Installation method of coke dry-quenching loading device

An installation method and technology of CDQ, applied in charging devices, coke ovens, coke cooling, etc., can solve the problems of unreasonable, complicated and unscientific installation process, and achieve the effect of high operation efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

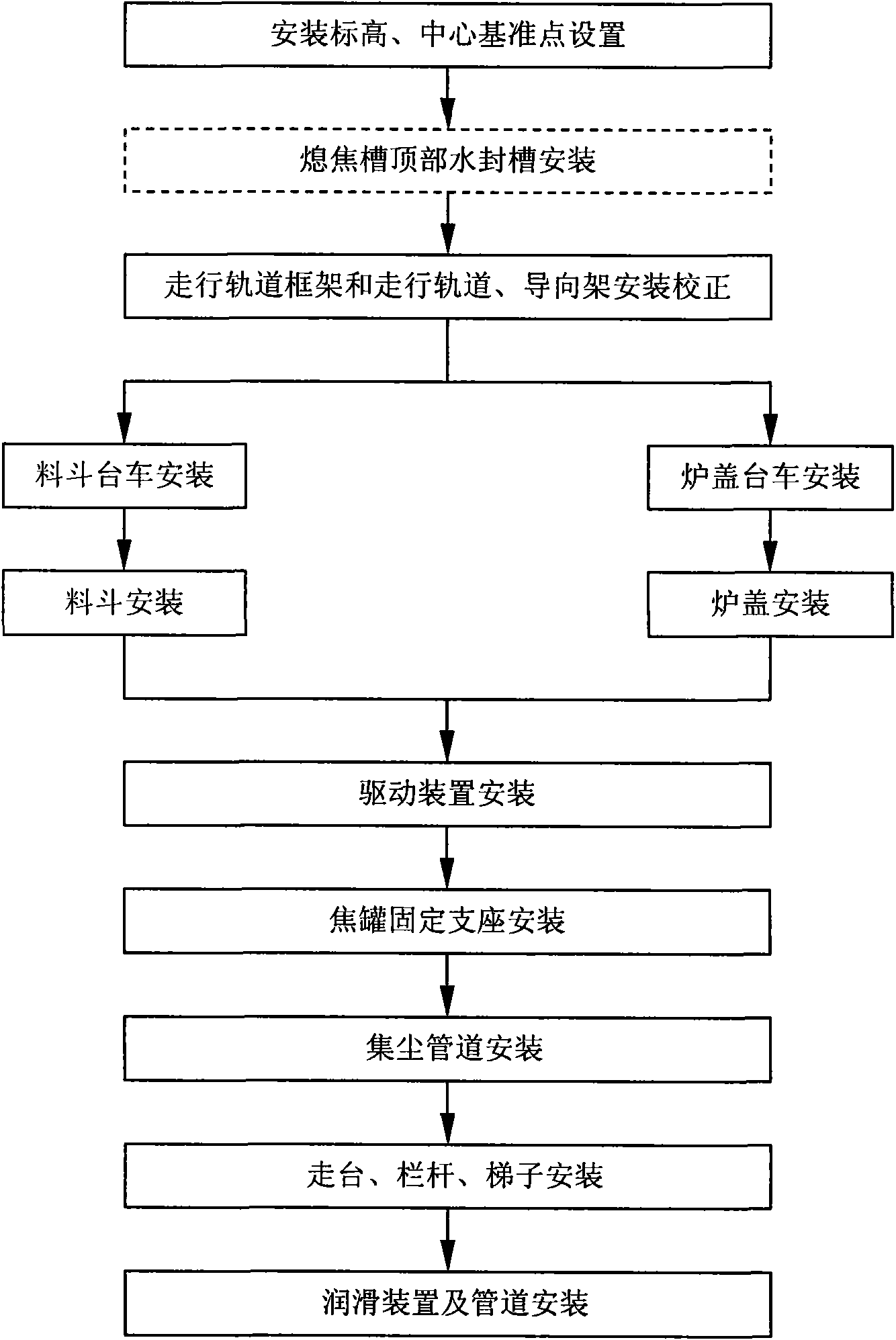

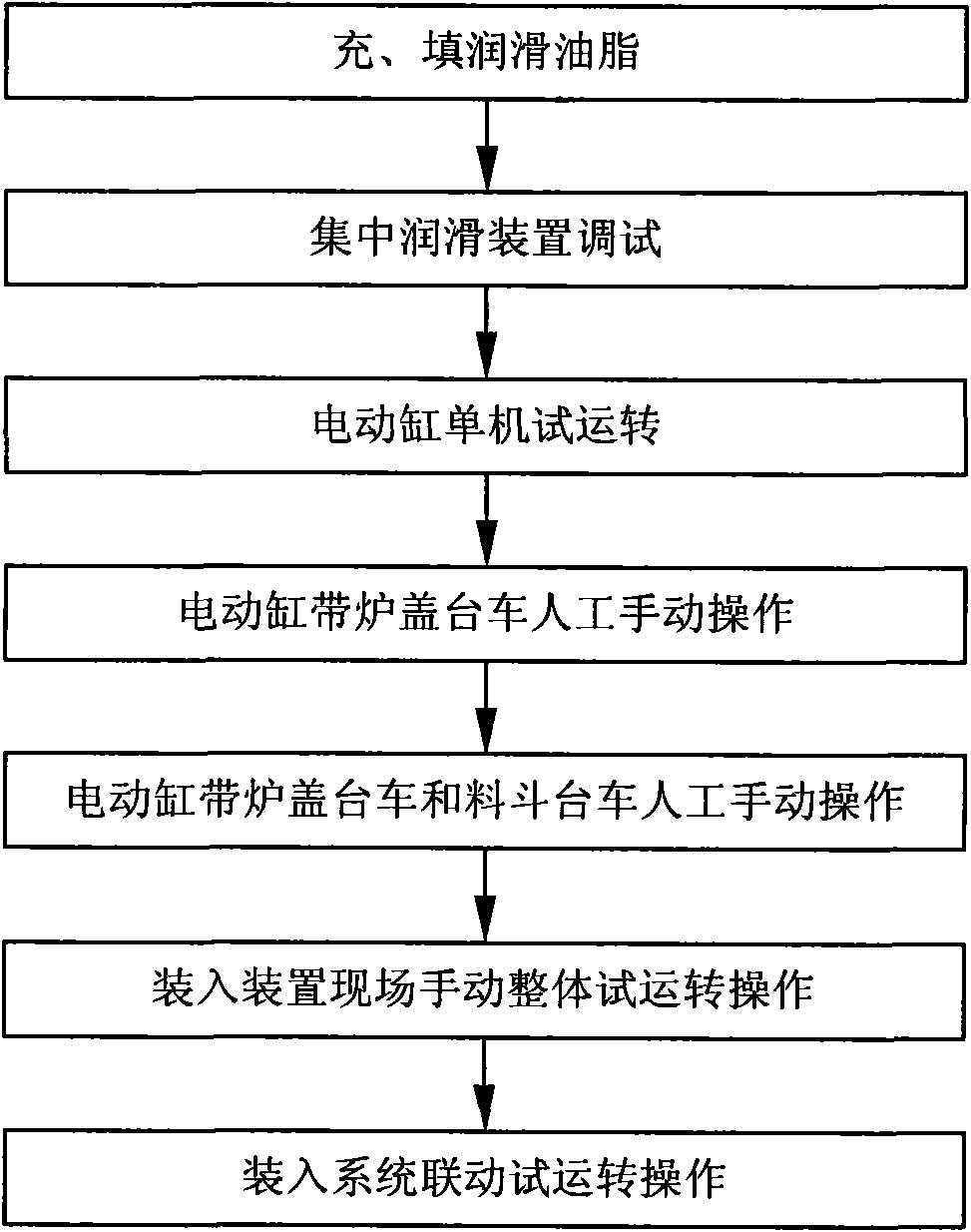

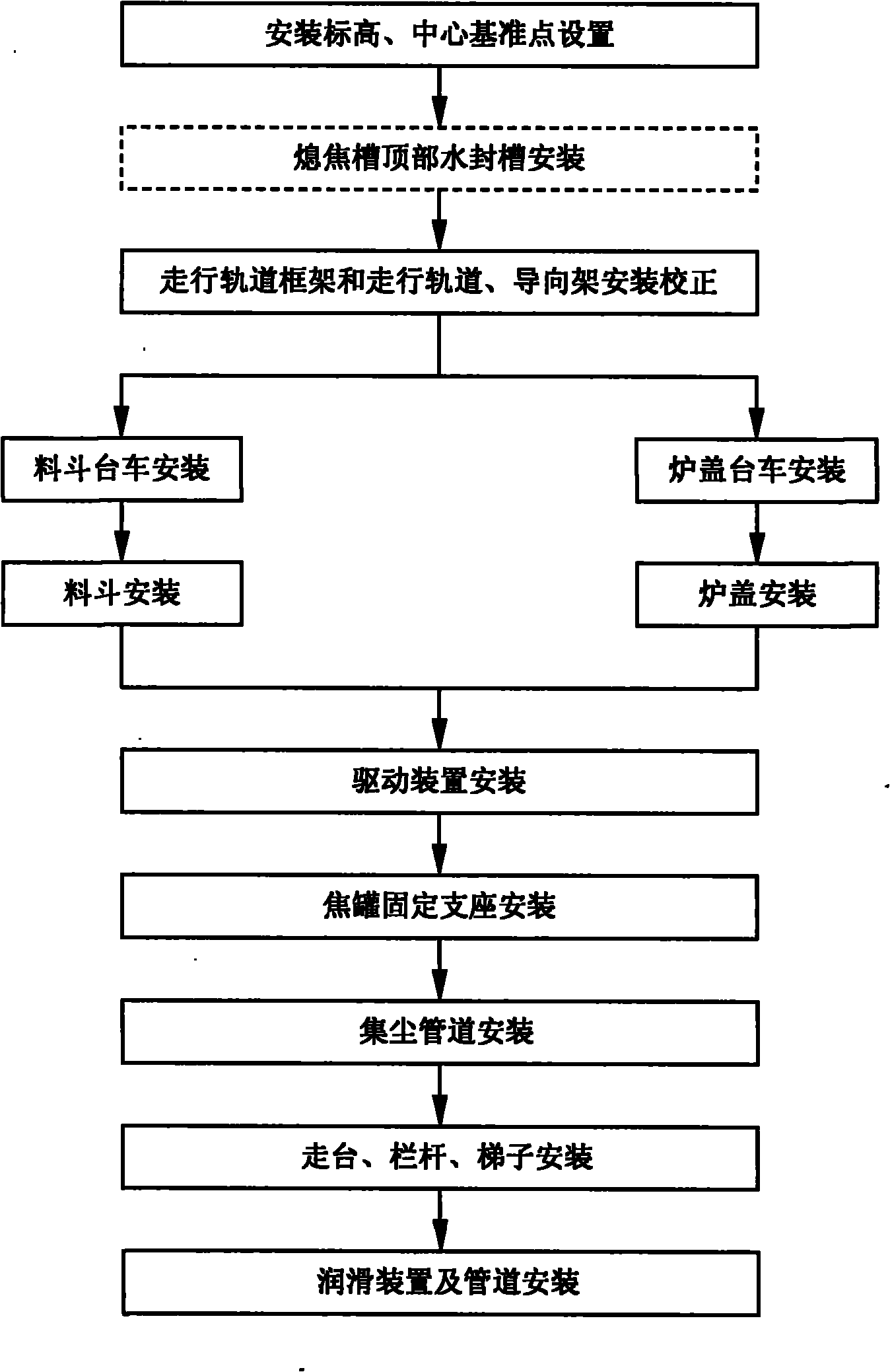

[0028] A method for installing a CDQ loading device, which is carried out in sequence as follows: a. Setting the installation elevation and center reference point, b. Installing the water seal tank on the top of the coke quenching tank, c. Installing the running track frame, running track, and guide frame Calibration, d. Installation of hopper trolley, e. Installation of hopper, f. Installation of furnace cover trolley, g. Installation of furnace cover, h. Installation of driving device, i. Installation of coke tank fixed support, j. Installation of dust collection pipe, k. Walking platform, railing, ladder installation, l. Lubricating device and pipeline installation.

[0029] Complete the following construction preparations before installation:

[0030] 1 The installation drawing of CDQ loading device and the equipment installation and operation instructions are ready.

[0031] 2 The factory assembly inspection records and test run records of the loading device are complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com