Patents

Literature

68results about How to "Strong concave and convex" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

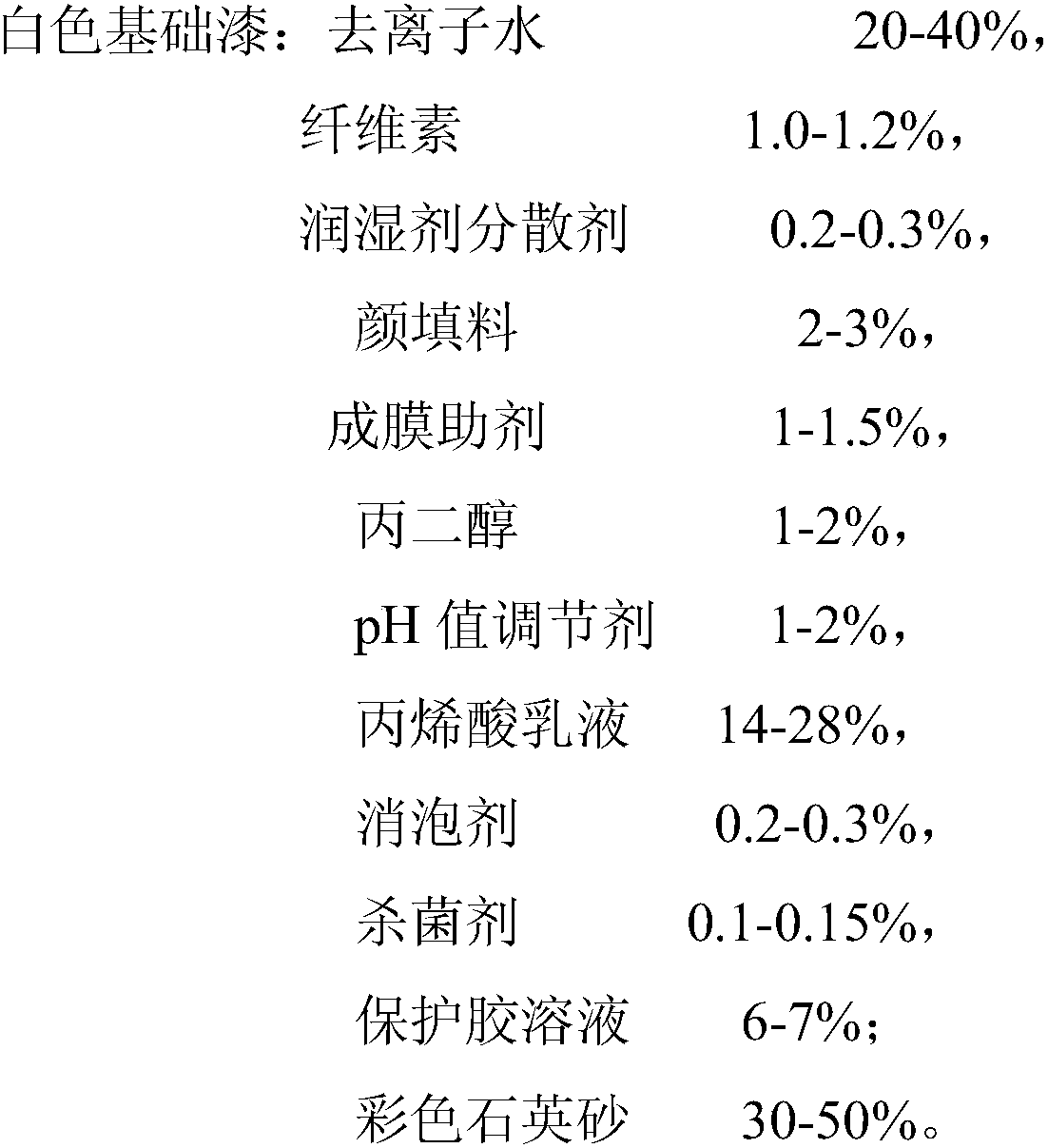

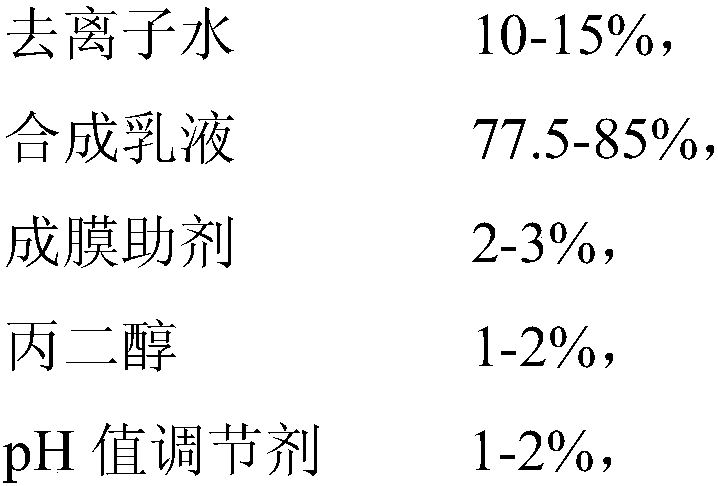

Novel vacuum sieved sand-in-water multicolor paint and preparation method thereof

The invention discloses a novel vacuum sieved sand-in-water multicolor paint and a preparation method thereof. The novel vacuum sieved sand-in-water multicolor paint comprises the following componentsby mass percentage: 40-50% of a disperse phase toning base paint, 30% of continuous phase varnish, and 20-30% of a protective glue solution. The paint film provided by the invention has strong concavo-convex feel, rich color, high simulation degree and high color retention after drying.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Artistic powder paint of mottle effect

InactiveCN1715348ARich sourcesLow priceArtist's paintsPolyurea/polyurethane coatingsMaterials sciencePigment

The artistic powder paint with mottle effect is prepared with resin and its curing system, deairing agent, flow assistant, pigment, stuffing, mottle agent, effect pigment, powder flow promoter, and through preparing base material with the first mentioned five materials, adding the other materials, dry mixing, and sieving. The artistic powder paint of the present invention has no toxicity, no pollution, high use effect and reasonable cost.

Owner:XUZHOU ZENITH COATING

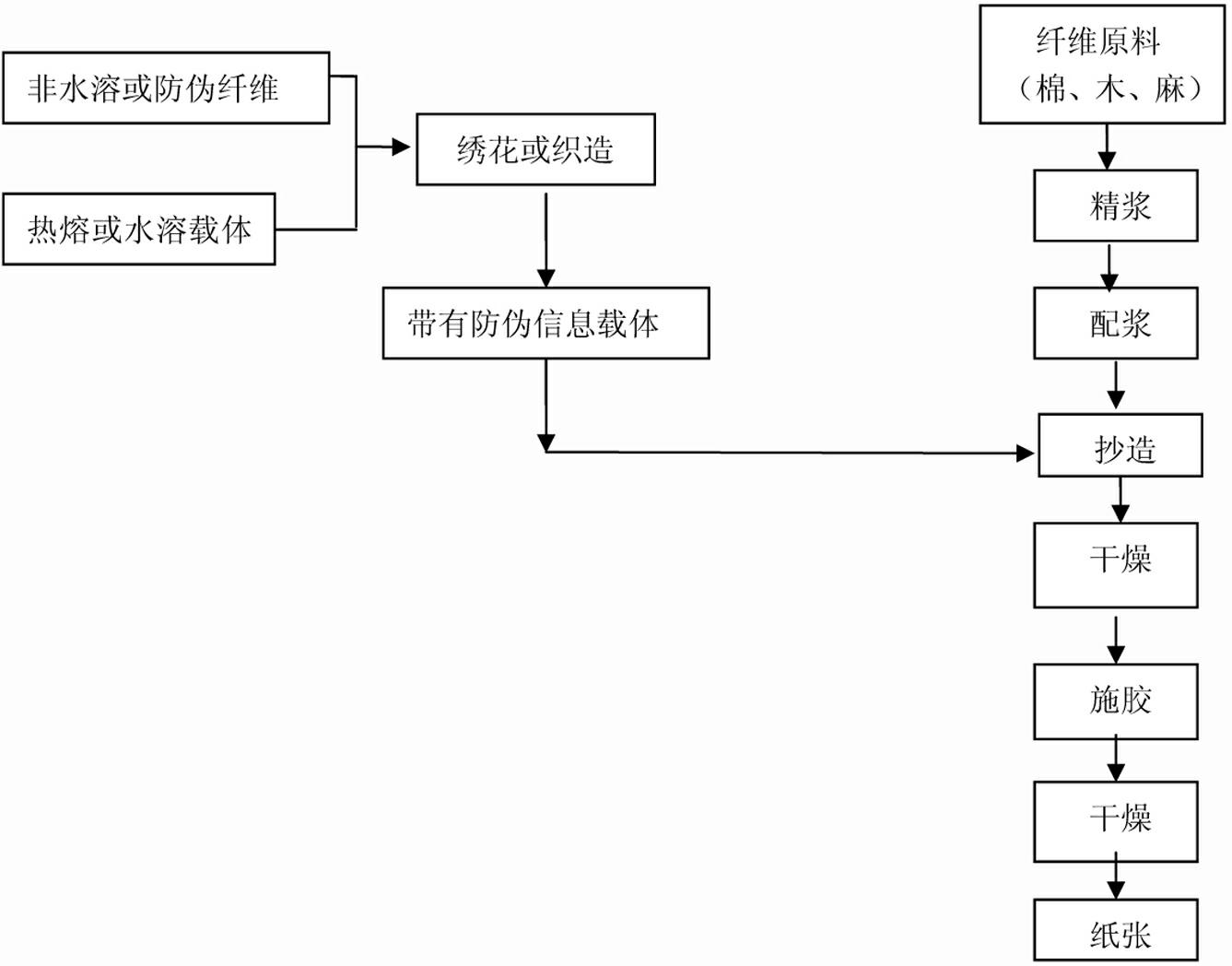

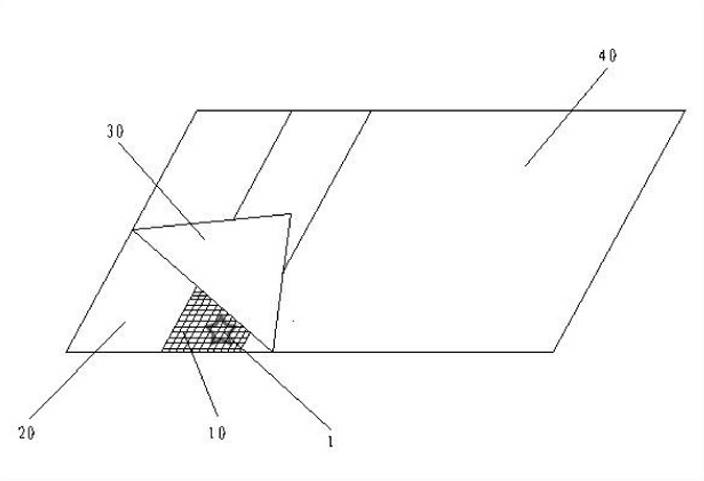

Multiple anti-counterfeit watermark paper and manufacturing method thereof

ActiveCN102191722ACompatible with and strengthen the concave-convex feelingDifficult to forgeNon-fibrous pulp additionFiberPhotoluminescence

The invention relates to multiple anti-counterfeit watermark paper and a manufacturing method thereof. The watermark paper is provided with patterns, figures or lines which are woven or embroidered by non-water-soluble fibers or anti-counterfeit fibers; and the paper has rich levels and a concavo-convex touch feel under transmission light. A film, non-woven fabric or woven fabric made from a water-soluble material or a hot-melting material is used as a carrier, so that the patterns, the figures or the lines are woven or embroidered on the carrier by using the non-water-soluble fibers or the anti-counterfeit fibers; and the carrier with the patterns, the figures or the lines is released in front of a paper machine net through a positioning and releasing device so that the carrier is combined with paper. Compared with the conventional watermark, the patterns, the figures or the lines of the watermark paper are more fine and smooth; meanwhile, during processing of the patterns, the anti-counterfeit fiber loaded with one or more pieces of anti-counterfeit information (such as fluorescence, color, temperature variation, photoluminescence, magnetism and the like) is adopted; therefore, the watermark is integrated with vision, touch and multiple anti-counterfeit effects of the anti-counterfeit material as well as combination of the vision, the touch and the multiple anti-counterfeit effects.

Owner:BAODING BANKNOTE PAPER CO LTD +1

Ceramics laser engraving process

InactiveCN104552578AAccelerateImprove yieldDecorative surface effectsCeramic shaping apparatusCeramicMaterials science

The invention relates to a ceramics laser engraving process. A ceramic base or ceramic piece is engraved with patterns by the laser technology; a ceramic product having high stereoscopic impression, clear layering, clear texture, bright color and rich beauty is produced by glazing, kiln-charging and burning; the ceramic product is well worthy of application and collection. The traditional manual engraving is replaced by laser processing, engraving speed is high, yield is high, quality is good, productivity is greatly improved, manpower is saved, energy is saved, and consumption is reduced. The modern laser technology is combined with the traditional ceramic process to produce the delicate ceramic product; the ceramics laser engraving process is a novelty in the production of crafts ceramics and has promising popularization prospect.

Owner:谢开强

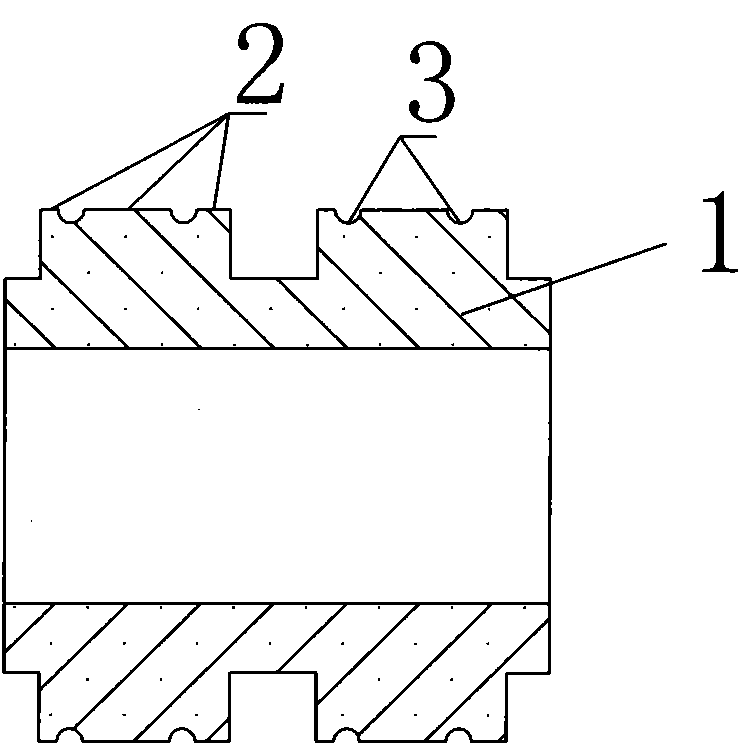

Rotary gold stamping embossing one-step forming version

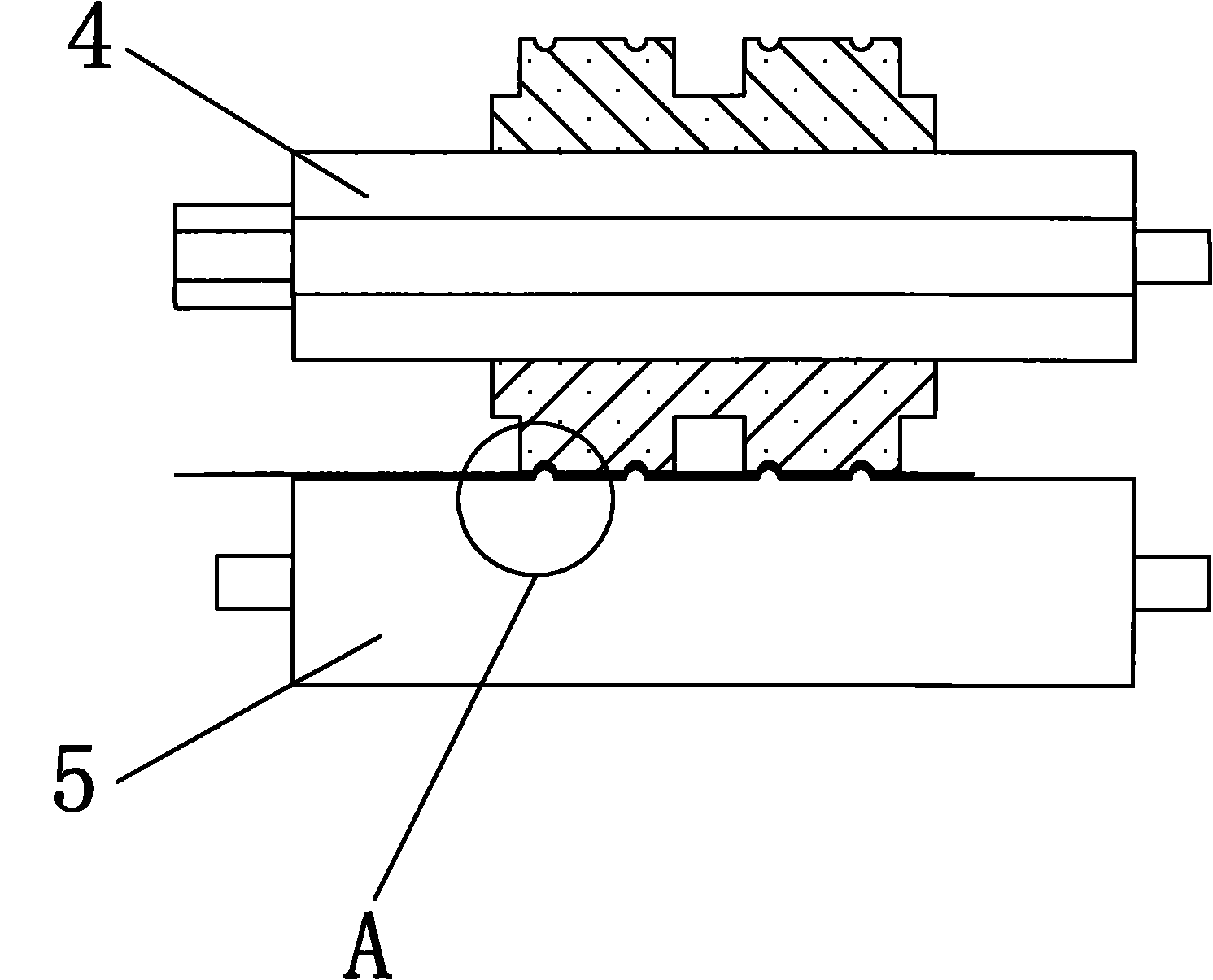

InactiveCN101804723AReduce production processImprove efficiencyBronze printingRotary pressesBobbinEngineering

The invention provides a rotary high-precision gold stamping embossing one-step forming version applied in the field of cork paper bobbin production; the version can realize the gold stamping embossing one-step forming; a gold stamping pattern and an embossing pattern have no dislocation and weakly depends on equipment personnel; the produced products have dazzlingly beautiful colors, clear impressions and accurate patterns and can be preserved for a long time; and the version can greatly increase the production efficiency and realize the purpose. The invention adopts the following technical scheme that the rotary high-precision gold stamping embossing one-step forming version comprises a rubber covered roller, a rolling wheel, a pattern needing to be embossed and installing shafts at two ends and is characterized in that embossing patterns are arranged on the gold stamping embossing version and gold stamping pattern surface of the contact surface of the rubber covered roller; and the depth of the embossment pattern arranged on the gold pattern surface is 20 mum to 50 mum.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

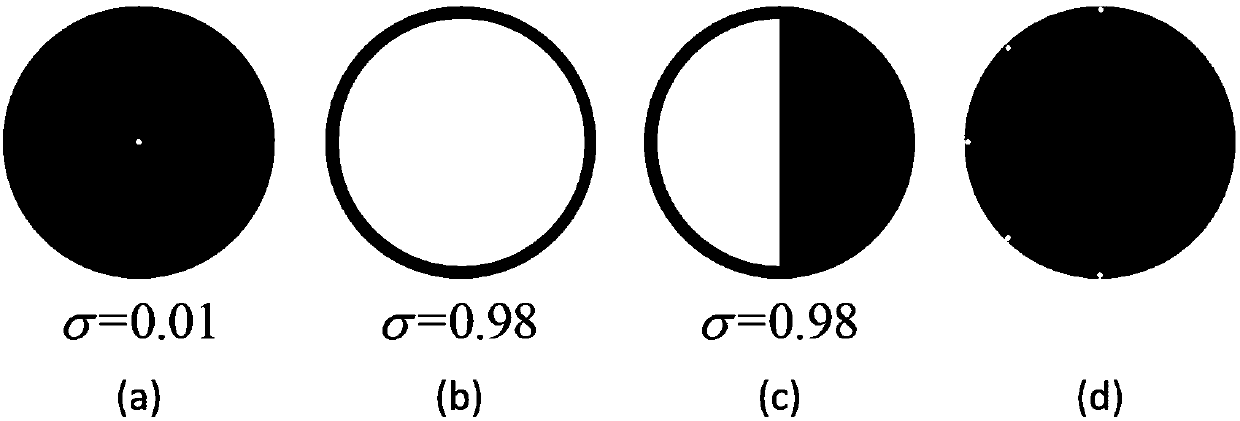

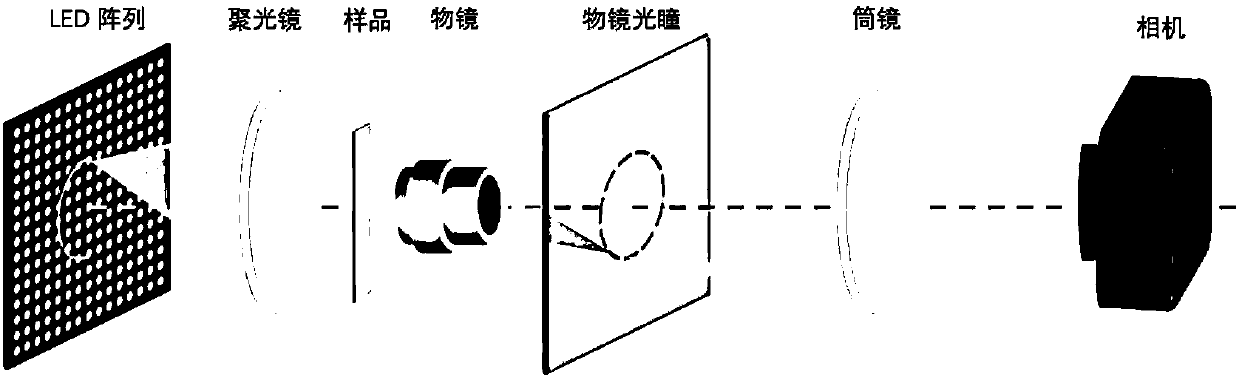

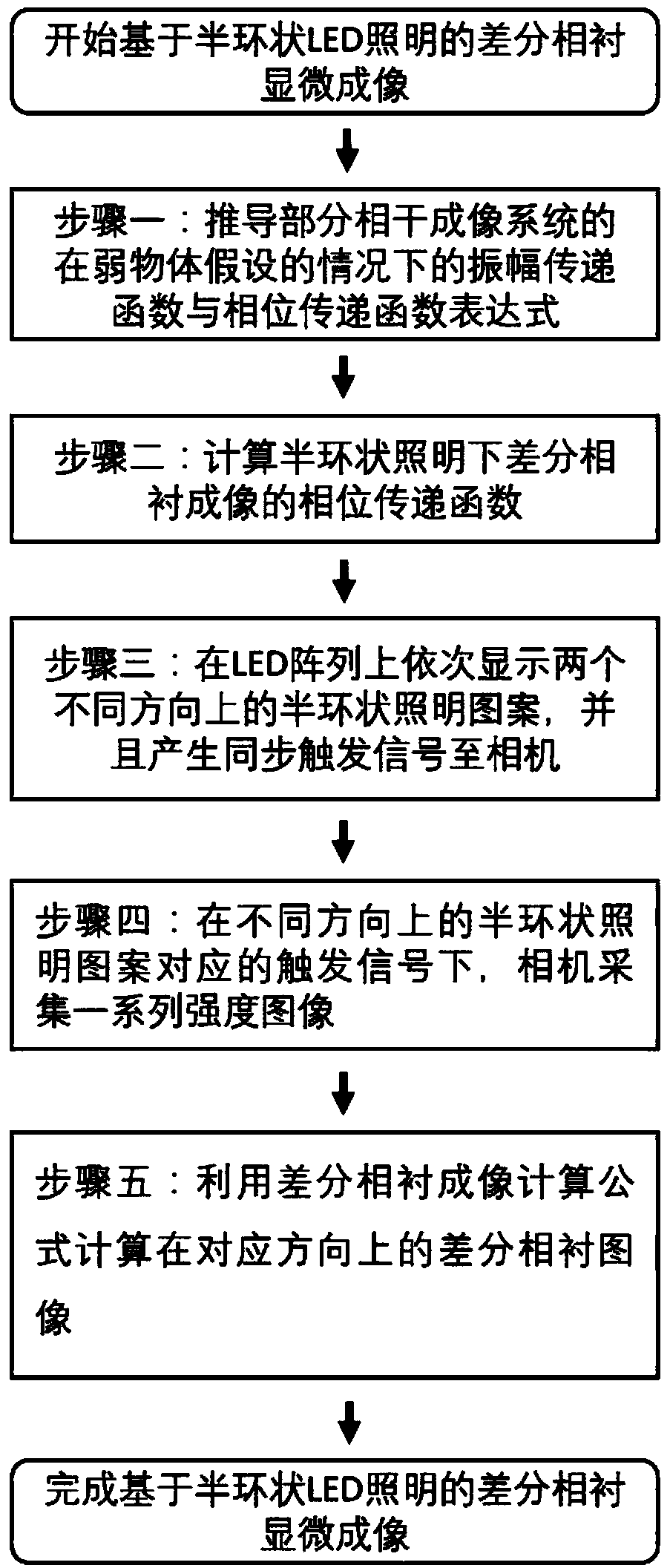

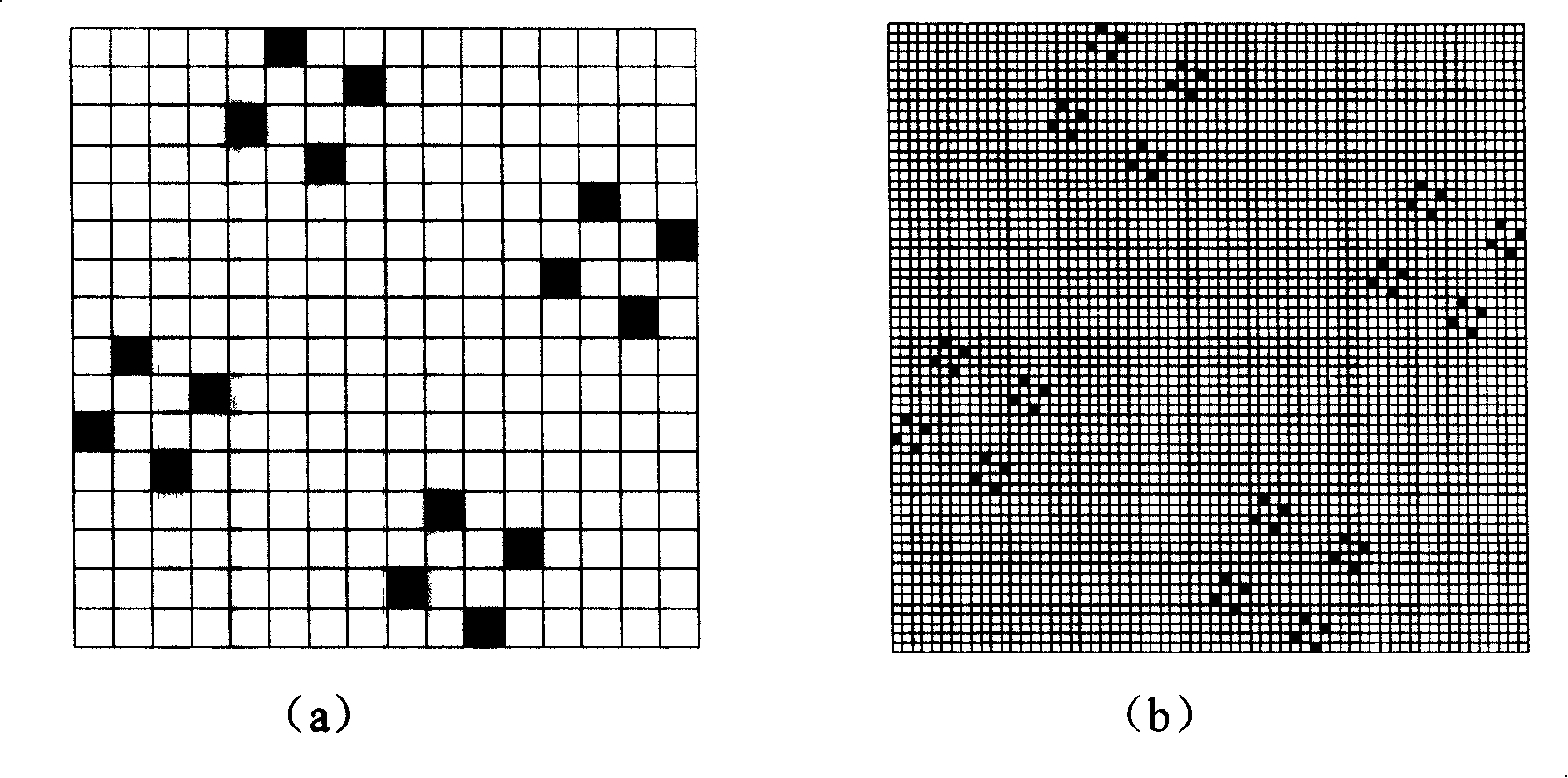

Differential phase contrast microscope imaging method based on half-ring-shaped LED lighting

ActiveCN107272178AStrong concave and convexGuaranteed image qualityMicroscopesLed arrayImaging quality

The present invention discloses a differential phase contrast microscope imaging method based on half-ring-shaped LED lighting. Firstly weak object approximation is used, and an optical transfer function expression of a weak object in a partial coherent illumination imaging system is deduced. A phase transfer function of differential phase contrast imaging in half-ring-shaped illumination is calculated. Two ring-shaped illumination patterns in different directions are orderly displayed on an LED array, and a synchronous triggering signal is generated and sent to a camera. The ring-shaped illumination pattern changes are changed, a synchronous triggering signal is generated and sent to the camera, in triggering signals corresponding to the ring-shaped illumination patterns in different directions, the camera collects a series of intensity images. Differential phase contrast images in different directions can be calculated by a differential phase contrast imaging calculation formula, and thus the differential phase contrast imaging can be realized in up, down, left and right directions and all different directions. According to the method, the low frequency of a low phase in a differential phase contrast image can be improved, thus the concave and convex sense of the differential phase contrast image is strong, and the imaging quality of the image is enhanced.

Owner:NANJING UNIV OF SCI & TECH

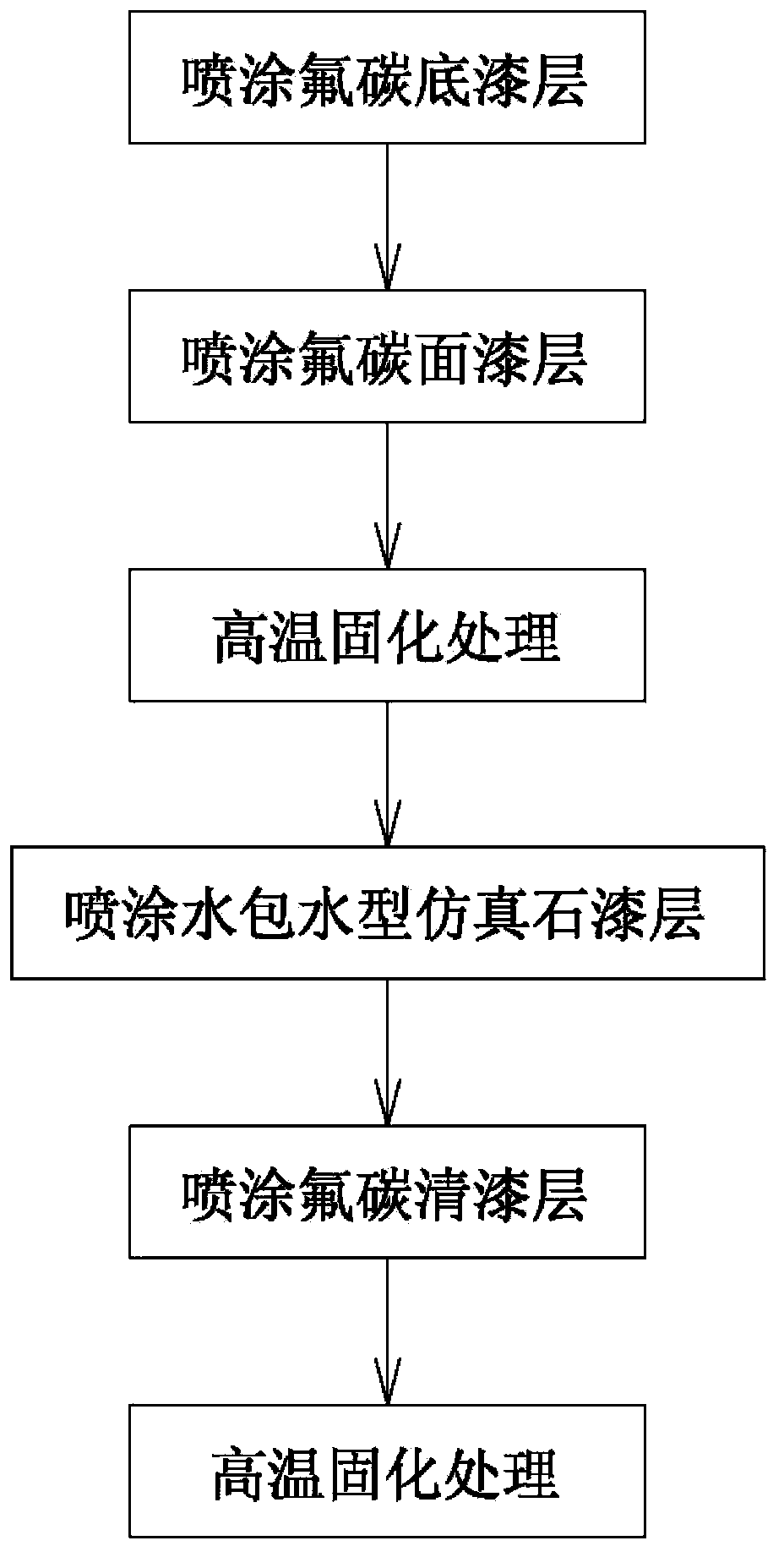

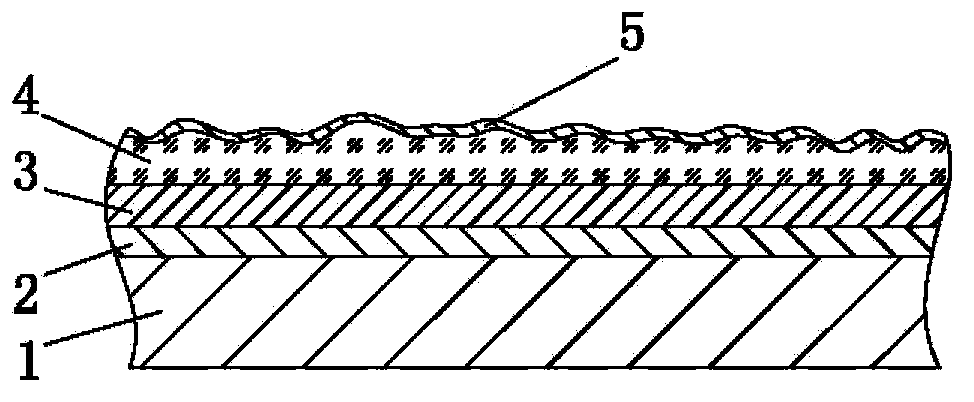

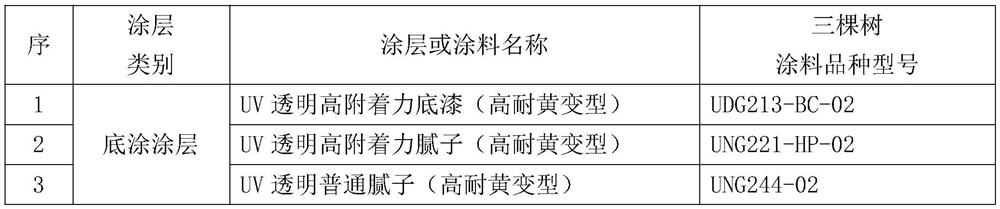

Three-dimensional fluorocarbon simulation mineral varnish aluminum veneer manufacturing technology and aluminum veneer thereof

ActiveCN103394453AHigh degree of simulationRich three-dimensional senseCovering/liningsPretreated surfacesThree dimensional simulationManufacturing technology

The invention discloses a three-dimensional fluorocarbon simulation mineral varnish aluminum veneer manufacturing technology. The three-dimensional fluorocarbon simulation mineral varnish aluminum veneer manufacturing technology comprises the steps of spraying a fluorocarbon base coating, spraying a fluorocarbon facial coating, carrying out high-temperature solidification treatment, spraying a water-in-water type simulation mineral varnish layer, spraying a fluorocarbon varnish layer, and carrying out solidification treatment. The invention discloses aluminum veneer at the same time. The aluminum veneer comprises an aluminum base plate, the fluorocarbon base coating, the fluorocarbon facial coating, the water-in-water type simulation mineral varnish layer and the fluorocarbon varnish layer, wherein the surface of the water-in-water type simulation mineral varnish layer and the surface of the fluorocarbon varnish layer are uneven. According to the aluminum veneer and the three-dimensional fluorocarbon simulation mineral varnish aluminum veneer manufacturing technology, water containing ingredients in water-in-water multicolor paint are utilized ingeniously, the characteristics that the water multicolor paint is boiled and evaporated in high temperature are utilized, and thus an extreme good uneven three-dimensional simulation mineral varnish effect is formed in the surfaces of plates through unique paint distribution and a solidification technology. Meanwhile, the weather-proof, self-cleaning, easy cleaning, outdoor gloss loss free advantages of fluorocarbon paint are combined.

Owner:SHANGHAI YARET IND GROUP

Artificial leather for leather carving and manufacturing method thereof

The invention provides artificial leather for leather carving and a manufacturing method thereof. The artificial leather for the leather carving comprises a layer capable of being wiped, a protective layer, a PU foamed layer, a side stretch knitted fabric layer and a setting layer which are sequentially fit from outside to inside. Decorative patterns are formed on the outer surface of the protective layer. The layer capable of being wiped is mainly used for a leather carving product with an antiquing effect. The artificial leather for the leather carving has the advantages that the side stretch knitted fabric is adopted as a base, so that the artificial leather has extensibility in radial direction and weft direction and is applicable to a leather carving product with strong concavo-convex sense; and the setting layer is added on the back, so that setting property of the leather carving can be guaranteed.

Owner:DADI FUJIAN TECH

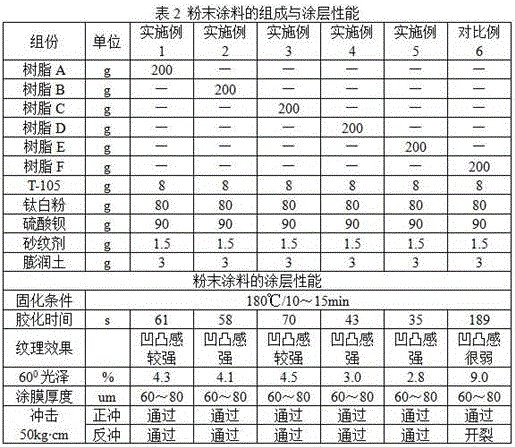

HAA solidified polyester resin for sand streak powder coating and preparation method thereof

InactiveCN106543418AClear sand textureLow glossPowdery paintsPolyester coatingsGlass transitionMechanical property

The invention discloses HAA solidified polyester resin for sand streak powder coating. The acid value is 20-25mg KOH, 200DEG C viscosity is 9000-15000mPa.s, and glass-transition temperature is 60-70 DEG C; the polyester resin is prepared by the following components in parts by weight from a melt phase polycondensation reaction: 30-40 parts of dihydric alcohol, 50-60 parts of aromatic diacid, 0.2-2.0 parts of polyol, 3-8 parts of an acidolysis agent, and 0.1-0.2 parts of a catalyst for esterification. The invention discloses a preparation method of polyester resin. The sand streak powder coating prepared by the polyester resin has the advantages of good sand streak forming effects, clear sand streak texture, good concavo-convex sense, and excellent mechanical properties of film; and the powder coating can be widely applied to coating in the fields of apparatus and instrument, power distribution cabinet, antitheft door, metal toy, household electrical appliance, furniture, decorative lighting, and the like.

Owner:GUANGZHOU KINTE IND

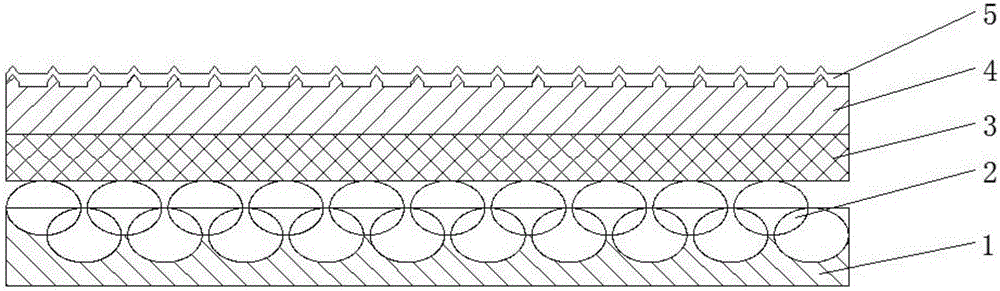

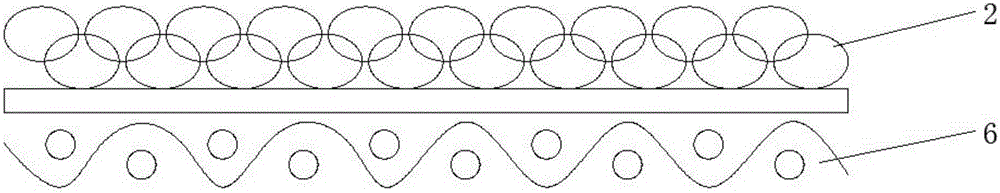

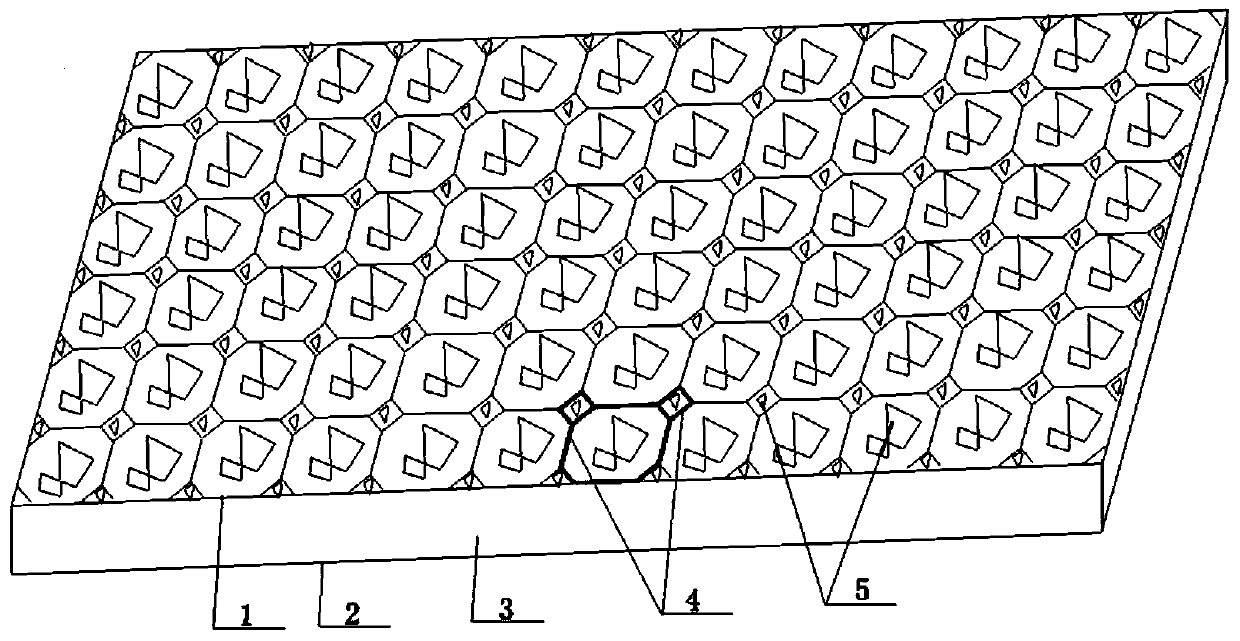

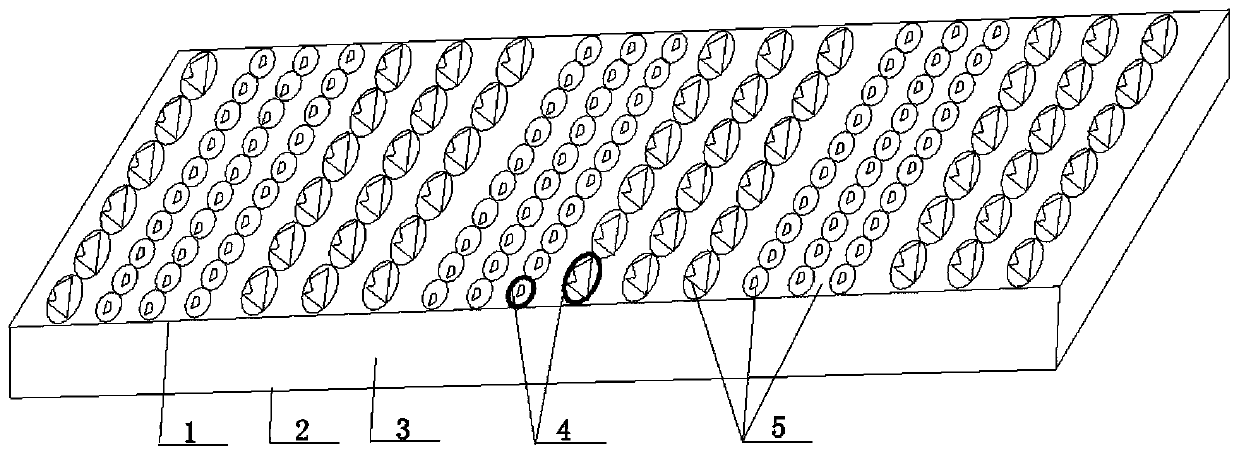

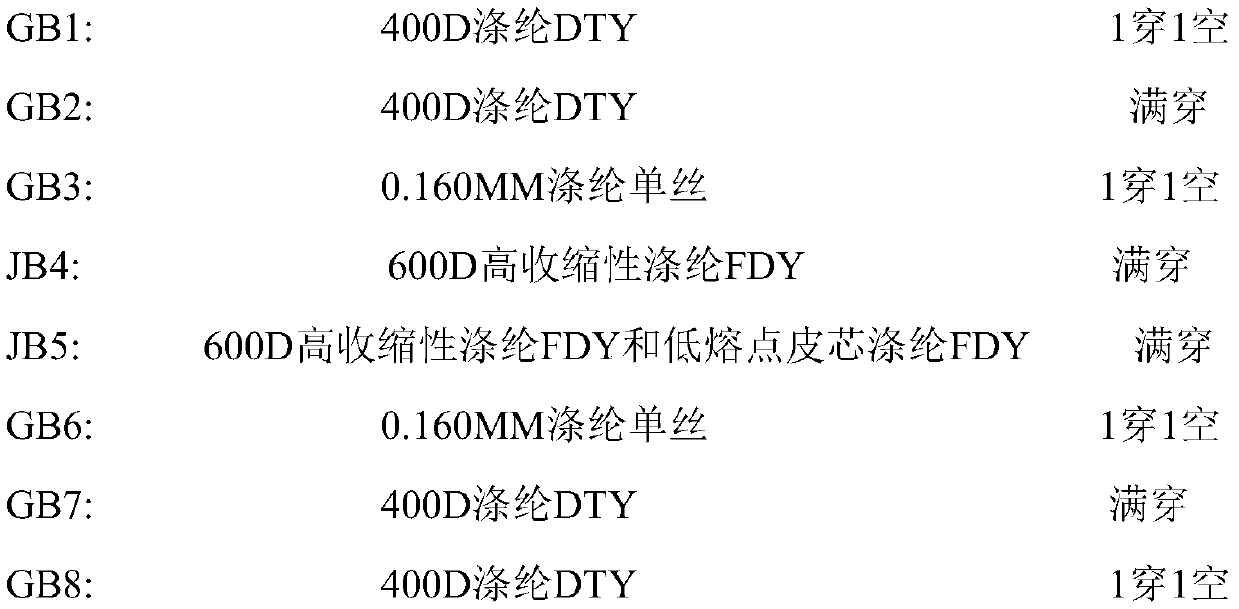

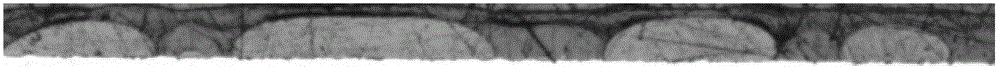

Thick warp-knitted spacer-fabric three-dimensional quilted mattress cover material and preparation method thereof

ActiveCN109898227AReduce production processShorten the production cycleWarp knittingHeating/cooling textile fabricsYarnBiomedical engineering

The invention discloses a thick wrap-knitted spacer-fabric three-dimensional quilted mattress cover material and a preparation method thereof. The cover material is provided with two jacquard combs and six floor combs, the comb bar arrangement from the front to the back of the machine is that GB1 and GB2 are only woven in the front needle bed, GB3, JB4, JB5 and GB6 are successively woven in a circle on the front and back needle beds, and GB7 and GB8 are only woven on the back needle bed; GB1 and GB2 pierce first and second system yarn, and GB7 and GB8 pierce the seventh and eighth system yarn; GB3 and GB6 pierce the third and sixth system yarn; JB4 and JB5 pierce the fourth and the fifth system yarn. The preparation method includes that the GB1 and the GB2 pierce the first and second system yarn in a full or empty manner; the GB7 and the GB8 pierce the seventh and eighth system yarn in a full or empty manner; the GB3 and the GB6 pierce the third or sixth system yarn in a full or empty manner; the JB4 pierces the fourth system yarn in a full manner, and the JB5 pierce the fifth system yarn in a full manner; woven fabric is thermally finished.

Owner:福建福联精编有限公司

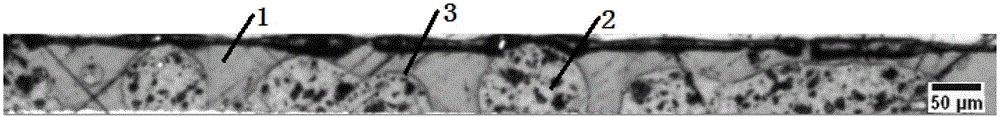

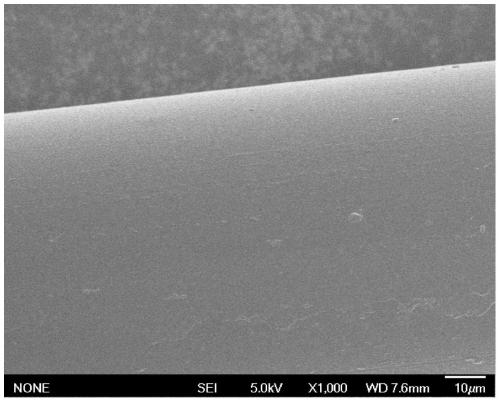

Secondary anodic oxidation treatment method used for aluminum alloy and capable of forming grain boundary pattern

InactiveCN107747115AStrong concave and convexRich color combinationAnodisationAlloy substrateGrain boundary

The present invention provides a secondary anodic oxidation treatment method used for an aluminum alloy and capable of forming a grain boundary pattern. The secondary anodic oxidation treatment methodcomprises: a, first polishing: polishing the surface of an aluminum alloy substrate, and cleaning; b, grain boundary etching; c, first anodic oxidation; d, second polishing: polishing the substrate,and cleaning, wherein the anodic oxidation film on the surface is uniformly removed, the bottom layer substrate is barely exposed, and the oxidation film on the inner wall of the concave groove of thegrain boundary is retained; and e, second anodic oxidation: carrying out second anodic oxidation treatment on the substrate, wherein a layer of an oxidation film with a required color is formed on the substrate surface area excluding the concave groove of the grain boundary, ie., the grain surface. According to the present invention, by adjusting the related molding process parameters, the grainsize of the material can be subjected to controlled distribution while the sizes and the shapes of each grain are different, such that the whole pattern is unique.

Owner:CHANGHONG PRECISION TOOL DONGGUAN CO LTD

Metal alike art type powder coating and preparation method thereof

ActiveCN103146288ACorrosion resistanceWith destructionPolyurea/polyurethane coatingsEpoxy resin coatingsFluorocarbonParticle system

The invention belongs to the field of a powder coating and particularly relates to a metal alike art type powder coating. The metal alike art type powder coating comprises an epoxy resin particle system and a fluorocarbon resin particle system, wherein the epoxy resin particle system contains epoxy resin, an adaptive curing agent A and a flatting agent A; the fluorocarbon resin particle system contains fluorocarbon resin, an adaptive curing agent B and a flatting agent B; and the weight part ratio of the epoxy resin particle system to the fluorocarbon resin particle system is (6-4):(4-6). According to the metal alike art type powder coating, the incompatibility of the flatting agent, the epoxy resin and the fluorocarbon resin is utilized for controlling the distribution the flatting agent, the epoxy resin and the fluorocarbon resin in coating layers, so that the flatting agent is evenly dispersed between the epoxy resin layer and the fluorocarbon resin layer to generate a visual effect of alternative dark and bright, and then a metal alike effect is achieved.

Owner:NINGBO SOUTH SEA CHEM

Multi-color three-dimensional laminated foaming printing method for textile fabric

InactiveCN107227637ARich color variationStrong concave and convexDyeing processColor printingPulp and paper industry

The invention discloses a multi-color three-dimensional laminated foaming printing method for a textile fabric. Foaming pulp and elastic white glue pulp are added in printing pulp; water and thickening agents are added for regulating the pulp to the proper concentration and thickness; an automatic walking table plate printing machine and multi-color printing are used; after the printing of one color, the cloth is subjected to primary baking by a medium-temperature baking oven; then, the next color is printed; after the printing, the proper-temperature baking is performed by a high-temperature baking oven, so that foaming pulp foams; the patterns left on the cloth surface can show the three-dimensional laminated raised effect; the multi-color three-dimensional laminated printing is used; the concave-convex effect is strong; the pattern color change is rich; the strong three-dimensional laminated raised effect is shown; the color of the multi-color foaming slurry can be freely regulated; mutual combination can be realized; the pattern design is richer; in addition, the attaching degree with the cloth is good; falling cannot easily occur through scratching.

Owner:绍兴柯桥立桐布业有限公司

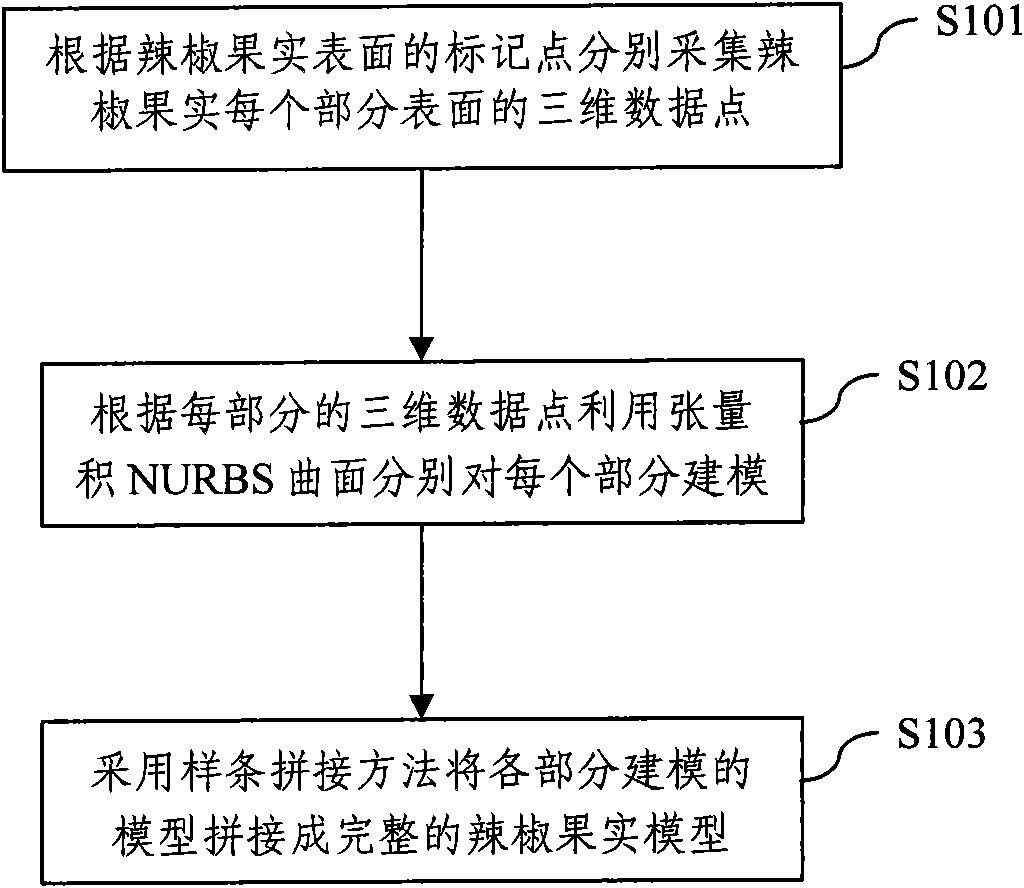

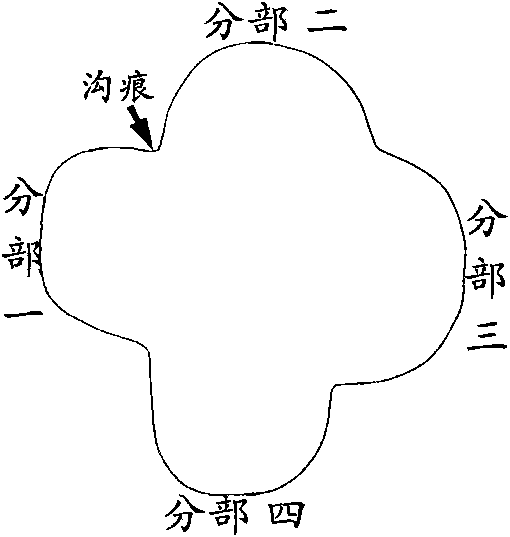

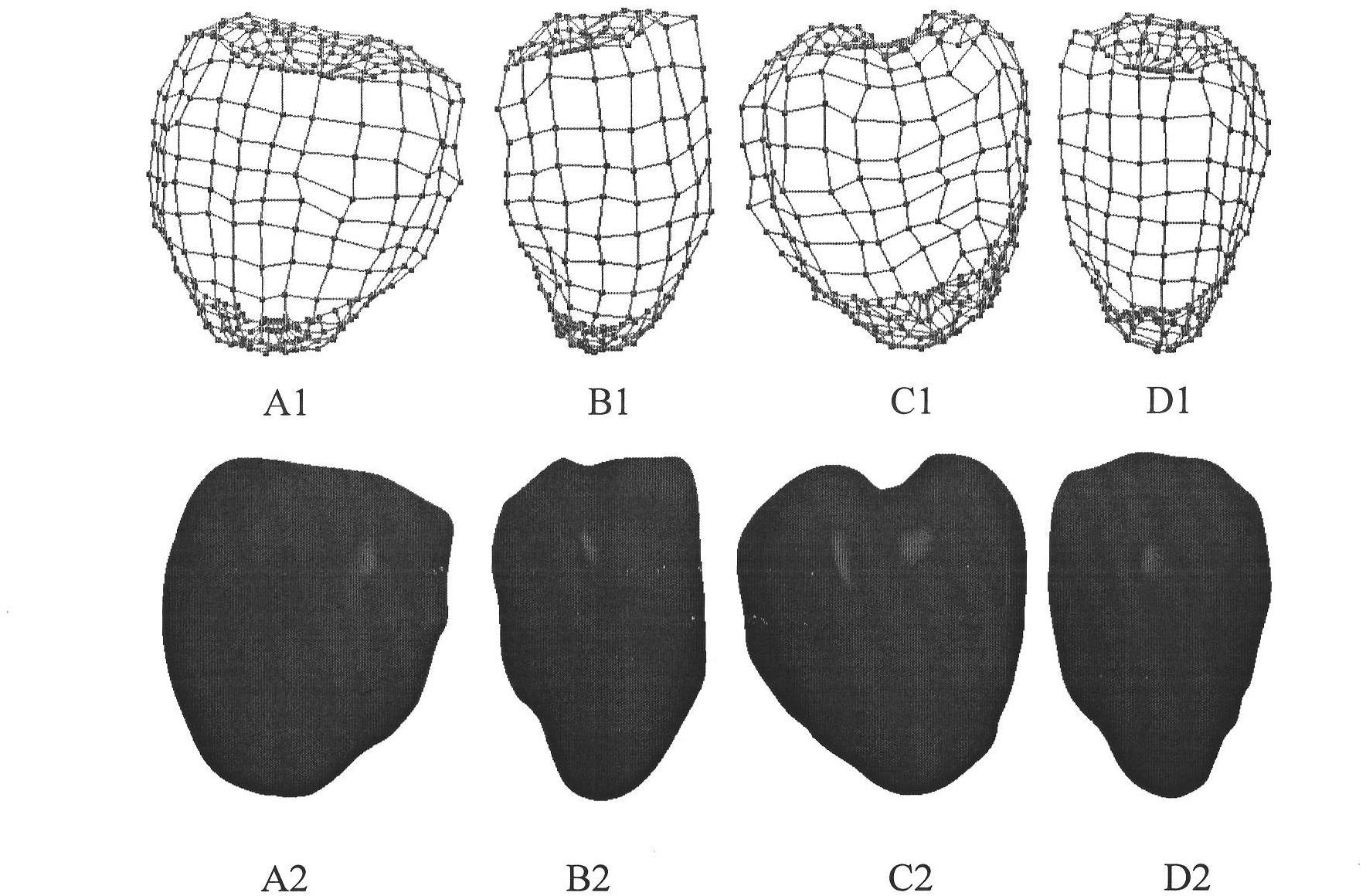

Geometric modelling method of hot pepper fruit

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

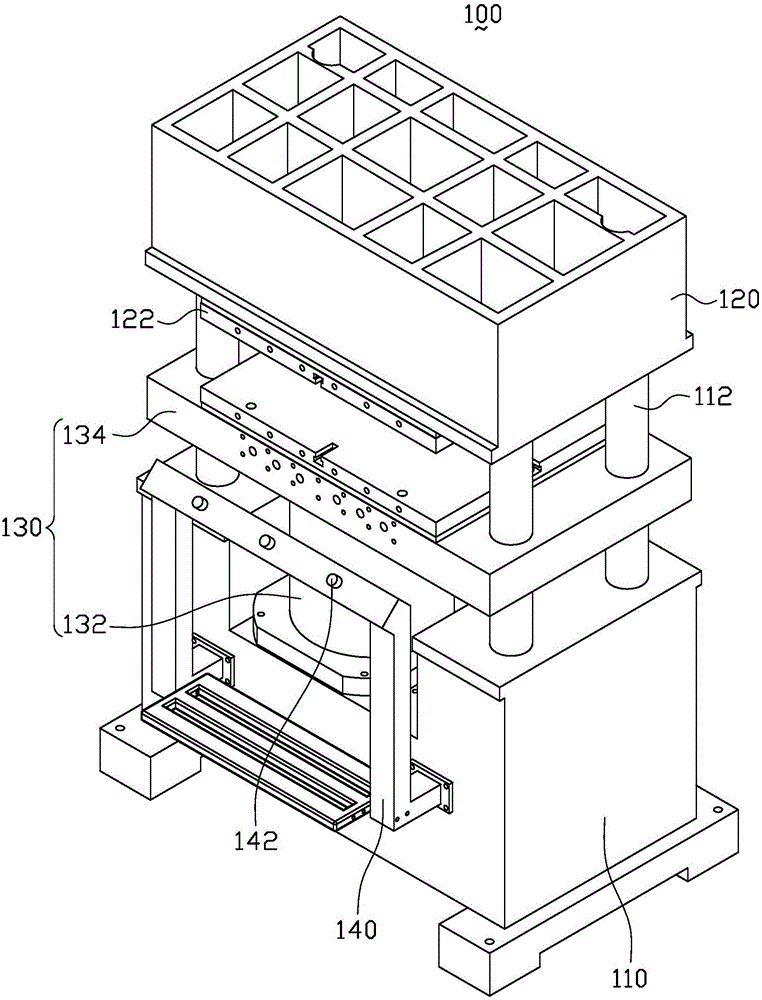

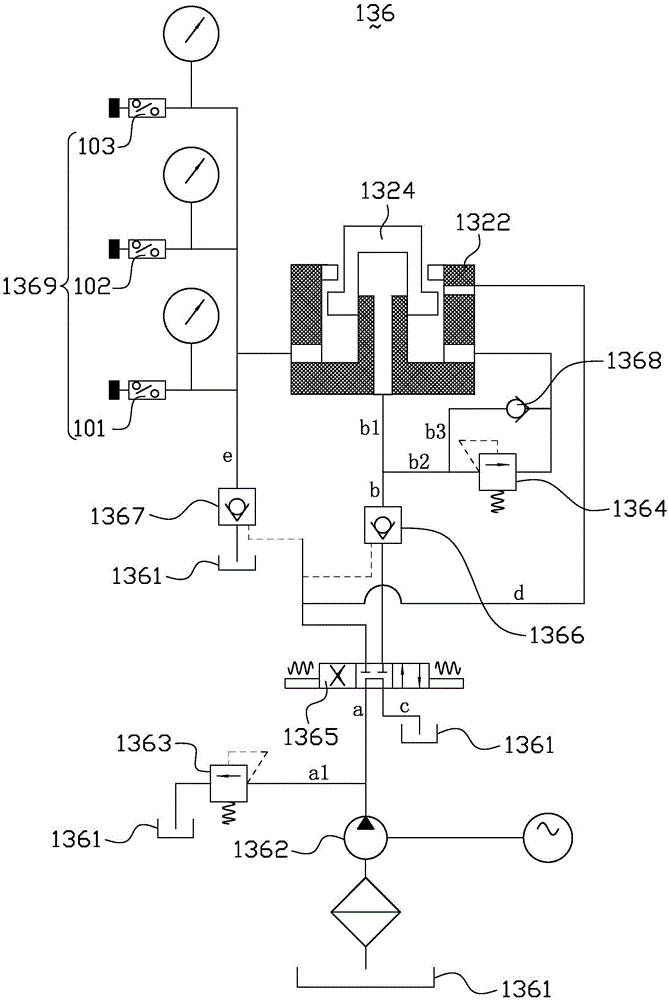

Relief molding process and device as well as relief product

ActiveCN105730121AIncrease productivityReduce manufacturing costLamination ancillary operationsLayered product treatmentSurface layerSquare Centimeter

The invention discloses a relief molding process comprising the steps of making a corresponding female die according to a selected pattern; sticking a hot melting core layer to a bottom-layer fabric, and sticking a surface-layer fabric to the hot melting core layer to form a molding material strip; arranging the female die on a relief molding device; placing the molding material strip on the relief molding device, and enabling the surface-layer fabric of the molding material strip to face the female die; carrying out hot compression on the molding material strip at least twice by using the relief molding device, wherein the hot compression temperature is 50-200 DEG C, the pressure firstly exerted on every square centimeter of molding material strip is 0.1-4MPa, and the first pressure exerting time is within 1-10s; carrying out second hot compression on the molding material strip by using the relief molding device to form a relief product, wherein the pressure secondly exerted on every square centimeter of molding material strip is 0.1-2MPa, and the second pressure exerting time is within 1-10s; and cooling the relief product by using the relief molding device before die opening. By using the relief molding process, a relief with a clear pattern can be made, and the relief product is high in production efficiency and low in production cost. The invention also relates to the relief molding device and the relief product.

Owner:罗实

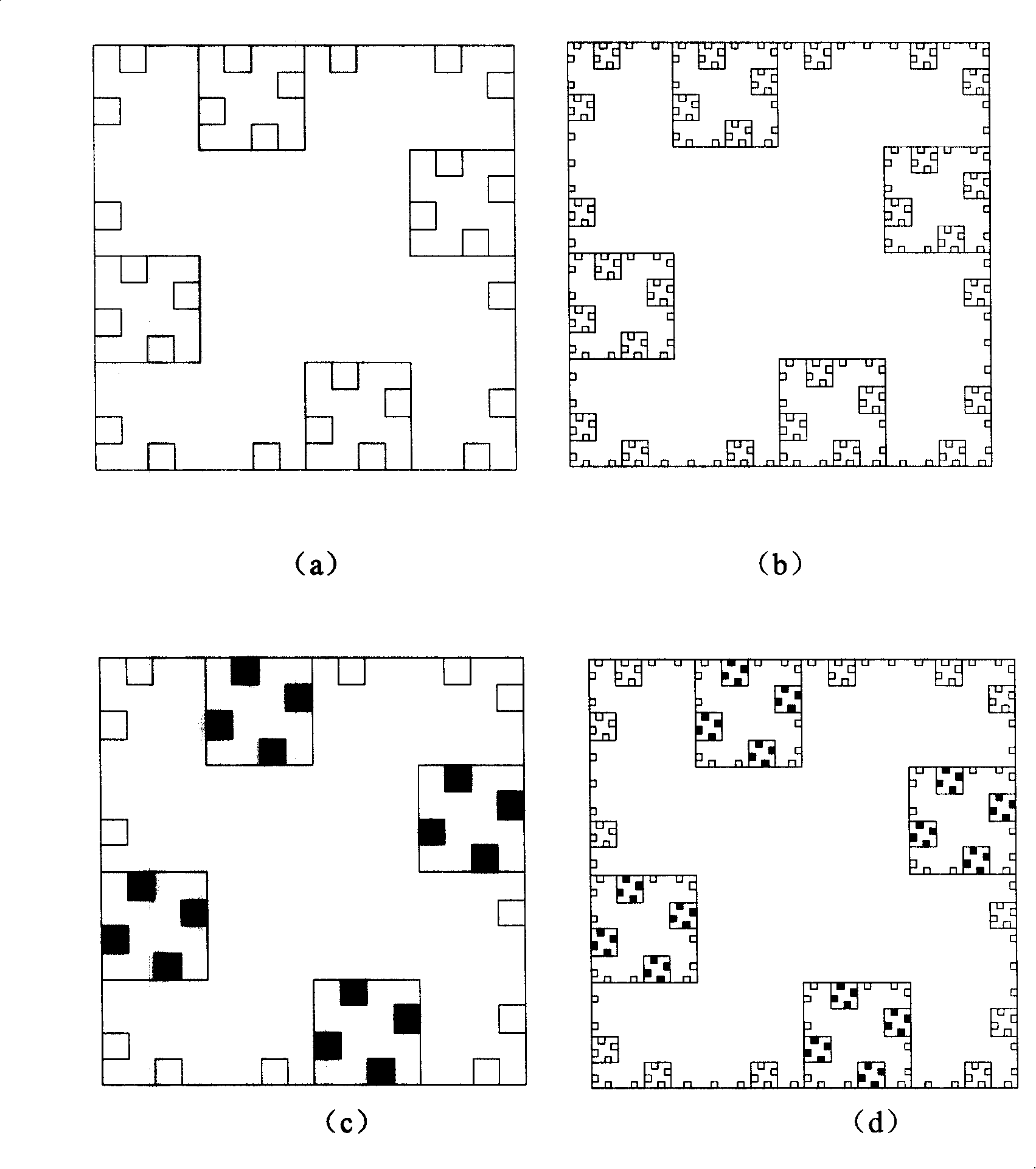

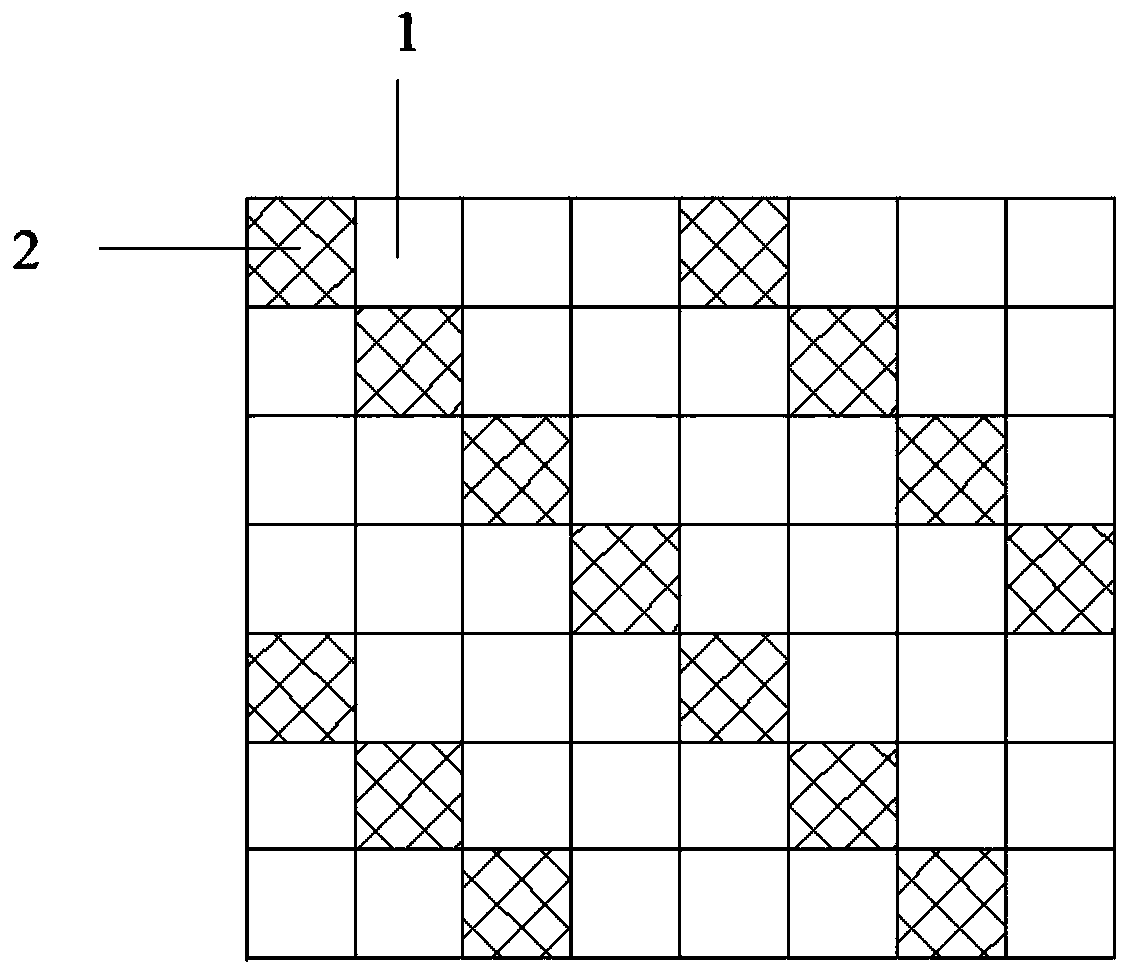

Technique for preparing digital kernel fabric

InactiveCN101210356ADelicate and rich decoration effectUniqueCard-punching apparatusPattern cardsEngineeringL-system

The invention relates to the preparation process of a digital wheat grain fabric capable of accurately drawing weave diagram and coloring, comprises (1) design and fabrication of a pattern card; (2) preparation of a loom; and (3) weaving by the loom. The process is characterized in that the design and fabrication of the pattern card includes the following steps of (1) designing a basic weave diagram of a fabric to form a circular fractal weave diagram by a computer based on L-system theory; (2) designing a superposed weave diagram superposing the fractal weave diagram; (3) superposing the superposed weave diagram and the fractal weave diagram by the computer to generate a digital wheat grain weave diagram; and (4) designing the digital wheat grain weave diagram, forming the pattern card and storing. The invention has the advantages that (1) less workloads are needed for drawing and coloring to prevent the occurrence of error, and the entire process has characteristics of fast, accurate, convenient, etc.; (2) the fractal weave diagram is superposed with the superposed weave diagram to generate the weave diagram of a target fabric, thus controlling the float length and ensuring fabric quality.

Owner:ZHEJIANG SCI-TECH UNIV

Production technology for 3D embossed wood floor

ActiveCN106313253AWith protectionEasy to useWood working apparatusFlooringPulp and paper industryOil paint

The invention discloses a production process for a 3D embossed wood floor. The production process comprises the steps that firstly, the floor is subjected to antique slot scraping, and the antique texture of the floor is more obvious in sense of concavo-convex, more natural and more three-dimensional; secondly, embossing is performed, then slotting is performed, the stability of the floor is improved, and expansion, caused by slotting firstly and thereafter embossing, of the floor is avoided; thirdly, the paint coating process is creatively improved, two paths of heavy sanding and three paths of light sanding are performed, bleached standing is performed for 7 days and thereafter light sanding is performed immediately, and then two varnish coatings are performed; and after light sanding, a varnish coating is performed, then the floor is polished, the floor is coated with ground color oil paint and transparent primer and then is coated with surface color oil paint and transparent finishing coat, and a finished product is obtained. The finished product has a unique wood print effect, that is, it looks like three layers of wood grains attached in a three-dimensional manner with the naked eye, the three-dimensional level is achieved, and the visual impact and visual beauty are given to people.

Owner:浙江上臣家居科技有限公司

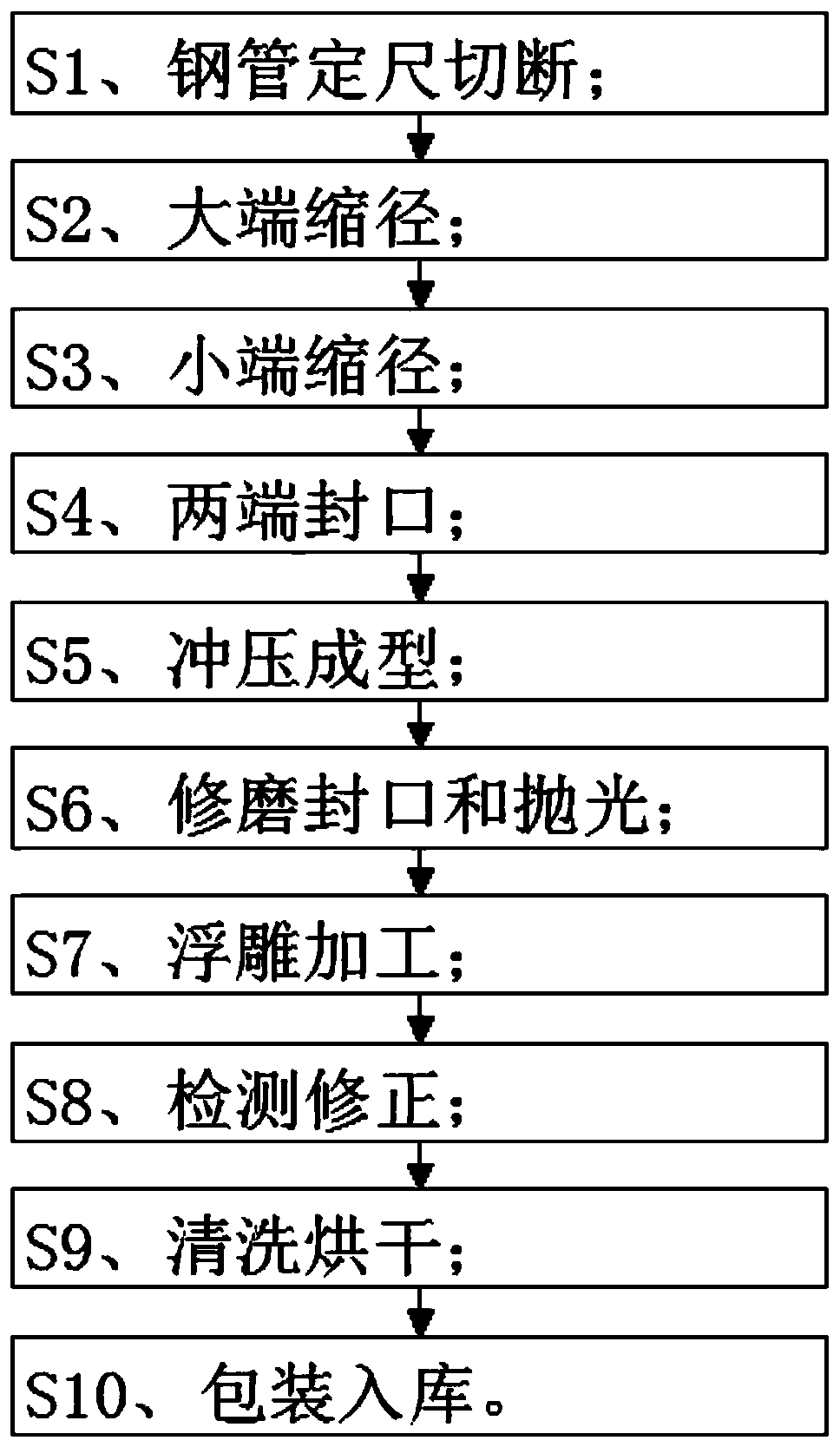

360-degree embossment whole-body anti-skid stainless steel chopstick processing process

The invention discloses a 360-degree embossment whole-body anti-skid stainless steel chopstick processing process and relates to the technical field of chopstick processing. The process comprises steps of sizing and cutting off a steel pipe, reducing the diameter of a large end, reducing the diameter of a small end, sealing two ends, performing punch forming, coping, sealing and polishing, performing relief machining, detecting and correcting, cleaning, drying, packaging and warehousing. Embossment processing is added on the basis of a traditional stainless steel surface polishing process, sostainless steel chopsticks have better dish clamping skid resistance and hand holding controllability after generating 360-degree concave-convex surfaces, for example, the stainless steel chopsticks do not slip when held by hands and do not slip when used for clamping dishes, and the use requirements of consumers are better met; through embossment processing, a 360-degree surface layer of a stainless steel chopstick has obvious and uniform concave-convex feeling, has stronger antiskid roughness and antiskid effect similar to those of bamboo chopsticks, does not damage the polished bright surface layer of the stainless steel, and can keep original glossiness of the stainless steel.

Owner:林灿纯

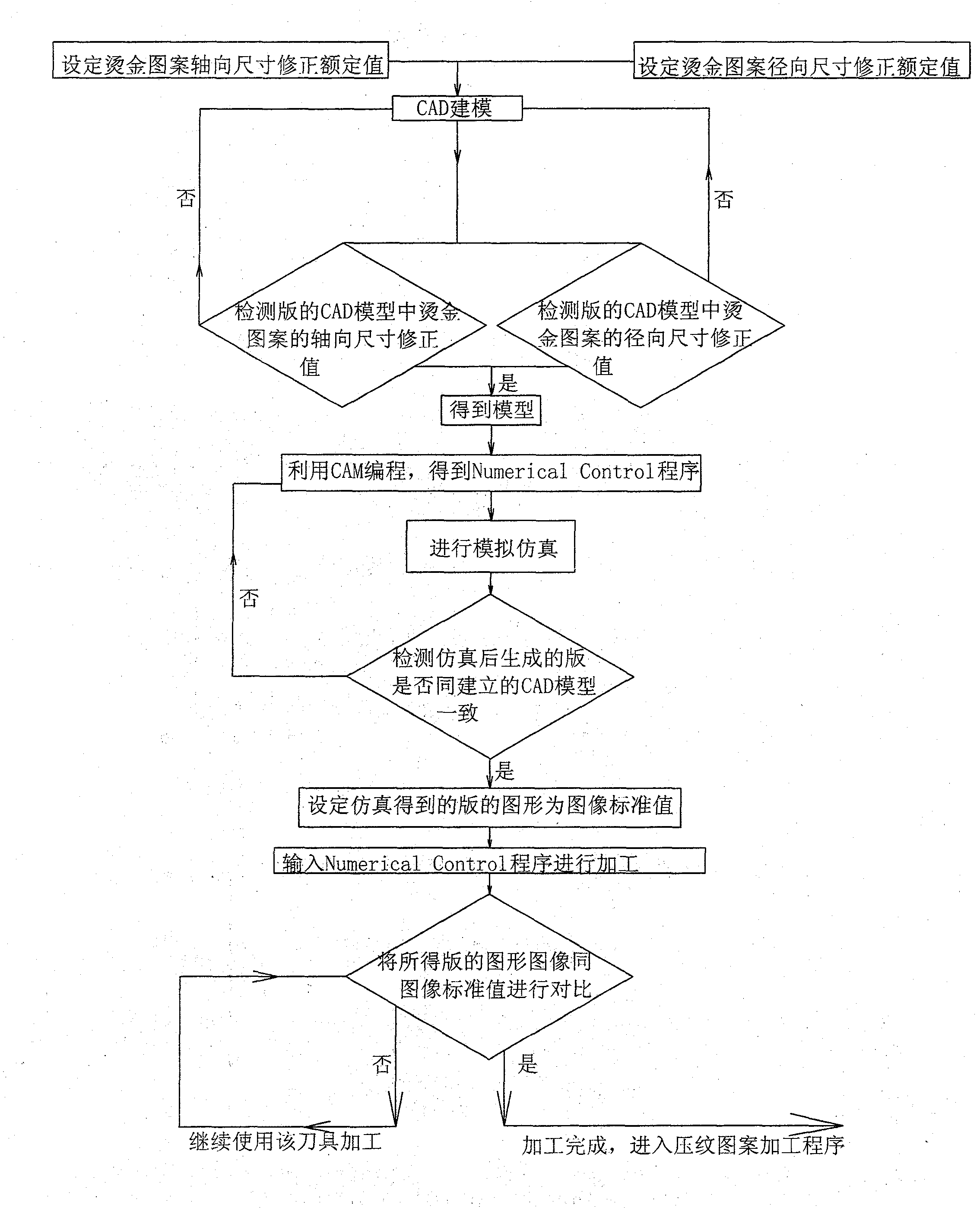

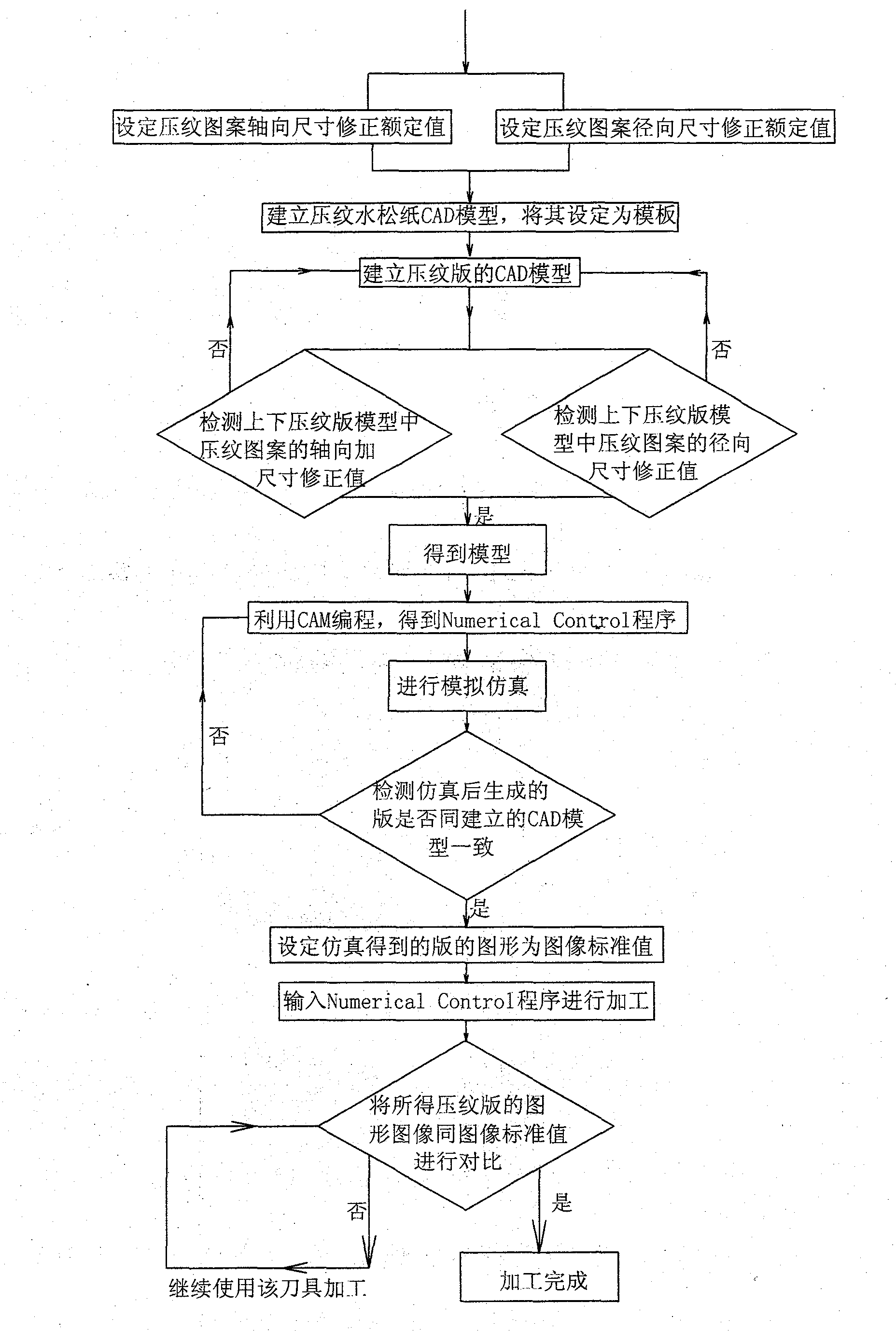

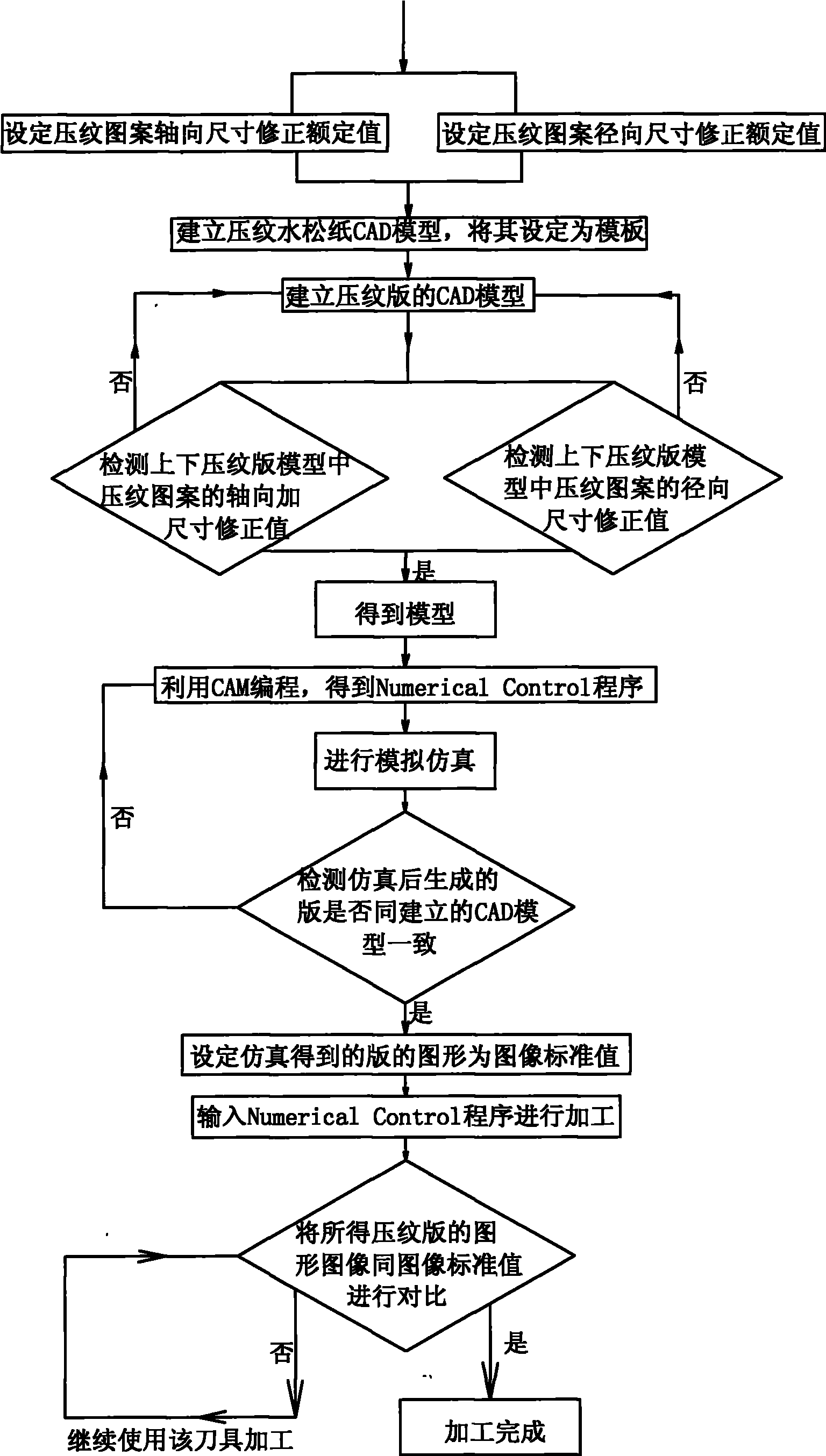

Production process of rotary gold stamping embossing one-step molding plate

InactiveCN102145570AHigh precisionAvoid damageProgramme controlComputer controlNumerical controlComputer Aided Design

The invention provides a production process of a rotary gold stamping embossing one-step molding plate, which utilizes the computer aided design to perform backward comparison for the predictable precision error value in the subsequent procedures automatically, therefore, the produced plate pattern has high precision, the color of the pressed product is dazzlingly beautiful, the indentation is clear, the printed pattern is accurate, the shelf life is long, and the damage to the strength of raw materials is small. The production process comprises the specific steps of: firstly setting the rated values of error and machining allowance, modeling according to the standard values, simulating after models are programmed, comparing the simulated data with the formerly built models, machining in numerical control equipment after the coincidence of the data and the built models, again comparing the machined finished product with the formerly set image standard value, and finally completing the product after coincidence. Through multiple comparison and detection, the requirement that what you see is what you get can be met, and the precision and quality of the gold stamping embossing plate are high.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

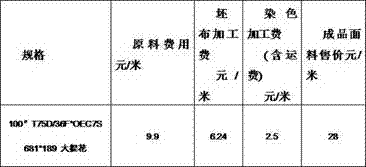

Production process of large-jacquard home-textile fabric interweaved by using double-color low-elasticity polyester filaments and coarse cotton

InactiveCN107447328ATo achieve the effect of alternating light and dark gradientsStrong concave and convexLiquid/gas/vapor textile treatmentSwivel-woven fabricsPolyesterEngineering

The invention provides a production process of a large-jacquard home-textile fabric interweaved by using double-color low-elasticity polyester filaments and coarse cotton. According to the production process, as raw materials, warp yarn uses T 75d / 36f low-elasticity double-screen semi-extinction filaments, and weft yarn uses 83.3 tex / OEC7S rotor spinning cotton yarn, wherein the warp density is 681 strands / 10 cm, the weft yarn is 83.3 tex rotor spinning cotton yarn, the weft density is 189 strands / 10 cm, and the width is 254 cm; the weaving process includes the steps of a sectional warping technology: the numbers of warping strands are 304*56+112*1 and 478*43+454*1, stripe width* stripe number is 47.19*56+17.39*1, and the displacement is 0.74; weaving; dressing; afterfinish: soft tentering shaping, pre-shrunking, calendaring, and soaking / rolling in turns. The production process uses the method of thick weft yarn and low weft density, so that the thickness and fullness of fabrics are embodied, the flower pattern is three-dimensional, and diverse stereo aesthetic feelings are added for the fabrics.

Owner:JIANGSU YUEDA HOME TEXTILE

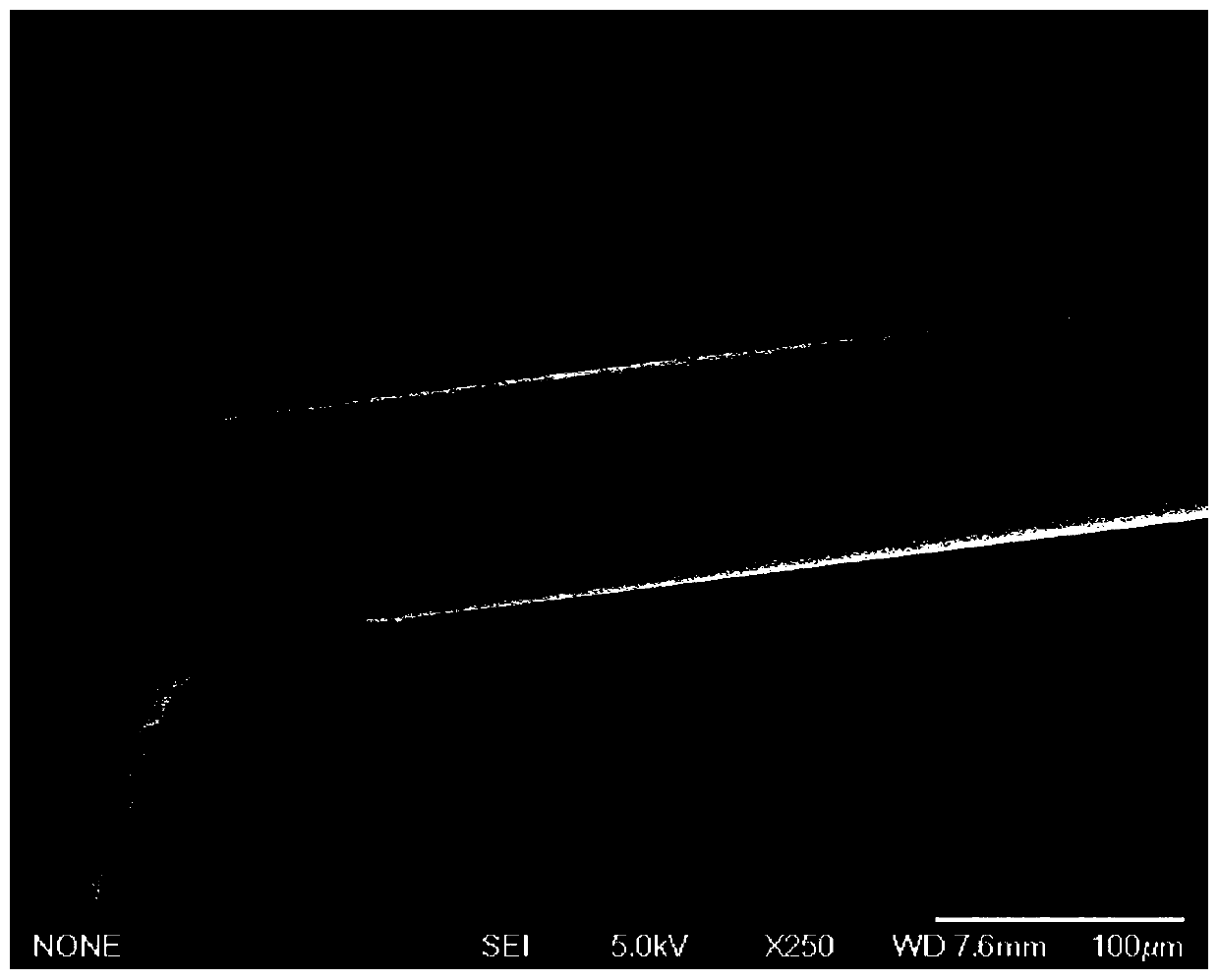

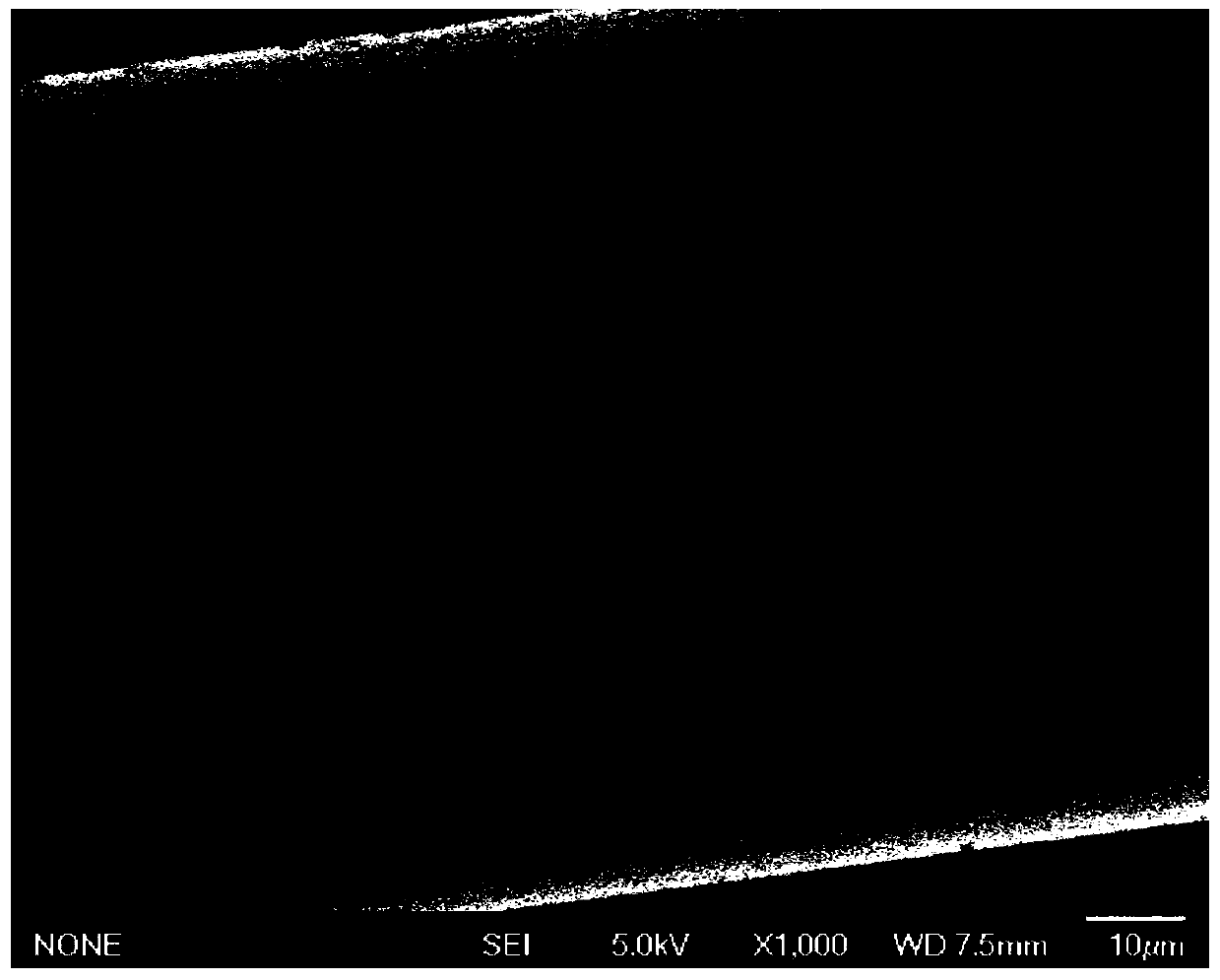

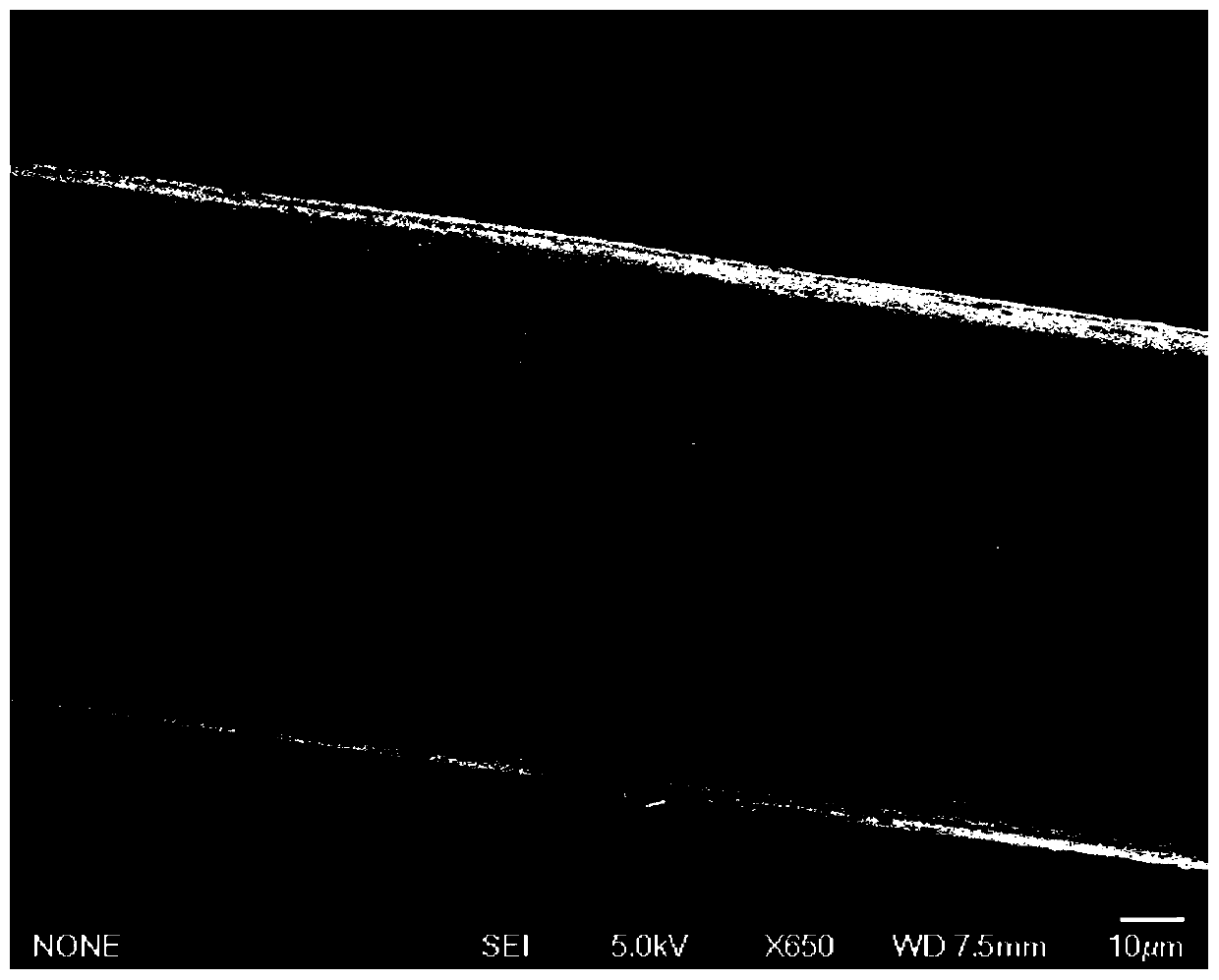

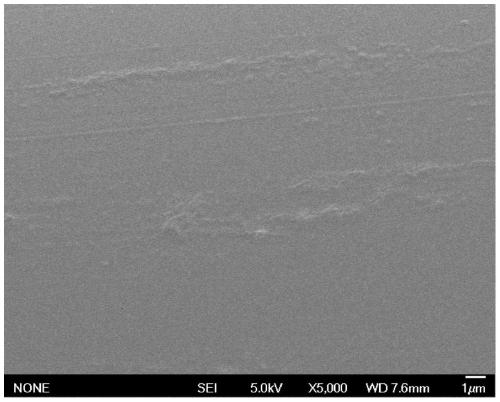

Two-dimensional ultrathin titania-modified polyester nano composite brush bristles and preparation method thereof

ActiveCN109837605AImprove spinnabilityIncrease sticky powderMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention provides two-dimensional ultrathin titania-modified polyester nano composite brush bristles and a preparation method thereof and belongs to the technical field of high molecular materials. The composite brush bristles herein are made from, by weight, 60-96 parts of a polyester, 0.1-20 parts of modified two-dimensional ultrathin nano TiO2, 0.5-2 pars of an antioxidant, and 0.5-8 partsof a lubricant; the modified two-dimensional ultrathin nano TiO2 is prepared by adding a surfactant into two-dimensional ultrathin nano TiO2 and carrying out surface modification; the modified two-dimensional ultrathin nano TiO2 is less than 50 nm in thickness and greater than 5 in diameter-to-thickness ratio. The invention also provides the preparation method of the two-dimensional ultrathin titania-modified polyester nano composite brush bristles. The two-dimensional ultrathin titania-modified polyester nano composite brush bristles have evidently uneven surface and are similar to wool in performance and structure.

Owner:芜湖万隆新材料有限公司

Paper surface carring technique

InactiveCN1513678AInhibit sheddingGood light transmissionStampsDecorative surface effectsPulp and paper industryControl unit

An antiforge carving-on-paper technique includes feeding raw paper onto equipment, setting up parameters, regulating the depth and position by control unit, carving and trimming. Said equipment is composed of feeder, driver, locating unit and control unit.

Owner:北京邮票厂有限公司

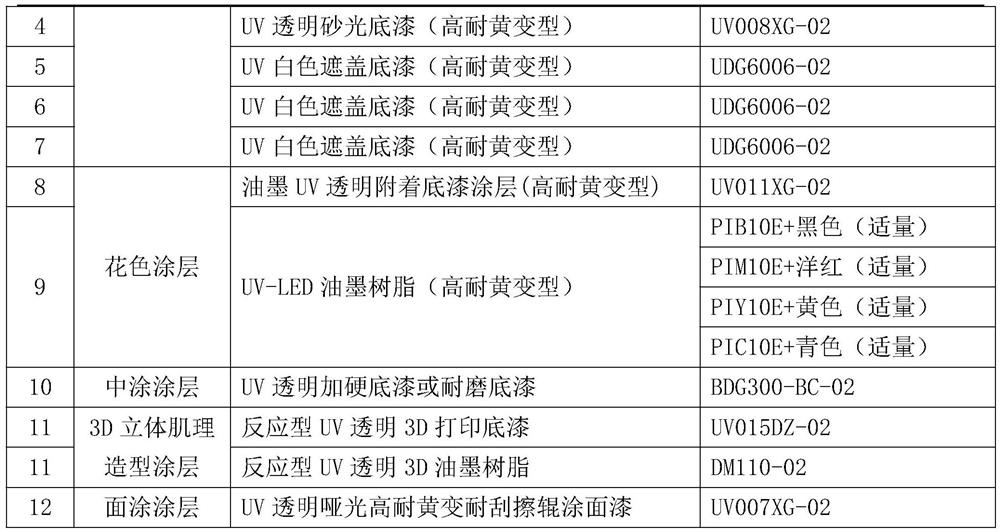

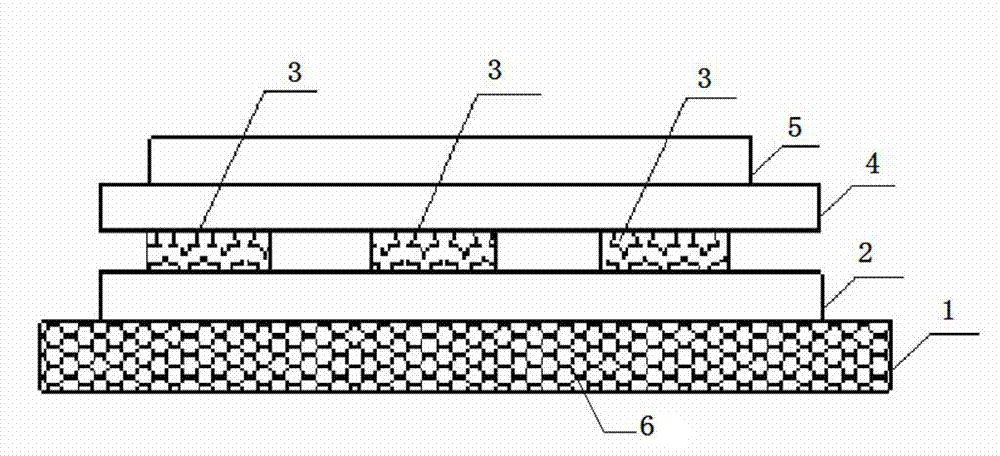

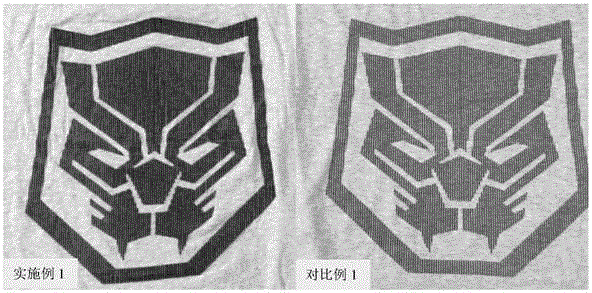

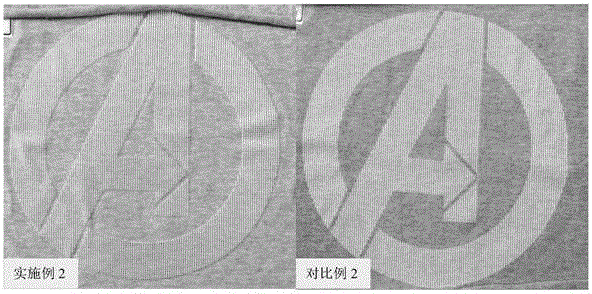

Preparation method of simulation wood grain three-dimensional decorative household board

ActiveCN114434998AIncrease production costGood value for moneyDuplicating/marking methodsPattern printingSurface coatingWood grain

The invention relates to a preparation method of a simulation wood grain three-dimensional decorative household board. The preparation method comprises the following steps: preparing a simulation wood grain digital color pattern standard image and a simulation wood grain digital black and white pattern standard image; standardizing the decorative surface of the base material; coating a base coating on the decorative surface; coating a color coating on the prime coating by using the simulation wood grain digital color pattern standard image; coating a floating coating on the pattern coating; the floating coating is coated with a reaction type UV transparent 3D primer coating; and a reaction type 3D ink coating is jet-printed on the position required by the liquid and uncured reaction type UV transparent 3D primer coating by using the simulated wood grain digital black and white pattern standard image, so that the reaction type UV transparent 3D primer and the reaction type 3D ink react to finally form a concave-convex effect layer, and the surface coating is coated on the obtained coating. The artificial wood grain three-dimensional decorative plate has a better artificial wood grain three-dimensional decorative effect, and the production process is simple, easy to implement, high in production efficiency and low in production cost.

Owner:小森新材料科技有限公司

Ventilating type simulation three-dimensional decorative film

InactiveCN103171357APrevent mildewImprove the three-dimensional effectSpecial ornamental structuresDiffuse reflectionSpecular reflection

The invention discloses a ventilating type simulation three-dimensional decorative film. The ventilating type simulation three-dimensional decorative film mainly comprises a PP base material, a special colour layer, a light coating, a pattern layer and a matte coating, wherein the PP base material is provided with a micropore so as to breath independently, the decorative film is prevented from mildewing, the service life of the ventilating type simulation three-dimensional decorative film is prolonged, the glossiness of the pattern layer is increased through the specular reflection of the light coating, the matte coating has a granular sensation in touching due to nonuniform thickness, and the diffuse reflection of the matte coating can cause patterns to achieve a better three-dimensional effect.

Owner:SUZHOU GUOHAO WALLPAPER

Toothbrush-shaped printing method

InactiveCN106494103AStabilityImprove the three-dimensional effectOther printing apparatusScreen printingEngineering

The invention discloses a toothbrush-shaped printing method. The toothbrush-shaped printing method comprises the following steps that firstly, a manufactured screen printing plate is installed through a flat screen printer or a circular screen printer and put onto a machine to be printed; secondly, hot-set right-angle printing ink is used for carrying out pattern thickness printing, and the screen plate is put into an oven to be dried; and thirdly, hot-set circular bead printing ink is used for carrying out pattern three-dimensional printing, and the screen plate is put into the oven to be dried. The number of printing times of the hot-set right-angle printing ink is controlled within 20-25, and pressure is gradually reduced by 0.2 MPa every 5 times of printing are carried out; the number of printing times of the hot-set circular bead printing ink is controlled within 3-8, and the pressure is gradually reduced by 0.2 MPa every 3 times of printing are carried out; and after each time of printing, the drying temperature ranges from 145 DEG to 160 DEG C, the drying time ranges from 45 seconds to 80 seconds, the height of each printing ink layer is not lower than 0.3 mm, the corresponding underpainting is transparent every one color is added, the thickness reaches 3 mm, and then a needed color is added. A brand-new printing method is created, toothbrush-shaped patterns are printed, a three-dimensional visual effect is achieved, and the hand feeling is soft and comfortable.

Owner:LEACHENG APPL

Ceramic products decorating method with relief effect

InactiveCN1704256AAppearance pattern is realStrong concave and convexOther printing apparatusClaywaresMetallurgyCeramic glaze

The invention provides a making method of ceramic relief effect which can prepare a special finishing material such as color or glaze. The material is immiscible with the glaze of the product's surface. Using the material to draw pictures on blank body and then glazing on its surface and firing it. When finished, the glaze shrinks around the picture to form relief effect.

Owner:潮州市永宣家用陶瓷制作厂有限公司

Manufacturing method of flip-flop lace

The invention relates to a manufacturing method of a flip-flop lace. The manufacturing method comprises the following steps of dispensing: putting a lower die of the flip-flop lace in a dispensing machine, and dispensing in a mold cavity of the lower die of the flip-flop lace by utilizing the dispensing machine so as to form a preset pattern; thermal forming: putting the lower die of the flip-flop lace in drying equipment so as to be heated and formed, so that the pattern is solidified; injection molding: putting the lower die of the flip-flop lace in an injection molding machine, closing an upper die of the flip-flop lace, so that a mold cavity of the upper die of the flip-flop lace is matched and combined with the mold cavity of the lower die of the flip-flop lace, and injecting plastic to the mold cavity of the upper die of the flip-flop lace and the mold cavity of the lower die of the flip-flop lace through the injection molding machine, so that the plastic is formed on the upper surface of the solidified pattern; and reclaiming: taking a formed product from the mold cavity of the lower die of the flip-flop lace, so that a finished product is obtained. According to the manufacturing method of the flip-flop lace, the dispensing molding process is combined with the injection molding process, a multicolored 3D pattern is generated by dispensing, and a multicolored molding effect which cannot be achieved by the injection molding process can be achieved.

Owner:梁宇声

Denim fabric preparation method

InactiveCN111020805AStrong concave and convexMeet the needs of warmthWool fibre washing/scouringDyeing processPolymer scienceDenim

The invention relates to a denim fabric preparation method which comprises the steps: twisting warp yarns and weft yarns, carrying out indigo dyeing on the warp yarns, then carrying out satin weavingon the weft yarns and the dyed warp yarns to obtain the fabric, and sequentially carrying out desizing, water washing, softening finishing and shaping to complete the denim fabric preparation. Compared with the methods in the prior art, the jean fabric can be washed with water to achieve the jean washing effect, and it can be guaranteed that the warm keeping requirement of the user can be met in autumn and winter cross seasons.

Owner:劲霸男装(上海)有限公司

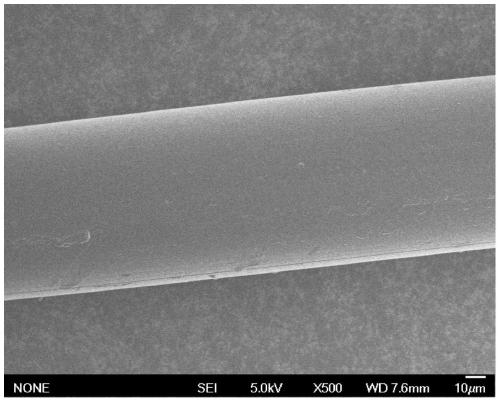

Inorganic nanometer silica modified PBT nanometer composite spinning material, and preparation method thereof

ActiveCN109957223AImprove spinnabilityStrong concave and convexMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention provides an inorganic nanometer silica modified PBT nanometer composite spinning material, and a preparation method thereof, and belongs to the technical field of high molecular material. The inorganic nanometer silica modified PBT nanometer composite spinning material is composed of, by weight, 60 to 96 parts of PBT, 0.1 to 10 parts of modified inorganic nano-silica, 0.5 to 2 partsof an antioxidant, and 0.5 to 8 parts of a lubricant. The invention also provides a preparation method of the inorganic nanometer silica modified PBT nanometer composite spinning material. According to the preparation method, surface modification of inorganic nanometer silica is carried out, an obtained product is adopted to fill PBT through uniform dispersion in the PBT matrix, and the compatibility is excellent, so that the polyester fiber is provided with excellent spinnability, and the surface of the prepared fiber has obviously concave and convex feel, the performance and the structure are similar to those of wool.

Owner:芜湖万隆新材料有限公司

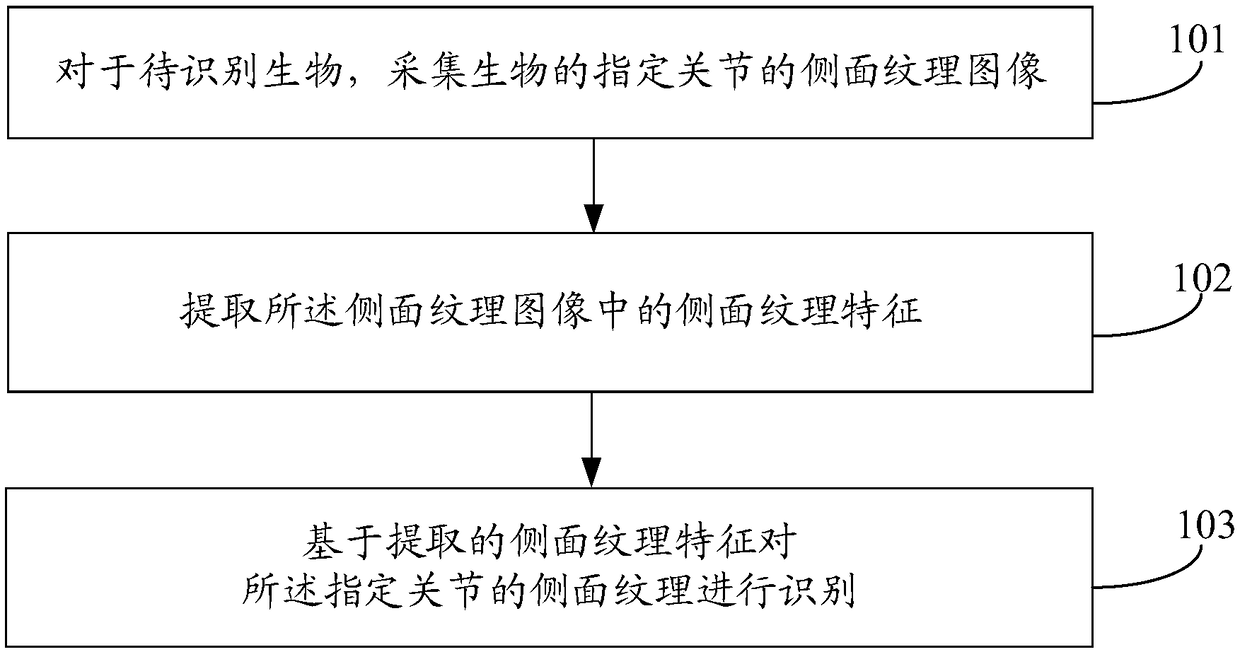

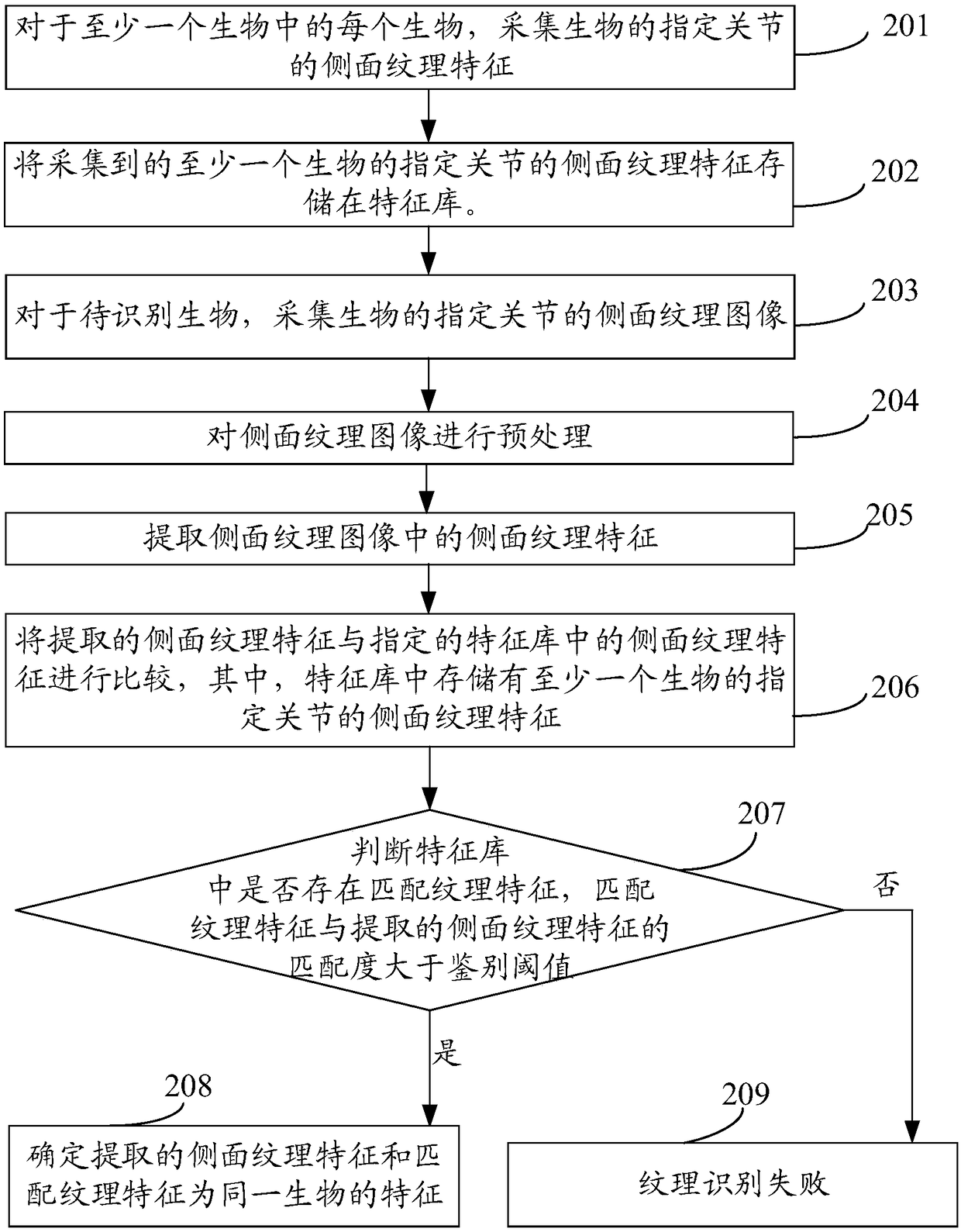

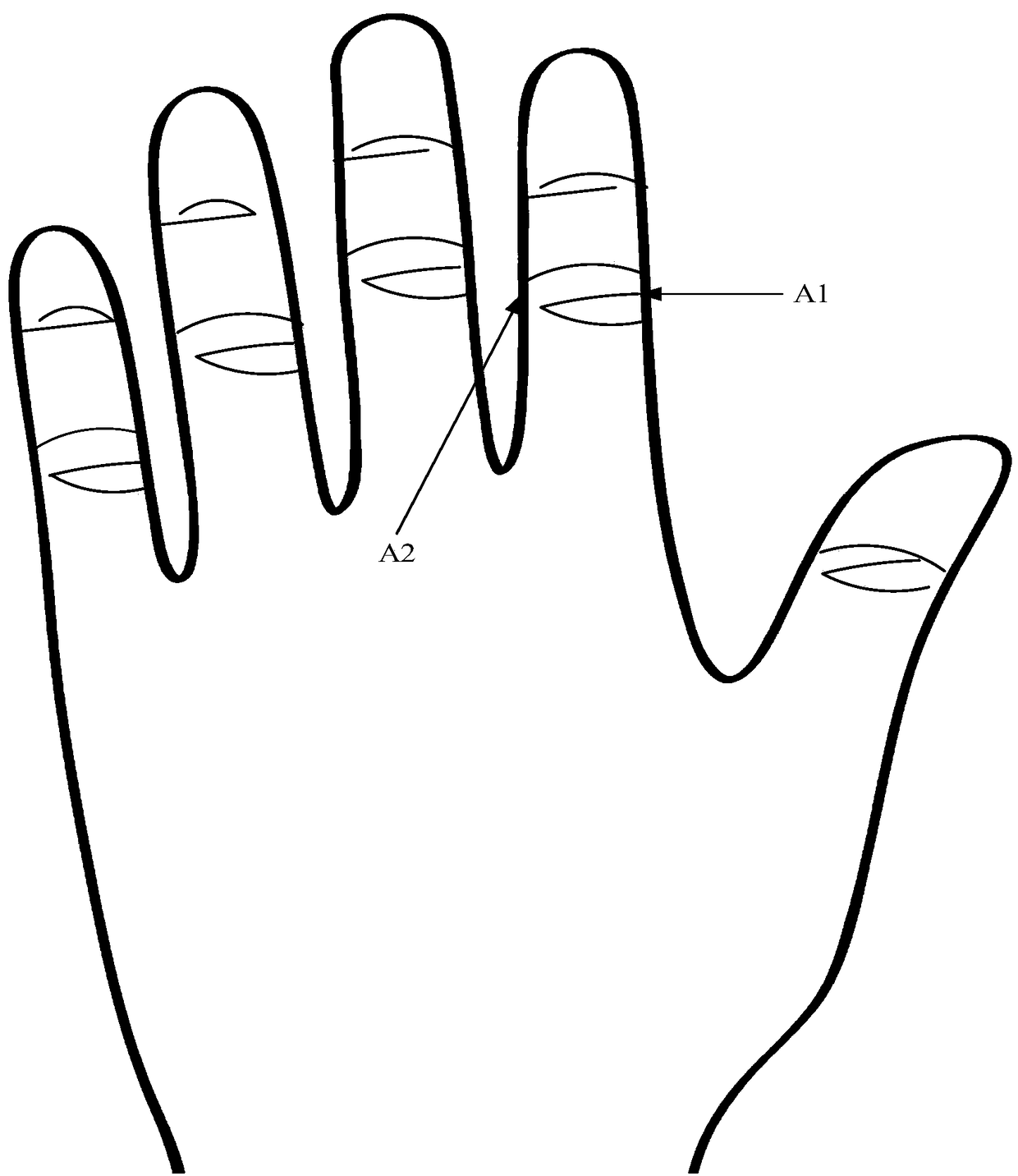

Texture recognition method and apparatus thereof

InactiveCN108764127AStrong concave and convexImprove accuracyImage analysisDigital data authenticationState of artTexture recognition

The application provides a texture recognition method and an apparatus thereof, and belongs to the field of biometric recognition. The method includes steps: acquiring a side surface texture image ofa specified joint of a living being for the to-be-recognized living being; extracting side surface texture characteristics in the side surface texture image; and recognizing side textures of the specified joint based on the extracted side surface texture characteristics. According to the method and the apparatus thereof, problems of low accuracy of texture characteristic extraction and low accuracy of texture recognition in the prior art are solved, and the method and the apparatus thereof can be used for biometric recognition.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com