Numerical control energy-saving drying device with constant temperature and air volume for film printing

A technology of film printing and air volume, which is applied to the general parts of printing machinery, printing, printing machines, etc., and can solve the problems of low degree of automation, high drying cost, and high energy consumption of drying devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

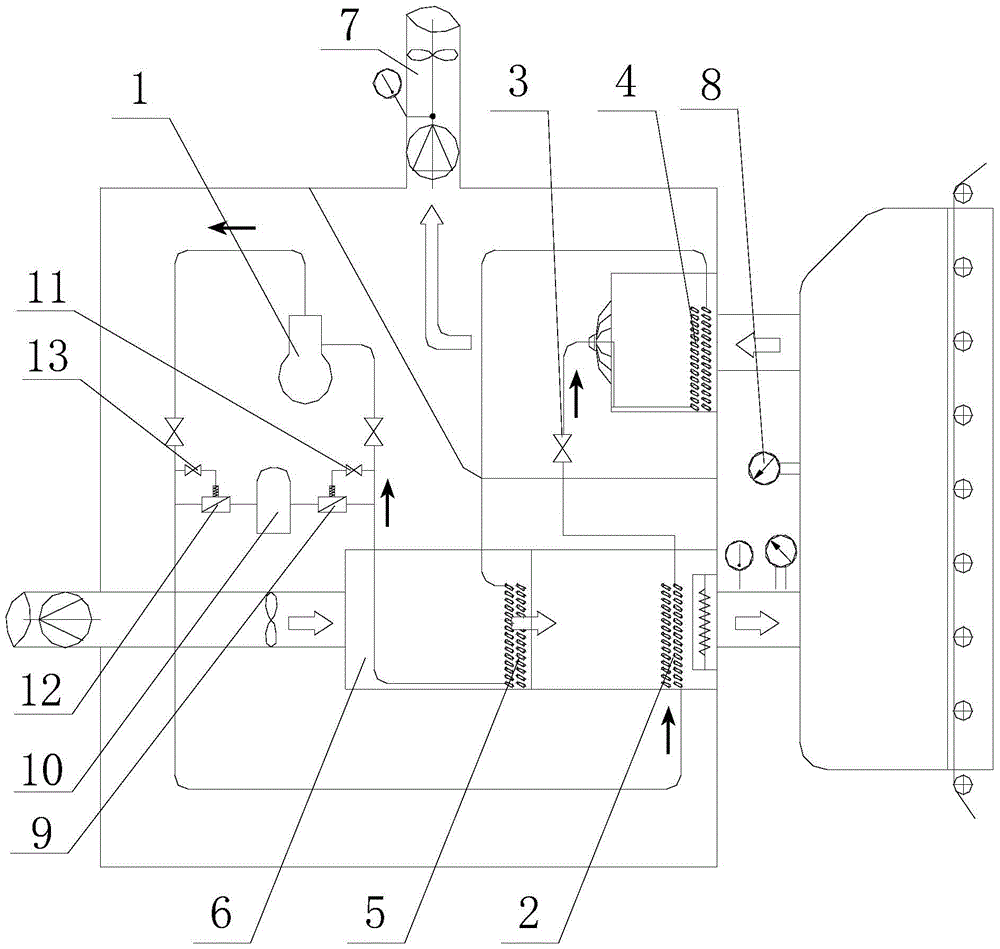

[0008] The present invention will be further described below in conjunction with accompanying drawing:

[0009] As shown in the accompanying drawings, the numerically controlled energy-saving drying device with fixed temperature and air volume for film printing includes a compressor 1 , a condenser 2 , an expansion valve 3 , a first-stage evaporator 4 and a second-stage evaporator 5 . The shell is divided into an air inlet chamber and an air outlet chamber, and a differential pressure feedback detection device 8 is connected to the oven of the film printing machine. There is an air inlet channel 6 on the air inlet chamber, and an air outlet channel 7 on the air outlet chamber. And the air outlet cavity is connected with the inlet and outlet of the film printing machine oven. There is an air outlet door and an induced draft fan in the air outlet channel 7. An air circulation system is formed by the air inlet cavity and the air outlet cavity. Fresh air passes through the air inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com