment installation, in particular to an installation method of a coke dry-quenching loading device. The installation method of the coke dry-quenching loading device comprises the following steps: a, installation of elevation and setting of central reference point; b, installation of a water sealed tank on the top of a quenching groove; c, installation and correction of a walking track frame, a walking track and a guiding frame; d, installation of a hopper trolley; e, installation of a hopper; f, installation of a furnace cover trolley; g, installation of a furnace cover; h, installation of a drive device; i, installation of a coke pot fixed support; j, installation of dust-collecting pipeline; k, installation of a walking table, a railing and a ladder; and l, installation of a lubricant device and a pipeline. In the invention, through the strictly-designed standard installation and detection reference, the installation method is simple, safe and reliable and has high work efficiency.

Owner:MCC5 GROUP SHANGHAI CORPORATION LIMITED

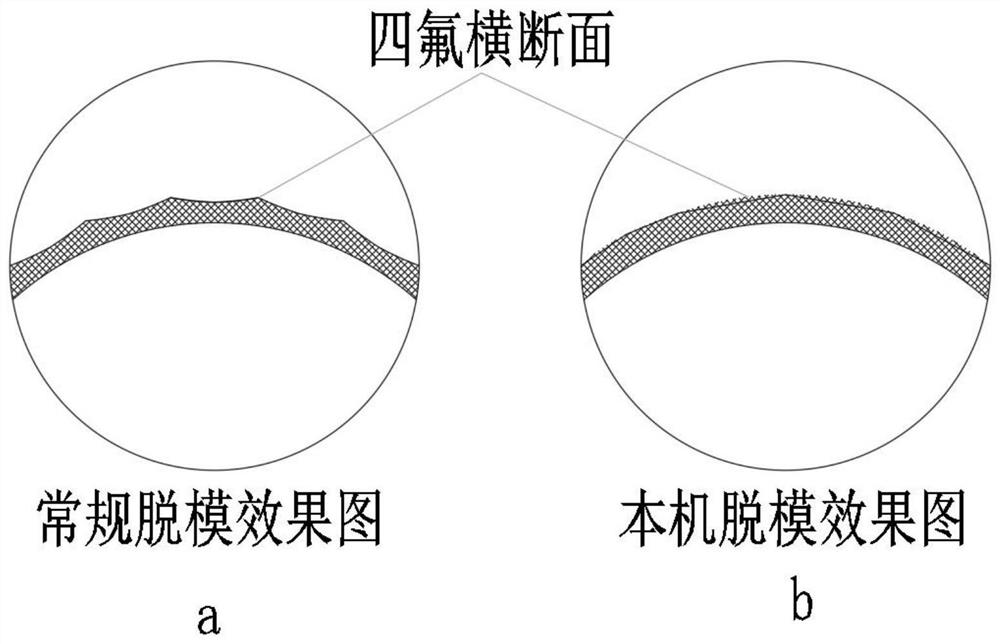

Polytetrafluoroethylene winding and demolding integrated machine

The invention discloses a polytetrafluoroethylene winding and demolding integrated machine. The machine comprises an equipment supporting frame and a polytetrafluoroethylene pipe mold, and is characterized in that a driving device for driving the polytetrafluoroethylene pipe mold to circumferentially rotate relative to the equipment supporting frame is arranged on the equipment supporting frame, and a pneumatic rolling mechanism corresponding to the polytetrafluoroethylene pipe mold in the circumferential direction is further arranged on the equipment supporting frame; the pneumatic rolling mechanism comprises a walking table, a rolling wheel and an air pump, the walking table axially moves relative to the polytetrafluoroethylene pipe mold, the air pump is fixed on the walking table and pushes the rolling wheel to abut against the polytetrafluoroethylene pipe mold, and the extension direction of the central axis of the rolling wheel is parallel to the center of the polytetrafluoroethylene pipe mold. According to the maching, the rolling mode between the rolling wheel and the PTFE pipe is thoroughly changed, so that the finished PTFE pipe with uniform pressure can be directly used, and the problems that the surface of a product produced in the prior art presents tiny edges and corners, and later machining is needed because the product cannot be directly demolded and disappeared are solved; according to the equipment scheme, working procedures, site occupation and cost expenditure are saved.

Owner:温州市氟塑设备制造厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com