Patents

Literature

458results about "Bronze printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

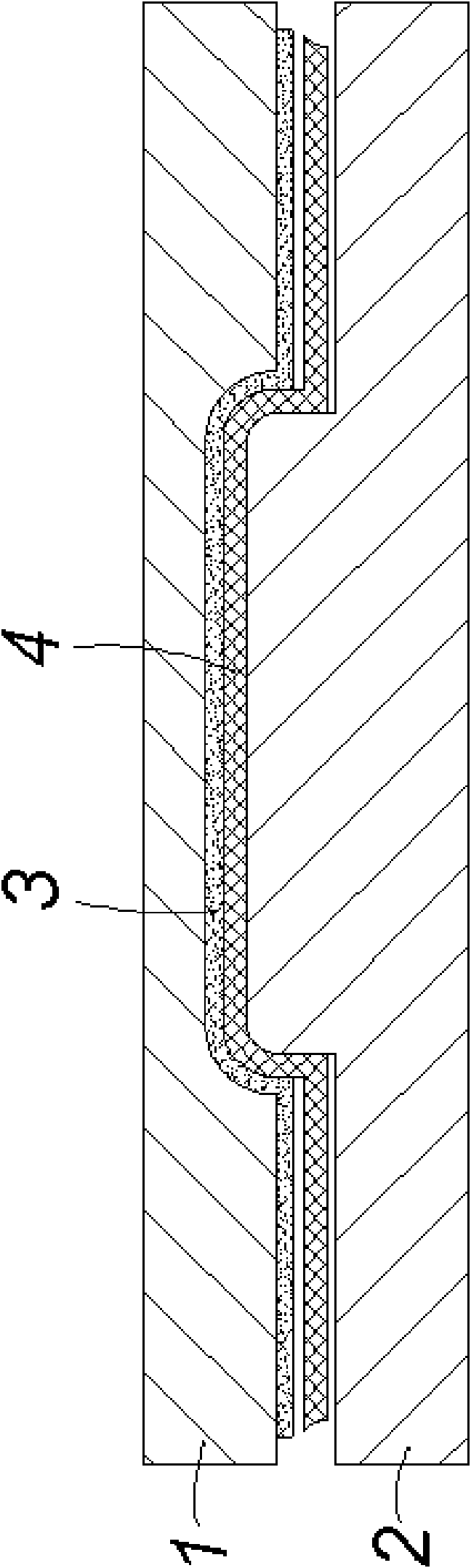

Complete equipment for tailoring

ActiveCN106367938AEasy to storeKeep drySevering textilesWork-collecting devicesEngineeringDrying Agents

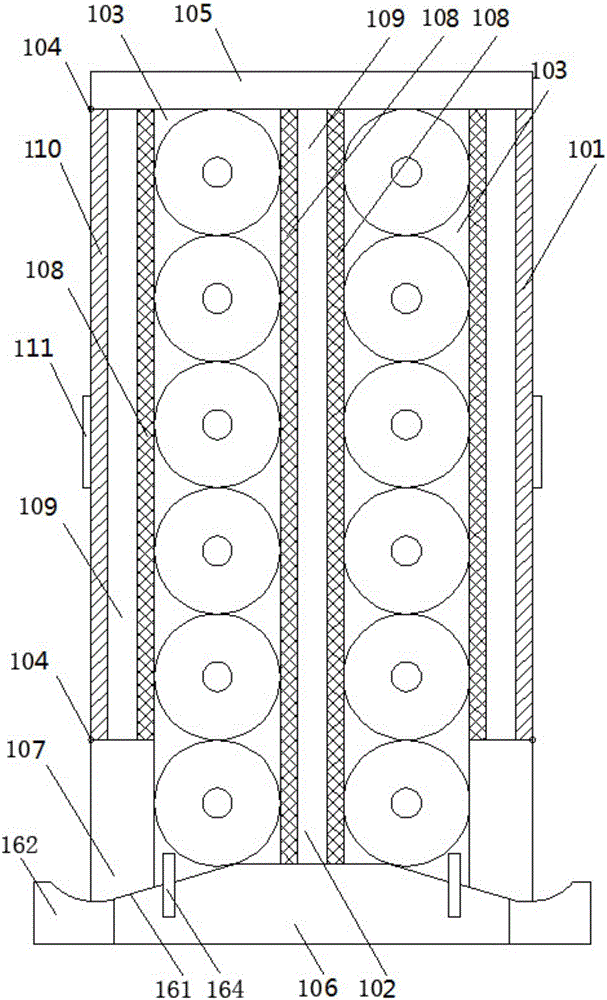

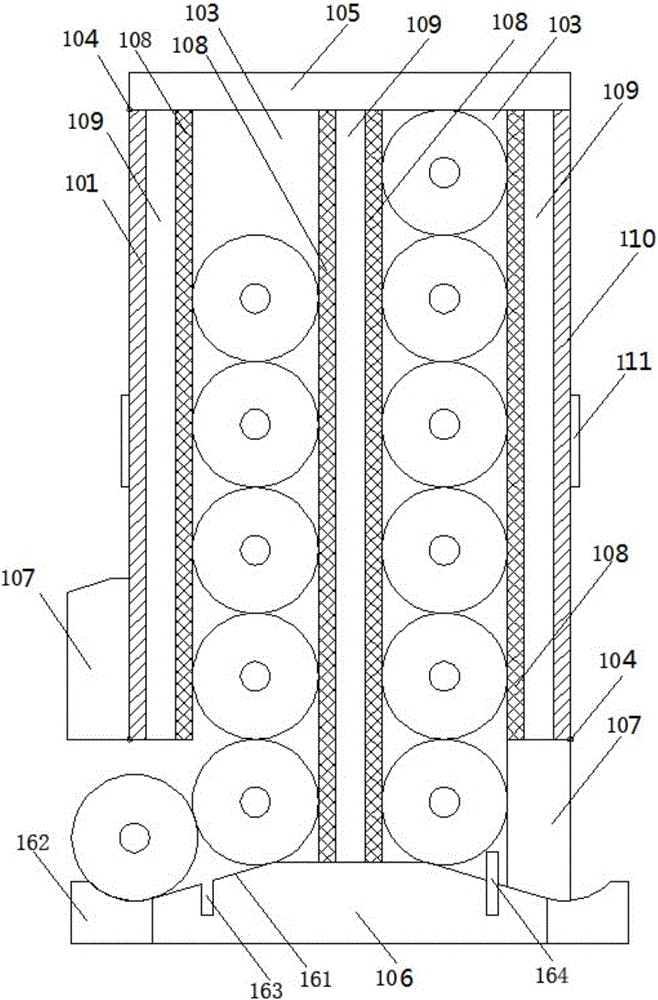

The invention discloses complete equipment for tailoring. The complete equipment comprises a fabric storage cabinet, a fabric cutting machine, a sewing machine, a button sewing machine and an ironing machine, wherein the fabric storage cabinet comprises a cabinet body; the cabinet body is divided into left and right fabric accommodating cavities by virtue of a drying agent separator which is arranged at the center of the cabinet body, and the length of each fabric accommodating cavity is equal to the diameter of the fabric; the top end of the cabinet body is connected with a cover plate through a rotary hinge; a base is arranged at the bottom end of the cabinet body; and bottom ends of left and right side walls of the cabinet body are respectively connected with an upward lifting door through the rotary hinge. The fabric storage cabinet can be used for greatly reducing the time for searching fabrics, the dryness of the environment in the cabinet body is effectively maintained, and long-term fabric storage is facilitated.

Owner:MEISHENG CULTURE INNOVATION HLDG

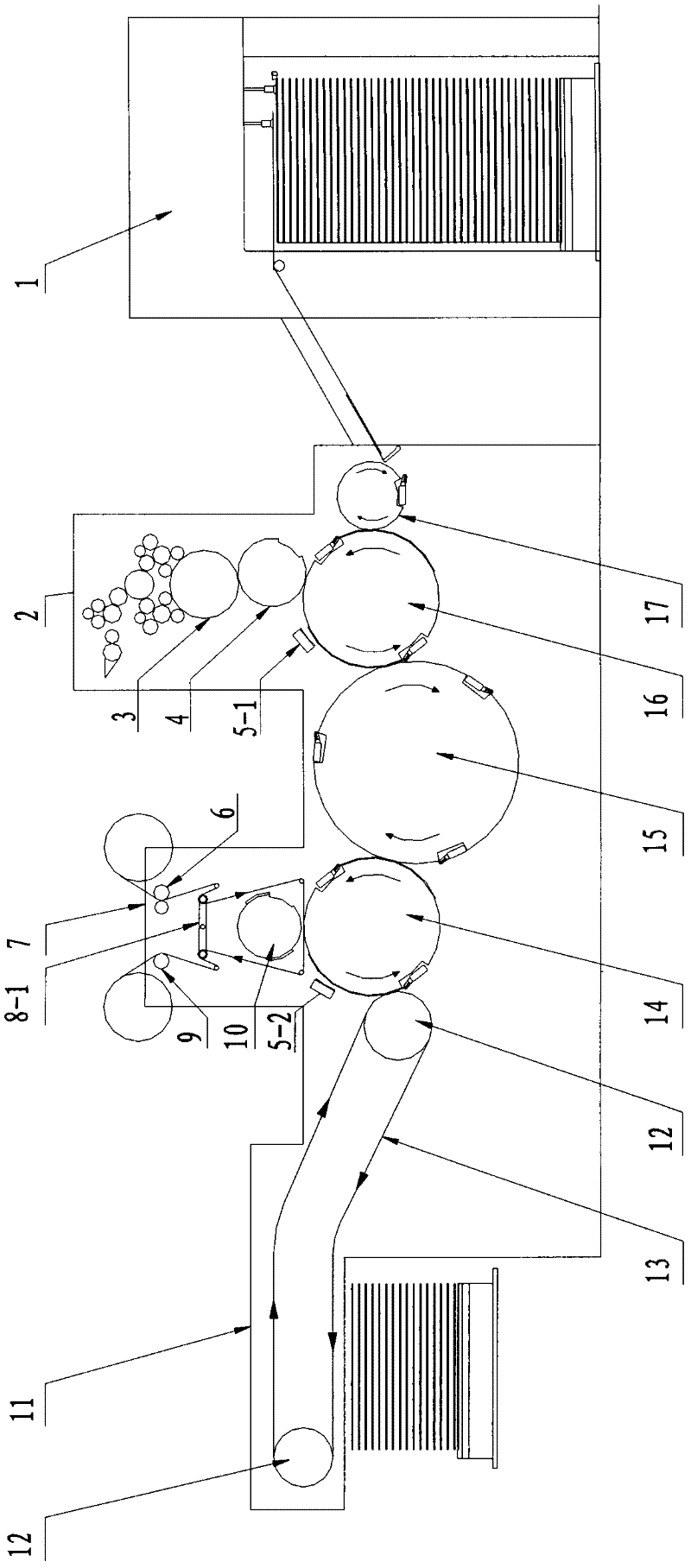

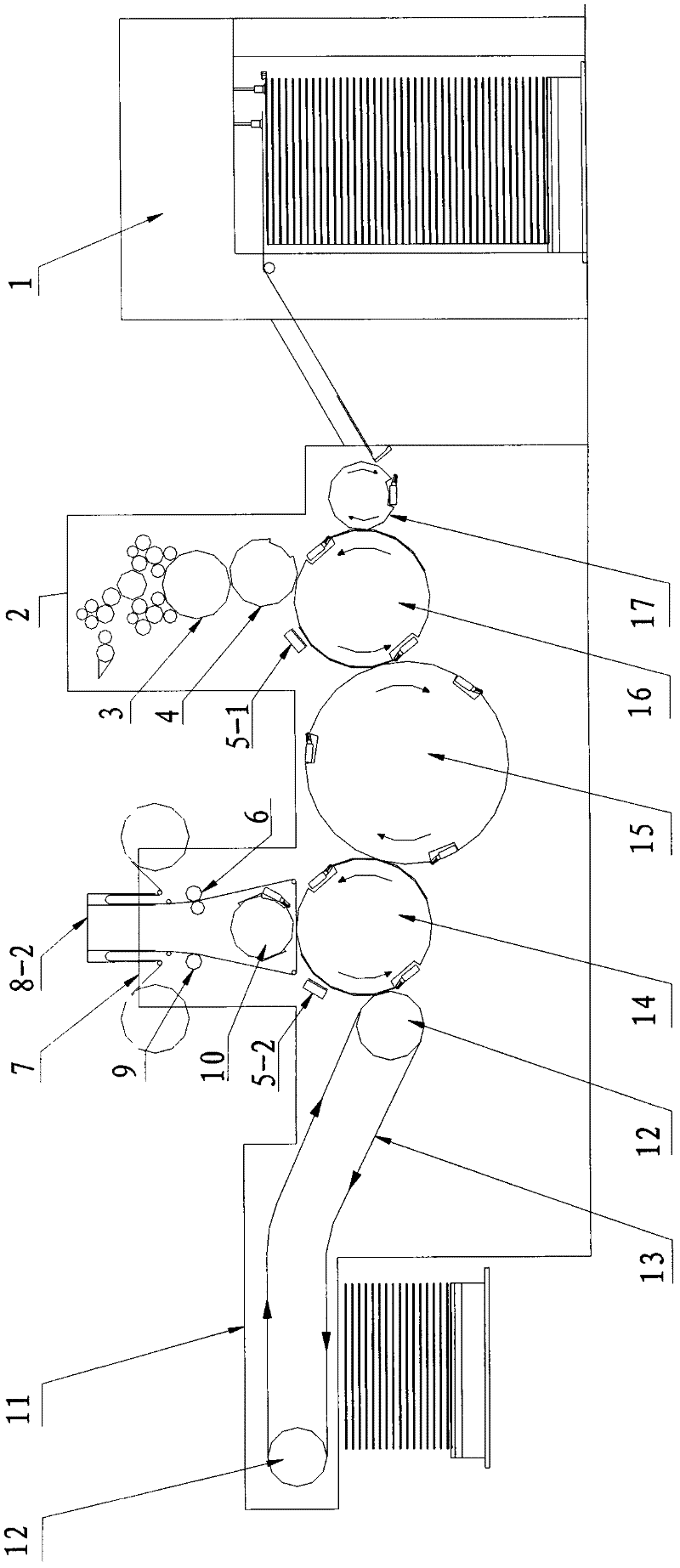

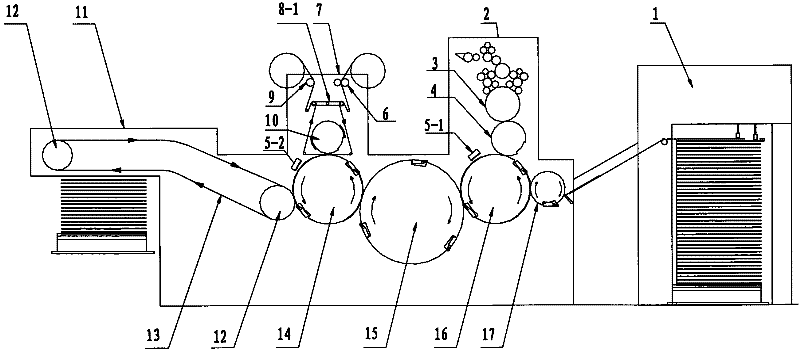

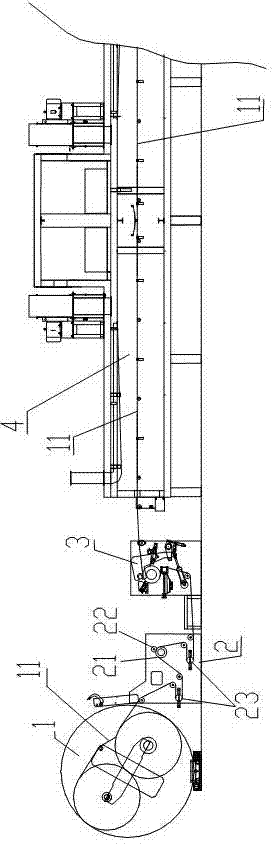

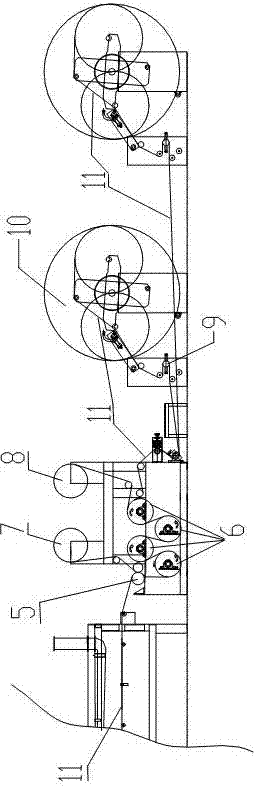

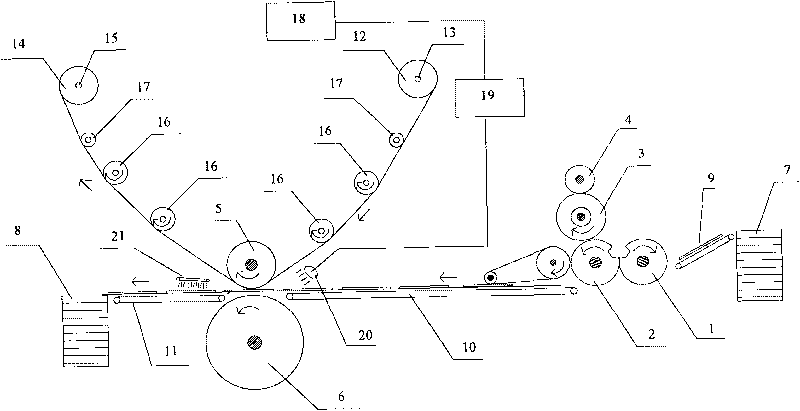

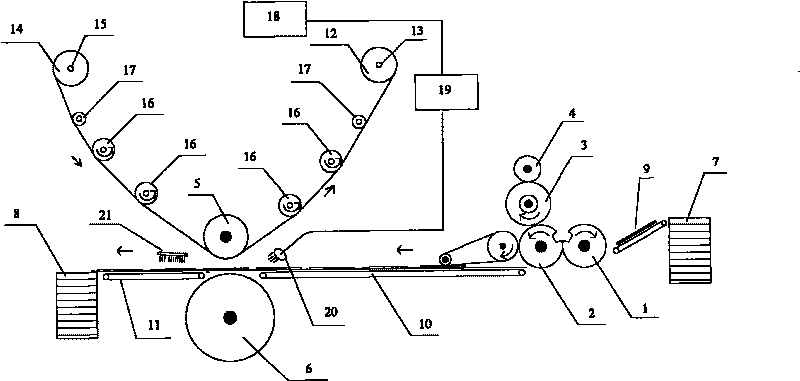

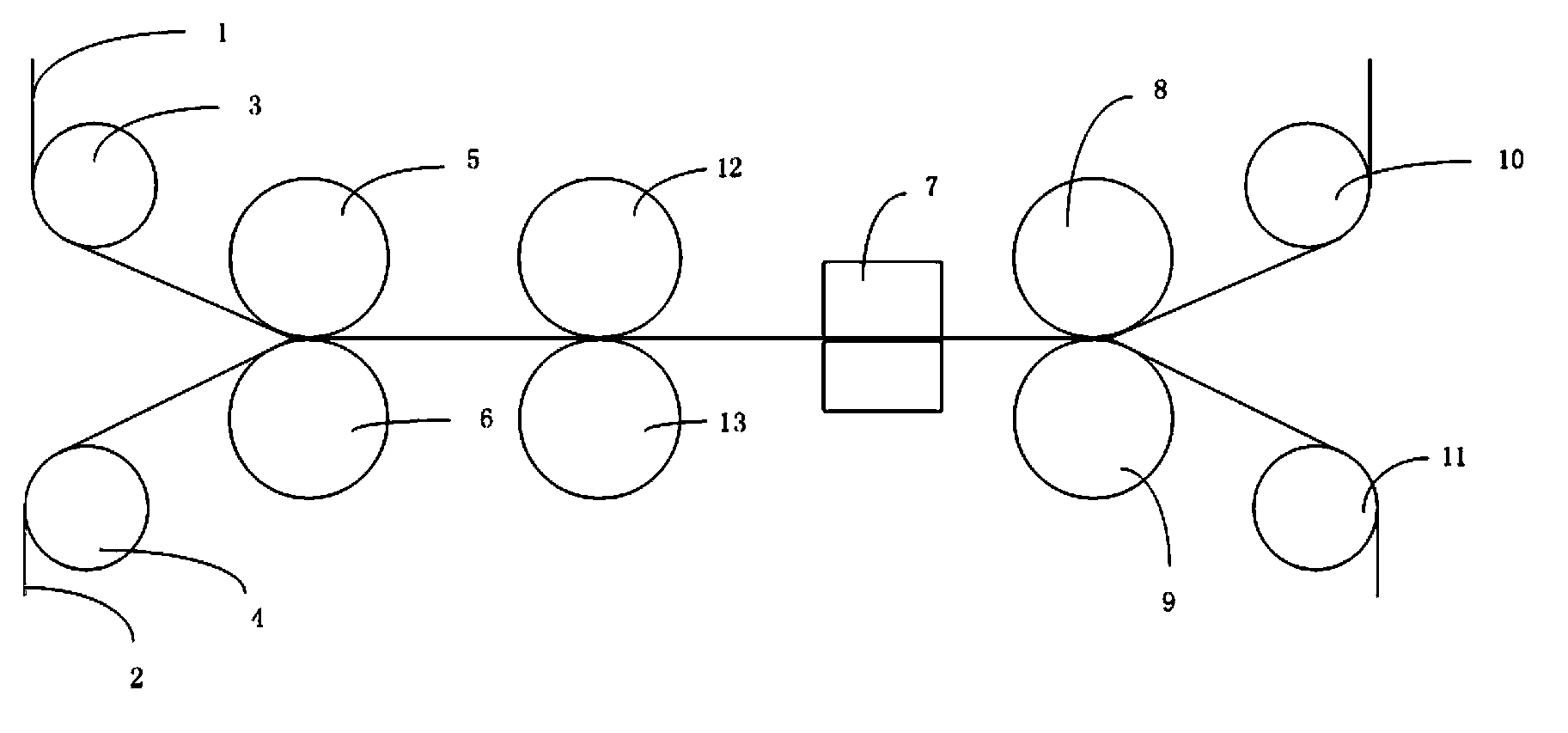

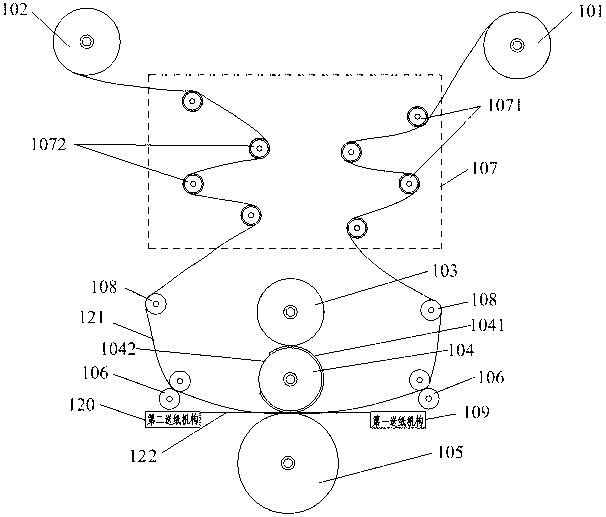

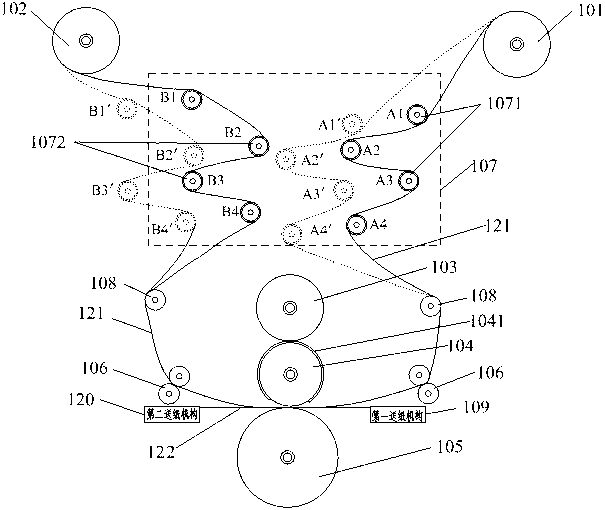

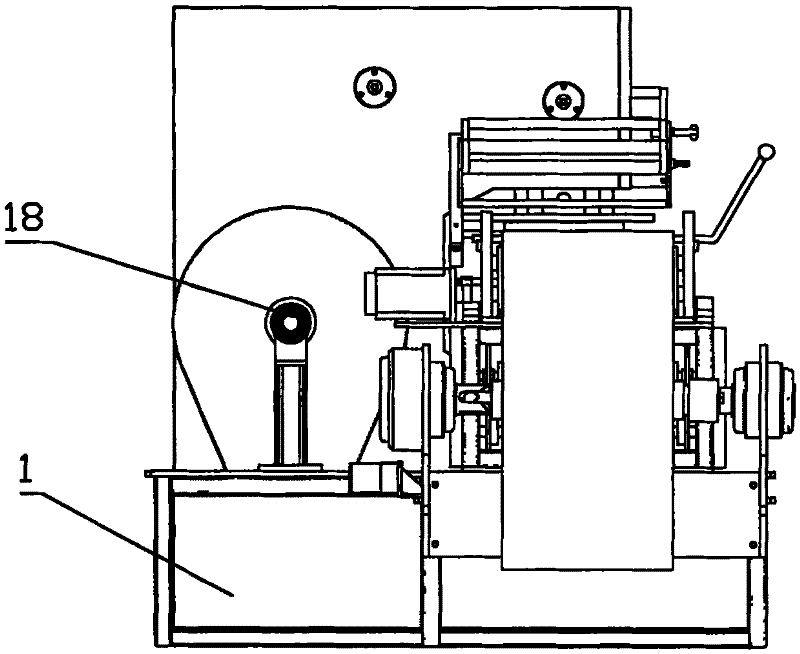

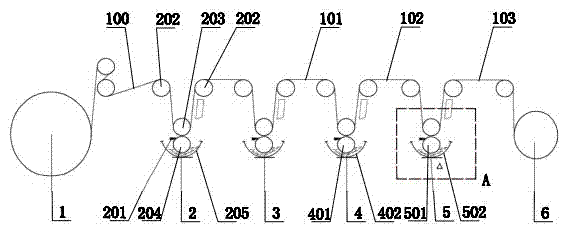

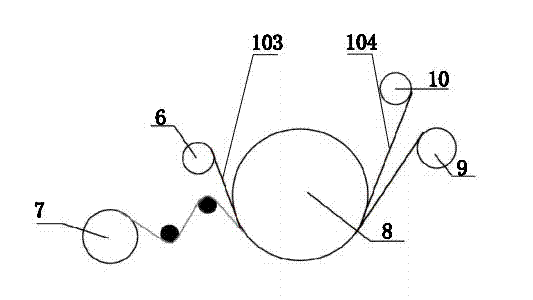

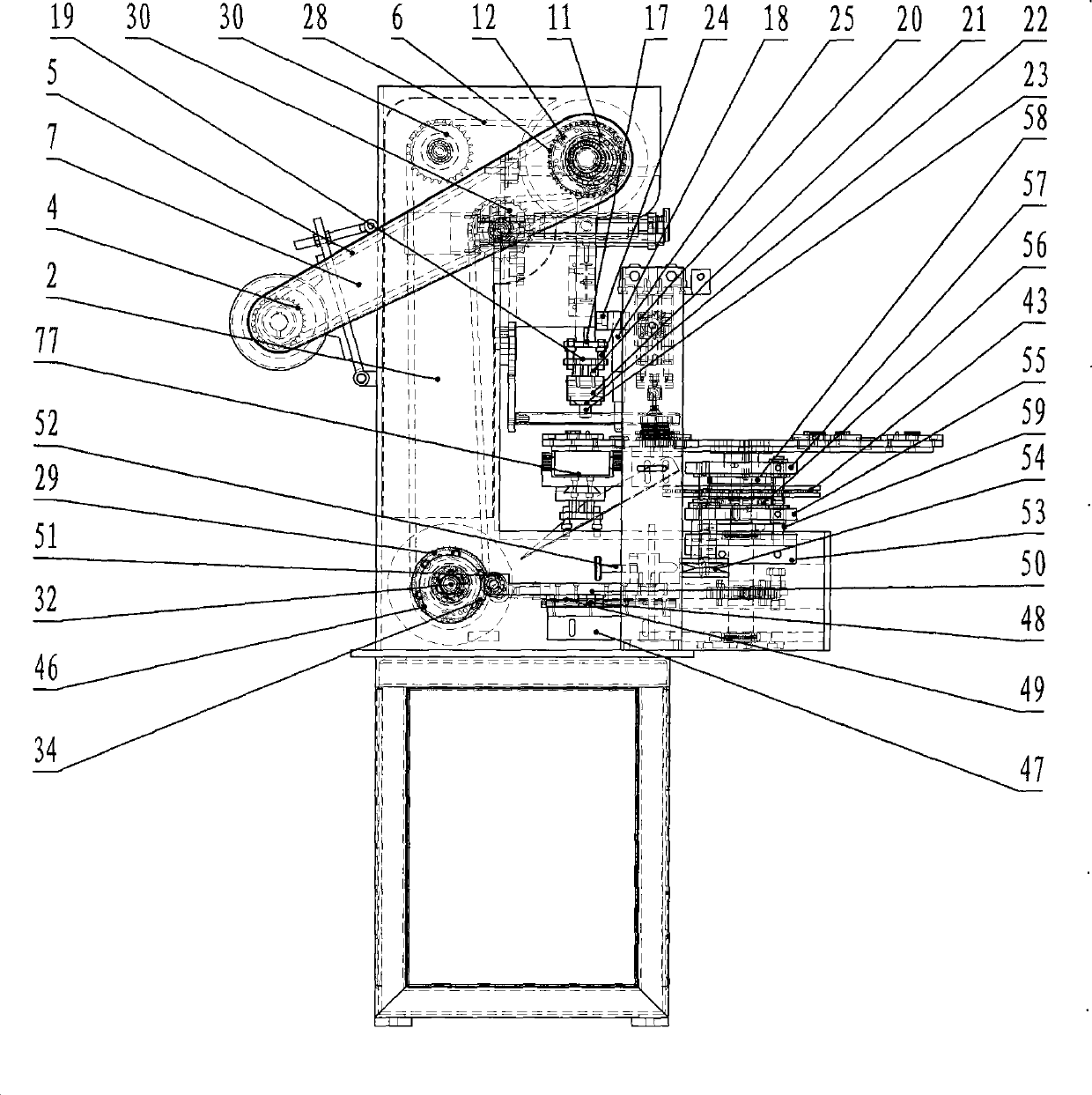

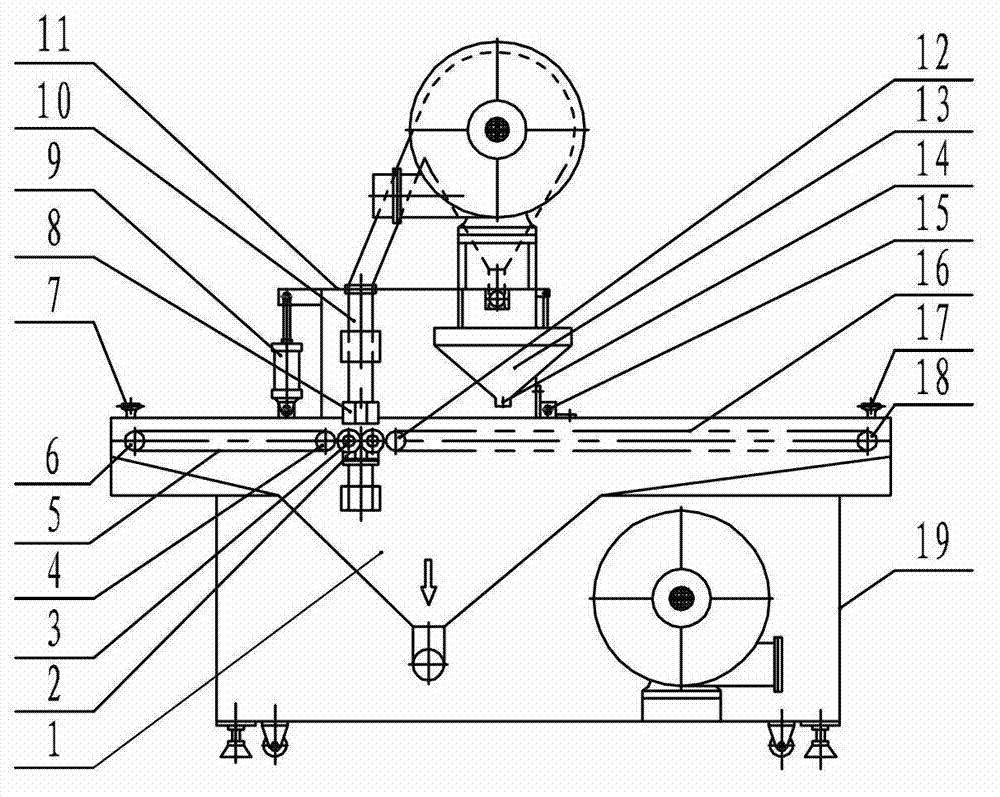

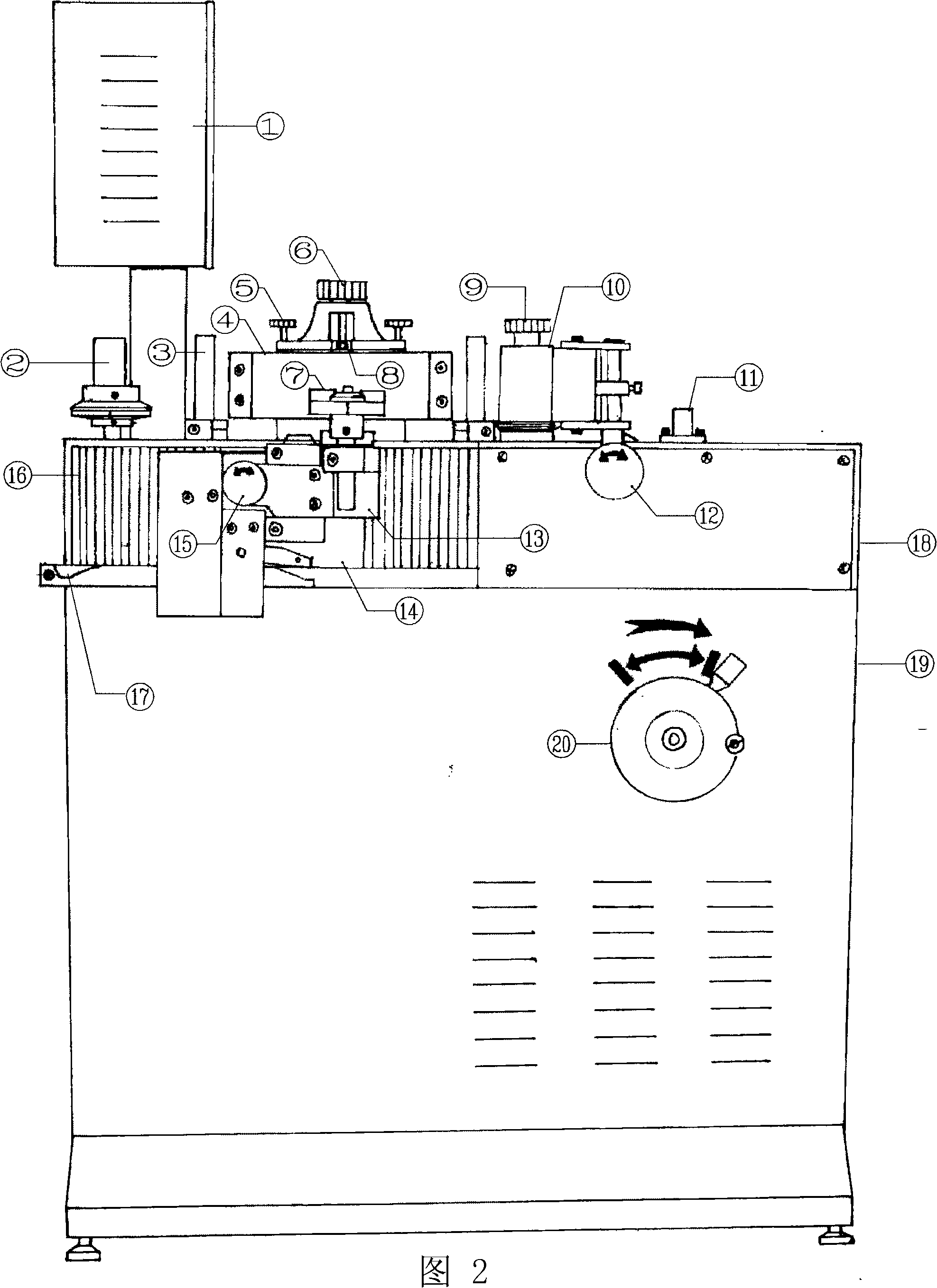

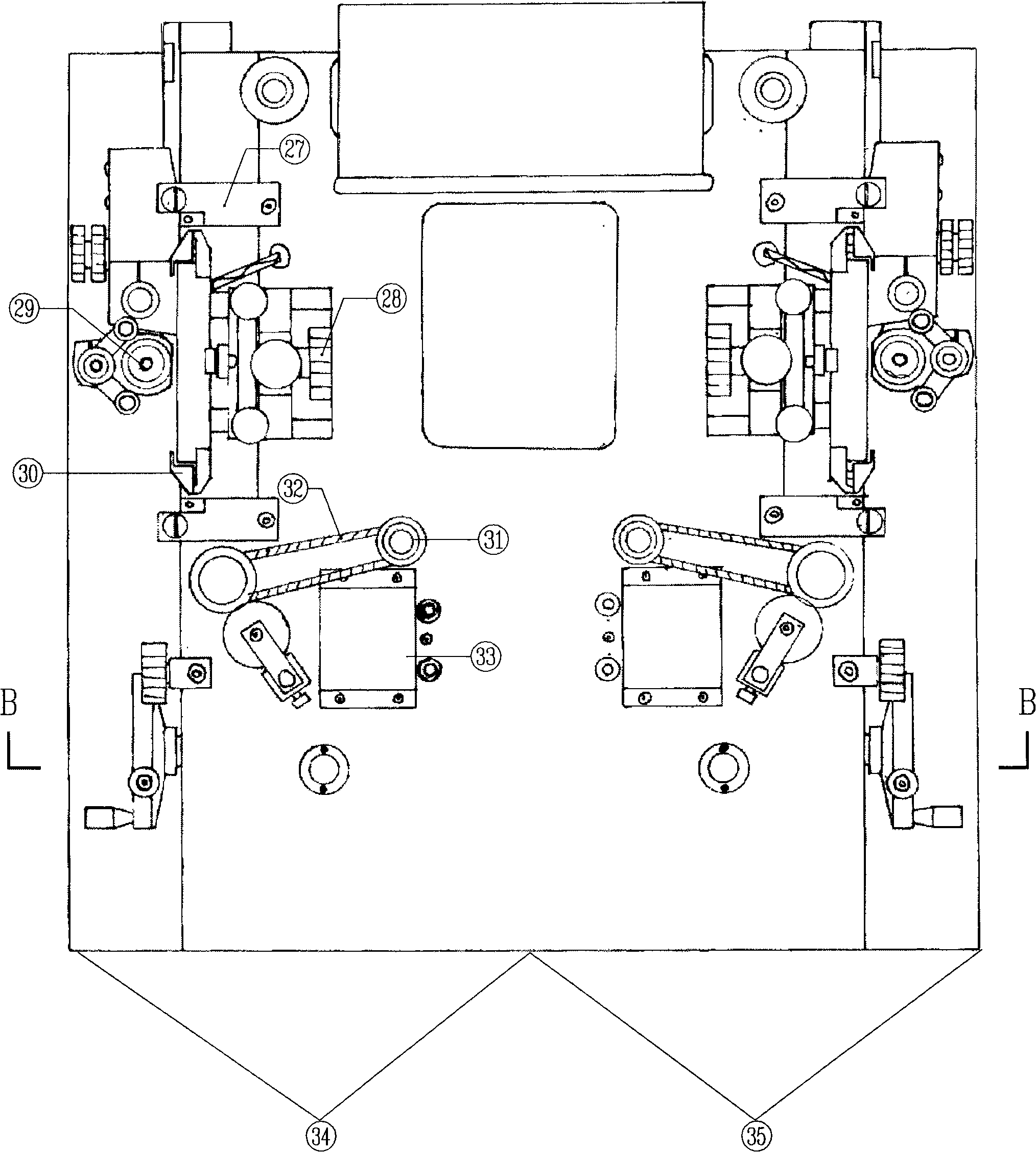

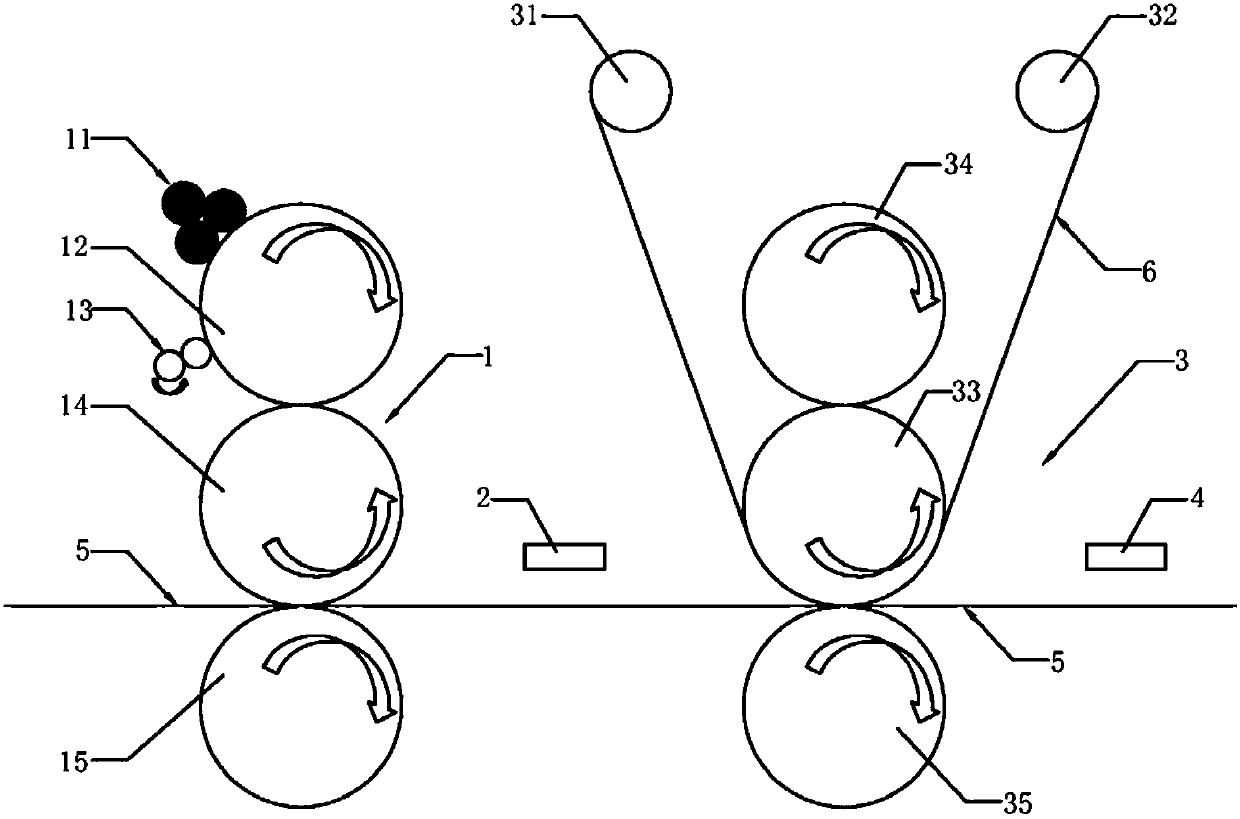

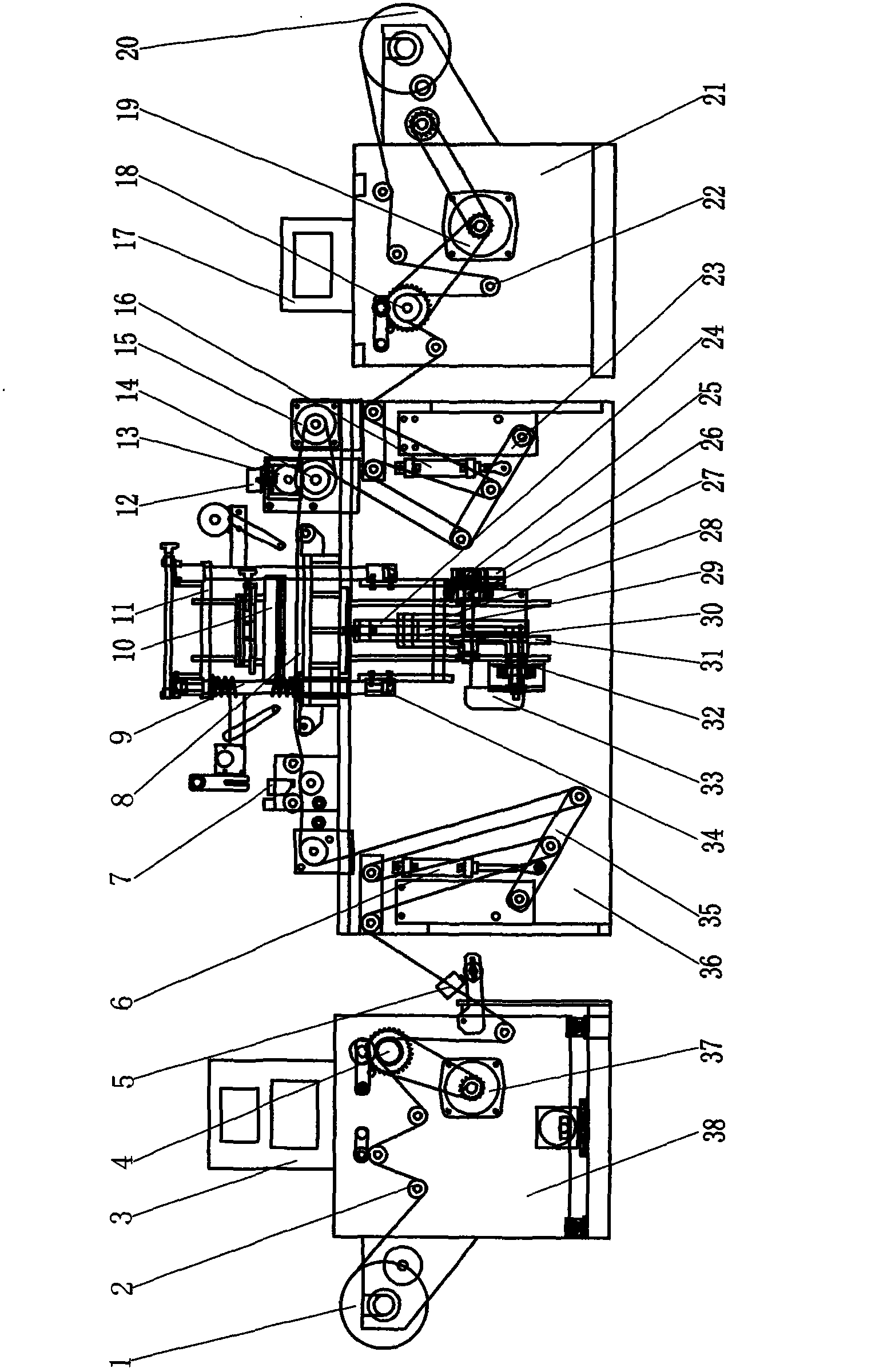

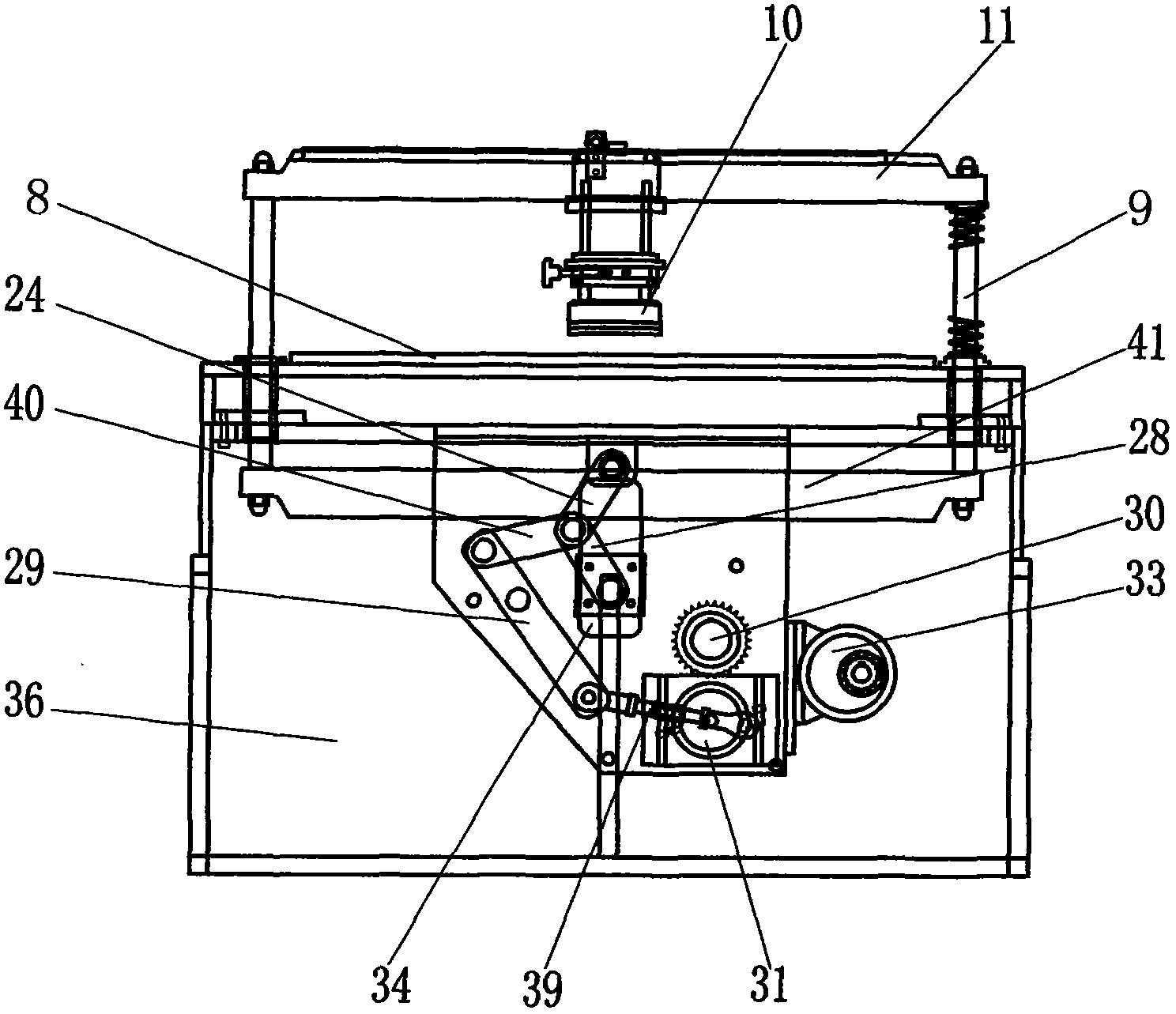

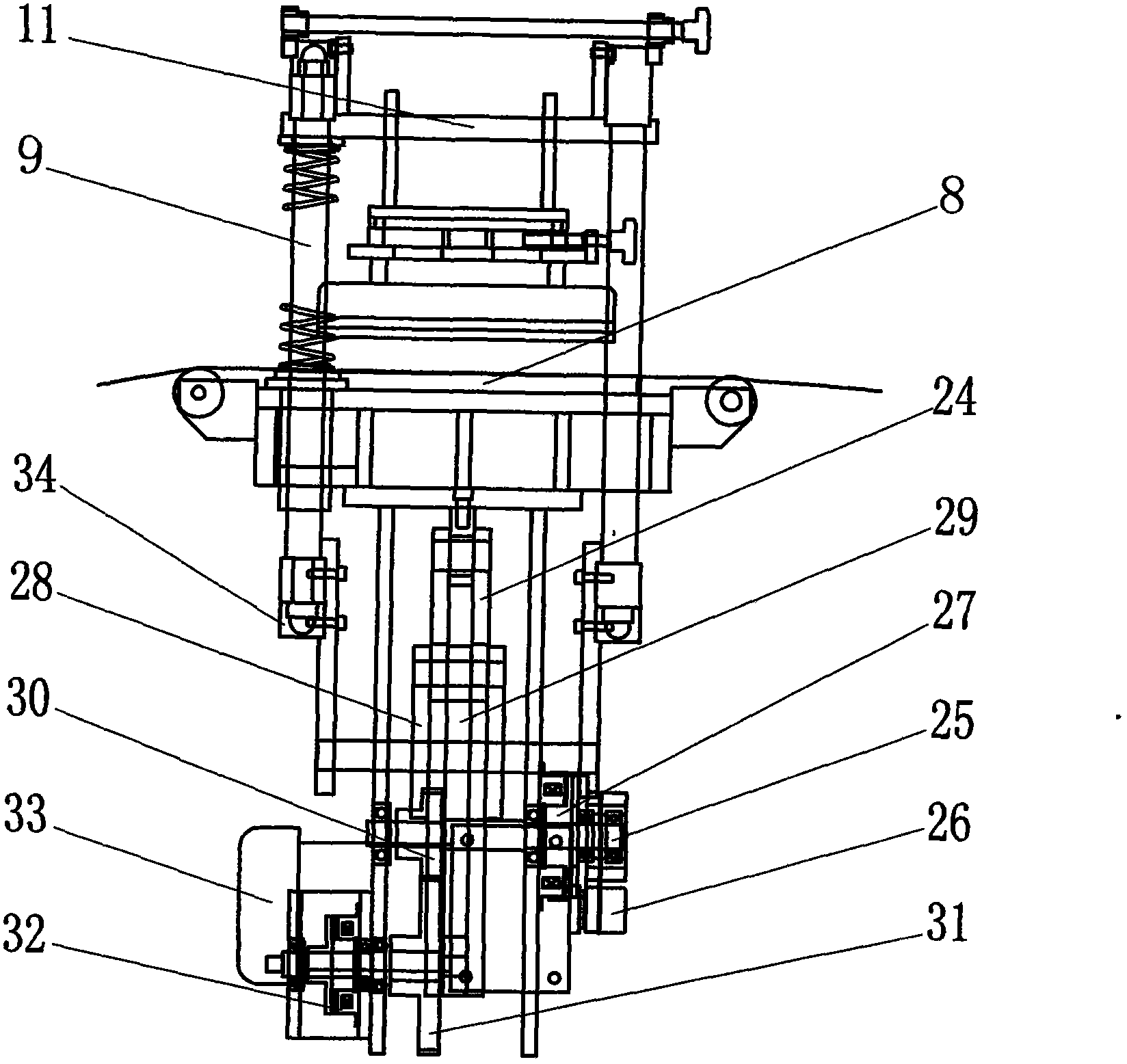

Single paper cold waving printing equipment and operation method thereof

The invention discloses single paper cold waving printing equipment. The equipment comprises a paper feeding unit, a gluing unit, a cold waving unit and a paper collection unit. An operation method of the equipment comprises the following steps of: conveying single paper to the gluing unit through the paper feeding unit; transferring an adhesive onto a part which is required to be subjected to cold waving on the paper, wherein the viscosity of the adhesive printed on the paper is improved by an ultraviolet (UV) curing device I; holding the paper by using a cripper on a cold waving printing roller; discharging electrochemical aluminum which is temporarily stored by using an aluminum storage device; recovering the electrochemical aluminum which remains after the cold waving by using a foil collection roller; pulling the electrochemical aluminum between an impression roller and the cold waving printing roller by using the aluminum storage device towards the paper feeding unit so as to realize the jumping of the electrochemical aluminum, and storing the electrochemical aluminum at the same time; curing a part which is just subjected to the cold waving by using a UV curing device II; and transferring the cured paper by using a chain towards a paper collection pile so as to realize the whole single paper cold waving process. The invention has the advantages that: due to the adoptionof an independent cold waving unit, the single paper is directly subjected to the cold waving, so that the jumping of the electrochemical aluminum can be realized and controlled, and the electrochemical aluminum can be greatly saved.

Owner:MASTERWORK GROUP CO LTD +1

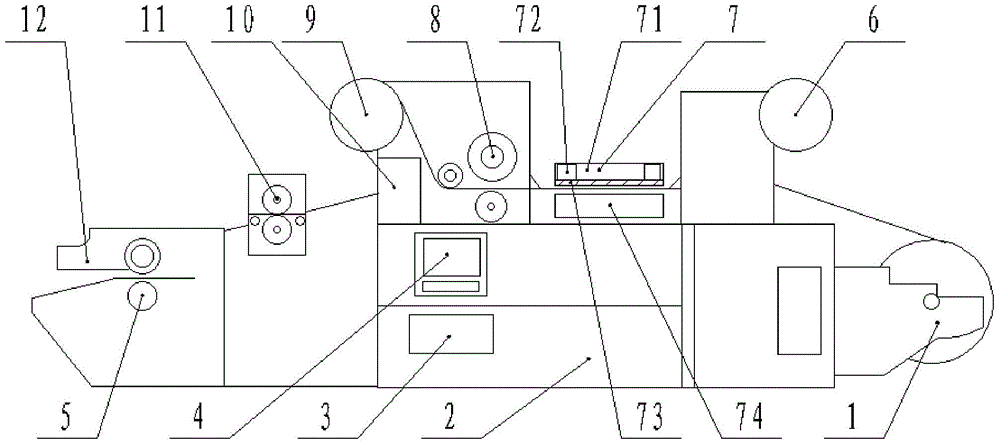

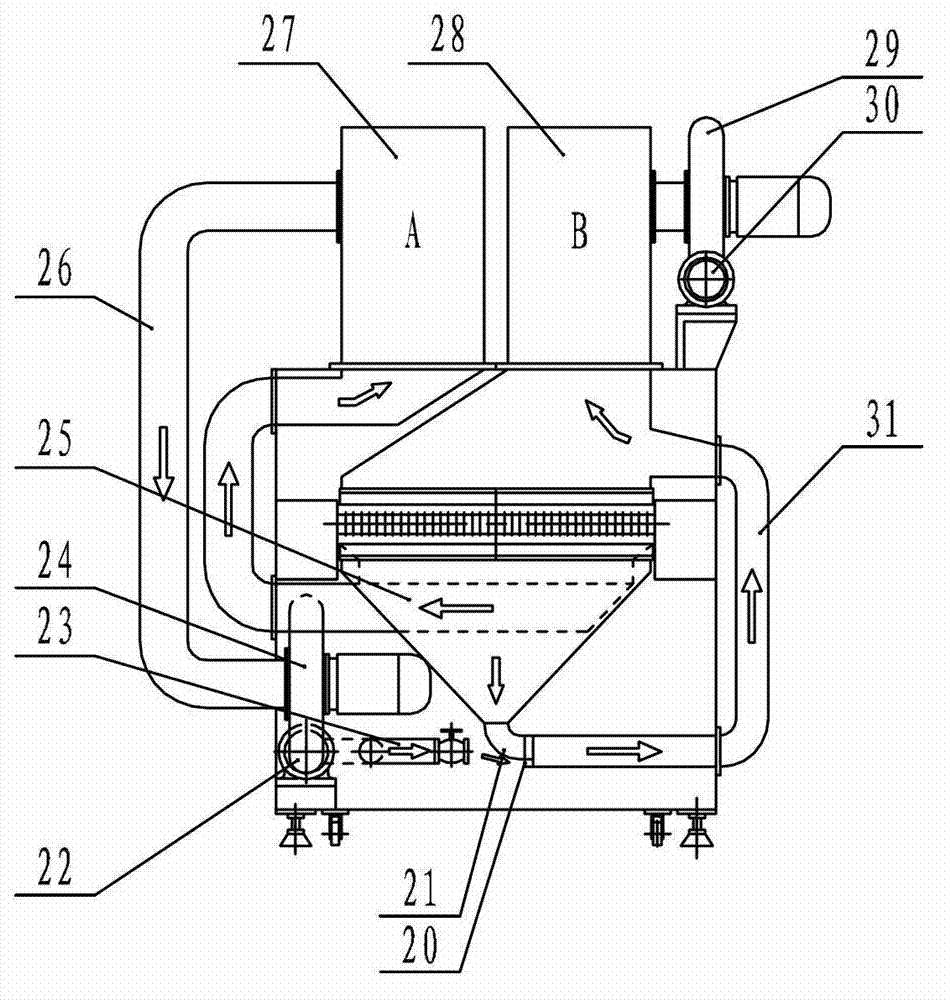

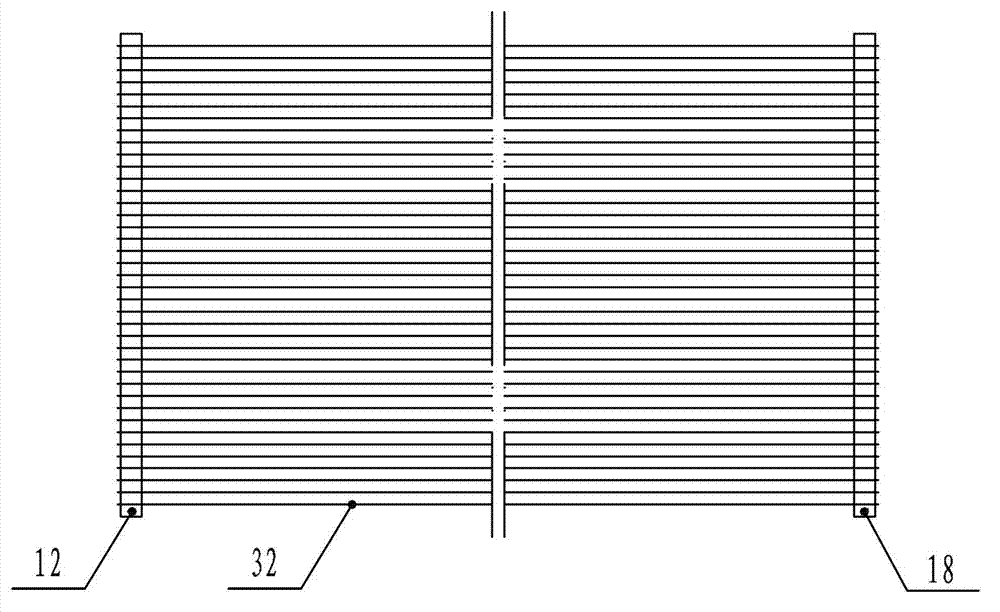

Production equipment for coating and gold-stamping amboss of wallpaper

InactiveCN102815023AAchieve stabilityMechanical working/deformationPaper/cardboardProduction lineControl system

The invention discloses production equipment for a coating and gold-stamping amboss of wallpaper. The production equipment mainly comprises a material discharging unit, a material discharging traction unit, a coating unit, an oven unit, an amboss gold stamping unit, a cooling unit, a material collecting unit and a control system controlling each structural unit, wherein the wallpaper raw material which needs to be machined sequentially penetrates through the material discharging unit, the material discharging traction unit, the coating unit, the oven unit, the amboss gold stamping unit and the cooling unit, and finally enters the material collecting unit, and the control system comprises control sensors arranged on the structural units and a controller transmitting a control instruction. After the production equipment is adopted, the coating, the gold stamping, the embossing and the separate coiling are combined on one production line, and the conventional method of segmenting can be changed. A PVC (polyvinyl chloride) coating semi-finished product is compounded with a gold film by the waste heat after the coating and the drying.

Owner:广东壹晨科技有限公司

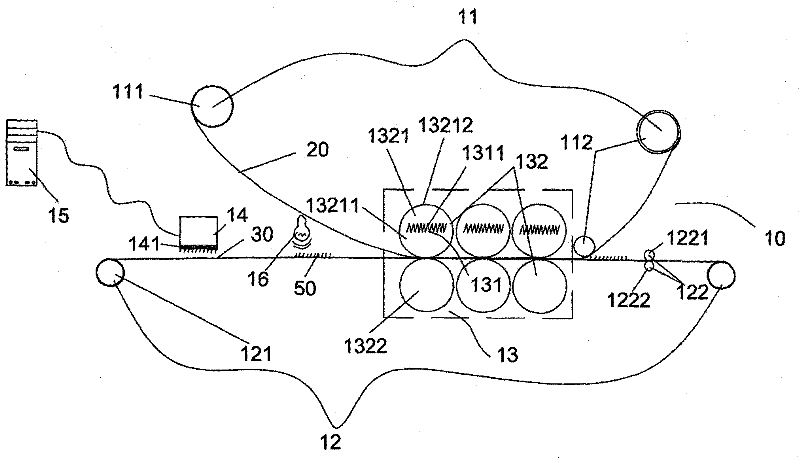

Thermoprinting equipment and thermoprinting method based on ink-jet printing device

InactiveCN102689497AHigh glossIncrease printing speedPattern printingBronze printingAdhesiveEngineering

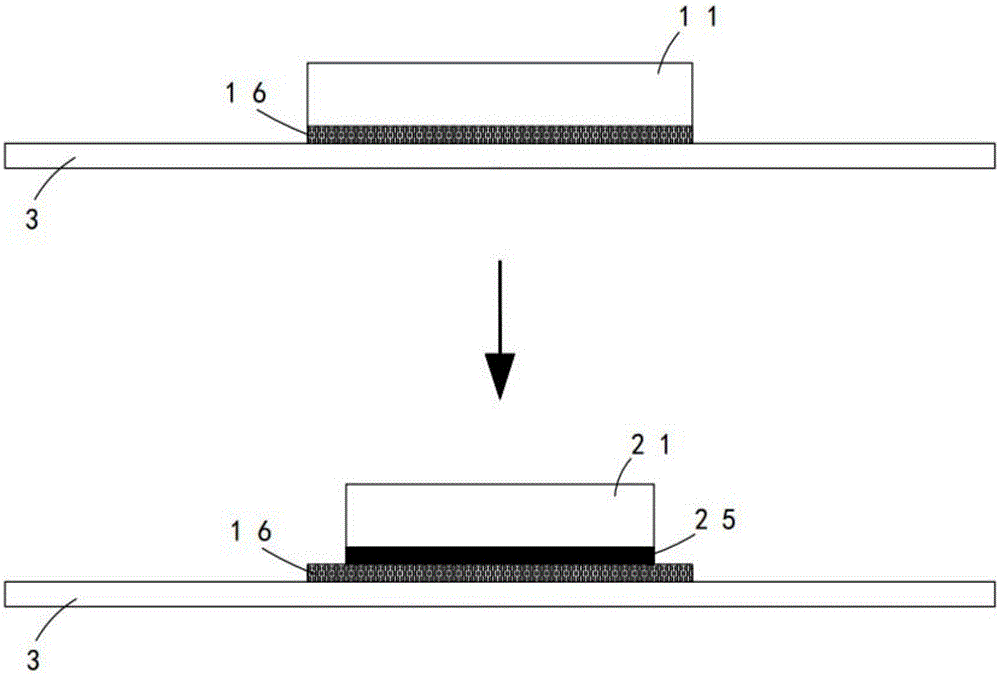

The invention relates to thermoprinting equipment and a thermoprinting method based on an ink-jet printing device. The thermoprinting equipment provided in the invention comprises a thermoprinting foil conveying device used for conveying thermoprinting foils, a printing stock conveying device used for conveying printing stocks and an pressing device used for bonding the thermoprinting foils and the printing stocks. The thermoprinting equipment is characterized by further comprising the ink-jet printing device used for carrying out jet-printing to print adhesives on the thermoprinting foils or the printing stocks; the adhesives are printed between the thermoprinting foils and the printing stocks. According to the invention, instead of in a coating way, the adhesives are printed on the thermoprinting foils by using the ink-jet printing device connected with a computer; no plate making is needed. When thermoprinting of variable graphic information is carried out, production efficiency is obviously improved; cost is saved; smoothness and glossiness of thermoprinting foil surfaces can be further improved; color and appearance of printed images and printed texts are better; and bonding strength between the thermoprinting foils and the printing stocks is strong even if thermoprinting is carried out on a porous material with strong permeability.

Owner:李华容

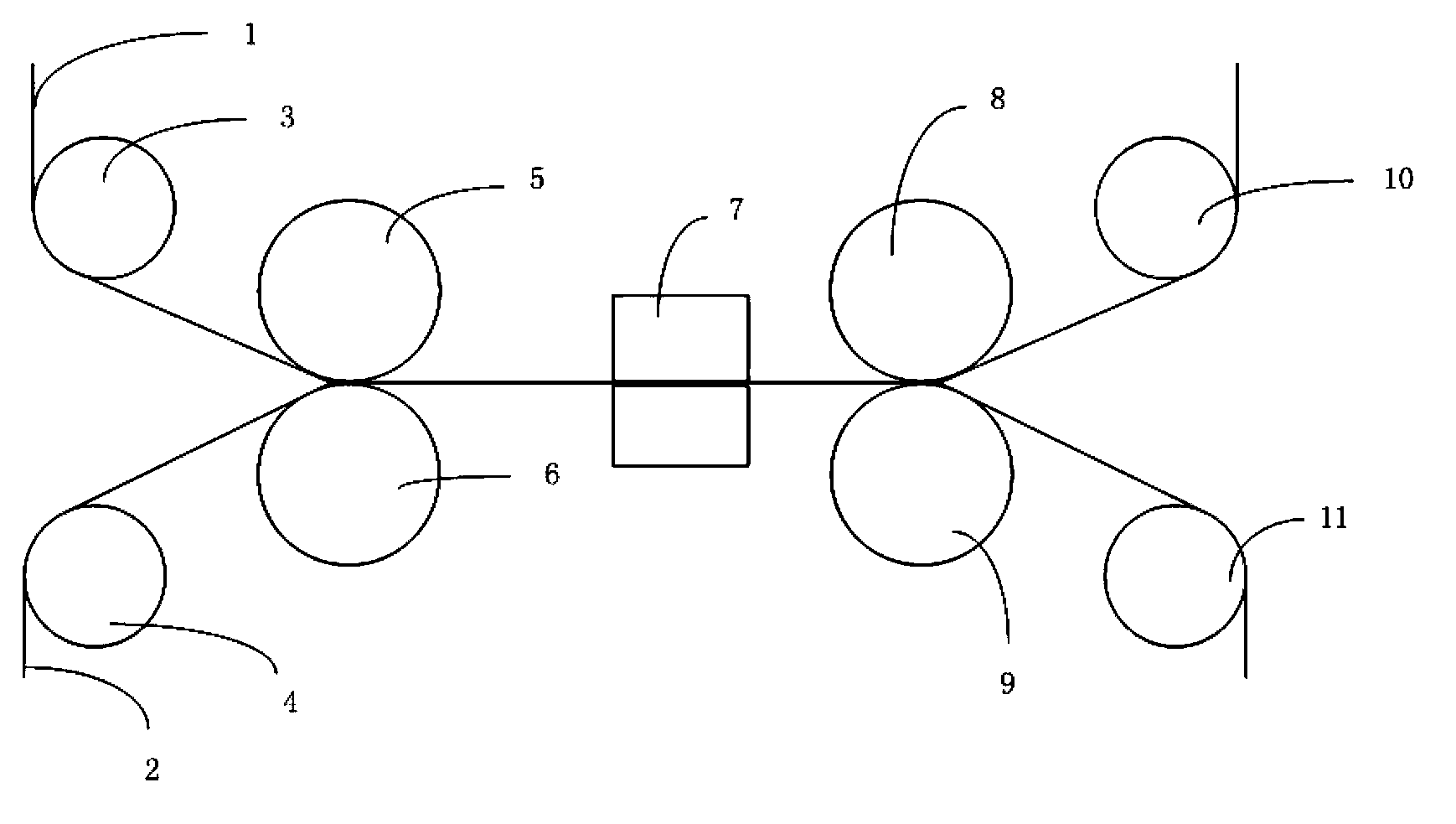

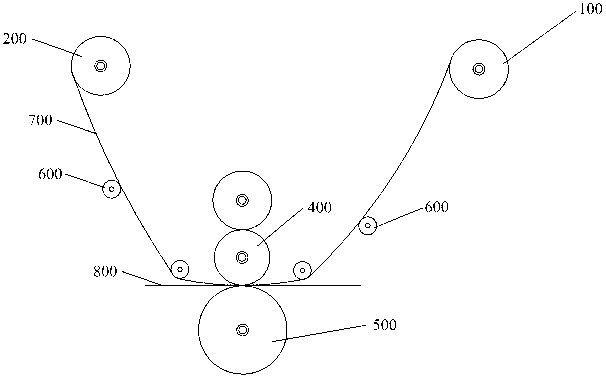

Cold foil printing equipment

ActiveCN101716850AReduce wasteIncrease productivityBronze printingRotary pressesHot stampingControl system

The invention provides cold foil printing equipment, which comprises a printing material feeding mechanism and a printing material collecting mechanism, wherein a first printing material delivery mechanism, a coating mechanism, a second printing material delivery mechanism, a press-in mechanism, a curing mechanism and a third printing material delivery mechanism are sequentially arranged between the printing material feeding mechanism and the printing material collecting mechanism; a hot stamping foil uncoiling mechanism is arranged above the second printing material delivery mechanism; and a hot stamping foil coiling mechanism is arranged above the third printing material delivery mechanism; the press-in mechanism comprises a coining roll and a transfer roll; the hot stamping foil uncoiling mechanism comprises an uncoiling roll and an uncoiling roll shaft; the hot stamping foil coiling mechanism comprises a coiling roll and a coiling roll shaft; a tension roll and a metal drawing roll are arranged between the coining roll and the uncoiling roll and the coiling roll; the coining roll is controlled by a jump clutch; the metal drawing roll, the uncoiling roll and the coiling roll are driven by a servo motor; and the servo motor is controlled by an electronic jump control system. The equipment can reduce the waste of the hot stamping foil to a maximum degree.

Owner:SHENZHEN JINJIA GRP

Gilding press

InactiveCN103660544ASimple structureEasy to operateRotary pressesBronze printingHot stampingPulp and paper industry

The invention provides a gilding press which comprises a paper transferring roller for transferring paper to be gilded, a film transferring roller for transferring hot stamping foils, a first gilding roller, a second gilding roller, a heating device for performing further treatment on paper and hot stamping foils which are pressed together, a motor for providing power for the rollers, wherein the first gilding roller and the second gilding roller are meshed with each other and used for pressing the paper and the hot stamping foils together. The gilding press has the advantages of being simple in structure, convenient to operate, high in working efficiency, good in gilded characters, patterns and the like and the like.

Owner:昆山亿达包装有限公司

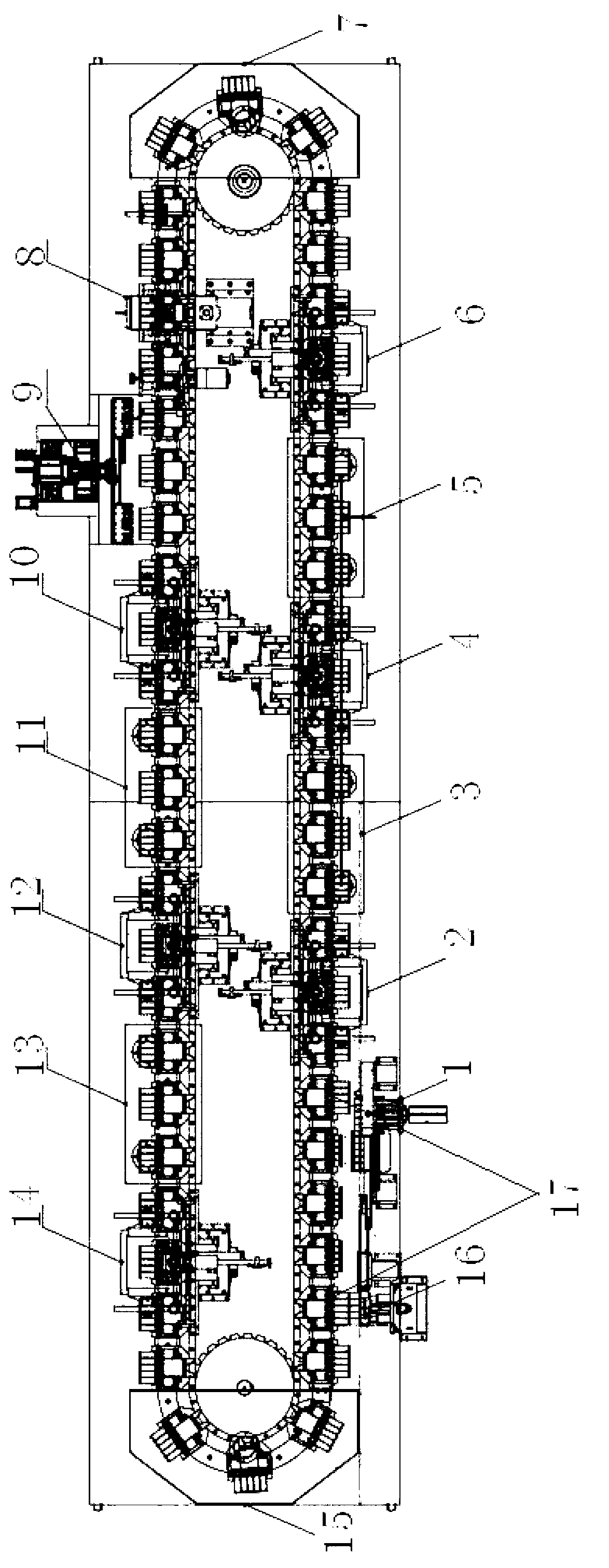

Lighter casing automatic screen printer

ActiveCN103273731ARealize automatic feeding processScreen printersBronze printingHot stampingScreen printing

The invention discloses a lighter casing automatic screen printer. The lighter casing automatic screen printer is a ring-shaped automatic screen printing production line which comprises an automatic charging portion, at least one A surface screen printing and drying portion composed of a screen printing portion and a drying portion, a hot stamping machine portion, an automatic casing overturning portion, at least one B surface screen printing and drying portion composed of a screen printing portion and a drying portion, and an automatic discharging portion which are arranged according to a production flow sequence, and the automatic screen printing production line further comprises a plurality of fixture mold cores moving along the whole production line. The lighter casing automatic screen printer achieves the full-automatic production of automatically charging of the screen printing of a lighter casing, automatically overturning of the lighter casing after the drying and the screen printing, and completing the screen printing and the drying of the other surface and the discharging process.

Owner:肇庆市百得工业制造有限公司

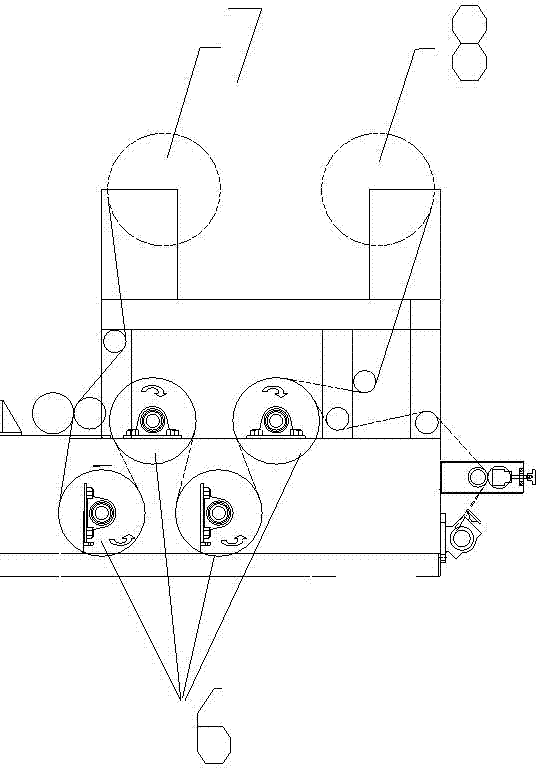

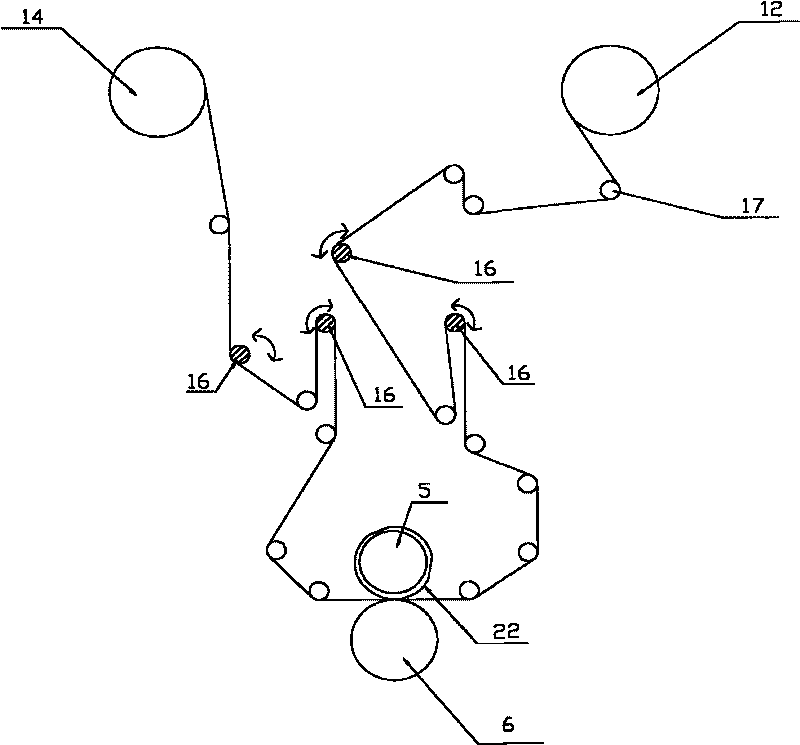

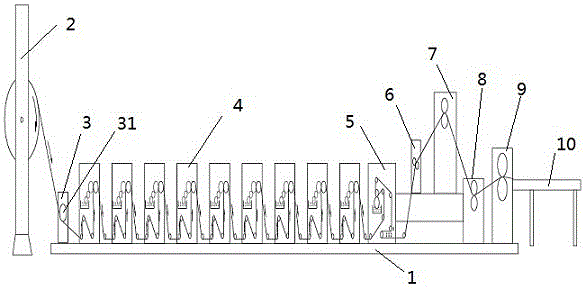

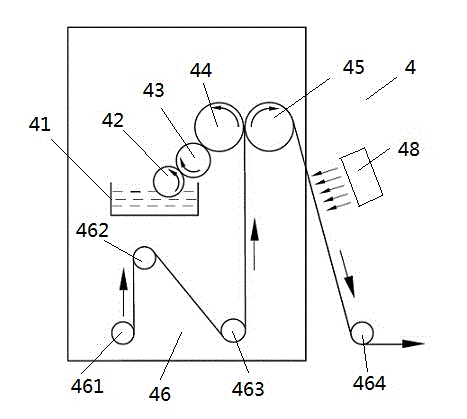

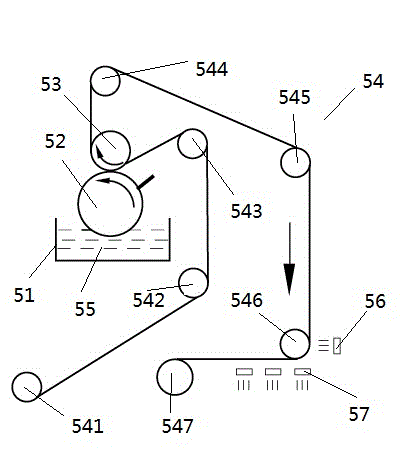

Cold wave device and method for saving cold wave foils

ActiveCN103264575AIncrease the lengthShorten the lengthBronze printingRotary pressesEngineeringPaper sheet

The invention discloses a cold wave device and a method for saving cold wave foils. The cold wave device comprises a foil supply roller, a foil withdrawing roller, a rubber roller, an impressing roller, a motive power roller, a regulating mechanism, a support frame and a controller, wherein rubber cloth and rubber cloth interleaving paper in the shape corresponding to patterns to be transferred are arranged on the rubber roller, and the rubber cloth covers the rubber roller and the rubber cloth interleaving paper. According to the invention, the rubber cloth interleaving paper in the shape corresponding to the patterns to be transferred is arranged on the rubber roller, when the part of the rubber roller without the rubber cloth interleaving paper rotates to a position in press fit with the cold wave foils, the motive power roller tightly clamps the cold wave foils so that the conveying of the cold wave foils between the rubber roller and the impressing roller stops. Meanwhile, the length of a cold wave foil supply part is prolonged by the regulating mechanism, and the length of a cold wave foil withdrawing part is shortened by the regulating mechanism, so when the cold wave foils do not need to be impressed on the paper, the transferring of the impressing part of the cold wave foils stops, the paper feeding speed, the foil supply speed and the foil withdrawing speed cannot be influenced, the production efficiency is ensured, and the cold wave foils are saved.

Owner:SHENZHEN JINJIA GRP +1

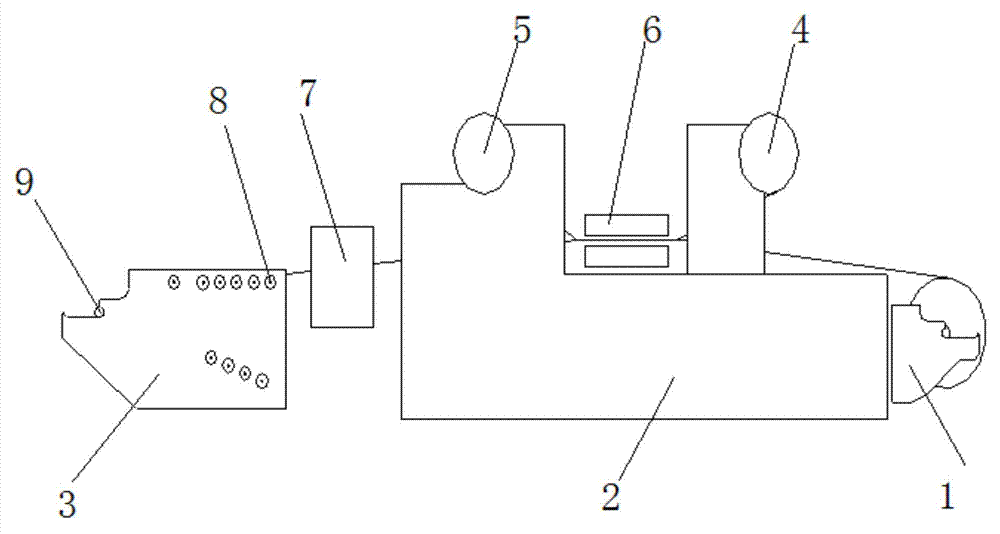

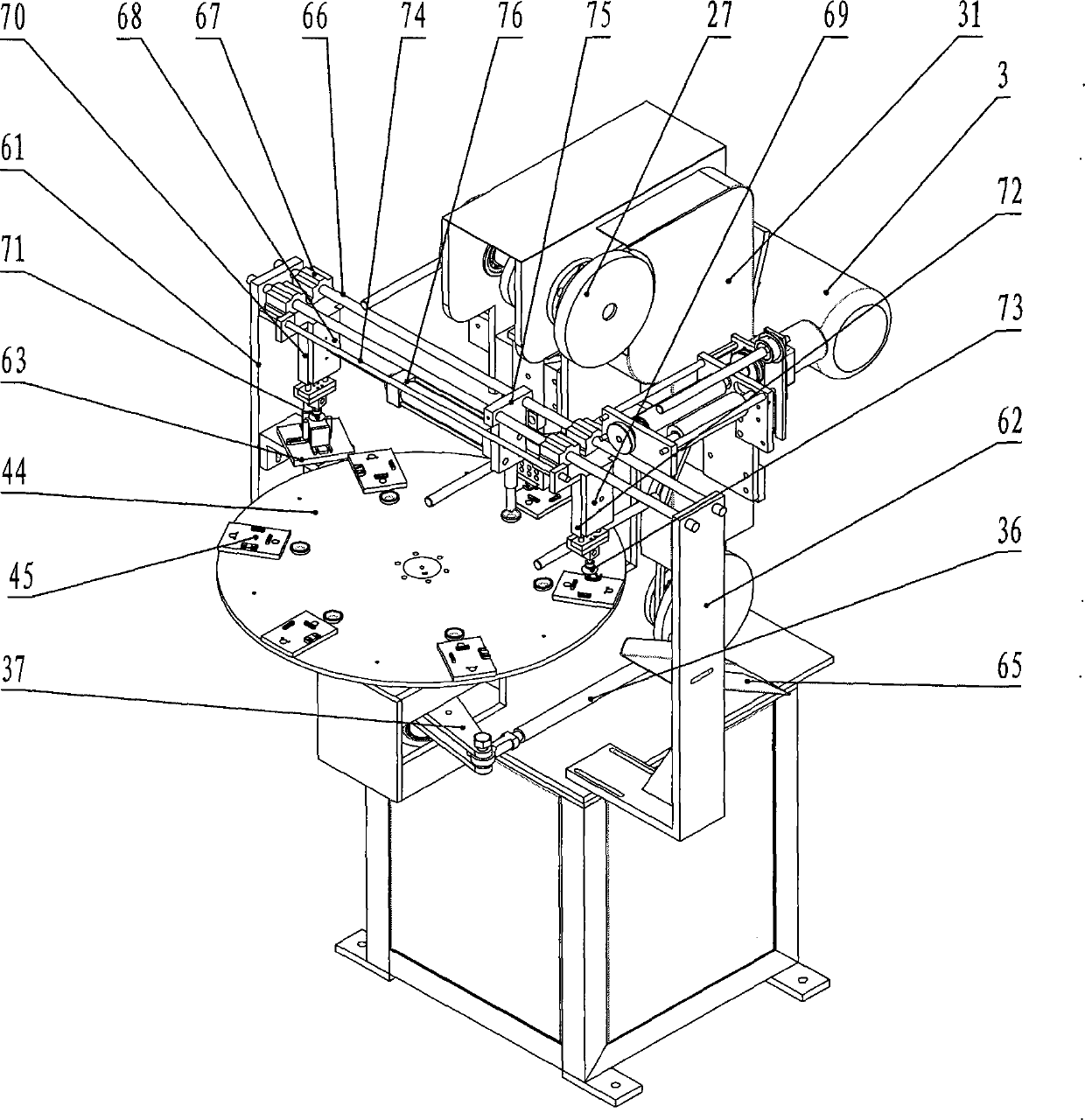

Fully-automatic shoe material stamping machine

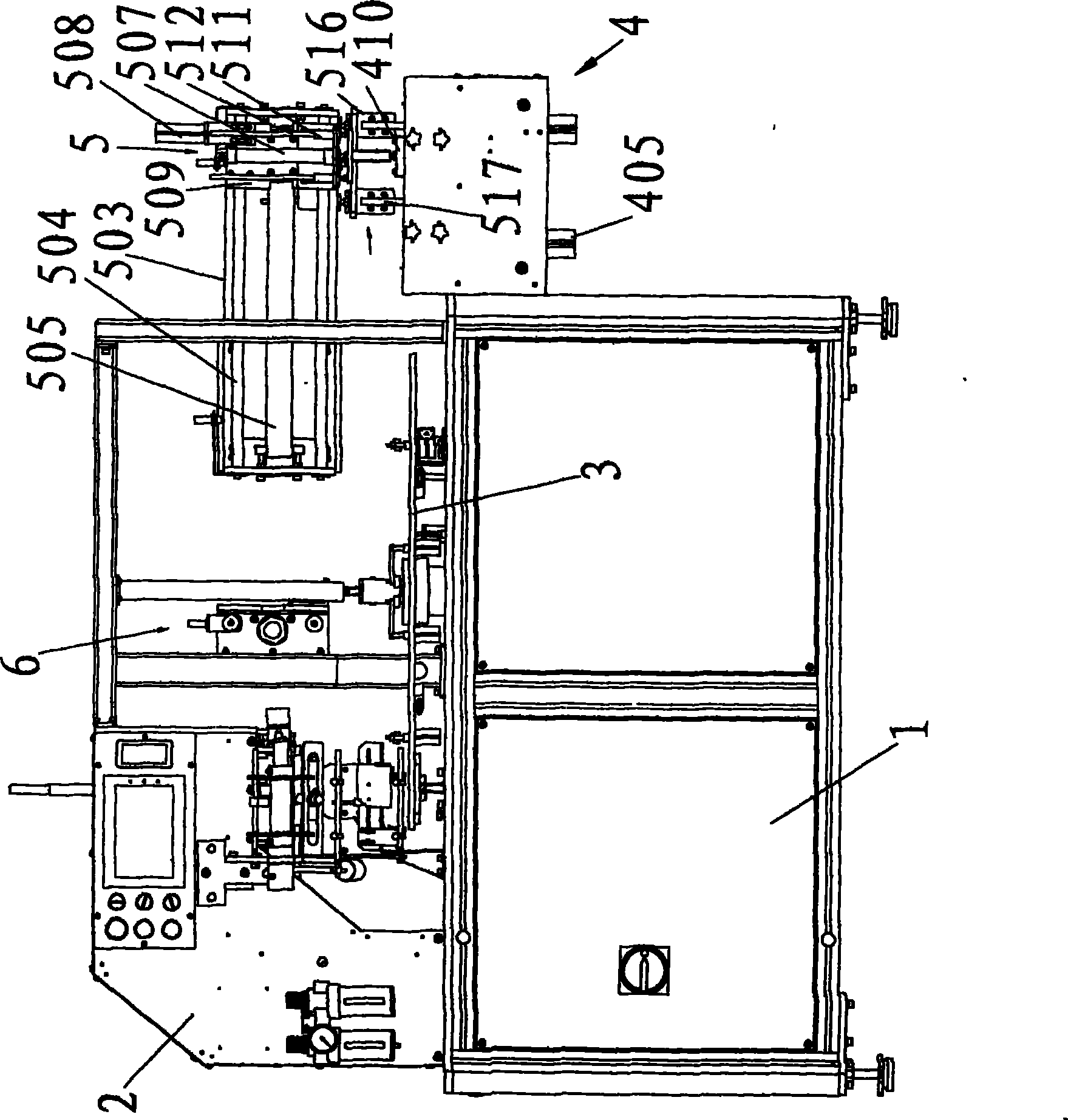

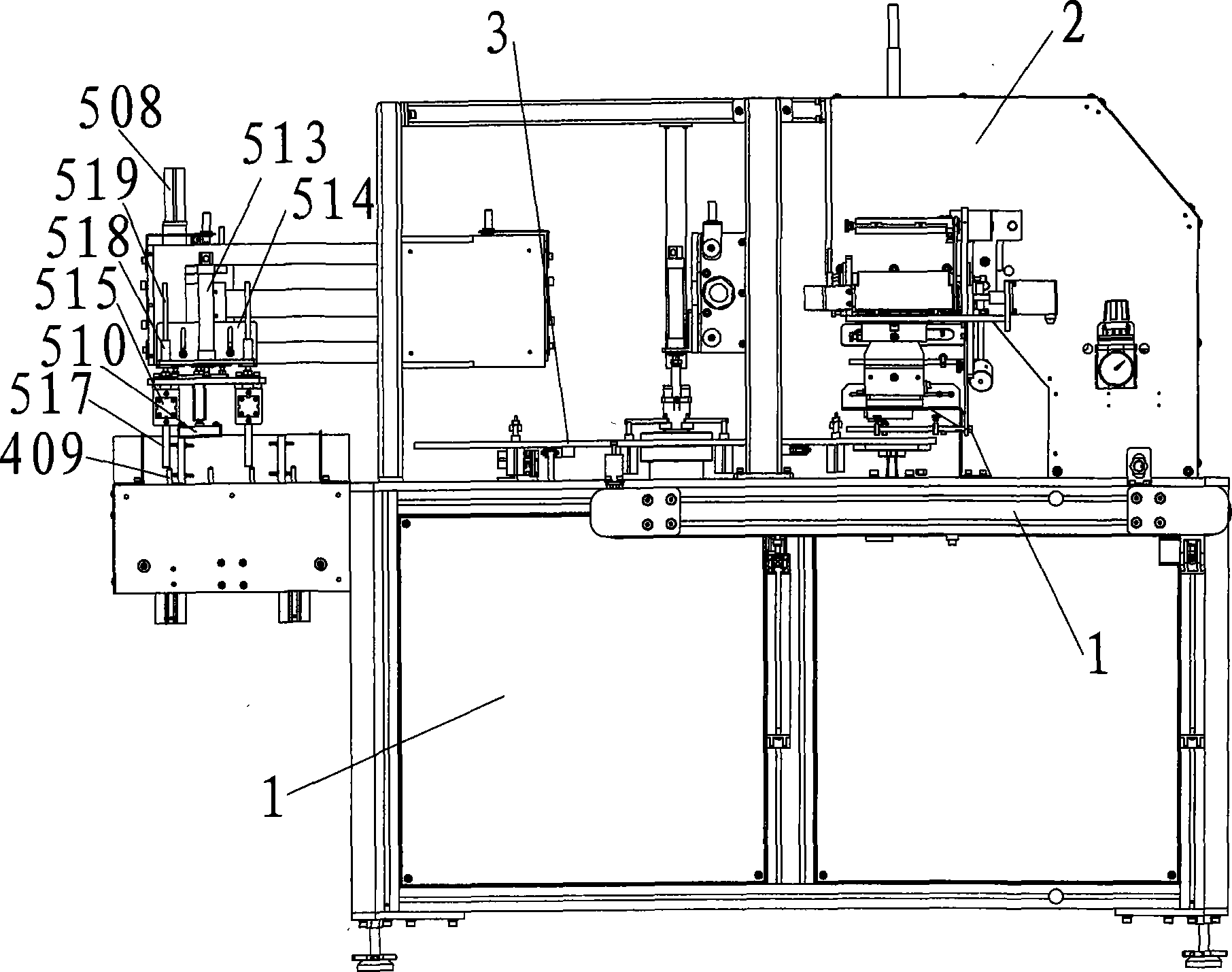

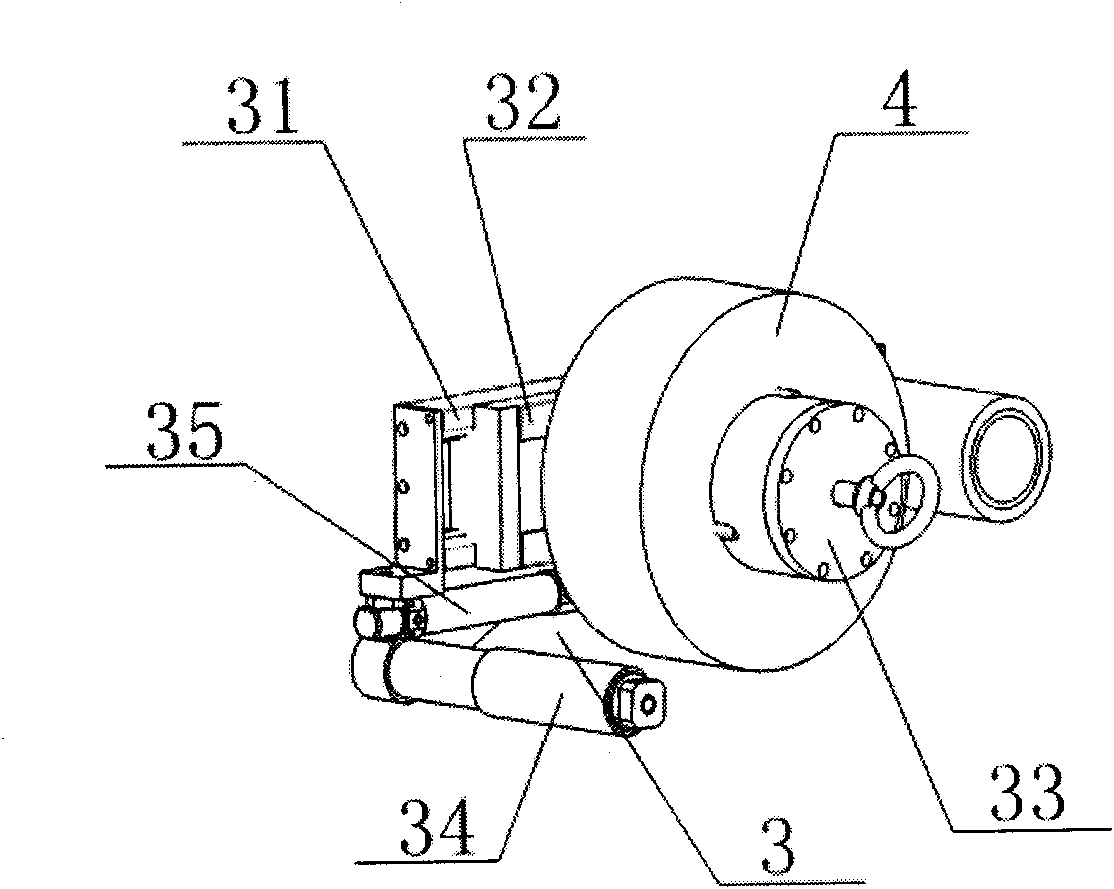

InactiveCN103072374AImprove turnover rateHigh degree of automationRotary pressesBronze printingEngineeringFully automatic

The invention provides a fully-automatic shoe material stamping machine. The fully-automatic shoe material stamping machine comprises a machine box, a stamping mechanism, a multi-station rotating plate mechanism, a material-conveying platform, a loading mechanism, an unloading mechanism and a transmission line, wherein the stamping mechanism and the multi-station rotating plate mechanism are respectively arranged on the machine box; the material-conveying platform, the loading mechanism, the unloading mechanism and the transmission line are respectively arranged on the machine box; the stamping mechanism, the loading mechanism and the unloading mechanism are correspondingly arranged around the multi-station rotating plate mechanism and are respectively and sequentially matched with corresponding stations of the multi-station rotating plate mechanism; the material-conveying platform is correspondingly arranged on one side of a loading position of the machine box and is sequentially matched with the loading mechanism above the material-conveying platform; and the transmission line is correspondingly arranged on one side of an unloading position of the machine box and is sequentially matched with the unloading mechanism above the transmission line. The automation degree is high, and the loading and unloading processes are completely finished by automatic machinery. Compared with the traditional manual loading and unloading processes, the fully-automatic shoe material stamping machine has the advantages that the labor can be greatly saved, the working efficiency is improved, and the turnover rate of materials is improved.

Owner:王显祺

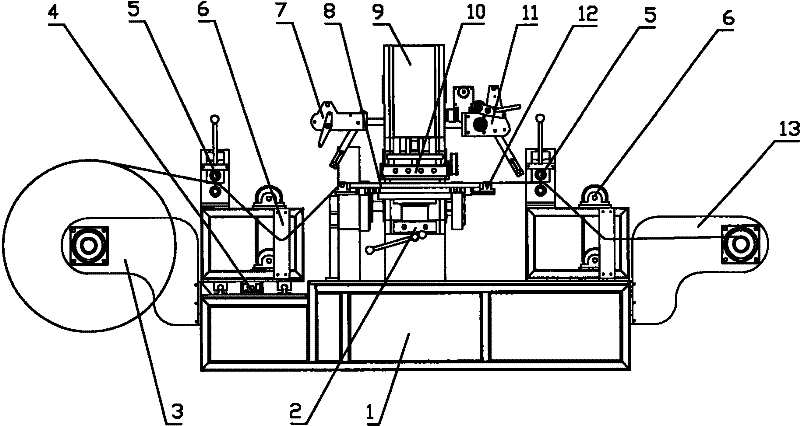

High-speed automatic hot foil printing machine for thermal-shrinkage film

InactiveCN102173194ASimple and fast operationImprove work efficiencyRotary pressesBronze printingHot stampingPolyvinyl chloride

The invention relates to a high-speed automatic hot foil printing machine for a thermal-shrinkage film, comprising a stand, a handpiece and a main motor. A work bench lifting mechanism is arranged in the middle of the upper front part of the stand and supports a work bench, the handpiece is arranged in the middle of the rear part of the upper surface of the stand, and a heating head is arranged at the lower side of the front part of the handpiece. The high-speed automatic hot foil printing machine is characterized in that the left end and the right end of the work bench are respectively provided with a guiding and locating device, a discharging frame is arranged on the left surface of the stand, a rectification mechanism is arranged at the left part of the upper surface of the stand, a floating mechanism is arranged at the upper side of the rectification mechanism, a dragging mechanism is arranged at the upper side of the floating mechanism, the floating mechanism is arranged at the right part of the upper surface of the stand, the dragging mechanism is arranged at the upper side of the floating mechanism, and a material collecting frame is arranged on the right surface of the stand. The invention solves the problem that the traditional hot foil printing machine can not be used for carrying out the continuous hot-stamping on materials, such as the thermal-shrinkage film, PVC (Polyvinyl Chloride), paper and the like, and is suitable for hot-stamping of characters or patterns.

Owner:QINGDAO HAIGANG GILDING PRESS EQUIP

Leather bronzing technique

InactiveCN101570800AImprove adhesionStrong three-dimensional senseTransfer printingDuplicating/marking methodsPowder coatingBronzing

The invention discloses a leather bronzing technique, which can thermally print gold powder coating on the leather surface, can ensure the lasting adhesion of the gold powder and further improve the third dimension of thermally printed patterns. The leather bronzing technique overprints embossing with convex and concave feelings on the leather via a template, before overprinting, silver paper coated with gold powder is paved on the leather, during overprinting, the gold powder on the silver paper is thermally printed onto the embossing surface by the template to form a gold powder coating. The technique combines bronzing and overprinting, overprints the patterns or decorative designs on the template onto the leather surface to form embossing with convex and concave feelings, and simultaneously thermally prints the gold powder coating on the silver paper onto the embossing surface under certain pressure and temperature, thus can transfer and print the gold powder coating onto the leather surface according to pictures and texts on the template and ensure lasting adhesion of the gold powder, meanwhile, the thermally printed patterns have great third dimension and lustre sensation, thus greatly improving the visual effect of leather products.

Owner:杨洪

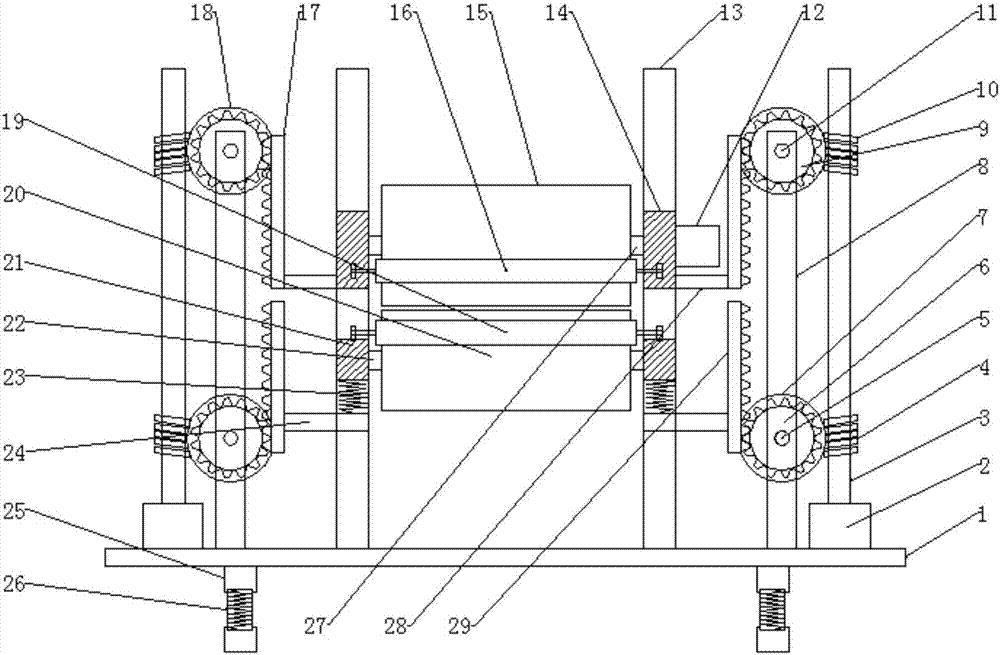

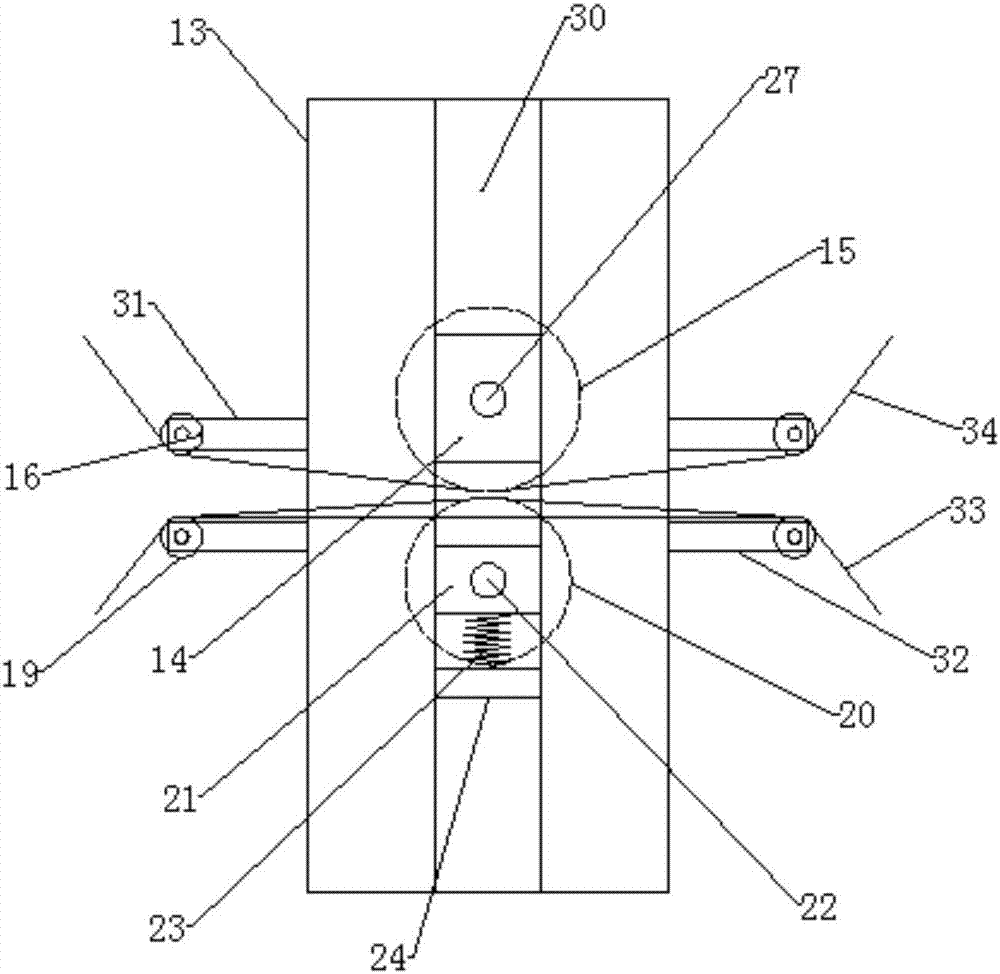

Roller type hot printing device for packaging printing production line

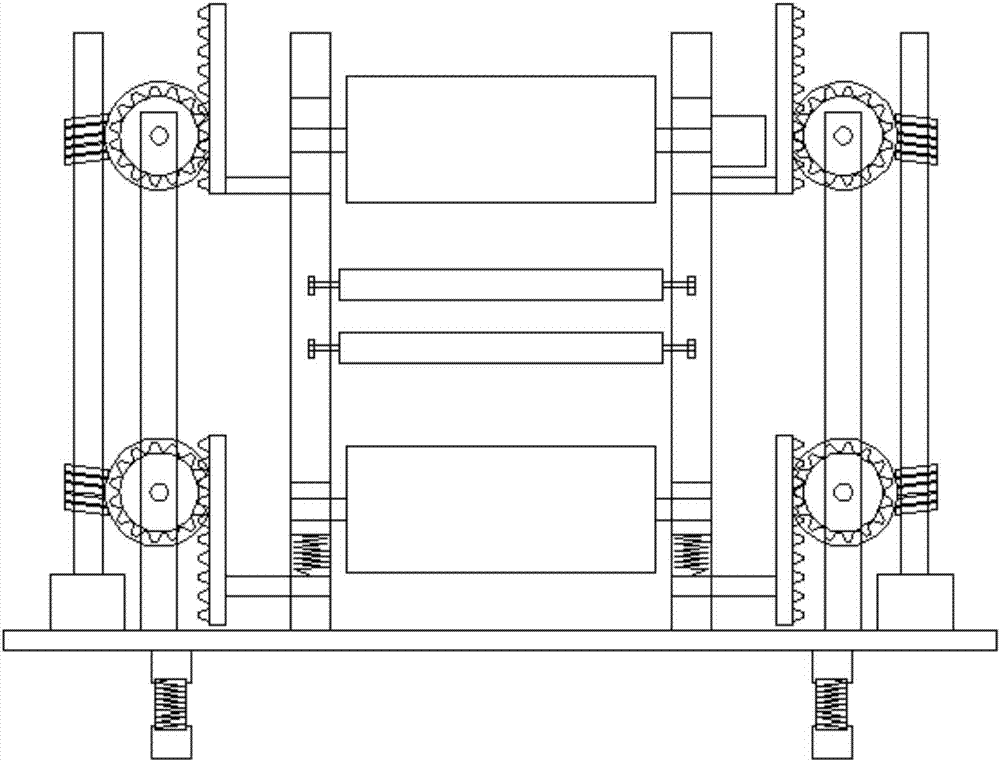

InactiveCN107187198AGuaranteed printing qualityMeet different production needsBronze printingRotary pressesProduction lineTurbine

The invention discloses a drum type hot stamping device for a packaging and printing production line, which comprises a base plate, a supporting leg, a shock absorbing device, a first supporting plate, a hot stamping roller, a backing roller, a first rotating shaft, a first slider, and a chute , the second rotating shaft, the second slider, the first rack, the first gear, the third rotating shaft, the first worm gear, the first helical tooth, the fourth rotating shaft, the spring, the second rack, the second gear, The fifth rotating shaft, the second worm gear and the second helical teeth, the present invention is provided with a first support plate, a chute and a second slider, so that when the thickness of the paper tape changes, the backing roller is always tightly attached to the hot stamping roller , to adapt to paper tapes of different thicknesses, with a first helical tooth, a second helical tooth, a first worm gear, a second worm gear, a first gear, a second gear, a first rack, a second rack, a first slide The block and the second slider adjust the distance between the backup roller and the hot stamping roller through the cooperation of the above components to meet different production needs. The operation is simple, convenient and practical.

Owner:FOSHAN ZHENGLUE INFORMATION TECH CO LTD

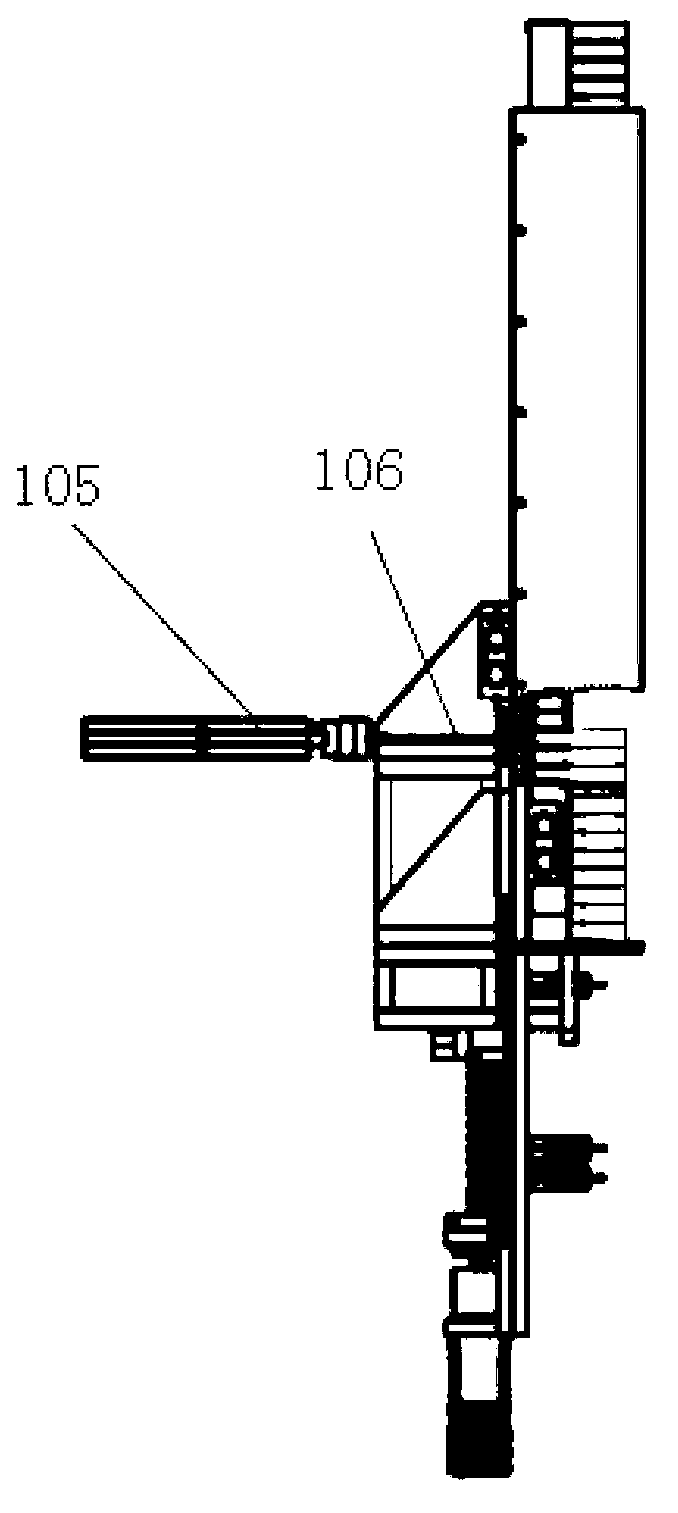

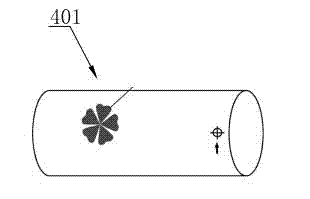

Digital holographic high-precision foil-feeding device of bronzing machine

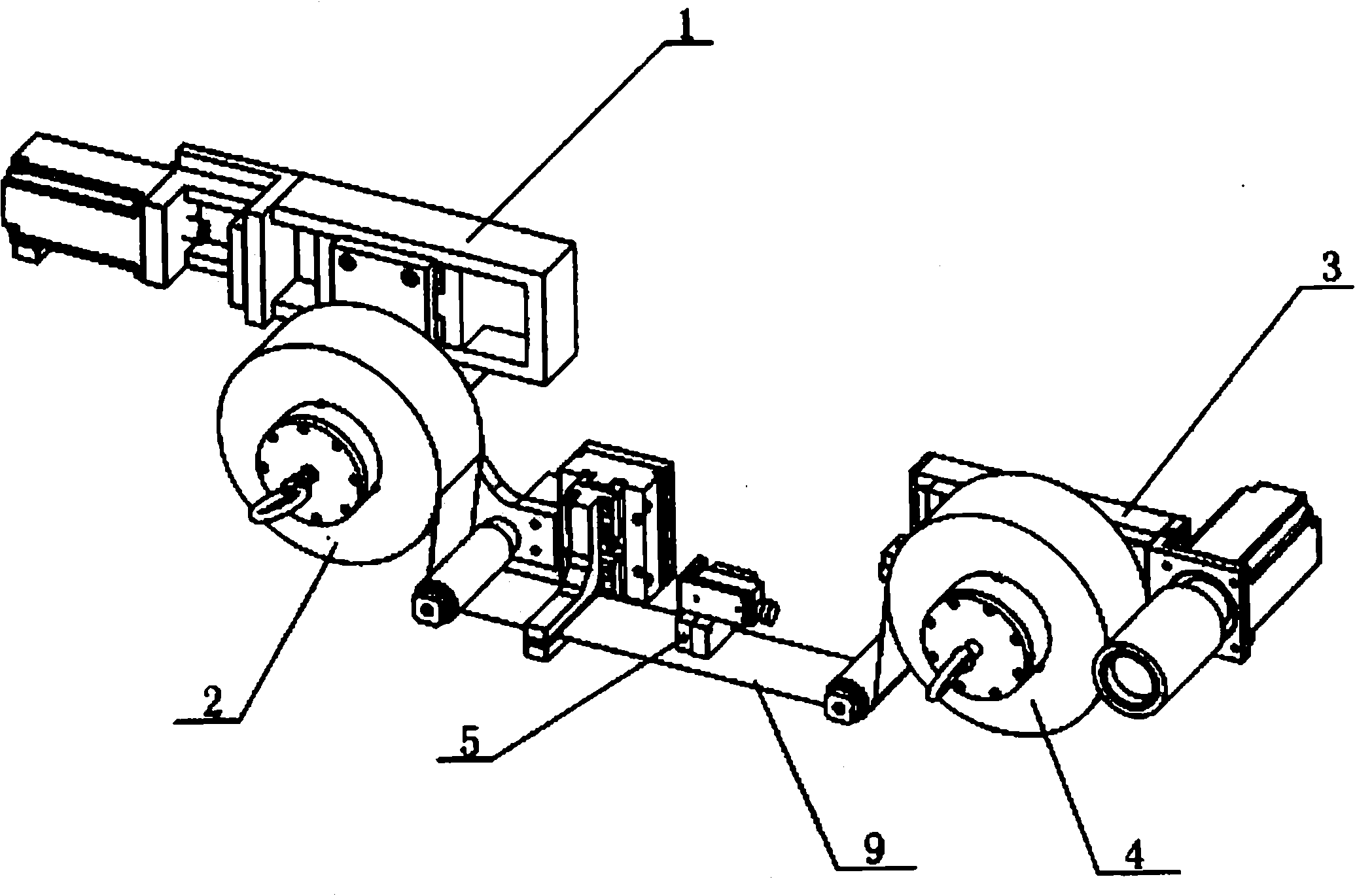

ActiveCN101982312AHigh foil speedHigh positioning accuracy of holographic marksBronze printingRotary pressesHot stampingAluminum foil

The invention relates to a digital holographic high-precision foil-feeding device of a bronzing machine, which comprises a foil-releasing device, a foil-coiling device and a color mark sensor, wherein the color mark sensor is positioned between the foil-releasing device and the foil-coiling device; the foil-releasing device can make a linear slide by means of a linear module slide block driven by a linear module servo motor and can finish the foil-feeding operation by a first servo motor, a hot stamping foil press mouth, a foil-releasing support plate, a first positioning guide shaft and a tensioning shaft; and the foil-coiling device can finish the foil-coiling operation by the cooperation of a compression cylinder, a tensioning wheel, a foil-pressing rubber roller and a second servo motor. Based on the two-step adjustment, the foil-feeding device ensures more precise foil-feeding operation, and the first servo motor and the second servo motor operate under a constant tension, thereby preventing the aluminum foil from deforming.

Owner:HEBEI YUTIAN XINGYE PRINTING MACHINERY

Gold and silver powder transfer printing process and equipment

InactiveCN102189859AQuality improvementSolve the problem that gold and silver powder transfer printing cannot be carried outTransfer printingPattern printingDisperse dyeEconomic benefits

The invention relates to a gold and silver powder transfer printing process and gold and silver powder transfer printing equipment. The process comprise the following steps of: 1, printing transfer printing paper, namely printing transfer printing patterns on blank printing base paper by using disperse dyes, printing a decolored glue block by using a decolorization glue printing device in an area required to be subjected to gold and silver powder transfer printing, and printing a gold and silver powder glue block by using a gold and silver powder printing device on the surface of the decolored glue block; and 2, printing the patterns on the transfer printing paper onto a load bearing object by using a printing machine in a transferred way. By the process and the equipment, common transfer printing operation and gold and silver powder transfer printing operation can be simultaneously finished in one process flow, so that human power and resources are greatly saved; the printing speed during continuous operation can reach 600 to 1,200 meters / hour, so that the printing speed and yield are greatly increased; simultaneously, the appearance of a high-quality final product is ensured, and the process and the equipment have obvious economic benefits.

Owner:JIANGSU LONGDA TRANSFER PRINTING TEXTILE

Stamping machine

InactiveCN104260547AEasy to dryImprove bronzing qualityRotary pressesBronze printingPulp and paper industry

The invention discloses a stamping machine. The stamping machine orderly comprises a stamping object loading device, a base and a receiving device; a stamping film loading device is arranged above the base at the end of the stamping object loading device, and a waste film receiving device which is used for receiving stamping film waste after stamping is arranged above the base at the end of the receiving device; a stamping device is further arranged on the base; a drying device is arranged between the receiving device and the base and the stamping object after being stamped passes through the drying device; a plurality of cooling rollers are arranged in the receiving device; the receiving device further comprises a receiving roller; the cooling rollers are located between the drying device and the receiving roller. The stamping machine has the advantages that the drying device is additionally arranged in front of the receiving device so that the stamping object can be dried quickly after being stamped, before being received, the finished stamping object firstly passes through the plurality of cooling rollers and can be cooled and solidified in the moving process, and finally, the stamping object is received by use of the receiving roller. The stamping machine guarantees that an aluminum layer can be securely printed on the stamping object and improves the quality of stamping.

Owner:林允杜

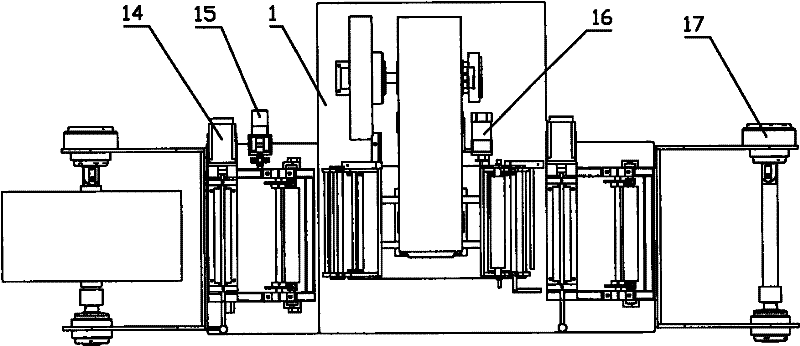

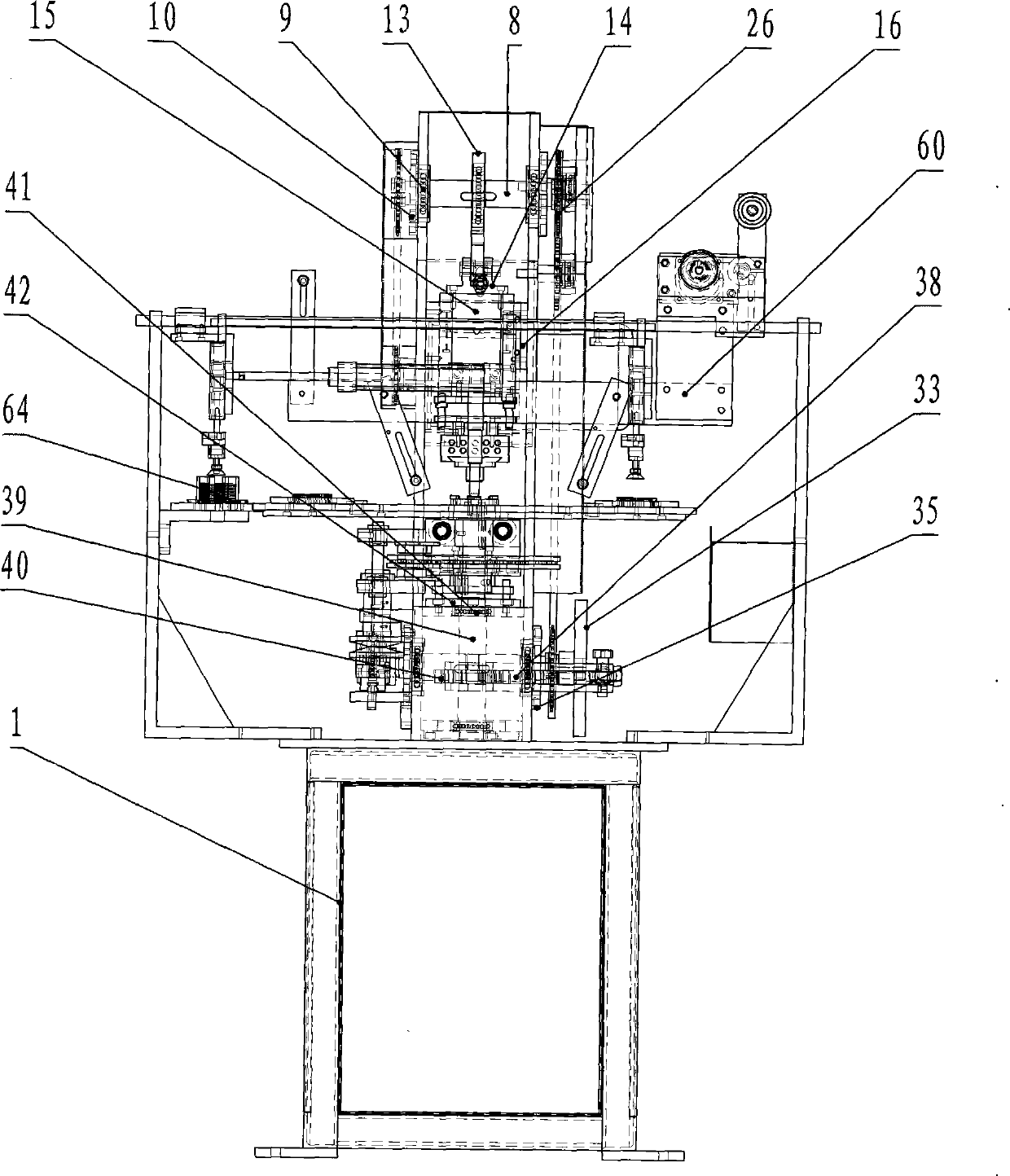

Mechanical-rotary-plate-type fully-automatic gilding press

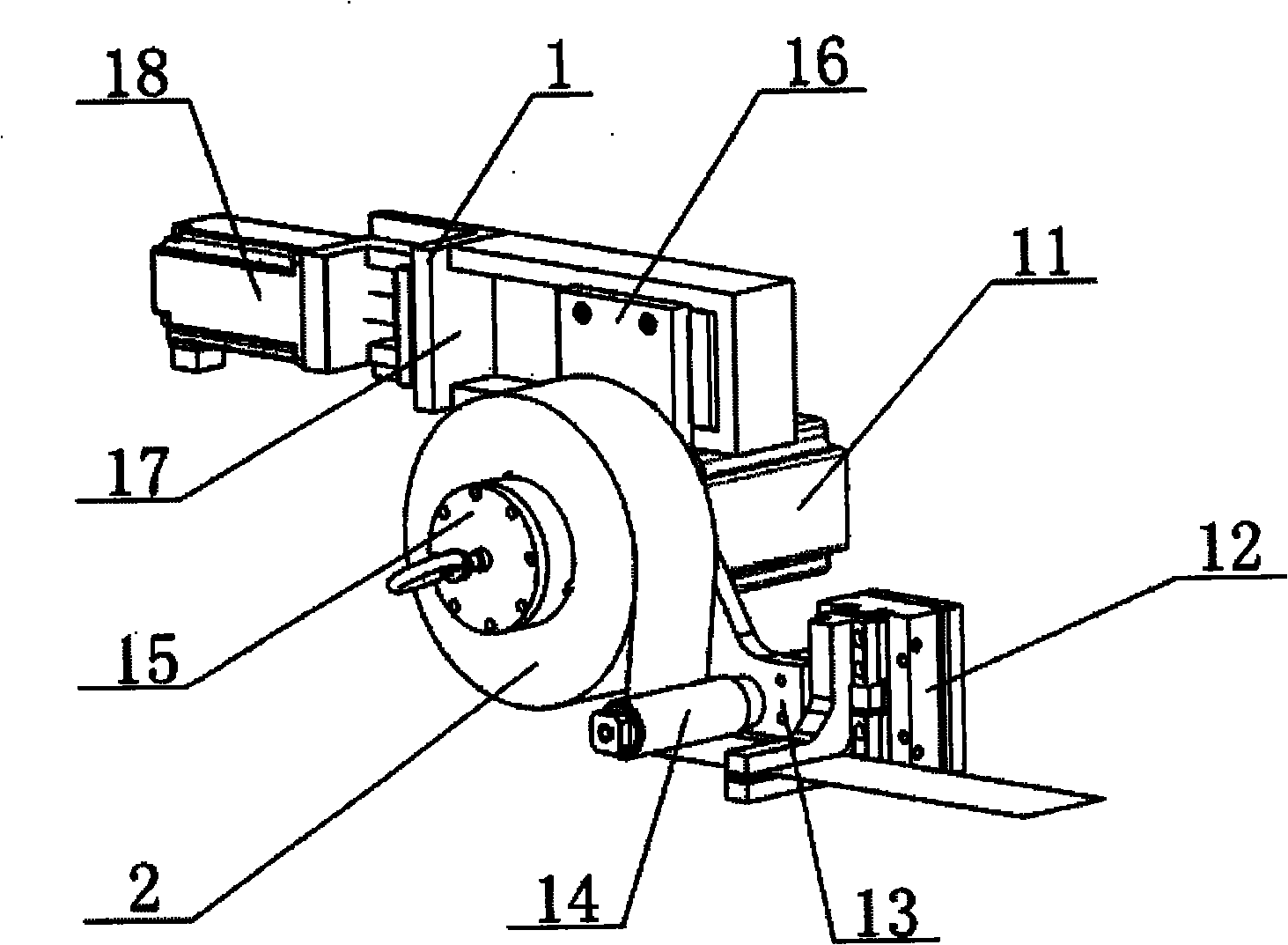

InactiveCN103273738AEasy to operateImprove work efficiencyBronze printingRotary pressesHot stampingCam

A mechanical-rotary-plate-type fully-automatic gilding press comprises a base and a main unit, and is characterized in that the main unit is installed on the upper portion of the base, the upper portion of the back of the main unit is provided with an active power motor, an output shaft of the active power motor is provided with a driving chain wheel which is provided with an active power chain, a rotary plate shaft base is installed on the lower portion of a machine body, the upper portion of a rotary plate main shaft is provided with a brake plate, the upper portion of the brake plate is a six-working-station rotary plate which is provided with six decoration pad tools, the left end of a rotary plate power shaft is provided with a cam, the left front side of the machine body is provided with a brake mechanism, and the front of the base is provided with an automatic feeding device and an automatic discharging device. The gilding press solves the problems that in the prior hot stamping art of small workpieces such as crafts, decoration boxes and small plastic pieces, labor intensity is large, work efficiency is low and the safety coefficient is low, and is suitable for being used for the hot stamping of identifications and patterns on small articles such as the crafts, decoration pads and the small plastic pieces.

Owner:QINGDAO HAIGANG GILDING PRESS EQUIP

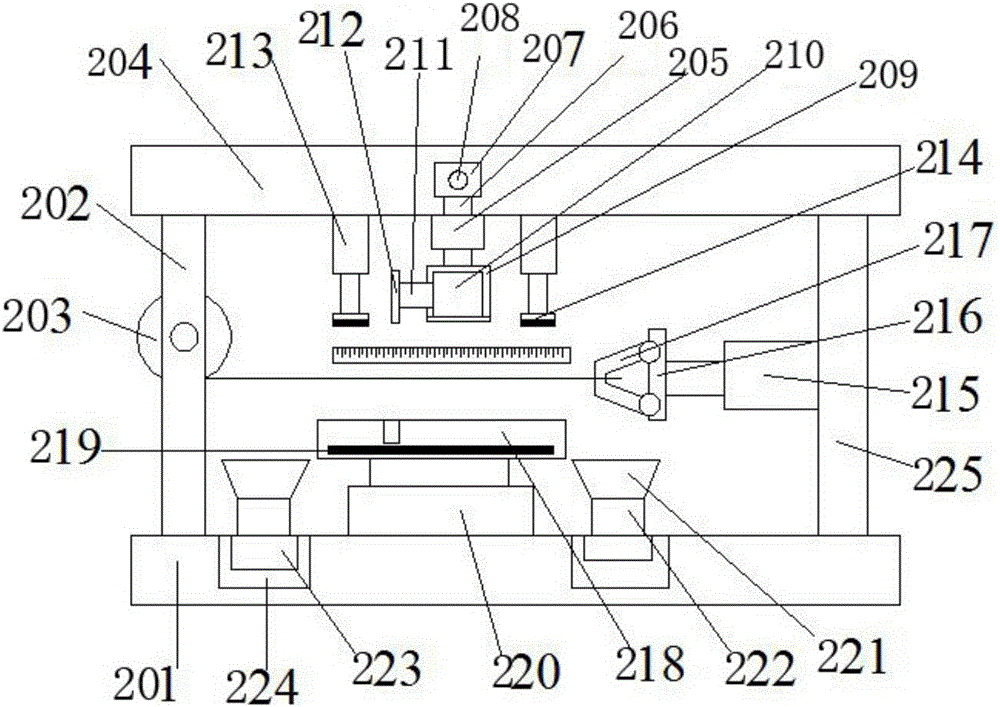

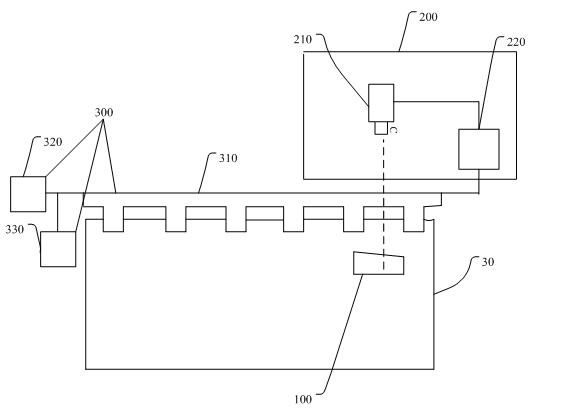

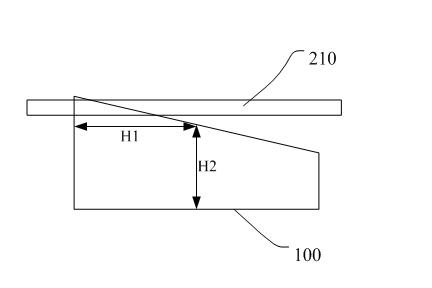

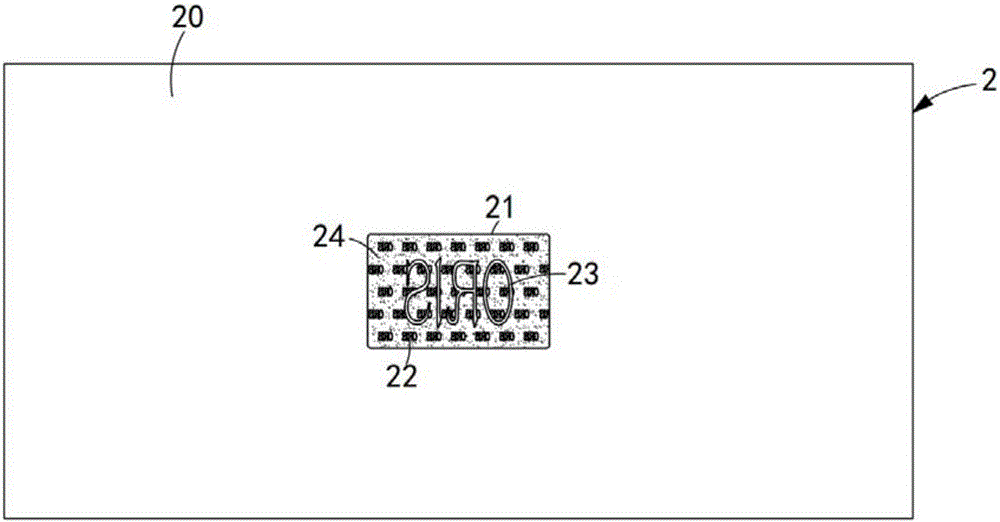

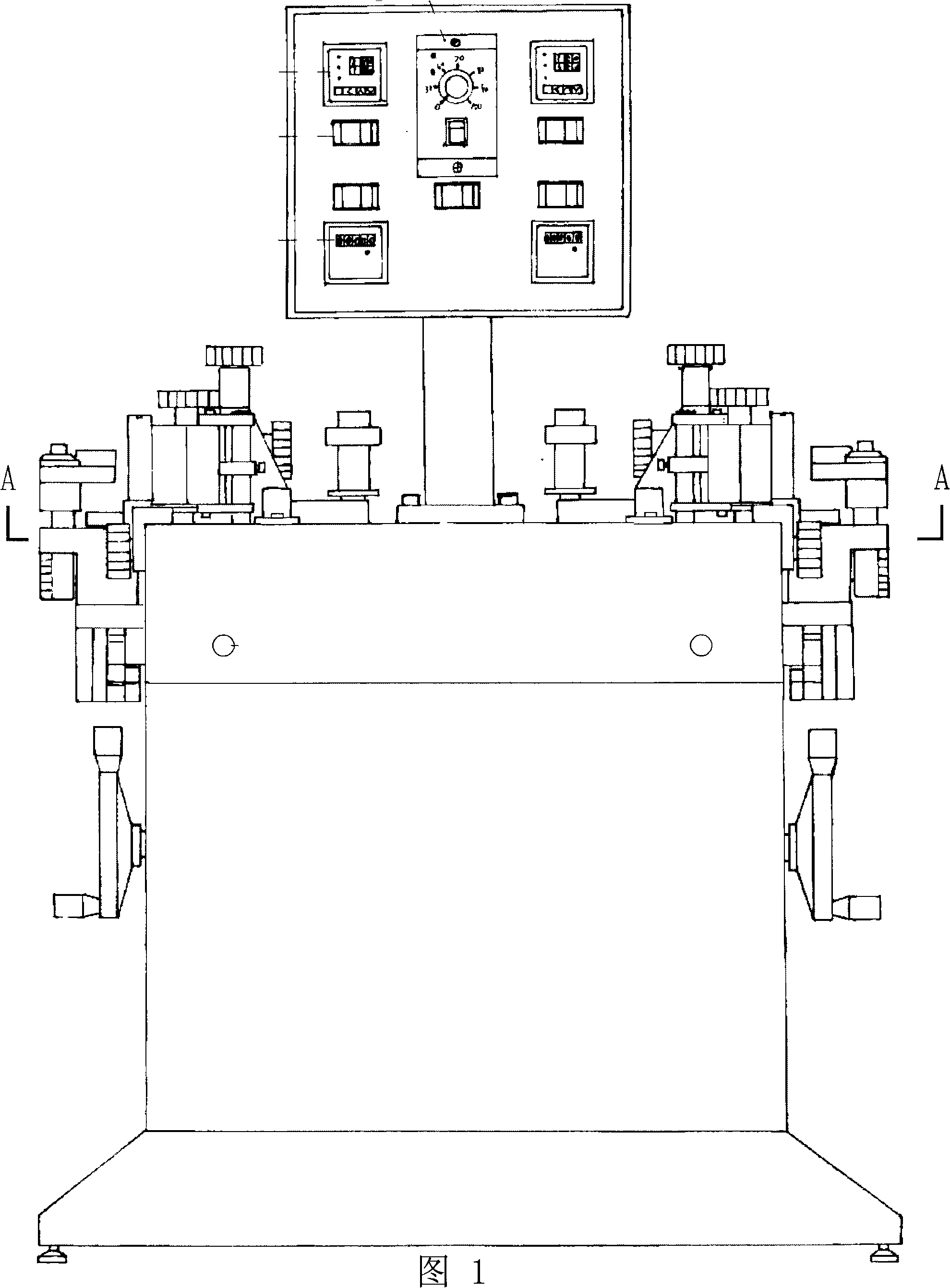

Electronic positioning device for single-piece paper gold stamping and die cutting equipment and method

ActiveCN102673113ARapid positioningPrecise positioningBronze printingRotary pressesElectricityComputer module

The invention discloses an electronic positioning device for single-piece paper gold stamping and die cutting equipment and a method, wherein the electronic positioning device comprises an image positioning module, a position determining system and a regulating device, the image positioning module is printed on a single-piece paper printed product, and the positioning determining system is electrically connected with the regulating device. The digital image processing technology is adopted, the mechanical performance influence is avoided, the single piece of paper is fast and accurately positioned, the positioning is accurate, the work efficiency is high, and good market application prospects are realized.

Owner:贵州省仁怀市申仁包装印务有限责任公司

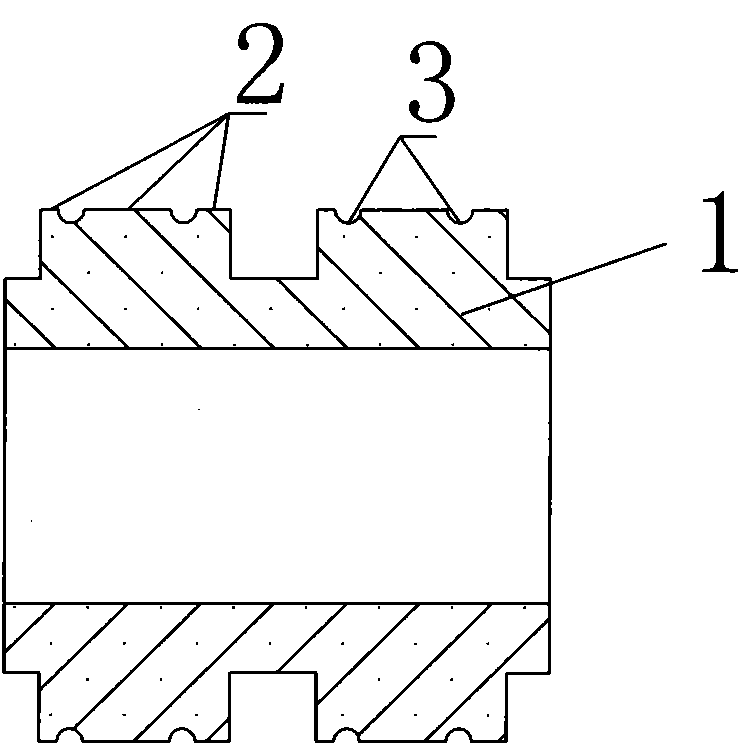

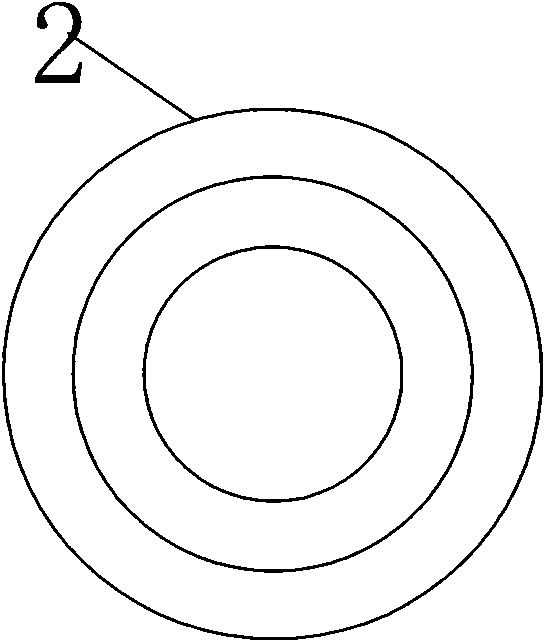

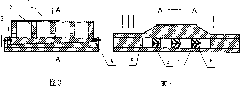

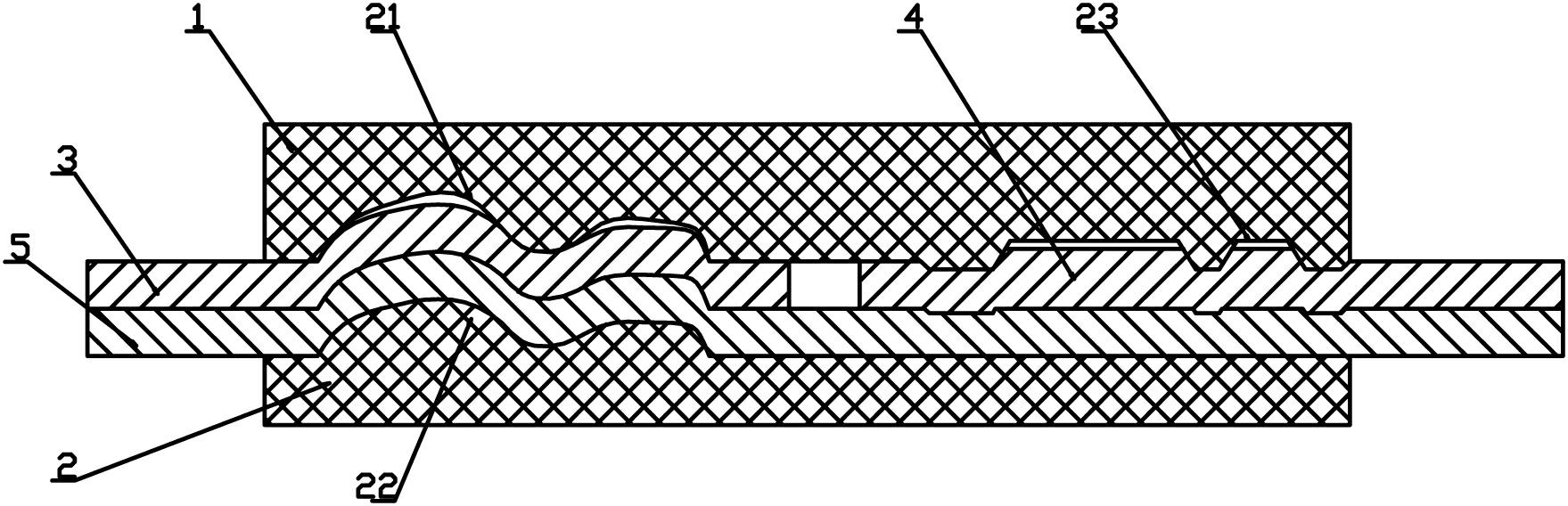

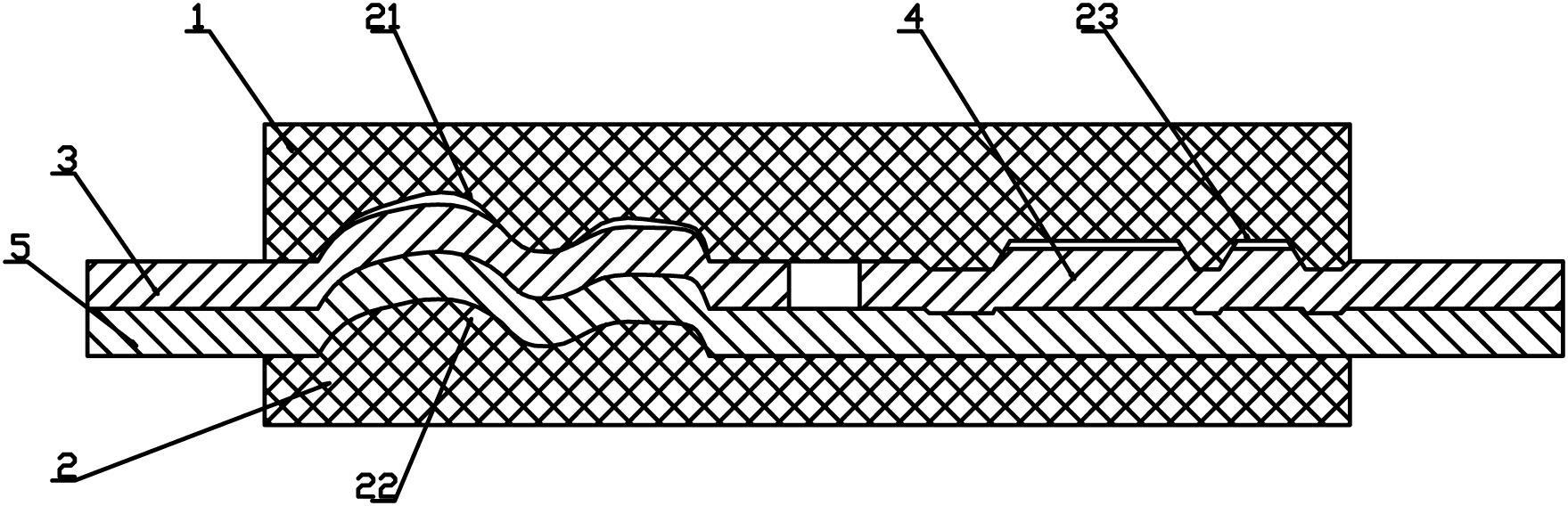

Rotary gold stamping embossing one-step forming version

InactiveCN101804723AReduce production processImprove efficiencyBronze printingRotary pressesBobbinEngineering

The invention provides a rotary high-precision gold stamping embossing one-step forming version applied in the field of cork paper bobbin production; the version can realize the gold stamping embossing one-step forming; a gold stamping pattern and an embossing pattern have no dislocation and weakly depends on equipment personnel; the produced products have dazzlingly beautiful colors, clear impressions and accurate patterns and can be preserved for a long time; and the version can greatly increase the production efficiency and realize the purpose. The invention adopts the following technical scheme that the rotary high-precision gold stamping embossing one-step forming version comprises a rubber covered roller, a rolling wheel, a pattern needing to be embossed and installing shafts at two ends and is characterized in that embossing patterns are arranged on the gold stamping embossing version and gold stamping pattern surface of the contact surface of the rubber covered roller; and the depth of the embossment pattern arranged on the gold pattern surface is 20 mum to 50 mum.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

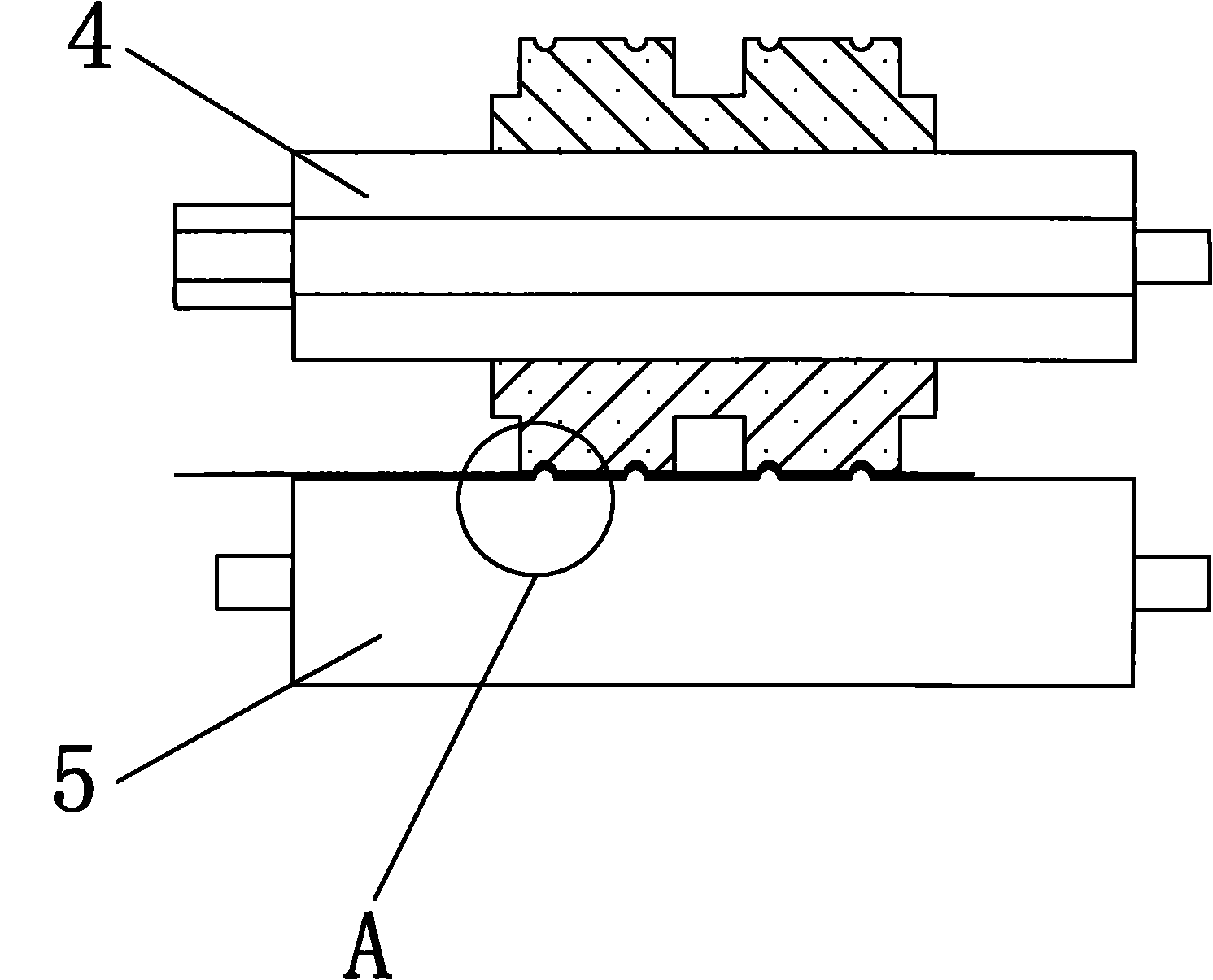

Horizontal flat pressing flat die-cutting creasing and thermoprinting machine

InactiveCN101797816AReduce scrap rateIncrease paper feed speedBox making operationsPaper-makingCardboardJackscrew

The invention discloses a horizontal flat pressing flat die-cutting creasing and thermoprinting machine. The machine is provided with an upper impressing pallet, a lower impressing pallet and a paper feeding mechanism, wherein the upper impressing pallet is provided with an eccentric shaft device, an upper wedge for the pressure adjustment of the lower pallet and a lower wedge for the pressure adjustment of the lower pallet are arranged below the lower impressing pallet, the upper impressing pallet is a hollow shell, the upper wedge for the pressure adjustment of the upper pallet and the lower wedge for the pressure adjustment of the upper pallet are laterally arranged in the hollow cavity, the left side wall and the right side wall of the hollow shell are respectively provided with a pressure adjustment jackscrew, the pressure adjustment jackscrews on the left side wall and the right side wall are positioned in the corresponding positions at the left end surface and the right end surface of the upper wedge for the pressure adjustment of the upper pallet, and a plurality of rib plates are fixed on the top surface of the hollow cavity. The horizontal flat pressing flat die-cutting creasing and thermoprinting machine has the advantages that both the upper pallet and the lower pallet can adjust the die-cutting pressure, and the phenomenon of failure to jack up the paper board is avoided.

Owner:李青安

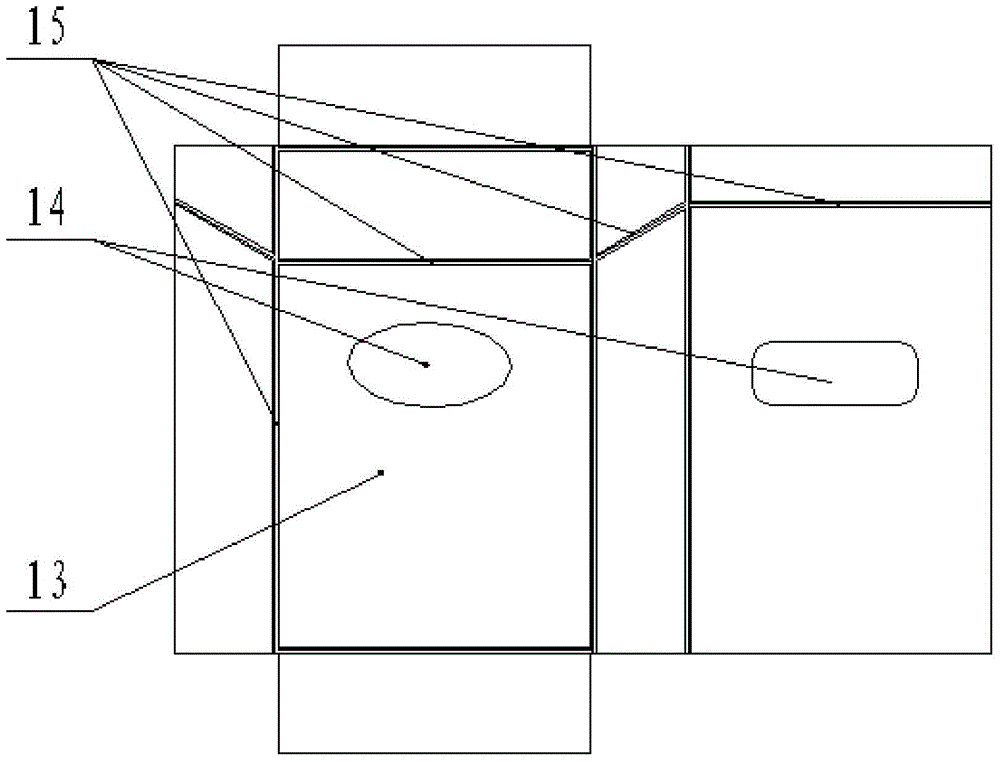

Processing method and integrated processing device for hard shell cigarette packaging box

InactiveCN104626738AIncrease productivityAvoid rubbingRotary pressesBronze printingCardboardEngineering

The invention belongs to the technical field of printing and packaging devices, and particularly relates to a processing method and integrated processing device for a hard shell cigarette packaging box. The processing method comprises the following steps that white cardboard rolls are uncoiled, gilded and printed to form semi-finished paperboards; the paperboard are dried; the pressing mark technology is carried out on the semi-finished paperboards to form a plurality of folding marks; die cutting is carried out on the semi-finished paperboards to form packaging paper; the packaging paper is folded and stuck to form the square and strips-shaped hard shell cigarette packaging box. The integrated processing device comprises a rack, an uncoiling mechanism, a gilding film paying-off device, a gilding mechanism, a printing mechanism, a waste film taking-up mechanism, a drying device, a pressing mark mechanism and a die cutting mechanism which are sequentially arranged on the rack. The gilding mechanism comprises an upper gilding and printing film and a gilding bearing base. A heating disc and a temperature sensor are arranged on the upper gilding and printing film. According to the processing method and device, the cigarette packaging and printing quality is better ensured, the production efficiency is high, and the production cost is saved.

Owner:CHUXIONG JIXING COLOR PRINTING

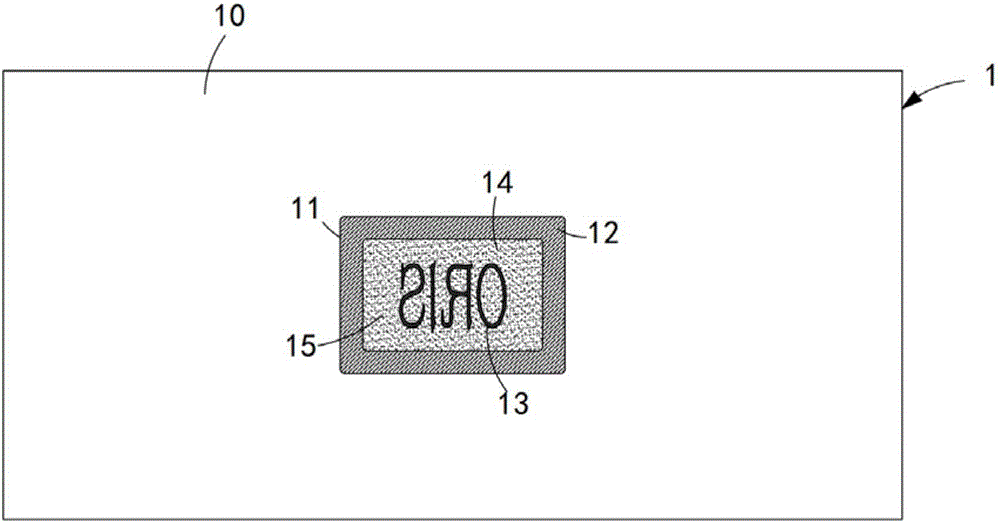

Combined high-precision hot-stamping printing plate and three-channel hot-stamping refraction anti-counterfeiting mark manufactured by same

InactiveCN107521223AOmit alignment setting datumSimplify control proceduresStampsBronze printingHot stampingLaser engraving

The invention relates to a combined high-precision hot stamping plate and a three-channel hot stamping refraction anti-counterfeiting mark, which aims to solve the technical problem of poor anti-counterfeiting effect of the traditional nesting overprinting, including a set of combined high-precision The laser engraving plate and two hot stamping films with different effects and colors, through the combination of the combined hot stamping plate and the hot stamping plate, combined with the structural design characteristics of the hot stamping mold and the hot stamping mold, realize the hot stamping plate and the hot stamping plate The three-channel refraction anti-counterfeiting logo is successively folded and ironed, so that different patterns, characters or lines can be observed from different viewing angles, which solves the technical problem that the folded ironing cannot form refraction anti-counterfeiting at various angles of view in the prior art.

Owner:HUZHOU XINTIAN GREEN PACKAGE PRINTING CO LTD

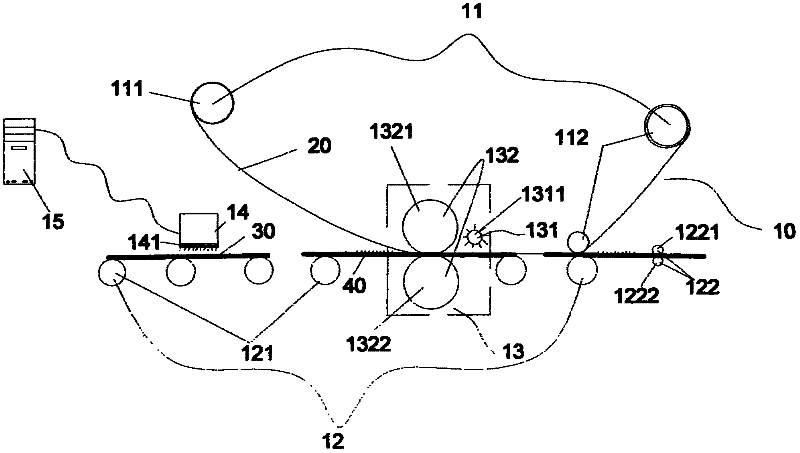

Gold stamping system for cigarette labels and gold stamping process for cigarette labels

ActiveCN102555436ATo achieve an organic combinationAccurate removalBronze printingRotary pressesHot stampingWaste product

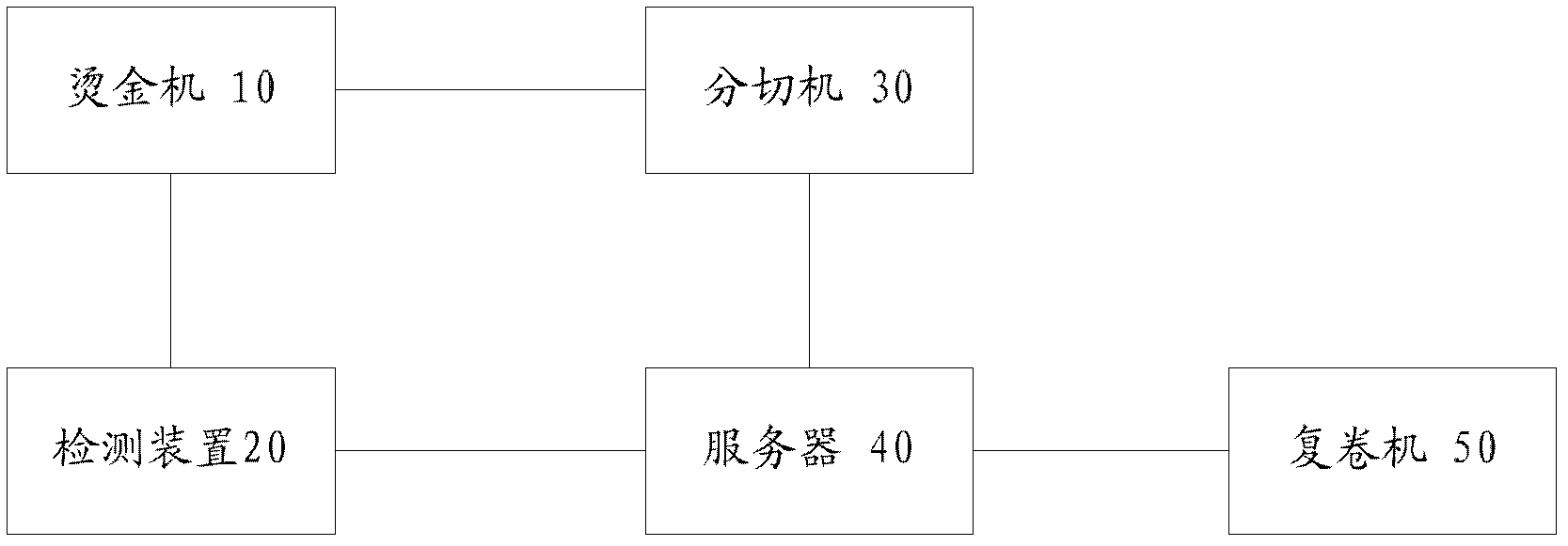

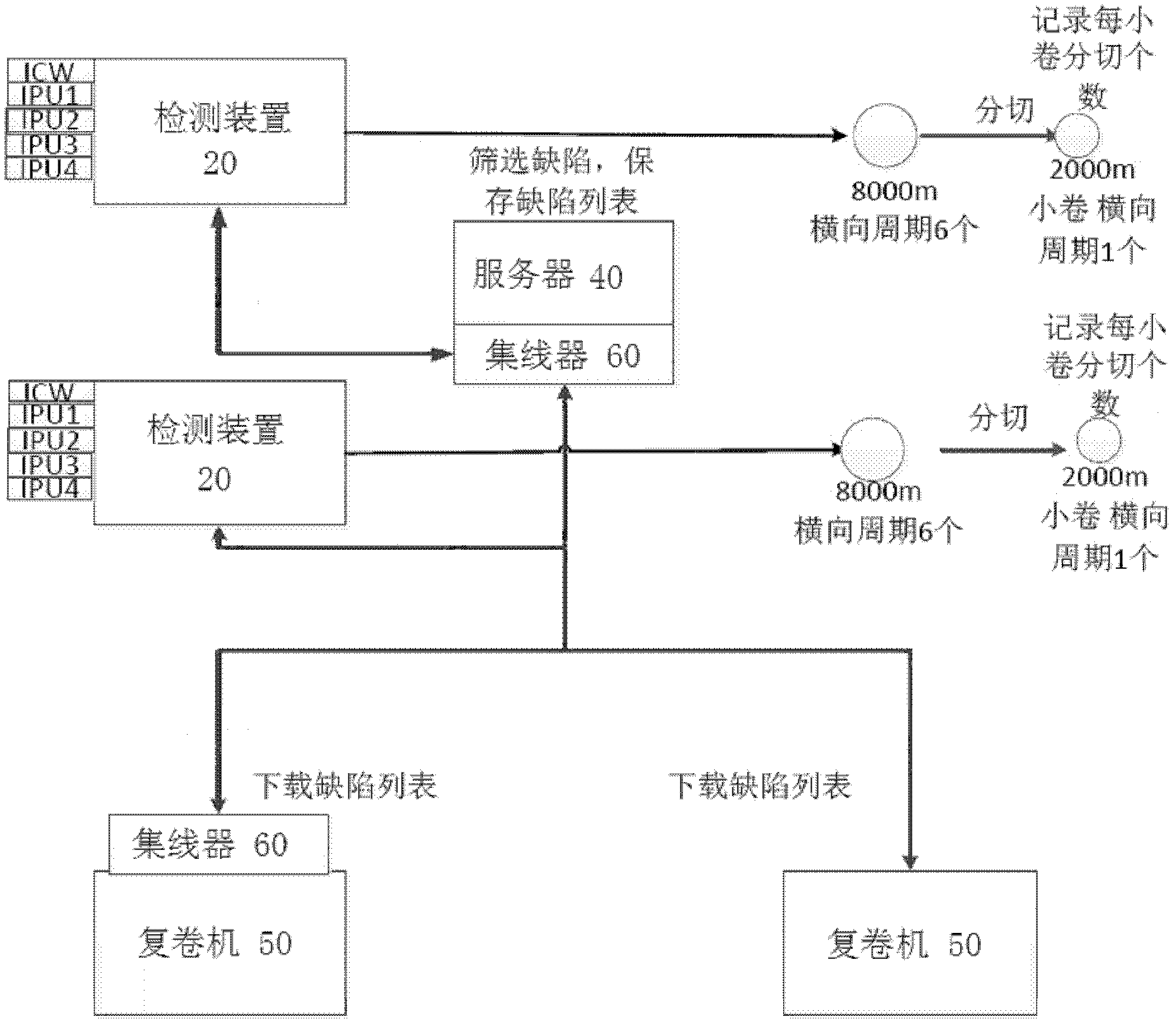

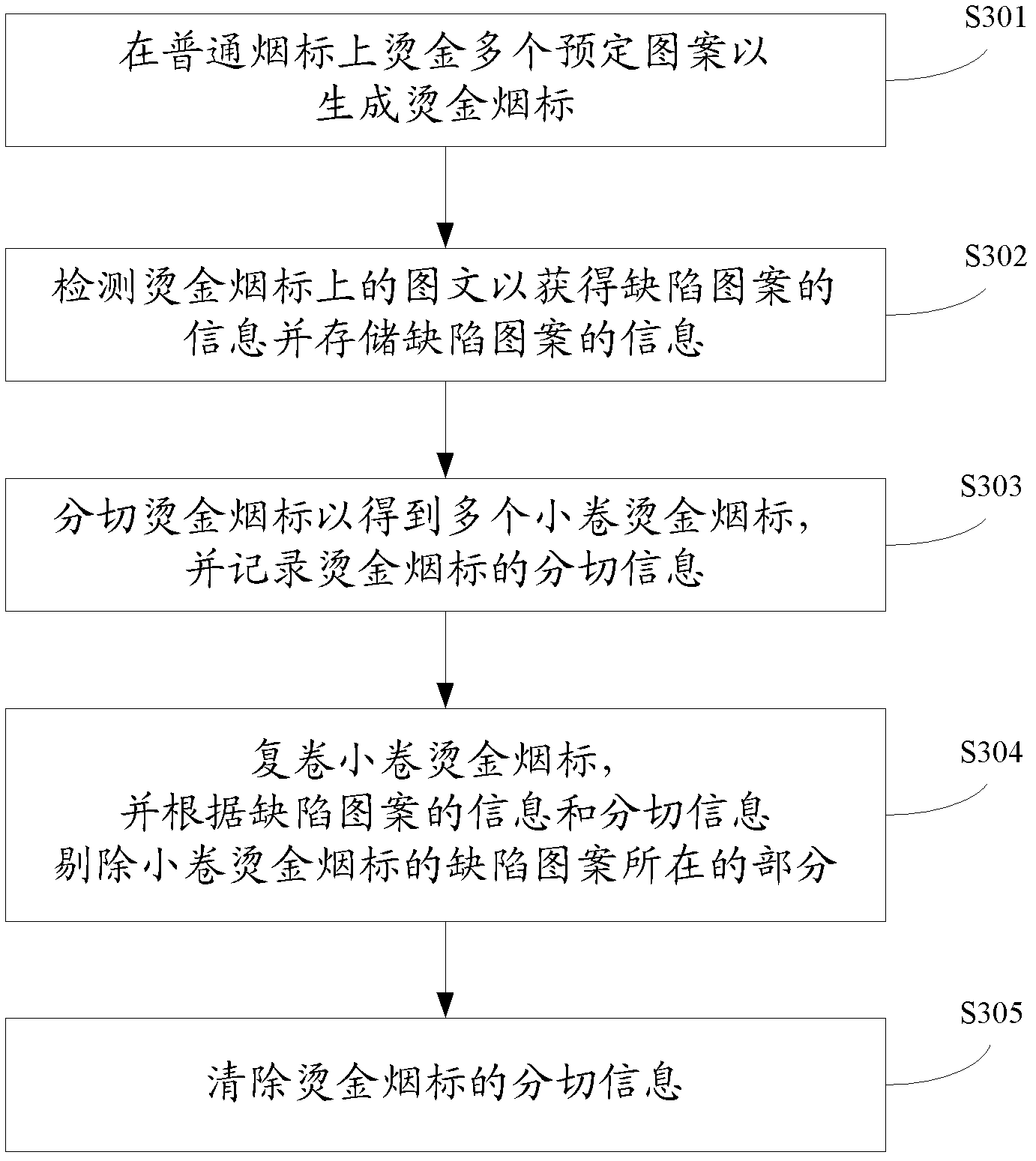

The invention provides a gold stamping system for cigarette labels and gold stamping process for cigarette labels. The gold stamping system for cigarette labels comprises a gold stamping machine, a detector, a splitting machine, a server and a rewinding machine, the gold stamping machine is used for realizing hot stamping of a plurality of predetermined patterns on a common cigarette label to form a gold-stamped cigarette label, the detector is positioned at the tail end of the gold stamping machine and used for detecting cigarette label image and text on the gold-stamped cigarette label to obtain information of defective patterns, the splitting machine is connected with the gold stamping machine and used for splitting the gold-stamped cigarette label into a plurality of small gold-stamped cigarette labels, the server is used for receiving and storing the information of defective patterns from the detector and receiving and storing splitting information of the splitting machine, the rewinding machine is connected with the server and used for rewinding the small gold-stamped cigarette labels and rejecting waste products in the small gold-stamped cigarette labels according to the information of the defective patterns and splitting information, and the information of the defective patterns and the splitting information are stored in the server. Detection records and the splitting information are organically combined by the aid of the server, parts with the defective patterns can be accurately rejected by the rewinding machine, work efficiency is improved, and production cost is saved.

Owner:东莞智源彩印有限公司 +1

Bronzing and concave-convex one-time forming method

InactiveCN102173195ACause the flower to fogCaused degreeBronze printingRotary pressesThermal insulationPrinting ink

The invention relates to a bronzing and concave-convex one-time forming method, which comprises the following steps: 1) producing a female die, a male die and a bronzing on a same group including an upper die and a lower die; 2) heating the upper die and / or the lower die to the temperature for bronzing; 3) arranging a thermal insulation layer between the female die or the male die and a printed product; and 4) arranging a bronzing transfer printing layer between the bronzing plate and the printed product; and realizing bronzing and concave-convex one-time forming through the above steps. By adopting the bronzing and concave-convex one-time forming method, the bronzing process and the concave-convex process can be merged, the printing quality is improved, and the adoption of the thermal insulation layer can avoid the problems of flower pulling and fogging of printing ink or decline in bright degree of color in concave and convex positions due to the temperature reason.

Owner:HUBEI GOLDEN THREE GORPRINTING IND

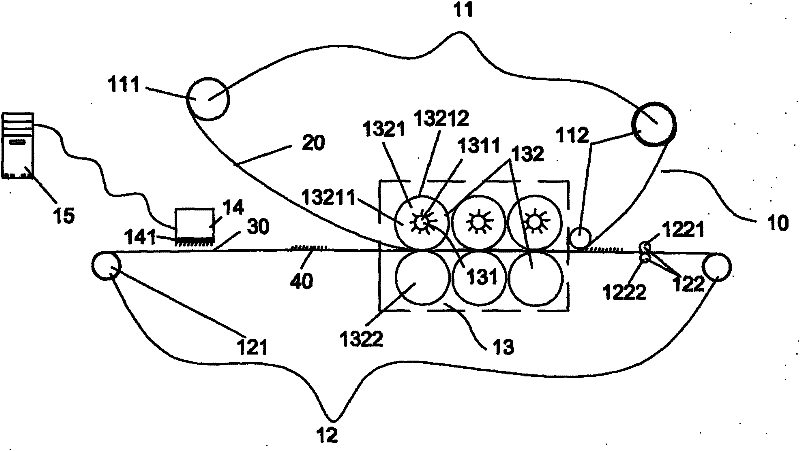

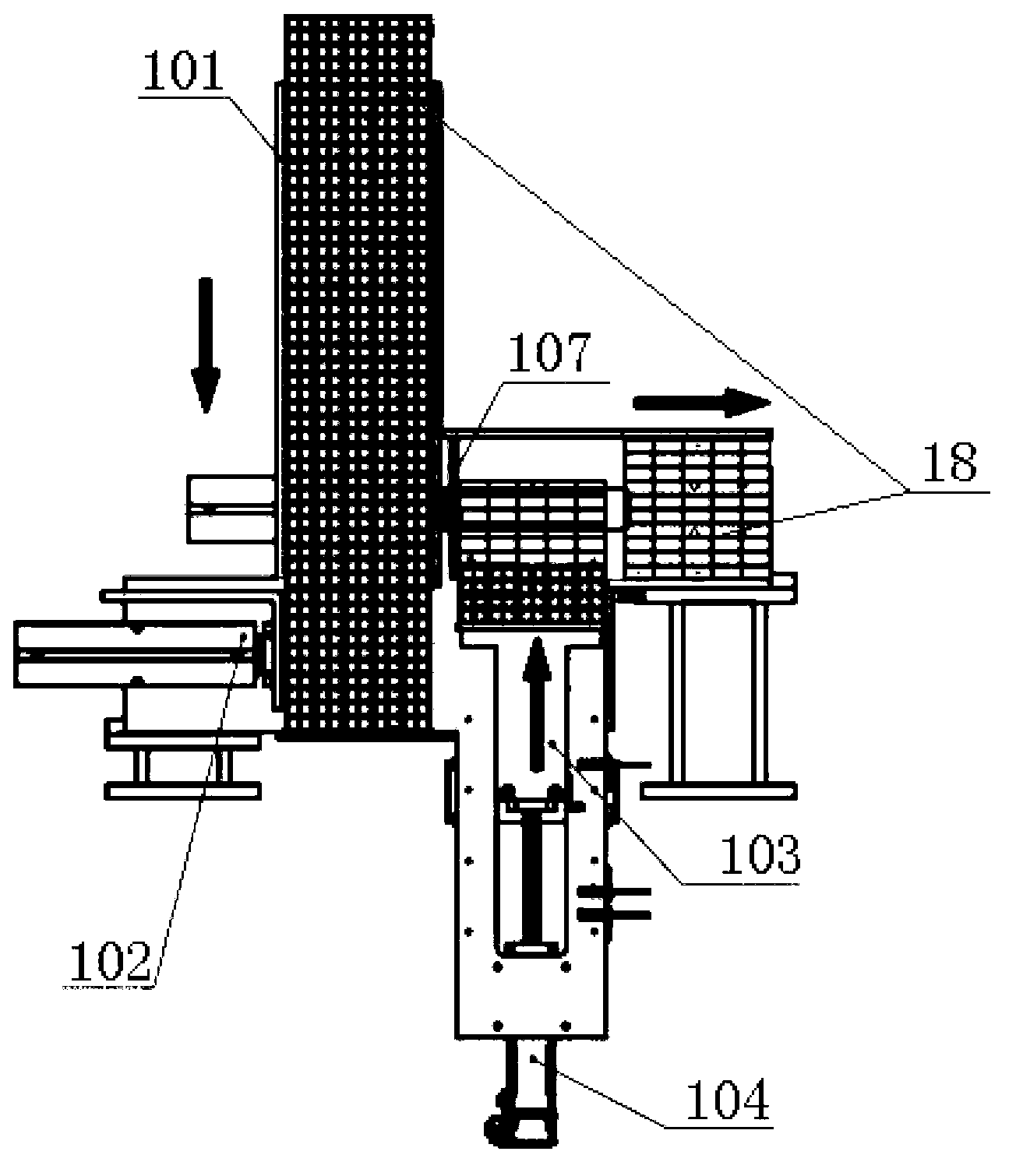

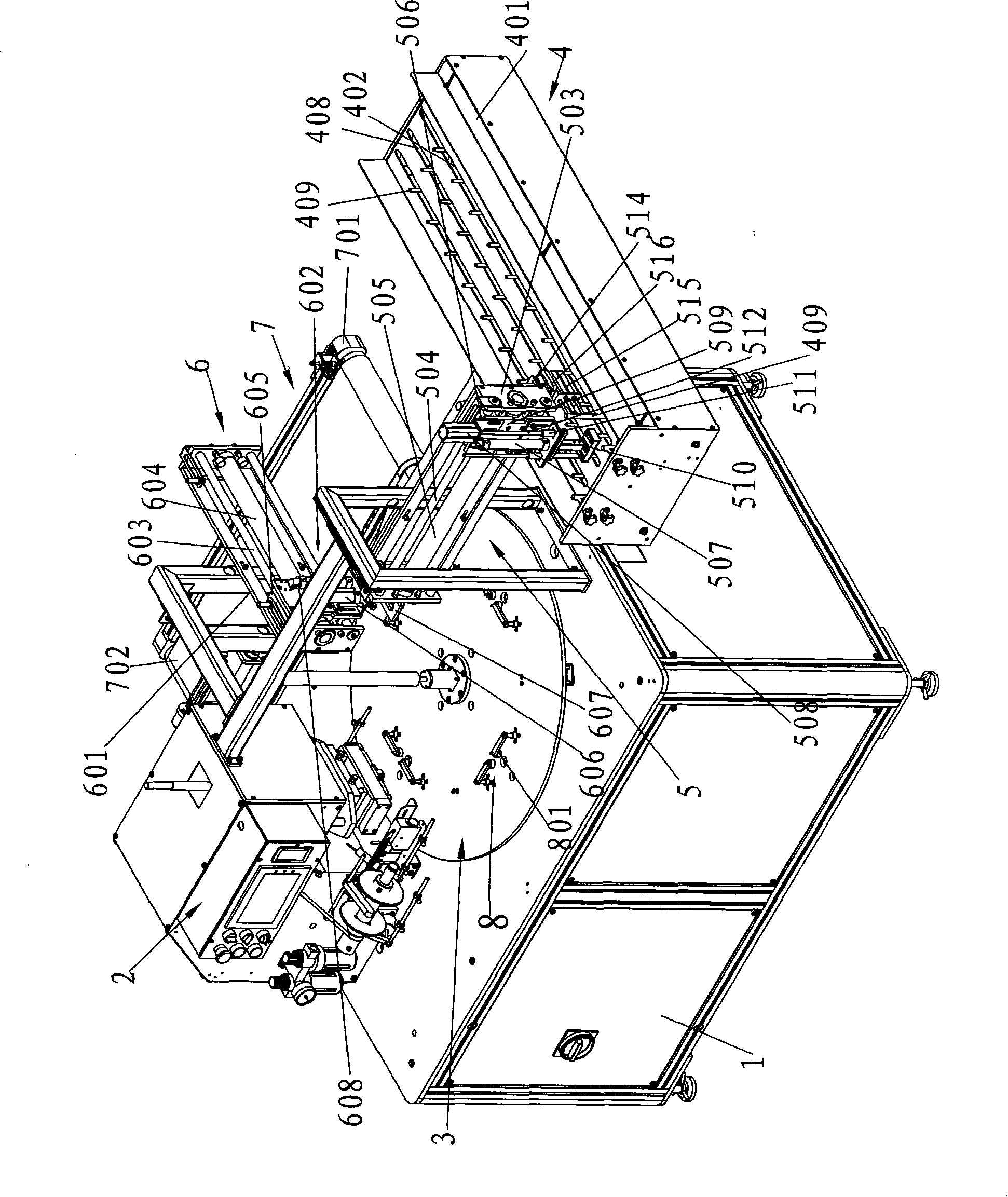

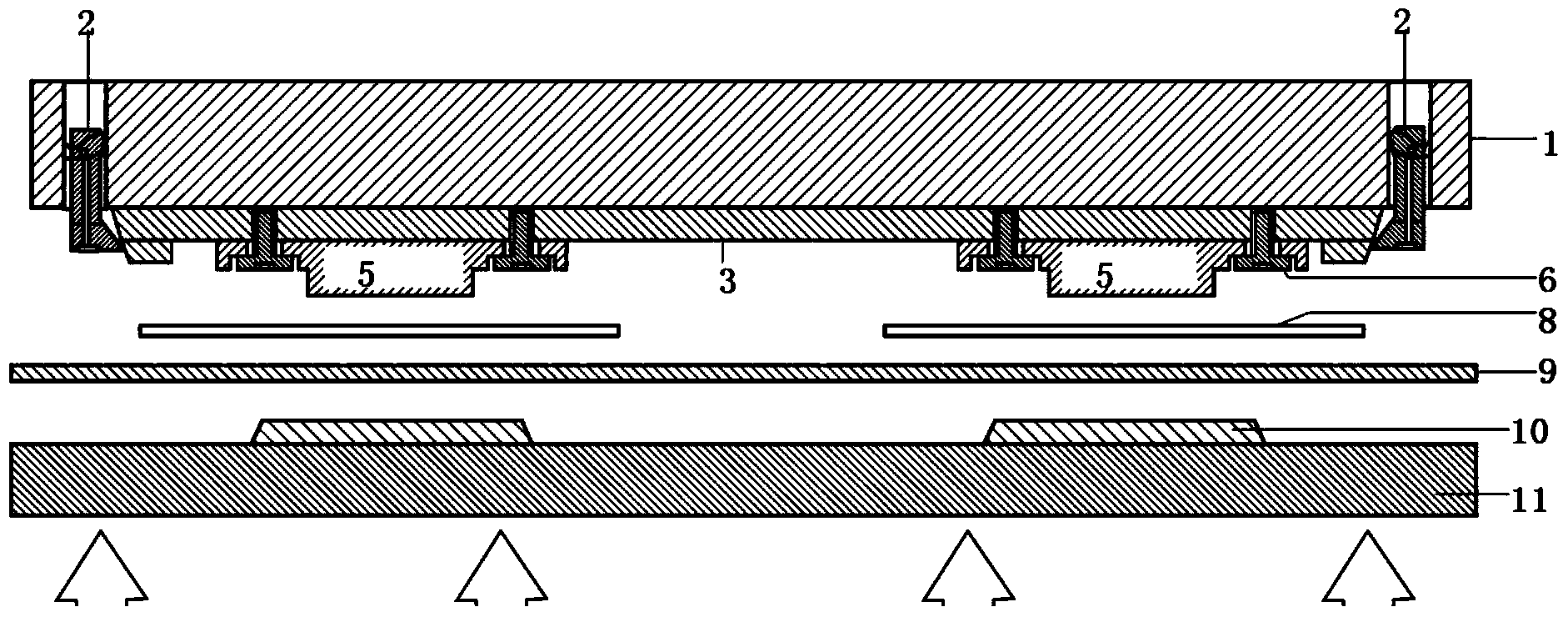

Freezing point printing and holographic gilding printing integrated printing equipment and application method thereof

ActiveCN104553292AGuaranteed uptimeGuaranteed compensation for overprint deviationScreen printersBronze printingTension controlPaper sheet

The invention discloses freezing point printing and holographic gilding printing integrated printing equipment and an application method thereof. The freezing point printing and holographic gilding printing integrated printing equipment comprises a base, a paper unwinding device, a paper guide mechanism, flexography units, a gravure freezing point unit, a tension control unit, a holographic gilding device, a concave-convex unit, a cutting unit and a finished paper collecting unit, wherein the paper guide mechanism is disposed on one side of the paper unwinding device, the plurality of flexography units are sequentially disposed on one side of the paper guide mechanism, and the gravure freezing point unit, the tension control unit, the holographic gilding device, the concave-convex unit, the cutting unit and the finished paper collecting unit are sequentially disposed on one side of the flexography units. The freezing point printing and holographic gilding printing integrated printing equipment has the advantages that printing combining multiple working procedures is achieved, freezing point printing and holographic gilding printing are integrated, the printing equipment is high in continuity, high in automation level, convenient to operate, stable in operation, good in printing effect, high in chromatography precision and high in yield, efficient and high-quality printing is achieved, production procedures are reduced, production time is saved, production efficiency is increased, and production cost is lowered.

Owner:KUNMING WEIJIAN KECHUANG PRINTING

Powder duster recycling and circulating system

ActiveCN103171275AAvoid damageSpeed up the flowBronze printingPrinting press partsSuction forcePowder mixture

The invention relates to a powder duster recycling and circulating system and belongs to the technical field of printing. An automatic powder sending, recycling and circulating device of the existing glitter powder machine is large in noise, distribution of wind power of a suction ventilator is unreasonable, and powder for printing is easily blocked. The powder duster is characterized in that due to the fact that a suction ventilator A is moved to the lower portion of the powder duster, noise decibels can be reduced; due to the fact that suction force of the suction ventilator A is larger than that of a suction ventilator B, printing materials are prevented from being absorbed by an upper powder suction hole; due to the fact that an air compensation channel is formed between a discharge pipe and a collecting powder recycling pipe, smooth flow of air-powder mixture is ensured; a bypass air outlet of the suction ventilator A is directed at the air compensation channel to assist the collecting powder recycling pipe in keeping smooth; and an air cylinder is used for supporting an upper rack, the route of the air cylinder can be set, adjustment of the position of an upper air suction hole can be achieved by controlling the air cylinder, and therefore time for adjusting the position of the upper air suction hole is reduced, and productivity of the powder duster is improved.

Owner:绍兴市宏大电器有限公司

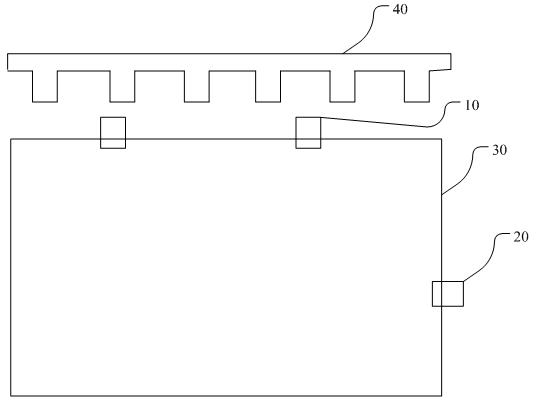

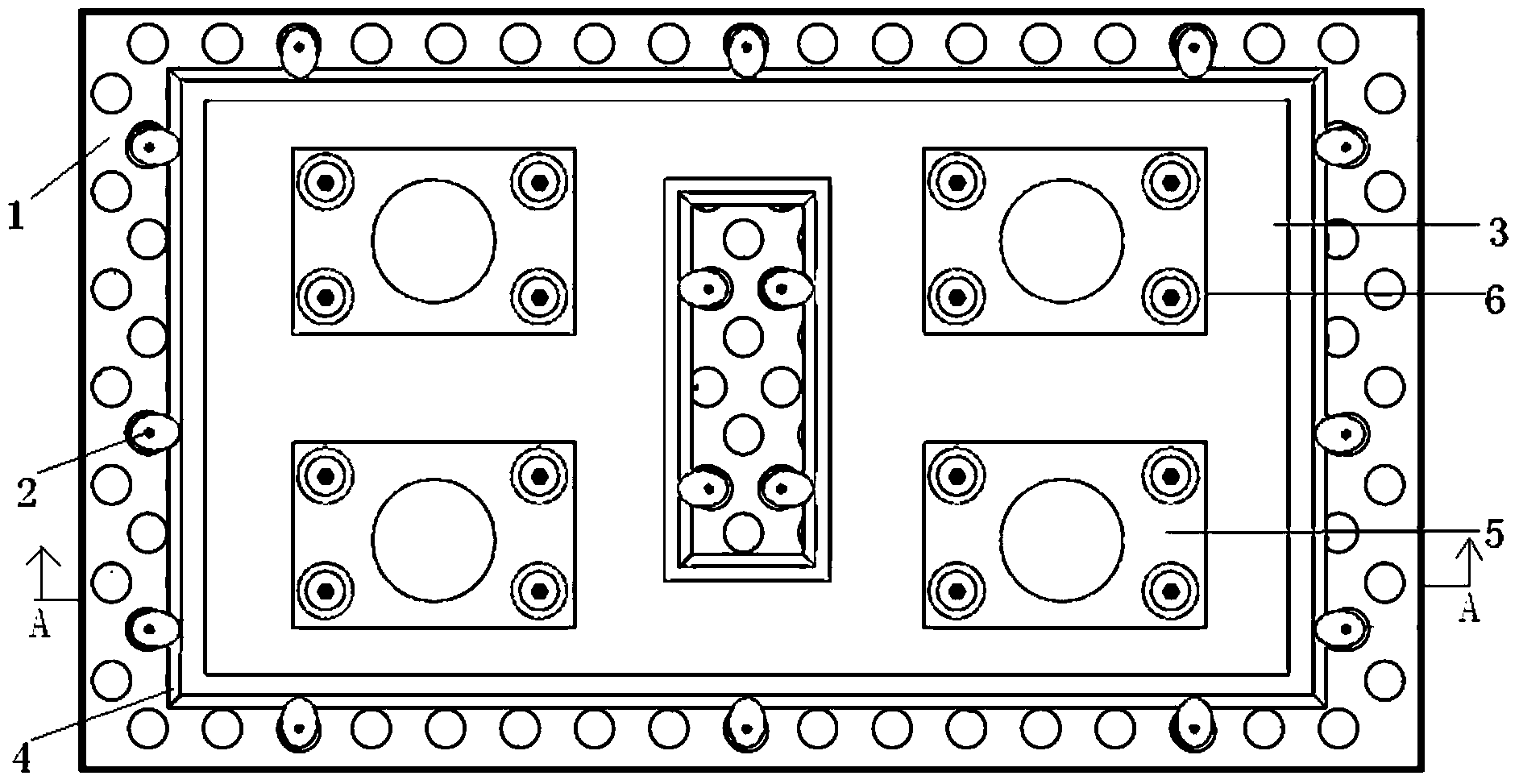

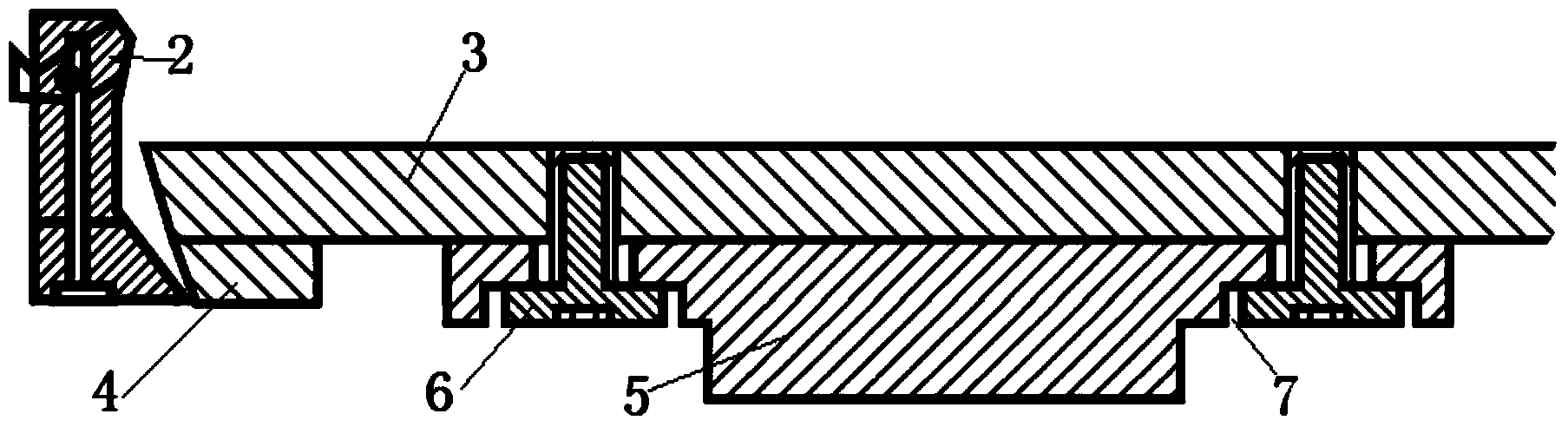

Integrated adjustable gold stamping plate

ActiveCN103552373AReduced adjustabilityShorten the timeBronze printingRotary pressesHoneycombEngineering

The invention provides an integrated adjustable gold stamping plate which at least comprises a honeycomb plate and gold stamping plates, a supporting plate is arranged between the honeycomb plate and the gold stamping plates and fixedly installed on the honeycomb plate, and the gold stamping plates are evenly distributed on the supporting plate, relatively fixed with the supporting plate and provided with 2-4 counter bores. The positions of the supporting plate corresponding to the counter bores are provided with threaded holes, countersunk head screws are arranged in the counter bores, penetrate through the counter bores and are screwed in the threaded holes, the gold stamping plates are relatively fixed with the supporting plate, adjusting gaps are reserved between the counter bores and the countersunk head screws, and the widths of the adjusting gaps are 0.3-0.8mm. The gold stamping plates perform gold stamping simply, are easy to adjust, convenient to dismantle and integrally adjustable and can meet the production requirements of high speed, high efficiency and high quality in modern production.

Owner:HUBEI ZHONGXIN JINGHUA COLOR PRINTING

Electric combined gold stamping machine

The invention relates to an electric combined gilding press which includes a heating hot stamping device arranged on a frame, a hot stamping foil transmitting and adjusting device, a transmission device, a main motor, a control device and a counting device; the transmission device includes a slide body reciprocating along a lead rail; the transmission device also includes a main shaft matched with the main motor, a foil collection drive gear and a slide body drive wheel arranged on the main shaft as well as a clutch; the clutch includes a clutch slide sleeve, a power clutch manual debugging wheel, a fork plate and a clutch check ring; the inside of the foil collection drive gear is provided with a clutch gag lever post parallel to the main shaft by spring; the outer circle of the slide body drive wheel is in a step shape with two levels; an inward step circle is provided with a location slot; an outward step circle is provided with a gear which can be engaged with a debugging gear on the axle of the power clutch manual debugging wheel; a connection rod is articulated between the slide body drive wheel and the slide body. The electric combined gilding press of the invention has the advantages of being quiet, low loss, high output capacity and good stamping quality.

Owner:黄修宝

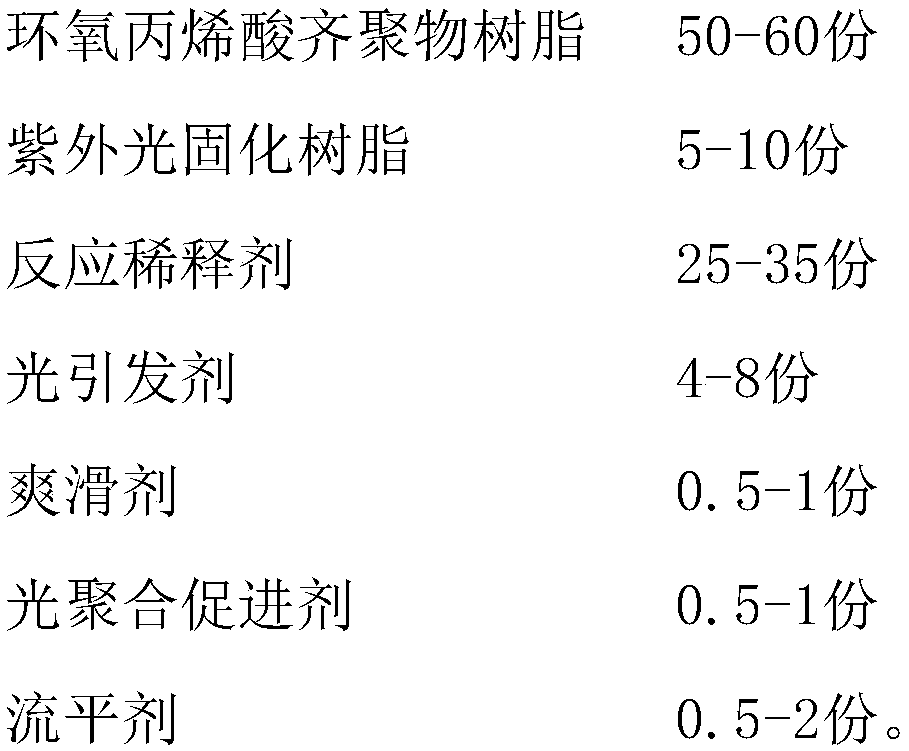

Offset printing connecting line cold-foil printing process and equipment

InactiveCN108045120AIncrease brightnessEnhance fine linesInksBronze printingMirror reflectionEngineering

The invention relates to the technical field of printing, in particular to an offset printing connecting line cold-foil printing process and equipment. The offset printing connecting line cold-foil printing process on the offset printing connecting line cold-foil printing equipment comprises the steps that A, gloss oil is printed, specifically, the gloss oil is printed on the surface of a printingsubstrate; B, curing is performed for the first time, specifically, the printing substrate printed with the gloss oil in step A is cured until the gloss oil is in a partially curing state, and printed matter with image-text gloss oil is obtained; and C, cold foil is compressed, specifically, the cold foil is pressed onto the surface of the printed matter obtained in step B, and then cured for thesecond time until the cold foil is completely cured to obtain a cold-foil printing product with image-text. The offset printing connecting line cold-foil printing process has simple operation, high production efficiency and low production cost; the prepared cold-foil printing product has higher flatness and leveling property, mirror reflection is generated, the brightness and the glossiness of the cold-foil printing product are effectively improved, the line fineness of image-text information of the cold-foil printing product is enhanced, the better net line effect is presented, the quality is stable, and the large-scale production is facilitated.

Owner:HUCAIS PRINTING

Film stamping machine capable of automatically rolling materials

InactiveCN102673115AEasy to useConvenient hot stampingBronze printingRotary pressesHot stampingEngineering

A film stamping machine capable of automatically rolling materials is characterized in that a discharging mechanism is installed on the left side of a base box, a material collecting mechanism is installed on the right side of the base box, a driving motor is installed in the base box, a chain wheel shaft, a pinion and a driving gear are connected with the upper portion of a main chain wheel of the driving motor, an eccentric direction adjusting connection rod is installed on the driving gear, the direction adjusting connection rod is connected with a driving connection rod, and a three-connection rod is connected with the upper end of the driving connection rod. A lifting sliding column is installed above the base box, an upper driving beam and a lower driving beam are assembled on the lifting sliding column, and a connection block shaft of the lower driving beam is connected with the lower end of the lower connection rod of the three-connection rod. A hot stamping device is installed in the middle of the upper driving beam, and a working platform is installed on the base box under the hot stamping device. The film stamping machine resolves the problem that the existing stamping machine has difficulty in stamping of soft objects like thin films and is an ideal device for stamping of soft thin objects like plastic films.

Owner:江敦景

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com