Rotary gold stamping embossing one-step forming version

A round embossing and embossing technology, applied in the field of hot stamping and embossing plates, can solve the problems of short retention time, high requirements for equipment and personnel, unfavorable flexible application, etc., and achieve the goal of reducing production processes, reducing production costs, and long retention time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

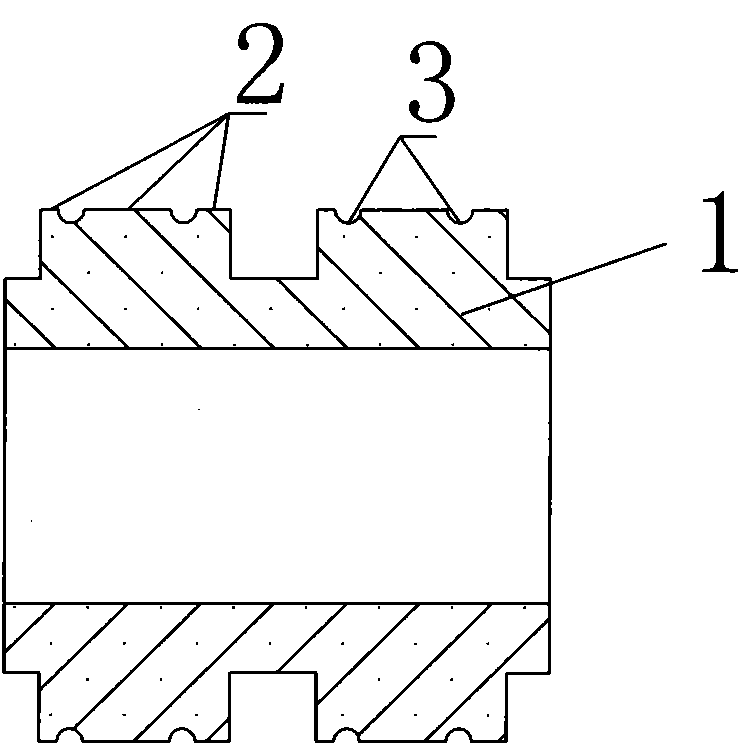

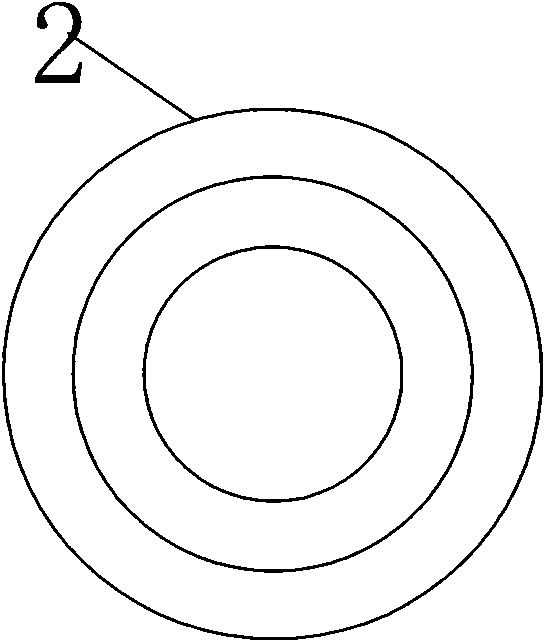

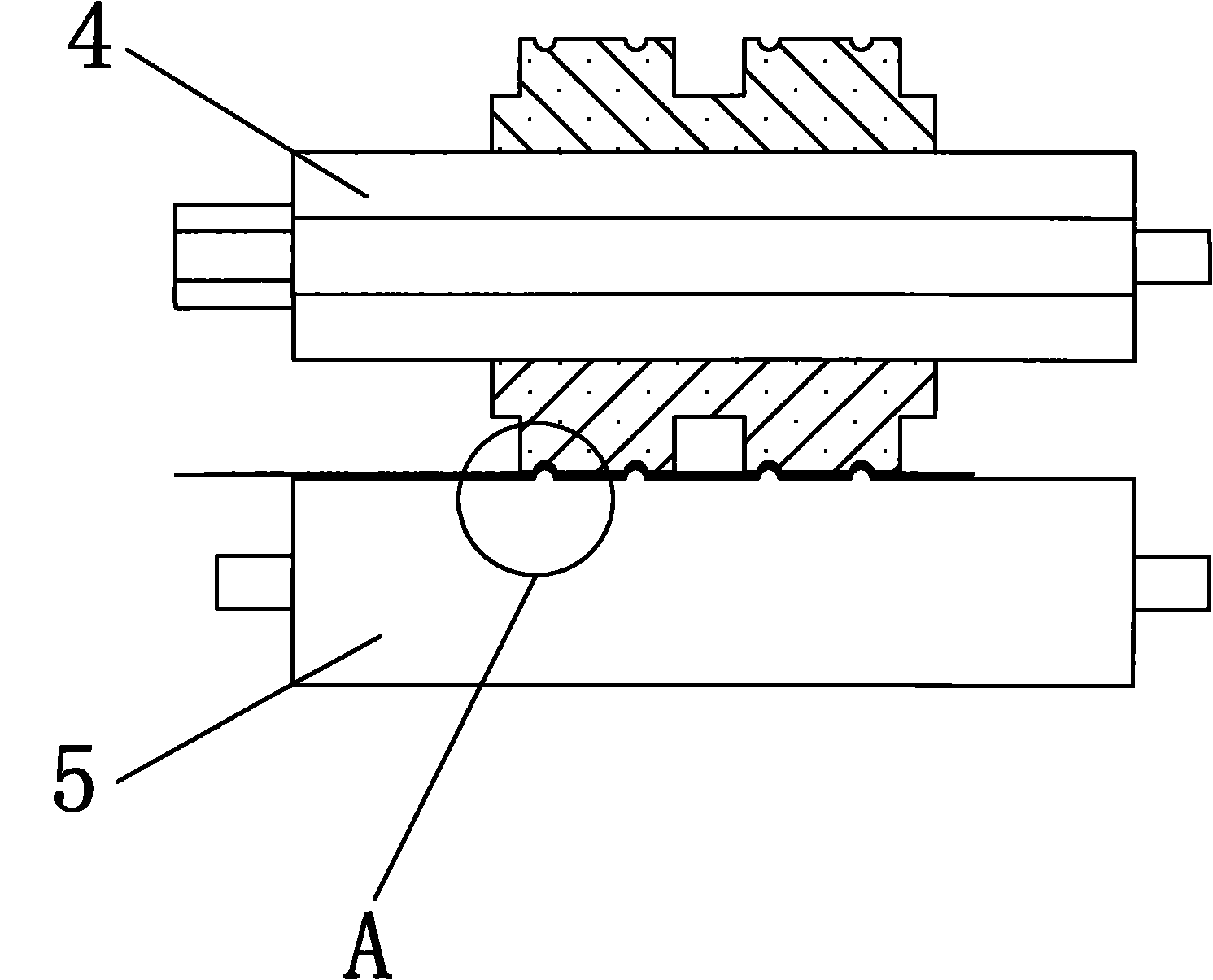

[0020] Such as figure 1 , 2 As shown in , 3, and 4, the circular stamping and embossing embossing plate of Yuxi (soft) cigarette tipping paper is pressed, and the surface of the shaft sleeve (1) is provided with "Yuxi", "YUXI" and raised round tables as the stamping surface ( 2), a diamond-shaped groove (3) is provided on the surface of the raised truncated cone, with a depth of 30 μm.

Embodiment 2

[0022] Such as figure 1 , 2 As shown in , 3 and 4, the circular stamping and embossing one-time molding version of Hongtashan classic 1956 (soft) cigarette tipping paper is pressed, and the surface of the shaft sleeve (1) is set with "Hongtashan", "classic 1956" and raised round tables as The bronzing surface (2) is provided with square grooves (3) on the surface of the raised round platform, and the depth is 25 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com