Ink-jet printing device

An inkjet printing device and printing head technology, applied in printing, typewriter and other directions, can solve the cumbersome process of silk screen typesetting, plate making, and repeated color registration, which is unfavorable to the personalized printing market, and the printing cost of small batches of multi-color personalized customized plates. Increase and other problems, to achieve the effect of reducing the cost of printing and ensuring the quality of printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The inkjet printing device and the fixing adjustment method of the object to be printed in a specific embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

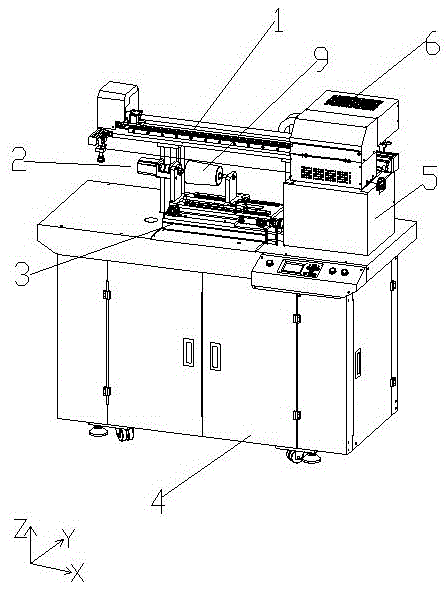

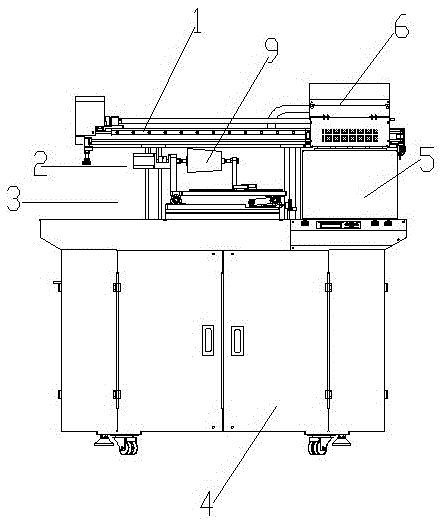

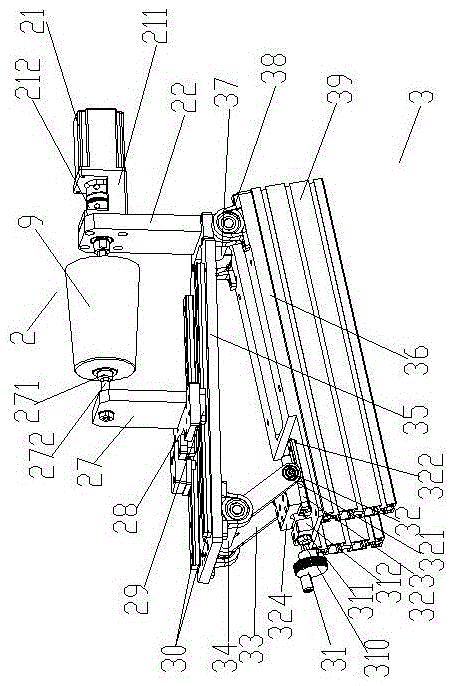

[0025] like Figure 1-2 As shown, the inkjet printing device in this embodiment includes a printing unit and a feeding unit. The printing unit includes a guide rail beam part 1 and a printing carriage 6. A printing carriage 6 is installed on the guide rail beam part 1. The printing carriage 6 can move along the guide rail beam. For relative movement, at least one print head is arranged on the printing carriage 6, and the printing carriage 6 is used to spray ink droplets on the object 9 to be printed to realize image or text printing. The feeding unit includes a base part 4, a cone fixing device 2 and a parallelism adjustment device 3. The feeding unit is arranged below the printing unit. The cone fixing device 2 and the parallelism adjustment device 3 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com