Medium and high temperature roller crusher with high efficiency composite cooling system

A roll crusher and composite cooling technology, which is applied in grain processing and other directions, can solve the problems of not being able to support the roll crusher for long-term, reliable, and safe work, and achieve the effect of accelerating heat transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

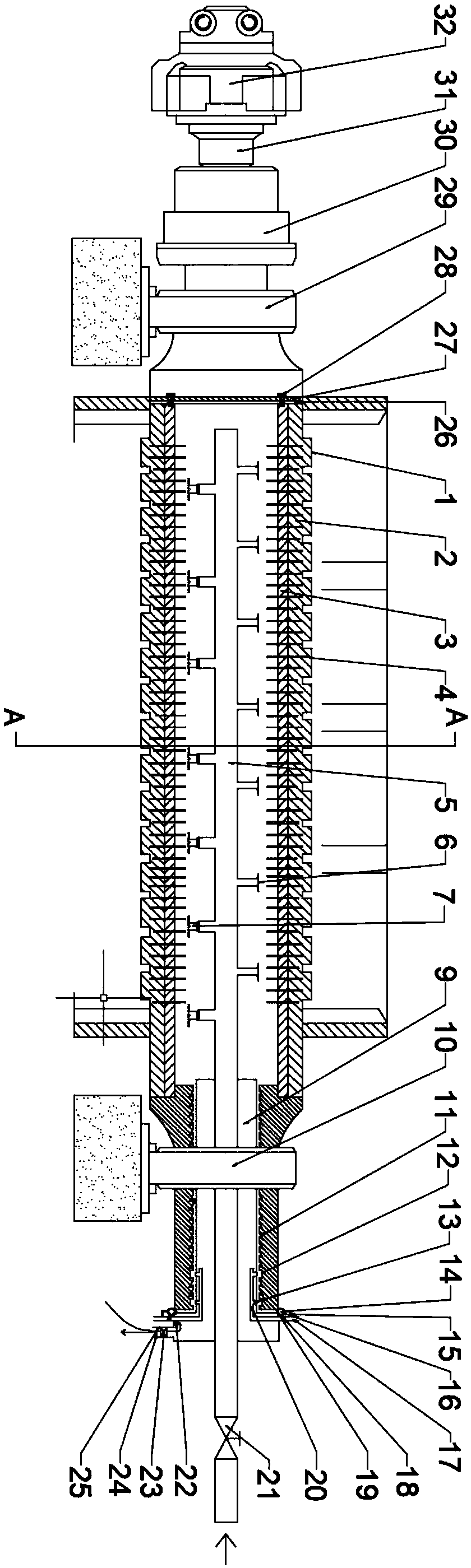

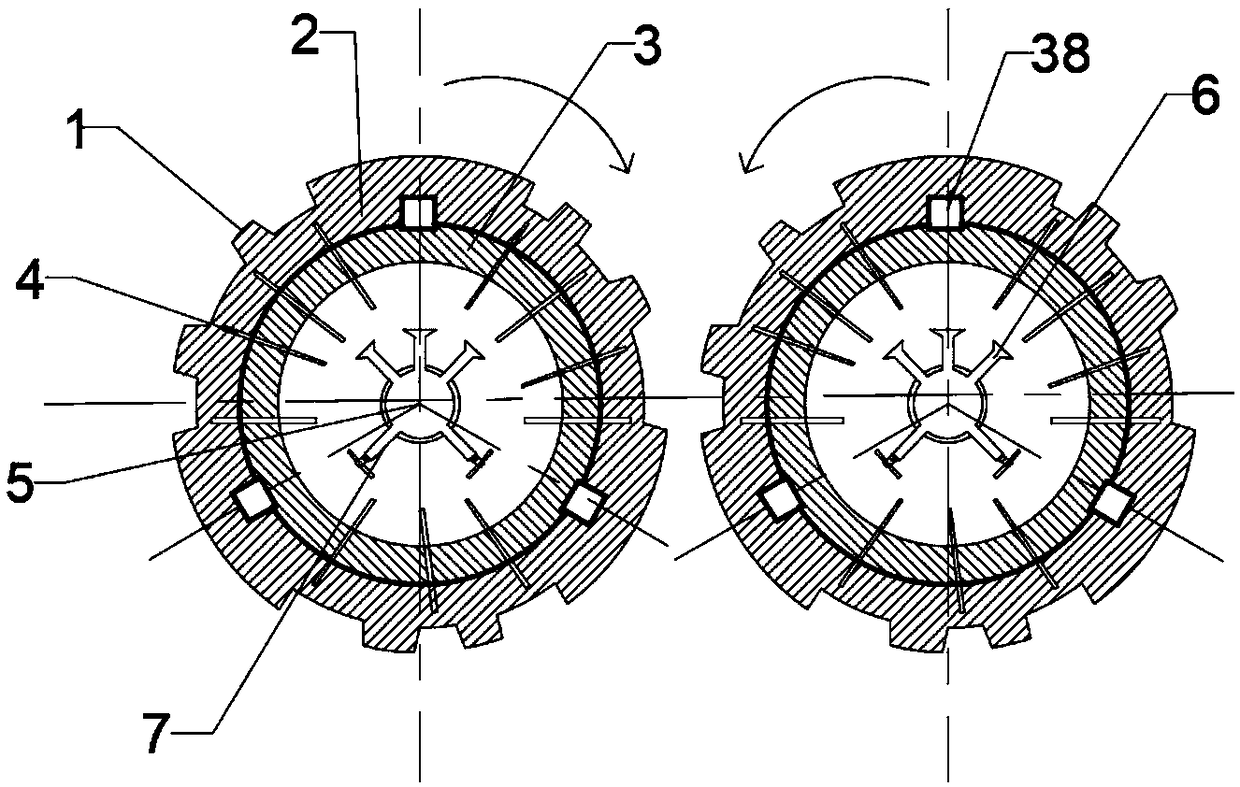

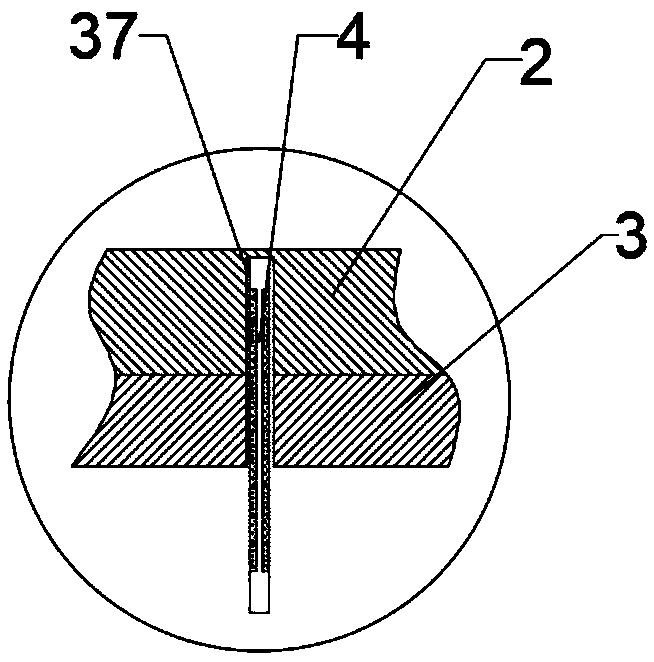

[0022] In order to further understand the content of the invention and its characteristics of the present invention, now in conjunction with the accompanying drawings, describe in detail as follows:

[0023] figure 1 Provided is a schematic view of the structure of the roller unit of the present invention, figure 2 given is figure 1 A-A sectional view in, a medium-high temperature roller crusher with high-efficiency composite cooling system, including transmission device, crushing unit, micro heat pipe cooling system, water cooling system, driven end sealing system and measurement and control system. The transmission device of the roller crusher is composed of a variable frequency motor 32, a hydraulic press 31 and a planetary reducer 30. The high-speed rotation energy of the variable frequency motor 32 is converted into low-speed output kinetic energy through the hydraulic press 31, and then the power is transmitted to the roller shaft 3. The planetary reducer 30 drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com