Digital jet printing machine and digital jet printing method

A printing machine and digital technology, applied in the field of textile digital jet printing machines, can solve problems such as inability to guarantee printing quality, increase production costs, and medium pollution, and achieve the effects of simple and reasonable structure, reduced production costs, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further description will be made below in conjunction with the accompanying drawings.

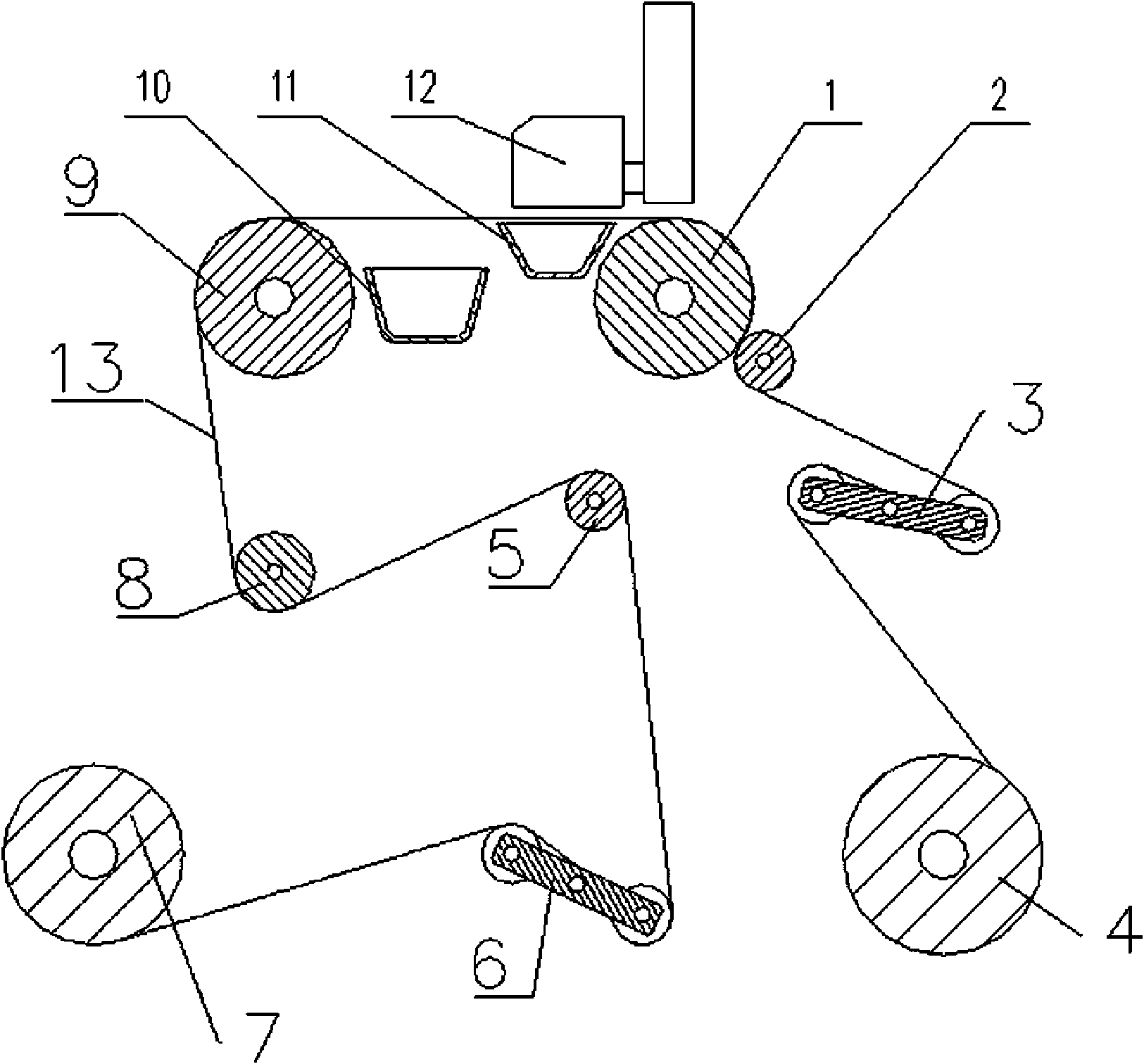

[0016] see figure 1 The digital jet printing machine of the present invention shown includes a discharge roller (unwinding device) 4, a rear tensioning device 3, a pressure roller 2, a driving roller 1, and an inkjet printing device arranged in sequence along the moving direction of the medium 13. 12. Heating and drying device 10 , main drive roller 9 , expansion roller 8 , rewinding tension roller 5 , front tensioning device 6 , and rewinding roller 7 . The rewinding roller 7 and the rewinding tension roller 5 constitute a rewinding device. The pressure roller 2 is pressed against the circumferential direction of the driving roller 1.

[0017] A collecting tank (waste ink collecting device) 11 is provided under the reverse side of the medium, opposite to the print head of the inkjet printing device 12 arranged above the front side of the medium. The heating and drying device 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com