Lighter casing automatic screen printer

An automatic screen printing and screen printing machine technology, which is applied to screen printing machines, printing machines, printing machines, etc., can solve the problems of semi-automatic production that cannot automatically complete the flipping of the casing, waste of labor resources, and affect production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

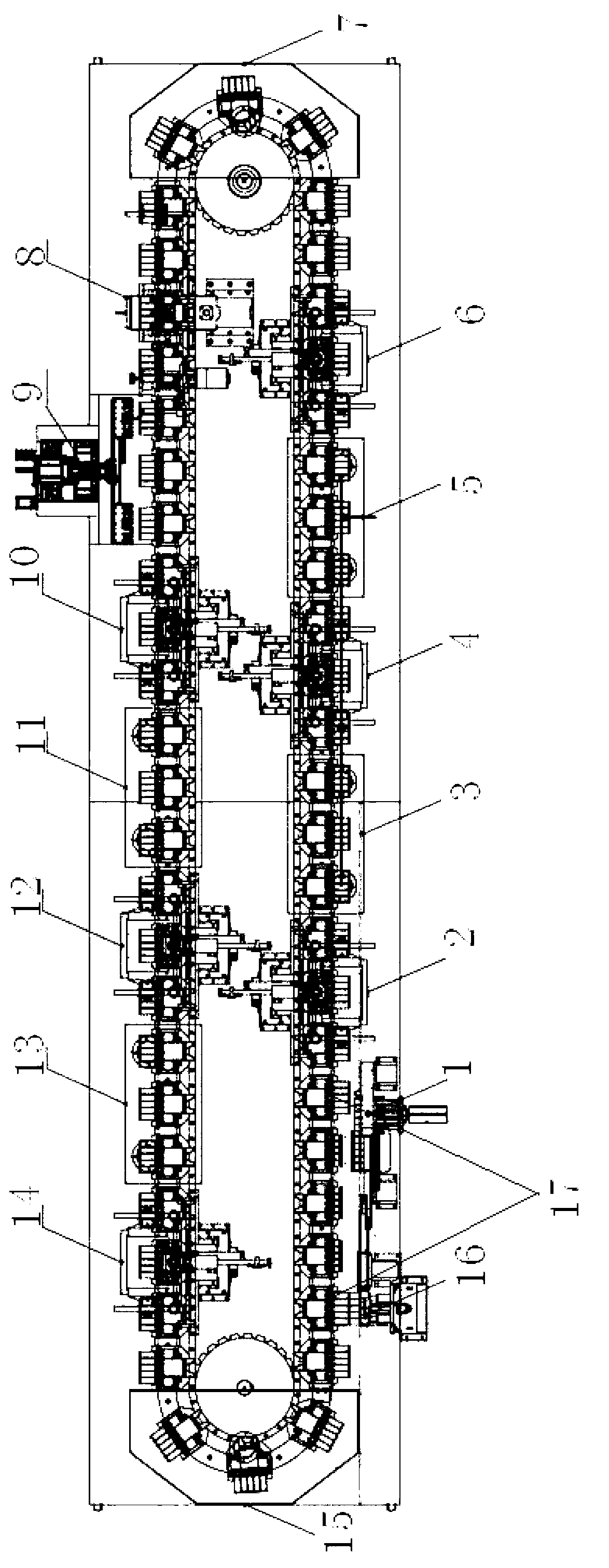

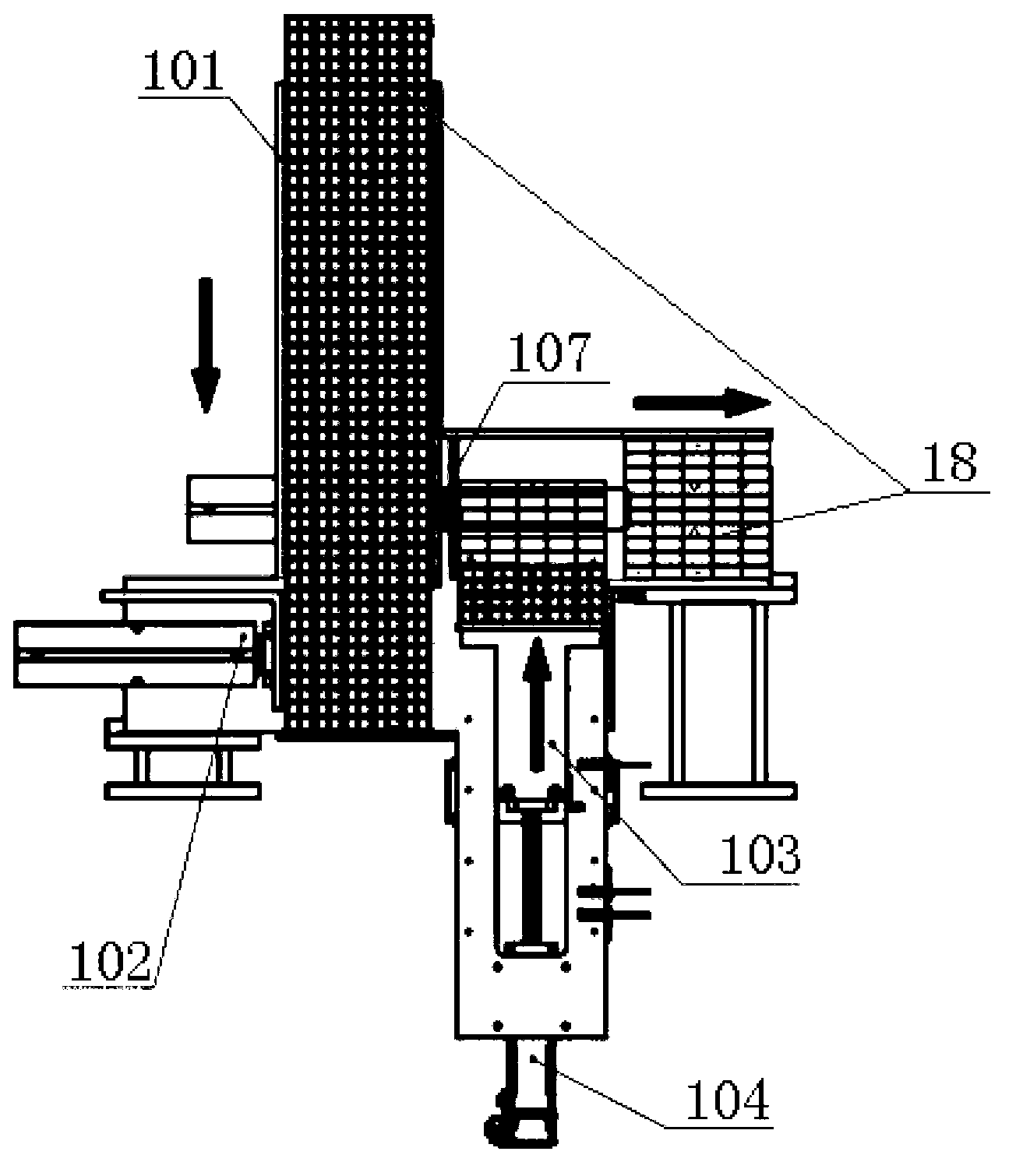

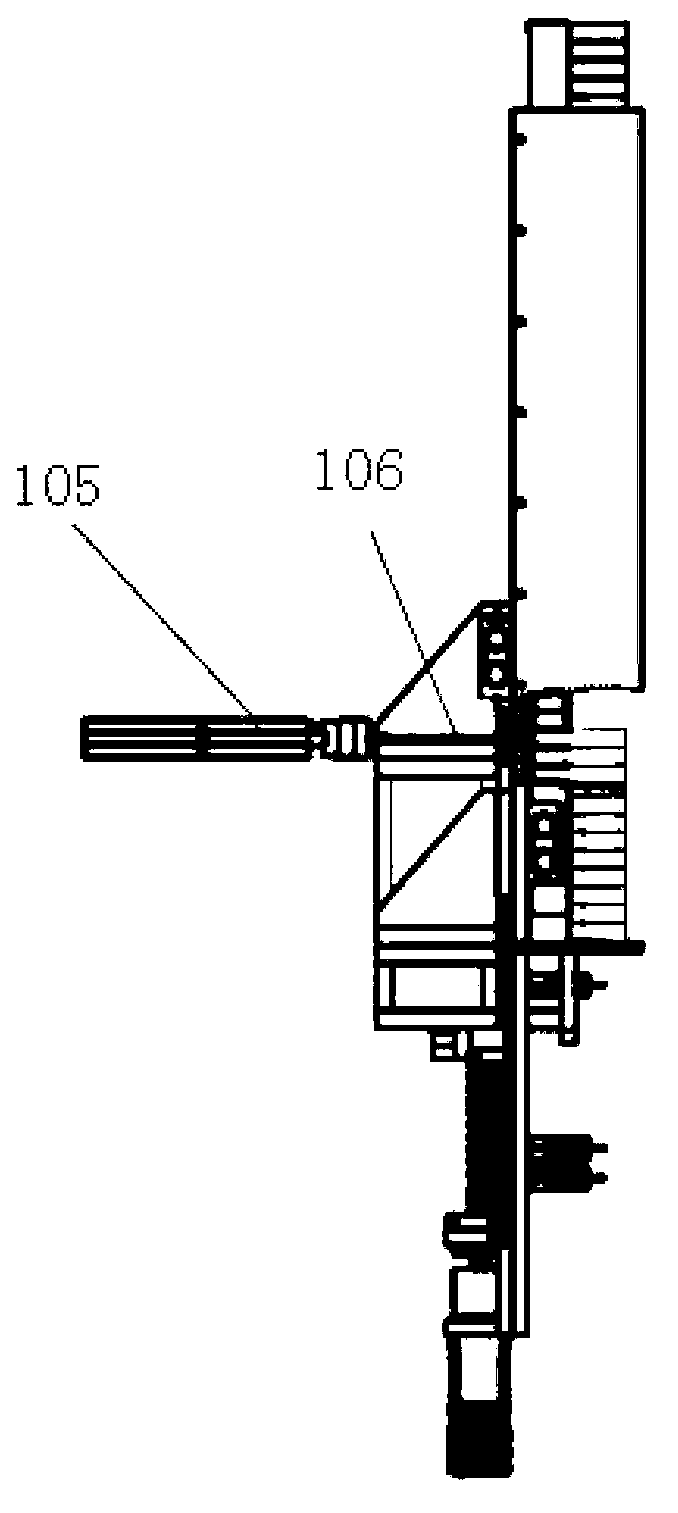

[0021] The following is a specific implementation of a preferred embodiment of the present invention, such as Figures 1 to 8 shown. An automatic screen printing machine for a lighter casing, the sequence includes an automatic feeding part, at least one A-side screen printing and drying part composed of a screen printing part and a drying part, a bronzing machine part, an automatic inversion casing part, and at least one The screen printing and drying part on the B side composed of the screen printing part and the drying part, and the automatic unloading part; the automatic screen printing production line is also provided with a plurality of fixture mold cores running through the entire production line. The bottom frame 18 is filled with the unscreened lighter case, and it is placed between the two side panels and the rear baffle of the storage rack 101 of the automatic feeding part 1. Slide and advance, and push the bottom frame cylinder 102 at a time to fill a box. The bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com