Online imprinting detection method and system

A detection system and detection method technology, applied in the direction of calculation, character and pattern recognition, computer parts, etc., can solve the problems of incomplete detection function and low detection accuracy, so as to improve the level of printing automation, improve product qualification rate, improve The effect of online detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

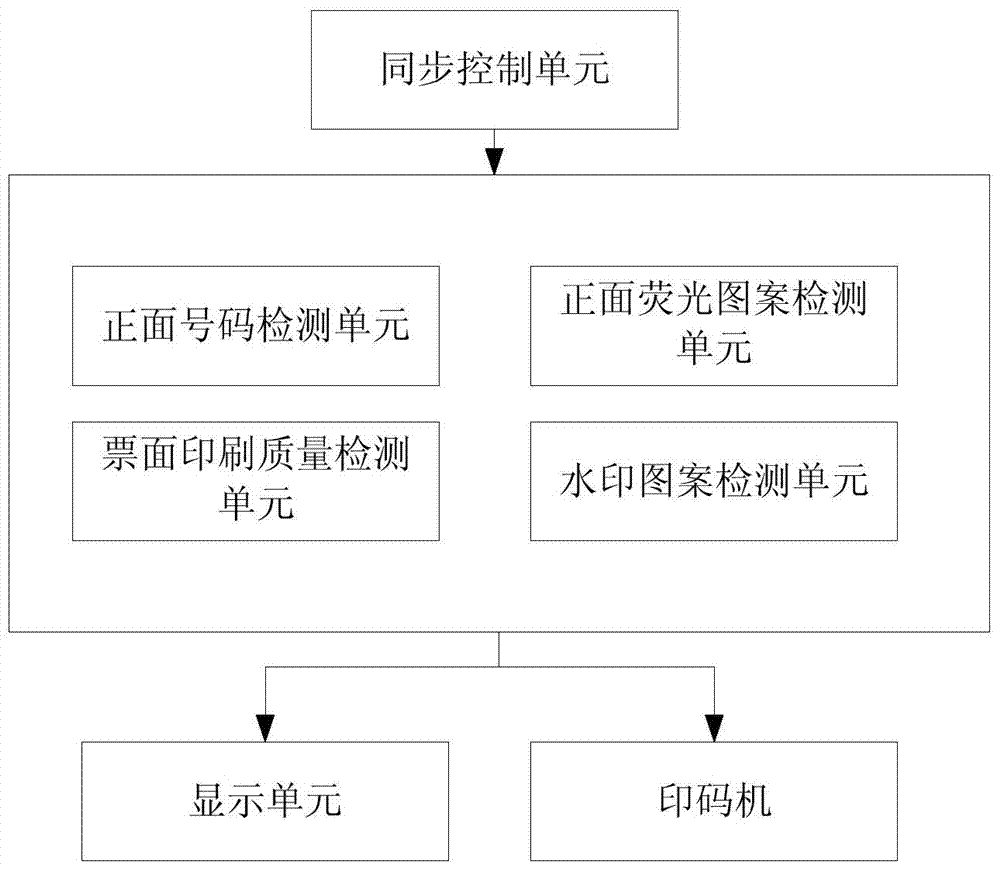

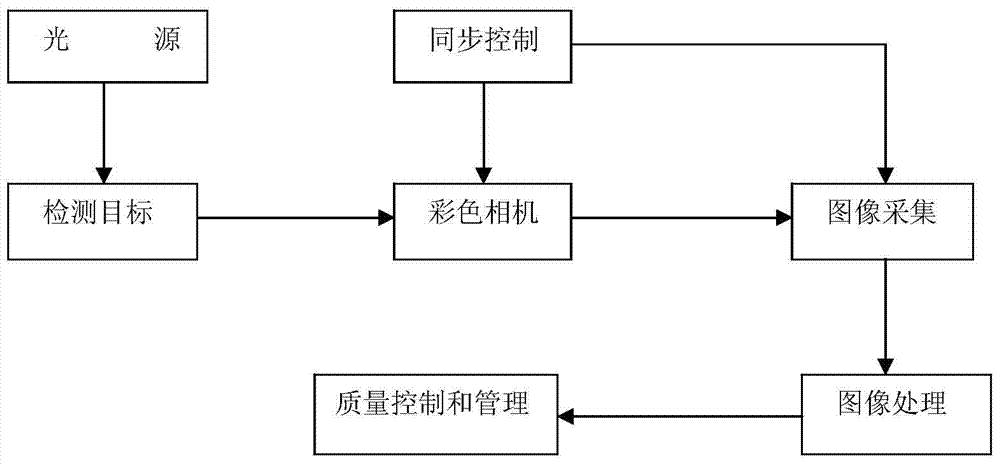

[0047] The present invention proposes an on-line detection method for printed codes. The method includes positive number detection, and adopts multiple color cameras and a multi-channel parallel high-speed image acquisition and operation processing system. The high-definition images obtained by the color cameras are collected through digital image acquisition and Processing, and comprehensively judge the processed data, detect the printing defects of the online printing products, and issue corresponding control commands when printing defects are found, so as to conduct online detection and real-time monitoring of the printing quality of the front number of the online printing products. In addition, the present invention also proposes an online code printing detection system, which includes more than one detection unit, such as a front number detection unit, which uses multiple color cameras and a multi-channel parallel high-speed image acquisition and calculation processing syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com