Sintering device, sintering cooler and its lamination sealing device

A sintered cooling machine and sealing device technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of adverse effects of waste heat recovery, air volume loss, thermal pollution and dust, etc., to improve the efficiency of waste heat recovery and reduce equipment Air leakage, improve the effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

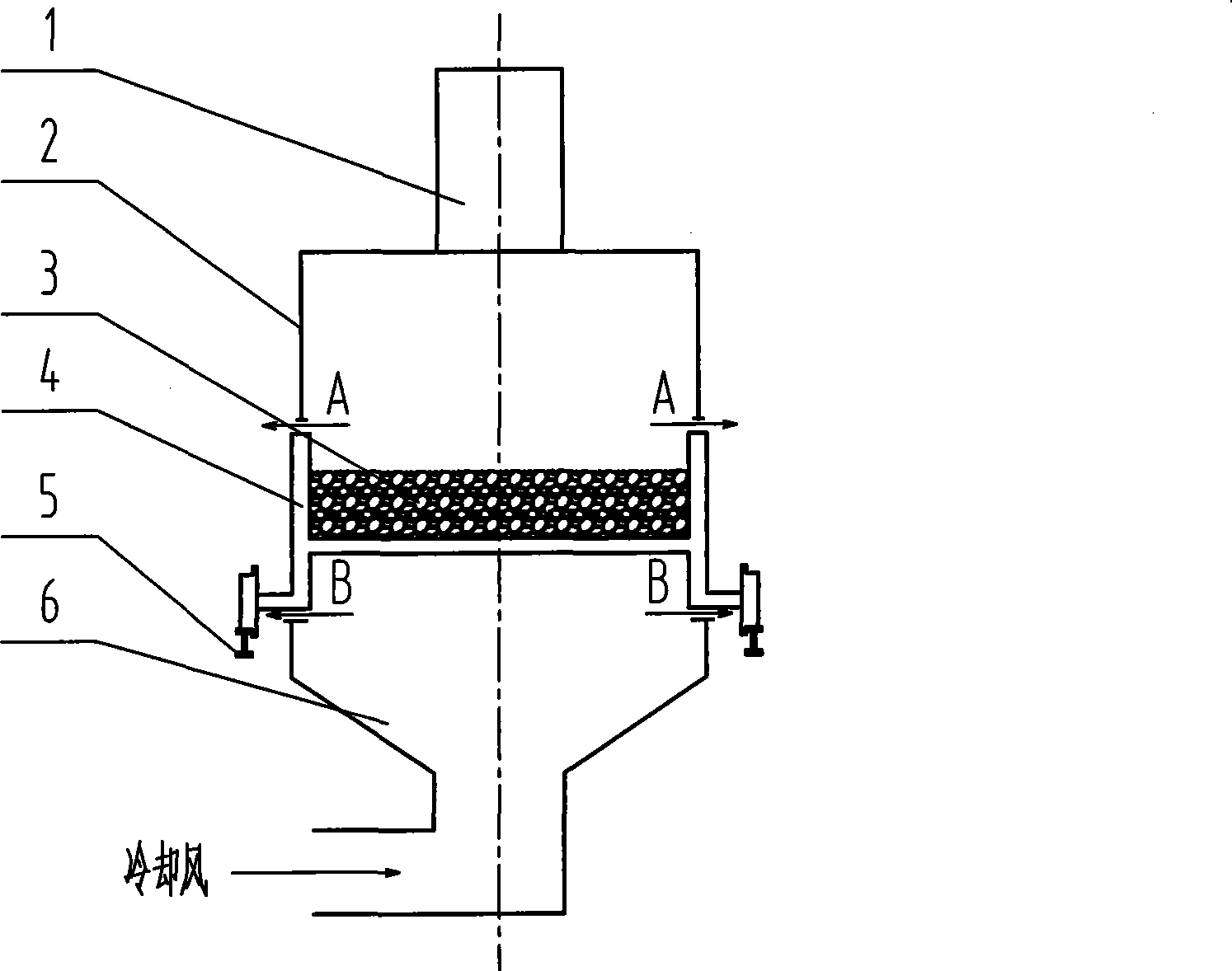

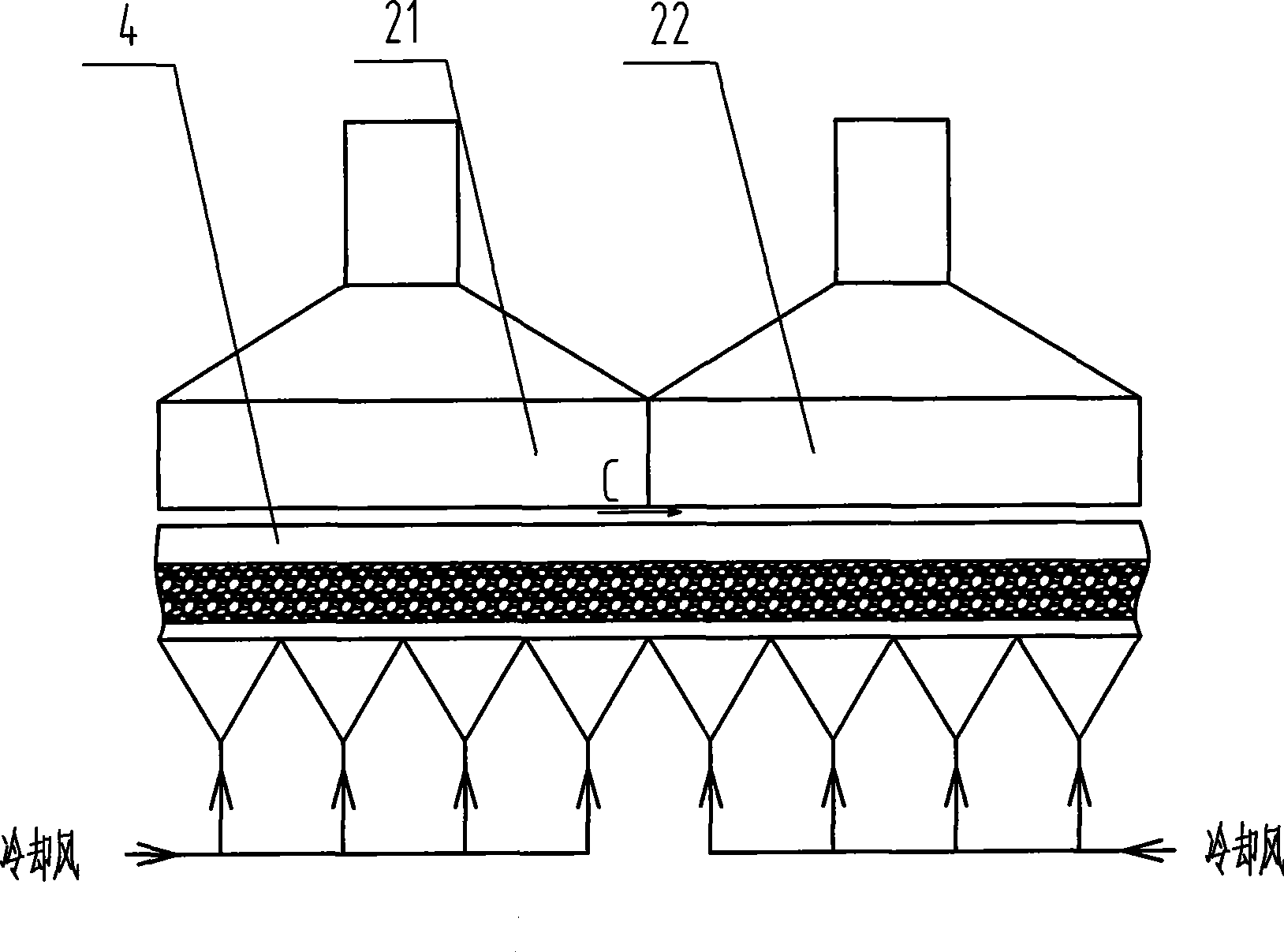

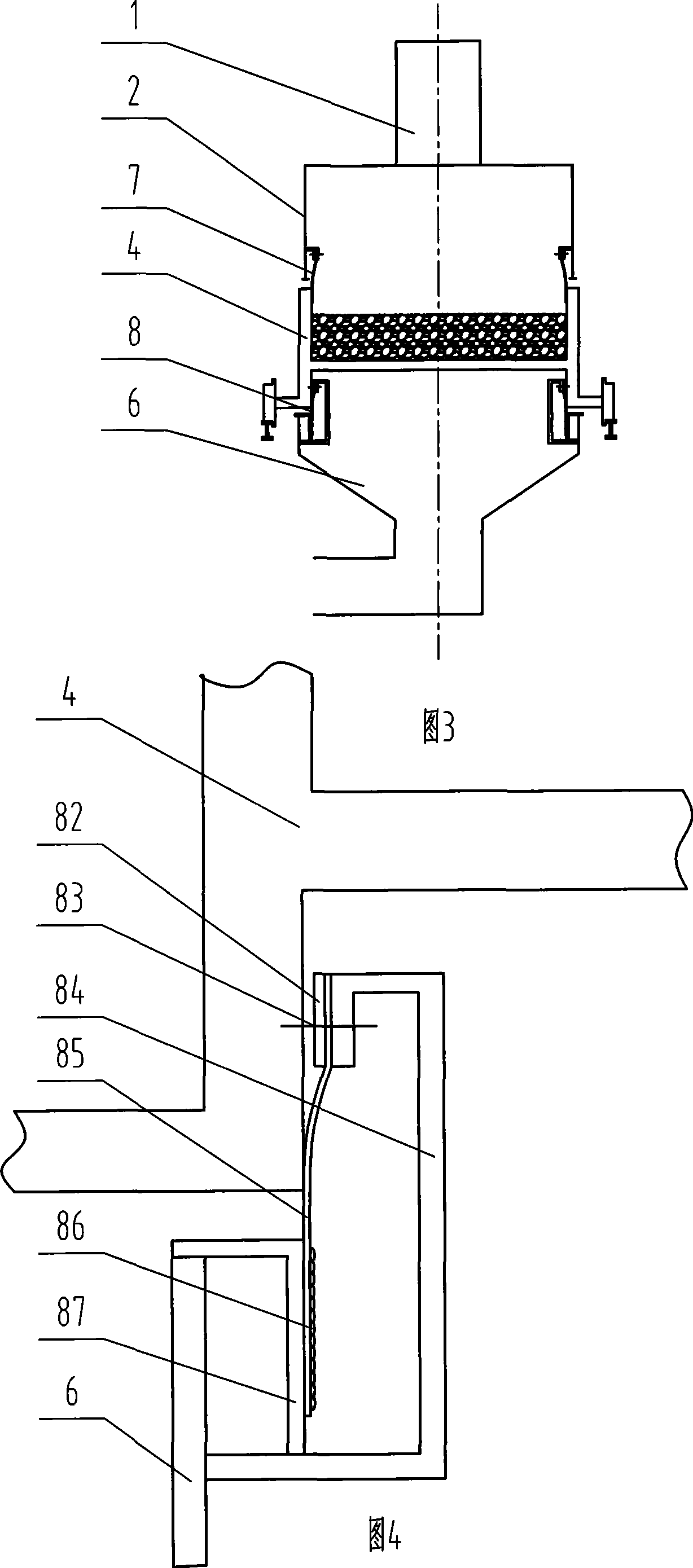

[0056] Firstly, the four sealing methods of the present invention will be described with reference to the accompanying drawings, namely 1. flexible sealing, 2. laminated sealing, 3. hanging sealing, and 4. mosaic sealing. Next, embodiments of the present invention will be described.

[0057] Also, in the context of the present invention, the trolley 4 is divided into two parts, namely an upper trolley part and a lower trolley part. The upper part of the trolley generally refers to the part of the trolley above the bearing plate carrying the sintered ore 3, and the lower part of the trolley refers to the part of the trolley under the bearing plate.

[0058] It should be noted that although the sintering cooling machine is used as an example for description below, the present invention is also applicable to general sintering machines. Specifically, because the existing sintering machine usually does not have a fume hood 2, in general, the sintering machine of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com