Detecting device of color plate printing production line

A detection device and production line technology, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of not being able to detect the tension of the steel belt, and can only detect the existence of the steel belt, and achieve optimization The effect of steel belt detection mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

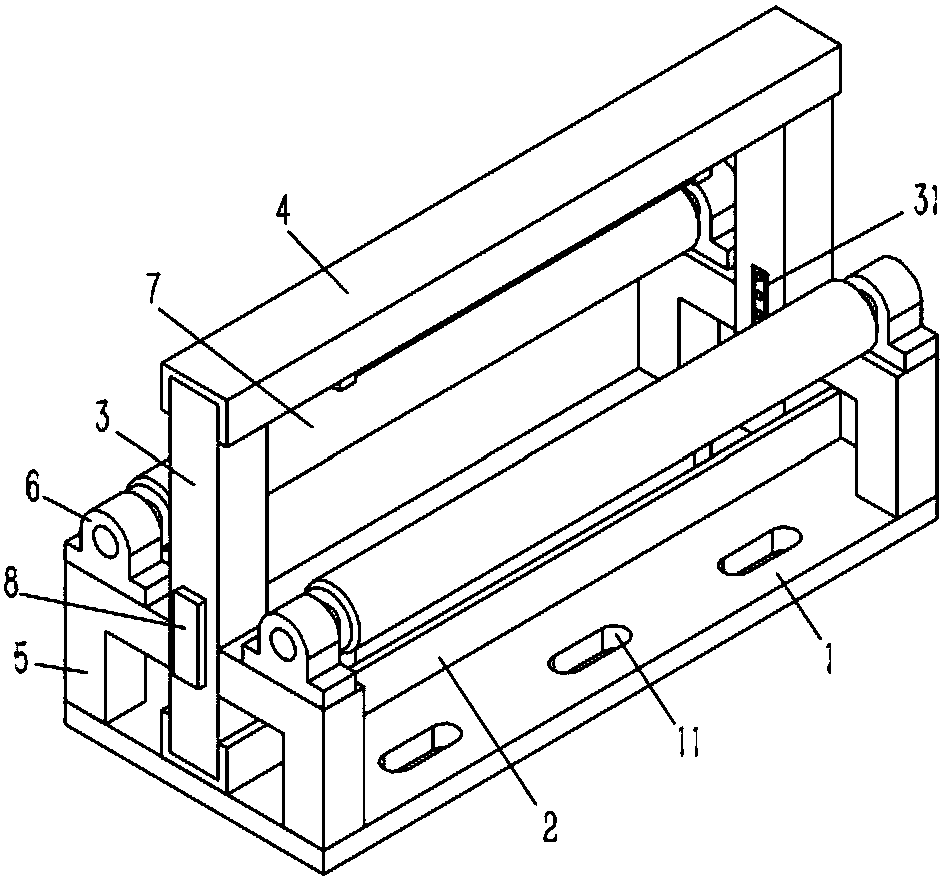

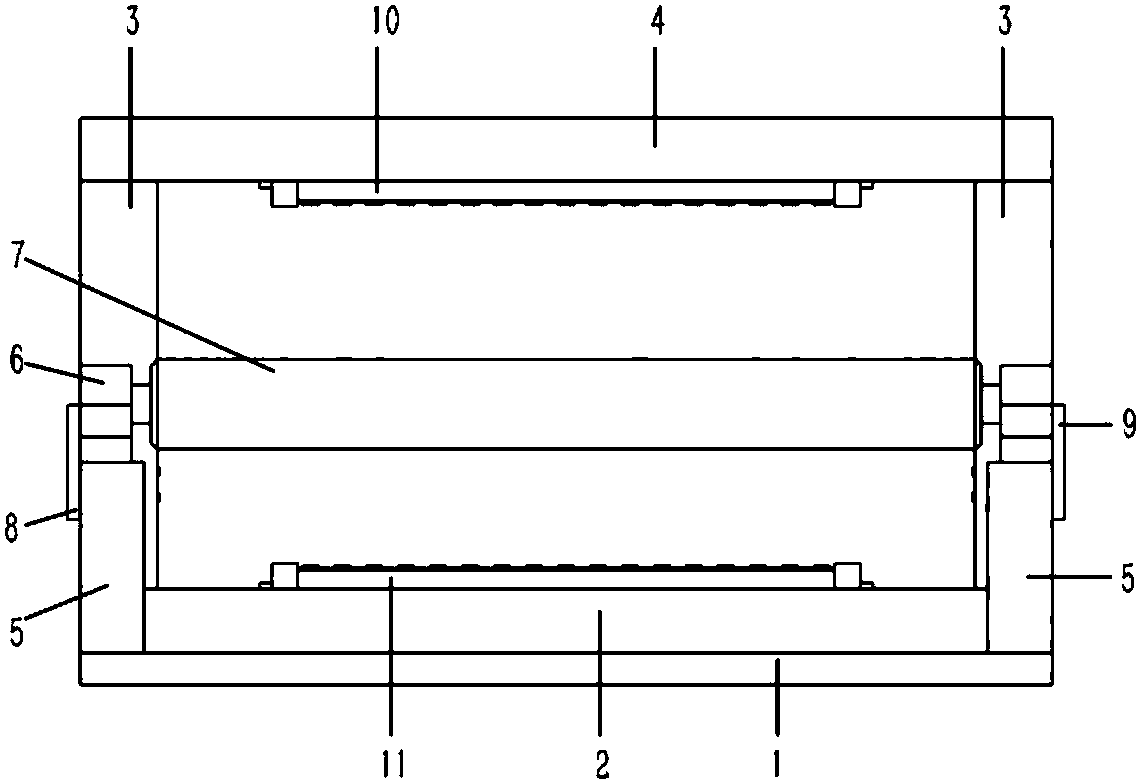

[0015] Example: see figure 1 , 2 As shown, a detection device on a color steel plate printing production line includes a fixed bottom plate 1, a horizontal lower channel steel 2 is fixed in the middle of the fixed bottom plate 1, and vertical square pipes 3 are inserted and fixed at both ends of the lower channel steel 2. , the upper end of the square tube 3 is plugged and fixed on the upper channel steel 4, and a light curtain sensor is arranged between the lower channel steel 2 and the upper channel steel 4. The light curtain sensor includes an infrared emission tube 10 and an infrared receiving tube 11. The tube 10 and the infrared receiving tube 11 are respectively inserted and fixed in the upper channel steel 4 and the lower channel steel 2; L-shaped auxiliary supports 5 are fixed on the side walls of the front and rear sides of the square tube 11, and the lower ends of the auxiliary supports 5 are fixed On the fixed base plate 1, a bearing seat 6 is fixed on the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com