Electric combined gold stamping machine

A combined hot stamping machine and electric technology, applied in the field of hot stamping machines, can solve the problems of high noise of the air compressor, waste of power and time, and restrictions on the operating place, and achieve the advantages of saving power, good stamping quality and low working noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

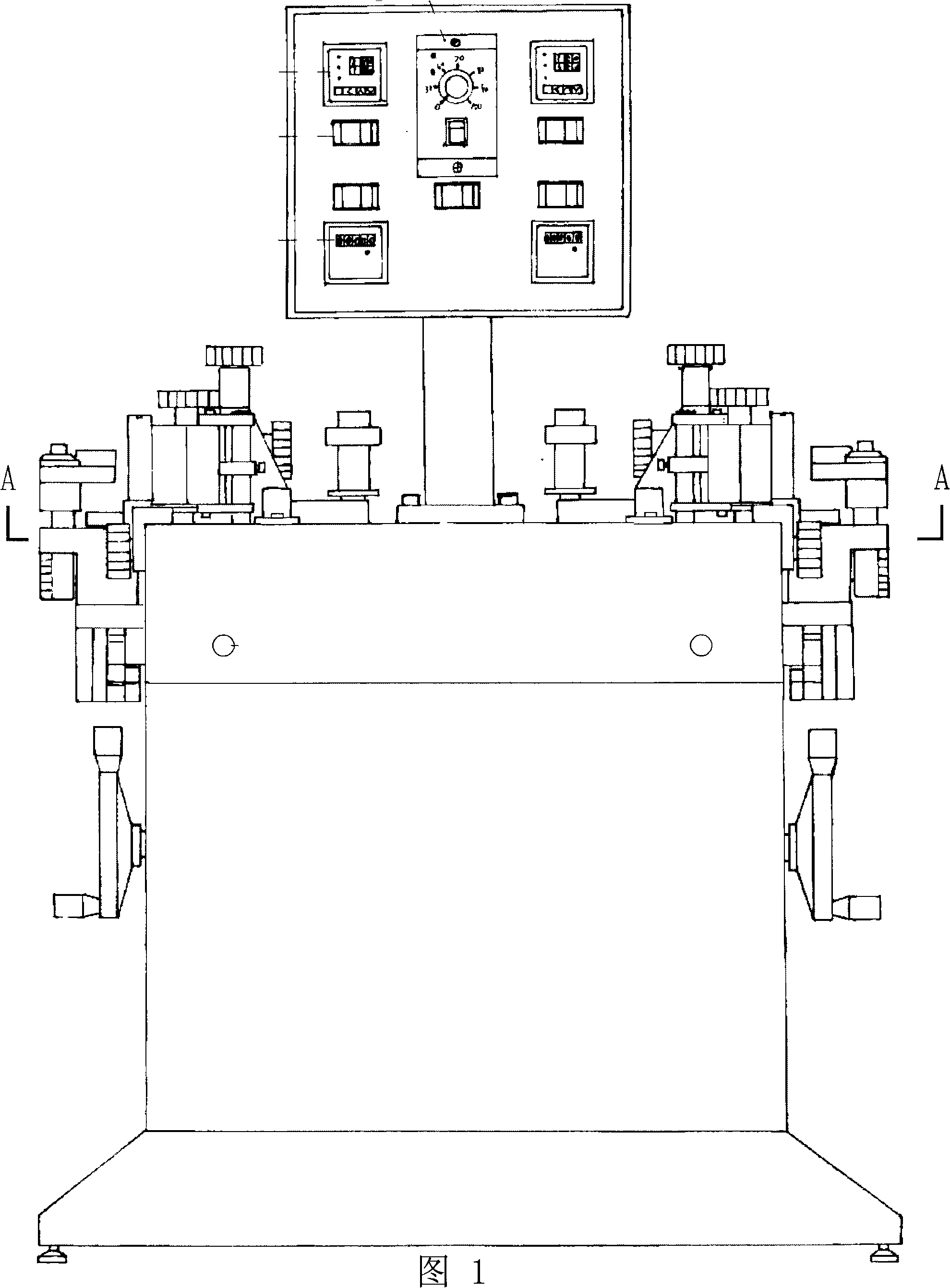

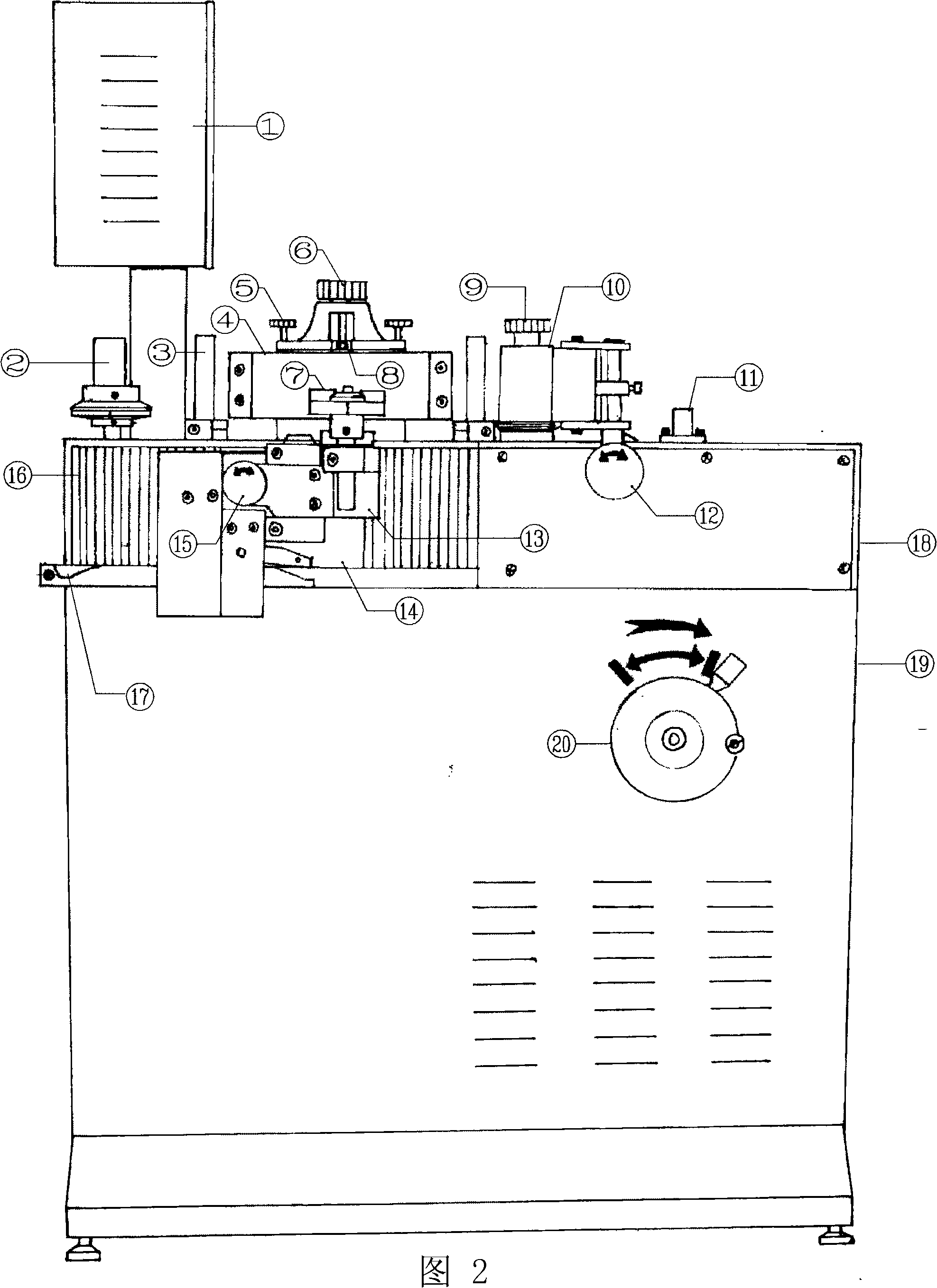

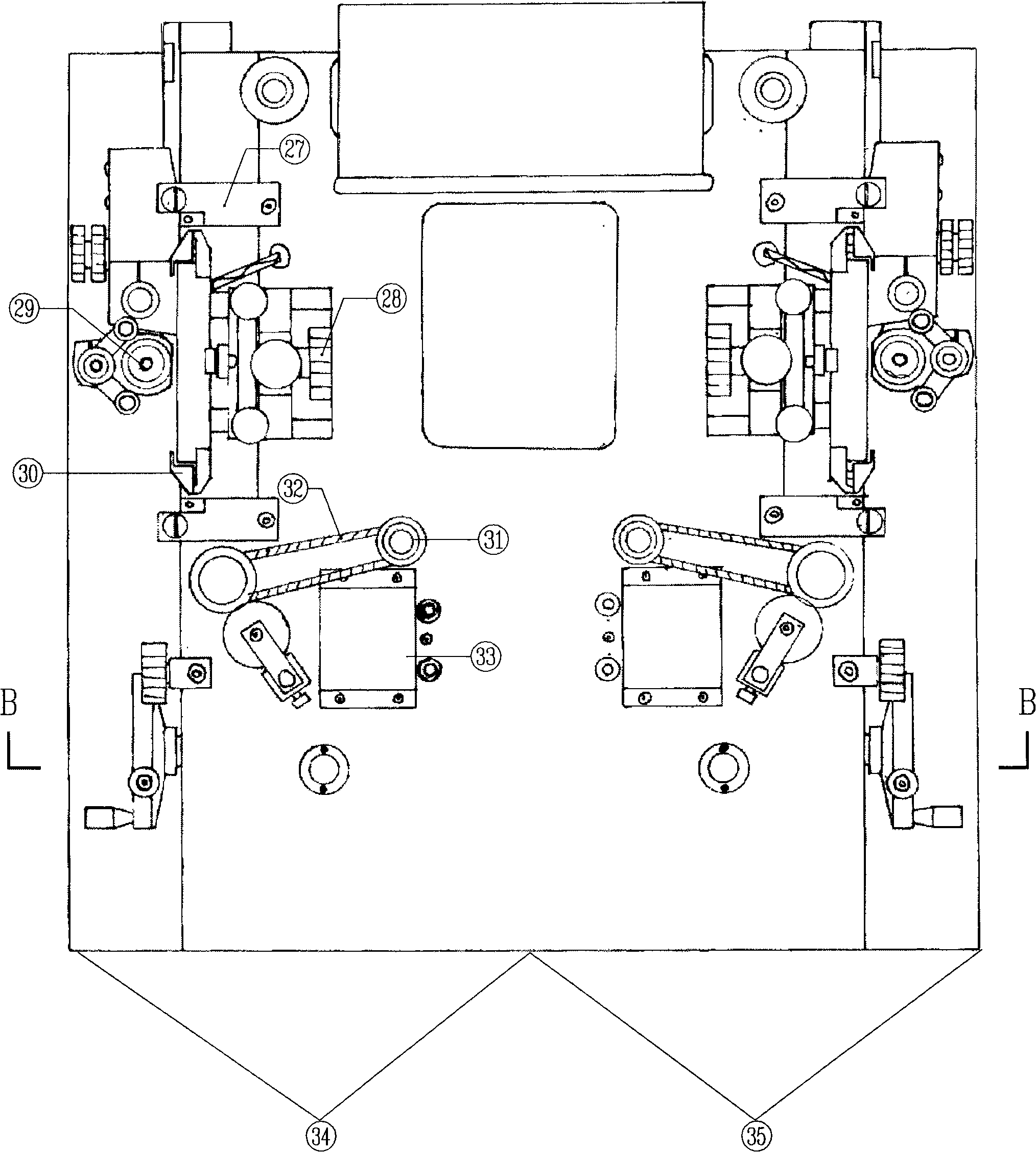

[0015] Accompanying drawing is a kind of specific embodiment of the present invention.

[0016] The electric combined hot stamping machine of the present invention includes a heating hot stamping device installed on the frame, a hot stamping paper transmission and adjustment device, a transmission device, a main motor, a control device, and a counting device, and the transmission device includes a sliding body that reciprocates along the guide rail 14. The transmission device also includes the main shaft 47 that cooperates with the main motor 73 through the pulley pair, the delivery drive gear 49 installed on the main shaft, the sliding body driving wheel 56, and the clutch; the clutch includes a clutch slip sleeve 51, a power clutch manual adjustment wheel 20. Fork plate 68, clutch retaining ring 53; clutch sliding sleeve 51 is slidably socketed on the main shaft, clutch block 65 is fixed on one side of the clutch sliding sleeve, and clutch bearing 52 is fixed on the outer cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com