Patents

Literature

728results about How to "Guaranteed printing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

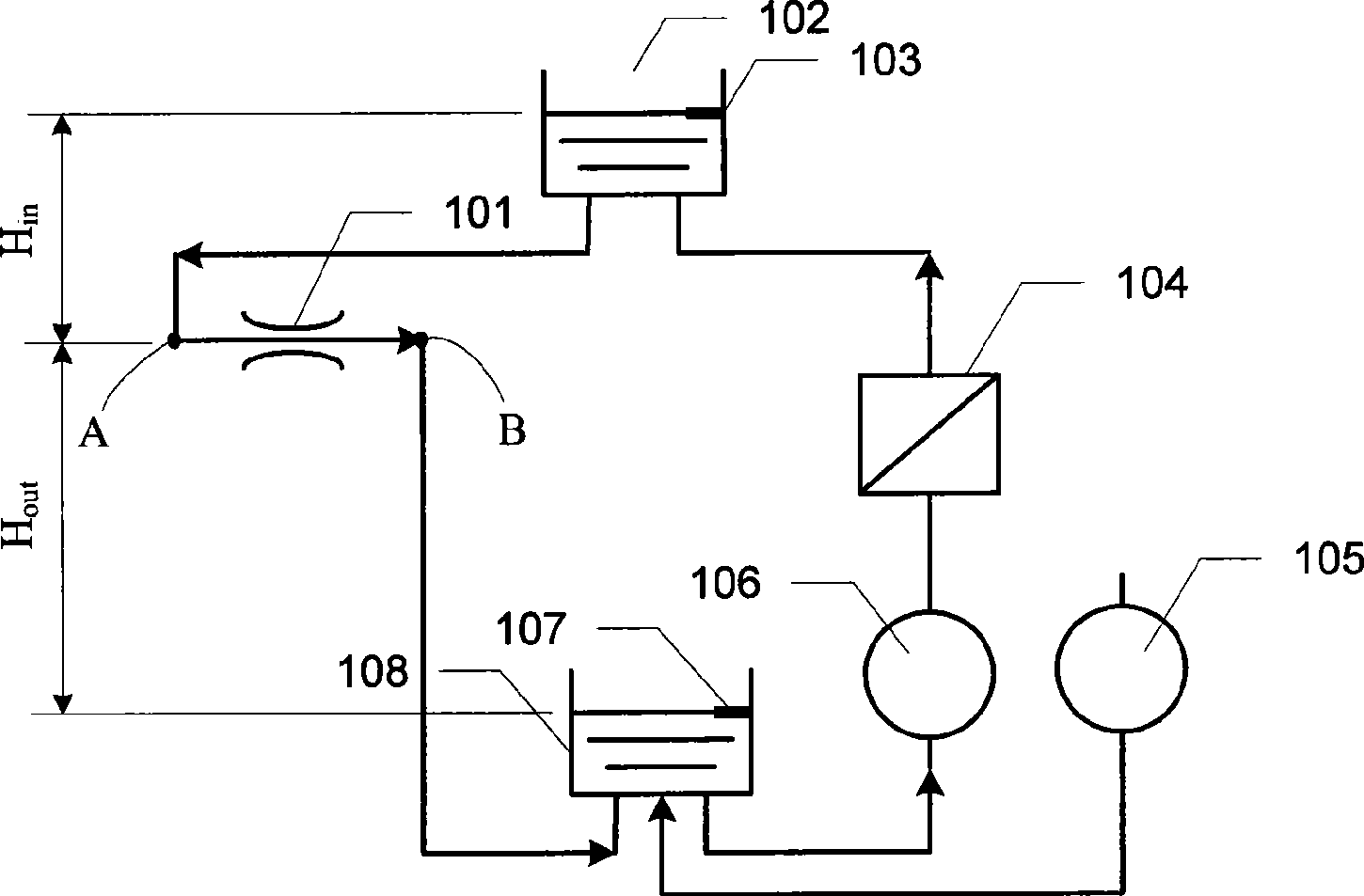

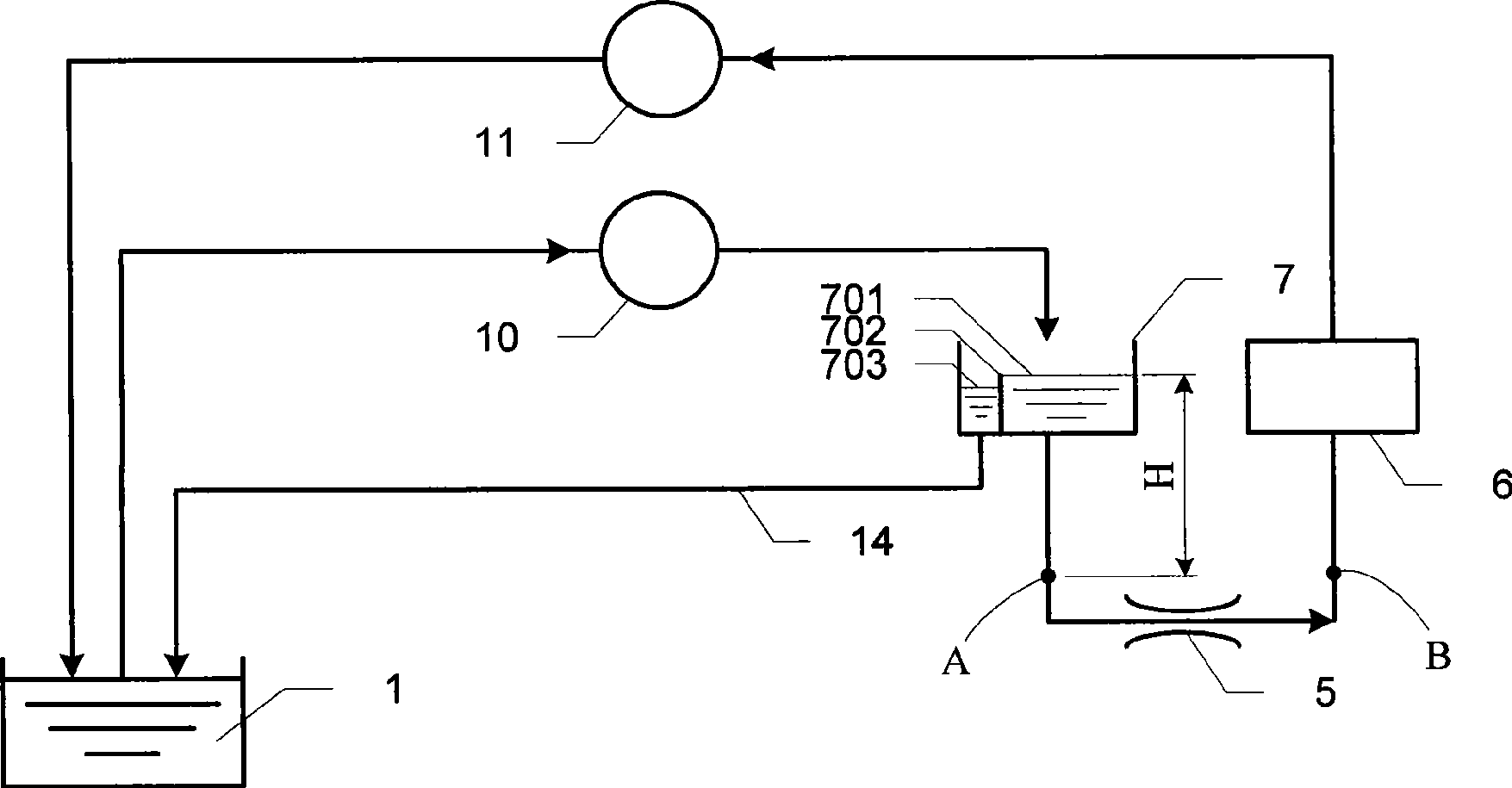

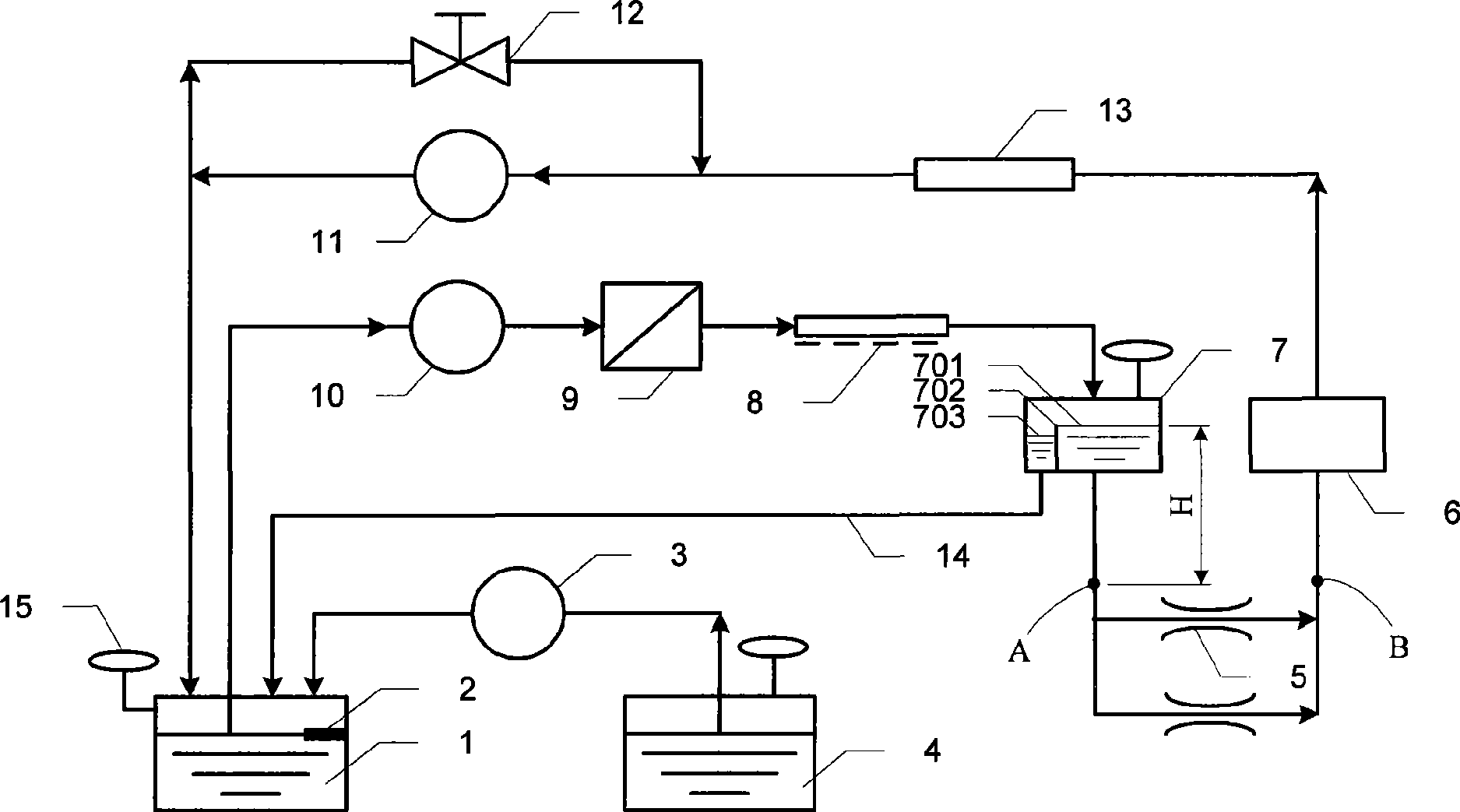

Cyclic ink supply method and cyclic ink supply system

InactiveCN101391530AGuaranteed print qualityReduce system complexityPrintingNozzlePulp and paper industry

The invention discloses a circulation ink supply method and a circulation ink supply system, relating to the ink supply technique. The method and the system can ensure the printing quality, simultaneously, the system complexity can be reduced and the system cost is saved. The circulation ink supply system provided by the embodiment comprises an ink box, an ink inlet pool which is provided with an overflow beam, a discharging trough and an ink supply trough, and an ink inlet pump; the ink inlet end of the ink inlet pump is connected with the ink box; the ink outlet end of the ink inlet pump is connected with the inlet of the ink supply trough of the ink supply pool; the discharging trough outlet of the ink inlet pool is connected with the ink box, wherein, the ink supply trough outlet of the ink inlet pool is connected with the nozzle inlet which is arranged below the ink supply trough of the ink inlet pool; the nozzle inlet is connected with the ink inlet end of at least one nozzle; the ink outlet end of at least a nozzle is connected with the nozzle outlet; the nozzle outlet is connected with the ink inlet end of a returning ink pump; the ink outlet end of the returning ink pump is connected with the ink box.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

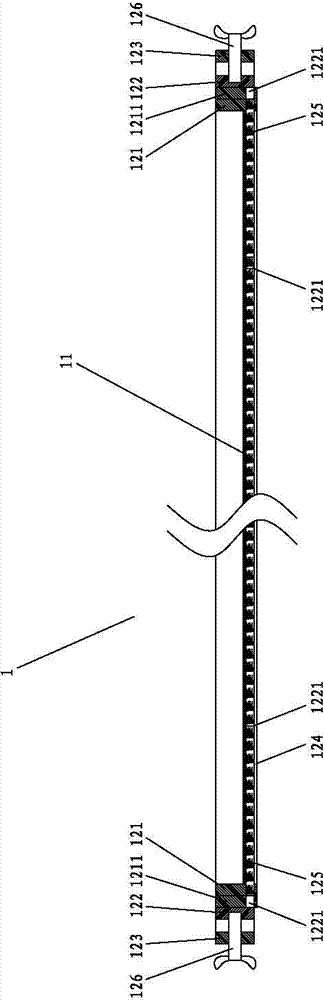

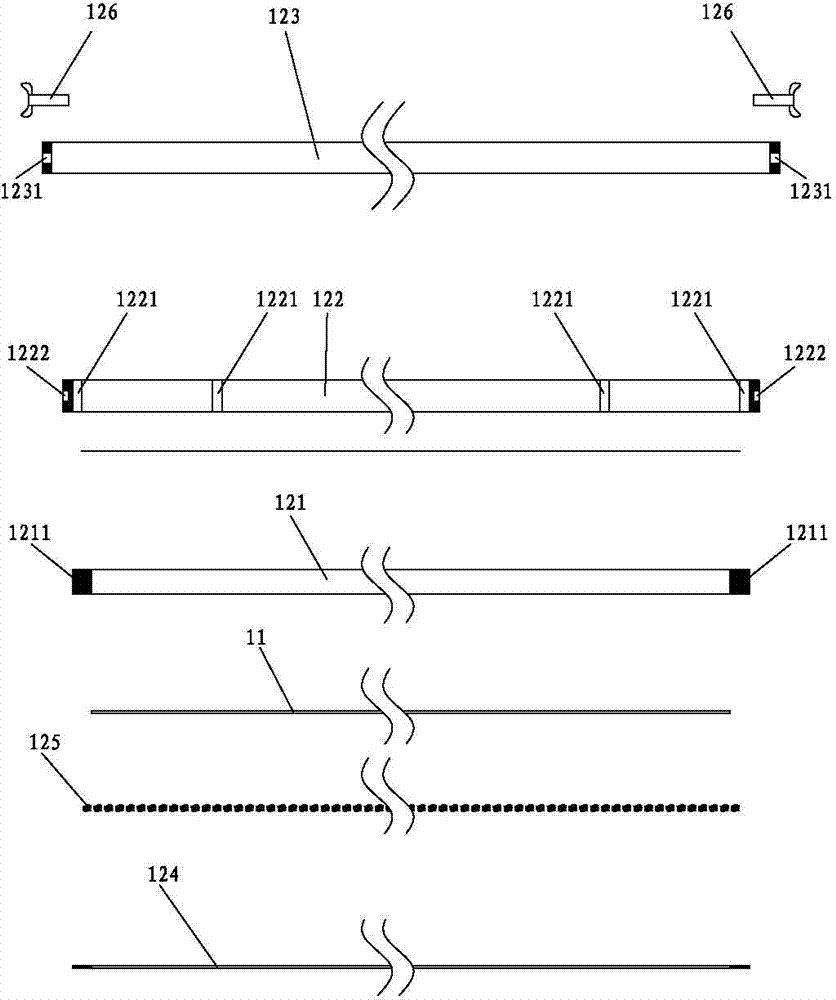

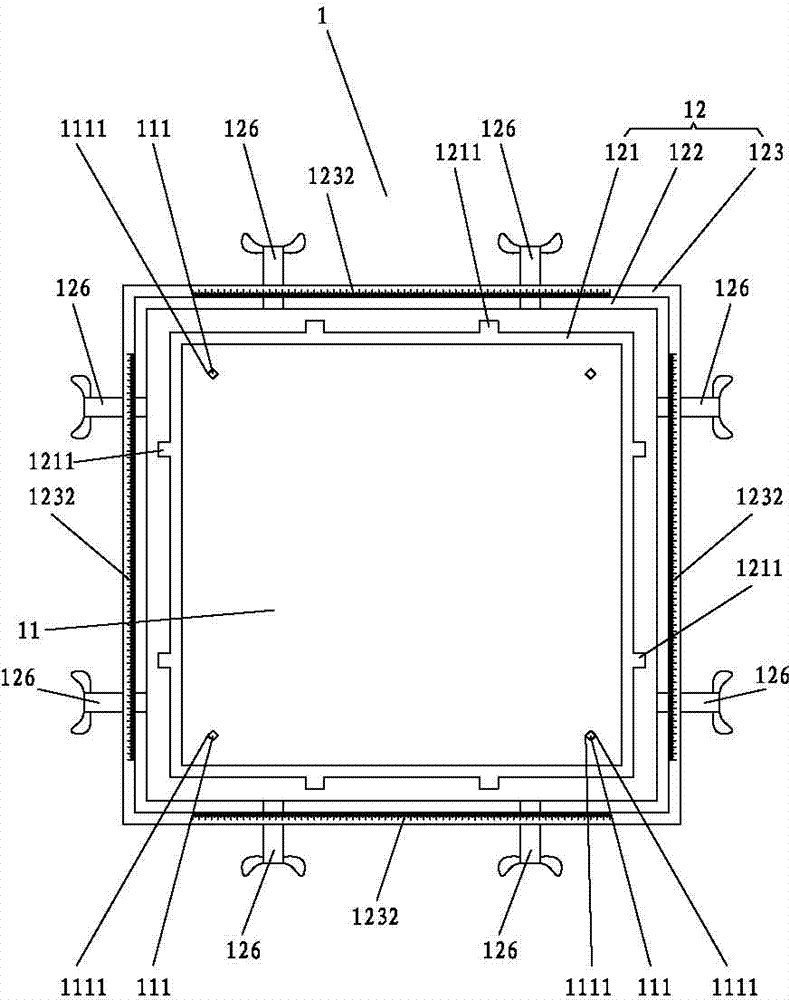

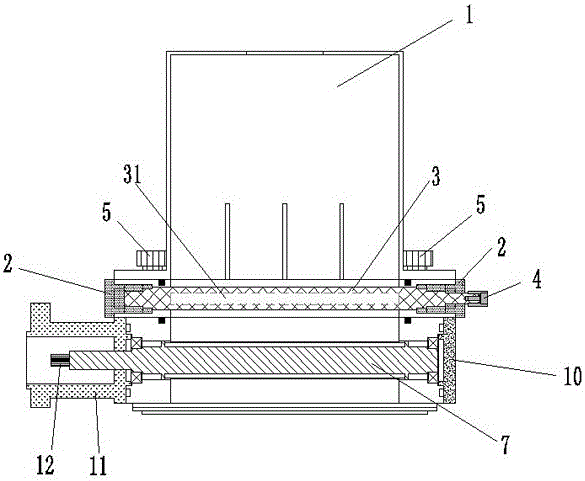

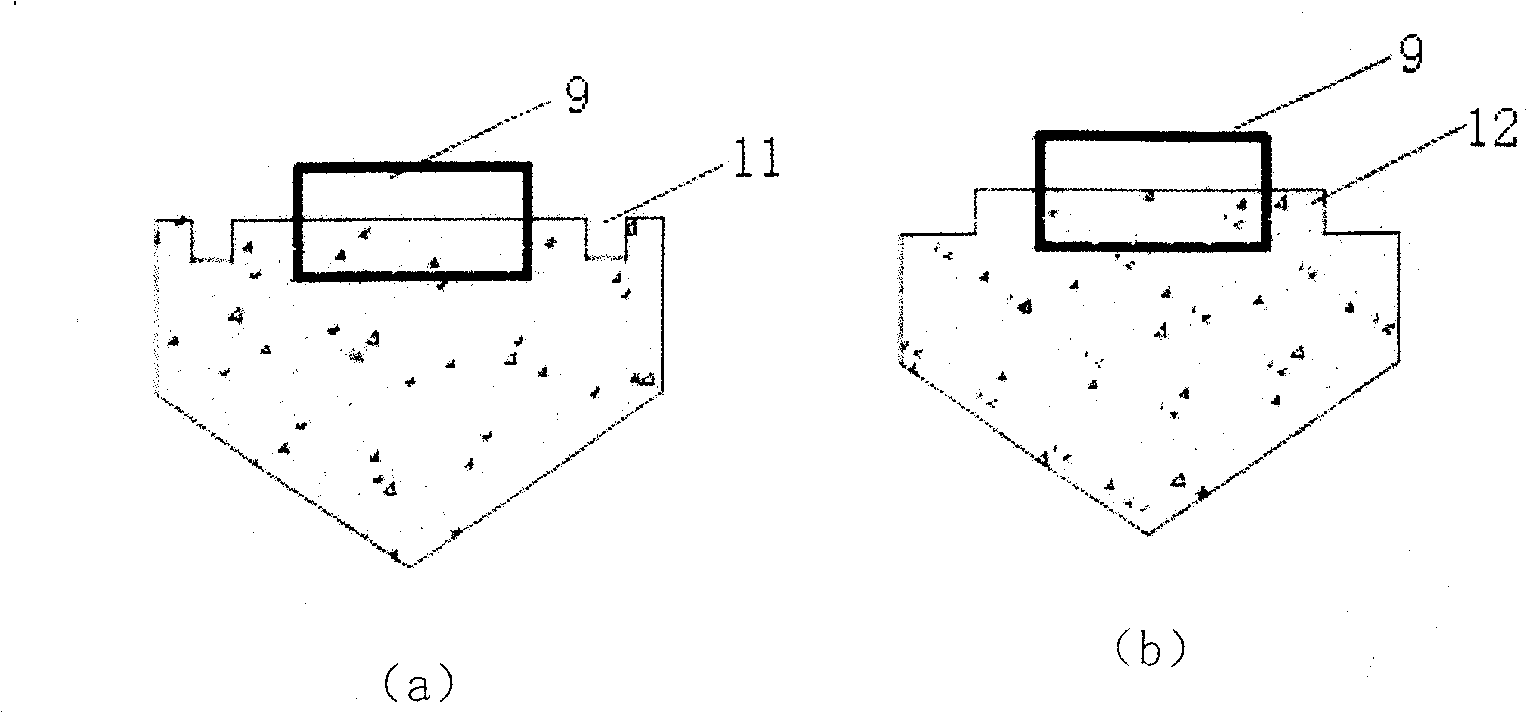

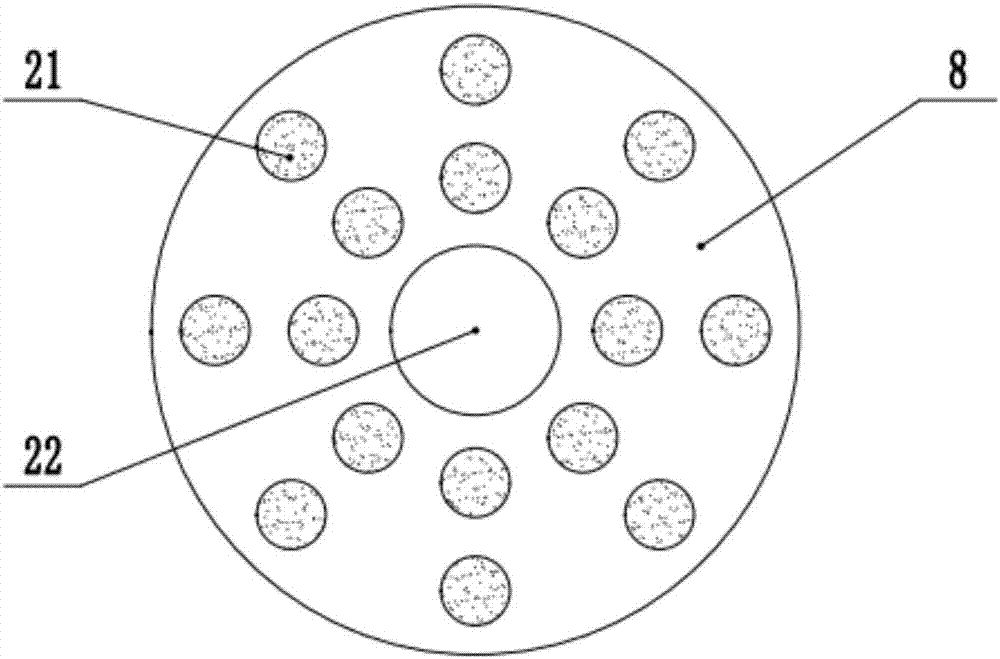

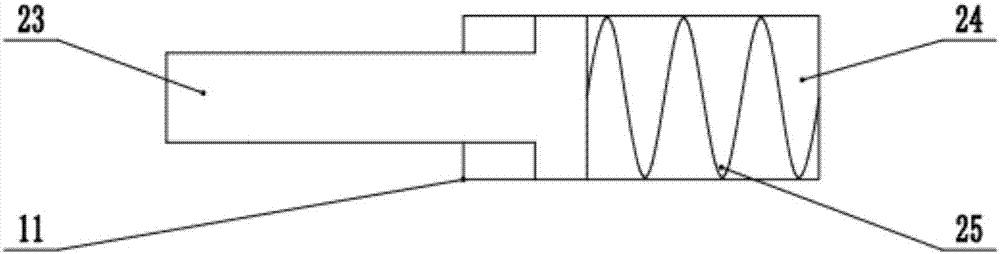

Silk screen printing plate, double-printing device, double-printing machine and double-printing process

ActiveCN104228321AAffect printing qualityGuaranteed printing qualityScreen printersScreen printingEngineering

The invention provides a silk screen printing plate. A screen frame comprises an inner screen frame, a middle screen frame and an outer screen frame. A sliding groove is formed in the middle screen frame. A sliding rail matched with the inner screen frame is formed on the inner screen frame. The middle screen frame is provided with a blocking frame. A plurality of springs are evenly distributed between the inner screen frame and the blocking frame. An adjusting bolt is arranged on the outer screen frame in a matched mode. A silk screen is provided with an adjusting aligning point. An adjusting aligning scale is arranged on the outer screen frame. Accordingly, by means of the silk screen printing plate, silk screen patterns can be adjusted and aligned effectively, high-quality double-printing is achieved, obvious deformation of the silk screen can be avoided effectively, and the printing quality of the silk screen patterns is guaranteed. The invention further provides a double-printing device, the double-station double-printing operation can be achieved, the silk screen printing plate is excellent in effect, and the double-printing efficiency and quality are improved remarkably. The invention further provides a double-printing machine which has the excellent effects of the silk screen printing plate and the double-printing device, and the double-printing efficiency and quality are improved remarkably. The invention further provides a double-printing process. The process is concise and clear and high in double-printing efficiency and quality.

Owner:SHISHI DECAI CHEM TECH

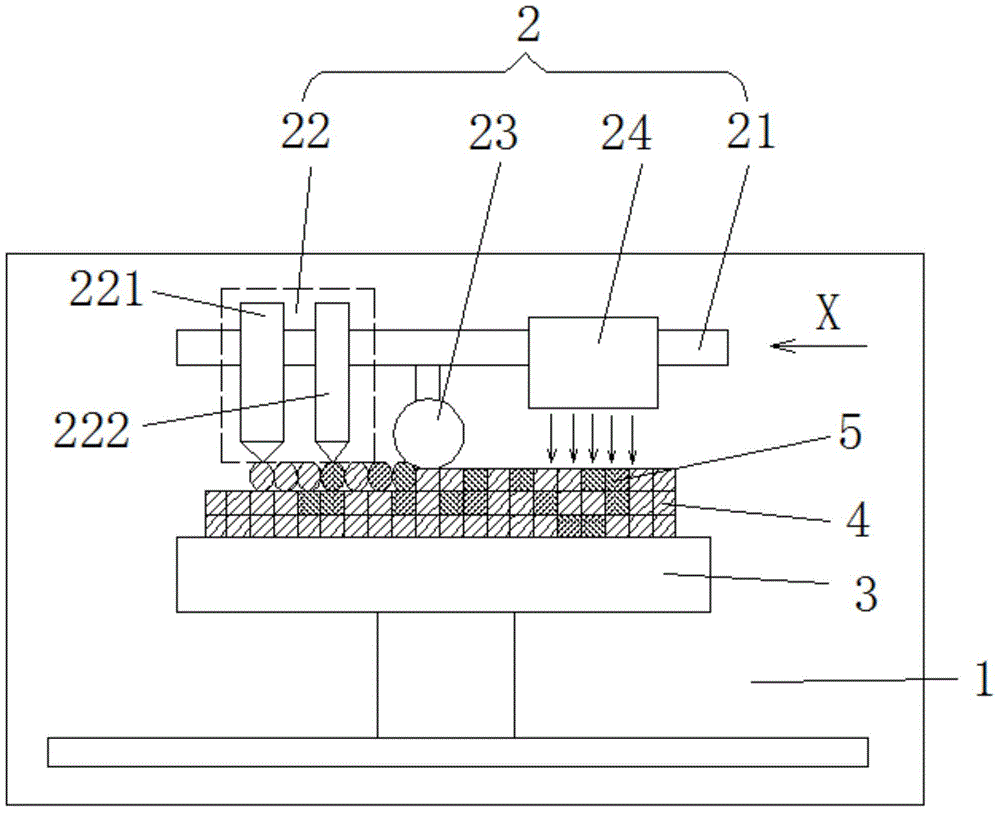

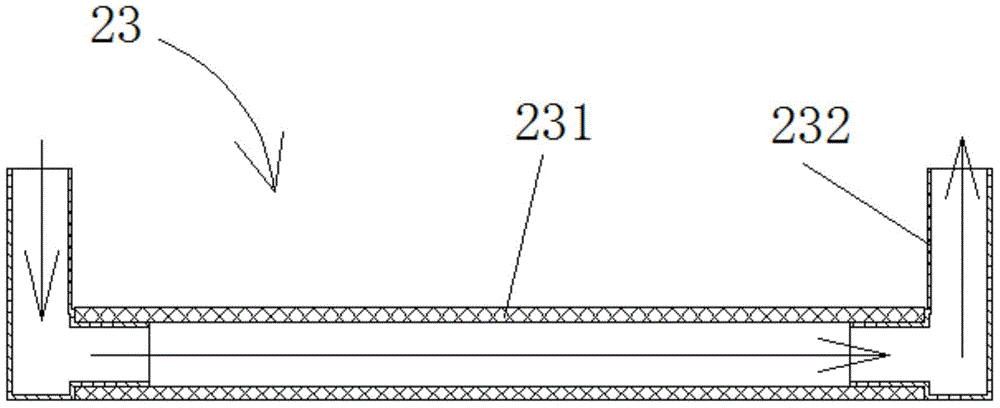

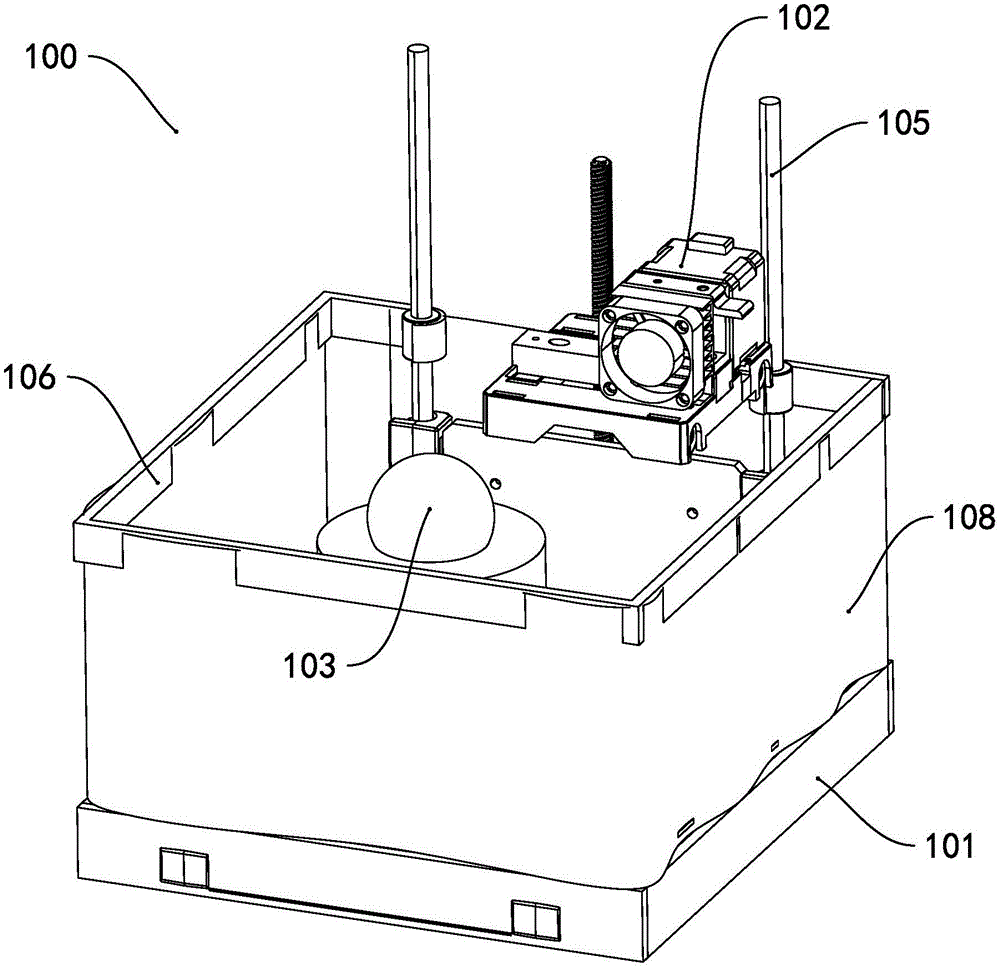

3D printing machine and 3D printing method

ActiveCN105172143AImprove printing efficiencyAchieve fixation3D object support structuresManufacturing data aquisition/processingHost materialEngineering

The invention discloses a 3D printing machine which comprises a printing chamber. A printing assembly and a bearing platform are arranged in the printing chamber. The printing assembly is arranged above the bearing platform. The printing assembly comprises a printing support, a printing head assembly and a curing lamp assembly, wherein the printing head assembly and the curing lamp assembly are connected to the printing support. The printing support moves in the printing direction. In the printing direction, the printing head assembly is located in front of the curing lamp assembly. The printing head assembly comprises a main printing head body of a printing model body and an auxiliary printing head body of a printing supporting material. The model main material is photosensitive resin. The printing temperature in the printing chamber is lower than the solidification temperature of the supporting material. The supporting material is solidified at the printing temperature. The invention further discloses a 3D printing method. By means of the 3D printing machine and the 3D printing method, the supporting material is removed easily.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD +1

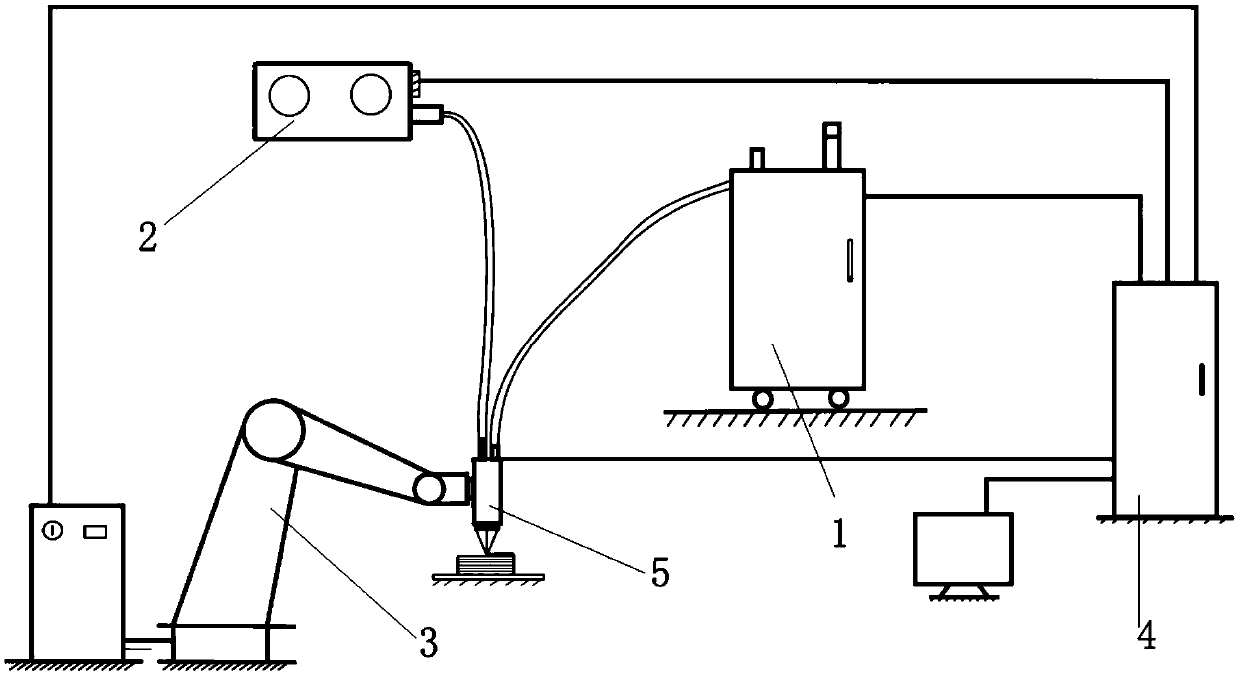

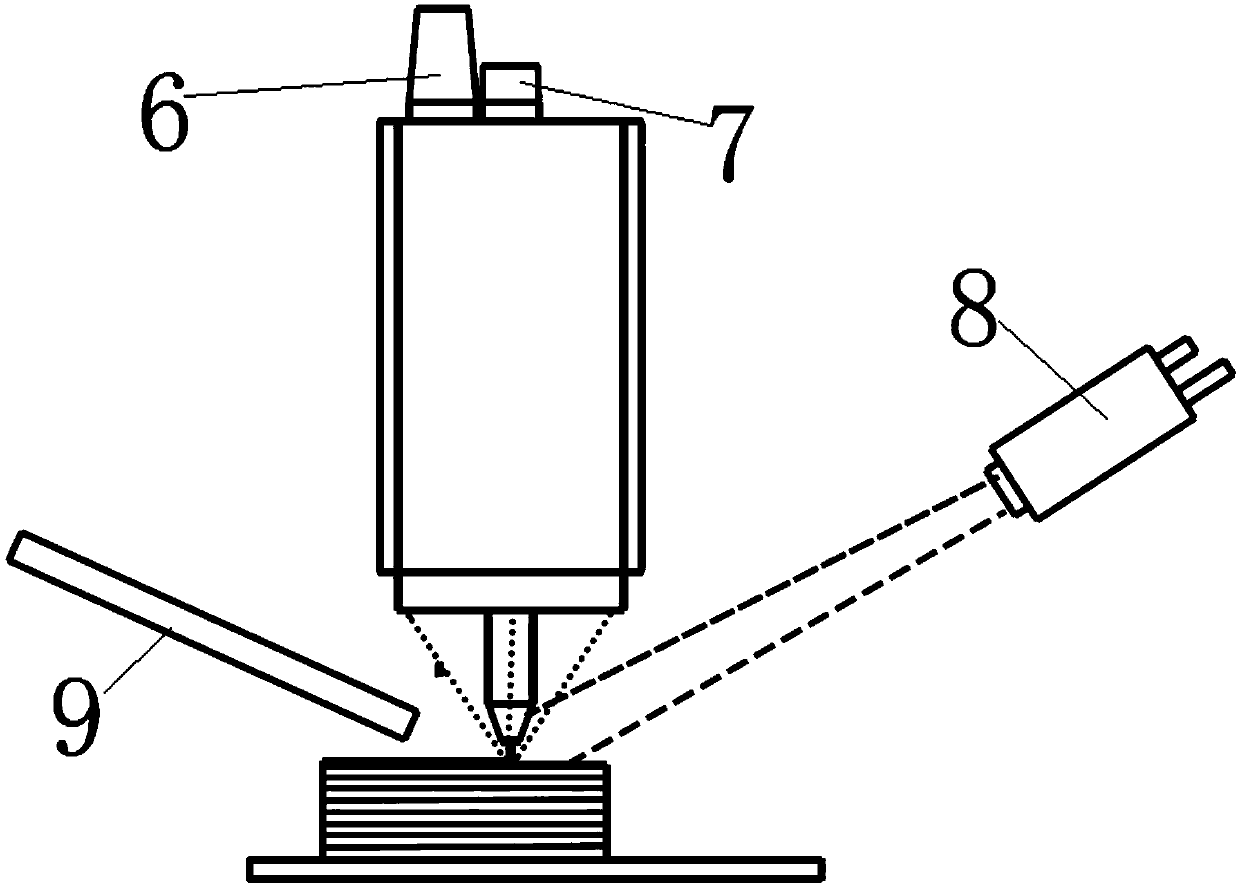

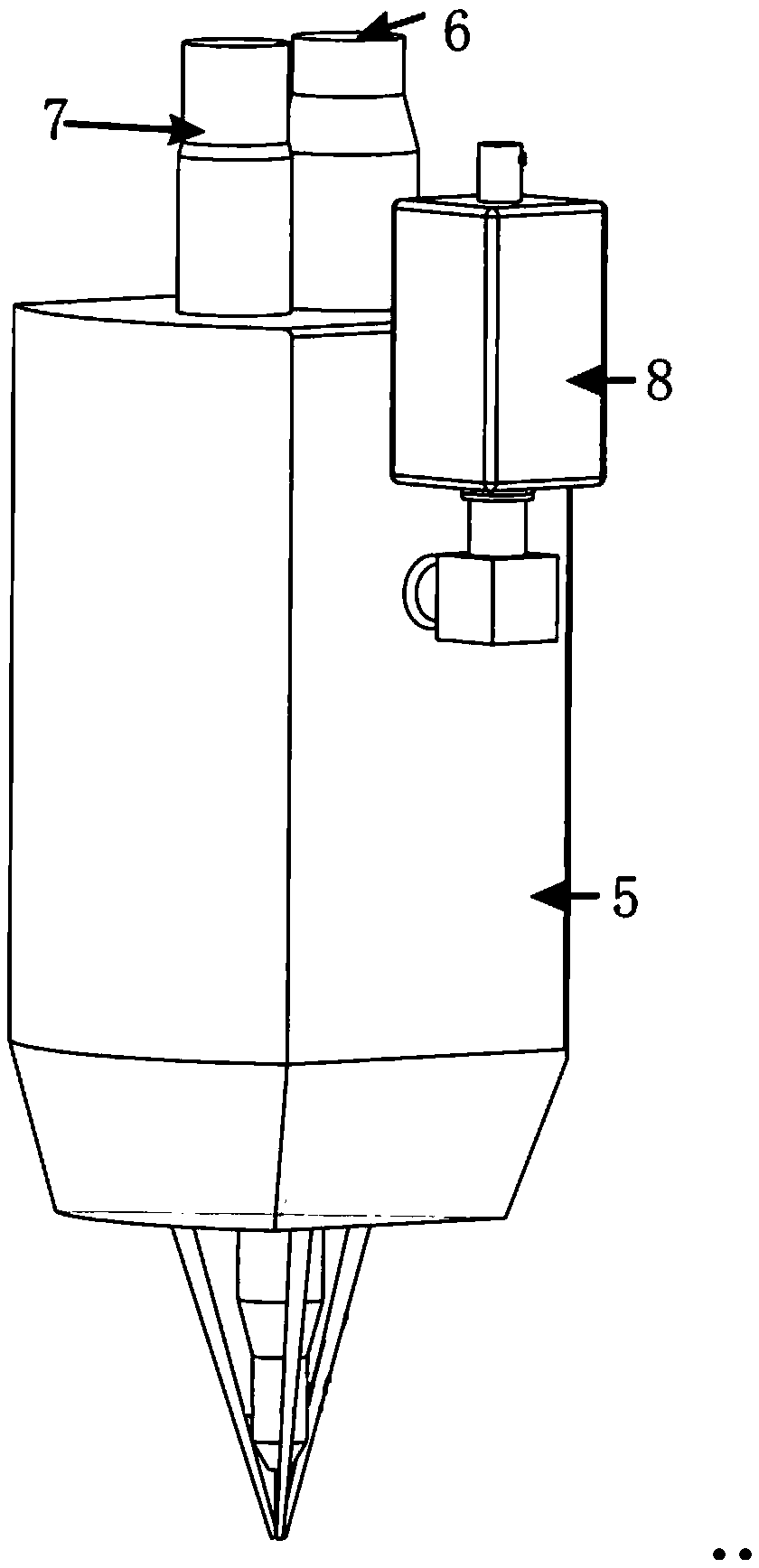

Laser-based inside-laser coaxial wire-feeding additive manufacturing system and forming method

InactiveCN109530918AReduce unevennessImprove deposition qualityAdditive manufacturing apparatusLaser beam welding apparatusMelting tankFeature structure

The invention discloses a laser-based inside-laser coaxial wire-feeding additive manufacturing system and a forming method. The laser-based inside-laser coaxial wire-feeding additive manufacturing system is formed by a laser, a wire feeder mechanism, a movement actuating mechanism, a molten pool shape monitoring feedback module and a system control module. After a part model is cut into slices, aninitial path is planned, input parameters and technological parameters in a technology database are compared, the molten pool temperature corresponding to technological parameters and input technology parameters under different feature structures is optimized, printing parameters and a robot code under an optimal path are generated, a high-speed infrared camera acquires molten pool shape parameters during the printing process and transmits to the system control module, the system control module compares the acquired molten pool shape data and the technology data of the technology database module, meanwhile, the molten pool temperature change is monitored, and the molten pool temperature is corrected through feedback-adjusting laser power and is monitored and feedback-adjusted in real time, so that the molten pool shape is uniform and consistent and the printing process is stably controlled during the printing process.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

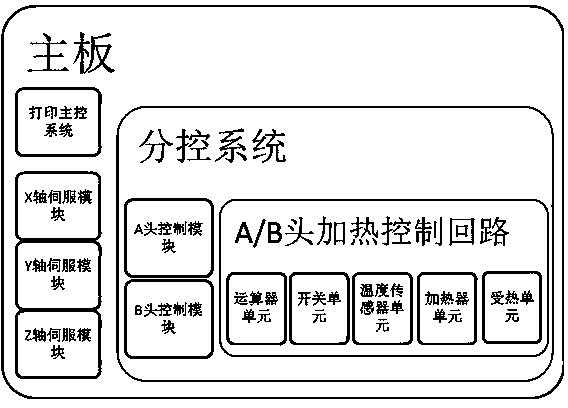

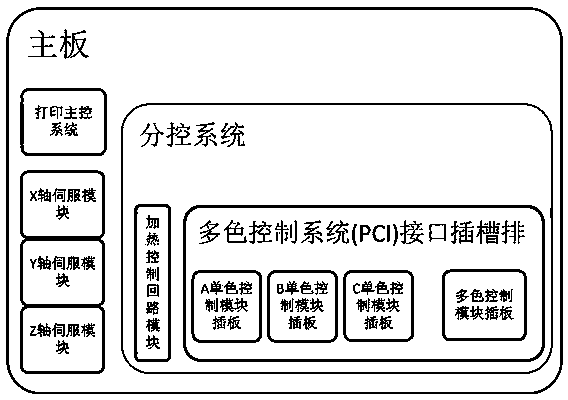

Control system for stackable multi-color-head three-dimensional printer capable of realizing precision printing

ActiveCN103448247AGuaranteed printing qualityEliminate the assembly processControl systemComputer printing

The invention discloses a control system for a stackable multi-color-head three-dimensional printer capable of realizing precision printing. A plurality of color heads of the stackable multi-color-head three-dimensional printer are used for separating hardware parts of a control loop and a heating control loop of each wire feeding pump from a motherboard to form a modular plug-board structure capable of easily ensuring the symmetry consistency; the modular plug-board structures are respectively plugged into interface slots of a heating system and a multi-color control system on the motherboard; by virtue of the symmetry consistency of technical indexes and parameter values of each wire feeding pump, multi-color fuse wires can be fused without temperature difference in a sprayer nozzle when a multi-color-head three-dimensional workpiece is printed, color wires are extruded, and high printing precision is realized. The mechanical strength of the printed workpiece reaches mechanical strength indexes of a material. Meanwhile, the control system is convenient to maintain and replace, simple in structure, stable and reliable; resources are saved, and the energy consumption and the cost are reduced.

Owner:辽宁重彩立体打印机有限公司

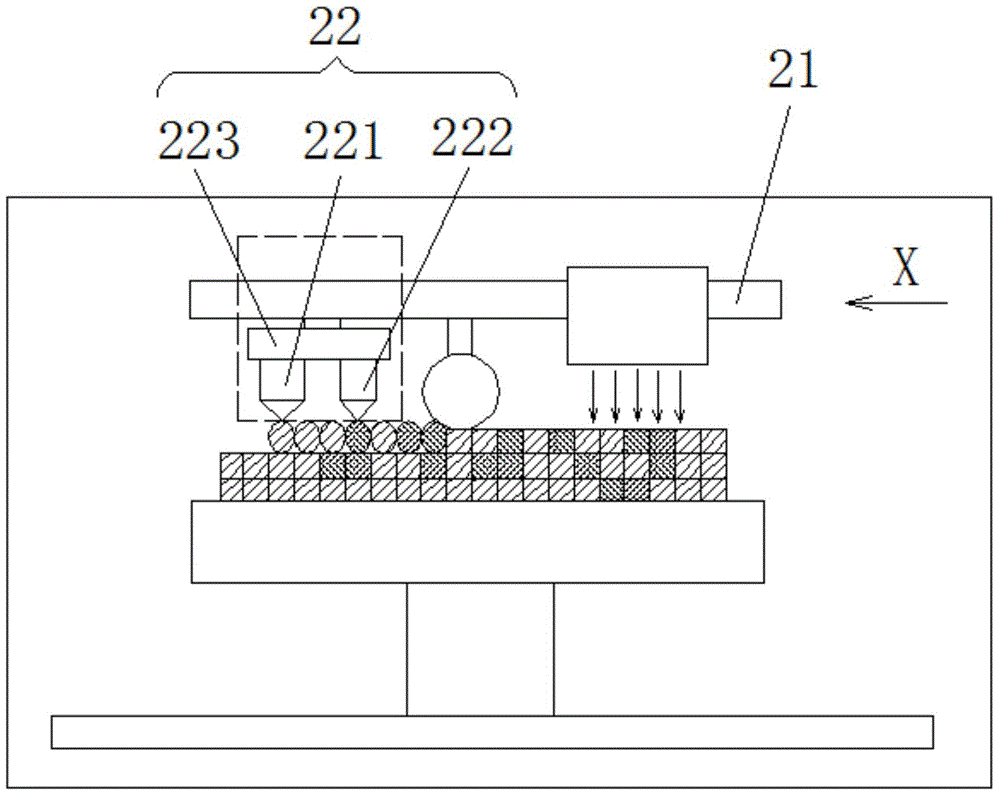

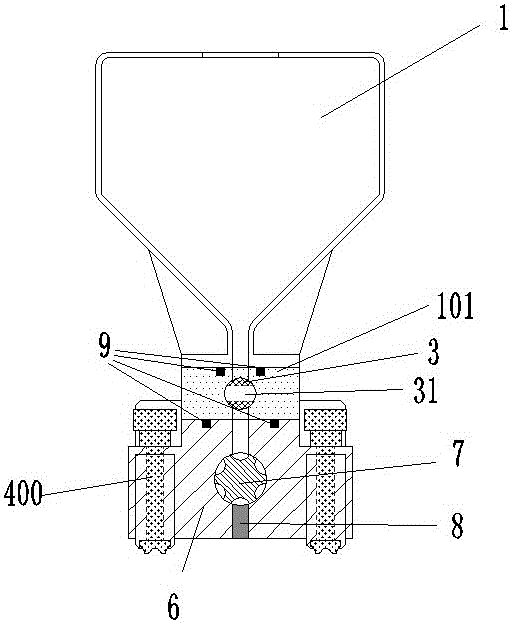

3D (three-dimensional) printing powder delivery and paving linkage type bidirectional powder paving device and equipment

PendingCN106696260AReduce splashReduce wasteAdditive manufacturing apparatus3D object support structuresLinkage conceptMental detachment

The invention relates to a 3D (three-dimensional) printing powder delivery and paving linkage type bidirectional powder paving device. The 3D printing powder delivery and paving linkage type bidirectional powder paving device comprises a worktable, a powder paving driving device, and a powder paving device, wherein the powder paving device is of a powder delivery and paving linkage structure and comprises a powder bin, a powder falling closing area, a quantitative powder delivery area and a powder paving part; the powder falling closing area is arranged at the bottom part of the powder bin, and a powder falling closing shaft is arranged in the powder falling closing area; a detachment and installation structure is arranged between an end cap of the powder bin and the bottom part of the powder bin; a powder bin pressing rotary button is arranged above a roller cylinder in the quantitative powder delivery area and is used for fixing the powder bin and the roller cylinder, a quantitative powder delivery roller is arranged in the quantitative powder delivery area, a powder falling port is arranged under the quantitative powder delivery roller, and the roller cylinder is detachably connected with the bottom part of the powder bin; a powder delivery and paving separation structure is arranged between the powder delivery and paving linkage structure and the powder paving driving device; the powder paving part is arranged at both sides of the roller cylinder, and each side is provided with a scraping knife. The 3D printing powder delivery and paving linkage type bidirectional powder paving device has the advantages that the whole structure is stable, the efficiency is improved by double scraping knives, the bidirectional powder paving function is realized, the aligning process of powder delivery and powder paving in working is not needed, the powder control accuracy is high, and the powder lifting and snapping are avoided; the structure is simple, and the detachment and cleaning are convenient.

Owner:安徽泰尔控股集团有限公司

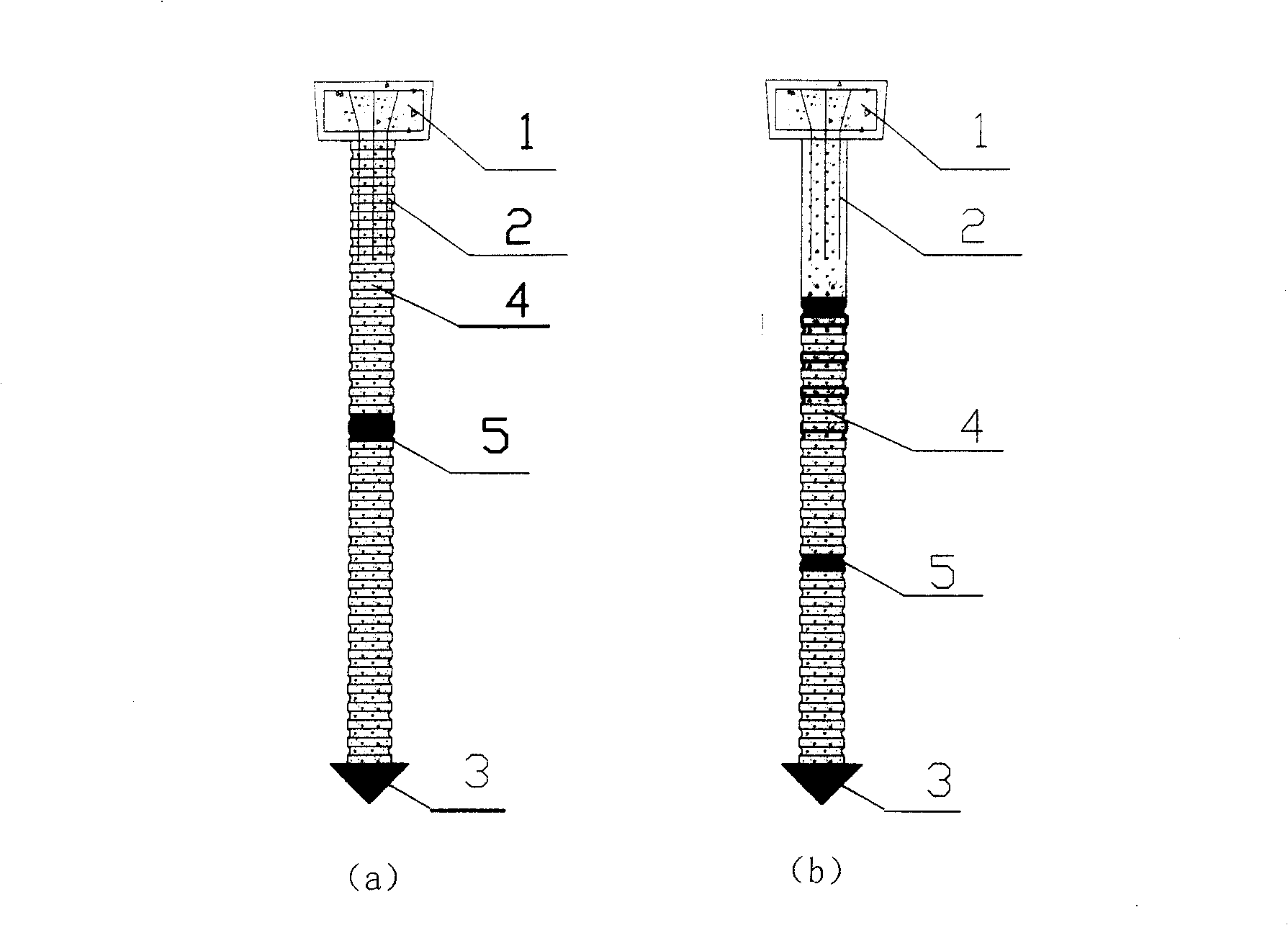

Plastic sleeve concrete pile and method thereof for reinforcing soft soil foundation

The invention relates to a plastic sleeve concrete pile and a construction method thereof. the plastic sleeve concrete pile comprises a cover board, plastic sleeves, pile tips, concrete and sleeve joints, wherein the top of each plastic sleeve is connected with the cover board and the lower part is connected with each pile tip, every two plastic sleeves are connected by the sleeve joint, and the concrete is poured in the plastic sleeves. The construction method comprises the following steps: connecting the prefabricated pile tips with the plastic sleeves, pulling the plastic sleeves together with the pile tips into an immersed tube after lifting the immersed tube at a certain height, starting a plastic sleeve concrete pile driver to drive the plastic sleeves with the pile tips together into the pile length designed depth, lifting the immersed tube after filling water into the plastic sleeves until 1 / 2-2 / 3 of pile length but remaining the plastic sleeves and the pile tips into the foundation, pumping filled water in the plastic sleeves, and pouring a concrete pile body and the cover board into the plastic sleeves to be made into the plastic sleeve concrete pile. The plastic sleeve concrete pile has small soil extrusion action, uneasy broken pile, flexible and rapid construction, easy control of pile body quality, higher bearing capacity of single pile and good cost performance; and the pouring is not influenced by outside.

Owner:HOHAI UNIV

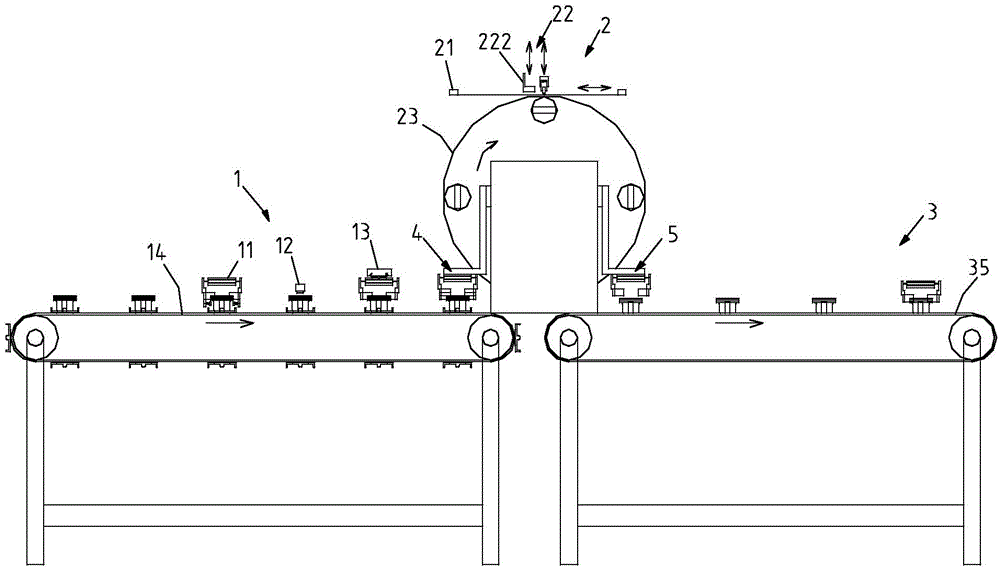

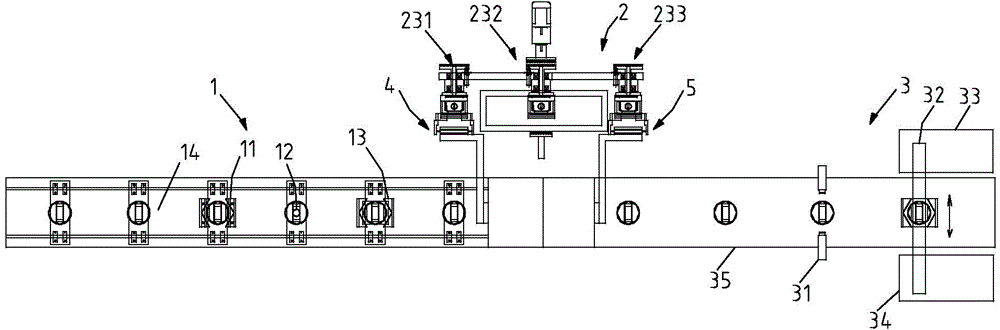

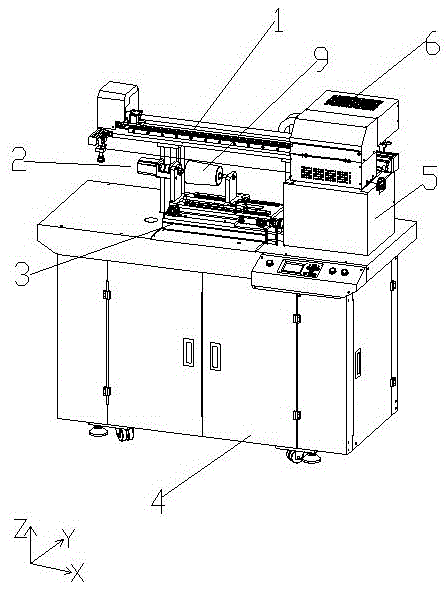

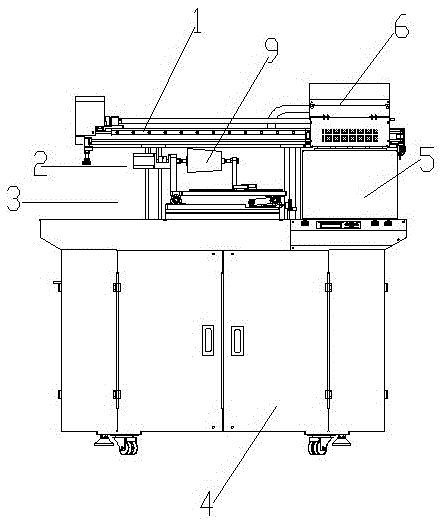

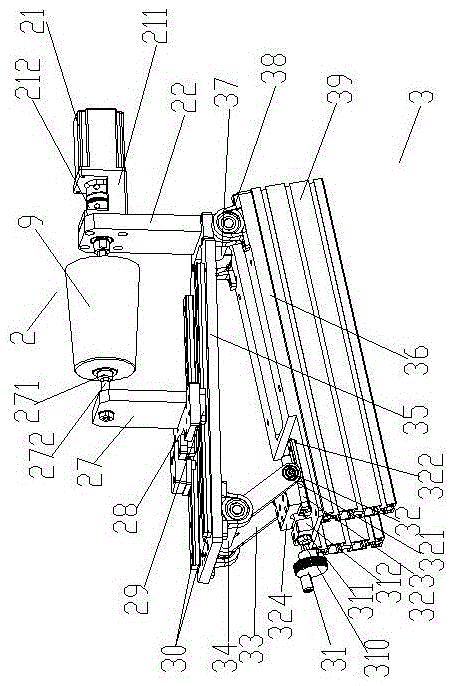

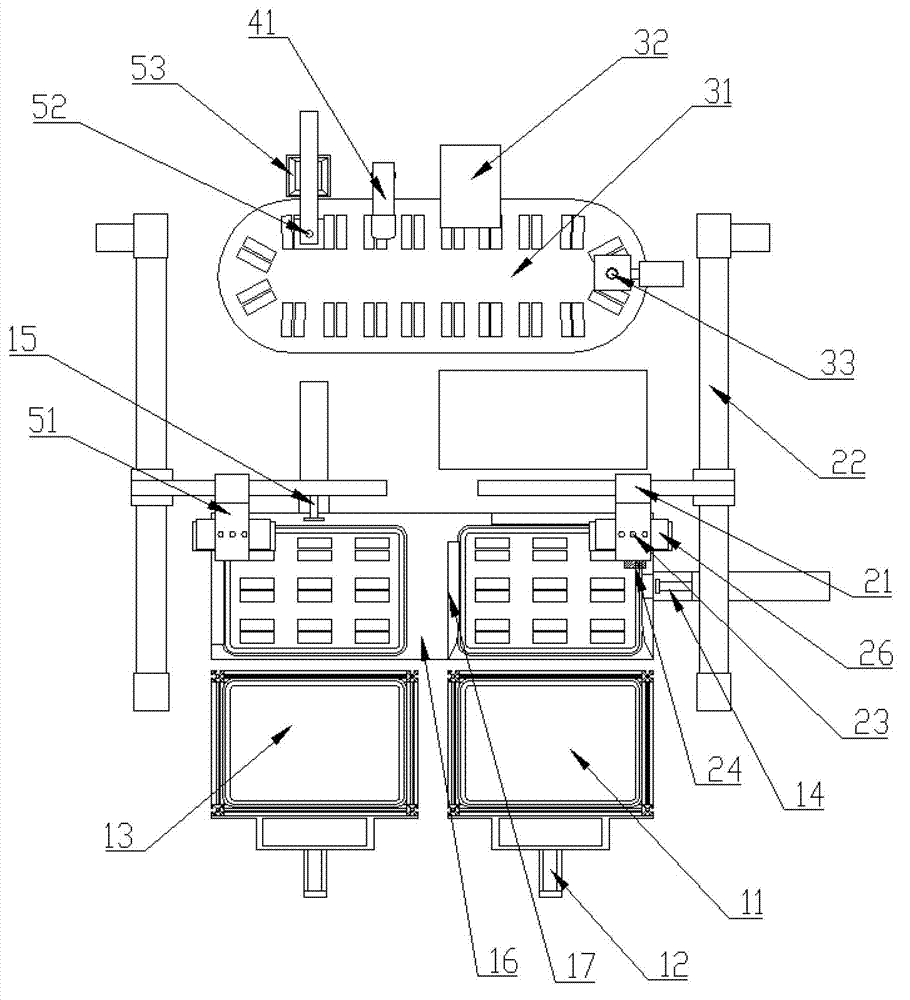

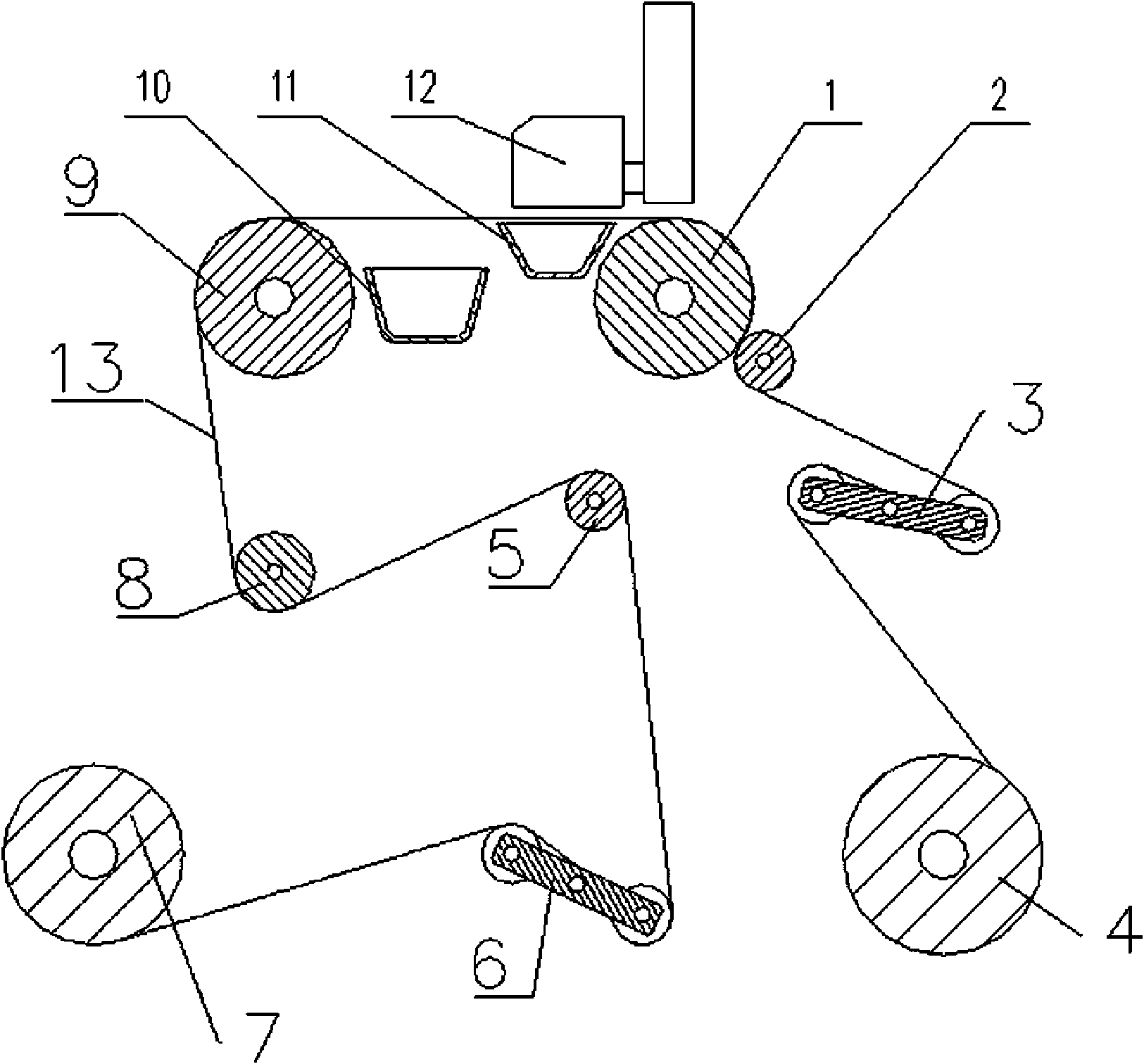

Full-automatic piston screen printer

ActiveCN104960323APrecise positioningGuaranteed printing qualityScreen printersPrinting press partsEngineeringWaste material

The invention discloses a full-automatic piston screen printer. The full-automatic piston screen printer comprises a loading correcting mechanism, a loading mechanism, a printing mechanism, an unloading mechanism and a sorting mechanism which are all sequentially arranged; the loading correcting mechanism sequentially comprises a positioning mechanism, a direction detecting camera, a position correcting mechanism and a loading conveyor belt which sequentially conveys a piston to the positioning mechanism, the direction detecting camera, the position correcting mechanism and the loading mechanism; the printing mechanism comprises a screen which can carry out reciprocating motion left and right, a printing head which can carry out reciprocating motion up and down and a four-station rotary plate used for connecting the loading mechanism, the printing head and the unloading mechanism; the sorting mechanism sequentially comprises a quality detecting camera, a sorting mechanical arm and an unloading conveyor belt which conveys the piston put by the unloading mechanism to the quality detecting camera and the sorting mechanical arm sequentially, and the two ends of the sorting mechanical arm are provided with a finished product stacking region and a waste material stacking region respectively. According to the full-automatic piston screen printer, manual loading is rapid and convenient, positioning of the piston is accurate, the printing quality is guaranteed, sorting is conducted automatically, and a large amount of labor can be saved.

Owner:浙江泽晨智能设备有限公司

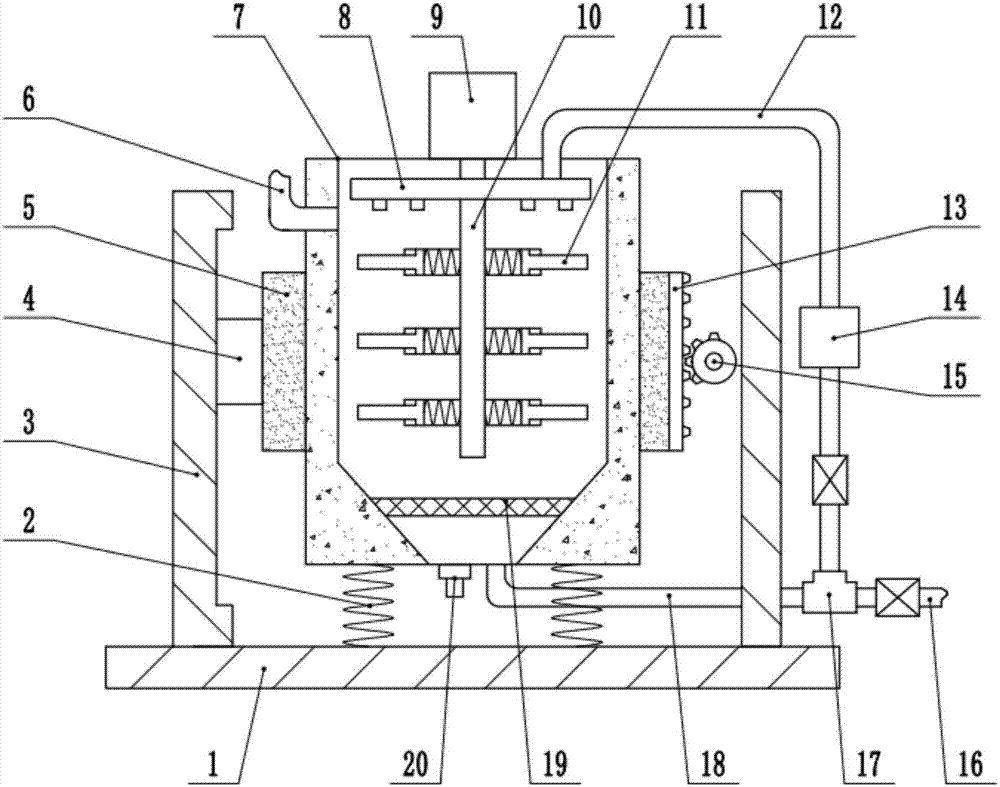

High efficiency printing ink mixing device used for printing production lines

InactiveCN107185444AIncrease the lengthWell mixedShaking/oscillating/vibrating mixersTransportation and packagingProduction linePrinting ink

The invention discloses a high efficiency printing ink mixing device used for printing production lines. The high efficiency printing ink mixing device comprises a pedestal, a support, a mixing barrel, and a mixing motor; the bottom of the mixing barrel is fixedly connected with the pedestal via first springs; two fixing supports are arranged on the left side and the right side of the mixing barrel symmetrically; a gear rack is fixedly arranged on the fixing support on the right side of the mixing barrel; the right side of the gear rack is provided with a semicircle gear matching the gear rack; the mixing motor is fixedly arranged on the top of the mixing barrel; an output terminal of the mixing motor is fixedly connected with a stirring shaft; a tunnel-shaped discharge port is arranged in the mixing barrel; the bottom of the discharge port is communicated with a liquid outlet pipe. The high efficiency printing ink mixing device is capable of increasing agitator arm length, increasing material mixing area, and realizing uniform mixing of printing ink; the high efficiency printing ink mixing device is provided with the mixing barrel capable of moving upward and downward, so that printing ink mixing uniformity is increased further; the discharge port is provided with a filter screen, so that discharge of impurities with printing ink is prevented, printing ink quality is improved, and printing quality is ensured.

Owner:FOSHAN ZHENGLUE INFORMATION TECH CO LTD

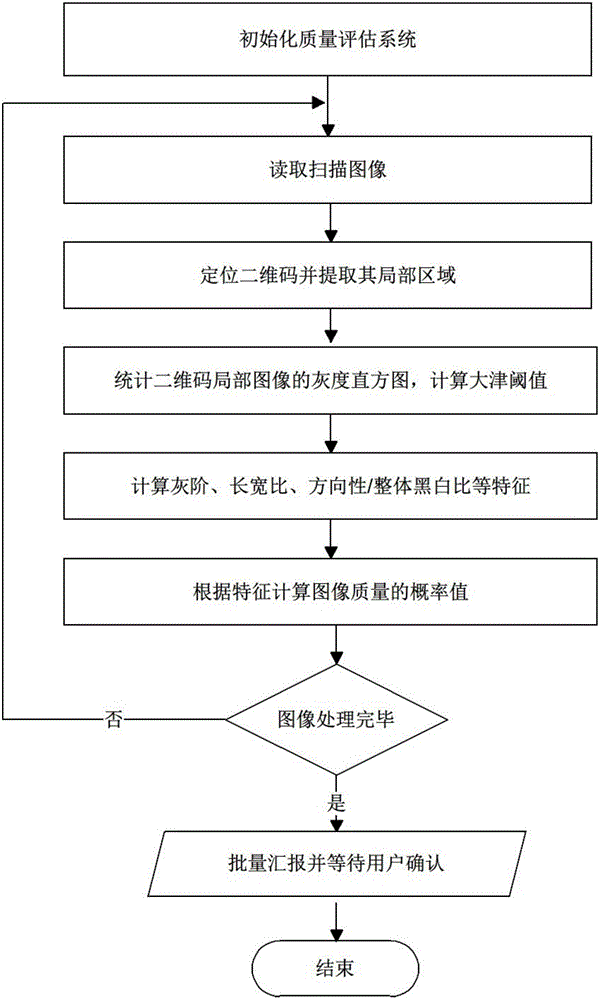

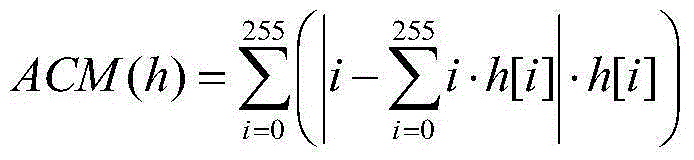

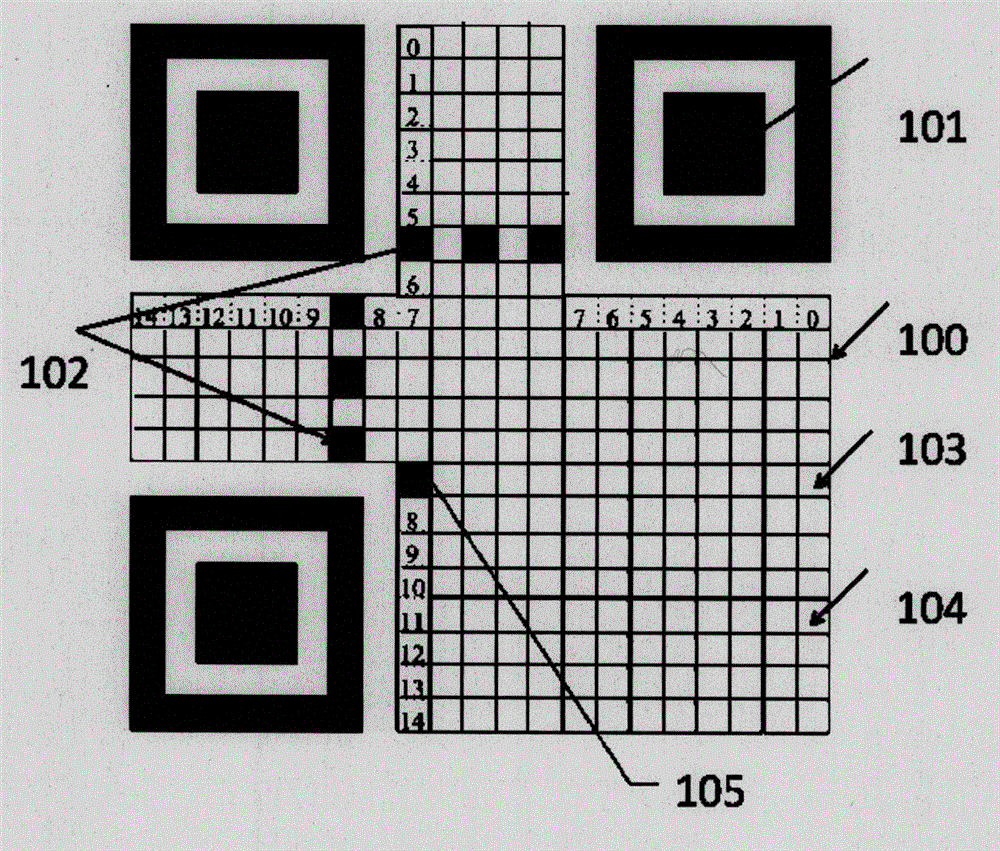

Two-dimension code printing quality online assessment method

ActiveCN105160339AGuaranteed print qualityAvoid wasting time and moneyCharacter and pattern recognitionSample imageQuality characteristics

The invention discloses a two-dimension code printing quality online assessment method. The method comprises the steps of: respectively extracting quality characteristics of qualified and unqualified two-dimension code images off line, and by means of synthetic training, obtaining a Bayes classifier parameter for determining whether the quality is qualified; loading the Bayes classifier parameter obtained by training into an online classifier; extracting quality characteristics of a two-dimension code image in an observed sample image, inputting the online classifier, and obtaining a qualified probability value; and if the qualified probability value of the observed sample is lower than a set threshold, determining that the observed sample is unqualified. By adopting the method provided by the invention, the decrease of the output quality of a two-dimension code printing machine or whether the storage loss of two-dimension codes reaches an assigned degree can be automatically discovered in time, and a worker can be prompted to maintain and replace the printing machine or to reprint bar codes, so that the printing quality of the two-dimension codes and the subsequent scanning efficiency are ensured, and the waste of time and financial resources caused by the output quality problem of the two-dimension codes is avoided.

Owner:SICHUAN UNIV

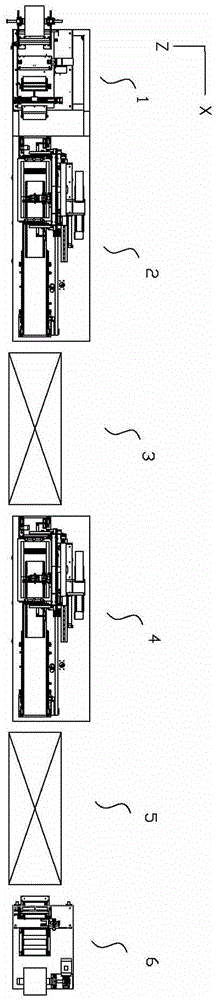

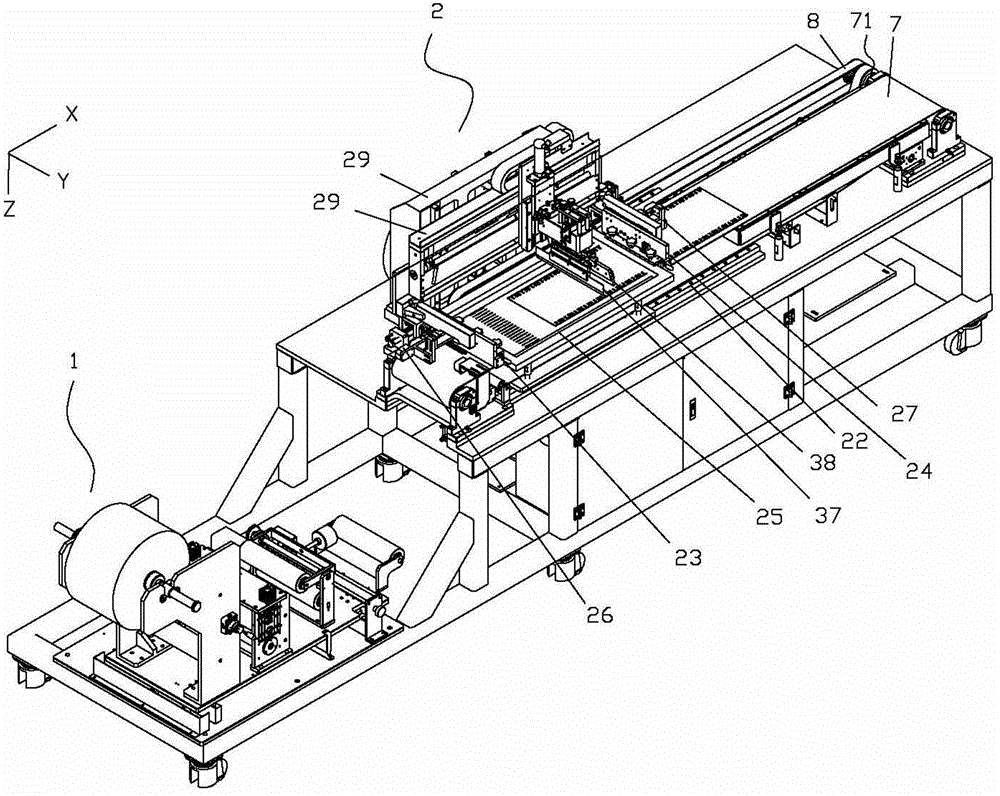

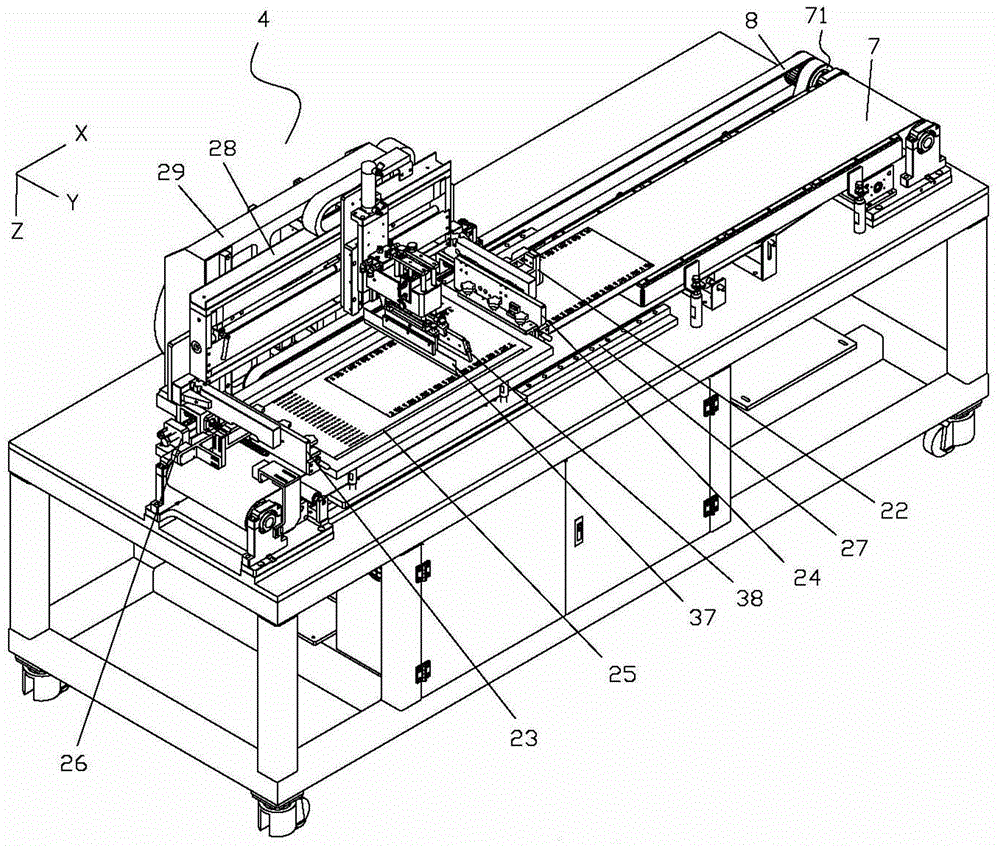

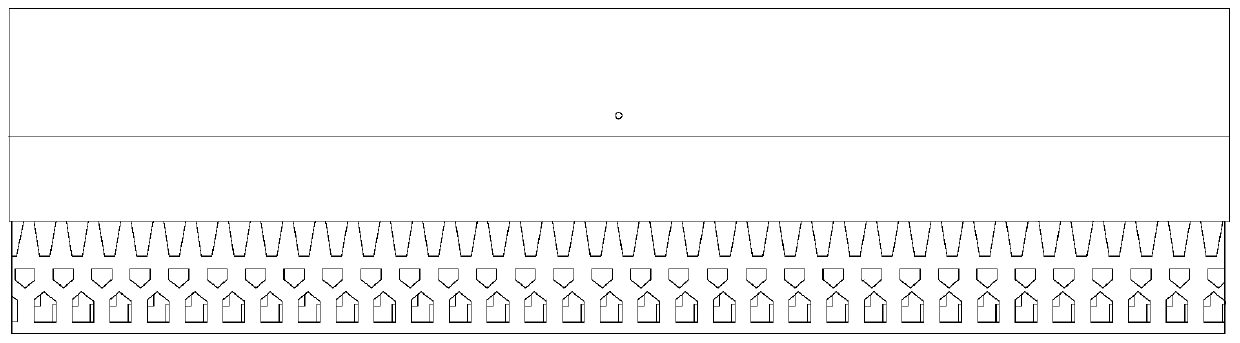

FPC (flexible printed circuit board) substrate continuous and uninterrupted screen printing ink operation line

InactiveCN104354454AIncrease printing speedImprove efficiencyScreen printersPrinting press partsScreen printingCooking & baking

The invention provides an FPC (flexible printed circuit board) substrate continuous and uninterrupted screen printing ink operation line, and relates to a technology for printing ink on a printed circuit board. The FPC substrate continuous and uninterrupted screen printing ink operation line comprises a first position screen printer, a first position baking oven, a second position screen printer, a second position baking oven and a conveying belt, wherein the first position screen printer, the first position baking oven, the second position screen printer and the second position baking oven are in sequential arrangement in the X direction, the conveying belt is used for conveying an FPC substrate in the X direction, and the FPC substrate sequentially penetrates and walks through the first position screen printer, the first position baking oven, the second position screen printer and the second position baking oven. The defect that the existing screen printing cannot realize the section-by-section uninterrupted printing on the coiled FPC substrate is overcome, infinitely extending ink lines (i.e., conducting lines) can be printed, and FPCs with the unlimited length can be prepared. The defect that the existing screen printing cannot realize the non-stop printing on the coiled FPC substrate is overcome, the continuous and uninterrupted ink printing on the whole coil of FPC substrate can be realized, the quality of the seamless butt joint printing is ensured, in addition, the printing speed is high, the efficiency is high, and the cost is low.

Owner:广东田津电子技术有限公司

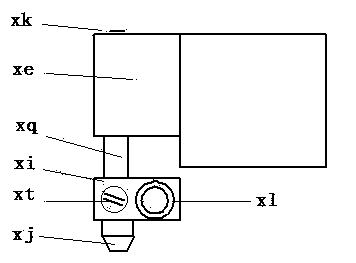

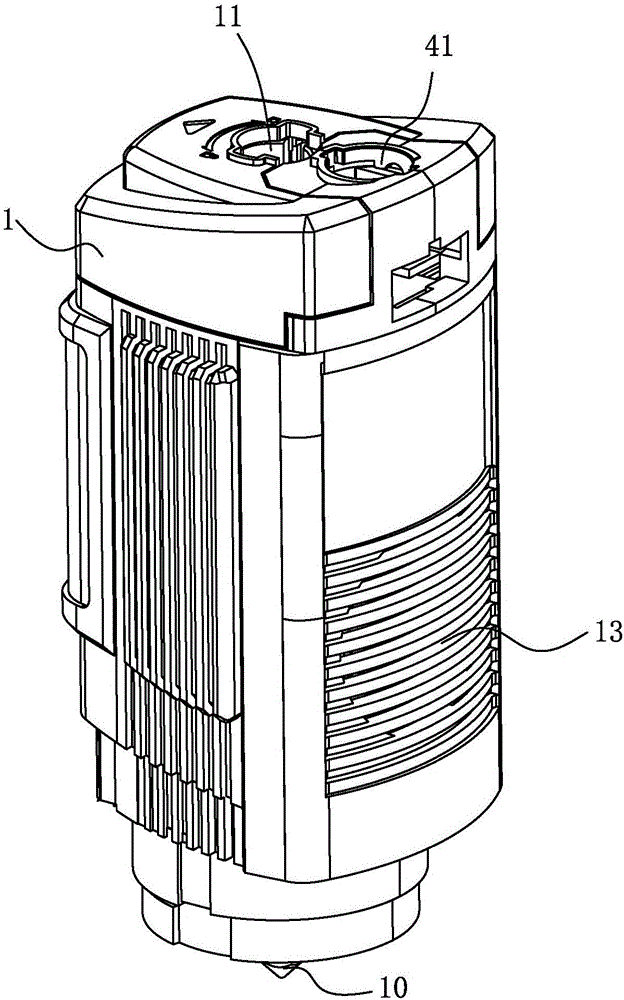

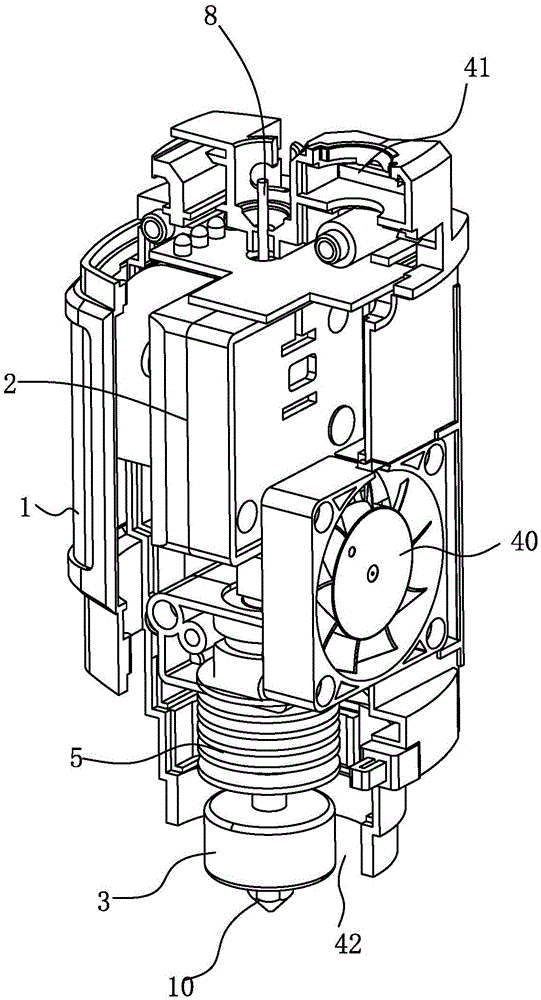

3D printing head with air inlet device and cooling method of printing head

InactiveCN106696256AStable structureGuaranteed printing quality3D object support structuresApplying layer meansCold airSpray nozzle

The invention provides a 3D printing head with an air inlet device and a cooling method of the printing head. The printing head comprises a shell and a heating assembly installed in the shell. A printing raw material enters the shell, then is heated and melted by the heating assembly and is discharged through a jet nozzle of the printing head, and printing operation is conducted. The printing head further comprises the air inlet device. The air inlet device comprises an air inlet formed in the upper portion of the shell and an air outlet formed in the lower portion of the shell. Outside cold air enters the shell through the air inlet, passes through the heating assembly and is exhausted through the air outlet. The 3D printing head with the air inlet device and the cooling method of the printing head have the following effects that for a conventional printing head, heat dissipation can be conducted on the printing head in time; and for products low in melting point and curing speed, the 3D printing head can directly accelerate the curing and stabilizing effects of the printing material, and accordingly the products in more complex shapes can be manufactured. In addition, the outside gas introduced through the air inlet device can serve as inert gas so that the raw material discharged by the jet nozzle of the printing head can be protected.

Owner:DONGGUAN RUIDI THREE DIMENSIONAL ELECTRONICS TECH

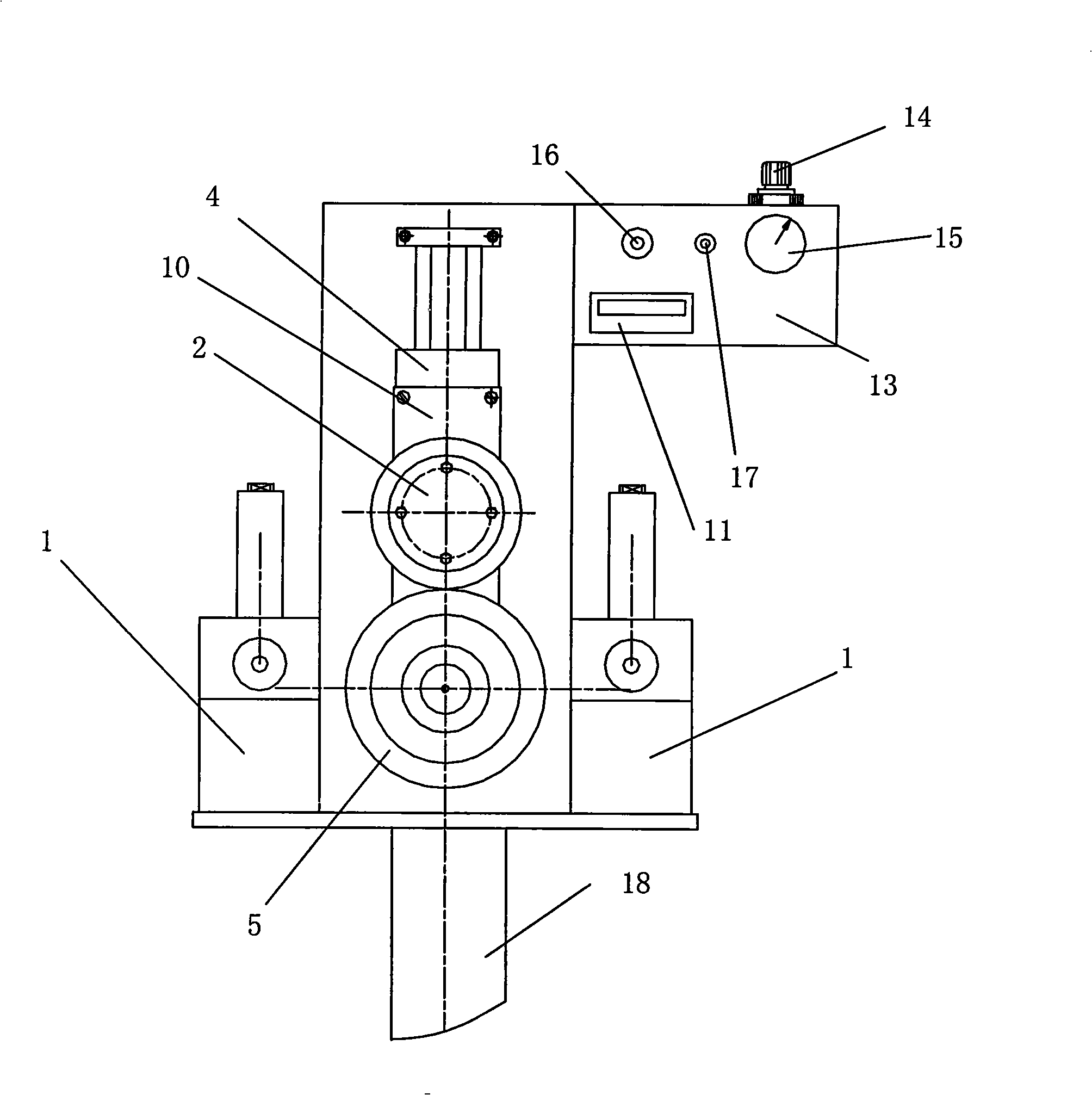

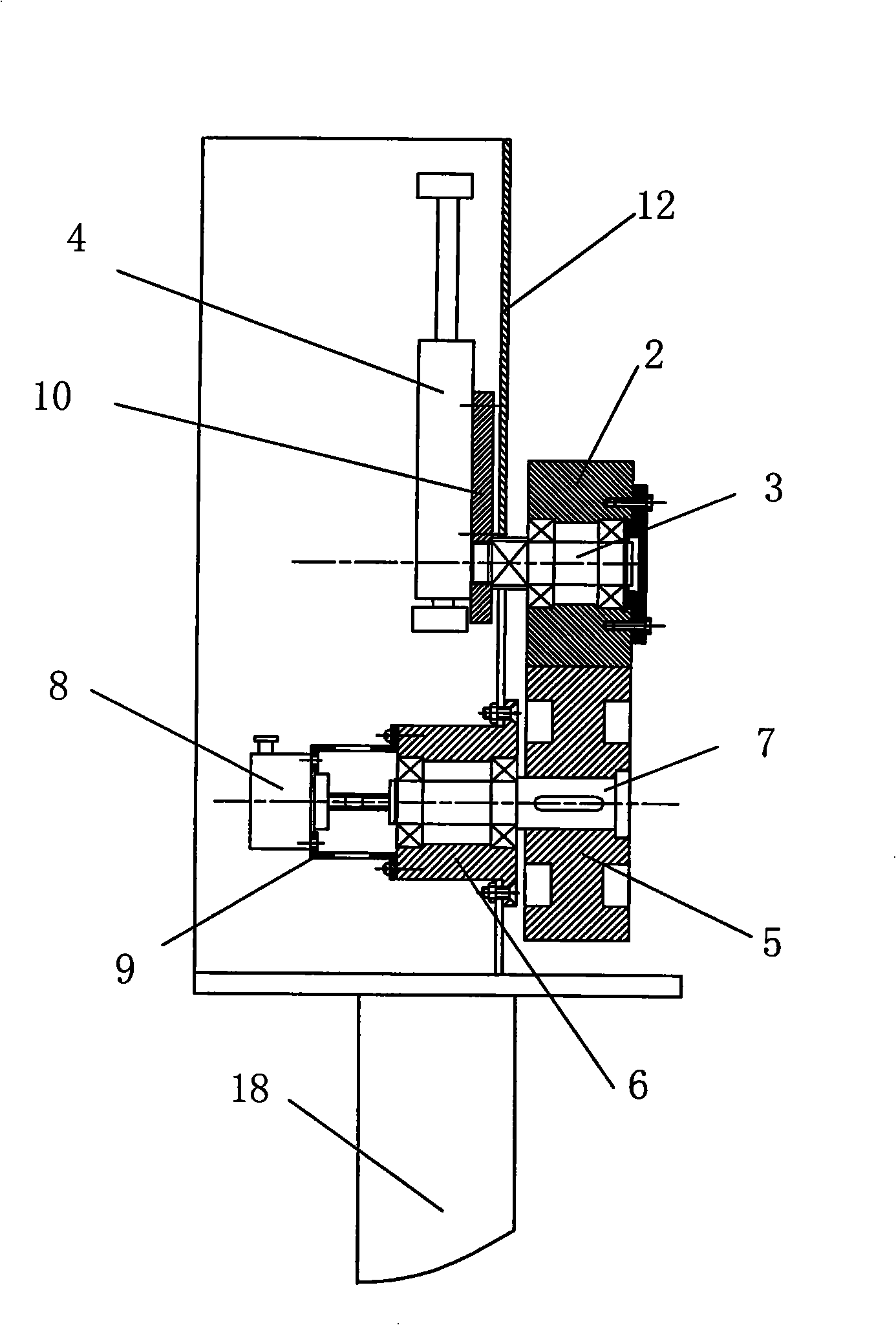

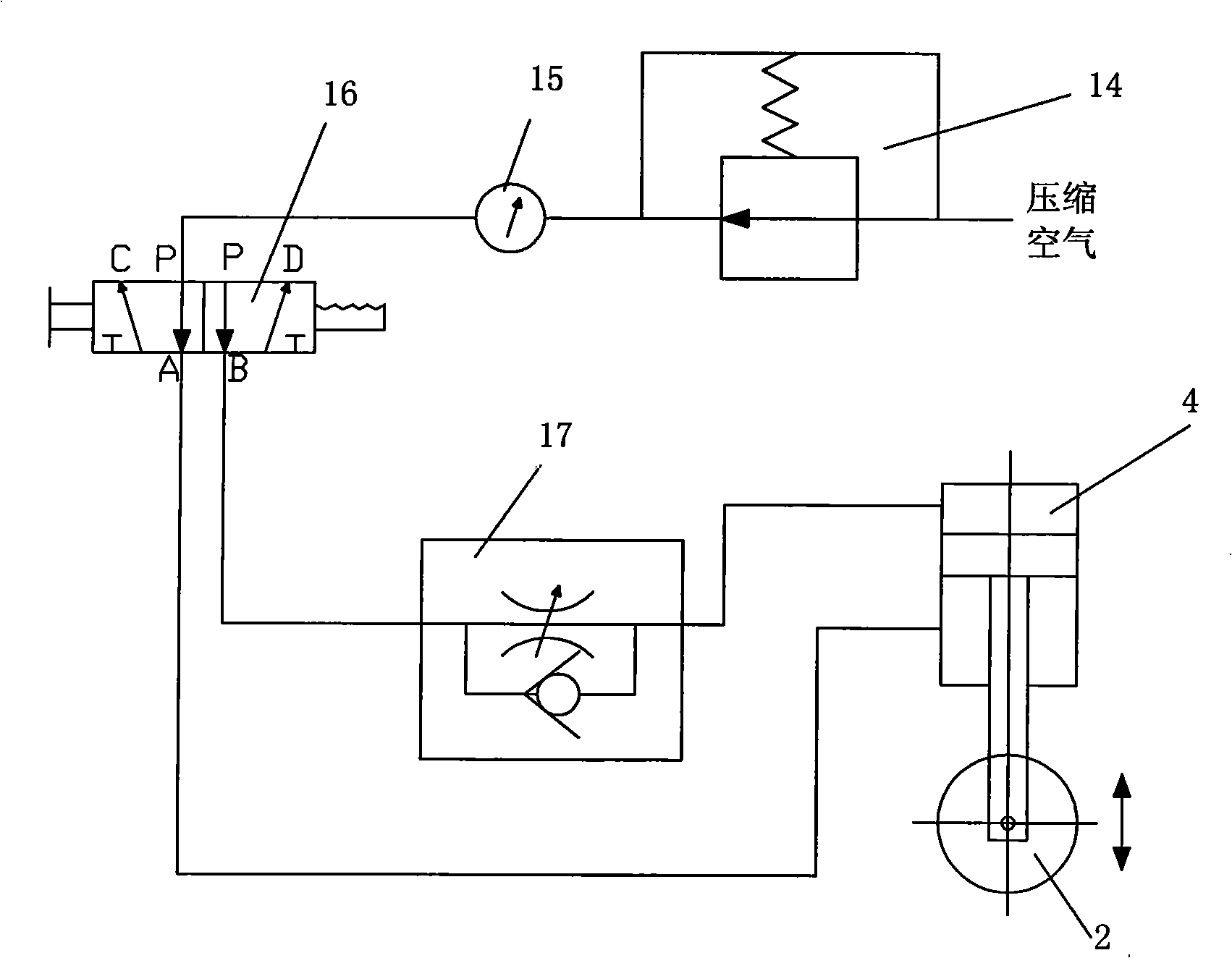

Pneumatic metering device for cable

InactiveCN101334272AGuaranteed to be straightKeep it straightUsing fluid meansEngineeringControl valves

The invention relates to a metering device of cables and discloses a pneumatic metering device used for cables. The device comprises a bracket, an upper clamping roller, and a lower supporting roller and a coder which are arranged on the bracket. The device is characterized in that a pneumatic slide valve and a corresponding gas control valve are arranged on the bracket, an upper clamping roller axis is fixed on the piston rod of the pneumatic slide valve, an upper clamping roller bearing is connected with the upper clamping roller axis, an upper clamping roller body is fixed on the upper clamping roller bearing, an upper supporting roller body is over against a lower supporting roller body up and down, and the gas control valve controls the piston rod of the gas control valve to move linearly up and down.

Owner:CHINA XIDIAN GRP CO LTD

Support structure design method for complex part SLM forming

ActiveCN110666170AGuaranteed validityGuaranteed printing qualityAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMachining process

The invention discloses a support structure design method, in particular a support structure design method for complex part SLM forming, and belongs to the technical field of selective laser melting forming process design. By means of the support structure design method for complex part SLM forming, the normal progress of the machining process can be ensured, and the machining quality is effectively improved. The support structure design method includes the steps of obtaining complex part forming parameters, determining the forming part placement angle in the complex part forming process, arranging an easily-removed strong supporting structure, leading in a printing model, and conducting part printing and forming.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

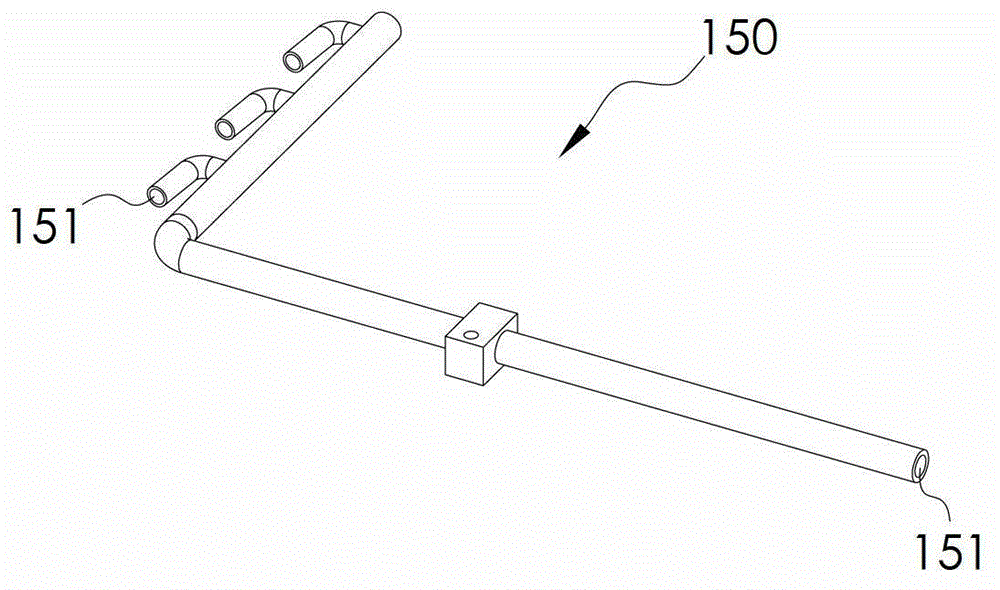

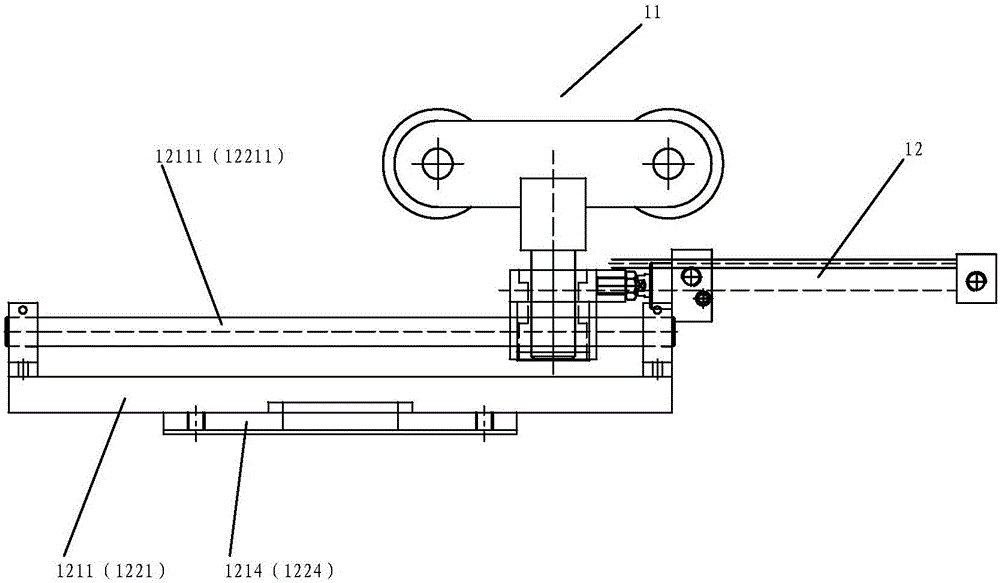

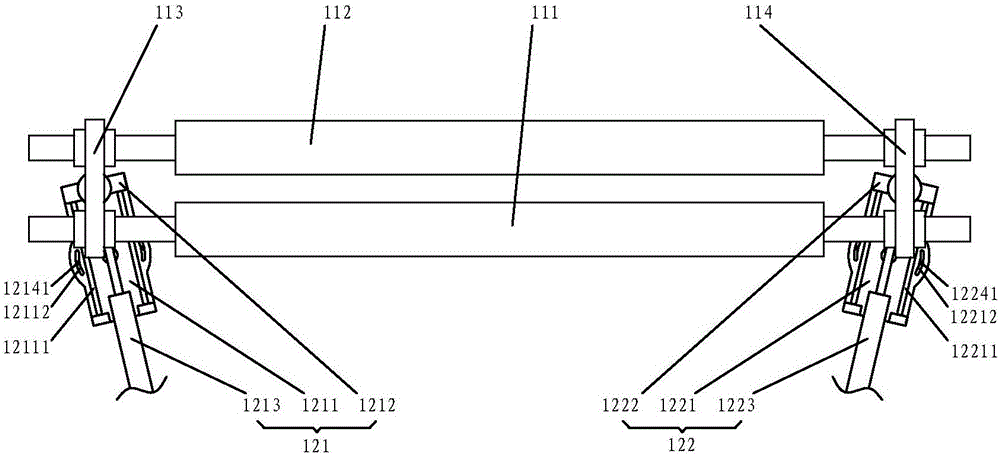

Cloth stentering mechanism, cloth stentering method and cloth feeding device having stentering mechanism

ActiveCN103332024AGuaranteed printing qualityAutomatic correction of conveying positionOther printing apparatusEngineeringNozzle

The invention relates to a cloth stentering mechanism, a cloth stentering method and a cloth feeding device having the stentering mechanism. The cloth stentering mechanism comprises a fixing board, a stentering roller hinged on the fixing board, and a compressing roller, a shelving roller and a guiding roller which are hinged on the fixing board and are parallel with the stentering roller, and a blowing tube connected on the fixing board, wherein pre-printing cloth is outputted from the cloth feeding mechanism and is wound around the stentering roller, the guiding roller, the shelving roller and the compressing roller sequentially, the cloth is tensioned through the stentering roller, the compressing roller, the shelving roller and the guiding roller, a guiding belt is at a lower portion of the compressing roller, a tail end of the cloth is compressed between the compressing roller and the guiding belt, an air inlet end of the blowing tube is connected with an air feeding device, and an air outlet end of the blowing tube is between the compressing roller and the guiding belt and faces towards one side of the fixing board. The cloth stentering mechanism can realize flattening of stentering crimping of the cloth especially a looped fabric and an elastic fabric, guarantees printing quality of the cloth, further guarantees no damage to a printing nozzle and can automatically correct a cloth conveying position according to a deflection condition of the cloth.

Owner:SHENZHEN TEXTALK GRAPHIC TECH

Ink-jet printing device

ActiveCN105479949AGuaranteed print qualityReduce printing costTypewritersPrinting inkInkjet printing

Owner:BEIJING MEIKEYI

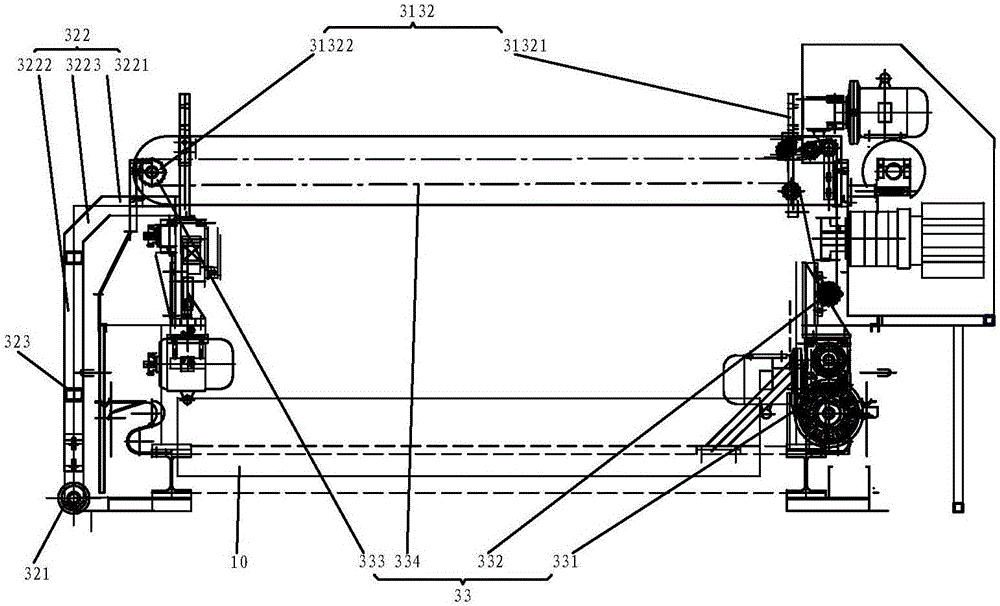

Cloth printing system

PendingCN106739478AAchieve corrective effectPromote repairLiquid surface applicatorsRotary pressesEngineeringBrush device

The invention provides a cloth printing system which comprises a machine frame, a cloth correcting device, a plurality of printing devices, a plurality of printing supports, a printing correction device, a scraper device, a plurality of cloth spreading drying devices, a conveying belt for driving cloth, a glue brushing device for brushing glue on the conveying belt, an ink scrubbing mechanism for scrubbing ink on the conveying belt and a conveying belt cleaning device for cleaning the conveying belt. The cloth printing system can efficiently correct the cloth, ink is added to printing rollers efficiently, working state conversion of a printing component is facilitated, the cloth printing system is flexible to operate and convenient to maintain, the printing rollers are independently driven in each direction, printing deviation in each direction is overcome, efficient and uniform ink scraping is performed on the printing rollers, the cloth is efficiently and fully dried before printing, glue is evenly smeared on the conveying belt, oil stain on the conveying belt is efficiently scrubbed, the conveying belt is efficiently cleaned, printing quality is greatly improved, and the practicality is high.

Owner:泉州市西格玛智能工业机械有限公司

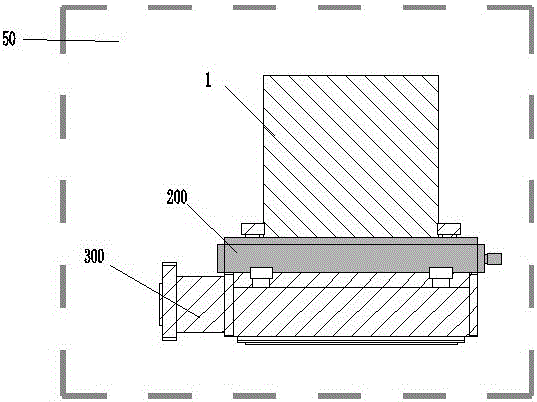

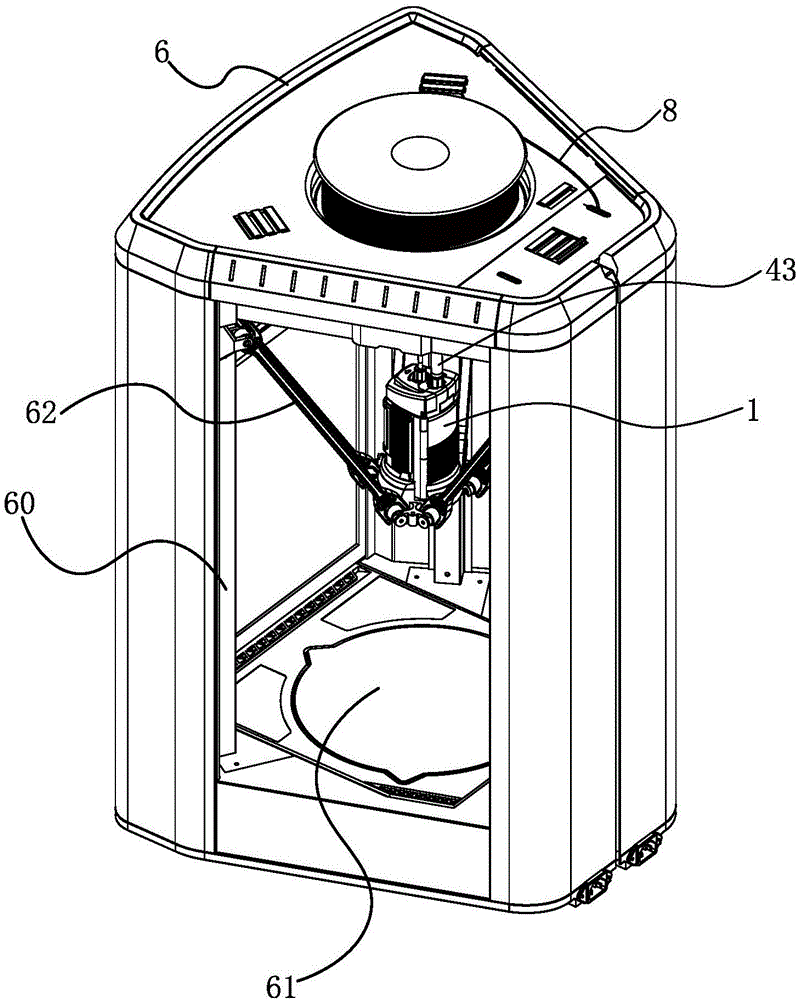

Three-dimensional printer and printing method thereof

ActiveCN105109043ASimple structureLow costAdditive manufacturing apparatusEngineeringElectrical and Electronics engineering

The invention provides a three-dimensional printer and a printing method of the three-dimensional printer. The three-dimensional printer comprises a printing platform, a printing head arranged above the printing platform, a forming base fixed onto the printing platform and used for bearing a three-dimensional printing entity, and guide rails arranged in the direction perpendicular to the printing platform, wherein a heating device is arranged below the printing platform; a heat insulation component is arranged on the periphery of the printing platform and is made of stretchable elastic materials. By means of the three-dimensional printer and the printing method of the three-dimensional printer, it is effectively ensured that a printed object is maintained within a temperature range, the changes of temperature between layers are not large, and the printing quality is ensured; the heat insulation component is simple in structure and low in cost; the height of the heat insulation component can be adjusted anytime according to the actual printing conditions, and the problems that a heat insulation component made of a rigid material is poor in adaptability and high in cost are solved.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Intaglio printing process of water-based ink

InactiveCN106956528AIncrease the number of screen threads and stitch anglesReduce layer depthOther printing apparatusEngineeringSpot color

The invention discloses an intaglio printing process of water-based ink. According to the process, laser electric carving intaglio plate rollers are adopted, the net lines of each plate roller are set to range from 80 lines to 110 lines, the needle angle of each plate roller is set to range from 130 degrees to 150 degrees, the layer plate depth in the plate roller printing process is set to range from 24 u to 28 u, and the on-site spot color plate depth is set to range from 28 u to 34 u. Through the adoption of the technical scheme of the process, the intaglio printing process of the water-based ink is obtained; due to the fact that the water-based ink is high in covering rate, good in online rate and good in glossiness, on the premise that the amount of the water-based ink is not changed, the product printing quantity is remarkably increased, the printing quality and the printing ratio are guaranteed, and the production cost is reduced; and intaglio printing equipment does not need to be modified greatly, the limiting factors of the water-based ink applied to intaglio printing are solved, and development of water-based ink printing is promoted.

Owner:一桶天下环保科技有限公司

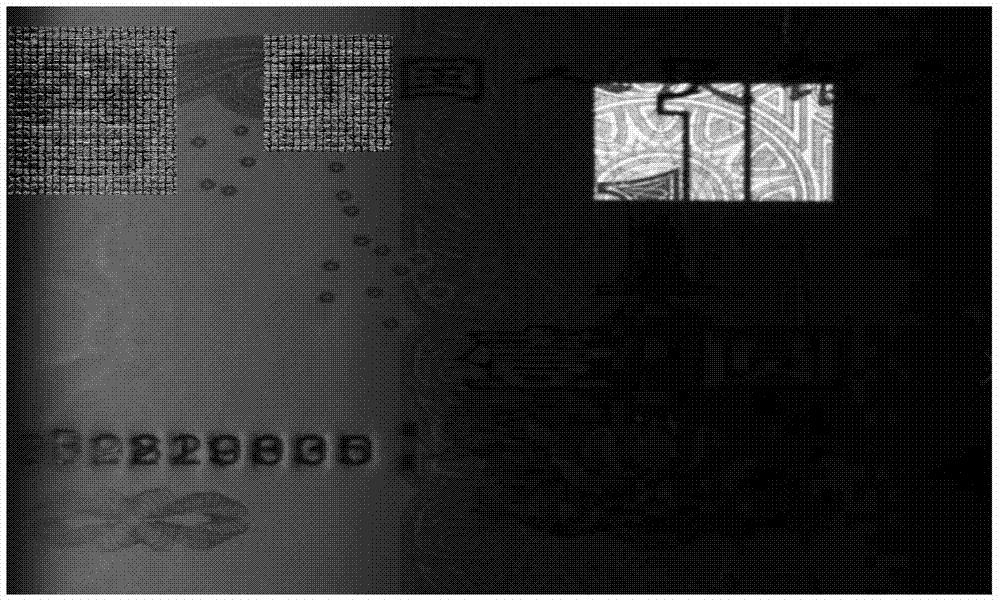

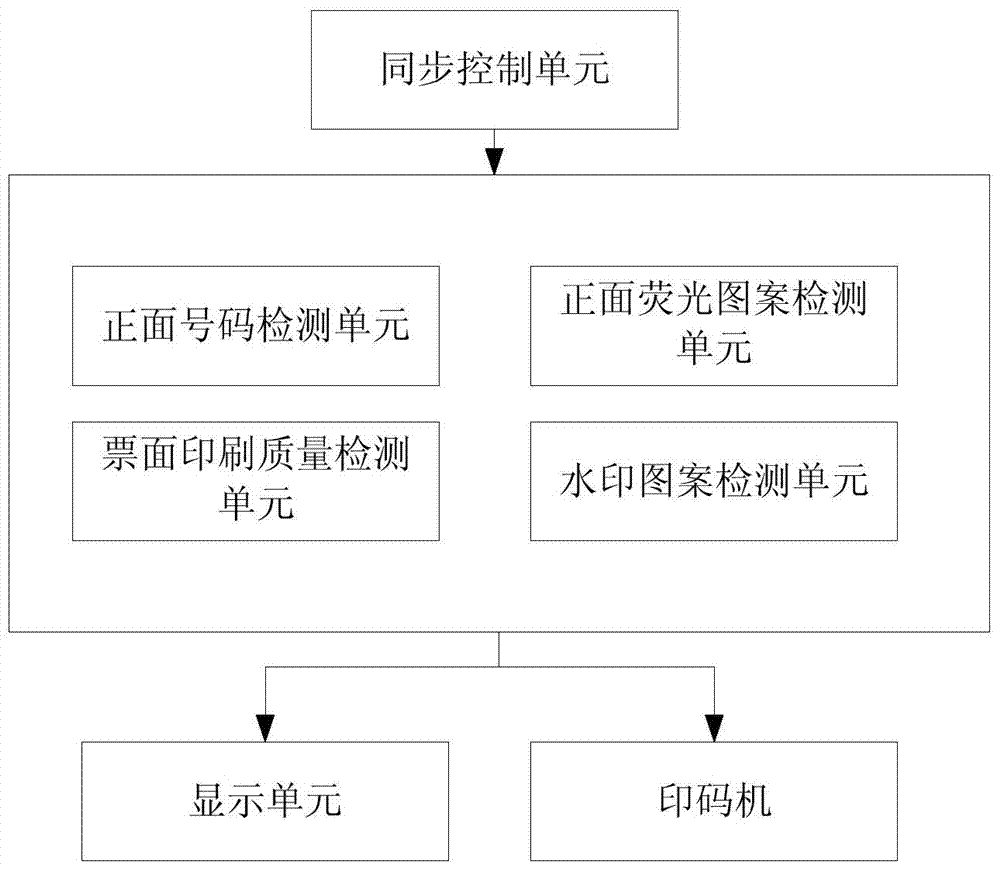

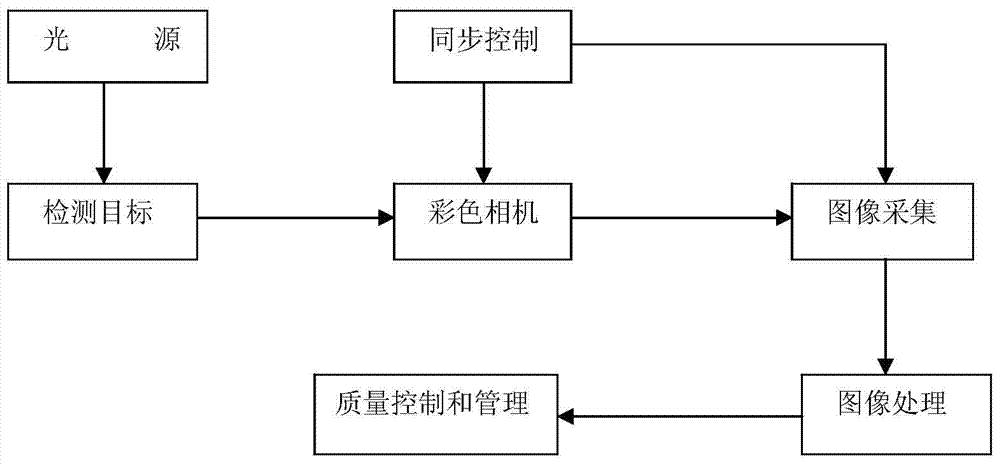

Online imprinting detection method and system

ActiveCN103679916AIntercept in timeQuality assuranceCharacter and pattern recognitionFluorescenceDisplay device

The invention discloses an online imprinting detection method and system. The system employs multiple colorful CCD (Charge Coupled Device) cameras and multiple parallel high-speed image collecting, operating and processing systems to detect and timely monitor printing qualities, including the front-side number printing quality, the front-side fluorescent pattern printing quality, the front and back side nominal value printing quality and the watermarking pattern printing quality (inverted note defect detection), for large RMB note products which are printed online; and the detection system emits a related command and an acousto-optic alarm signal the moment that continuous wastes or severe wastes are detected, thereby controlling an imprinting machine to stop running. Operation interfaces of different detection functions are integrated in a terminal display with a big screen for concentrated display, wherein the interfaces are clear, and operation is convenient. Number printing is the last procedure for RMB note printing, the printing quality detection after number printing can be used to verify defects detected in the previous procedures and intercept products missed in detection, thereby ensuring the quality of delivered products, and improving the production efficiency.

Owner:BEIJING BANKNOTE PRINTING +2

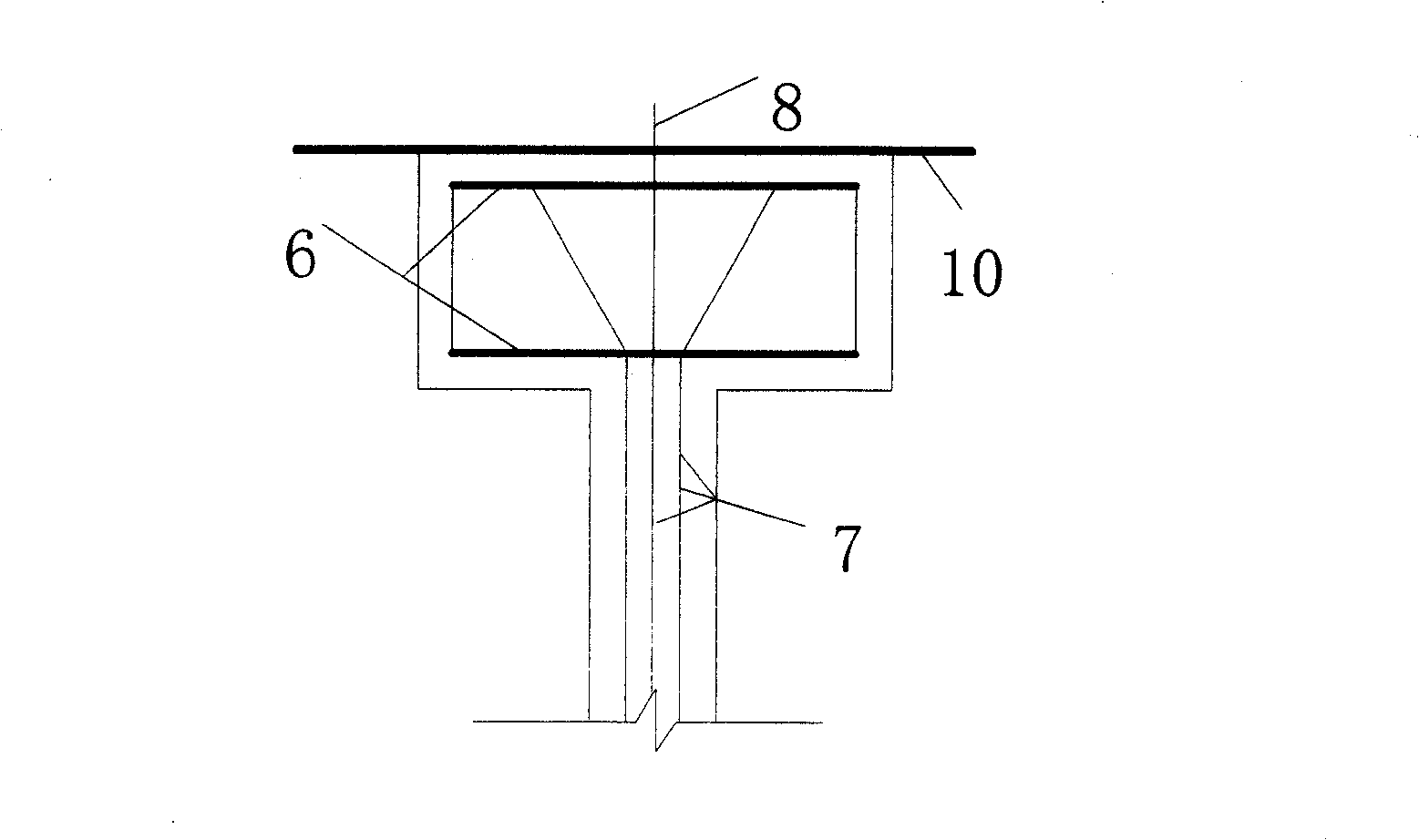

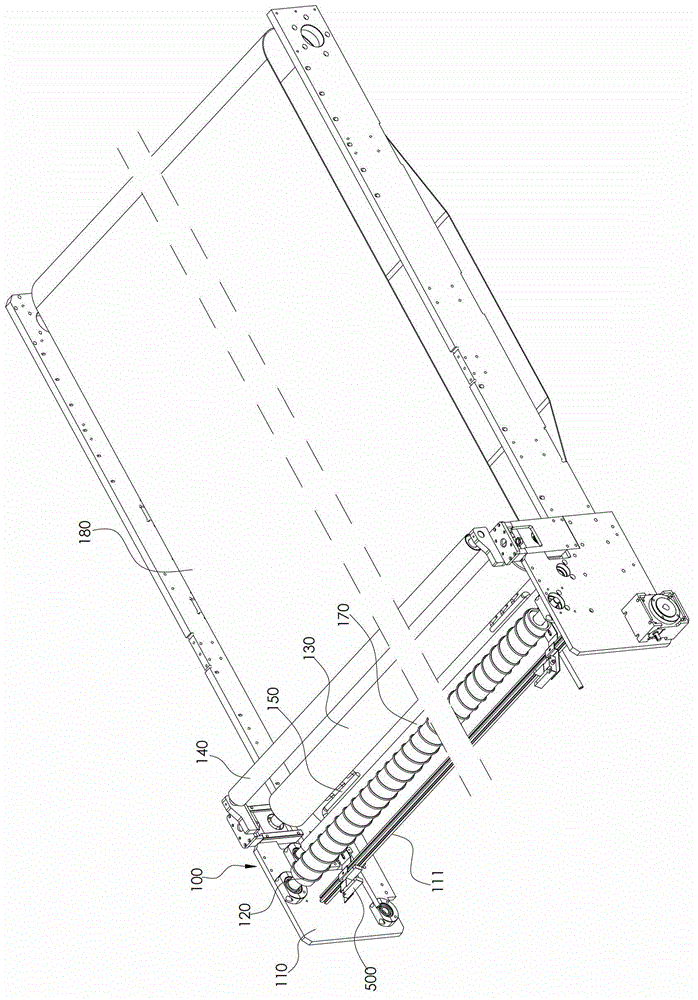

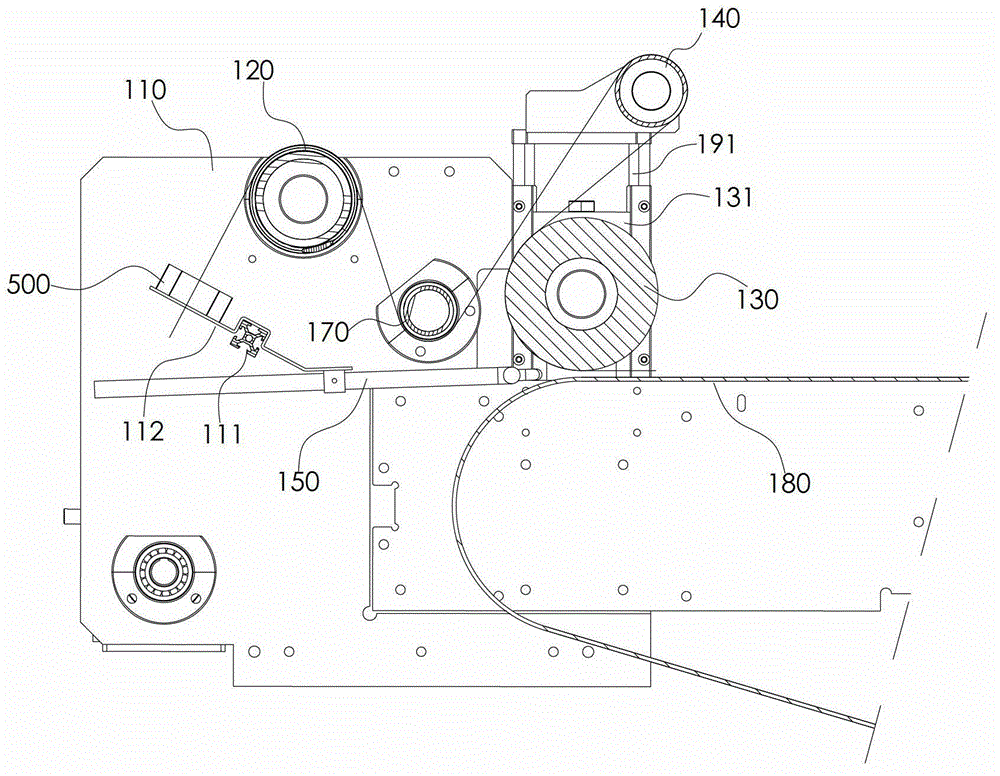

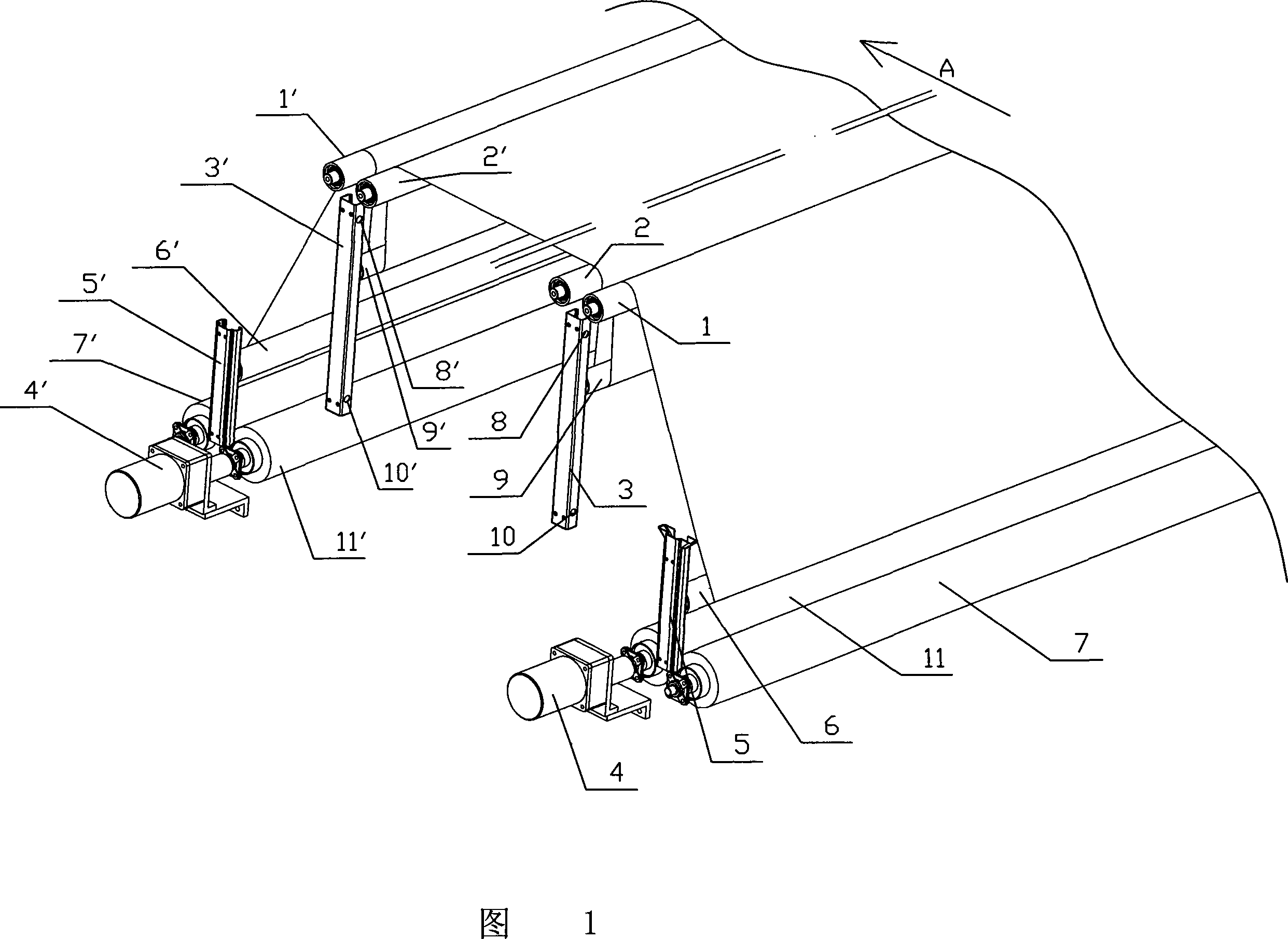

Cloth conveyor of ink-jetting printing machine

ActiveCN101073954AGuaranteed printing qualityTypewritersOther printing apparatusEngineeringMechanical engineering

The invention is concerned with a cloth sending and receiving equipment to inkjet printing machine, relating to cloth sending framework and cloth receiving framework. There are cloth sending tension framework and cloth receiving tension framework between the cloth sending framework and cloth receiving framework. The cloth sending tension framework relates to two roller canisters to sending and leading of cloth and cloth sending tension roller canister, and the tension roller canister of cloth sending moves up and down along the cloth sending tension leading groove, and the cloth rounds the cloth sending tension framework and sends into the cloth sending framework and cloth receiving framework through the two leading roller canisters to sending and leading cloth. The cloth receiving tension framework relates to two roller canisters to leading and receiving cloth and cloth receiving tension roller canister, and the tension roller canister of cloth receiving moves up and down along the cloth receiving tension leading groove, and the cloth rounds the cloth receiving tension framework and sends into the cloth sending framework and cloth sending framework through the two leading roller canisters to receiving and leading cloth. It assures the quality of print and the sent cloth is direct and the cloth will pull tightly during the receiving.

Owner:杭州开源电脑技术有限公司

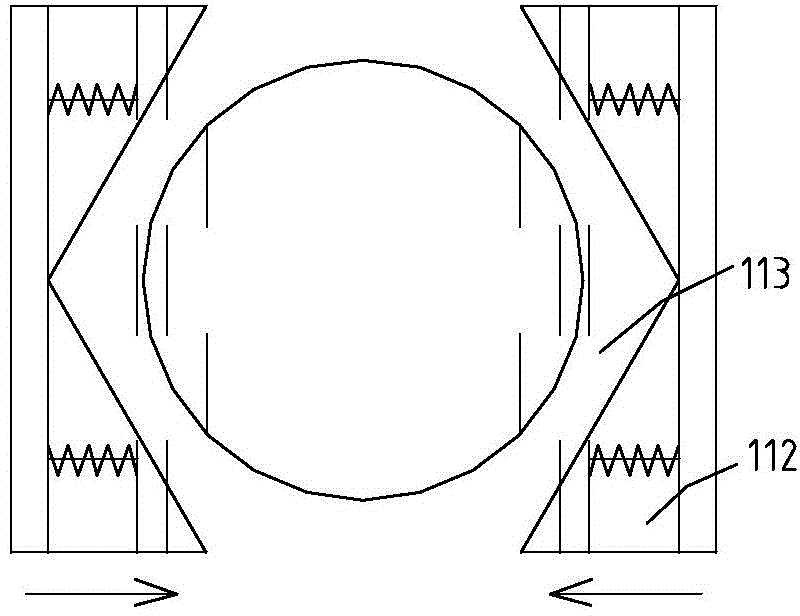

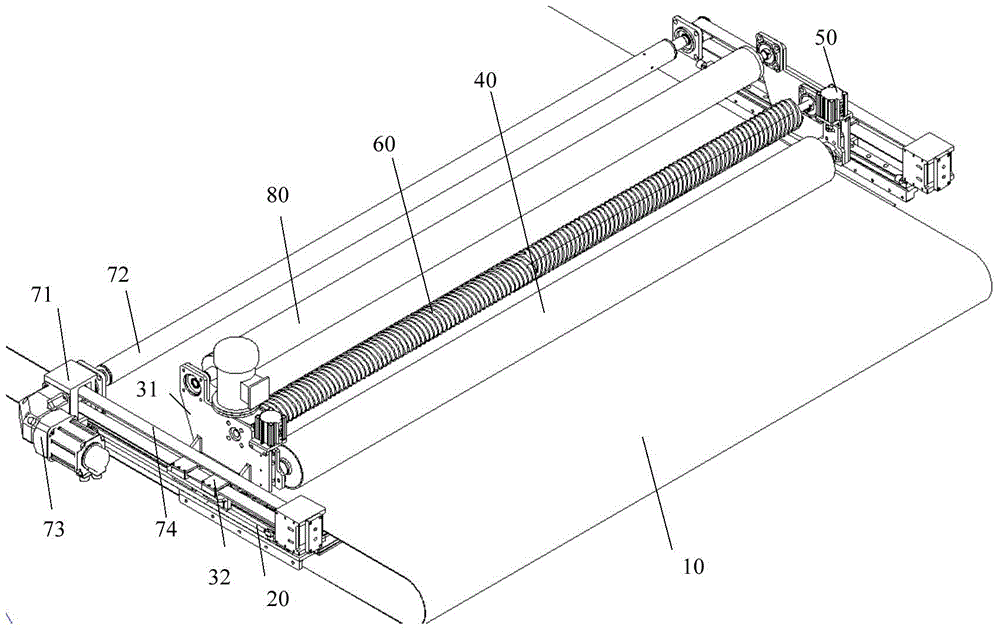

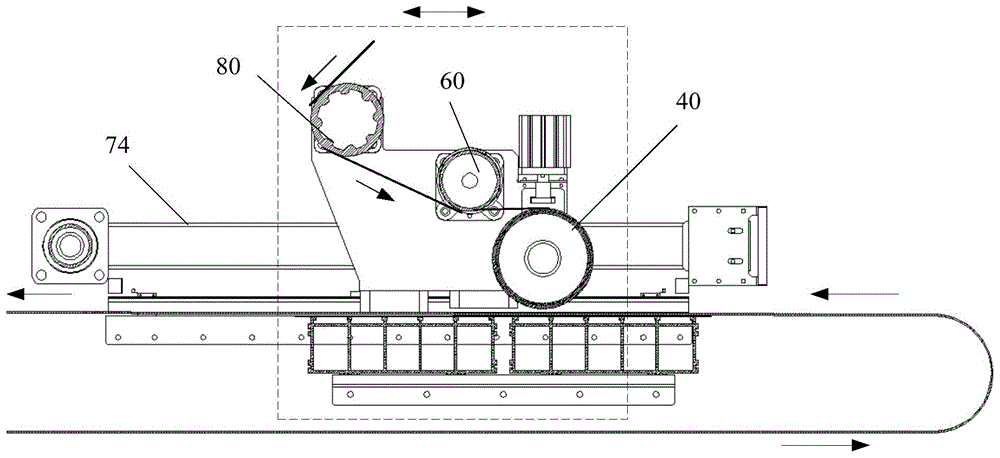

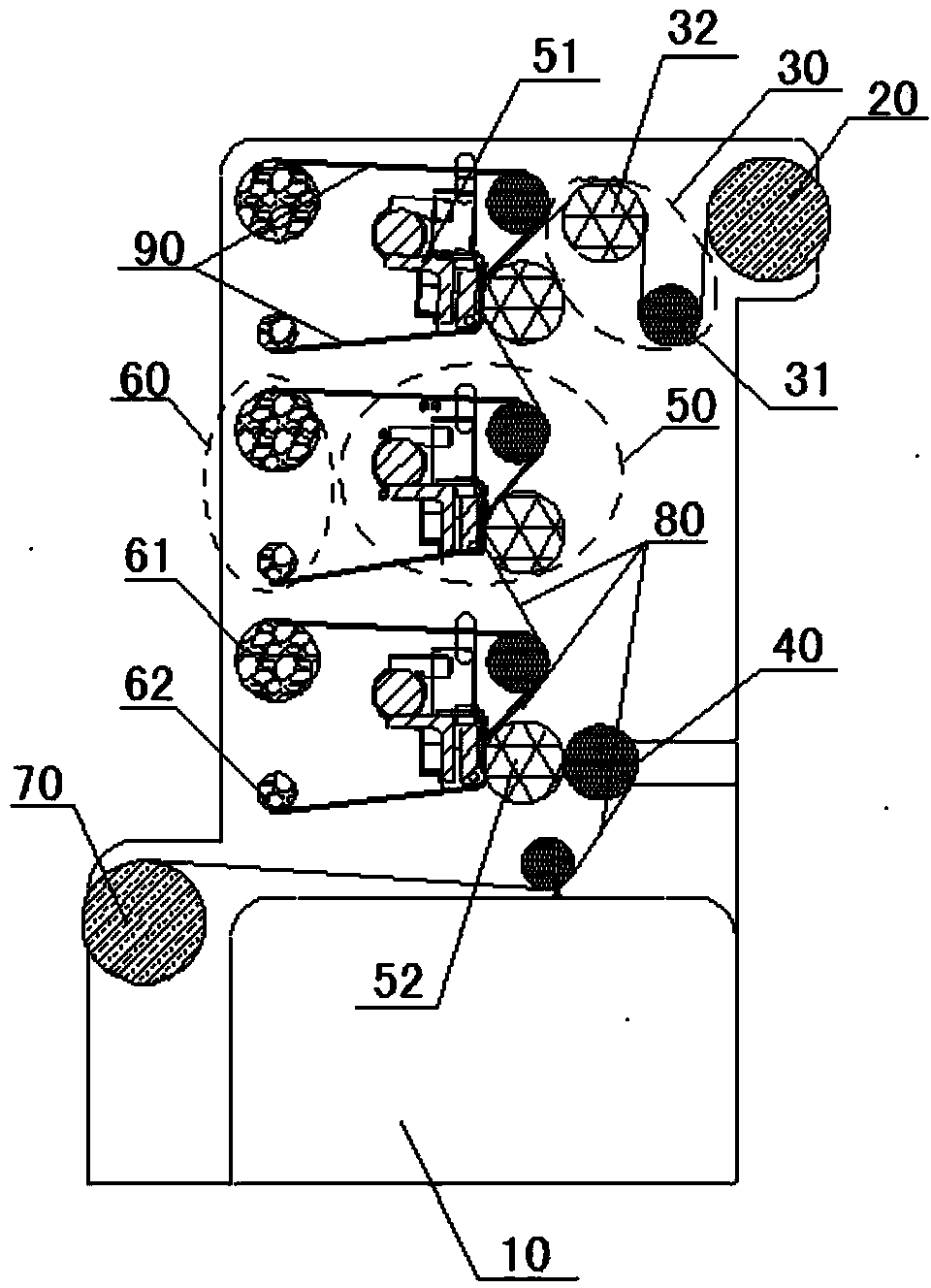

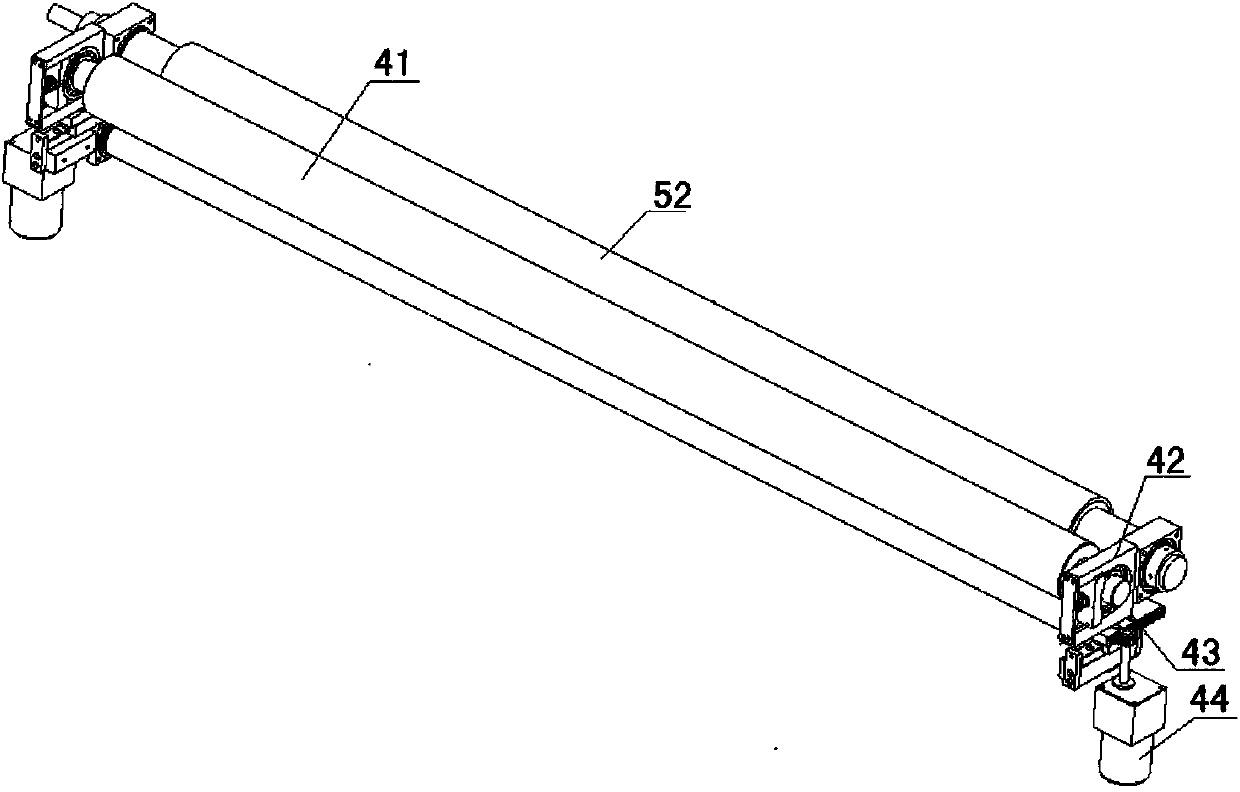

Cloth spreading device of digital printing machine

ActiveCN104476913AGuaranteed printing qualityGuaranteed printing accuracyRotary pressesEngineeringDigital printing

The invention provides a cloth spreading device of a digital printing machine. The two sides of a guide belt of the digital printing machine are each provided with a sliding rail. A sliding mechanism is mounted on each sliding rail. The two ends of a cloth pressing roll and the two ends of a two-way spreading roll are mounted on the sliding mechanisms located on the two sides of the guide belt respectively. Therefore, in the operating process, when a textile arrives at a feed port, the two-way spreading roll makes the textile completely spread out in the transverse direction so as to guarantee that the textile can smoothly arrive at the cloth pressing roll; through control over thrust of air cylinders and under the action of self weight of the cloth pressing roll, the textile is pressed by the cloth pressing roll onto the upper surface of the guide belt and effectively pasted to the surface of the guide belt, and a servo power mechanism controls movement of the cloth pressing roll on the sliding mechanisms so as to make the cloth pressing roll and the guide belt move relatively and synchronously. As a result, the textile on the cloth pressing roll is smoothly pasted to the guide belt in a wrinkleless mode, and subsequent printing quality and accuracy are guaranteed.

Owner:SHENZHEN RUNTIANZHI DIGITAL EQUIP

Matt color ink jet printer paper paint and preparation method thereof

InactiveCN101446055AImprove adsorption capacityLow costPaper coatingCoatingsRoom temperatureSilicon dioxide

The invention relates to matt color ink jet printer paper paint and a preparation method thereof. The preparation method is characterized in that the method comprises the following steps: adding dispersant into deionized water to be dissolved at the room temperature; adding modified bentonitic clay to the dissolved deionized water and dispersing at the room temperature; adding silicon dioxide to the modified bentonitic clay dispersion liquid for dispersion, and obtaining mixed dispersion liquid; adding an adhesion agent to the mixed dispersion liquid while stirring; adding a silicone antifoaming agent, PDMDAAC and carboxymenthyl cellulose in sequence, and obtaining paint liquid after evenly blending and stirring. Because the modified bentonitic clay is utilized as the pigment to prepare the paint for the matt color ink jet printer paper, good water absorption performance, good color fixation performance, high color density, good color reductibility and no infiltration of the matt color ink jet printer paper can be ensured, and the purpose of reducing the cost of the matt color ink jet printer paper can be achieved.

Owner:JIANGNAN UNIV

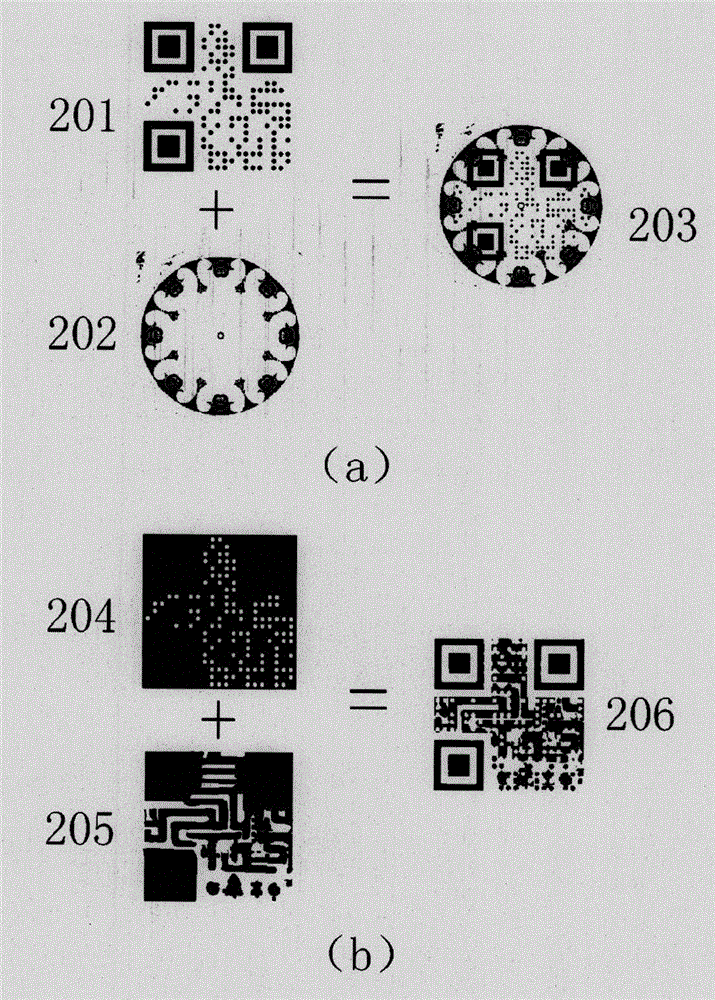

Commodity package and logo variable information on-line tagging method and reading method

InactiveCN106886809AGuaranteed printing qualityCo-operative working arrangementsTypewritersInformation processingSynchronous control

The invention relates to a commodity variable information on-line tagging method in the field of information processing, is realized through a commodity package and logo variable information on-line tagging device, and is characterized in that a jet printing unit of codes is erected on a common printing machine, thereby realizing on-line tagging of variable information while performing traditional printing, and before jet printing, at least one kind of processing including tension detection of printing media, ripple expelling processing of a ripple expelling shaft aiming at occurrence of ripples of the printing media and EPC processing of an out-of-position nozzle of the printing media needs to be performed, and at least two of the jet printing unit, an LED UV solidifying unit and an on-line detection unit are synchronously controlled. The implementation effects of the commodity variable information on-line tagging method are that on-line tagging of variable information can be performed while logo images are printed, the printing quality of the logo images and the requirement of high-speed printing can be guaranteed, and one-logo one-code variable information tagging can be performed at the same time.

Owner:顾泽苍

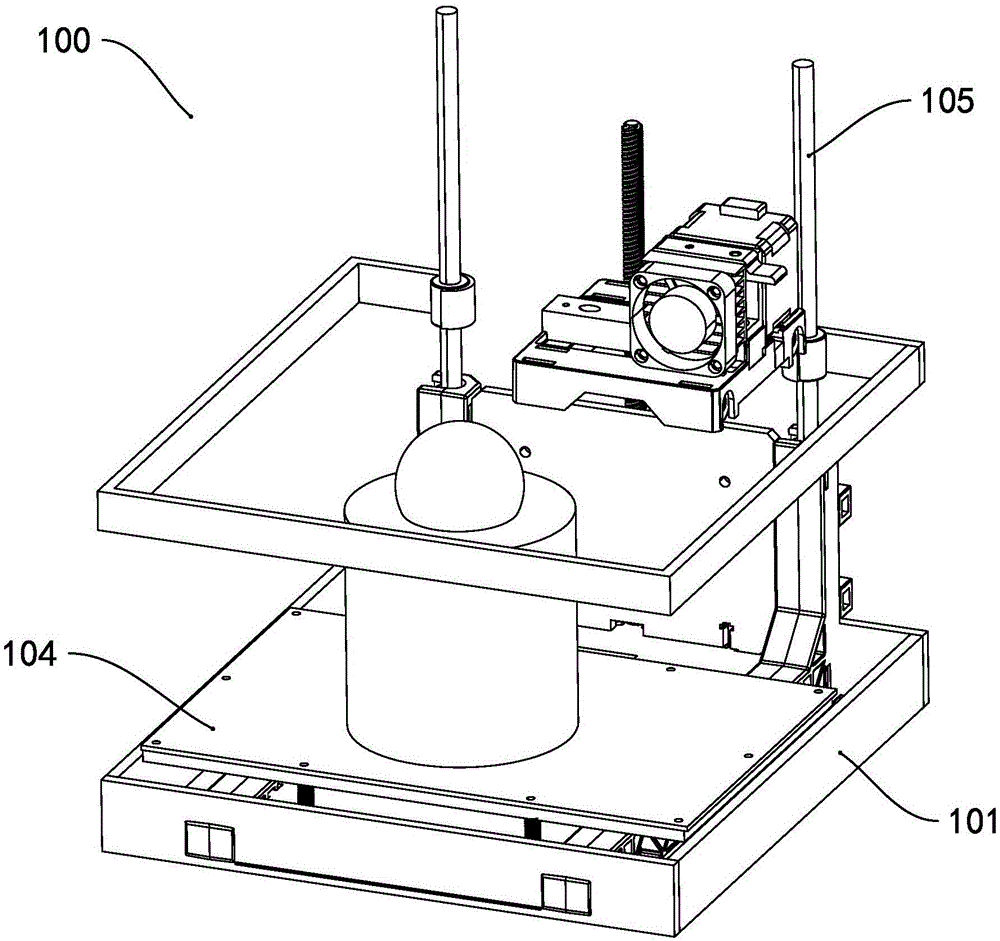

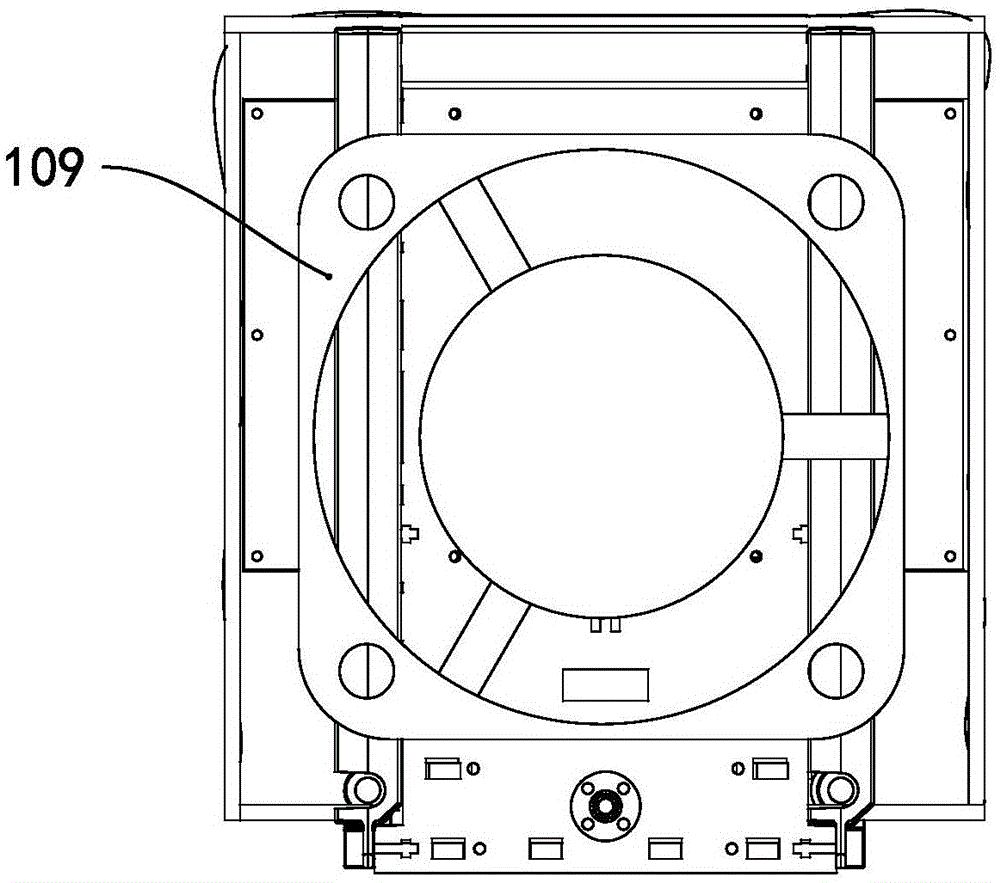

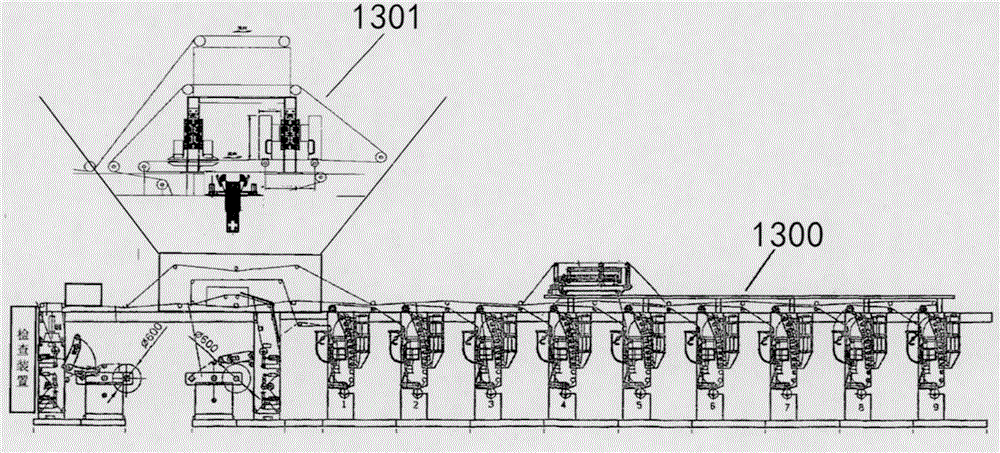

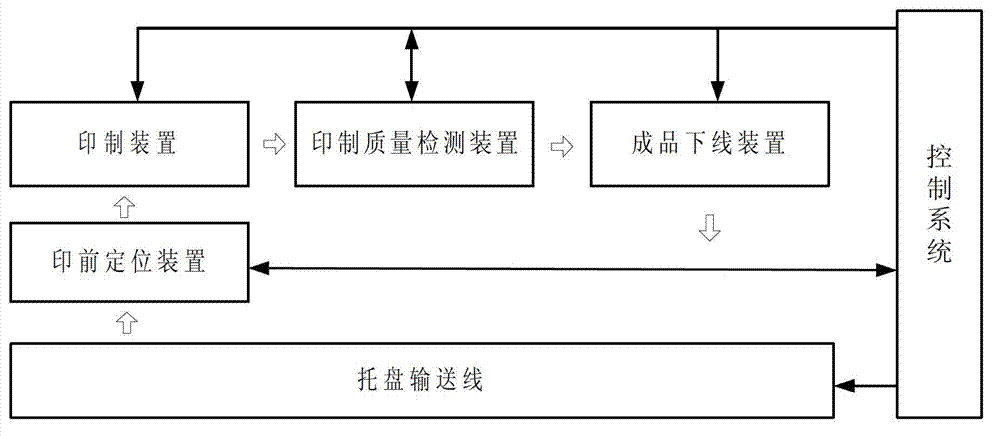

Automatic printing production line

ActiveCN102896884AReduce labor costsIncrease productivityTransfer printingPrinting press partsManipulatorElectricity

The invention provides an automatic printing production line. The production line comprises a control system, and a tray conveying line, a pre-printing positioning device, a printing device, a printing quality detection device and a finished product discharging device which are electrically connected with the control system. According to the automatic printing production line, a first manipulator grabs products to be printed from trays on the tray conveying line, adjusts the direction and places the products to be printed on a printing conveying line, the products to be printed are printed by a transfer printing machine, printing quality is detected, and a second manipulator directly moves unqualified products to an unqualified product conveying line and moves qualified products to the trays of the tray conveying line. The process is completely controlled by the control system and automatically finished, so that labor cost is greatly saved, production efficiency is improved, and the printing quality can be ensured.

Owner:临沂恒元城市建设运营有限公司

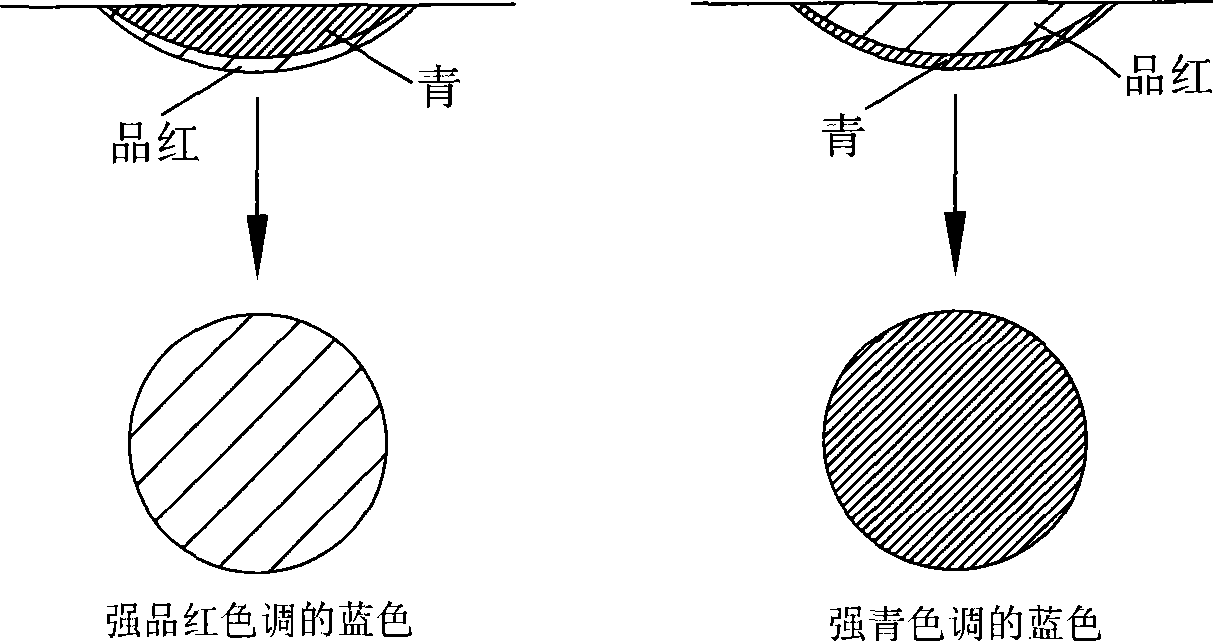

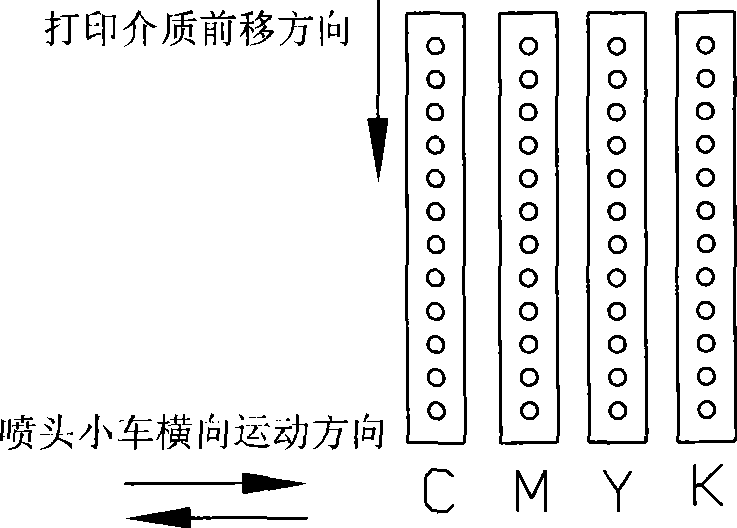

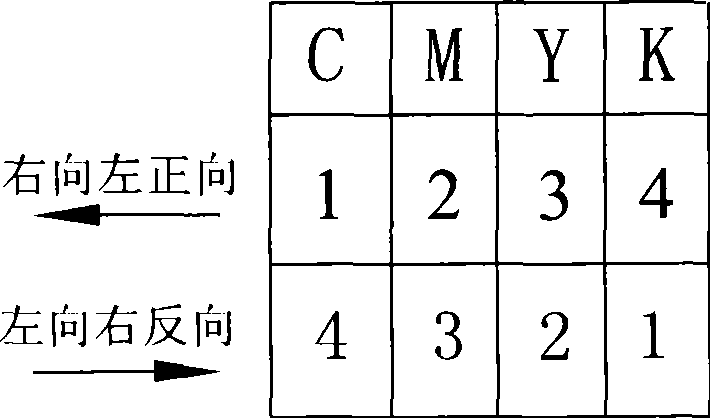

Arrangement method of different color ink nozzle for colorful ink jet printer

InactiveCN101456294AEliminates the problem of different shades of the same colorGuaranteed printing qualityPrintingHueEngineering

The invention discloses a method for arranging ink nozzles with different colors of a color inkjet printer. In particular, the method comprises: a cyan ink nozzle and a magenta ink nozzle and a cyan ink nozzle and a yellow ink nozzle of the printer are arranged along the feeding direction of print medium, and when the printer works, along with step feed of the print medium, the cyan ink and the magenta ink and the cyan ink and the yellow ink can be sprayed on the print medium respectively according to a fixed order. In the method, because the cyan ink nozzle, the magenta ink nozzle and the yellow ink nozzle are orderly arranged along the feeding direction of the print medium, the cyan ink and the magenta ink and the cyan ink and the yellow ink sprayed by the inkjet device are always sprayed on the print medium according to the fixed order regardless of left print and right print of the printer, thereby solving the problem existing in the prior printer that the hue of the same color is different in the bi-directional printing and ensuring the printing quality of the printer.

Owner:BEIJING MEIKEYI

Digital jet printing machine and digital jet printing method

InactiveCN101638001AReduce manufacturing costLow costDyeing processOther printing apparatusInkjet printingMechanical engineering

The invention provides a digital jet printing machine which not only does not have a belt guide device and a washing device, but also can guarantee the printing quality, protect environment and can reduce cost. The digital jet printing machine comprises a front tension device and a rear tension device which are arranged at the front end and the rear end of a medium and tension the medium, an inkjet printing device used for printing patterns at the front surface of the tensioned medium, and a waste ink collecting device which is arranged at the lower part of the reverse side of the medium withprinted patterns and is used for collecting ink leaking from the reverse side of the medium. The invention also provides a digital jet printing method.

Owner:南京德众数码科技有限公司

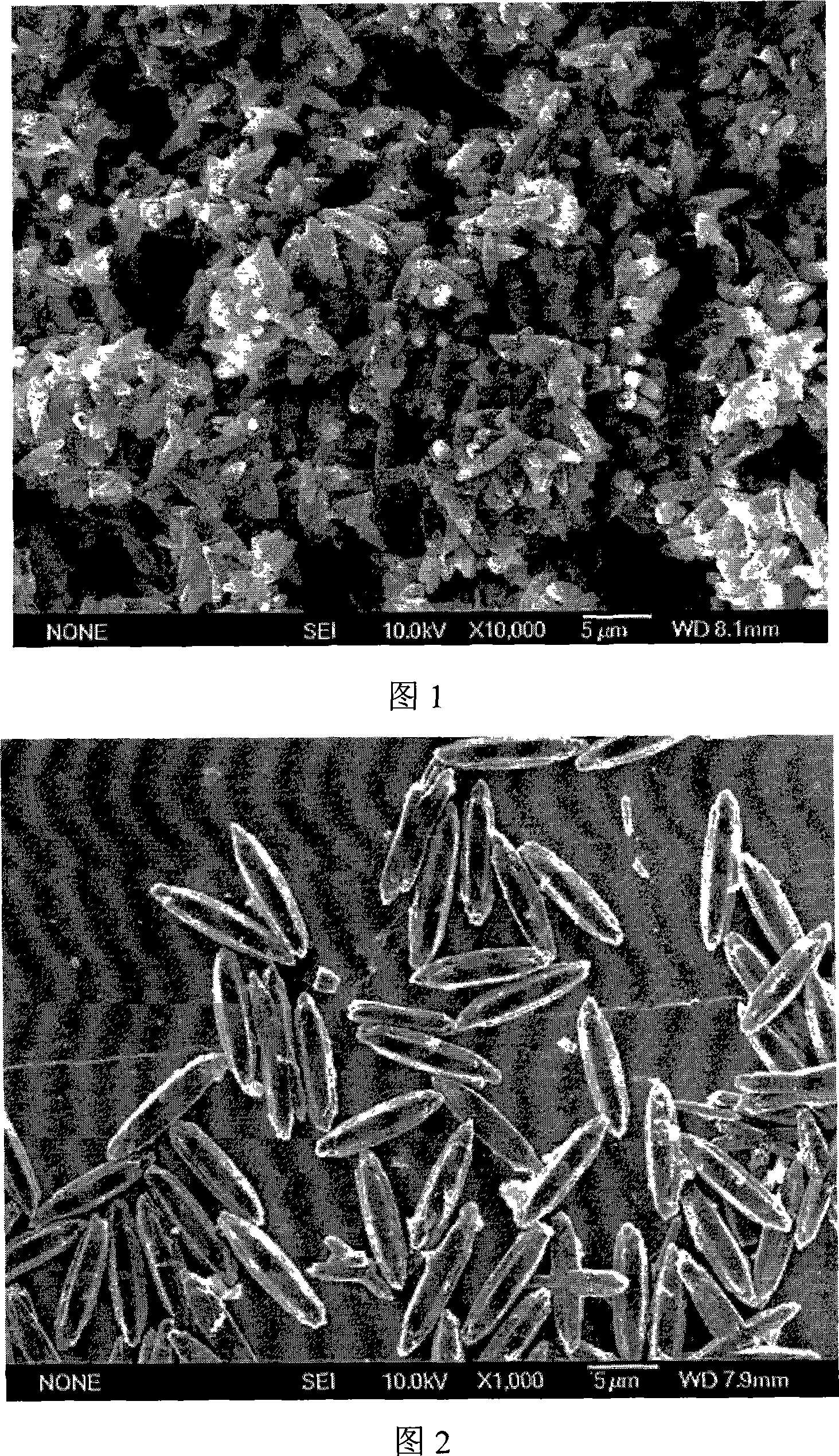

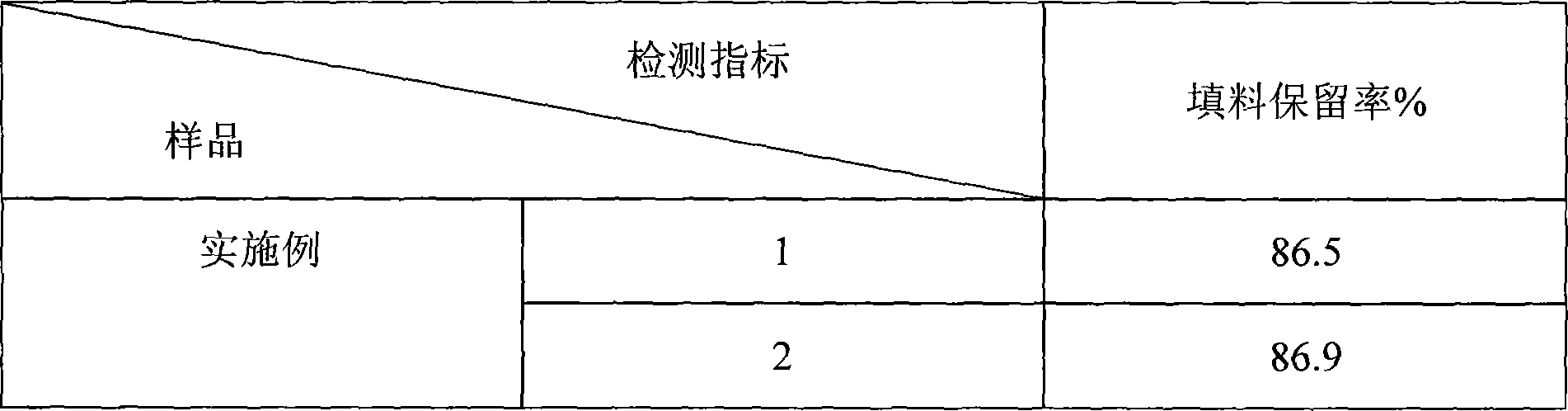

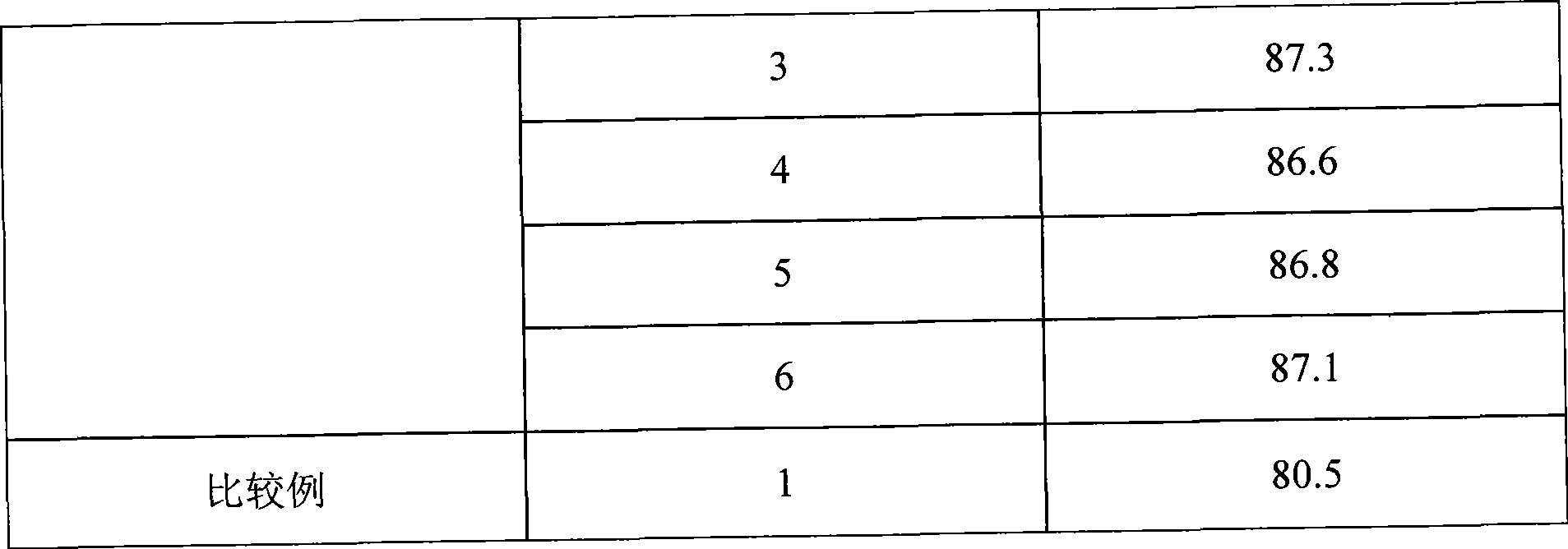

Method for manufacturing rice-shaped precipitated calcium carbonate

InactiveCN101209851AImprove smoothnessReduce smoothnessCalcium/strontium/barium carbonatesCoatings with pigmentsFiberCarbonization

The invention provides rice-shaped precipitation calcium carbonate, a preparation method and the application thereof. The preparation method comprises the steps that: (1) crystal control agent is added into calcium hydroxide aqueous suspension to obtain mixture; (2) the mixture of the first step is communicated with carbon dioxide for carbonization reaction until the pH value of the mixture reaches 6.5-8.5 and the rice-shape calcium carbonate is collected from the reaction products; the crystal control agent is soluble carbonate. The rice-shape calcium carbonate of the invention has moderate length diameter ratio, which is easier to be maintained in paper fiber than ordinary light calcium carbonate, and increases the smoothness of the paper at the same time; furthermore, the invention not only preserves the printing quality of the paper, but also reduces the consumption of filler and increases retention rate, meanwhile, the manufactured paper has superior characteristics of high stiffness and high smoothness and has no problems of alkali recycling and discharging, being easy for implementing industrialized production.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

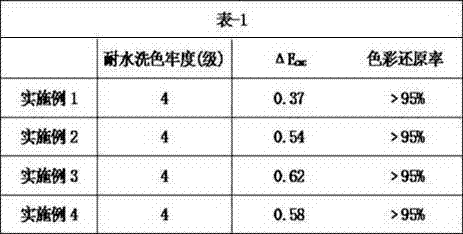

Water-based nano pigment ink for textile printing

The invention relates to ink and in particular relates to water-based nano pigment ink for textile printing. According to the formula, the ink mainly comprises the following components in parts by weight: 12.4-18.6 parts of water-based pigment slurry, 9.5-14.9 parts of a water-based resin, 5.3-9.6 parts of a quick-dry type solvent, 5.4-9.8 parts of a moisturizing solvent, 0.5-2 parts of a surfactant, 0.05-0.2 part of an antibacterial agent and 50.9-65.55 parts of deionized water. According to the ink disclosed by the invention, textiles do not need to be preheated and heated, and the ink refers to healthy and environment-friendly water-based nano pigment ink which can be directly printed on the textiles. Moreover, a digital ink-jet printing textile prepared by the ink has excellent color fastness to washing, color reduction rate and excellent handfeel.

Owner:南京鼎科纳米技术研究所有限公司

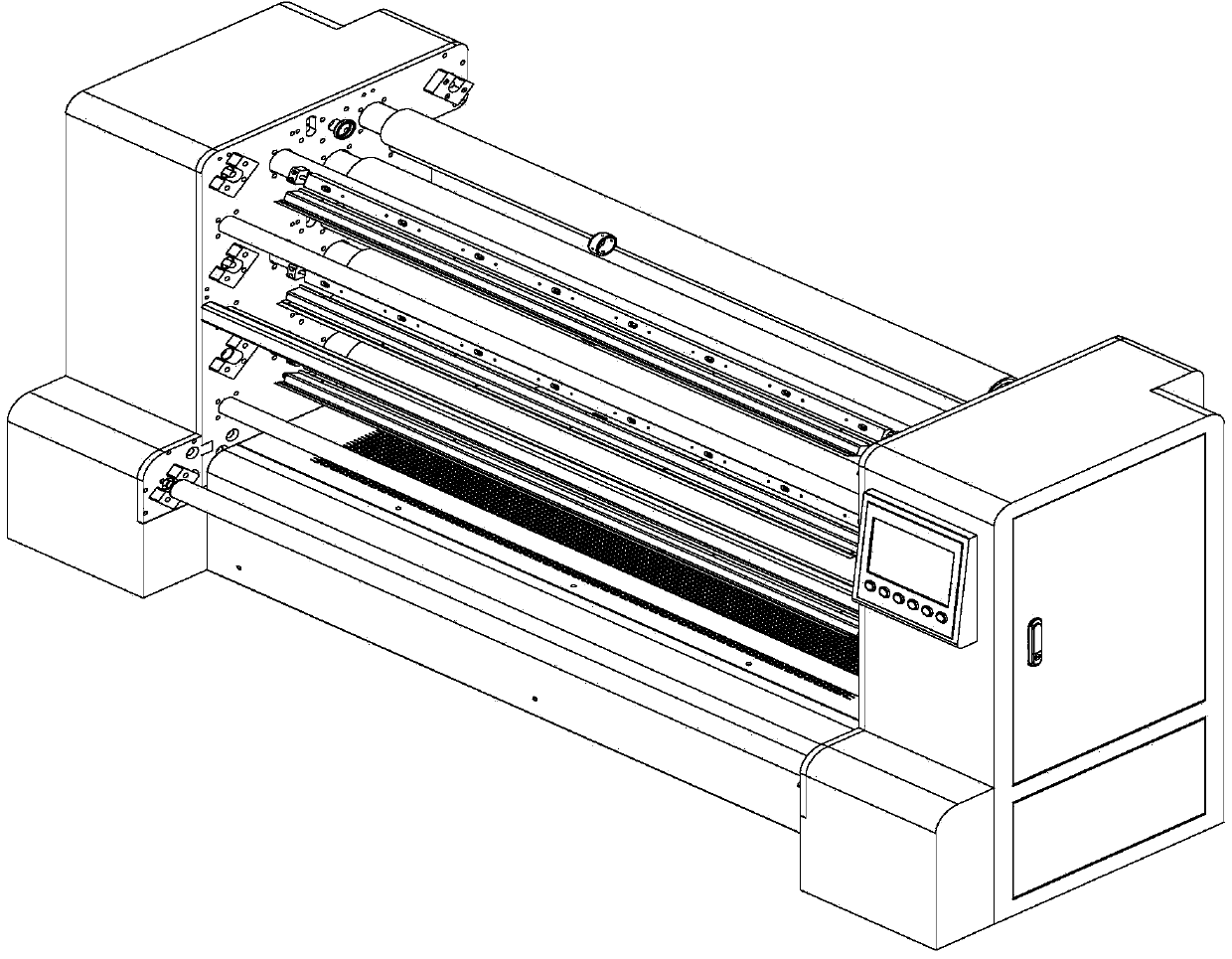

Large-size thermal color printer

The invention discloses a large-size thermal color printer which comprises a stand, medium-placing rollers which are parallelly installed on the stand, a front constant tension assembly, a rear constant tension assembly, a printing mechanism composed of at least three printing assemblies and a ribbon conveying mechanism composed of at least three pairs of ribbon assemblies. By the adoption of the printing mechanism in upper and lower parallelism and through the front constant tension assembly and the rear constant tension assembly, constant-tension and constant-speed conveying of a printing medium can be guaranteed so as to prevent wrinkling and slipping of the printing medium. In addition, through a regulating mechanism for flatness and levelness of a print head, it can be ensured that the print head is stably contacted with the rubber covered rollers, and printing quality is guaranteed. Thus, printing of large-size color photo images is finally realized.

Owner:QUFU YUQIAOFU TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com