A printing flattening device for textile fabrics

A textile fabric and printing technology, which is applied in the field of textile processing, can solve the problems of uneven fabric surface wrinkles, ink accumulation, lack, etc., to achieve the effects of avoiding ink accumulation, improving the smoothing effect, and improving the printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

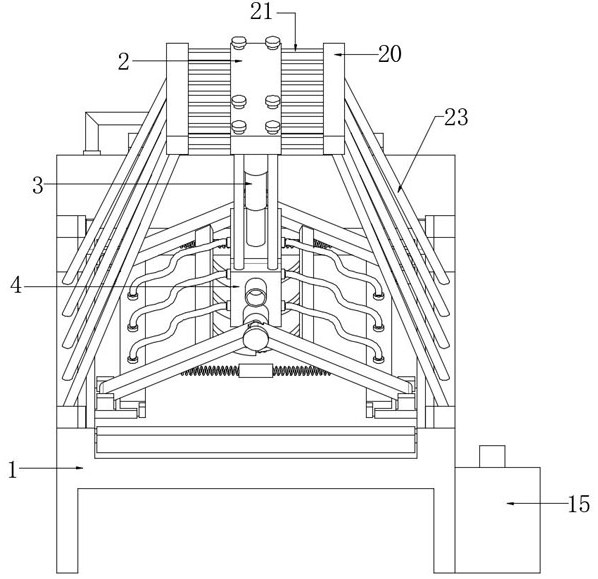

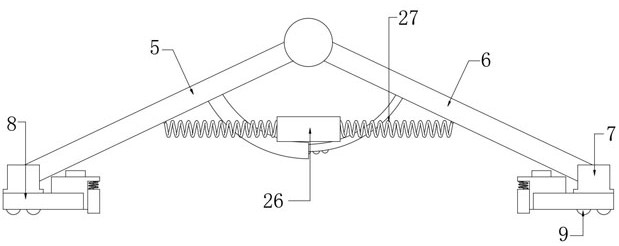

[0033] A printing flattening device for textile fabrics, such as figure 1 and figure 2 As shown, including the outer box 1, one side of the outer box 1 is set as an inclined plane, and a top platform 2 is arranged above the inclined surface, and the bottom of the top platform 2 is provided with a circular groove, and the inner wall of the circular groove is connected with a first bolt. Hydraulic rod 3, the other end of the first hydraulic rod 3 is connected with the processing box 4 by bolts, and the two ends of the processing box 4 are provided with a left strut 5 and a right strut 6, between the left strut 5 and the right strut 6 Connected by bearing rotation, and the bottom ends of the left pole 5 and the right pole 6 are connected with a connection block 7 by bolts, a smoothing assembly is arranged below the connection block 7, and a dust suction assembly is provided on the processing box 4.

[0034] Further, such as image 3 As shown, the smoothing assembly includes a ...

Embodiment 2

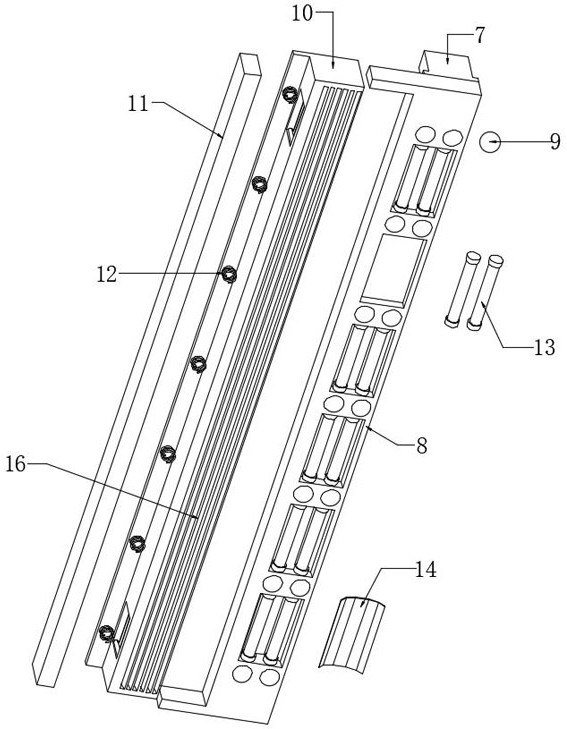

[0036] Further, such as figure 1 , image 3 and Figure 4 As shown, the dust suction assembly includes a vacuum cleaner 15, a dust suction strip 16 and an air inlet 17, the vacuum cleaner 15 is connected with one side of the outer wall of the outer box 1 by bolts, the air inlet 17 is connected with the inner wall of the processing box 4 by bolts, and the dust suction strip 16 and the bottom inner wall of the functional box 10 are connected by bolts; the vacuum cleaner 15 is provided with a dust suction port 18, and the dust suction port 18 and the air inlet 17 are connected by a hose, and the functional box 10 and the processing box 4 are connected by bolts There are a plurality of dust suction pipes 19, and the dust on the surface of the cloth is absorbed and removed by the dust suction assembly during the smoothing operation, so as to prevent the dust on the surface of the cloth from affecting the ink printing quality in the subsequent printing operation.

[0037] Going a ...

Embodiment 3

[0039] Going a step further, as in Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, there are brackets 28 connected by bolts between the two left struts 5 and the right struts 6, the outer wall of one side bracket 28 is connected with a plurality of speed reduction tubes 29 by bolts, and the outer wall of the other side bracket 28 is connected by bolts There are a plurality of insertion rods 30, the insertion rods 30 are slidingly connected with the inner wall of the deceleration cylinder 29, and the inner wall of the deceleration cylinder 29 is provided with a semicircular retaining groove 31, and the outer wall of one side of the insertion rod 30 is equidistantly provided with a plurality of grooves, the grooves The inner wall of the inner wall is slidingly connected with a stopper 32, and the limit spring 33 is connected between the stopper 32 and the inner wall of the groove of the insertion rod 30 by bolts, and the deceleration cylinder 29 and the insertion rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com