Patents

Literature

30results about How to "Affect printing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

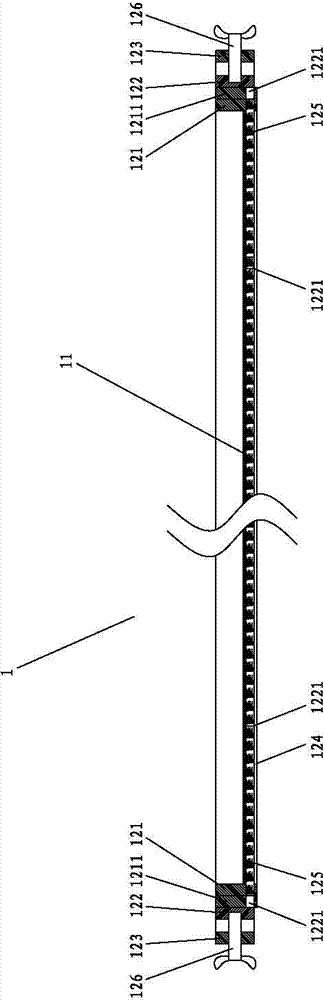

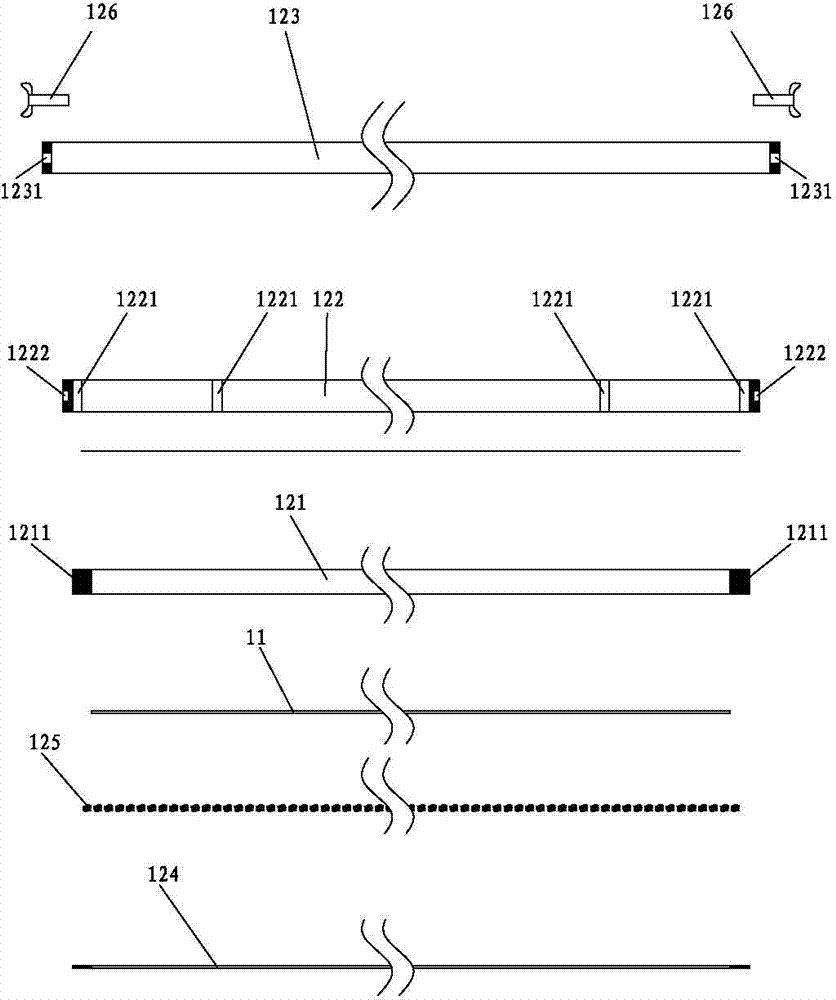

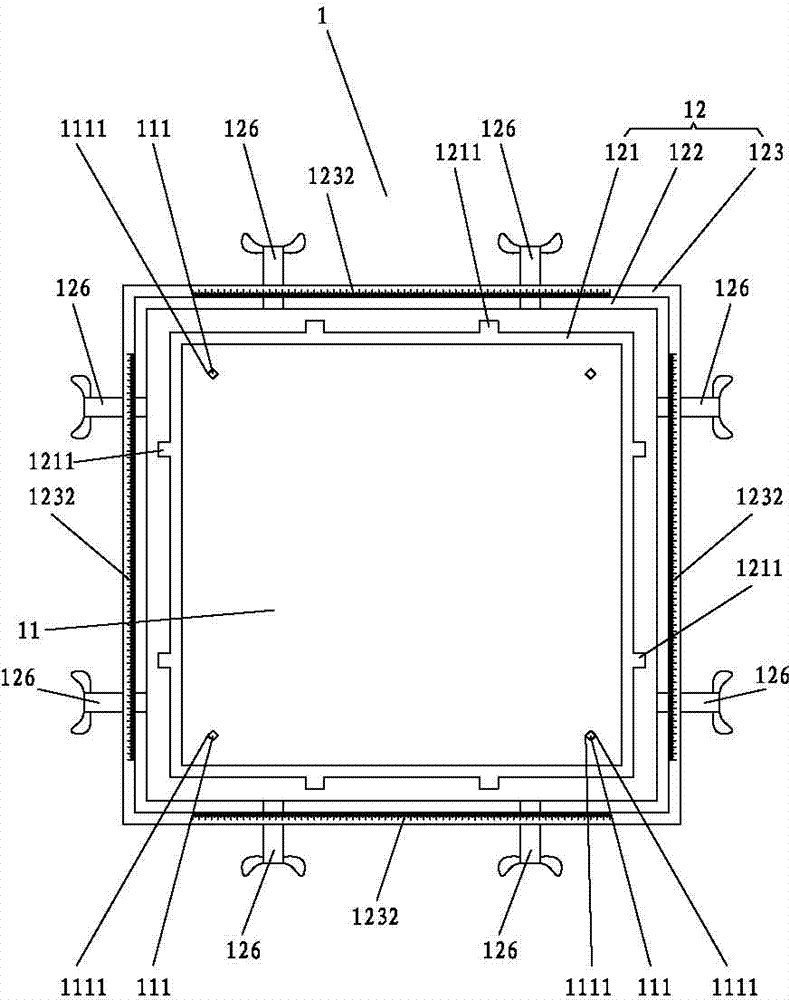

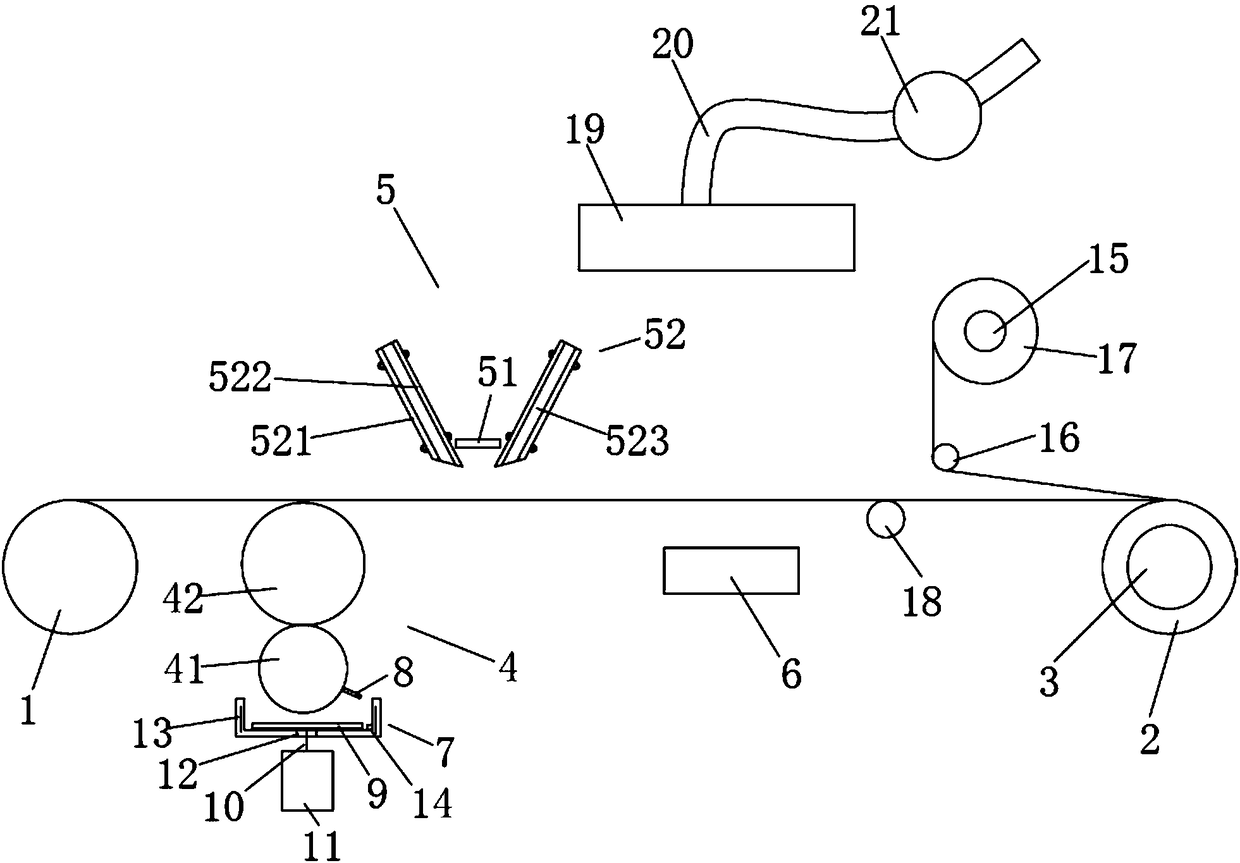

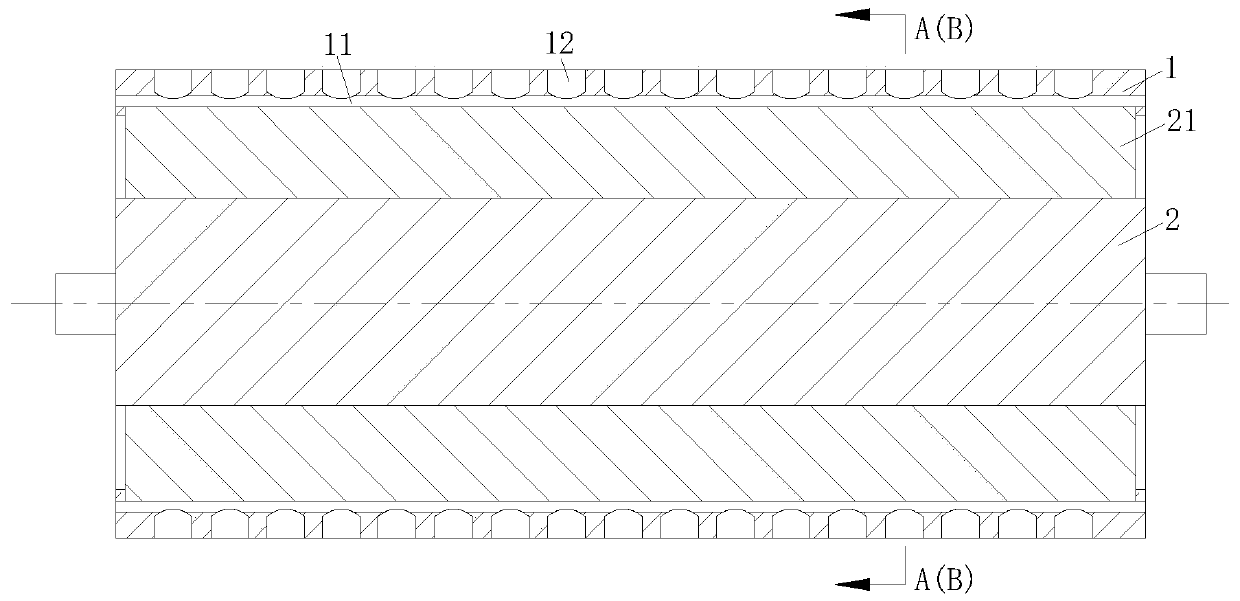

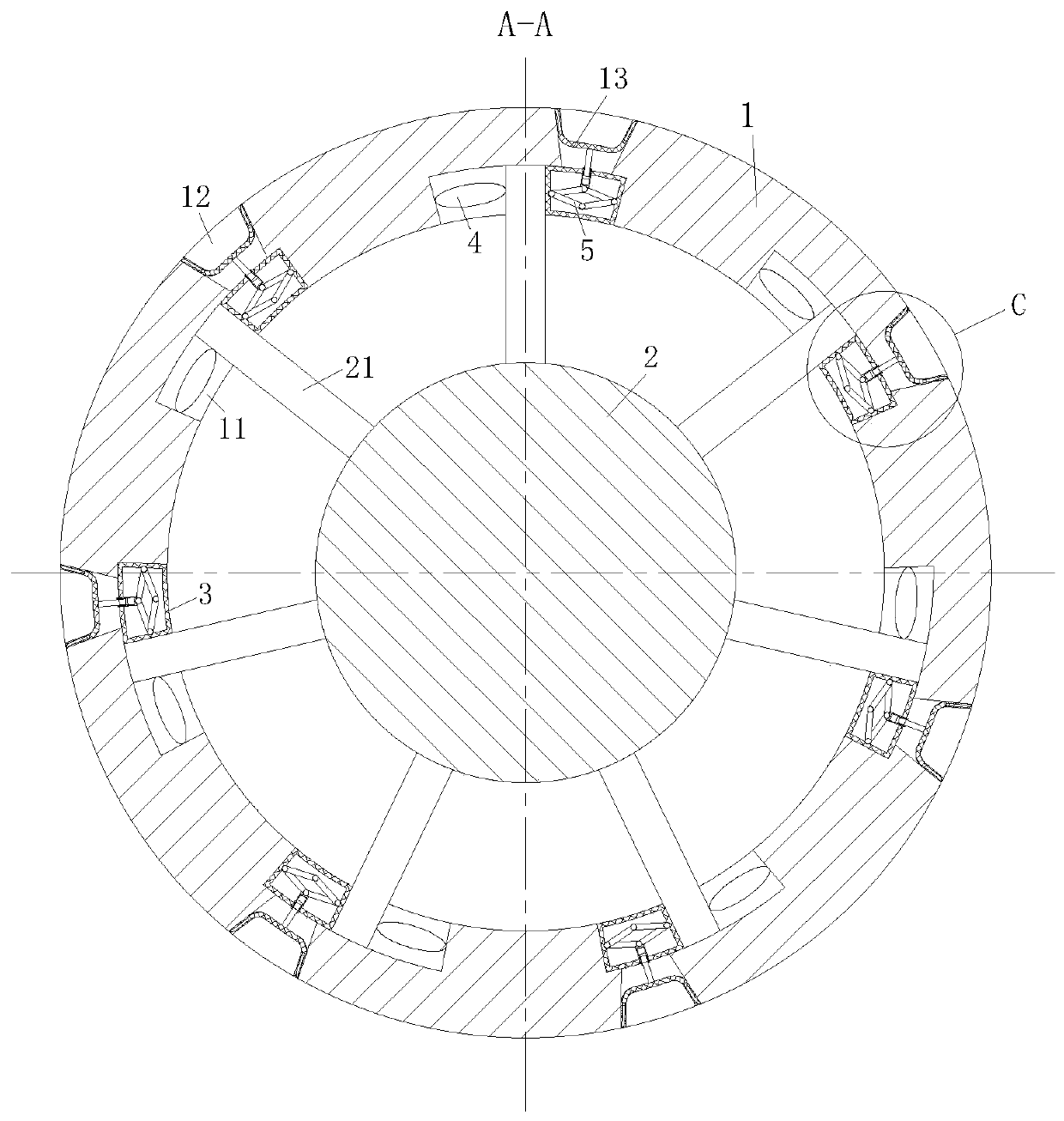

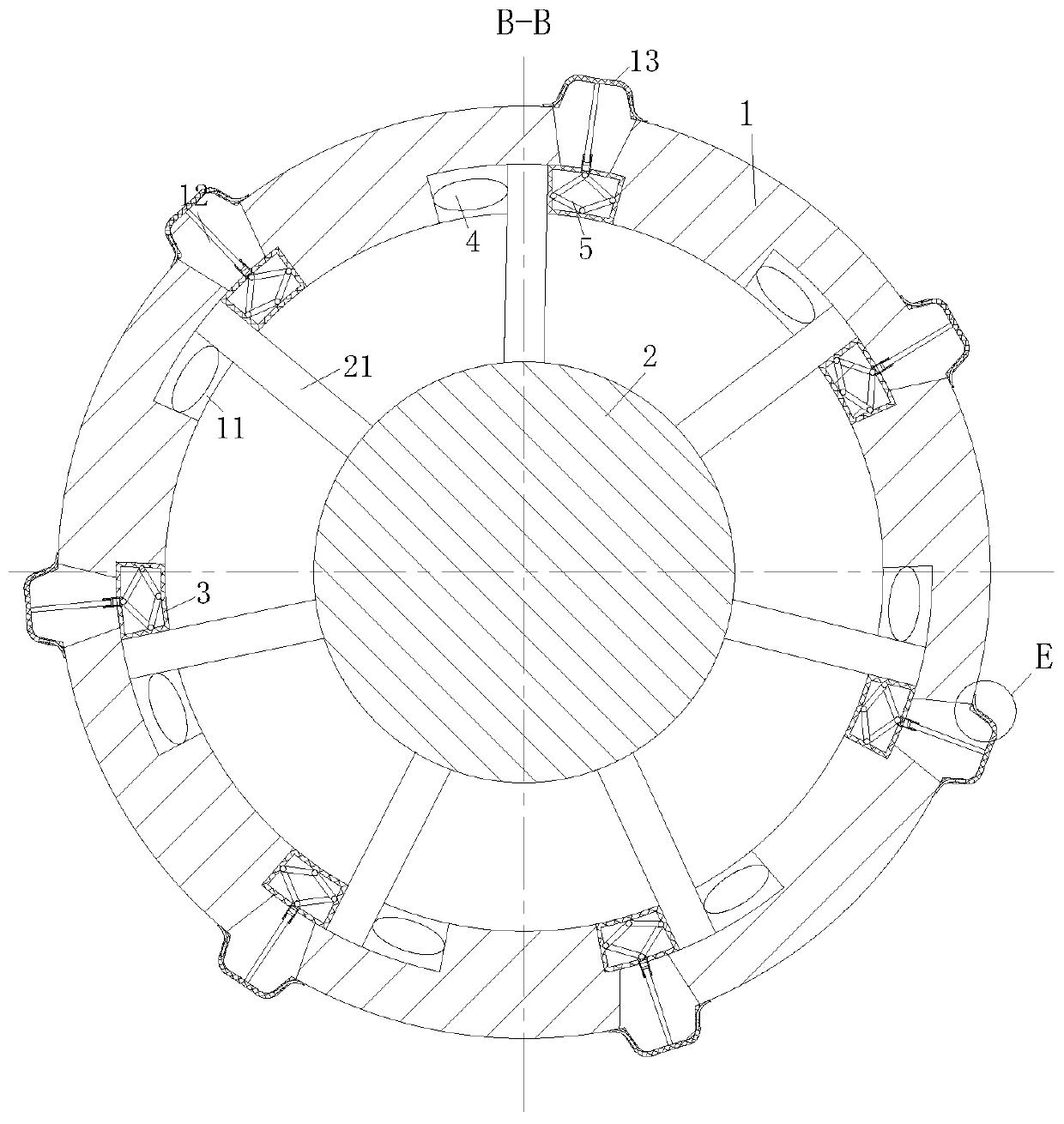

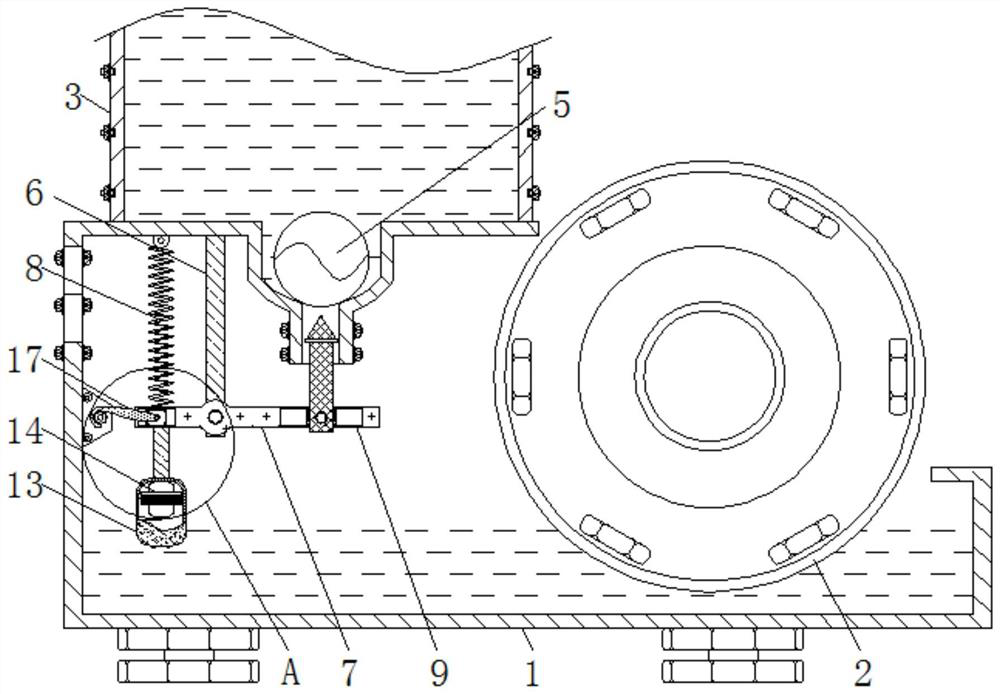

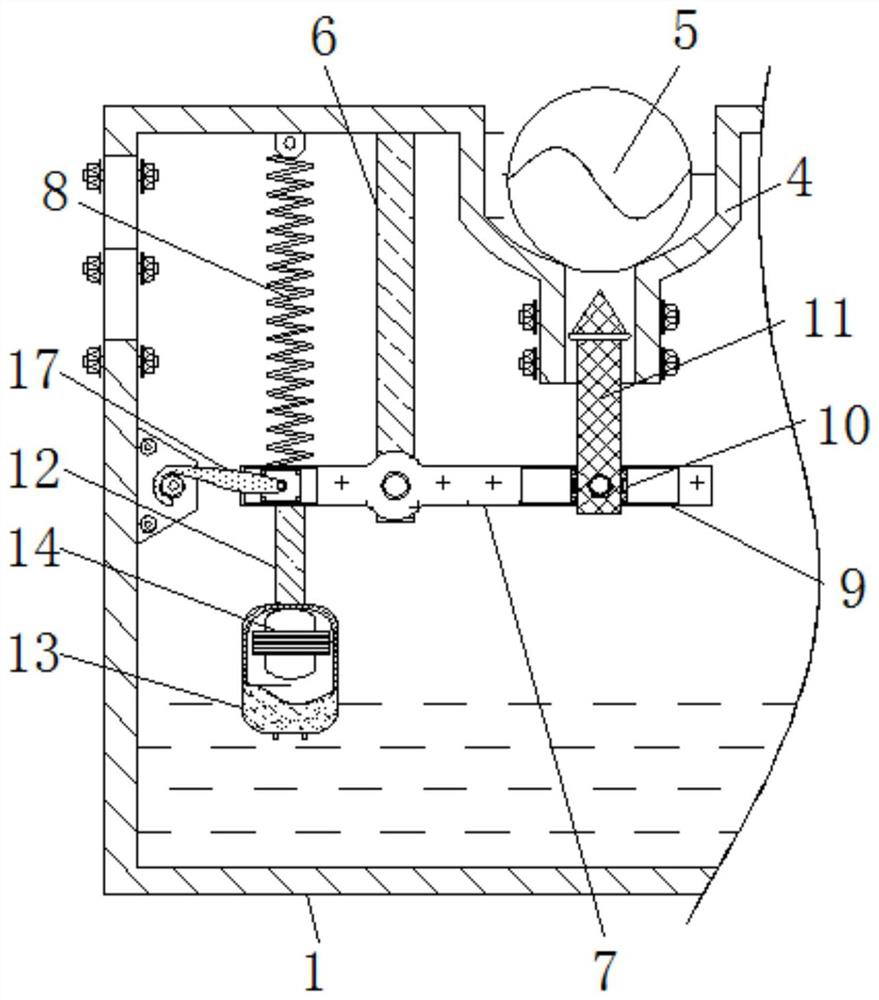

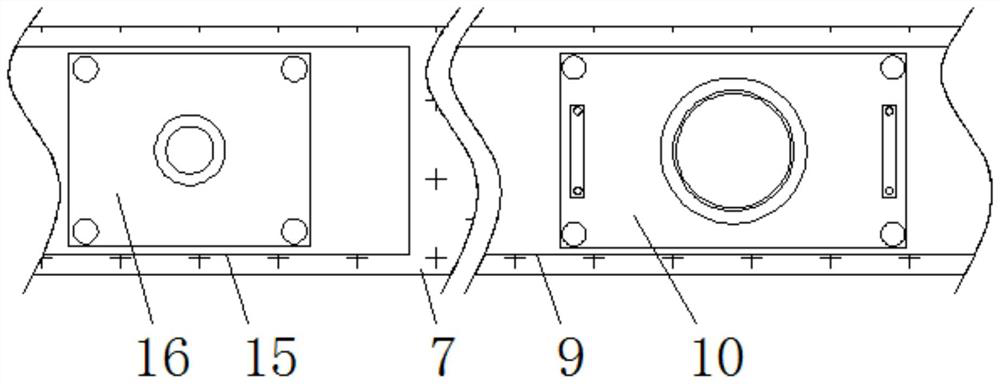

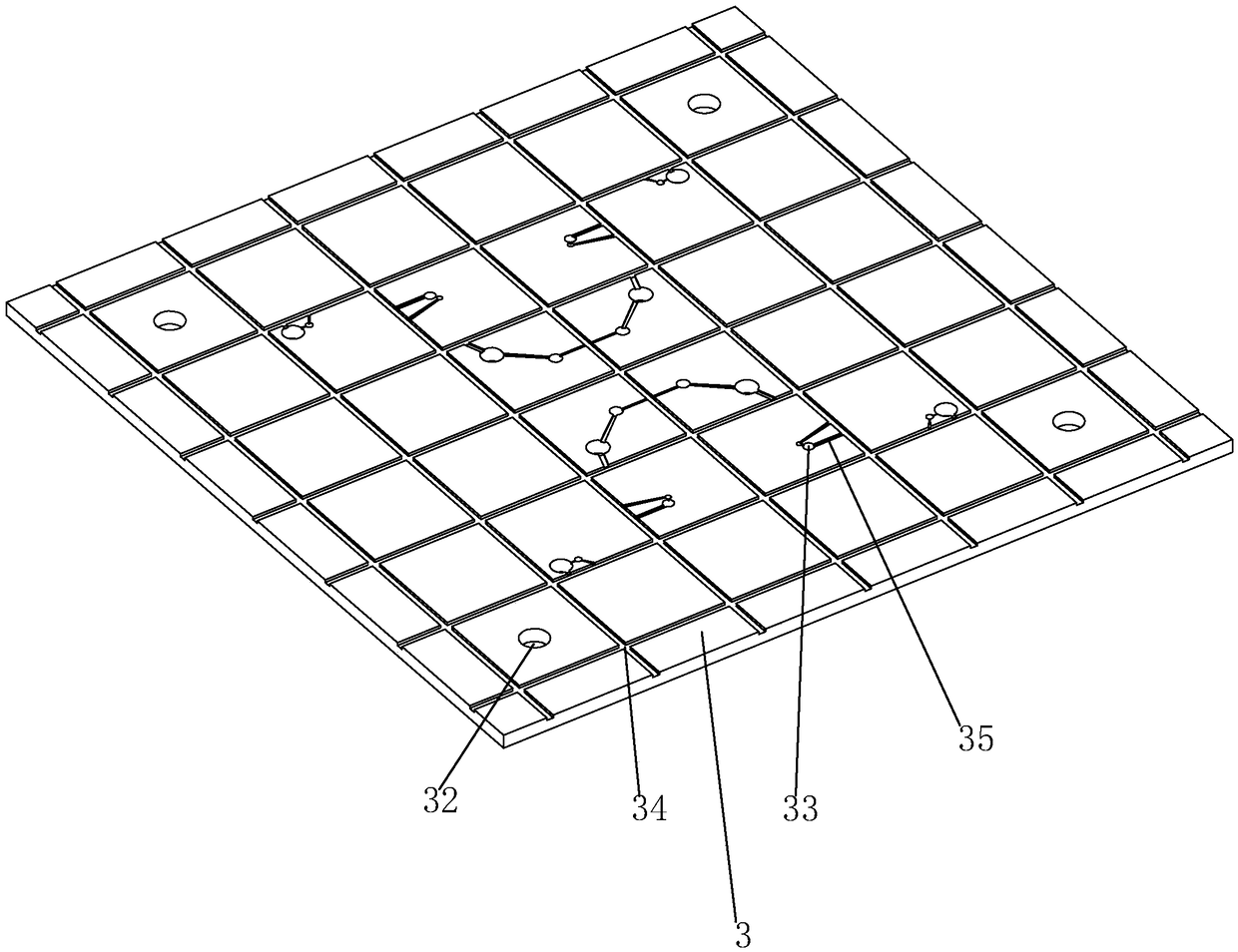

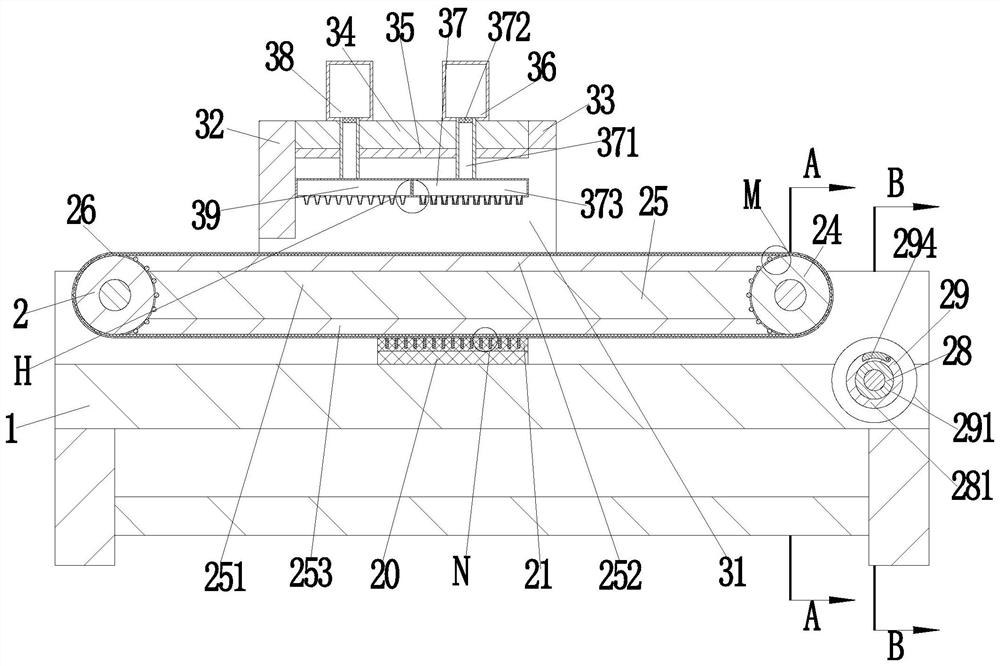

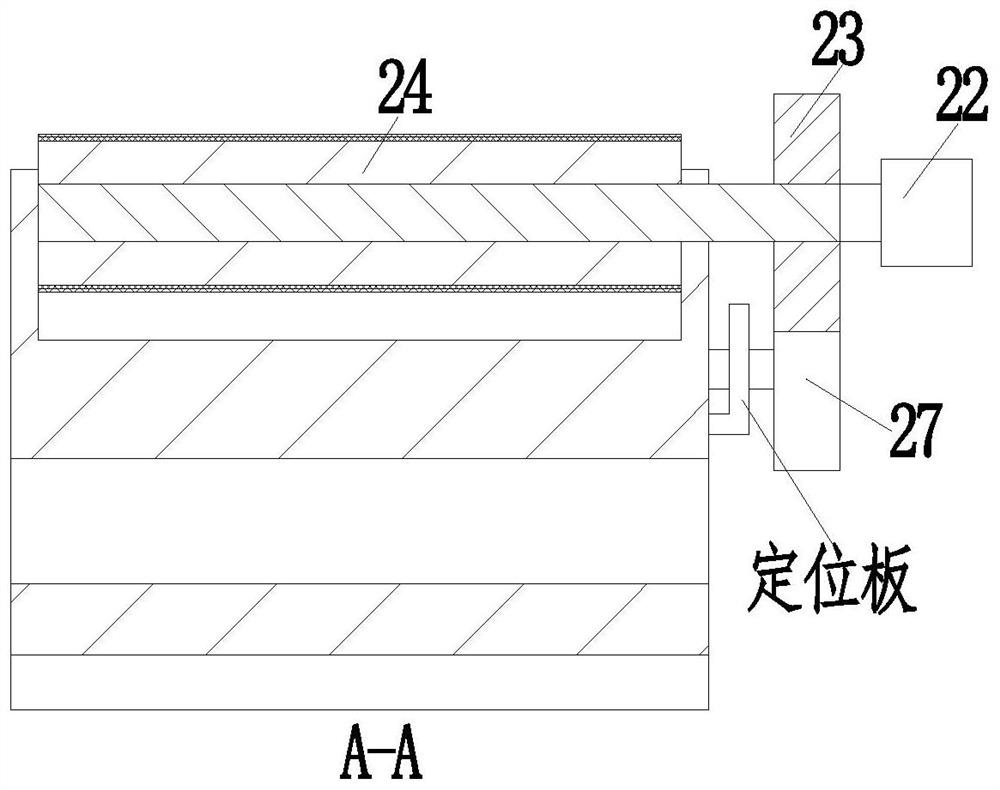

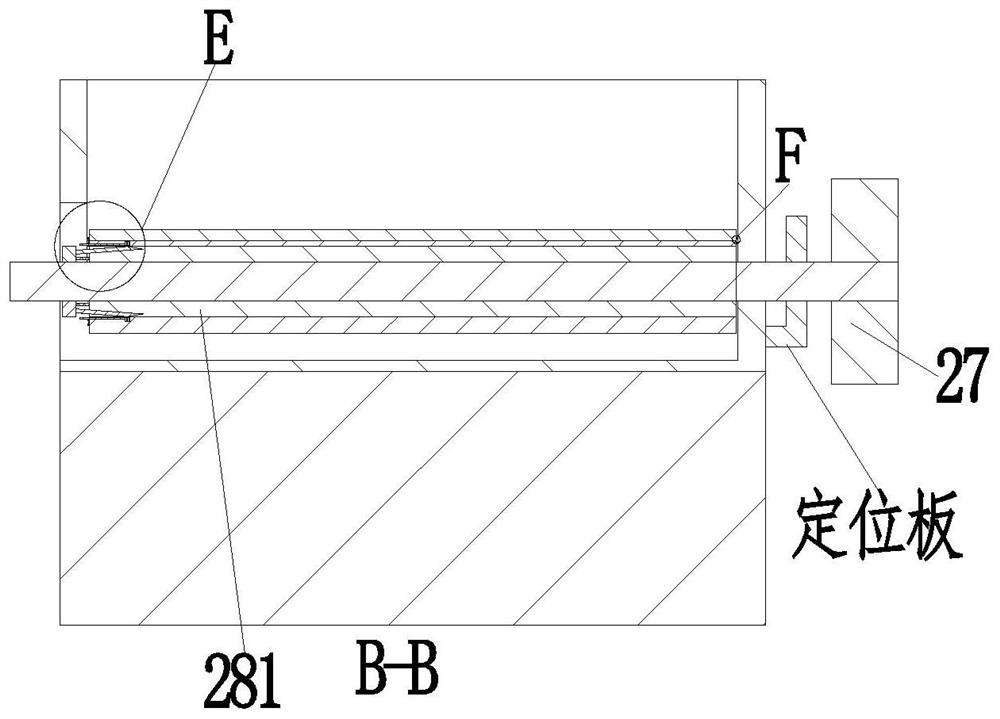

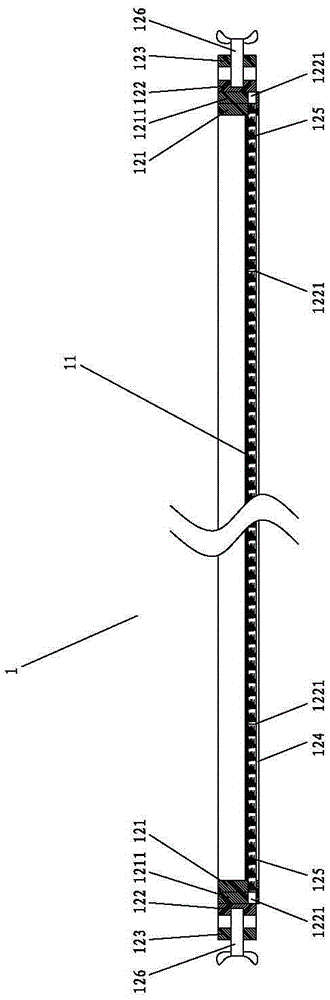

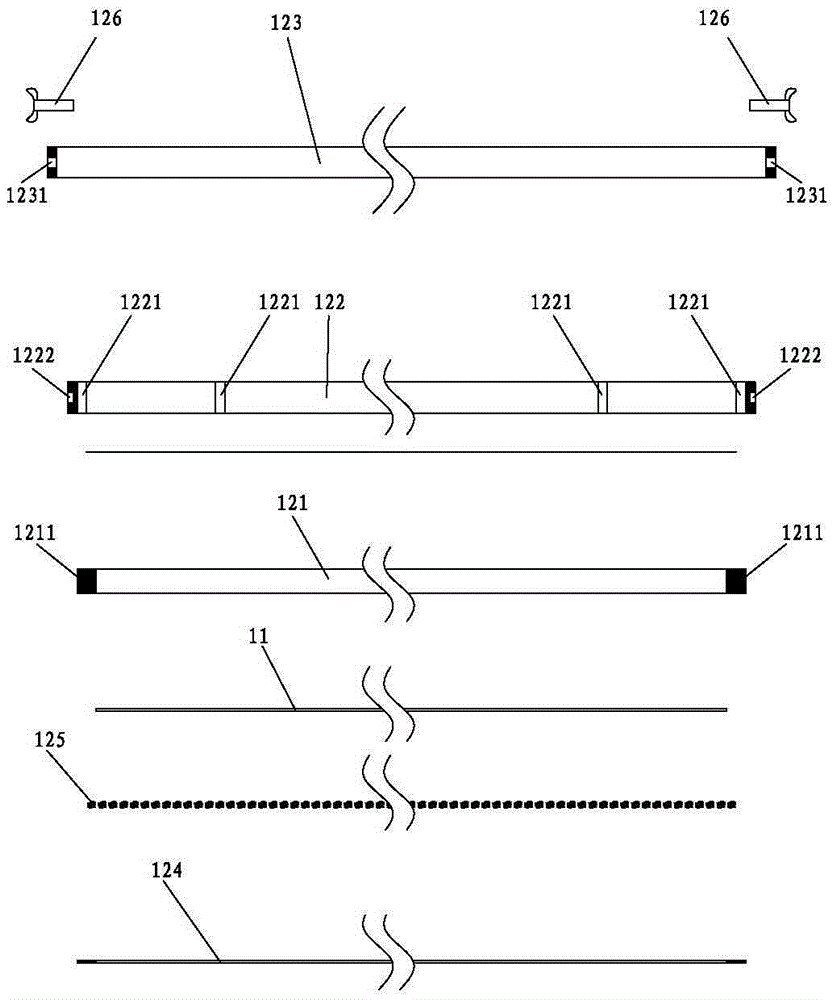

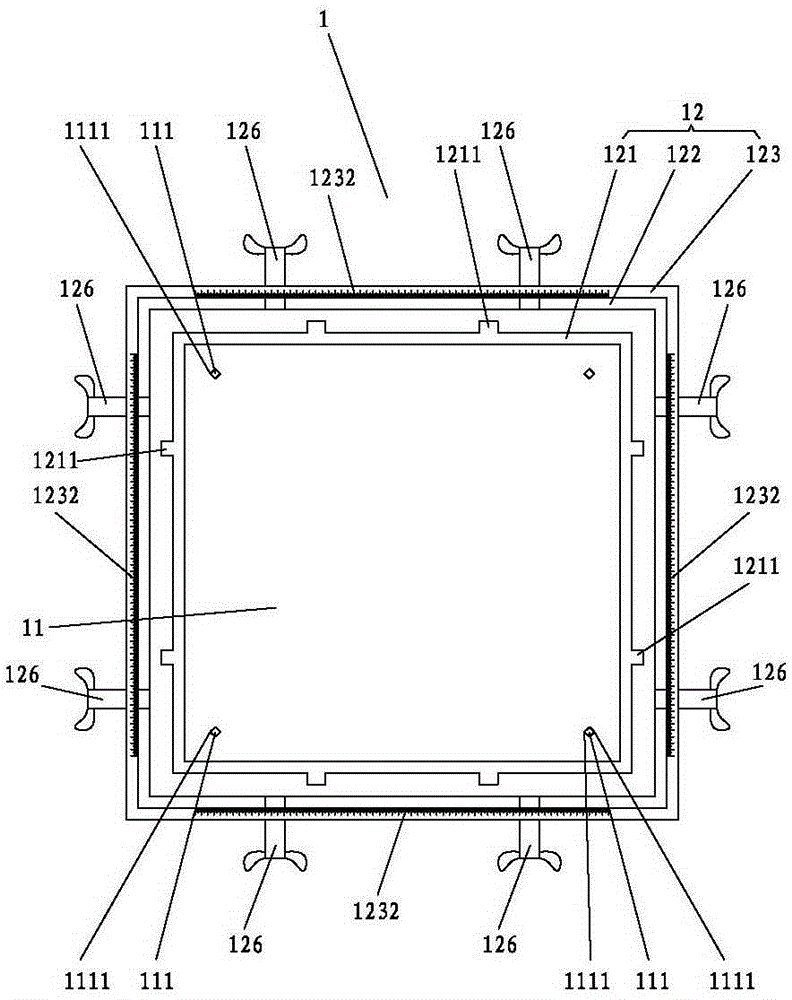

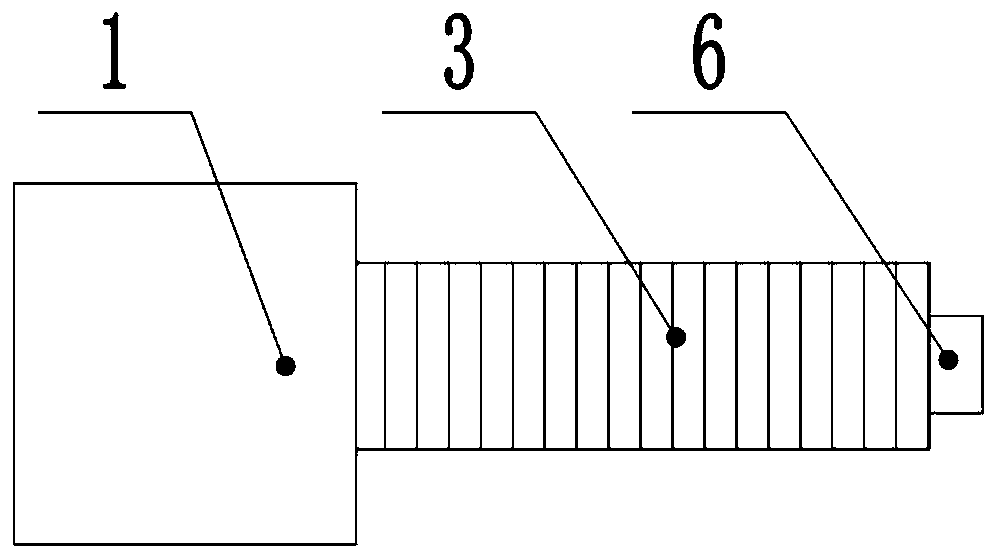

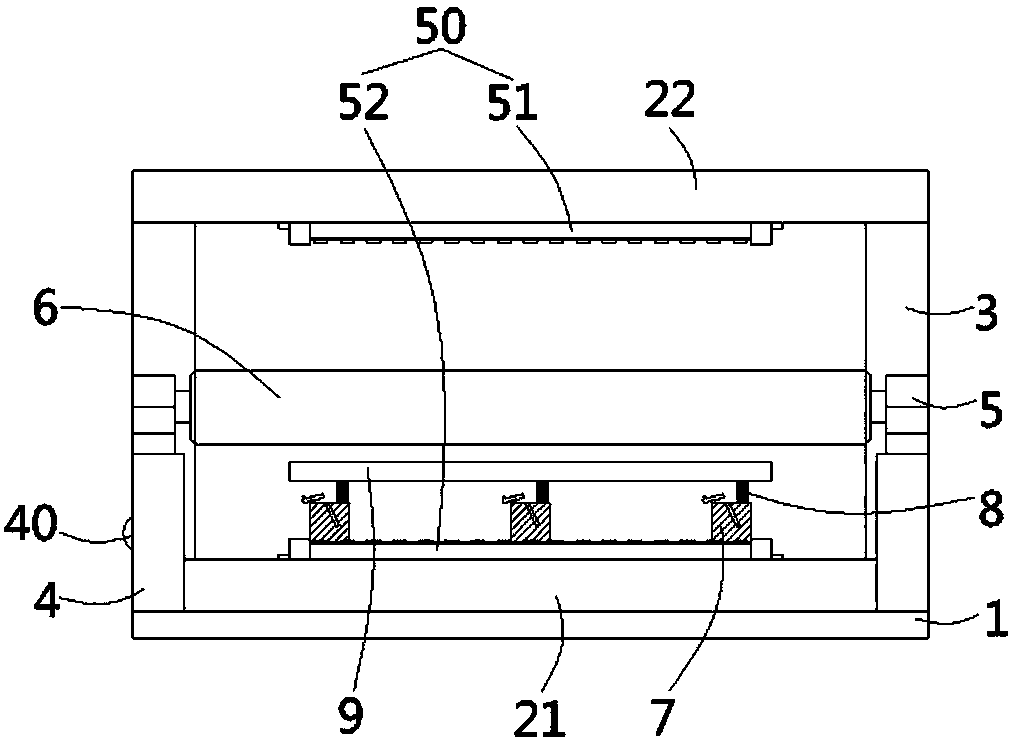

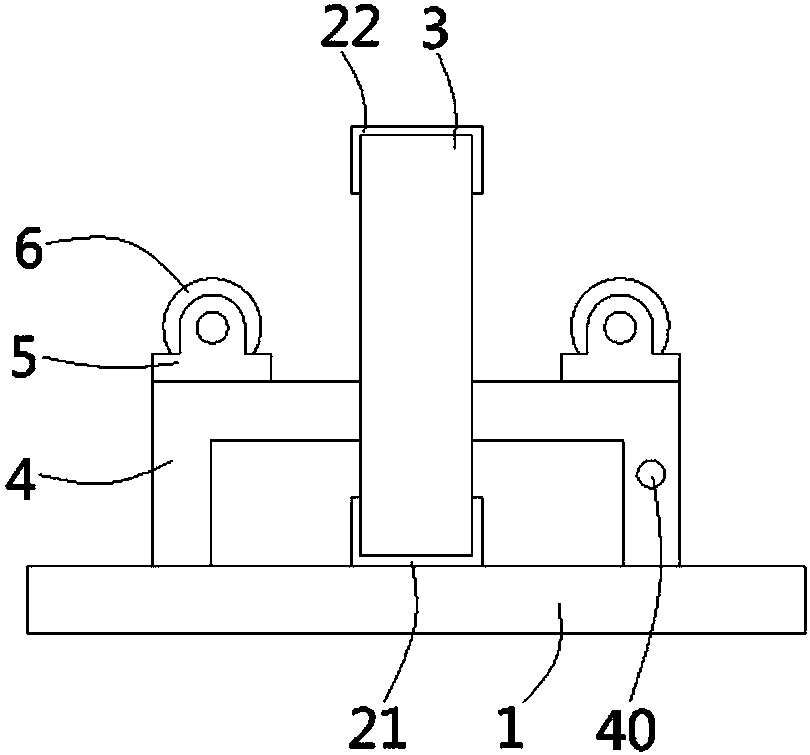

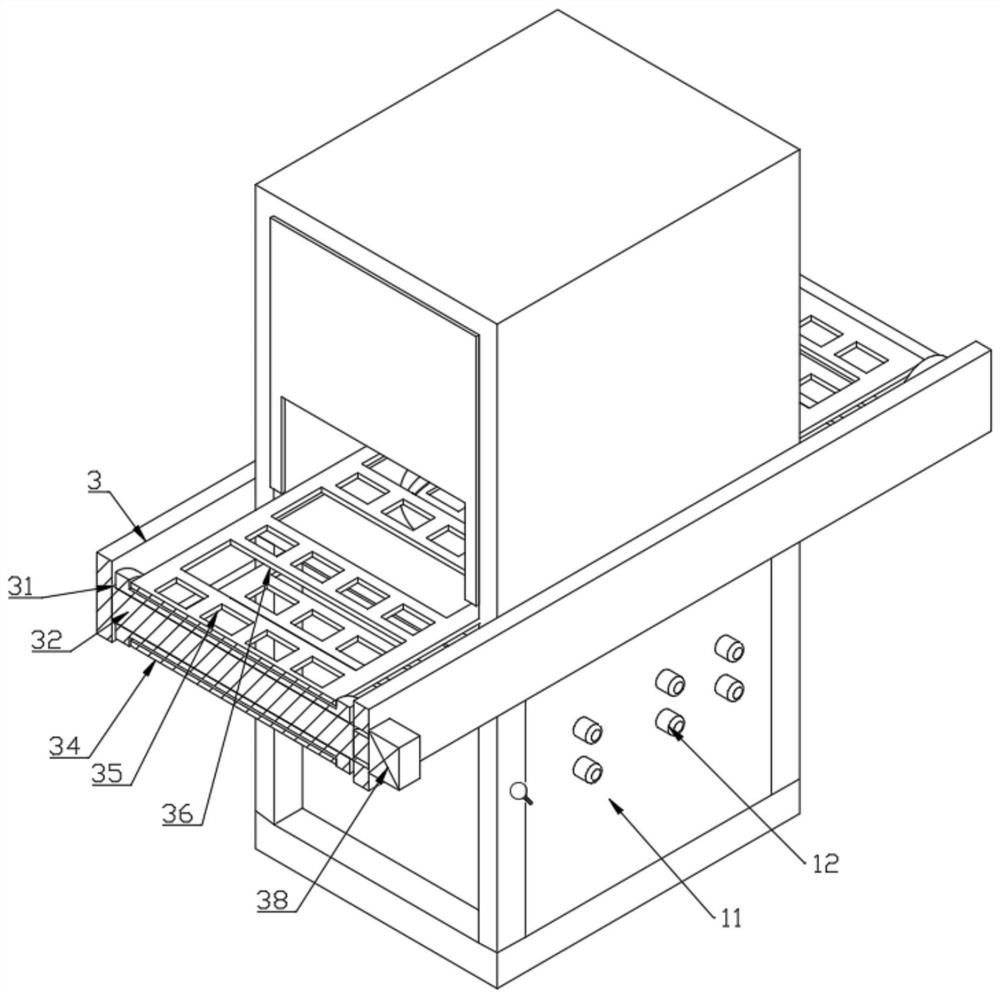

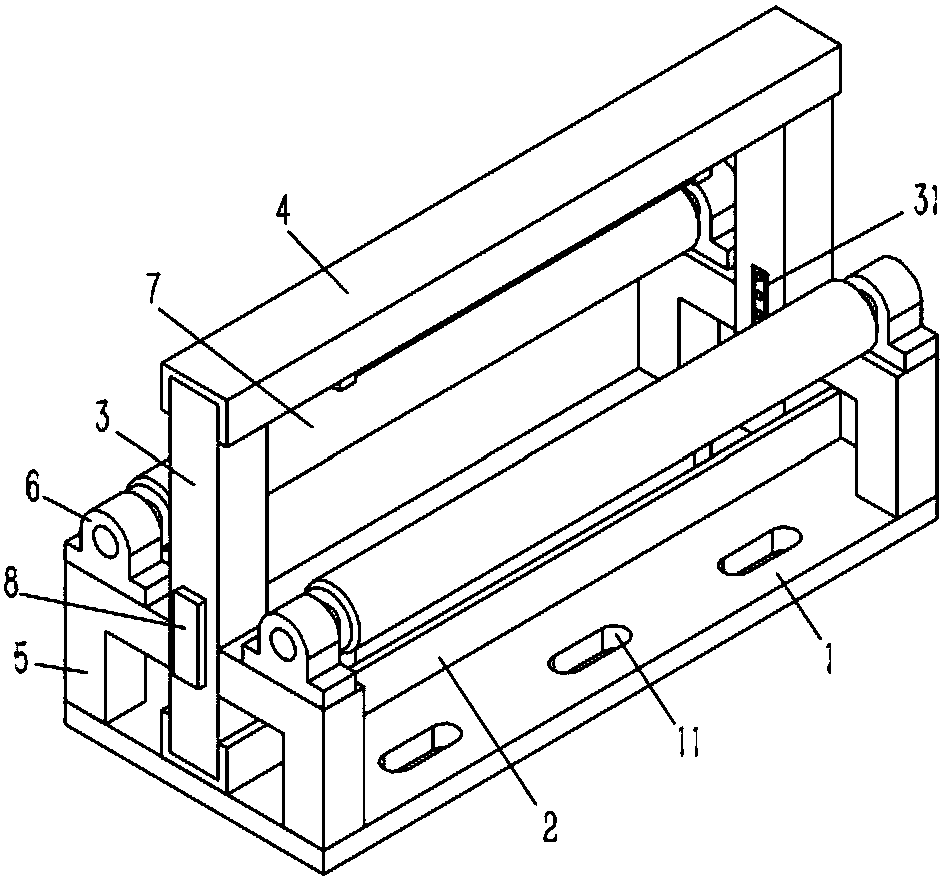

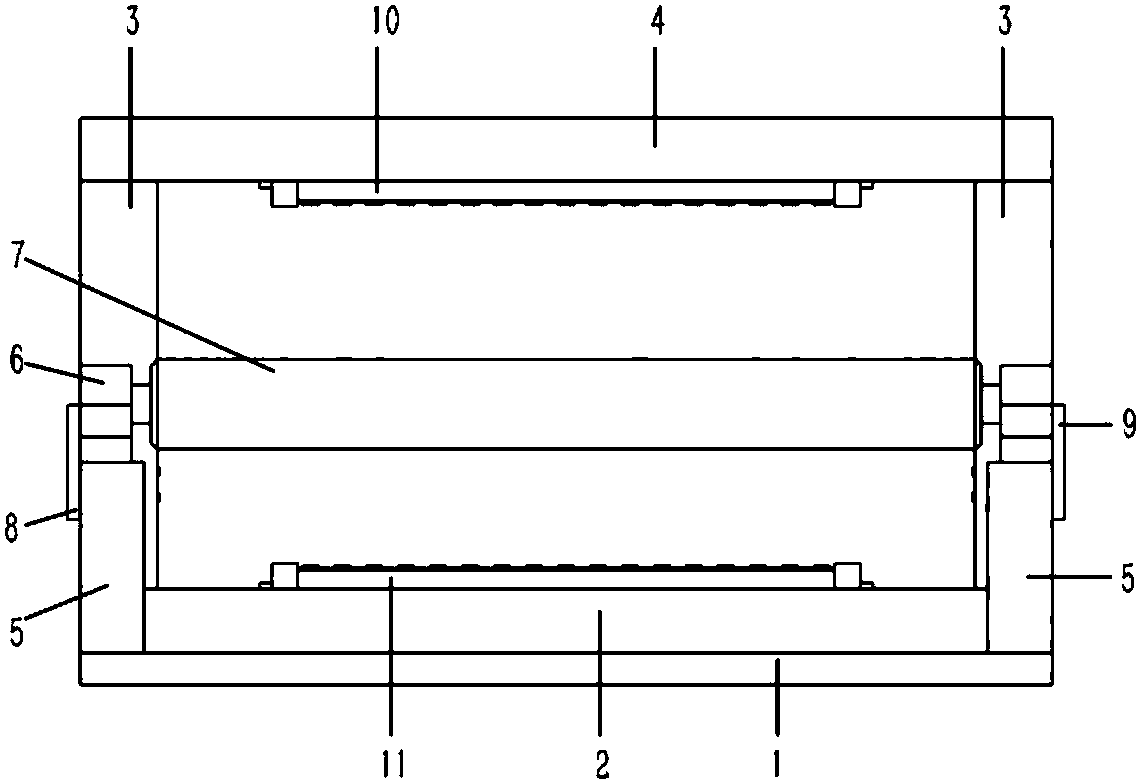

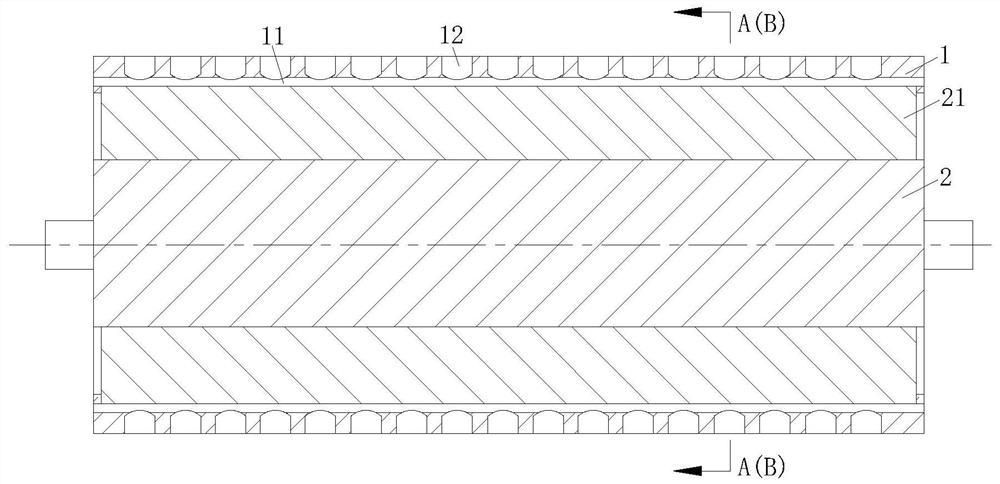

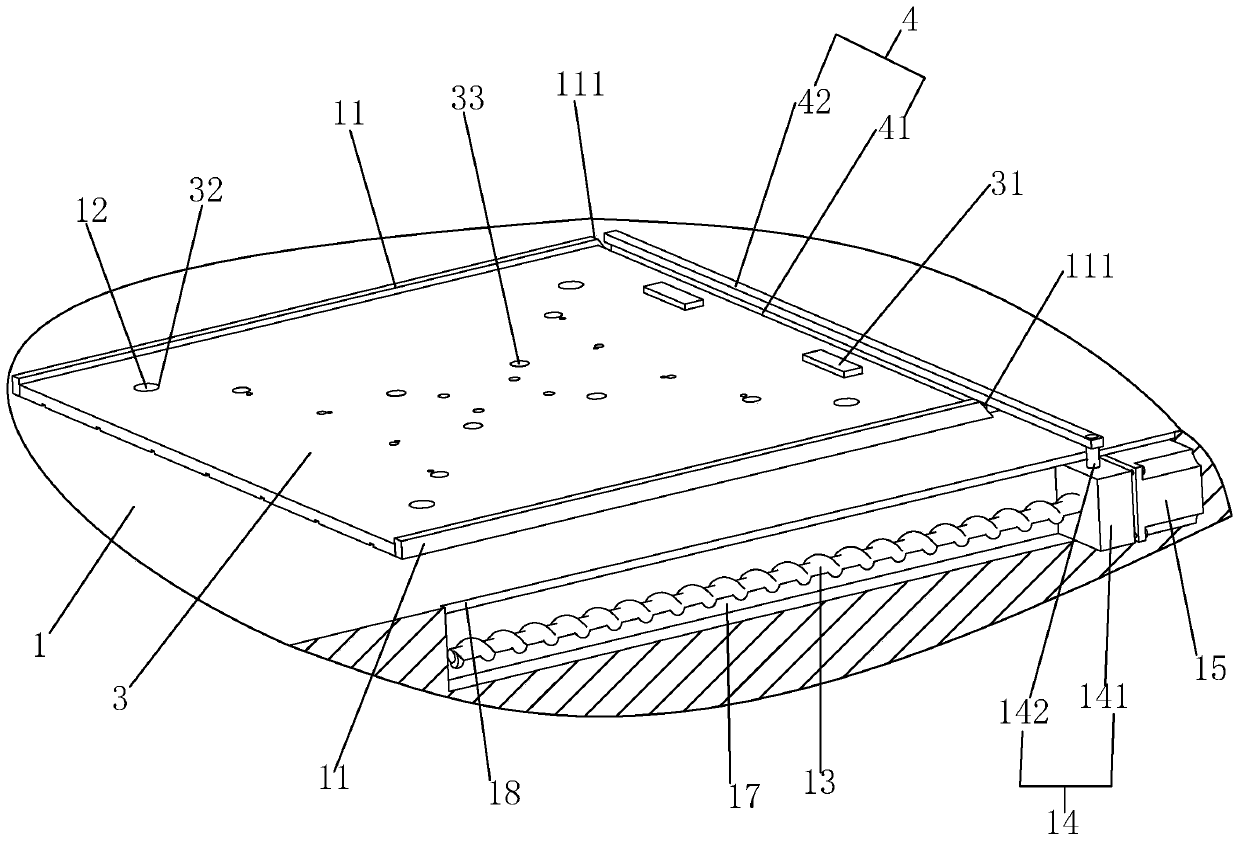

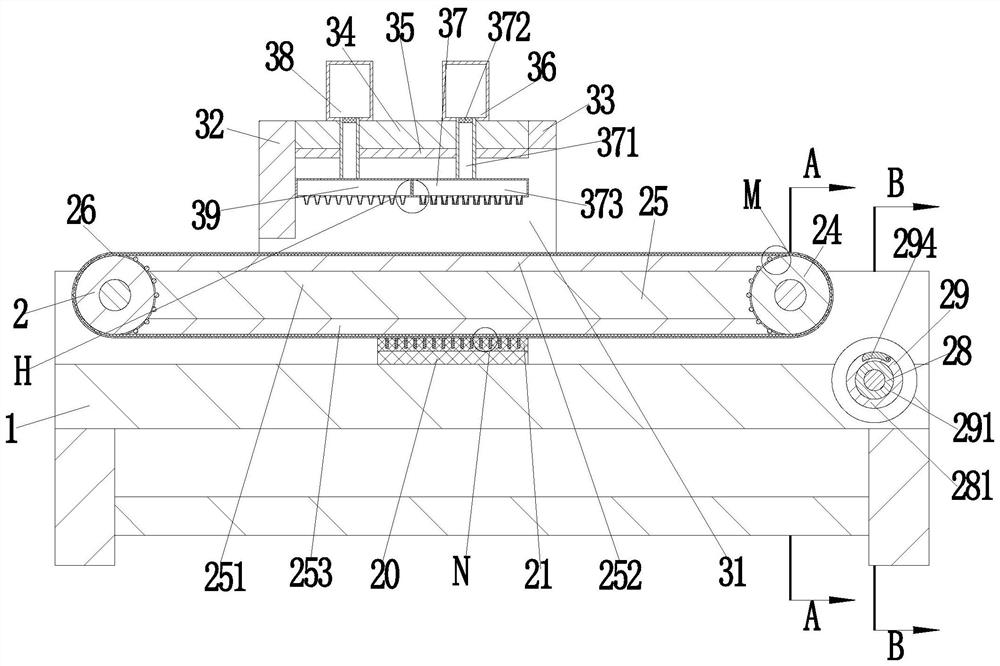

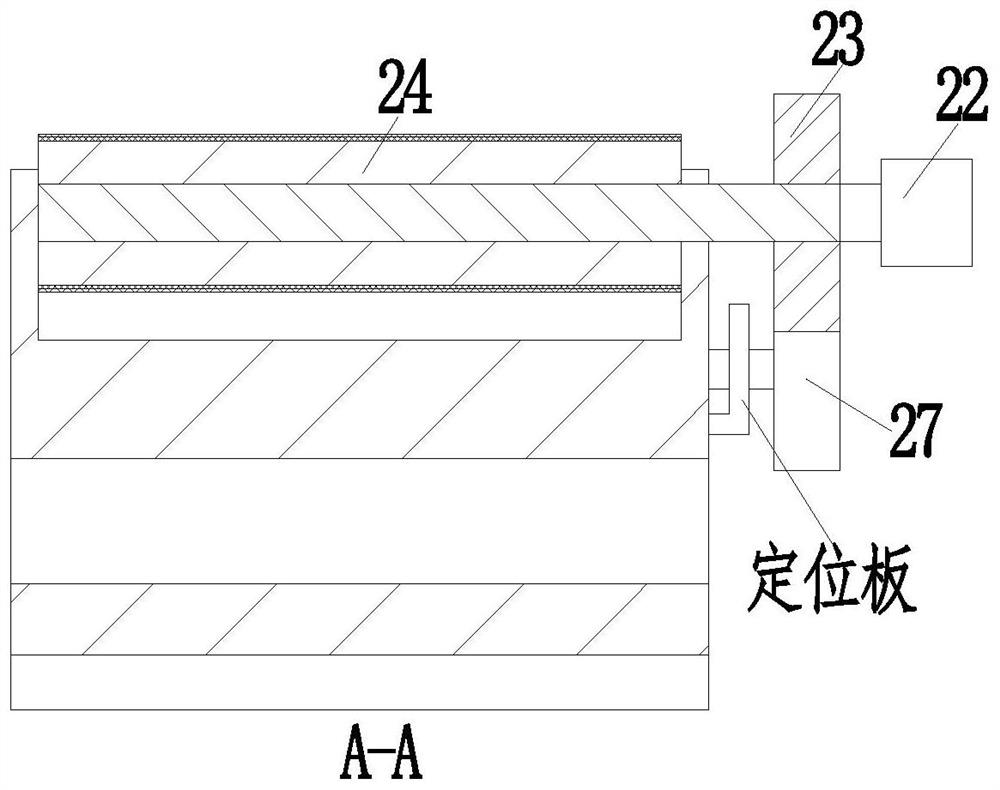

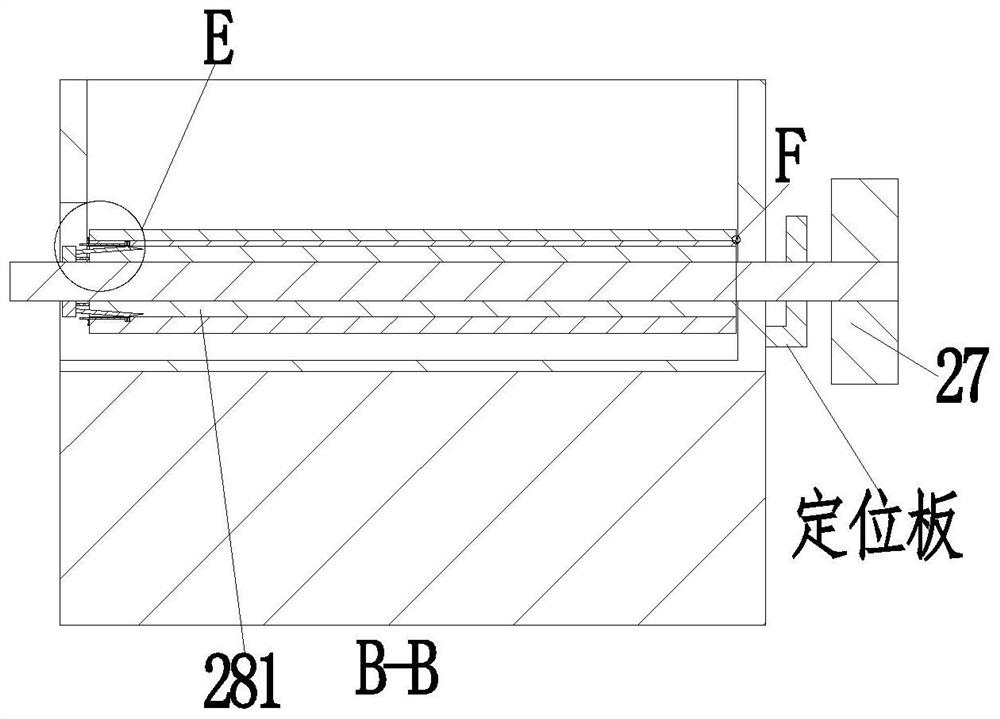

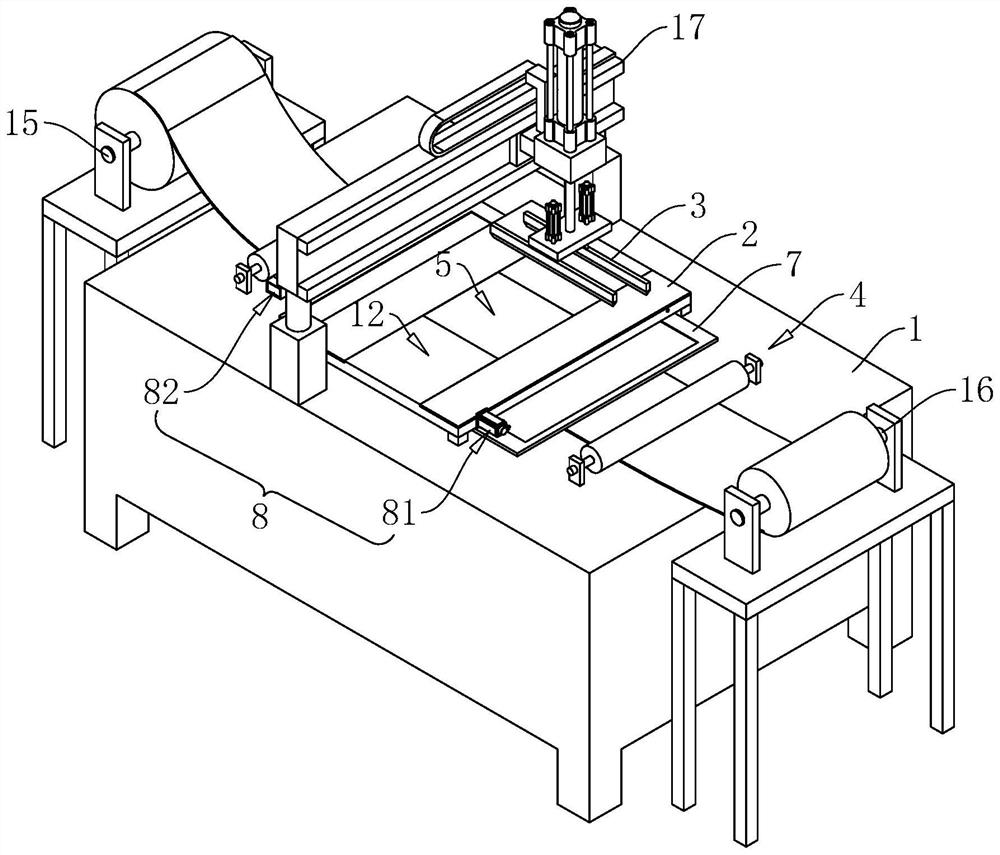

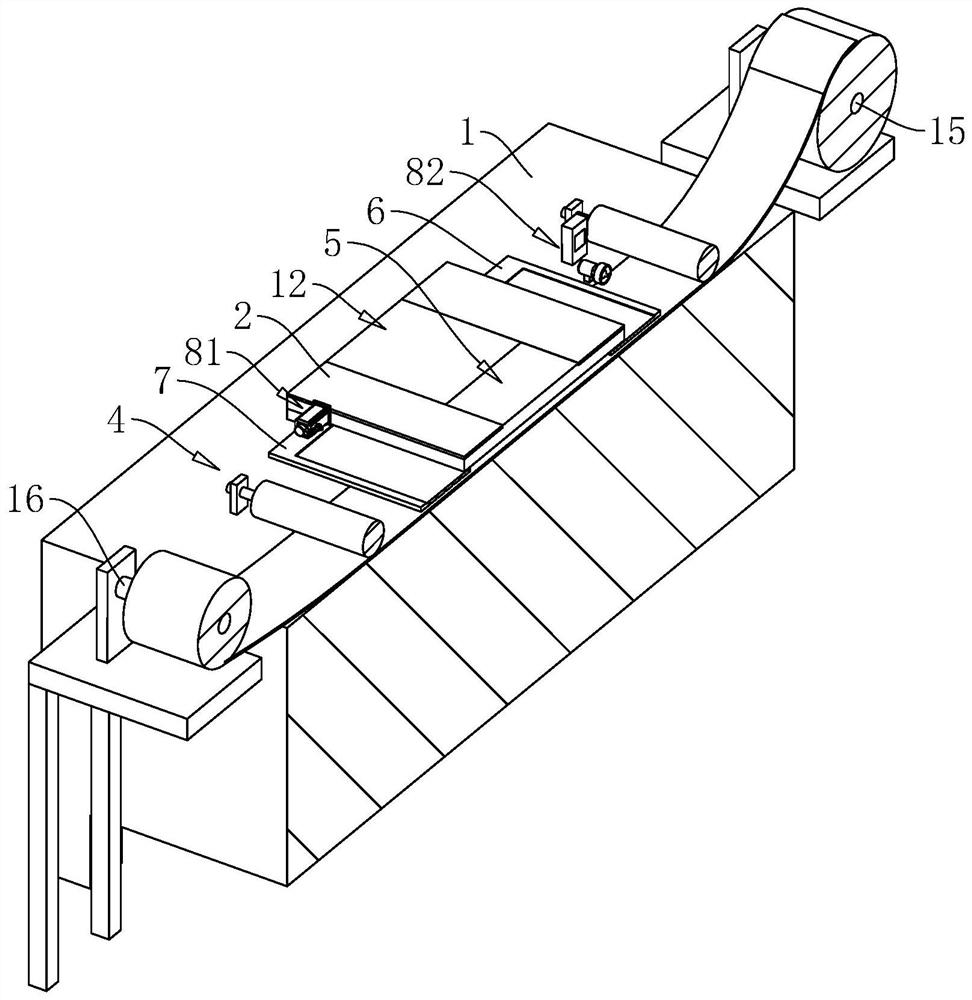

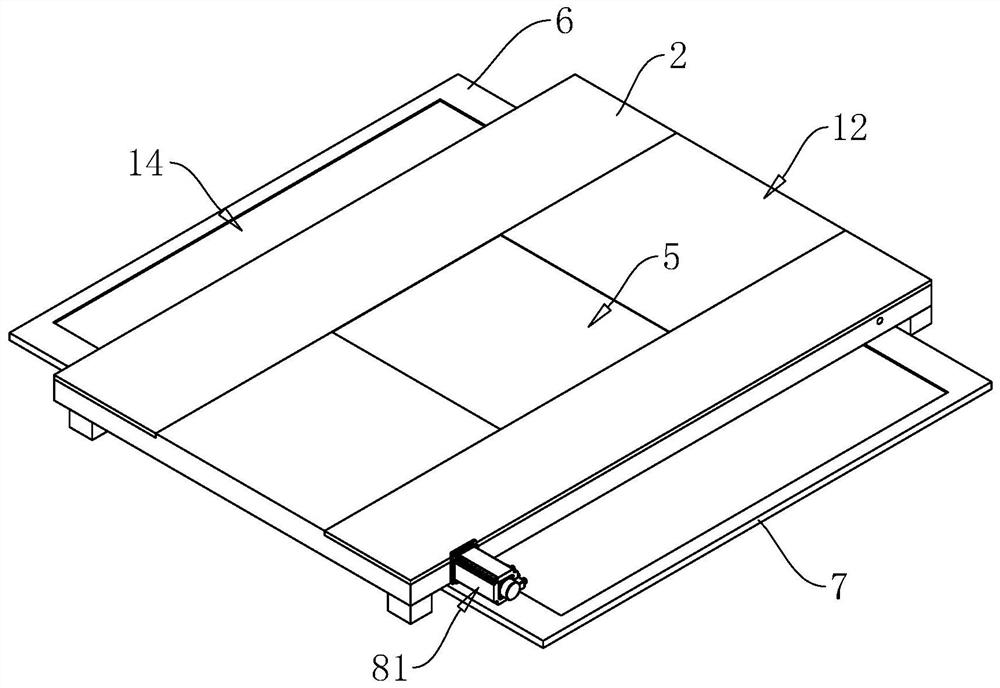

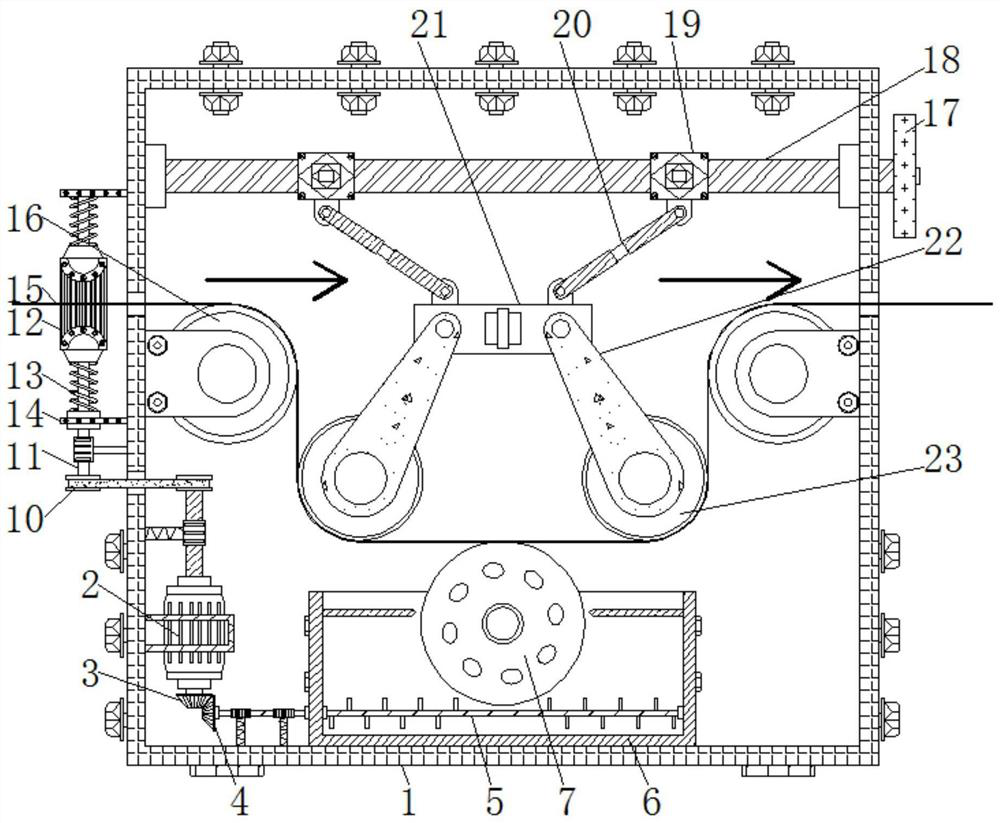

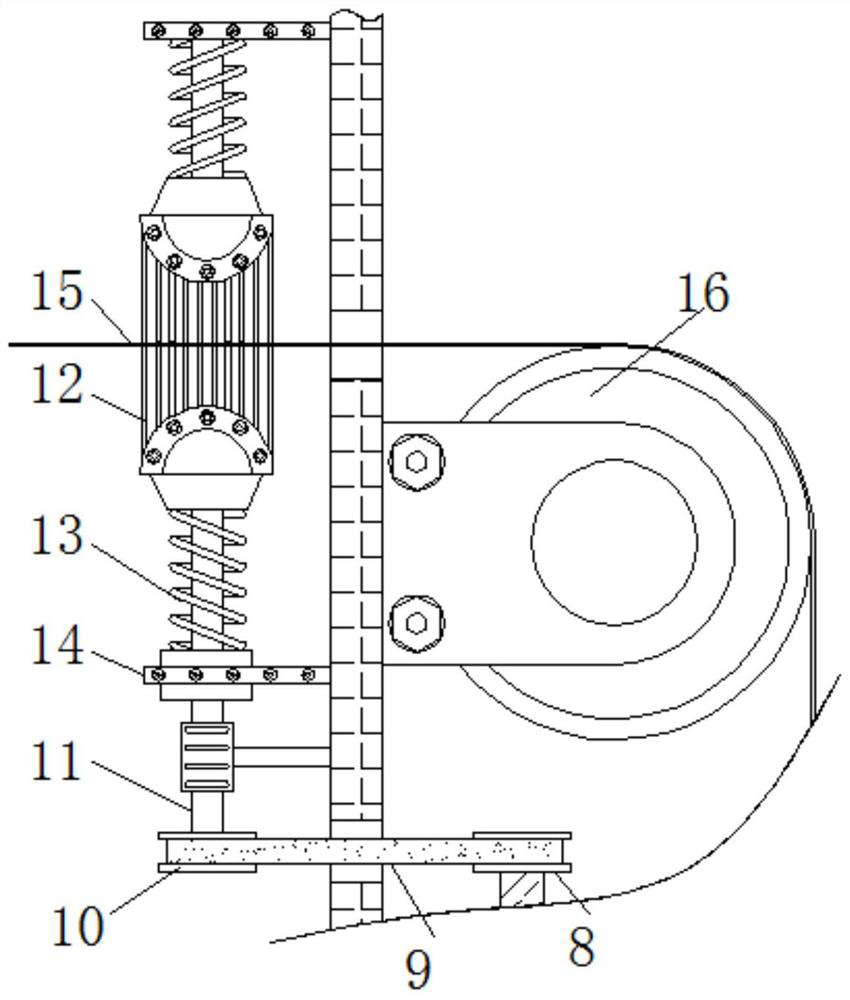

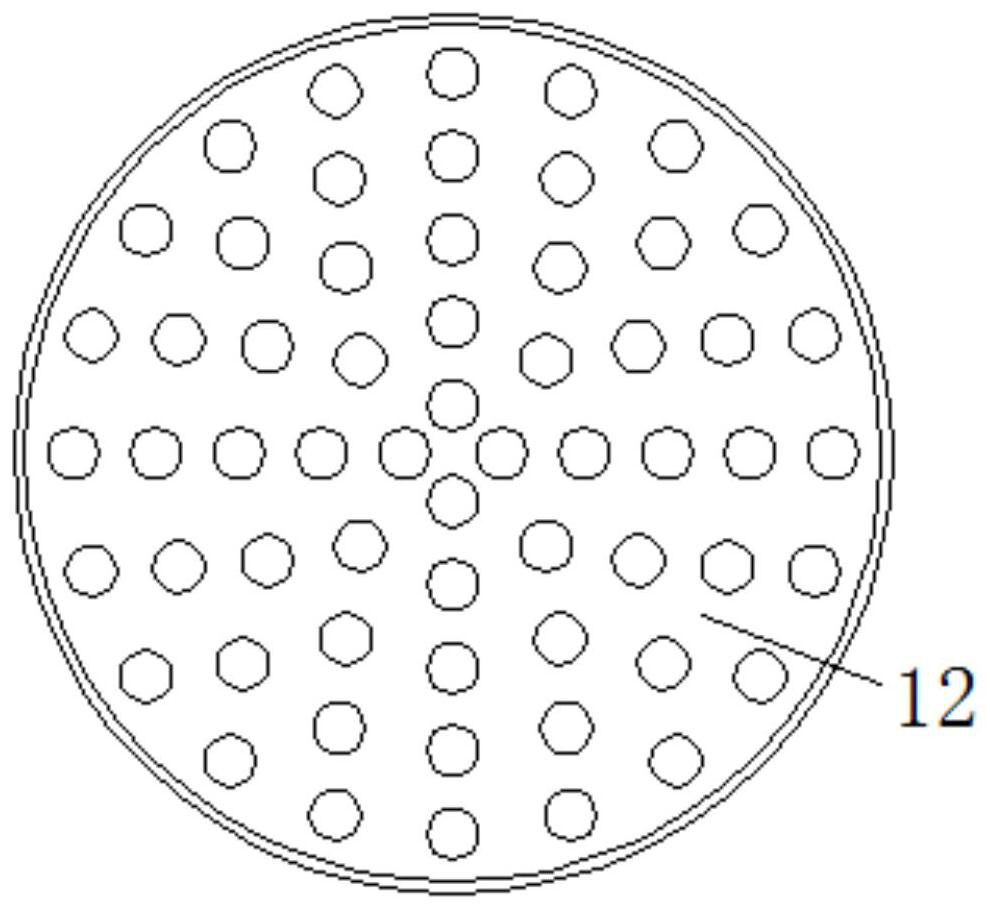

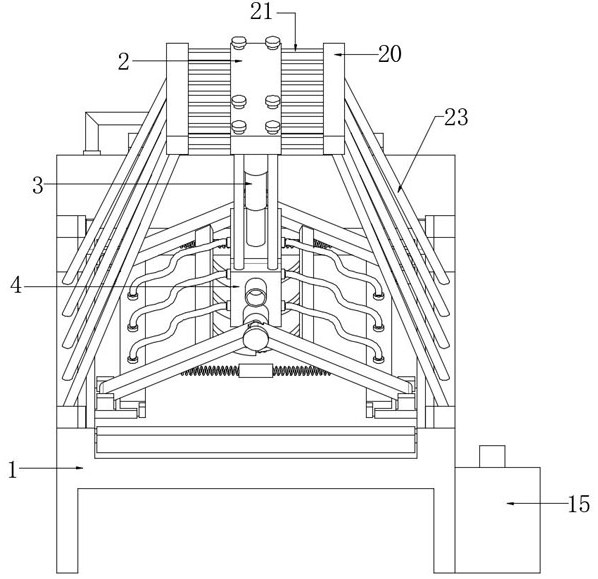

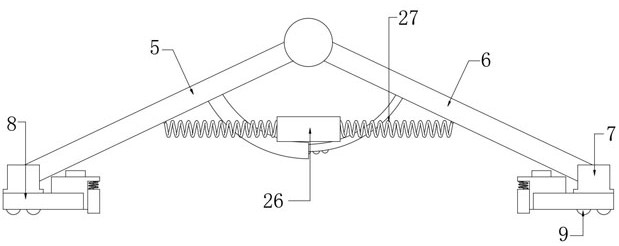

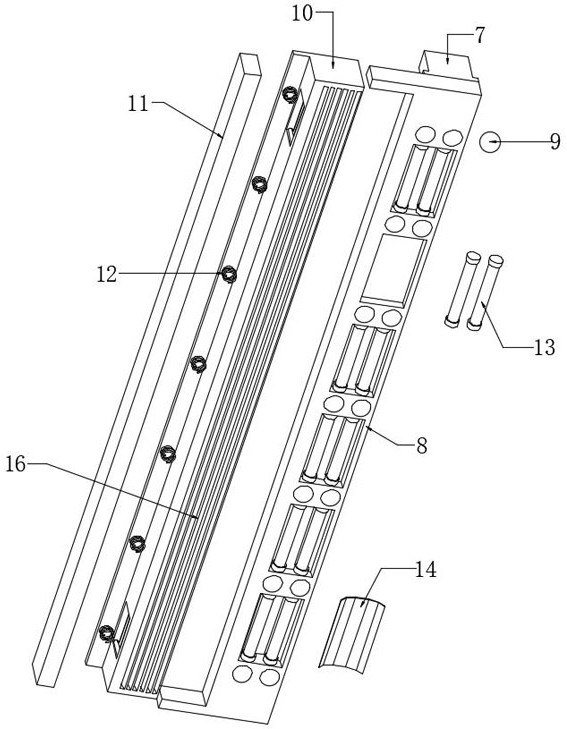

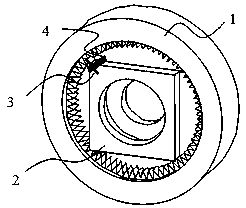

Silk screen printing plate, double-printing device, double-printing machine and double-printing process

ActiveCN104228321AAffect printing qualityGuaranteed printing qualityScreen printersScreen printingEngineering

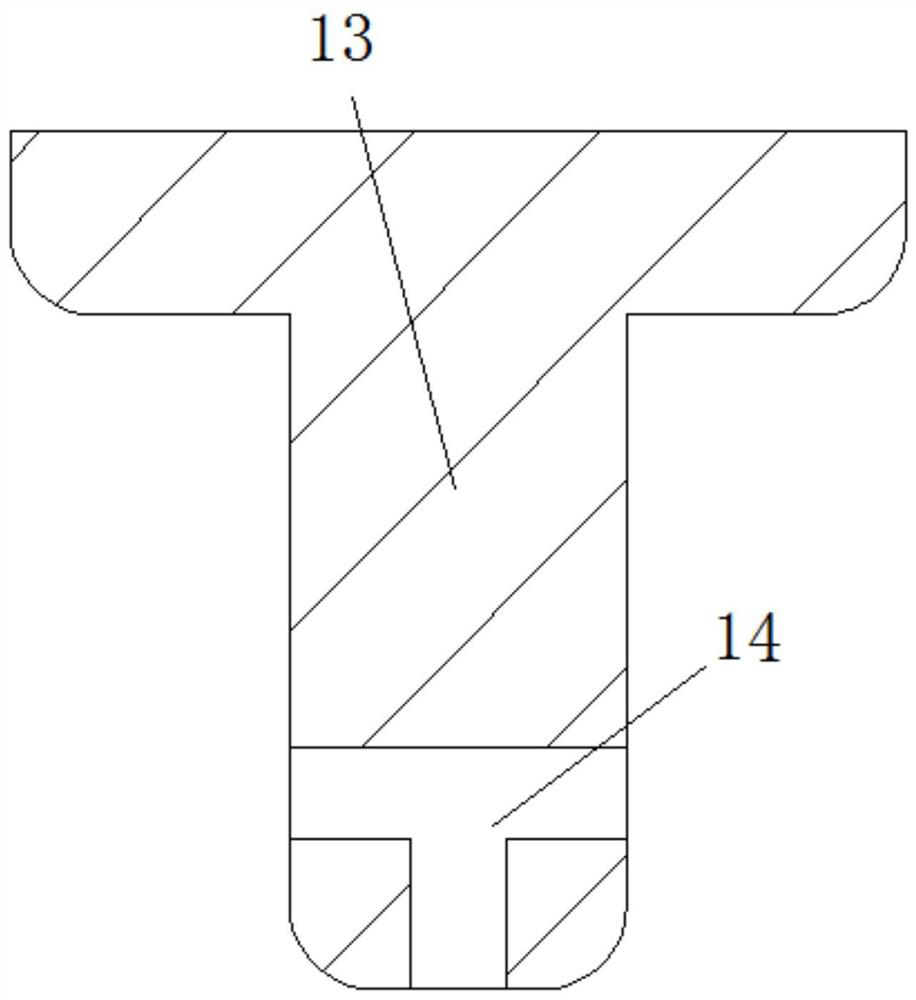

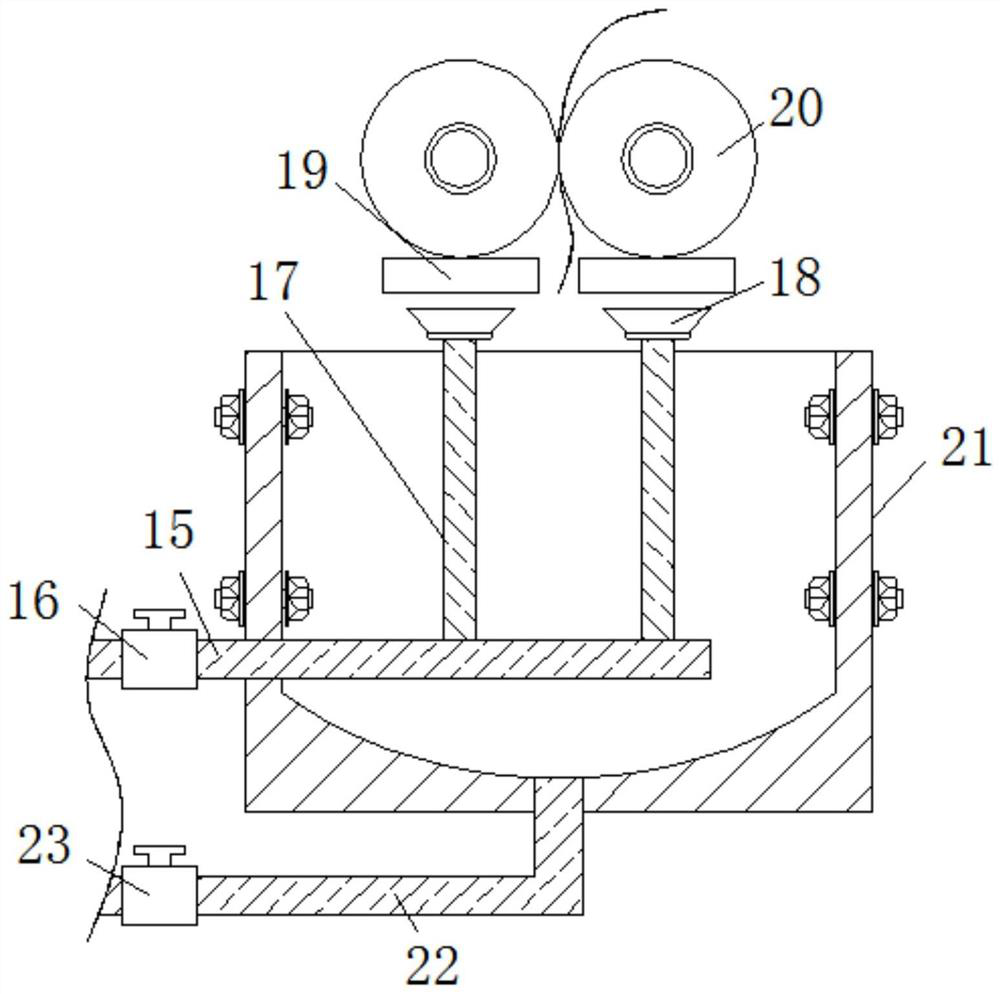

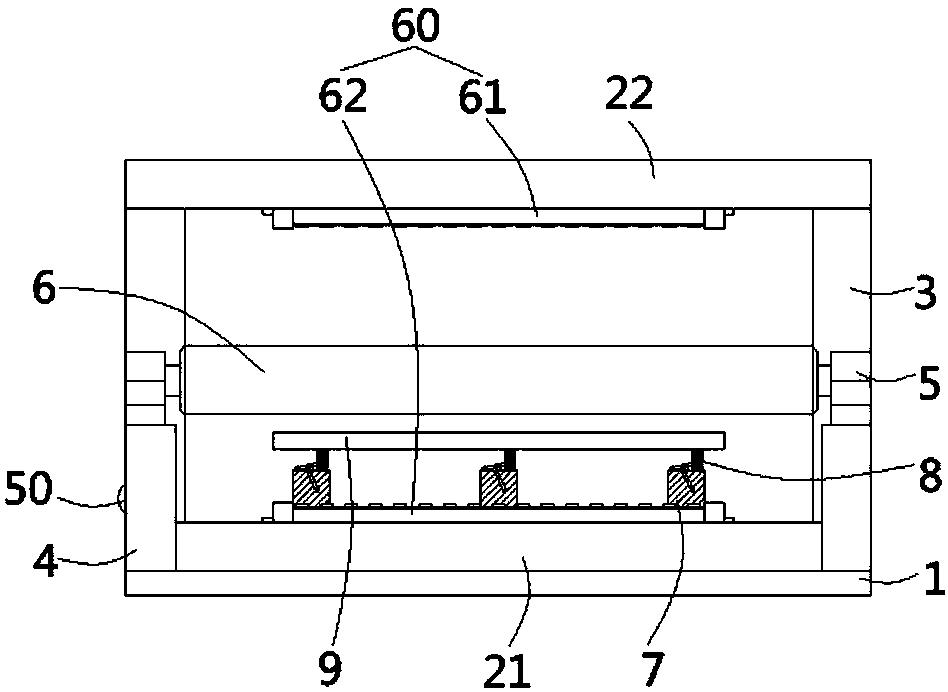

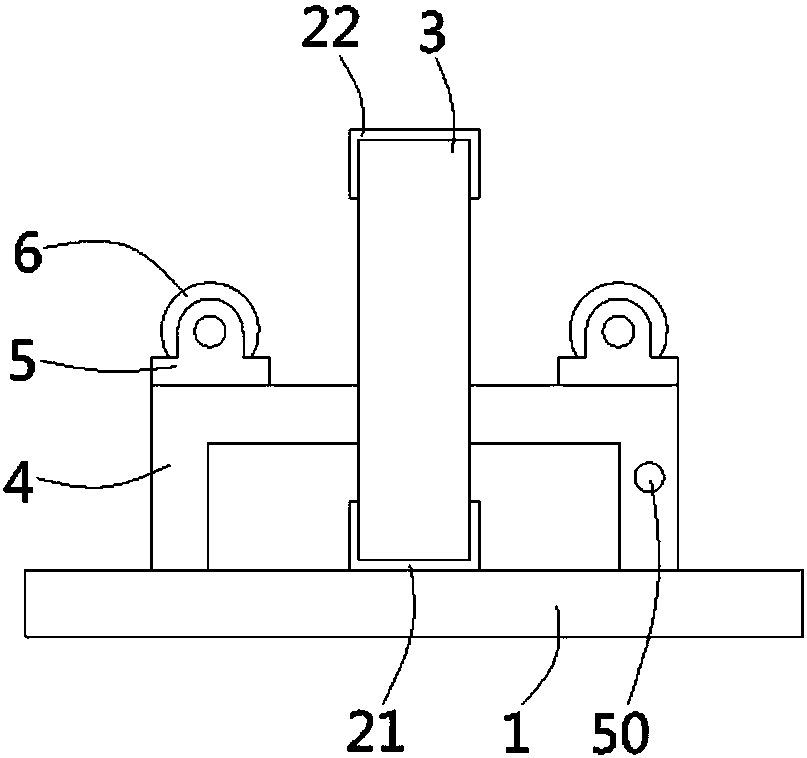

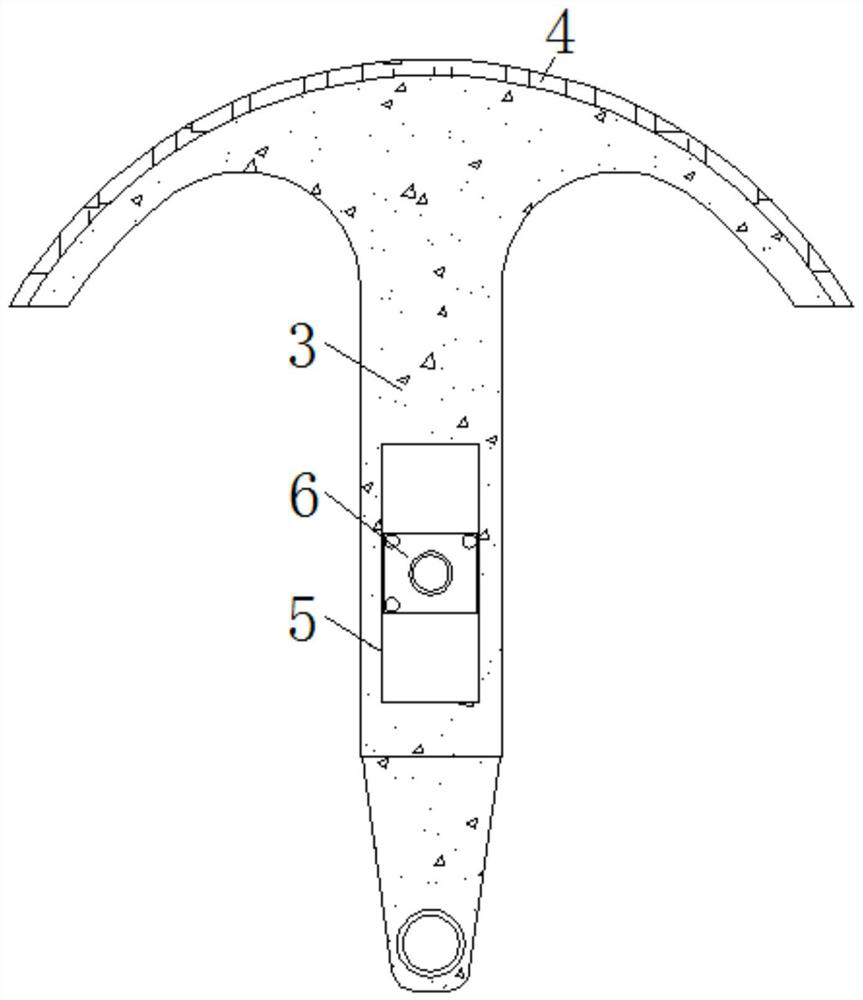

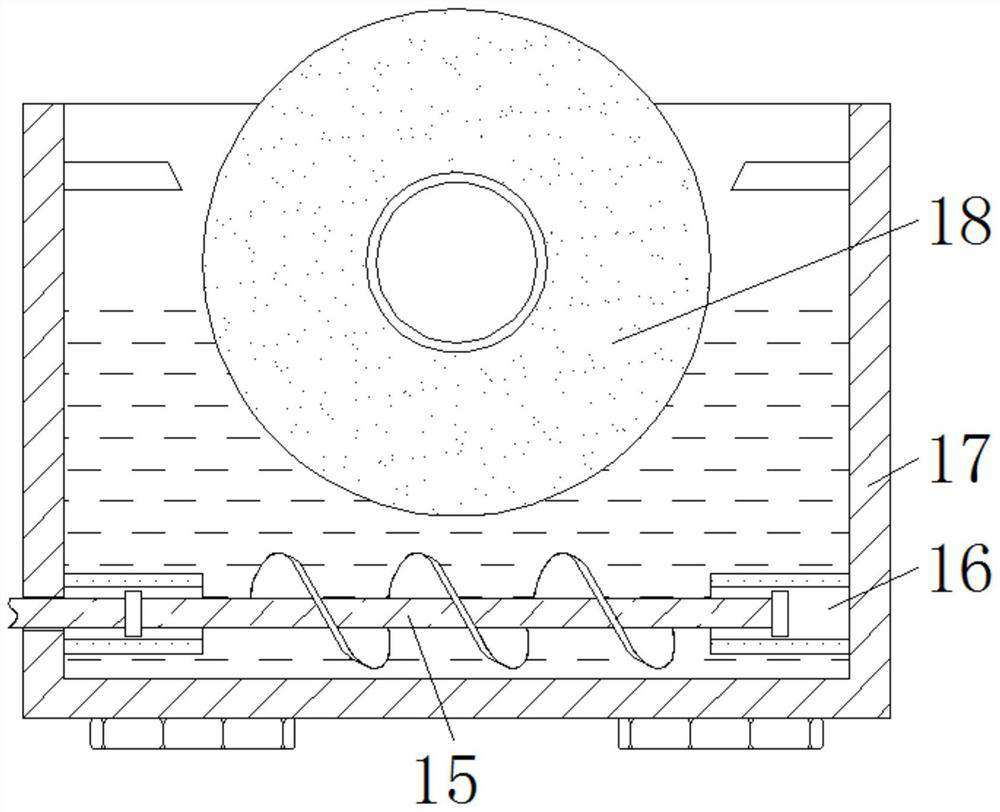

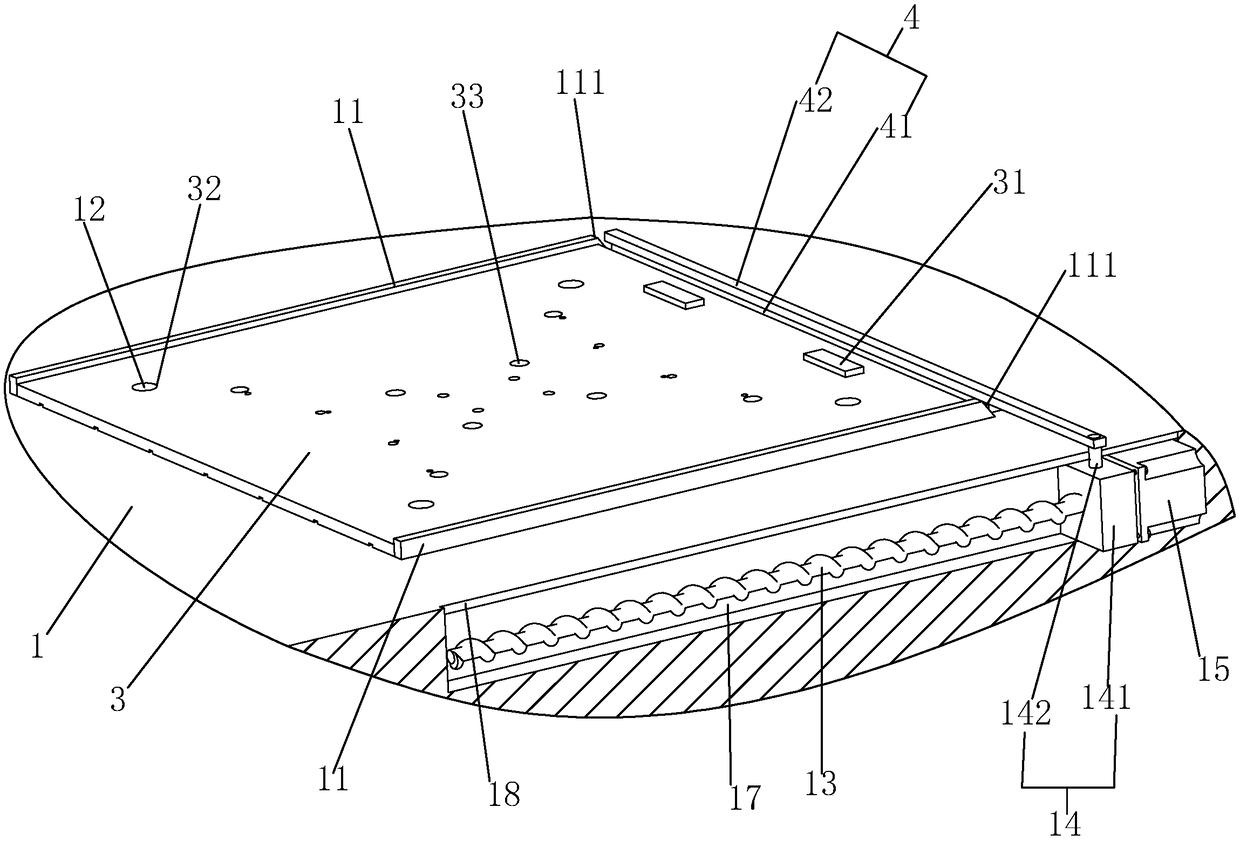

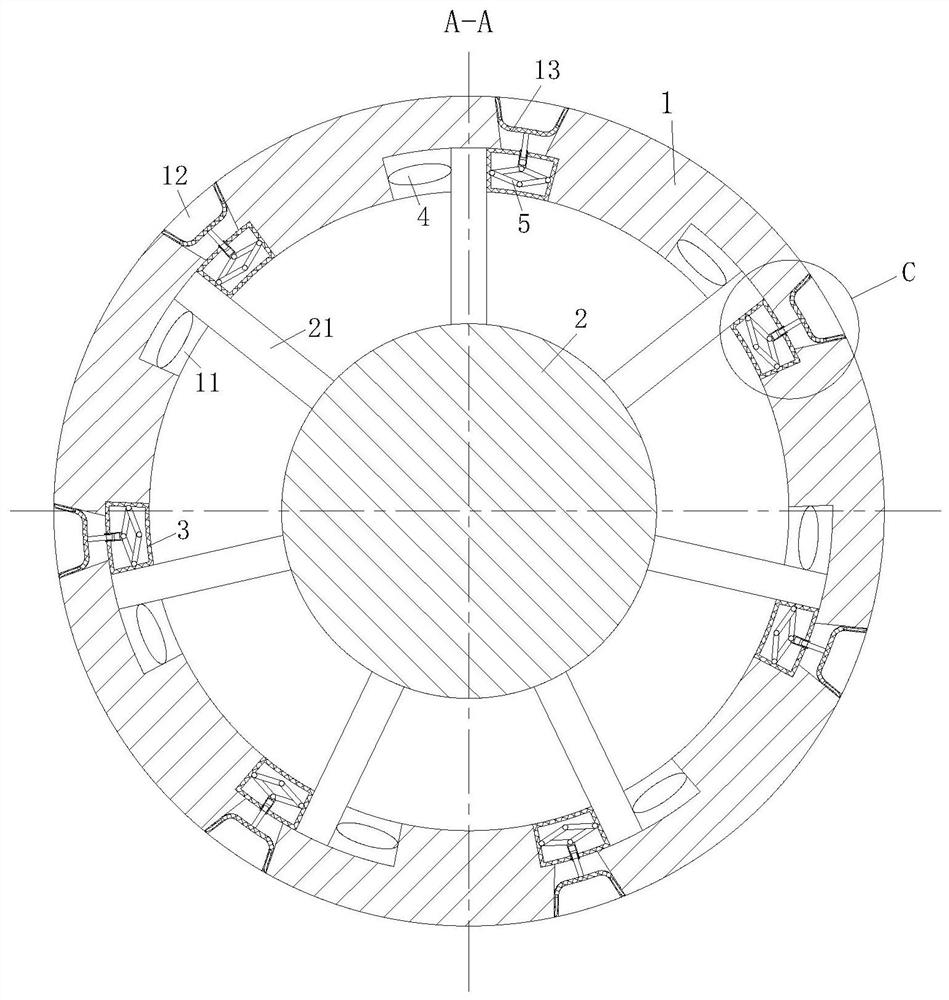

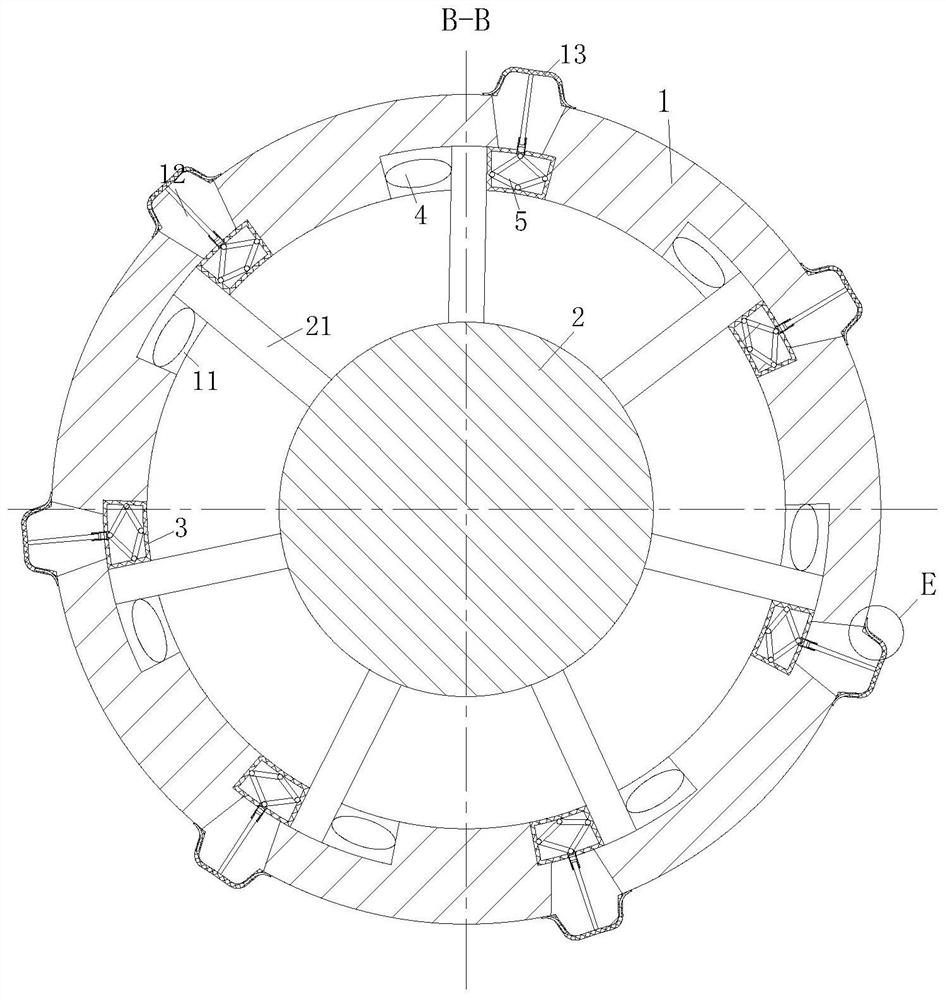

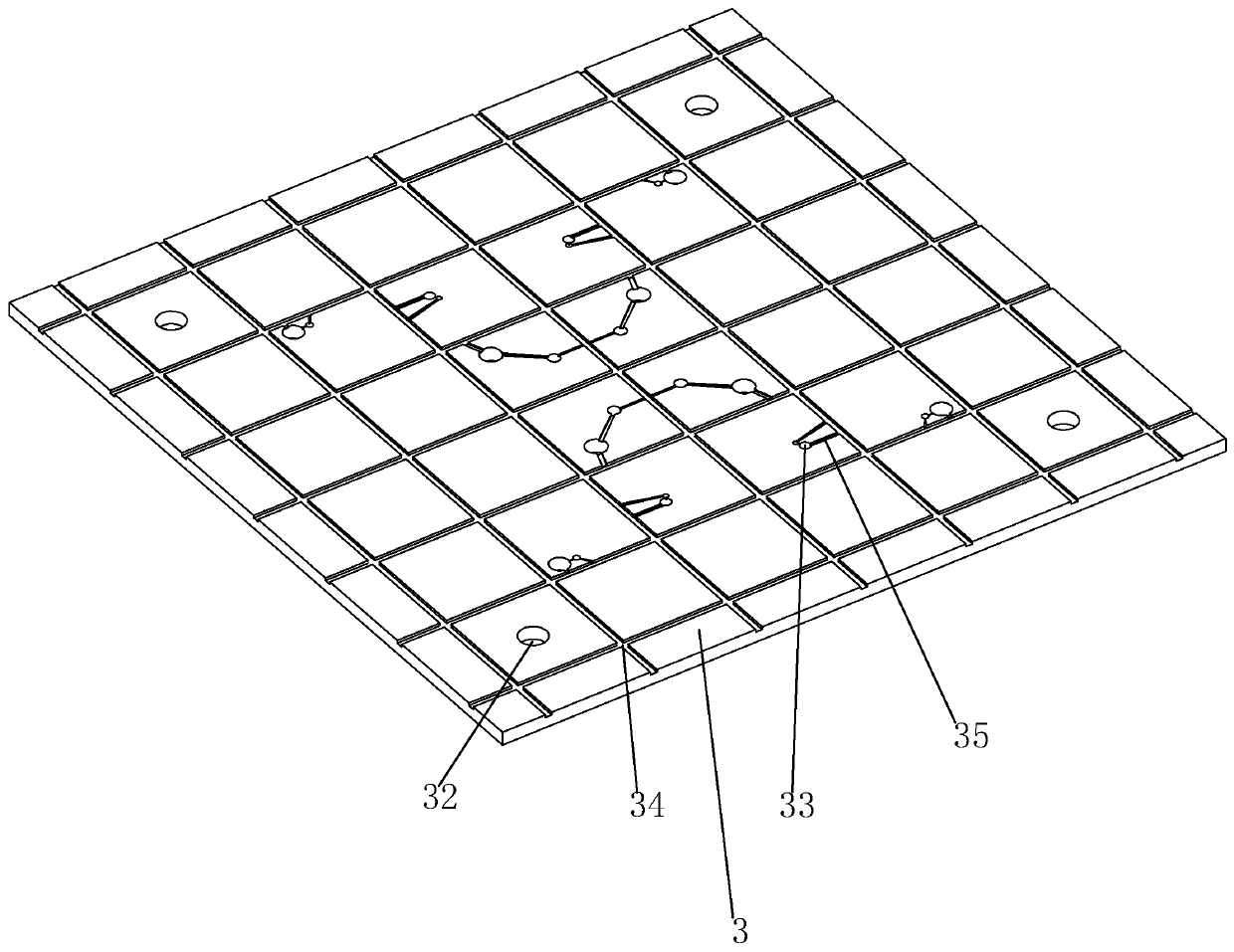

The invention provides a silk screen printing plate. A screen frame comprises an inner screen frame, a middle screen frame and an outer screen frame. A sliding groove is formed in the middle screen frame. A sliding rail matched with the inner screen frame is formed on the inner screen frame. The middle screen frame is provided with a blocking frame. A plurality of springs are evenly distributed between the inner screen frame and the blocking frame. An adjusting bolt is arranged on the outer screen frame in a matched mode. A silk screen is provided with an adjusting aligning point. An adjusting aligning scale is arranged on the outer screen frame. Accordingly, by means of the silk screen printing plate, silk screen patterns can be adjusted and aligned effectively, high-quality double-printing is achieved, obvious deformation of the silk screen can be avoided effectively, and the printing quality of the silk screen patterns is guaranteed. The invention further provides a double-printing device, the double-station double-printing operation can be achieved, the silk screen printing plate is excellent in effect, and the double-printing efficiency and quality are improved remarkably. The invention further provides a double-printing machine which has the excellent effects of the silk screen printing plate and the double-printing device, and the double-printing efficiency and quality are improved remarkably. The invention further provides a double-printing process. The process is concise and clear and high in double-printing efficiency and quality.

Owner:SHISHI DECAI CHEM TECH

PVC (Poly Vinyl Chloride) thermal contraction printing film

The invention discloses a PVC (Poly Vinyl Chloride) thermal contraction printing film, which is characterized in that 0.8-1.2 parts by weight of cation quaternary ammonium salt or nonionic esters antistatic agent are added into components; the added antistatic agent is firstly coupled and processed by coupling agent adaptive to the antistatic agent; in the film preparation process, the cation quaternary ammonium salt or a nonionic esters antistatic agent solution layer are applied to the surface of the film; and therefore the surface resistivity of the film is 108-1010 omega. Two different applied antistatic agents are applied to successively perform action. On the premise that other performances of the PVC thermal contraction printing film are guaranteed to be substantially unchanged, static charges in the production process are effectively prevented or eliminated from generating and accumulating, and the shortage brought by the static charges is avoided, and pollution on printing because the antistatic agent is excessively separated out can be avoided.

Owner:YIXING GUANGHUI PACKAGE

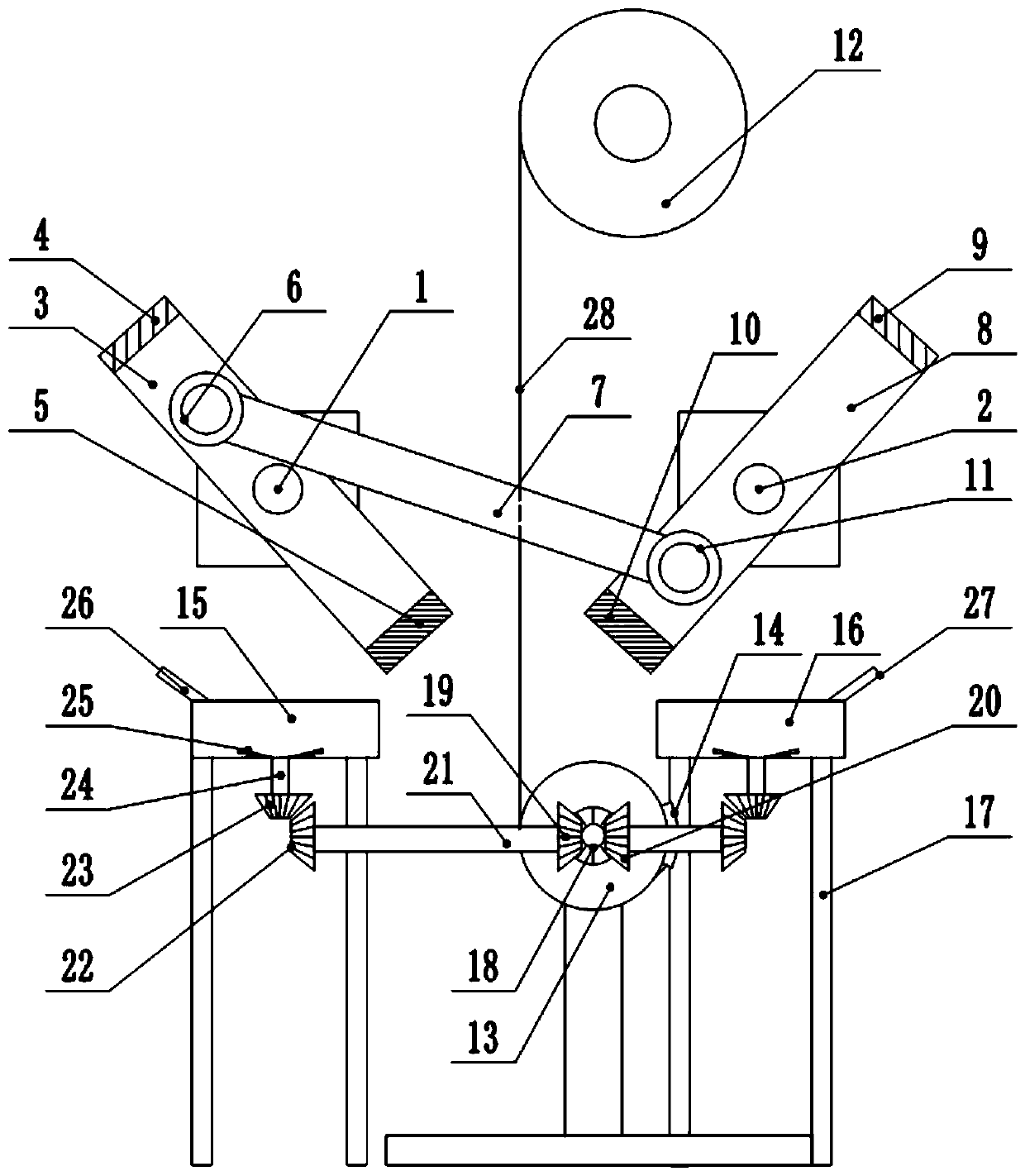

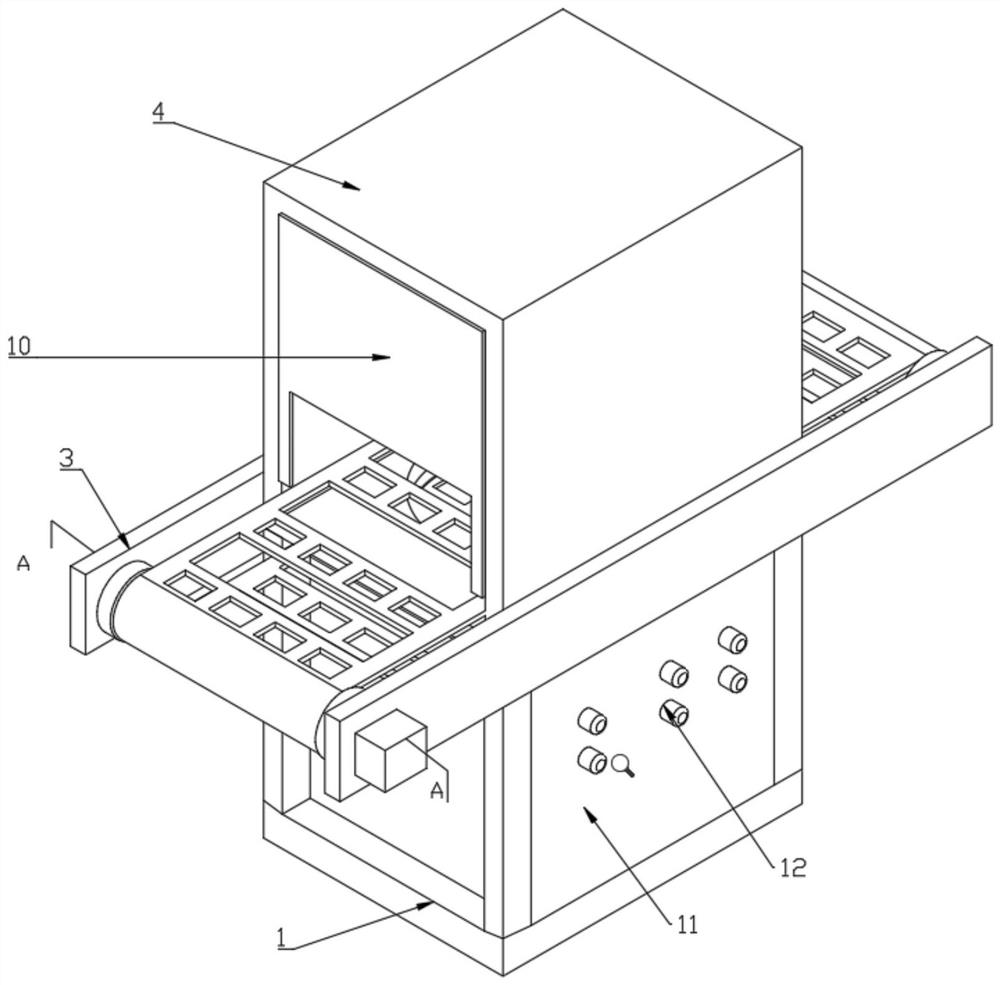

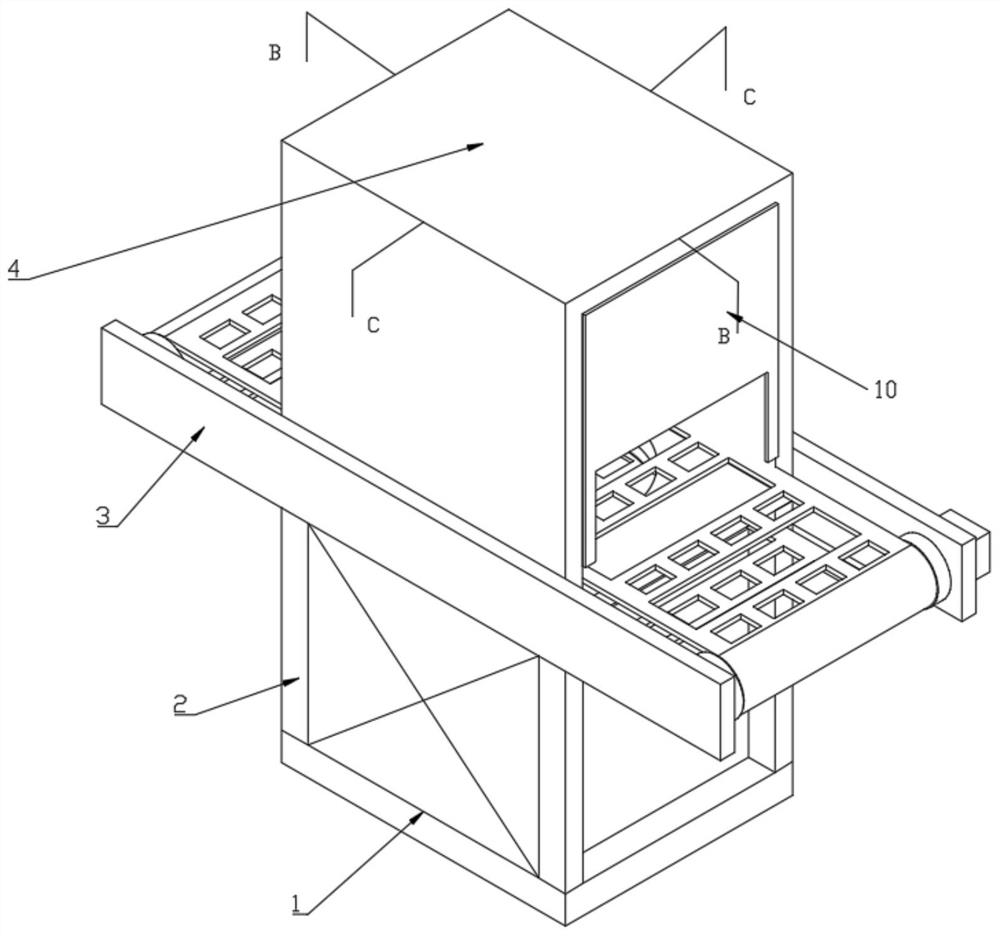

Special printer

InactiveCN108116036ASimple structureLow production costRotary pressesPrinting press partsOrienteeringEngineering

The invention provides a special printer, and relates to the technical field of a printing technical device. The special printer comprises a loading roller and a collecting roller; the collecting roller is connected with a first motor; a printing device, a magnetic orienteering device, and a curing device are further arranged between the loading device and the collecting roller; the printing device comprises an ink applying roller, the upper part of the ink applying roller is provided with a printing roller; the magnetic orienteering device comprises a magnetic orienteering mother set, both sides of the magnetic orienteering mother set are provided with magnetic shield plates; lower ends of the magnetic shield plates are inclined towards the magnetic orienteering mother set. The special printer has the beneficial effects of being simple in structure and low in manufacturing cost; the special printer can satisfy the development demand of high-speed printing at present and is good for popularization and promotion.

Owner:佛山市高明金盾恒业电脑特种印刷有限公司

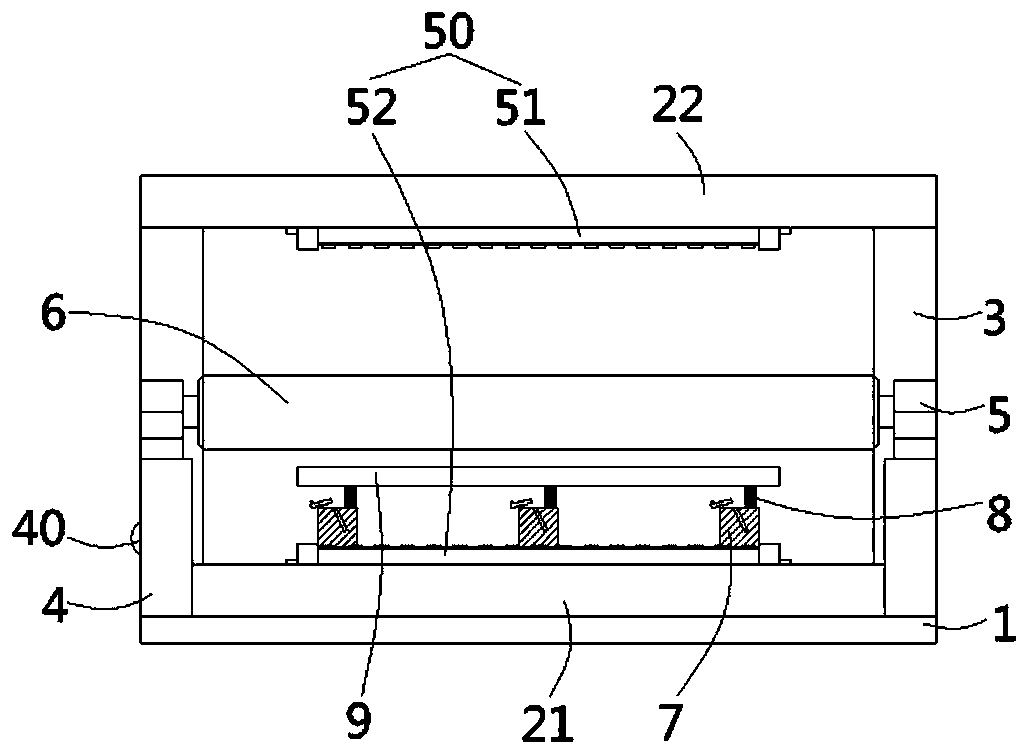

Cloth printing device

ActiveCN108297539AMeet the requirements of double-sided printingFast dryingRotary pressesPrinting press partsEngineeringElectrical and Electronics engineering

Owner:NINGBO WENZE TEXTILE CO LTD

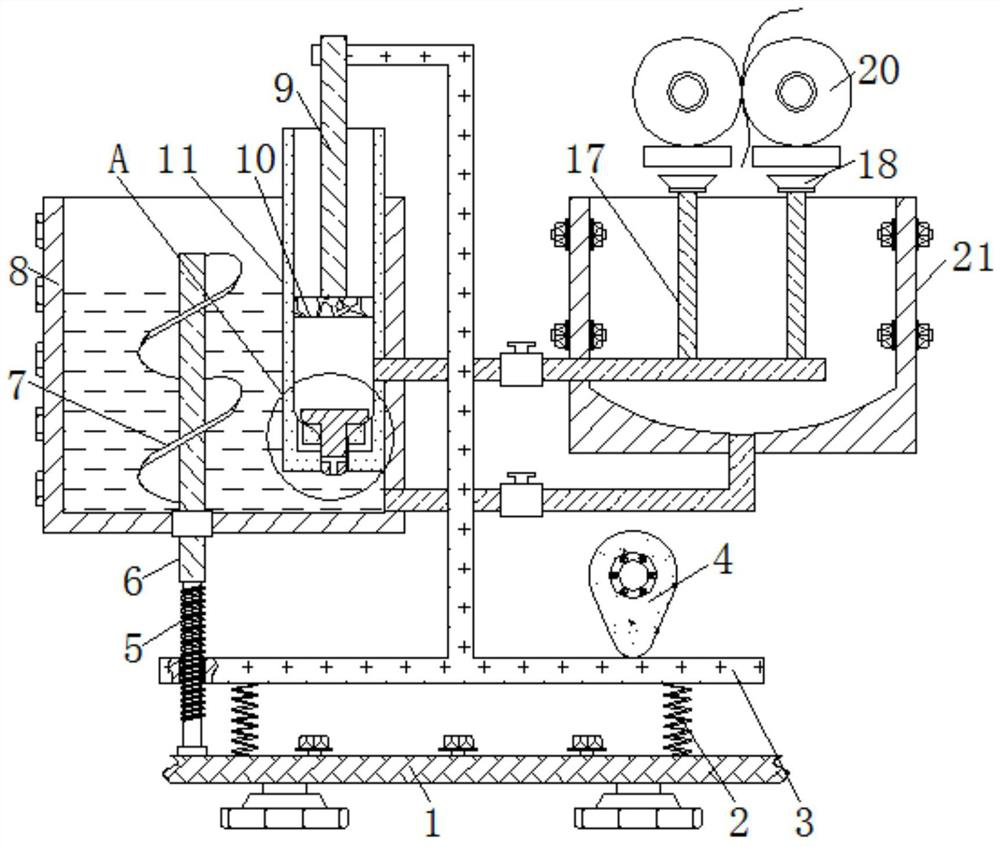

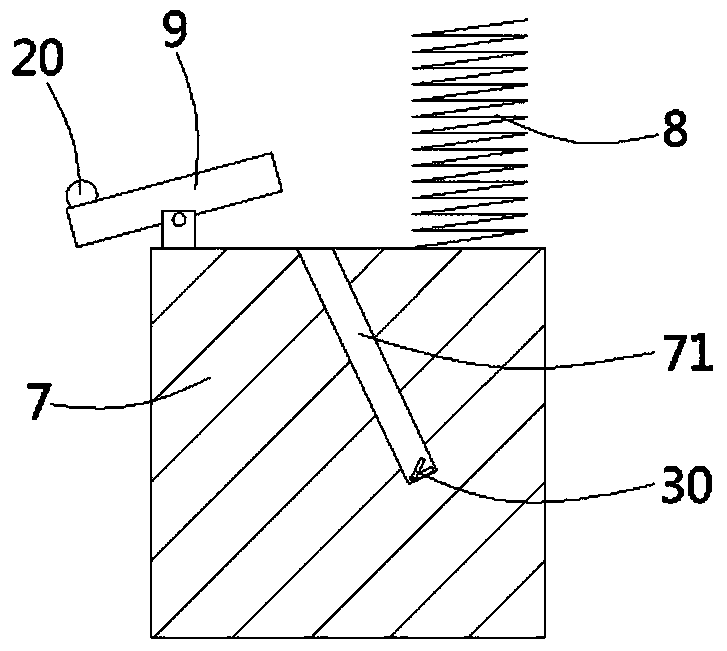

Energy-saving printing device capable of preventing printing quality from being influenced by ink splashing

InactiveCN112918105AAffect printing qualityAvoid compromising print qualityInking apparatusPrinting press partsEngineeringMechanical engineering

The invention relates to the technical field of printing, and discloses an energy-saving printing device capable of preventing printing quality from being influenced by ink splashing. The energy-saving printing device comprises a supporting plate, wherein a compression spring is fixedly connected to the top of the supporting plate, a movable rod is fixedly connected to the side, away from the supporting plate, of the compression spring, an eccentric cam is movably connected to the top of the right side of the movable rod, a screw rod is in threaded connection with the interior of the left side of the movable rod, and a stirring rod is fixedly connected to the top of the screw rod. According to the energy-saving printing device capable of preventing the printing quality from being influenced by ink splashing, during printing, the movable rod can periodically move up and down under the action of the eccentric cam and the compression spring, an impeller is further made to periodically rotate forwards and backwards in an ink pool, and therefore the effect of preventing the printing quality from being influenced by ink precipitation is achieved. The movable rod drives a piston rod to periodically move up and down, and ink in a piston cylinder can be periodically sprayed to a sponge block, so that the effect of avoiding ink waste caused by ink splashing is achieved.

Owner:王川

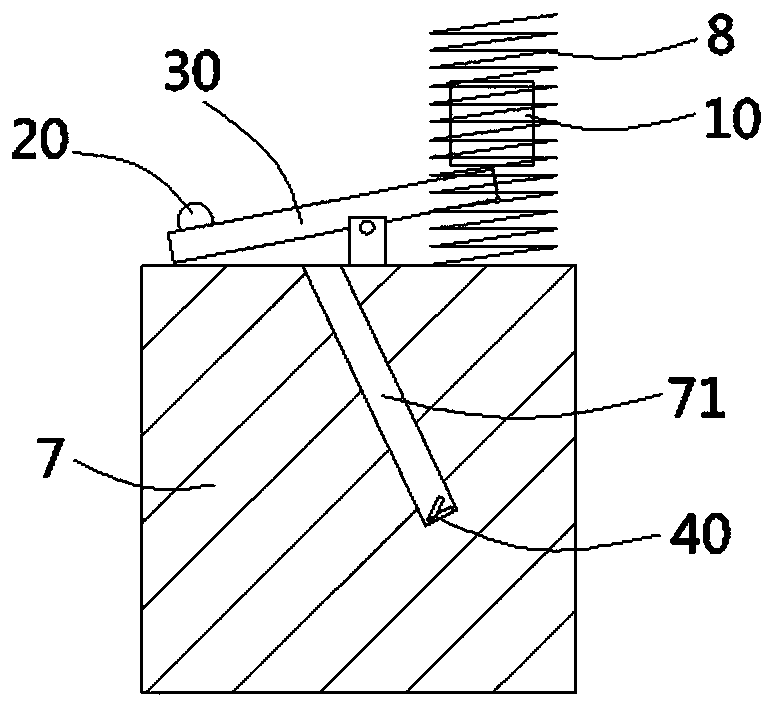

Steel band detection device on color steel plate production line

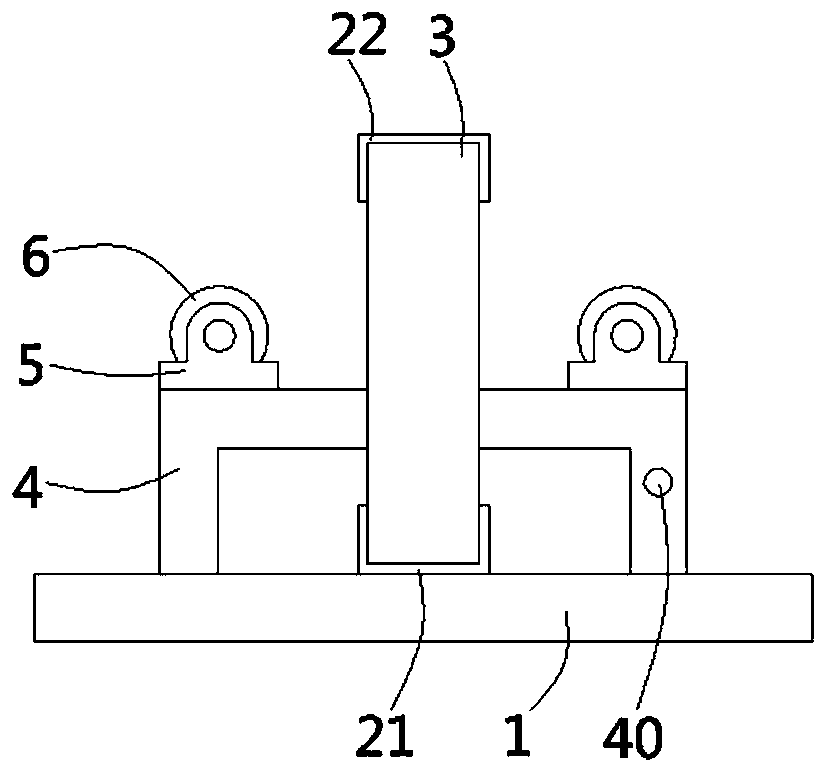

ActiveCN108345043AAffect printing qualitySlack detection is fastConveyorsOptical detectionProduction lineArchitectural engineering

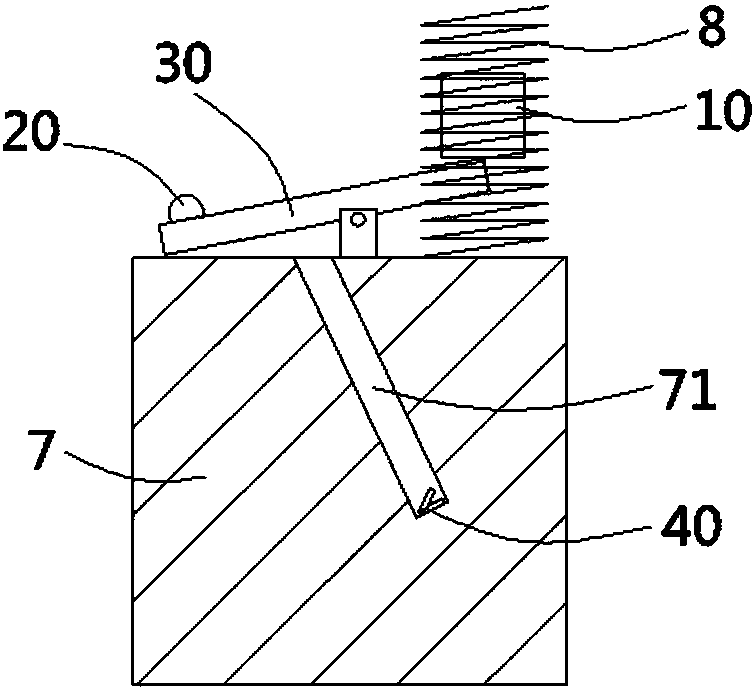

The invention discloses a steel band detection device on a color steel plate production line. The device comprises a bottom plate. The central section of the bottom plate is fixedly provided with lower groove steel. The two ends of the lower groove steel are fixedly provided with support columns. The upper end of each support column is fixed to upper groove steel. The central section of the lowergroove steel is fixedly provided with a support seat. A groove channel forms on the upper end surface of the support seat. A pressure spring is arranged on the upper end surface of the support seat ofone side of the groove channel. The two ends of the pressure spring abut against the support seat and a transverse detection plate. The middle inner wall of the pressure spring is fixedly provided with a pressing plate. The high end of a seesaw is located right below the pressing plate and a rolling ball is placed on the low end of the seesaw. The seesaw crosses over the upper portion of the groove channel and a bottom is hinged to the support seat. A guide groove and a through hole which are connected form on the seesaw. The through hole is located right above the groove channel. A switch isarranged in the groove channel. The side wall of the support seat is provided with an alarm lamp. The alarm lamp and the switch are electrically connected in a parallel mode. In the invention, whether a steel band exists in a conveyor line can be detected, and simultaneously, whether the steel band is loosened during a conveying process can be detected too.

Owner:杭州普络飞新材料科技有限公司

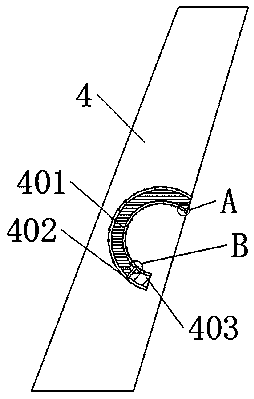

Transmission shaft

The invention belongs to the technical field of shafts, and particularly relates to a transmission shaft. An outer shaft and an inner shaft are included. The interior of the outer shaft is of a cavitystructure, and the inner shaft is inserted and connected in the outer shaft. Rotation grooves are evenly formed in the inner cavity wall of the outer shaft, rotation plates are evenly arranged on theouter wall of the inner shaft, the rotation plates are rotationally inserted and connected in the rotation grooves, one sides of the rotation plates are connected to the side walls of the rotation grooves through elastic seal bags, and the other side faces of the rotation plates are connected to the other side walls of the rotation grooves through air bags. The outer shaft is evenly provided witha set of gas blowing ports, and the gas blowing ports are located above the elastic seal bags. When the outer shaft continuously rotates due to inertia, the rotation plates can extrude the elastic seal bags, meanwhile, gas generated by the elastic seal bags is controlled to be blown out of the gas blowing ports, accordingly, printing materials left on an outer shaft outer ring after printing product printing are cleaned, the situation that when the transmission shaft is used for printing a printing product in the later period, the printing quality of the printing product is influenced is avoided, and accordingly, the practicability of the transmission shaft is improved.

Owner:欧伯朗精工(江苏)有限公司

Printing device capable of preventing excessive ink from causing contamination and affecting printing quality

InactiveCN112918104AAffect printing qualityImprove printing qualityInking apparatusPrinting press partsProcess engineeringMechanical engineering

The invention relates to the technical field of printing, and discloses a printing device capable of preventing excessive ink from causing contamination and affecting printing quality. The printing device comprises an ink fountain, wherein an ink coating roller is movably connected to the right side in the ink fountain; an ink storage box is welded to the top of the ink fountain; a funnel groove is welded to the bottom of the ink storage box; and a hole blocking ball is movably connected to the interior of the funnel groove. According to the printing device capable of preventing the excessive ink from causing contamination and affecting the printing quality, when the ink is insufficient, the ink in the ink storage box can enter the ink fountain at the moment, when the ink is sufficient, ink adding can be automatically stopped, and therefore the effect that the usage amount of the ink is strictly controlled, and the printing quality is improved is achieved. When the ink amount is at the maximum value, ink adding is stopped, otherwise, when the ink content is normal, a swing rod can provide supporting force for a second sliding block at the moment, it is guaranteed that ink adding is started when the ink amount is at the minimum value, and therefore the effect that it is guaranteed that the ink content is within a reasonable range is achieved.

Owner:王剑

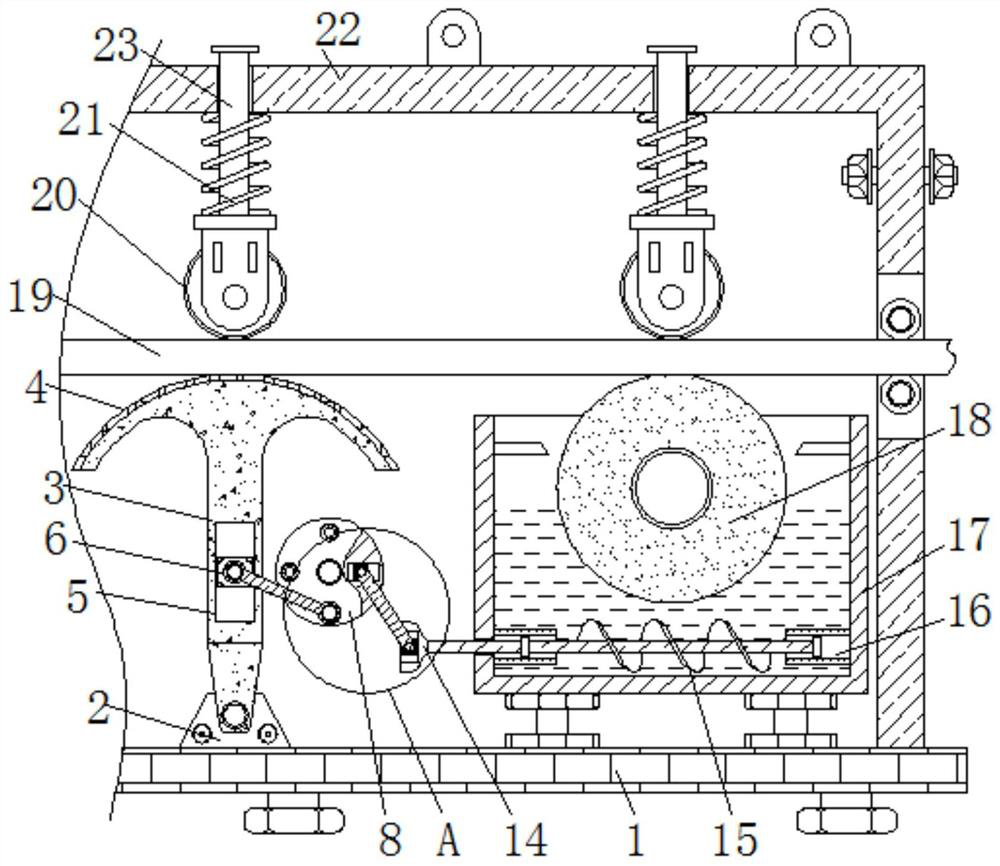

Intaglio printing device capable of preventing cloth from being contaminated with dust and preventing printing quality from being affected

InactiveCN113022122AAffect printing qualityRotary intaglio printing pressPrinting press partsEnvironmental engineeringMechanical engineering

The invention relates to the technical field of printing, and discloses an intaglio printing device capable of preventing cloth from being contaminated with dust and preventing printing quality from being affected. The intaglio printing device comprises a supporting table, a trapezoidal plate is welded to the top of the supporting table, an oscillating bar is riveted to the front face of the trapezoidal plate, an arc-shaped cleaning head is fixedly connected to the top of the oscillating bar, a first sliding groove is formed in the oscillating bar, a first sliding block is slidably connected in the first sliding groove, and a first connecting rod is riveted to the front face of the first sliding block. According to the intaglio printing device capable of preventing the cloth from being contaminated with dust and preventing printing quality from being affected, a driving rotary disc drives the first connecting rod to move, at the moment, the arc-shaped cleaning head can sweep the bottom of a cloth body left and right, and therefore the effect of preventing the cloth surface from being contaminated with dust and preventing the printing quality from being affected is achieved. The driving rotary disc drives a second connecting rod to rotate, at the moment, a stirring impeller can stir ink in an ink box, and therefore the effect of preventing ink precipitation from affecting the cloth printing quality is achieved.

Owner:张小琴

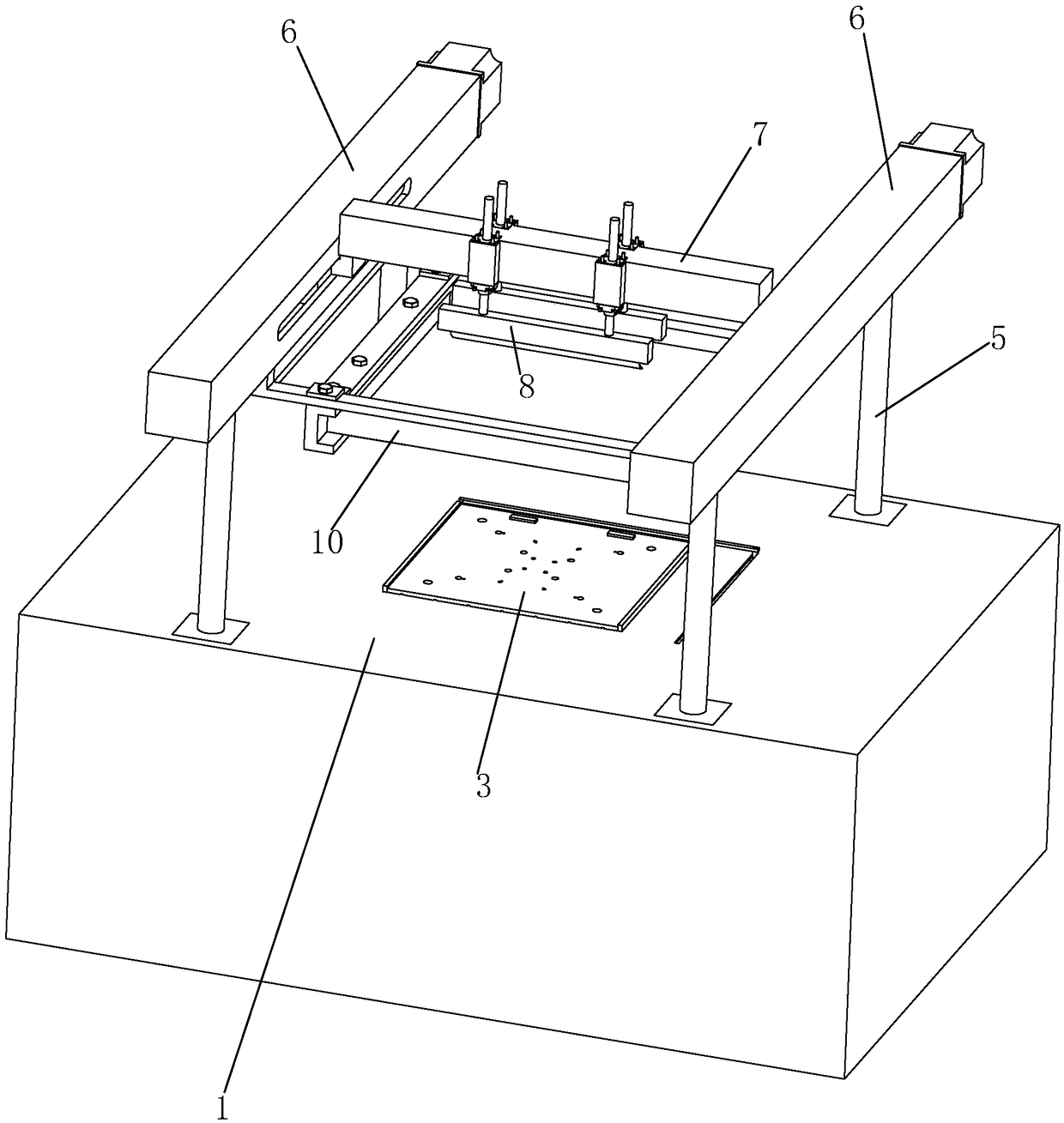

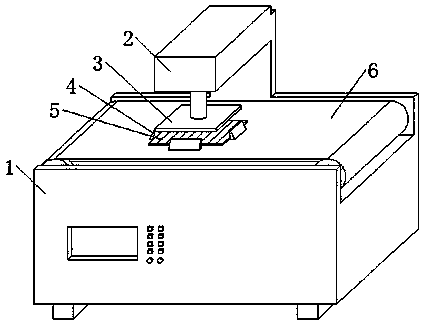

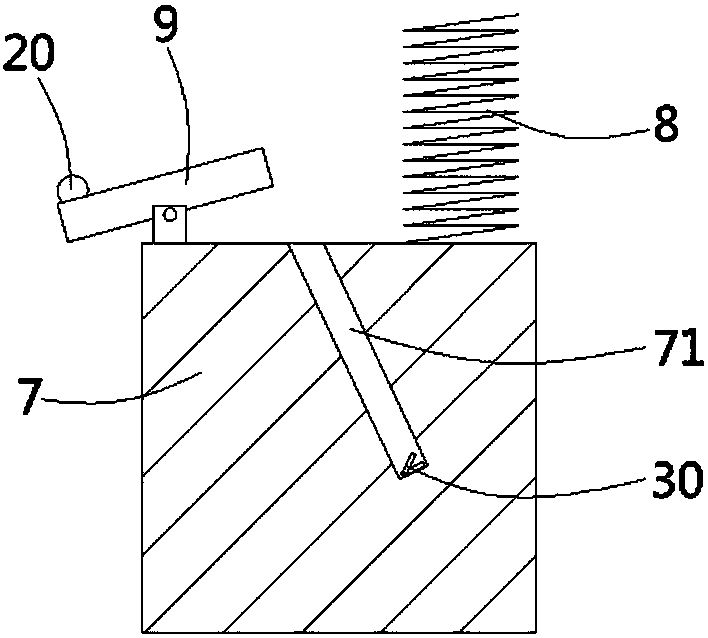

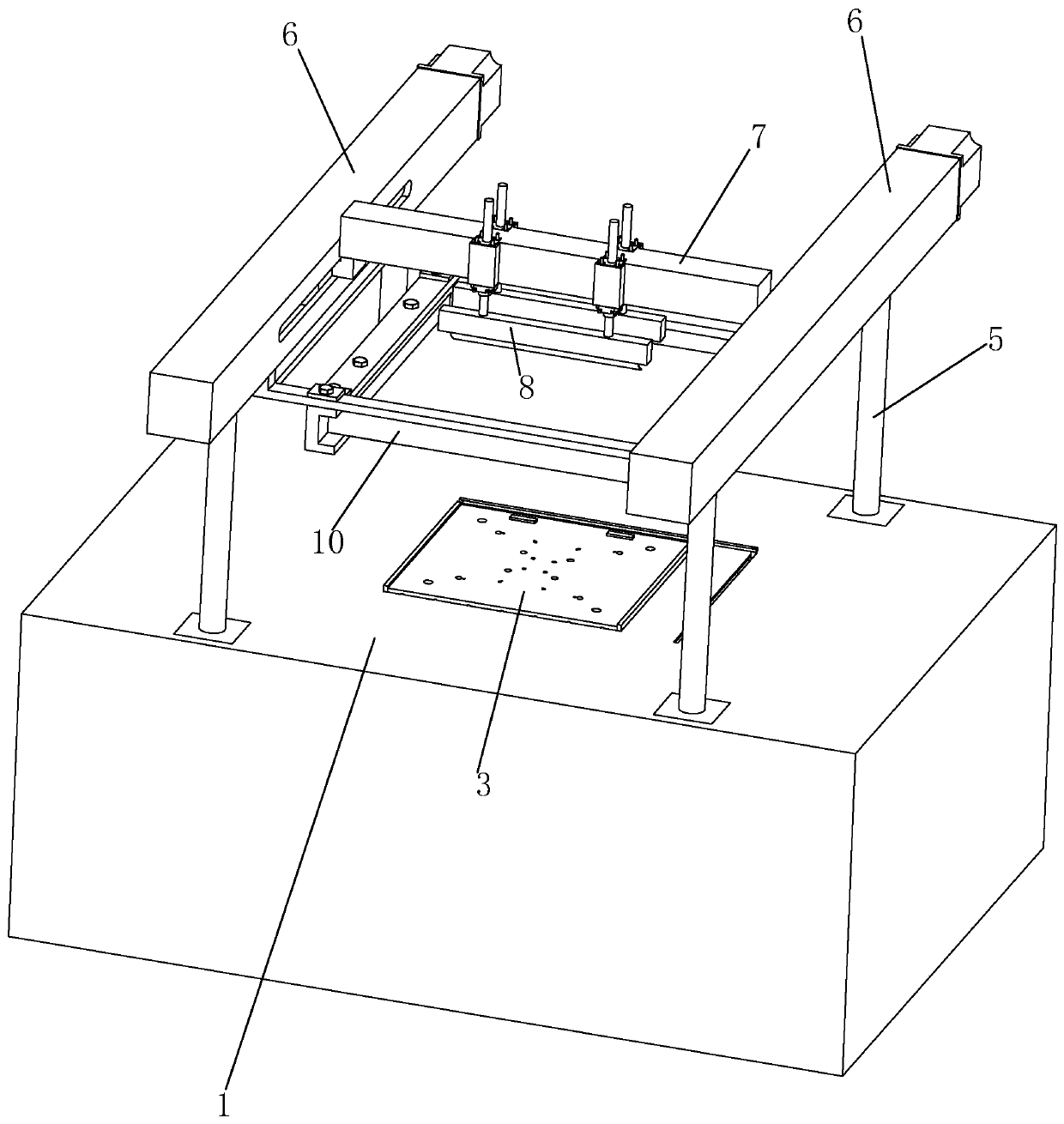

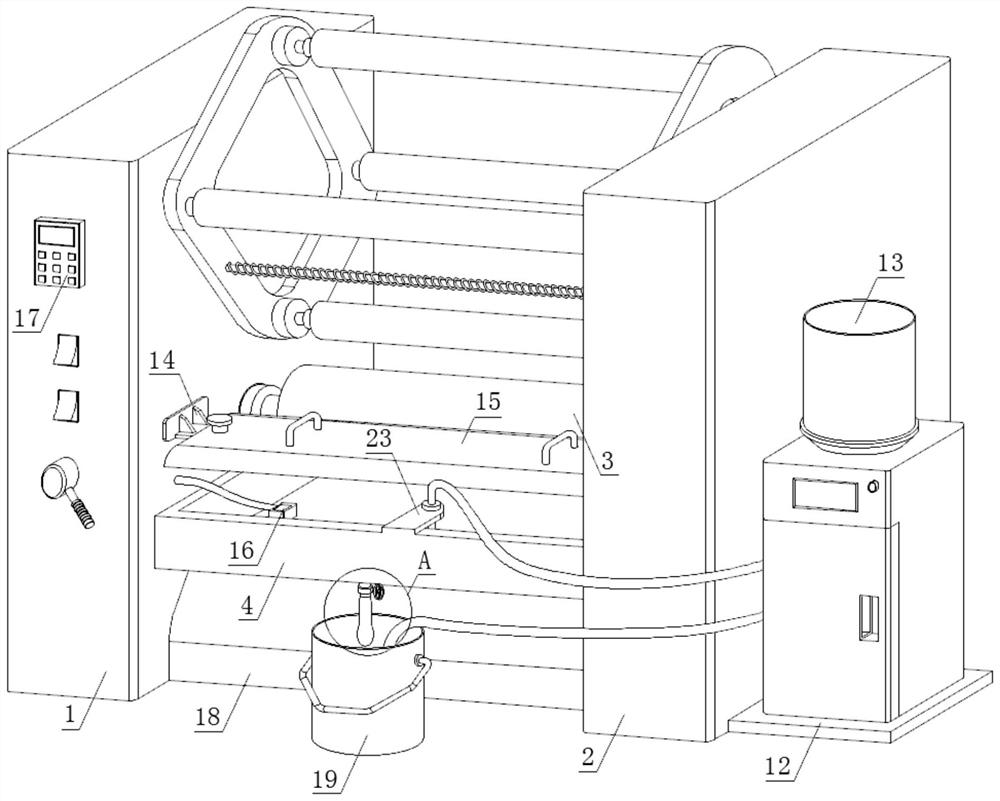

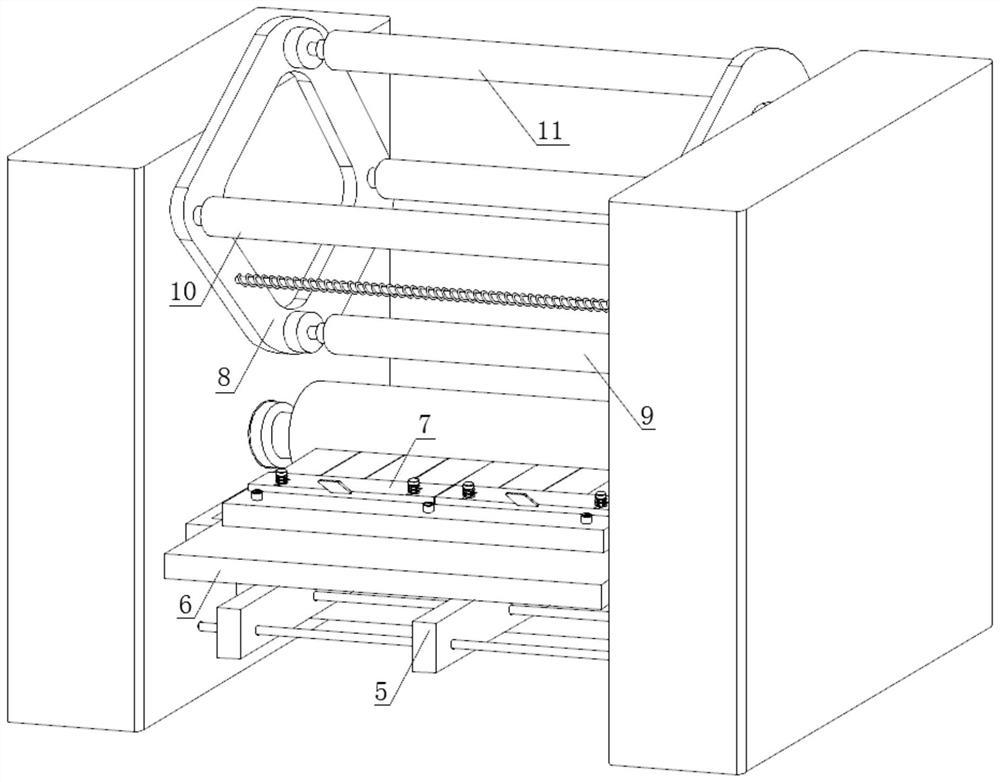

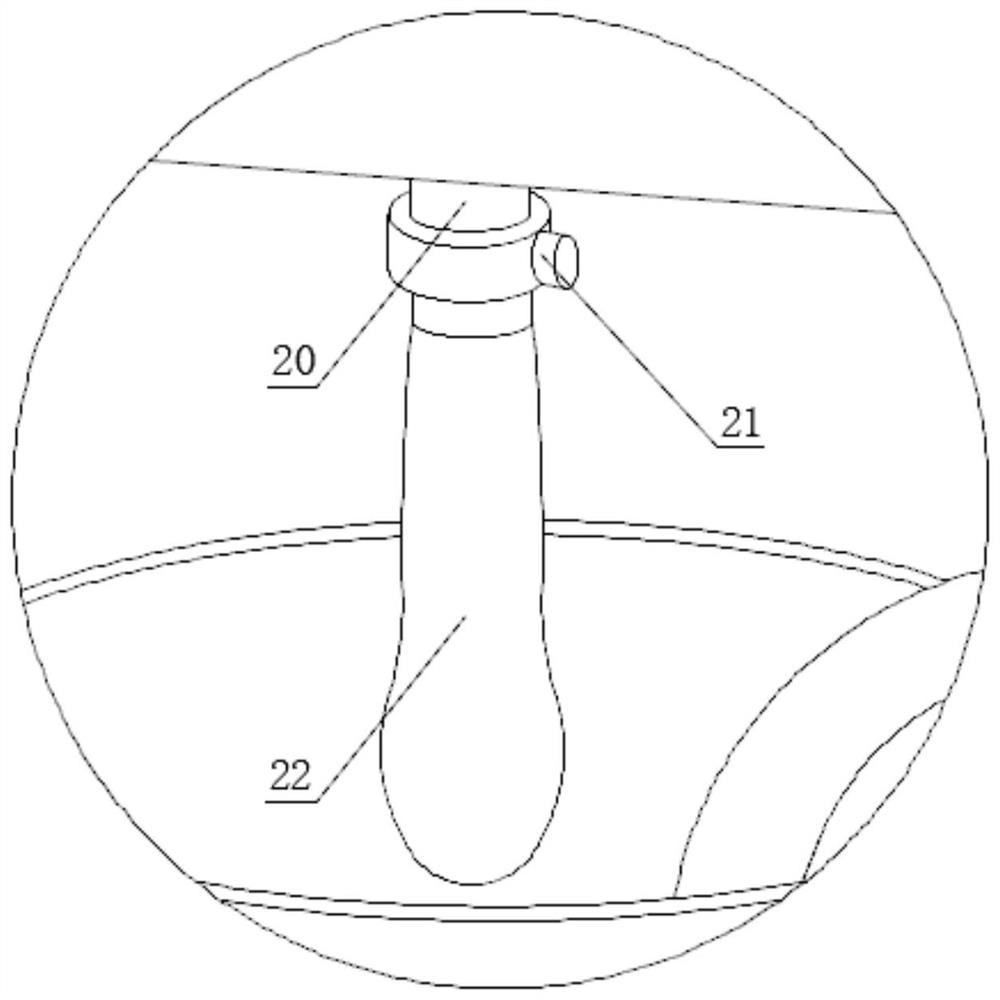

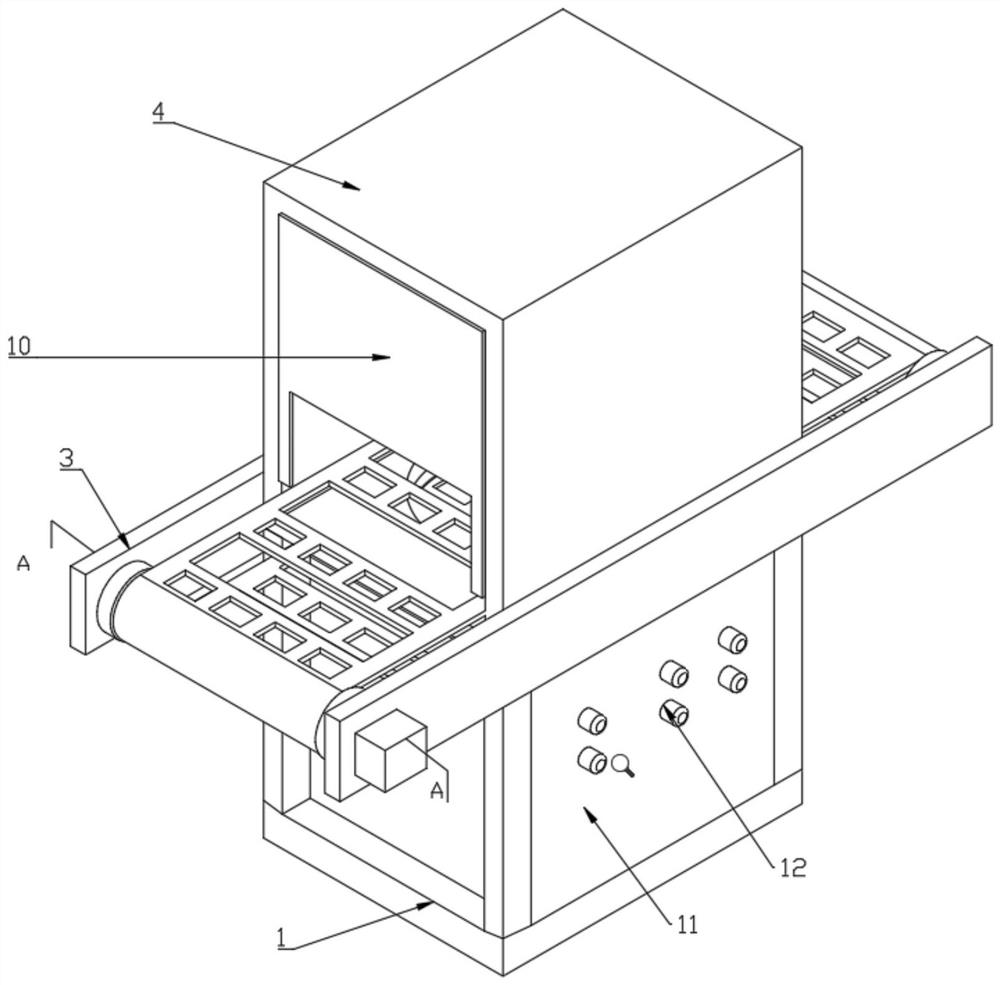

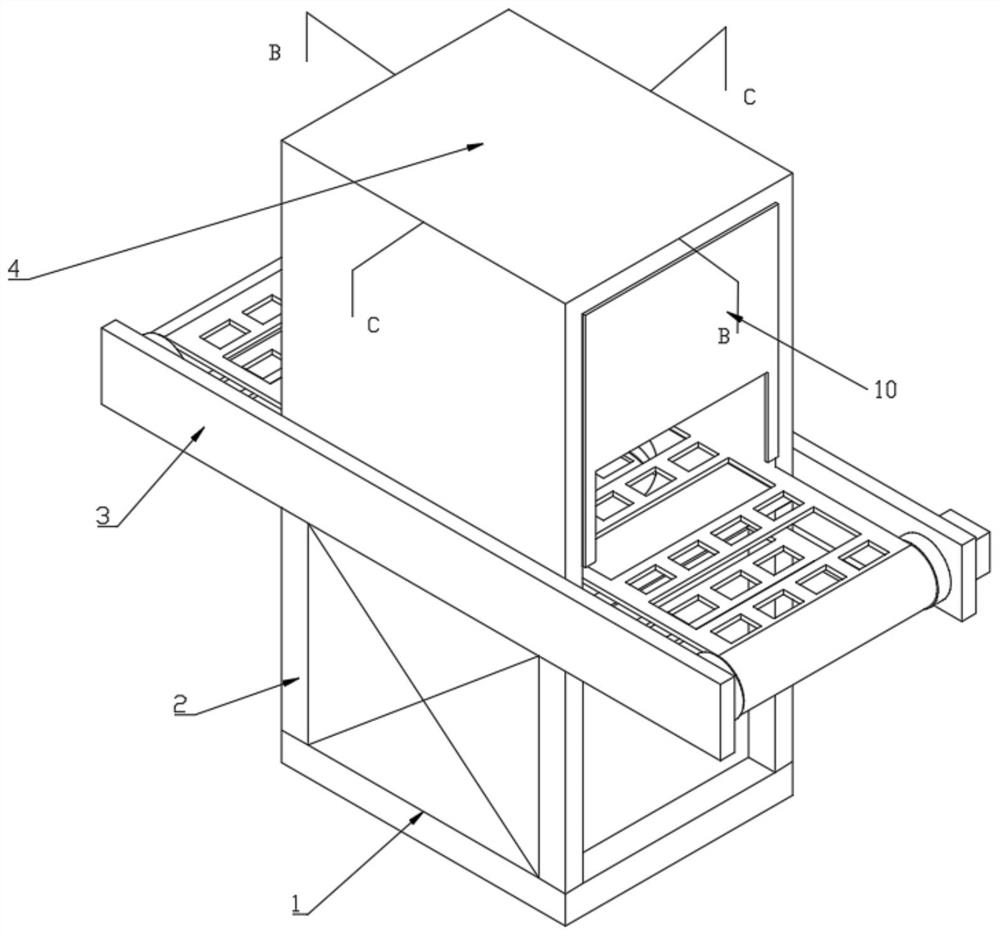

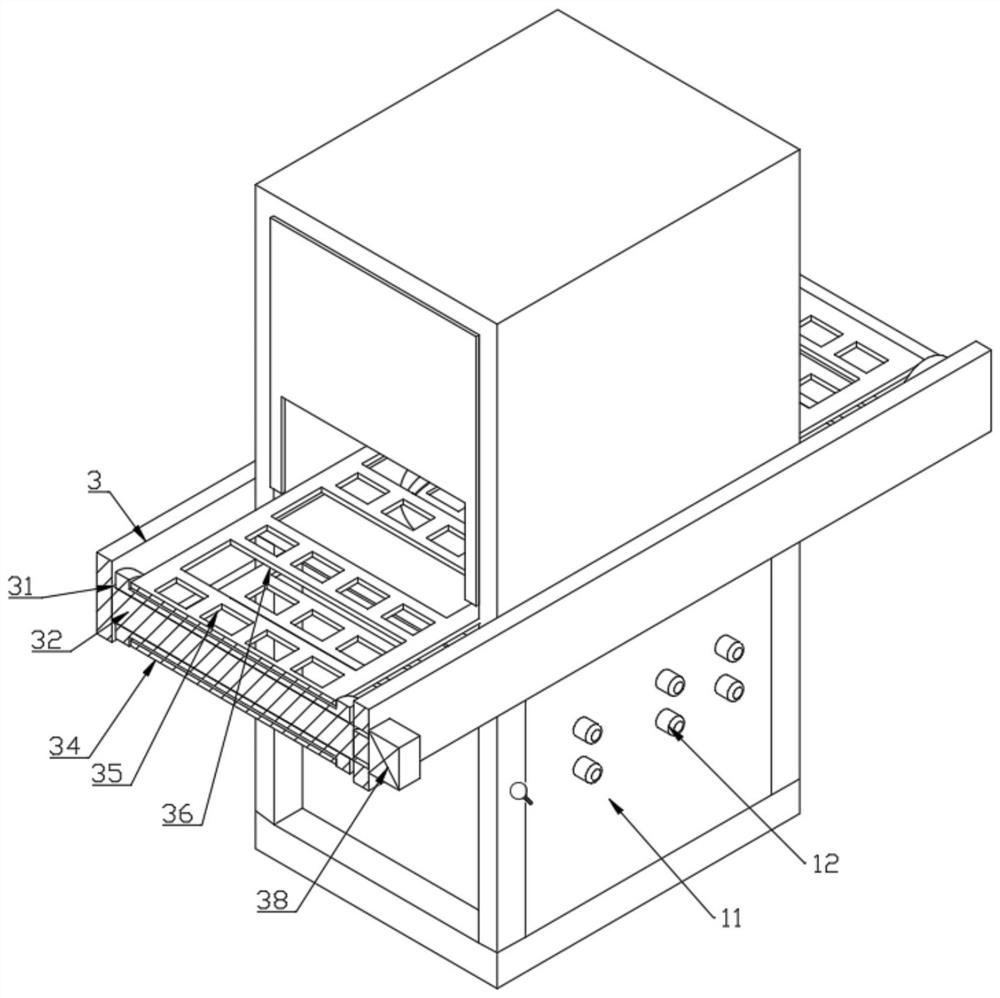

Printing machine for penetrating hole with silver paste of PCB

ActiveCN108770237AReduce pollutionAffect printing qualityPrinted element electric connection formationEngineeringSilver paste

The invention relates to the technical field of circuit board printing, in particular relates to a printing machine for penetrating a hole with silver paste of a PCB. The printing machine comprises aworkbench, a lifting rack, a mesh plate and a controller, wherein the lifting rack is arranged on the workbench, the mesh plate is arranged on the lifting rack, the controller is used for controllingthe lifting rack to ascend and descend, a cushion plate is arranged on the workbench arranged below the mesh plate and is used for placing a circuit board, a cleaning brush is arranged on the workbench and is used for cleaning the cushion plate, a driving device is arranged on the workbench and is used for driving the cleaning brush to move and clean along a surface of the cushion plate in a reciprocating way, the driving device is electrically connected with the controller, the controller is used for controlling the driving device to work, and the lifting rack and the driving device asynchronously work. The printing machine for penetrating the hole with the silver paste of the PCB has the advantage that the pollution of the cushion plate is reduced.

Owner:HANGZHOU LINAN PENGYU ELECTRONICS

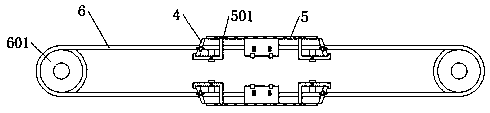

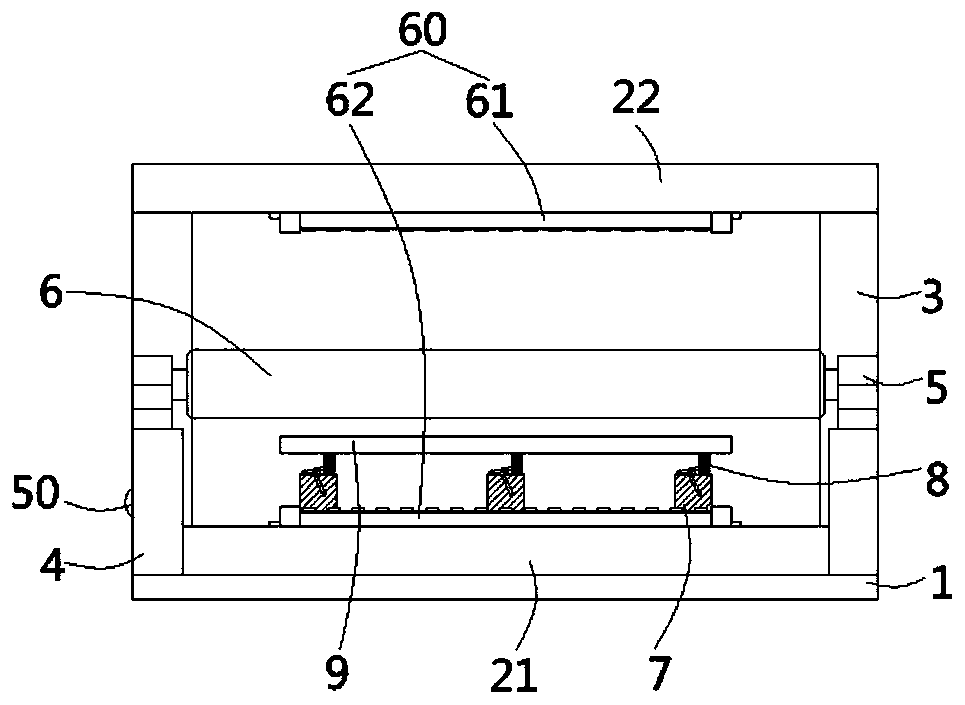

Intelligent textile spray printing machine

ActiveCN112248660AAvoid wastingReduce subsequent processingTypewritersOther printing apparatusTextile fiberRubber sheet

The invention relates to an intelligent textile spray printing machine which comprises a workbench, a conveying device and a spray printing device, the conveying device is arranged in the middle of the workbench, the spray printing device is arranged at the upper end of the middle of the workbench, and the conveying device comprises a rubber plate, a sponge block, a first motor, a large gear, a round roller, a supporting plate, a supporting belt, a small gear, a sleeve and a positioning cylinder. According to the machine, textile fabrics are conveyed through the conveying device, the surface of the supporting belt is cleaned, the fabrics obtained after the completion of spray printing are rolled, textile chippings attached to the textile fabrics are cleaned and collected through the sprayprinting device, the textile fabrics are sensed, and when the fabrics are hollow or made of cotton and linen materials, materials sprayed by a first spray head and a second spray head only make contact with the portions where textile fibers exist so that waste of the materials is prevented, subsequent processing is reduced, and the aesthetic degree of spray printing of the textile fabrics is improved.

Owner:江苏汉印机电科技股份有限公司

A screen screen, double printing device, double printing machine and double printing process

ActiveCN104228321BAffect printing qualityGuaranteed printing qualityScreen printersScreen printingTextile printer

The invention provides a silk screen printing plate. A screen frame comprises an inner screen frame, a middle screen frame and an outer screen frame. A sliding groove is formed in the middle screen frame. A sliding rail matched with the inner screen frame is formed on the inner screen frame. The middle screen frame is provided with a blocking frame. A plurality of springs are evenly distributed between the inner screen frame and the blocking frame. An adjusting bolt is arranged on the outer screen frame in a matched mode. A silk screen is provided with an adjusting aligning point. An adjusting aligning scale is arranged on the outer screen frame. Accordingly, by means of the silk screen printing plate, silk screen patterns can be adjusted and aligned effectively, high-quality double-printing is achieved, obvious deformation of the silk screen can be avoided effectively, and the printing quality of the silk screen patterns is guaranteed. The invention further provides a double-printing device, the double-station double-printing operation can be achieved, the silk screen printing plate is excellent in effect, and the double-printing efficiency and quality are improved remarkably. The invention further provides a double-printing machine which has the excellent effects of the silk screen printing plate and the double-printing device, and the double-printing efficiency and quality are improved remarkably. The invention further provides a double-printing process. The process is concise and clear and high in double-printing efficiency and quality.

Owner:SHISHI DECAI CHEM TECH

A cloth printing device

ActiveCN108297539BMeet the requirements of double-sided printingFast dryingRotary pressesPrinting press partsTextile printerEngineering

Owner:NINGBO WENZE TEXTILE CO LTD

A cardboard fixing mechanism for paper printing

ActiveCN109677008BEasy to fixAffect printing qualityPaper-makingBox making operationsPaperboardElectric machinery

Owner:浙江骏驰纸制品有限公司

Steel band detection mechanism in color steel plate printing production line

ActiveCN108363113ASlack detection is fastAccurate slack detectionOptical detectionProduction lineArchitectural engineering

The invention discloses a steel band detection mechanism in a color steel plate printing production line. The mechanism comprises a base plate, transverse lower channel steel is fixed in the middle ofthe base plate, vertical pillars are fixed at the two ends of the lower channel steel respectively, and the upper ends of the pillars are fixed to upper channel steel; and vertical bearers are fixedin the middle of the lower channel steel, a channel is molded in the upper end surface of each bearer, the upper end surface, at the two sides of the channel, of the bearer is provided with a pressurespring and a teeterboard, the two ends of the pressure spring abut against the bearer and a horizontal detection board respectively, the middle of the teeterboard is hinged to the bearer, the higherend of the teeterboard is positioned at one side of the channel and under the detection board, the lower end of the teeterboard accommodates a ball, the channel is internally provided with a switch cooperated with the ball, the sidewall of the bearer is provided with an alarm lamp, and the alarm lamp is connected with the switch in parallel. The mechanism can detect whether there is a steel band in a transfer line as well as whether the steel band is loosened in the conveying process.

Owner:王政达

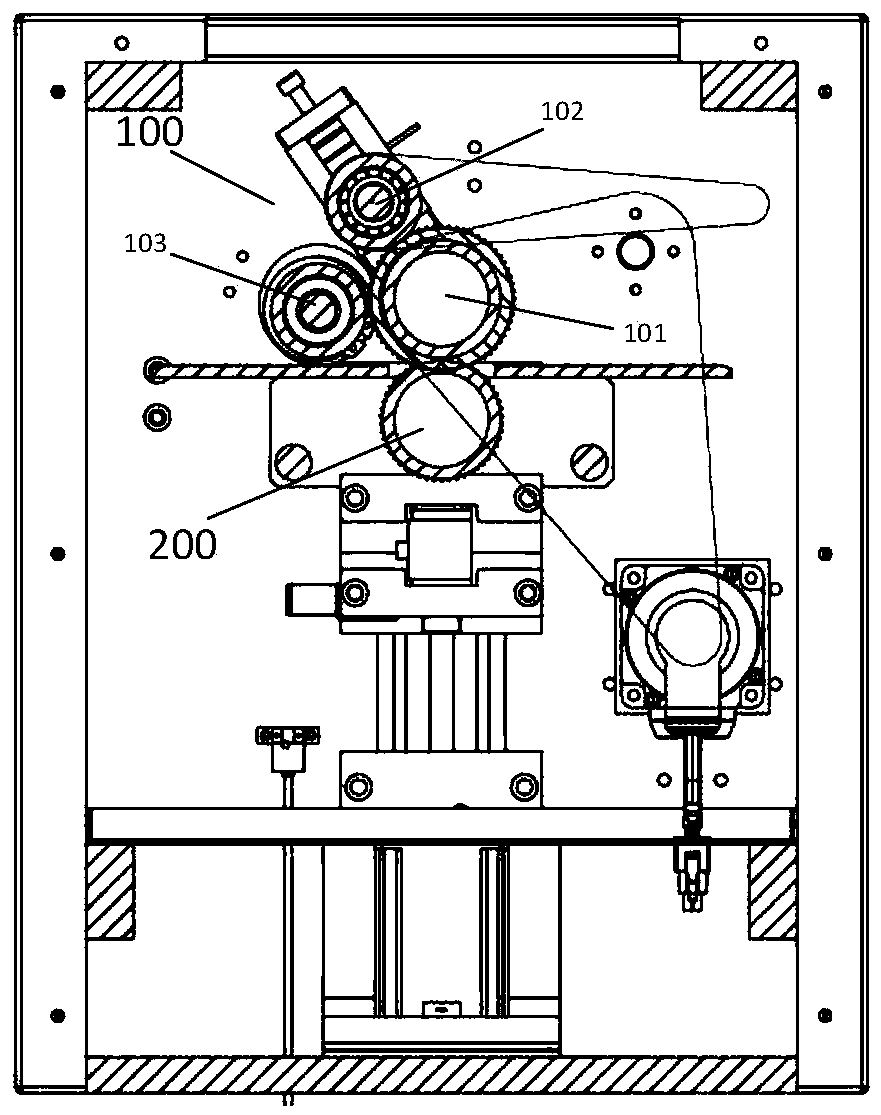

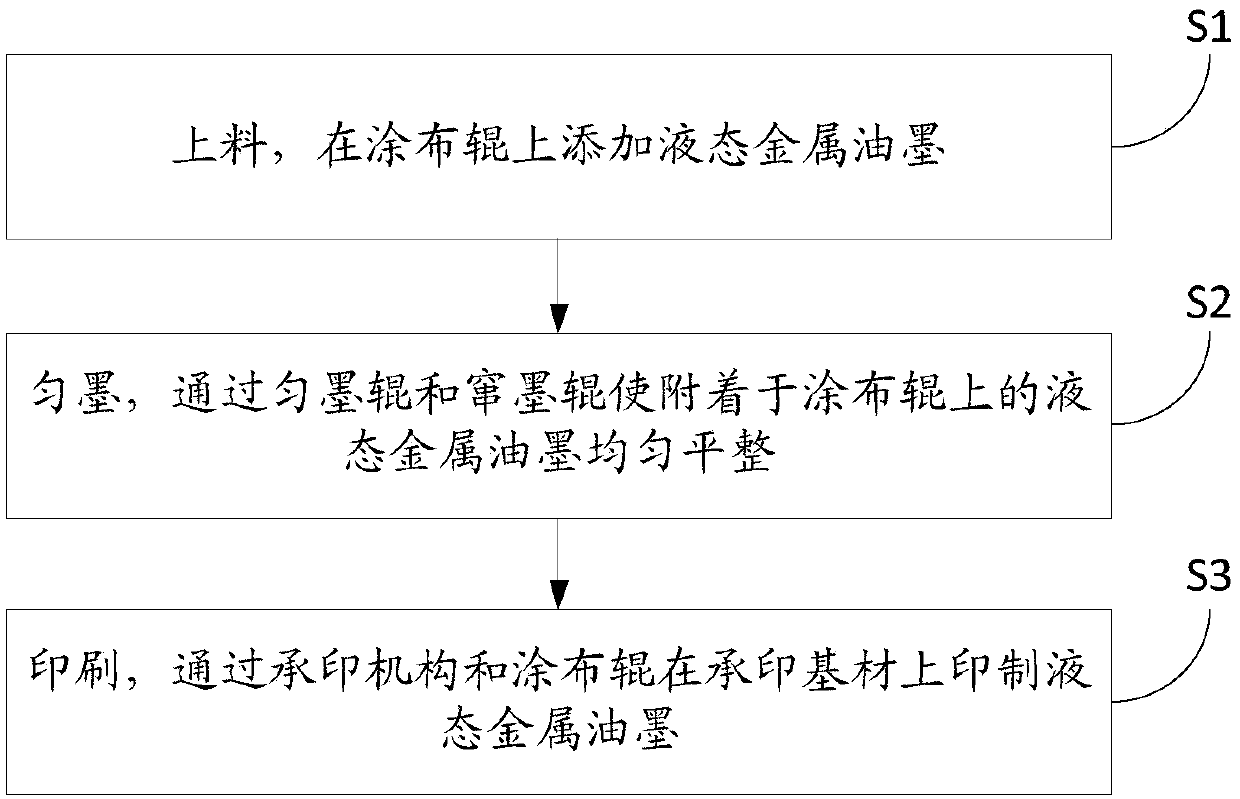

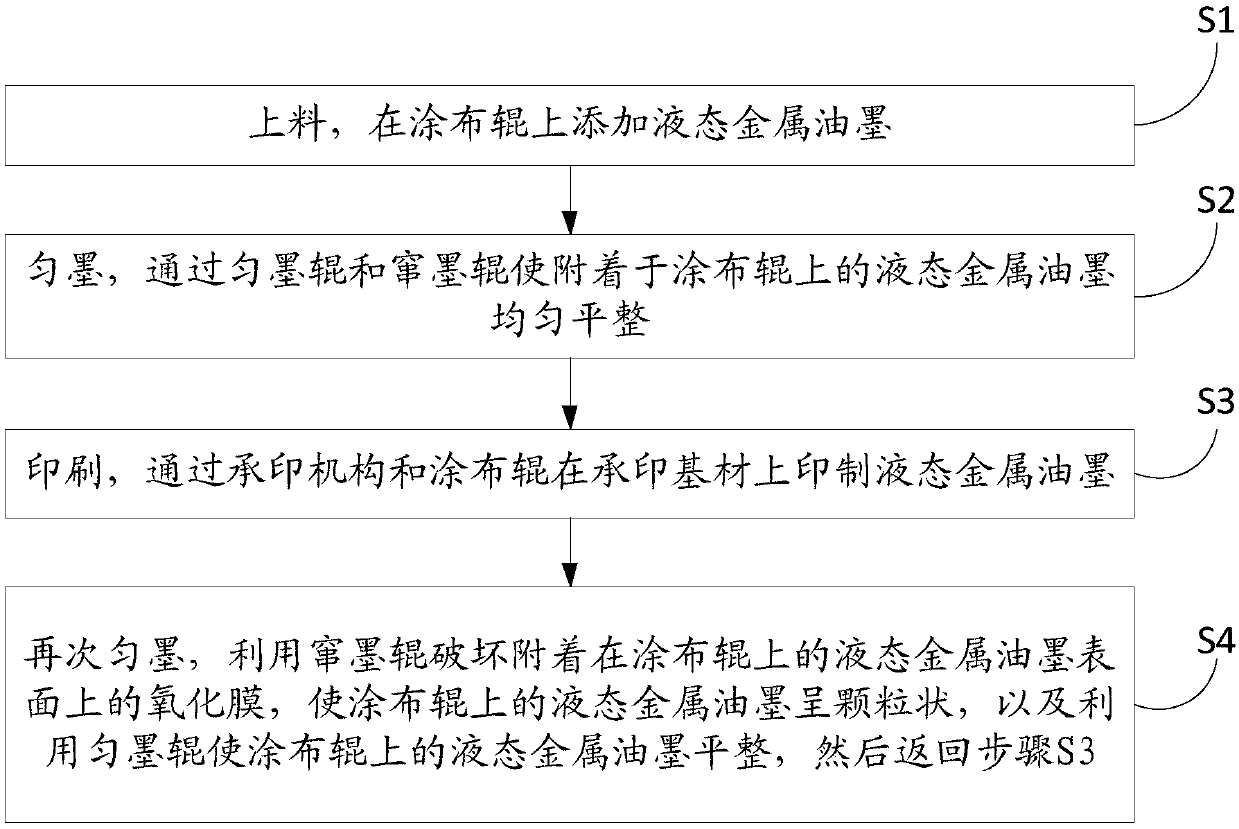

Printing device and printing method

PendingCN111452496AAffect printing qualityRotary pressesOther printing apparatusEngineeringMechanical engineering

The invention provides a printing device and a printing method, and relates to the technical field of plane printing. The printing device includes a coating mechanism and a printing mechanism; the coating mechanism includes a coating roller, an ink distribution roller and an ink shifting roller, and the ink distribution roller and the ink shifting roller respectively act on the coating roller; wherein the adhesive force relationships between the coating roller, the ink distribution roller or the ink shifting roller and the liquid metal satisfy the following relationship that: the ink shiftingroller is smaller than or equal to the coating roller and larger than the ink distribution roller, or the ink shifting roller is smaller than the coating roller and greater than or equal to the ink distribution roller. The invention provides the printing device. According to the printing device, the maximum amount of the liquid metal can be attached to the coating roller, the ink shifting roller can drive the liquid metal to be distributed along the axial direction of the coating roller, and the liquid metal attached to the coating roller can be leveled through the distribution roller; and therefore, the requirements of liquid metal printing can be met.

Owner:BEIJING DREAM INK TECH CO LTD

Energy-saving LED UV curing device suitable for metal flat plate printing

The invention discloses an energy-saving LED UV curing device suitable for metal flat plate printing. The energy-saving LED UV curing device suitable for metal flat plate printing comprises a base, four supporting columns are fixedly arranged on the upper end face of the base, a power supply module for providing electric energy for a curing mechanism is fixedly arranged on the upper end faces of the supporting columns, and a plurality of control buttons are arranged on one end face of the power supply module. A shell is fixedly arranged on the upper end faces of the four supporting columns, and a conveying mechanism used for transferring a metal flat plate is arranged on the end faces of the two sides of the shell. According to the energy-saving LED UV curing device, by arranging the curing mechanism, dust is removed before the metal flat plate is printed, it is avoided that dust enters the metal flat plate, and the printing quality of the metal flat plate is affected, and it is avoided that during metal flat plate printing, the metal flat plate falls due to dust; and meanwhile, by arranging a dust removal assembly, after the curing mechanism is used, external dust can be prevented from entering the curing mechanism, and the situation that next use is affected can be avoided.

Owner:杭州中粮美特容器有限公司

Detecting device of color plate printing production line

InactiveCN107902486AOptimizing the steel belt detection mechanismAffect printing qualityFilament handlingEngineeringProduction line

The invention discloses a detecting device of a color plate printing production line. The detecting device of the color plate printing production line comprises a fixing bottom plate; lower groove steel is fixed at the fixing bottom plate; vertical square tubes are fixed at the two ends of the lower groove steel in an inserting manner and the upper ends of the square tubes are fixed at upper groove steel in an inserting manner; a light screen sensor is arranged between the lower groove steel and the upper groove steel and comprises an infrared emitting tube and an infrared receiving tube; theinfrared emitting tube and the infrared receiving tube are respectively fixed in the upper groove steel and the lower groove steel in an inserting manner; L-shaped auxiliary supports are fixed on thefront side walls and the rear side walls of the square tubes; the lower ends of the auxiliary supports are fixed at the fixing bottom plate and bearing seats are fixed at the upper end surfaces of theauxiliary supports; the two ends of a carrier roller is hinged to the bearing seats and vertical inserting grooves are formed in the square tubes and located below the carrier roller; a grating sensor is arranged between the square tubes and consists of an emitter and a receiver which are correspondingly fixed in the inserting grooves of the square tubes. The device is capable of detecting the transportation process of a steel strip and detecting whether the steel strip is slack during the transportation at the same time.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

a drive shaft

ActiveCN110116545BImprove practicalityAffect printing qualityShaftsRotary pressesDrive shaftEngineering

Owner:欧伯朗精工(江苏)有限公司

A printing machine for through-hole silver paste on pcb board

ActiveCN108770237BReduce pollutionAffect printing qualityPrinted element electric connection formationSilver pasteEngineering

The invention relates to the technical field of circuit board printing, in particular relates to a printing machine for penetrating a hole with silver paste of a PCB. The printing machine comprises aworkbench, a lifting rack, a mesh plate and a controller, wherein the lifting rack is arranged on the workbench, the mesh plate is arranged on the lifting rack, the controller is used for controllingthe lifting rack to ascend and descend, a cushion plate is arranged on the workbench arranged below the mesh plate and is used for placing a circuit board, a cleaning brush is arranged on the workbench and is used for cleaning the cushion plate, a driving device is arranged on the workbench and is used for driving the cleaning brush to move and clean along a surface of the cushion plate in a reciprocating way, the driving device is electrically connected with the controller, the controller is used for controlling the driving device to work, and the lifting rack and the driving device asynchronously work. The printing machine for penetrating the hole with the silver paste of the PCB has the advantage that the pollution of the cushion plate is reduced.

Owner:HANGZHOU LINAN PENGYU ELECTRONICS

Printing device for film of packaging bag and printing process thereof

ActiveCN114228327AAffect printing qualityEasy to operateRotary pressesPrinting press partsPaperboardThin membrane

The invention discloses a printing device for a film of a packaging bag and a printing process thereof, belongs to the technical field of film production, and aims to solve the problems that when a printing roller rotates, printing ink adhered to the printing roller easily flies away at the edge position to form flying ink, and the flying ink is adhered to the film to influence the film printing quality. The problems that an existing printing device lacks the function of automatically adjusting the concentration of printing ink in a trough, and the printing quality of a thin film is affected due to the fact that the printing ink is too thick are solved. The end, close to the printing roller, of the clamping plate is controlled to tilt by pressing the handheld pressing plate, the clamping plate and the clamping base plate are used for clamping paperboard, the paperboard is suspended above the rotation starting end of the printing roller in cooperation with the U-shaped bracket to block flying ink, the feeder is arranged on one side of the ink groove, and the consistency sensor and the electronic viscometer are used for detecting the ink concentration. The ink tank, the ink transfer barrel and the ink barrel are communicated through the liquid conveying pipe, the discharging pipe and the liquid return pipe to circularly adjust and add the ink; the problem that the film printing quality is affected by misting ink and ink concentration is effectively solved.

Owner:浙江方鼎包装科技有限公司

An intelligent textile printing machine

ActiveCN112248660BAvoid wastingReduce subsequent processingTypewritersOther printing apparatusTextile printerTextile fiber

The invention relates to an intelligent textile printing machine, which includes a workbench, a transportation device and a spray printing device. The transportation device is installed in the middle of the workbench, and the spray printing device is installed at the upper end of the middle part of the workbench. The transportation device includes a rubber plate. , sponge block, motor one, large gear, round roller, support plate, support belt, pinion, sleeve and positioning cylinder, the present invention transports through the transport device textile, and simultaneously cleans the surface of the support belt and sprays the After the finished fabric is rolled up, the textile debris attached to the textile fabric is cleaned and collected by the jet printing device, and the textile fabric is sensed. When the fabric is hollowed out or made of cotton and linen, the first nozzle and the second nozzle The printed material is only in contact with the part where the textile fiber exists, so as to prevent material waste, reduce subsequent processing, and improve the aesthetics of textile cloth printing.

Owner:江苏汉印机电科技股份有限公司

A steel strip detection device on a color steel plate production line

ActiveCN108345043BSlack detection is fastAccurate slack detectionConveyorsOptical detectionElectrical connectionStructural engineering

The invention discloses a steel band detection device on a color steel plate production line. The device comprises a bottom plate. The central section of the bottom plate is fixedly provided with lower groove steel. The two ends of the lower groove steel are fixedly provided with support columns. The upper end of each support column is fixed to upper groove steel. The central section of the lowergroove steel is fixedly provided with a support seat. A groove channel forms on the upper end surface of the support seat. A pressure spring is arranged on the upper end surface of the support seat ofone side of the groove channel. The two ends of the pressure spring abut against the support seat and a transverse detection plate. The middle inner wall of the pressure spring is fixedly provided with a pressing plate. The high end of a seesaw is located right below the pressing plate and a rolling ball is placed on the low end of the seesaw. The seesaw crosses over the upper portion of the groove channel and a bottom is hinged to the support seat. A guide groove and a through hole which are connected form on the seesaw. The through hole is located right above the groove channel. A switch isarranged in the groove channel. The side wall of the support seat is provided with an alarm lamp. The alarm lamp and the switch are electrically connected in a parallel mode. In the invention, whether a steel band exists in a conveyor line can be detected, and simultaneously, whether the steel band is loosened during a conveying process can be detected too.

Owner:杭州普络飞新材料科技有限公司

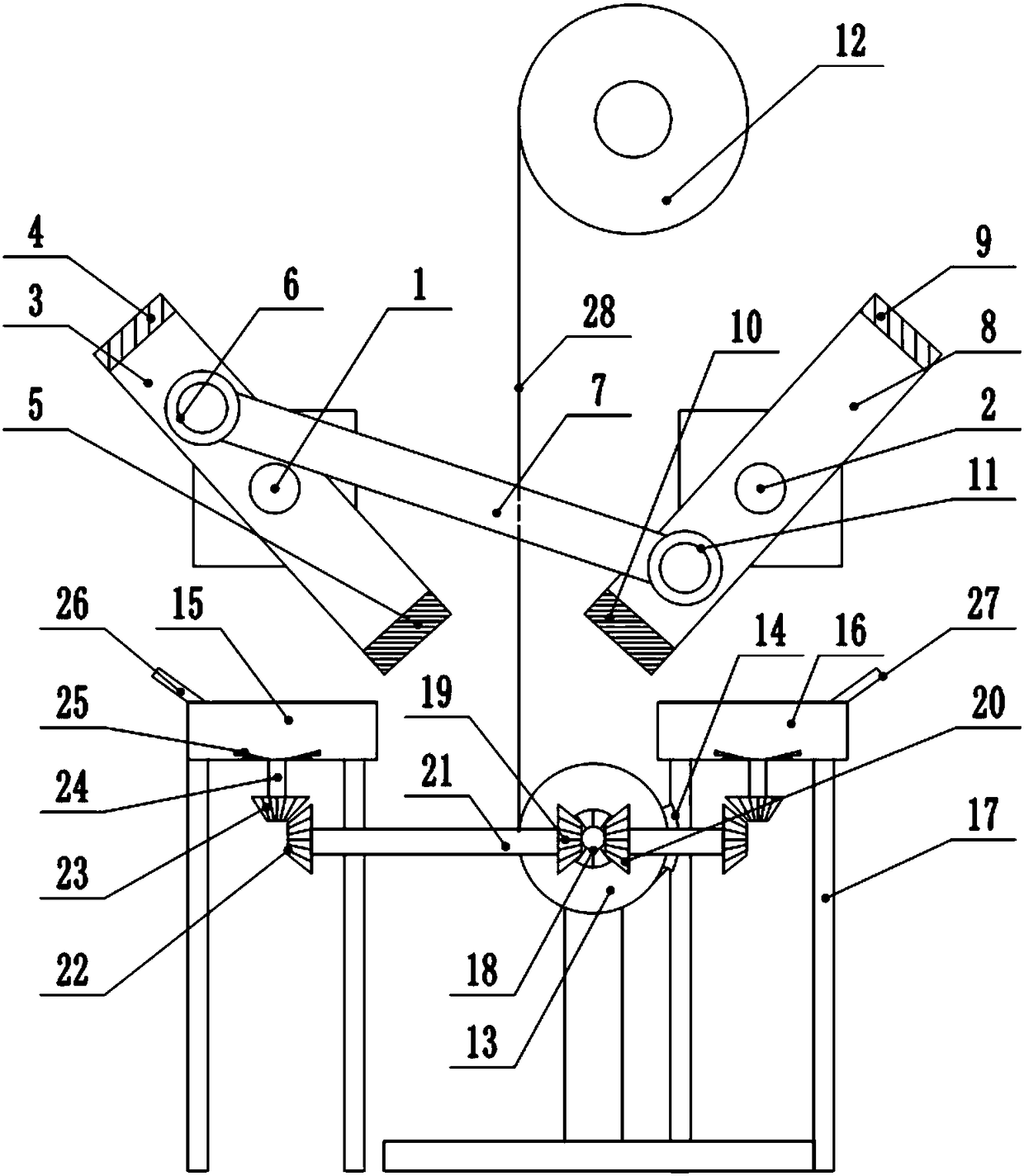

Automatic intelligent production line for ribbon production

PendingCN114654872AAvoid compromising print qualityAffect printing qualityScreen printersScreen printingProduction lineProcess engineering

The invention discloses an automatic intelligent production line for ribbon production, and relates to the technical field of printing equipment.The automatic intelligent production line comprises a printing platform, a printing plate and a scraping plate, the printing plate and the scraping plate are arranged on the printing platform, and the scraping plate is arranged on the side, away from the printing platform, of the printing plate; the printing platform is provided with a conveying mechanism used for conveying a substrate, the printing plate is provided with an oil outlet part, a shielding assembly is arranged between the printing plate and the printing platform, the shielding assembly is movably arranged at the oil outlet part, and the printing platform is provided with a control mechanism used for controlling the shielding assembly to move. The method has the effect of improving the substrate printing quality.

Owner:仙桃市华夏服饰有限公司

An energy-saving leduv curing device suitable for metal lithography

ActiveCN113291053BAffect printing qualityInhibit sheddingPrinting press partsDust controlEngineering

The invention discloses an energy-saving LEDUV curing device suitable for metal lithographic printing, which includes a base, four support columns are fixedly arranged on the upper end surface of the base, and a set is fixedly arranged on the upper end surface of the support column for providing electric energy to the curing mechanism. The power supply module, one end of the power supply module is provided with a plurality of control buttons, the upper end of the four support columns is fixed with a housing, and the two sides of the housing are provided with a transportation mechanism for transferring the metal plate. By setting the curing mechanism to remove dust before entering the metal lithography, avoid dust entering the metal plate, affecting the printing quality of the metal plate, avoiding the metal plate falling off due to dust during metal lithography, and setting the dust removal component to make the curing After the mechanism is used, it can prevent external dust from entering, which will affect the next use.

Owner:杭州中粮美特容器有限公司

Fabric printing and dyeing device capable of effectively preventing printing quality from being influenced by printing ink precipitation

PendingCN113232410AAffect printing qualityAvoid affecting printing qualityRotary pressesOther printing apparatusTextile printerPrinting ink

The invention relates to the technical field of fabrics, and discloses a fabric printing and dyeing device capable of effectively preventing printing quality from being influenced by printing ink precipitation. The fabric printing and dyeing device comprises a printing and dyeing box, the left side of the interior of the printing and dyeing box is fixedly connected with a bidirectional driving motor, the bottom of the bidirectional driving motor is fixedly connected with a driving cone pulley, and the right side of the bottom of the driving cone pulley is in engaged connection with a driven cone pulley. According to the fabric printing and dyeing device capable of effectively preventing the printing quality from being influenced by printing ink precipitation, a rotating disc is rotated, a pressing roller can stretch a fabric body at the moment, and therefore the effect of preventing fabric looseness from influencing the printing and dyeing quality is achieved; the bidirectional driving motor is started, and a stirring device stirs in an ink tank, so that the effect of preventing the printing and dyeing quality from being influenced by ink precipitation is achieved; and a driving turntable drives a driven turntable to rotate, so that a rotating brush cleans the upper and lower surfaces of the fabric body, and the effect of preventing dust on the surface of the fabric from affecting the printing and dyeing quality is achieved.

Owner:闫舒舒

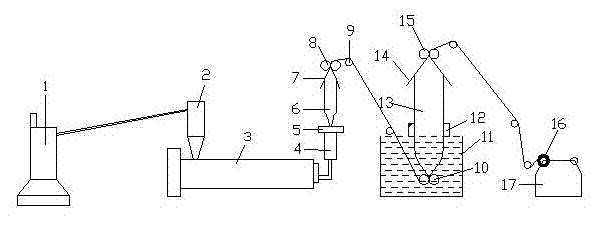

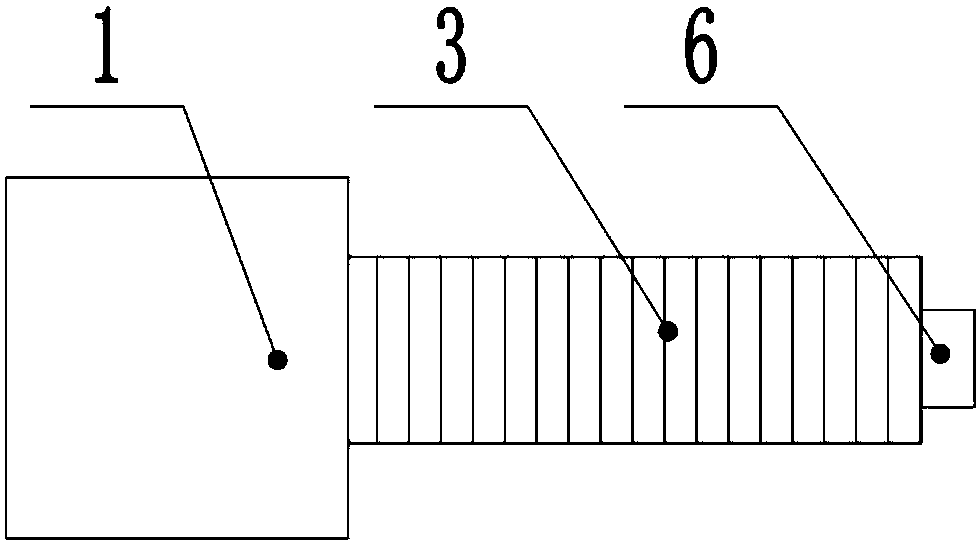

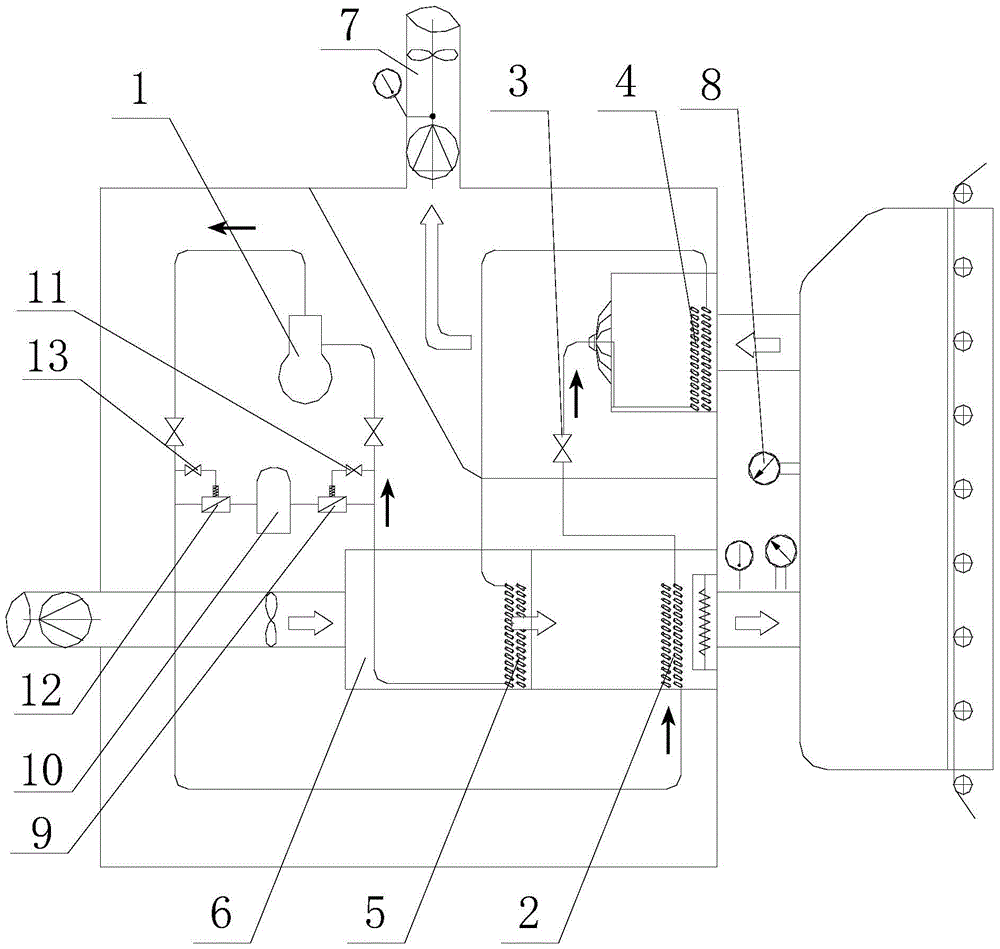

Numerical control energy-saving drying device with constant temperature and air volume for film printing

ActiveCN104960336BImprove waste heat recovery efficiencyFast printPrinting press partsNumerical controlAir volume

The invention discloses a temperature and air-volume constant value numerical control energy-saving drying device for thin-film printing. The temperature and air-volume constant value numerical control energy-saving drying device for thin-film printing mainly solves the problems that an existing drying device is high in energy consumption, high in drying cost and low in degree of automation. The temperature and air-volume constant value numerical control energy-saving drying device for thin-film printing is characterized in that a draught fan, a second-stage evaporator (5), a condenser (2) and an electric heater are connected into an air inlet channel (6), a first-stage evaporator (4) is connected to an air outlet channel (7) in the shell, an outlet of a compressor (1) is connected with the condenser (2), the first-stage evaporator (4) and the second-stage evaporator (5) in series, an outlet of the second-stage evaporator (5) is communicated with an outlet of the compressor (1), a heat supply temperature detection device and a heat supply air-volume detection device connected with a controller are arranged on the air inlet channel (6), and an air outlet temperature detection device connected with the controller is arranged on an air outlet (8). The temperature and air-volume constant value numerical control energy-saving drying device for thin-film printing has the advantages of being low in energy consumption, low in drying cost and high in degree of automation.

Owner:HEILONGJIANG SHENGDA TECH CO LTD

A printing flattening device for textile fabrics

ActiveCN113524895BImprove smoothing effectImprove surface printing effectMechanical cleaningPressure cleaningTextile printerMechanical engineering

The invention belongs to the technical field of textile processing, in particular to a printing and flattening device for textile fabrics, aiming at the lack of a smoothing device for the cloth in the currently widely used printing machines, and the fact that the cloth in the printing operation will have surface wrinkles and unevenness, As a result, the pattern is unclear and the ink is accumulated after printing, which affects the overall effect of the cloth. The following scheme is proposed, including the outer box, one side of the outer box is set as a slope, and a top platform is set above the slope, and The bottom of the top platform is provided with a circular groove, and the inner wall of the circular groove is fixedly connected with the first hydraulic rod. The present invention adopts the method of pressing down to separate the left and right poles of the smoothing assembly, and uses the pressing plate to smooth the surface of the cloth to be processed after being placed, so as to ensure the flatness of the surface of the cloth to be printed, thereby improving the surface of the textile cloth. Printing effect, avoiding ink accumulation and unclear patterns caused by wrinkles on the surface of the fabric during printing.

Owner:南通寝尚纺织品有限公司

A steel belt detection mechanism on a color steel plate printing production line

ActiveCN108363113BSlack detection is fastAccurate slack detectionOptical detectionProduction lineStructural engineering

The invention discloses a steel band detection mechanism in a color steel plate printing production line. The mechanism comprises a base plate, transverse lower channel steel is fixed in the middle ofthe base plate, vertical pillars are fixed at the two ends of the lower channel steel respectively, and the upper ends of the pillars are fixed to upper channel steel; and vertical bearers are fixedin the middle of the lower channel steel, a channel is molded in the upper end surface of each bearer, the upper end surface, at the two sides of the channel, of the bearer is provided with a pressurespring and a teeterboard, the two ends of the pressure spring abut against the bearer and a horizontal detection board respectively, the middle of the teeterboard is hinged to the bearer, the higherend of the teeterboard is positioned at one side of the channel and under the detection board, the lower end of the teeterboard accommodates a ball, the channel is internally provided with a switch cooperated with the ball, the sidewall of the bearer is provided with an alarm lamp, and the alarm lamp is connected with the switch in parallel. The mechanism can detect whether there is a steel band in a transfer line as well as whether the steel band is loosened in the conveying process.

Owner:王政达

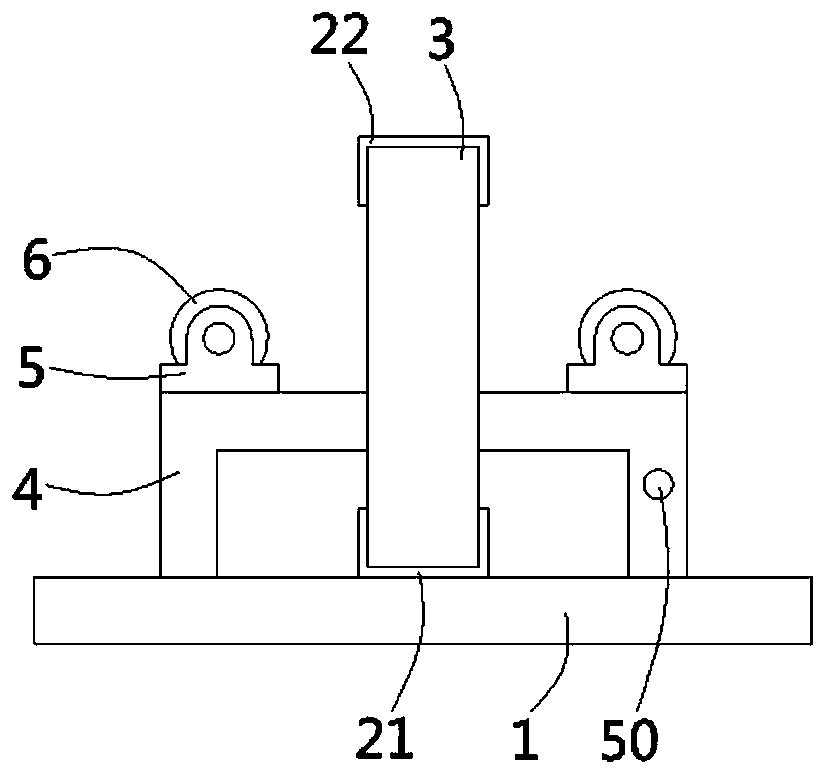

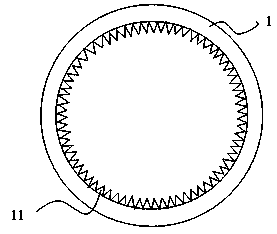

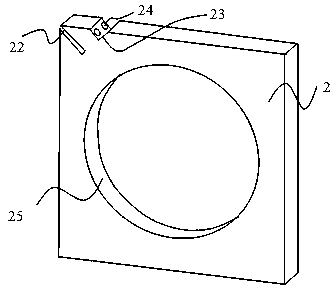

Design method for novel printing table paper anti-loose device

InactiveCN109927402AAffect printing qualityImprove stabilityScreen printersPulp and paper industryToughness

The invention discloses a design method for a novel printing table paper anti-loose device. The device comprises a table roller (1), a bearing fixing block (2), an elastic sheet (3) and a rectangularclamping groove (22); the elastic sheet (3) is embedded in the rectangular clamping groove (22) of the top corner of the bearing fixing block (2); the elastic sheet (3) is embedded in gears (11); thetable roller is a hollow cylinder and comprises the multiple gears (11); the bearing fixing block is a hollow body (25), and the top corner of the bearing block is provided with the rectangular clamping groove; and the bearing fixing block is provided with a small notch (23) and a screw hole (24). The design method has the beneficial effects that table top paper is tightened in the printing process, the situation that table top paper is bulged due to toughness, and the printing quality is affected is prevented, and the equipment stability is improved.

Owner:ZHEJIANG FORTUNE ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com