Design method for novel printing table paper anti-loose device

A technology for printing tabletops and design methods, applied in printing, printing machines, rotary printing machines, etc., can solve the problems that the tabletop paper is easy to loosen, bulge, and affect the rate of high-quality products, and achieve the effect of improving the stability of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings.

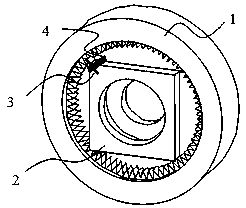

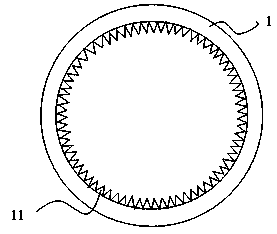

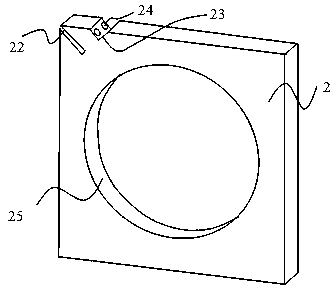

[0014] In this specific embodiment, a new design method of the printing table paper anti-loosening device, such as figure 1 As shown, it includes a table roller (1), a bearing fixing block (2), an elastic sheet (3) and a rectangular slot (22); the table roller is a hollow cylinder and contains several gears (11); The bearing fixing block is a hollow body (25) with a rectangular slot at the top corner of the bearing block; a small notch (23) and a screw hole (24) are designed on the bearing fixing block. in:

[0015] The number of the gears (11) is 72, the shape is sawtooth, and the height of the gears is 5mm.

[0016] The width of the rectangular slot (22) is 0.4 mm.

[0017] The thickness of the elastic sheet (3) is 0.38mm.

[0018] Insert the elastic sheet (3) into the top corner rectangular slot (22) of the bearing fixing block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com