Patents

Literature

177results about How to "Easy to smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

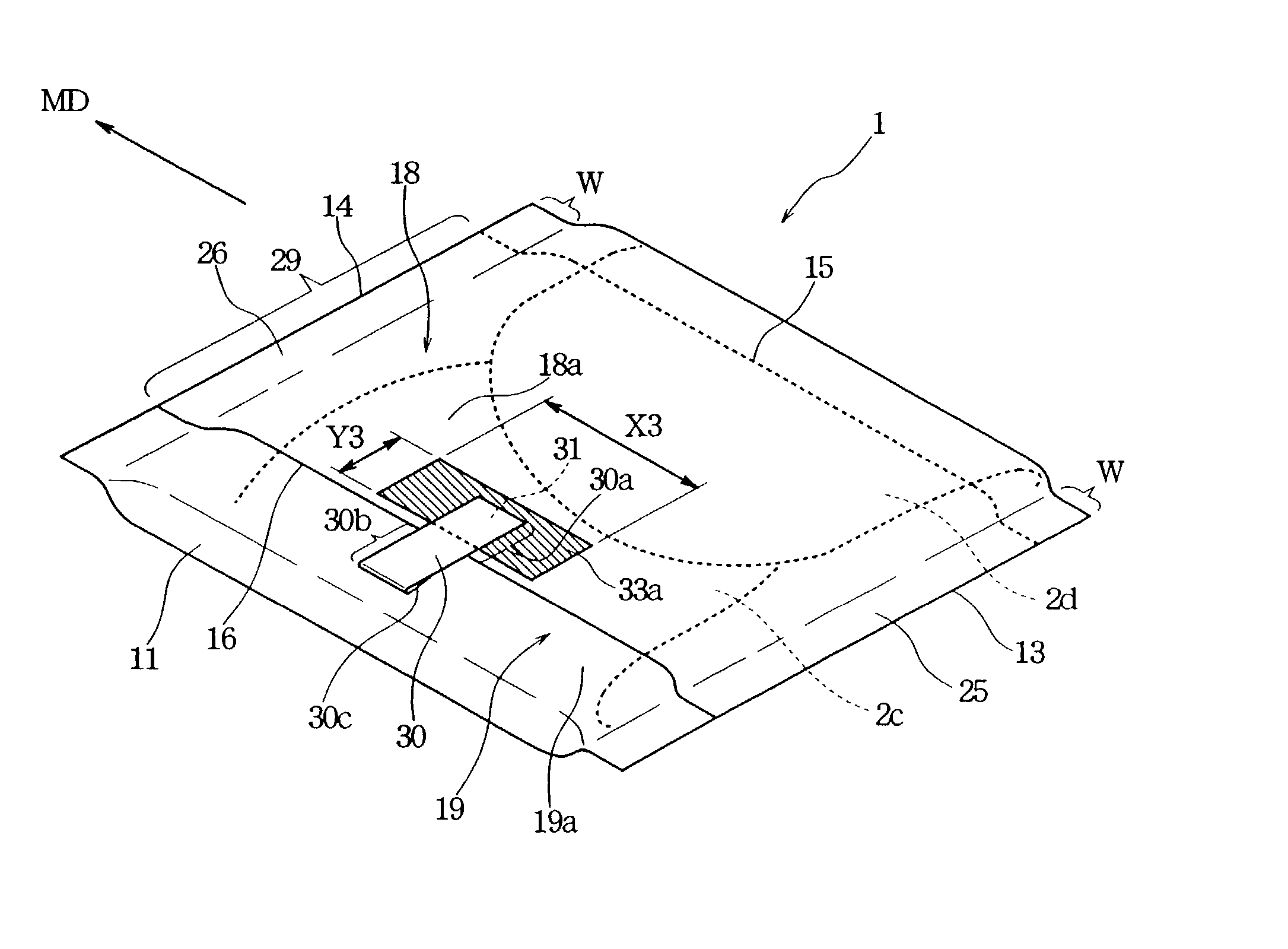

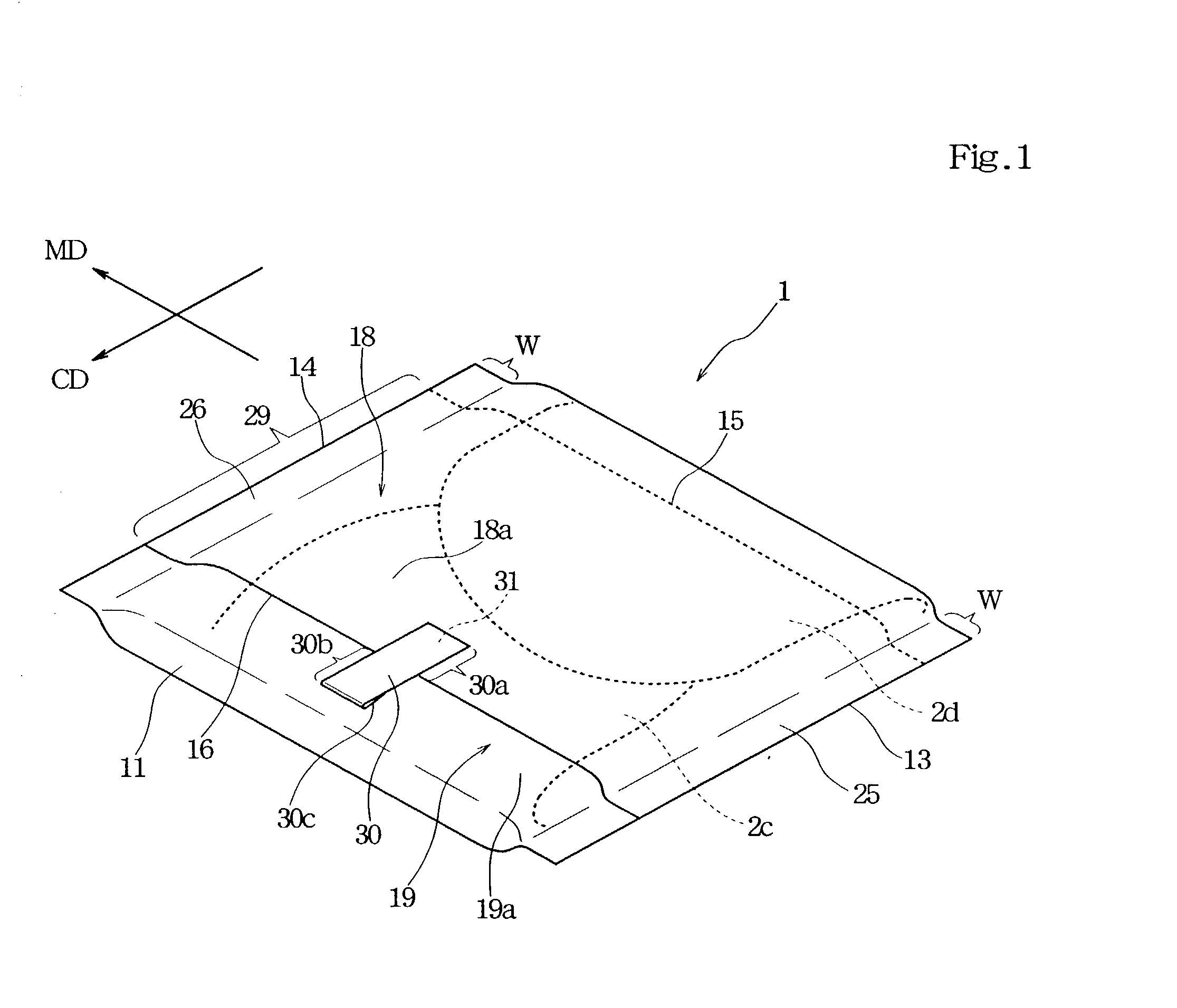

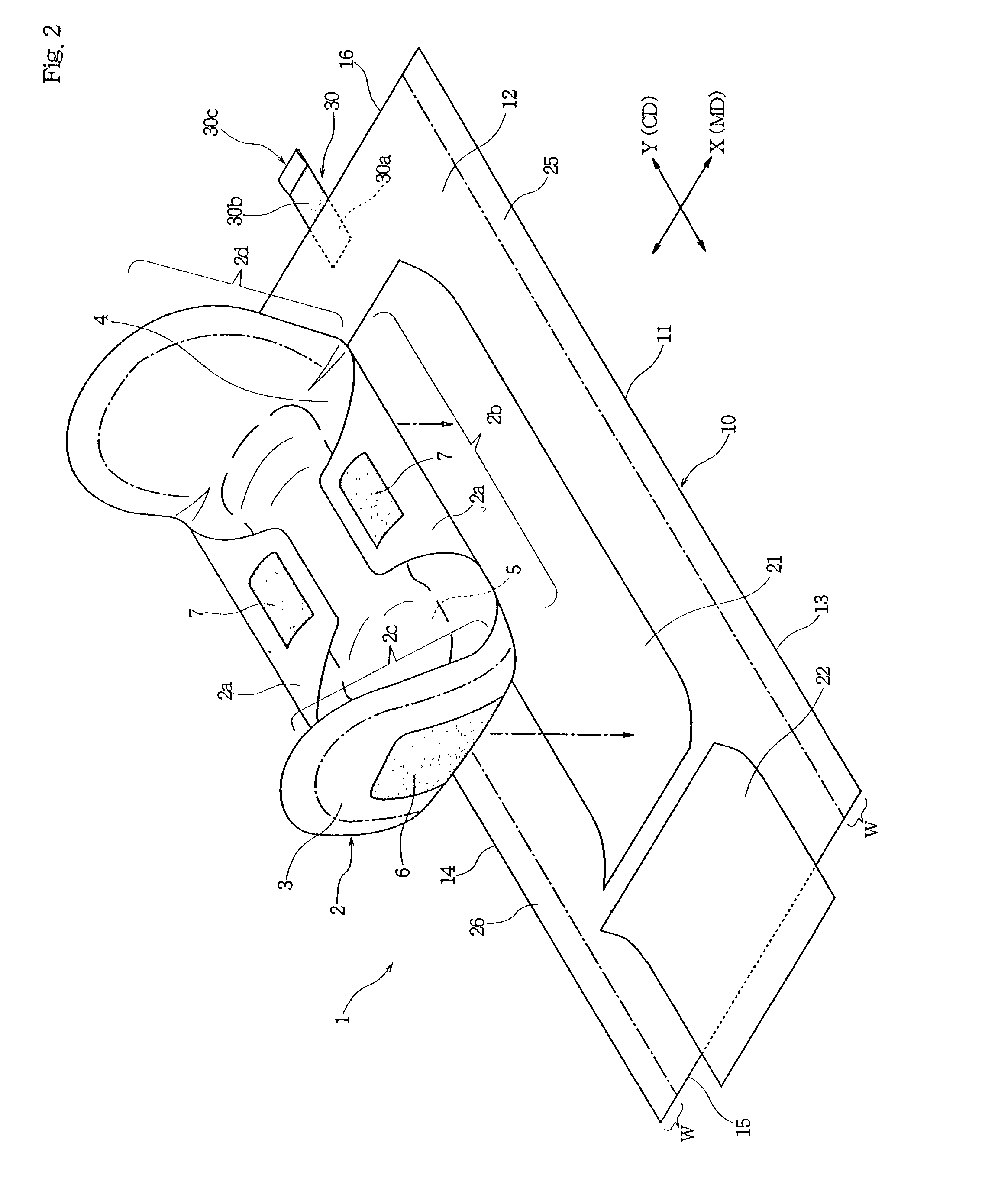

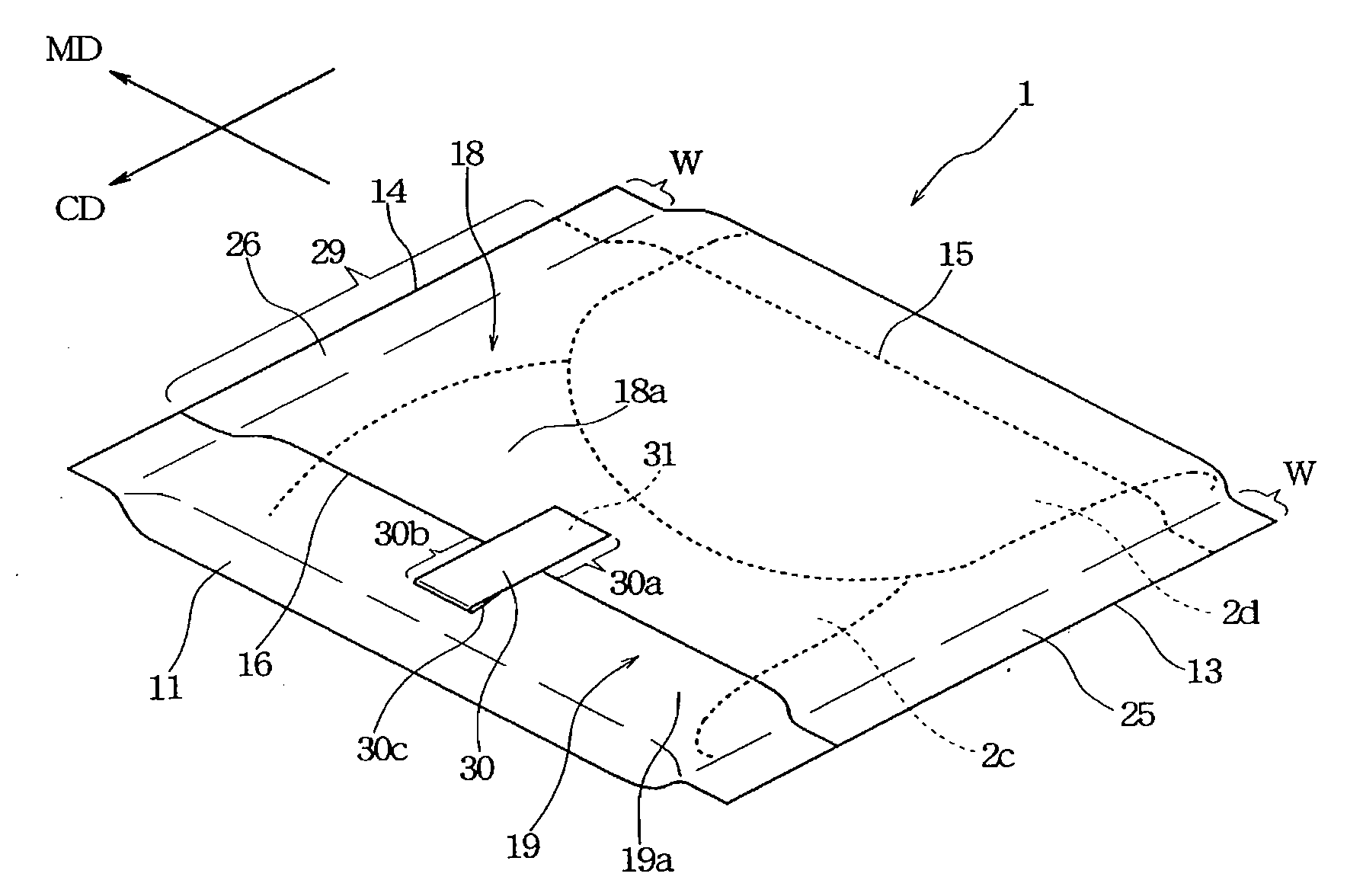

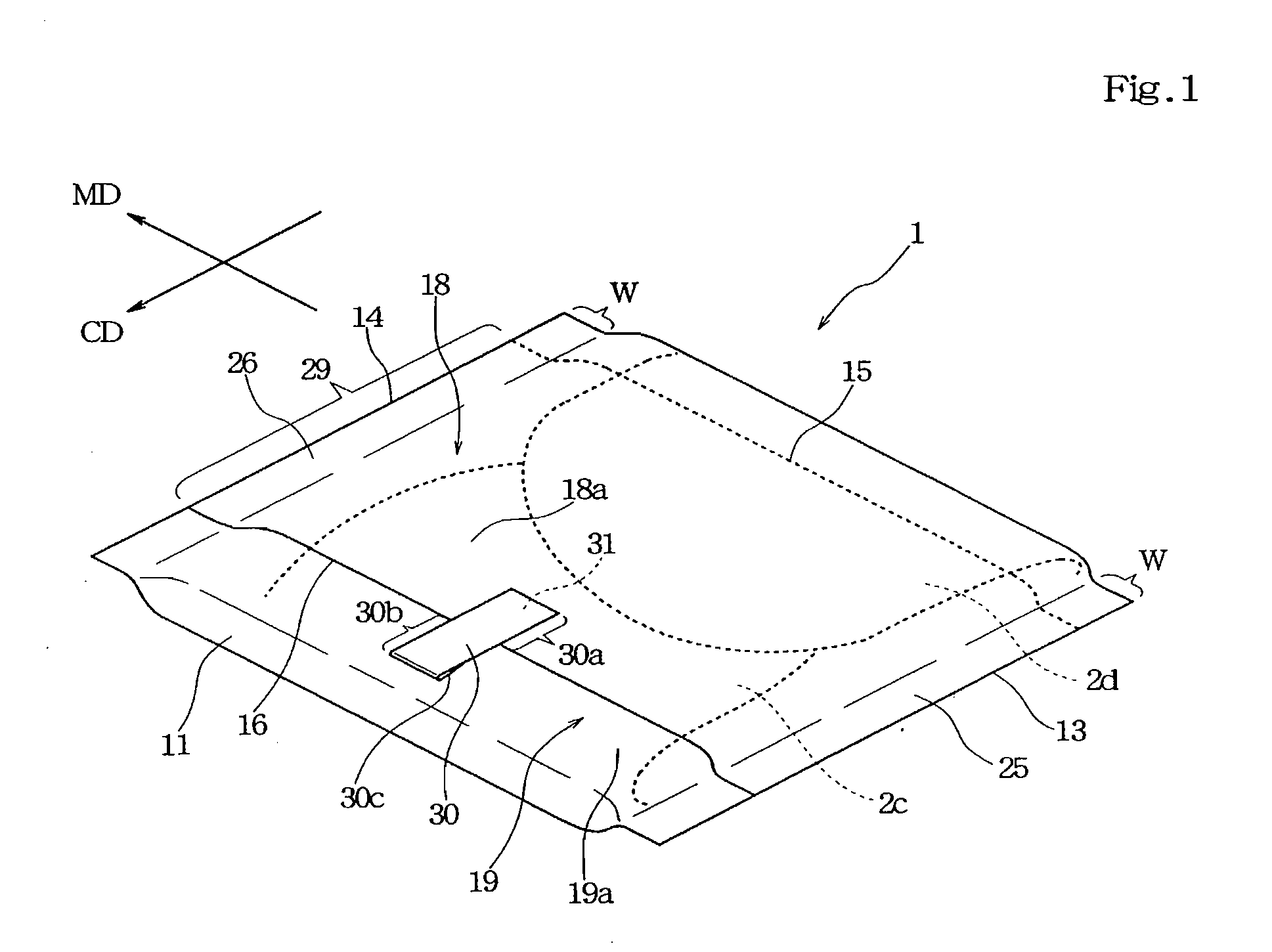

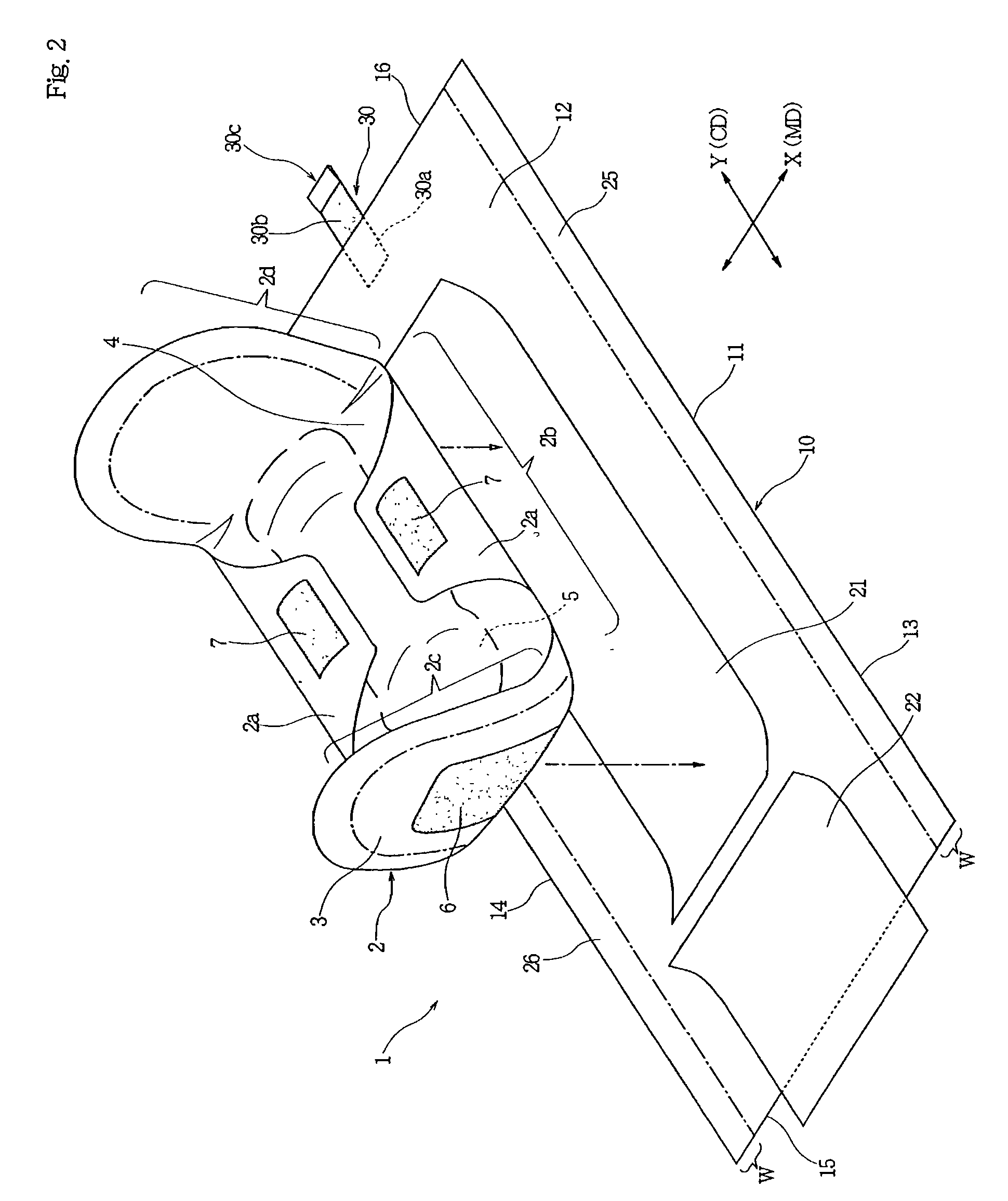

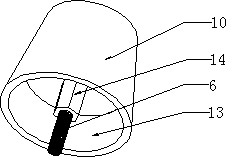

Individual package of absorbent article

InactiveUS20030065302A1Stay softMaintain forceContainers for flexible articlesCatheterEngineeringUltimate tensile strength

An individual package of an absorbent article permits a base end of a tape to be bonded with sufficiently large bonding strength without complicating packaging process and increasing manufacturing cost. The absorbent article is wrapped by a package sheet having side edge portions and end edges, and one end edge is overlapped over the other end edge. The package sheet is sealed along the side edge portions, a base end of a tape is fixed on the surface of the package sheet located outside in an overlapping portion, and a free end of the tape extends across one end edge and is releasably adhered on the outer surface of the package sheet adjacent one end edge. The package sheet has a surface, on which the base end of the tape is fixed, the surface being smoothed by a smoothing process.

Owner:UNI CHARM CORP

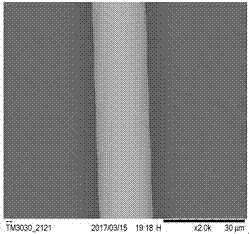

Method for preparing polyacrylonitrile-based carbon fiber precursor fiber

ActiveCN101161880AConducive to smoothHigh tensile strengthMonocomponent synthetic polymer artificial filamentWet spinning methodsElastic modulusAmmonium hydrogen sulfite

The invention provides a preparation method for polyacrylonitrile base carbon fiber protofilament. ammonium persulfate-ammonium sulfite or ammonium hydrogen sulfite is used as the aqueous phase suspension copolymerization of a initiation system for preparing polyacrylonitrile base carbon fiber protofilament which uses polymers as raw materials; polymers are made into 16-20Wt percent of slurry at -18-0 DEG C, vacuumized to 40-95 Kpa and dissolved for 1-2 hours at 40-55 DEG C; then spinning stock solution at 70-80 DEG C is extruded into a spinning pipe in coagulation bath via a spinneret to be shaped, and PAN nascent fiber is obtained through the minus elongation of the coagulation bath; the PAN nascent fiber has desolventize flushed away by hot water, and is simultaneously stretched, oiled, dried for densification, baked and elongated to obtain PAN base protofilament, and the tensile strength is no lower than 6.60N / dtex; the carbon fiberstrength is 3.30-4.01Gpa, and the elastic modulus is 210-262Gpa. The main technical indexes of the present invention are equivalent to the similar products in America, Japan and other countries.

Owner:吉林碳谷碳纤维股份有限公司

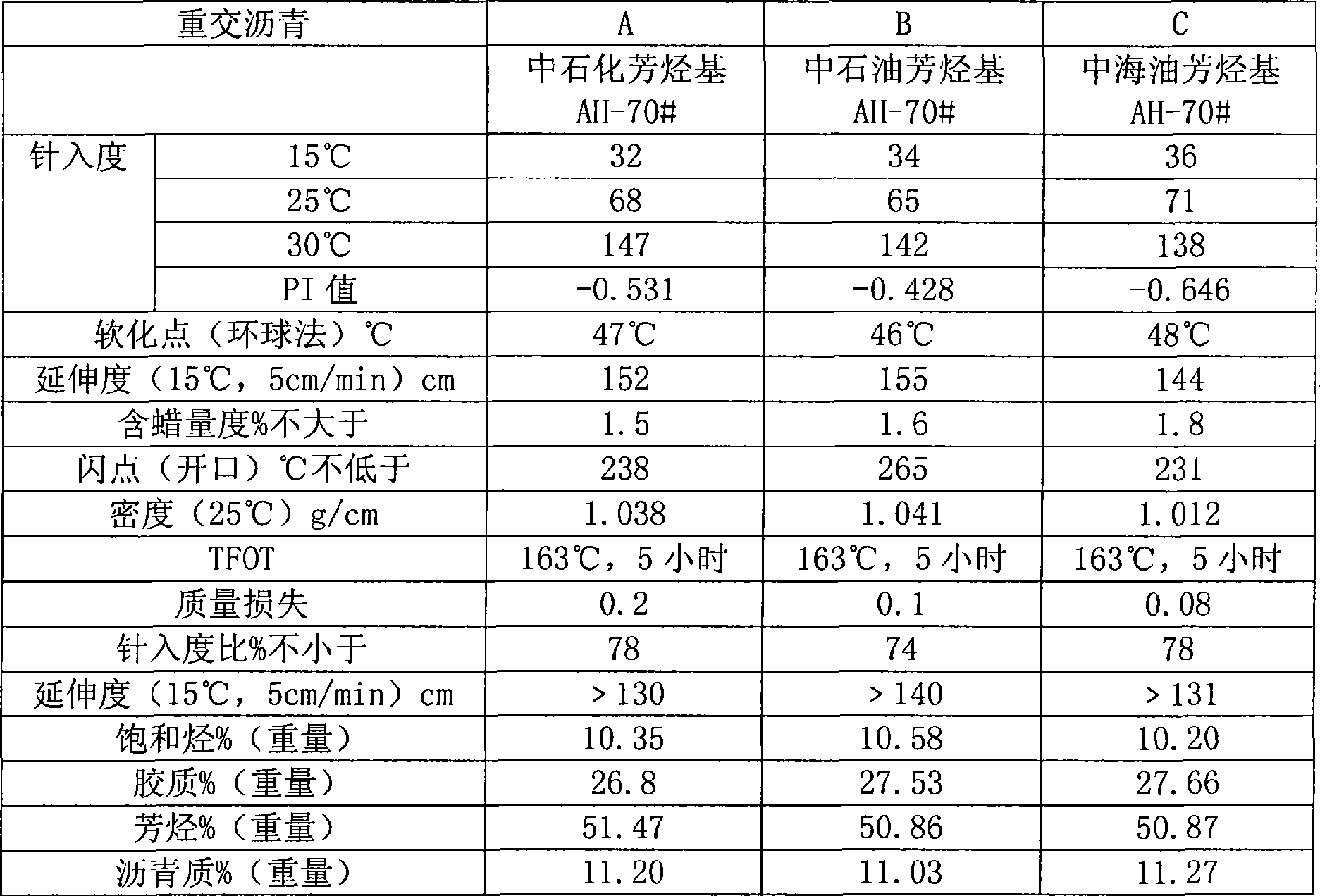

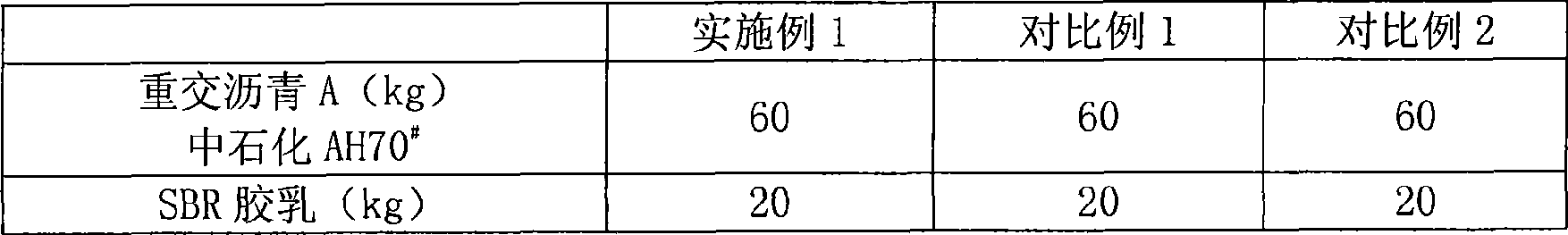

High strength cold state asphalt fissure cementation water-proof glue and preparation thereof

ActiveCN101475748AGood anti-aging performanceImprove high temperature performanceOther chemical processesBuilding insulationsTO-18Adhesive

The invention relates to high-strength cold asphalt crack-pouring waterproof adhesive and a preparation method thereof. The waterproof adhesive comprises the following components in portion by weight: 15 to 20 portions of modifier polymer, 2.0 to 3 portions of dispersant, 0.5 to 2.0 portions of stabilizing agent, 50 to 60 portions of heavy rubber asphalt, 1.5 to 2.0 portions of emulsifying agent, 15 to 18 portions of purified water, and 4 to 16 portions of curing agent. The waterproof adhesive has the advantages of simple preparation, reliability and excellent properties, can be widely applied to crack pouring for large traffics in cities and countryside, heavy loading high-grade roads, stress absorbing structural layers, waterproof and mist sealing layers or layer sealing mat coats and the like, and remarkably improves water proofing, skid resistance, flatness and abrasion resistances of the roads.

Owner:钦兰成

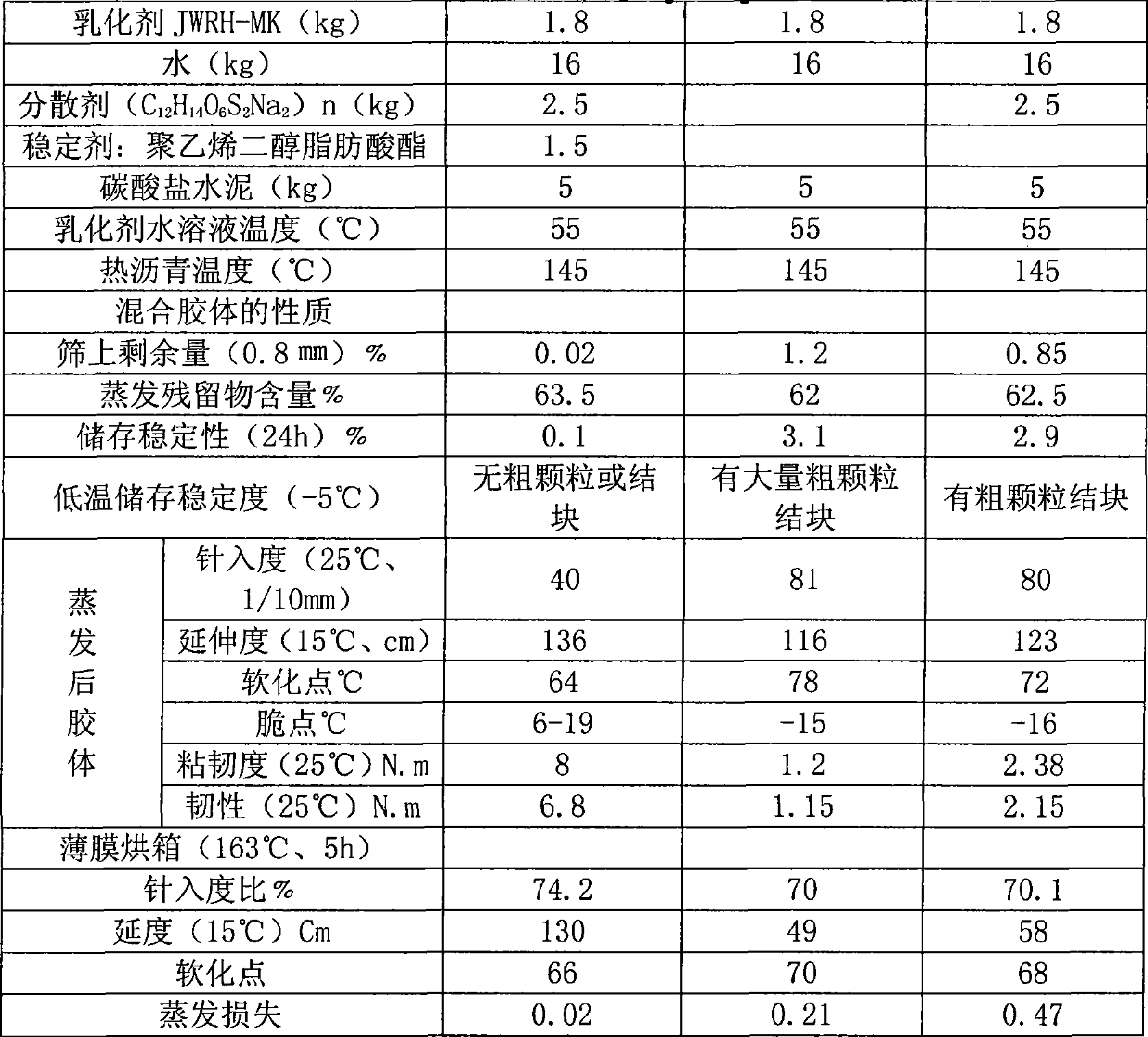

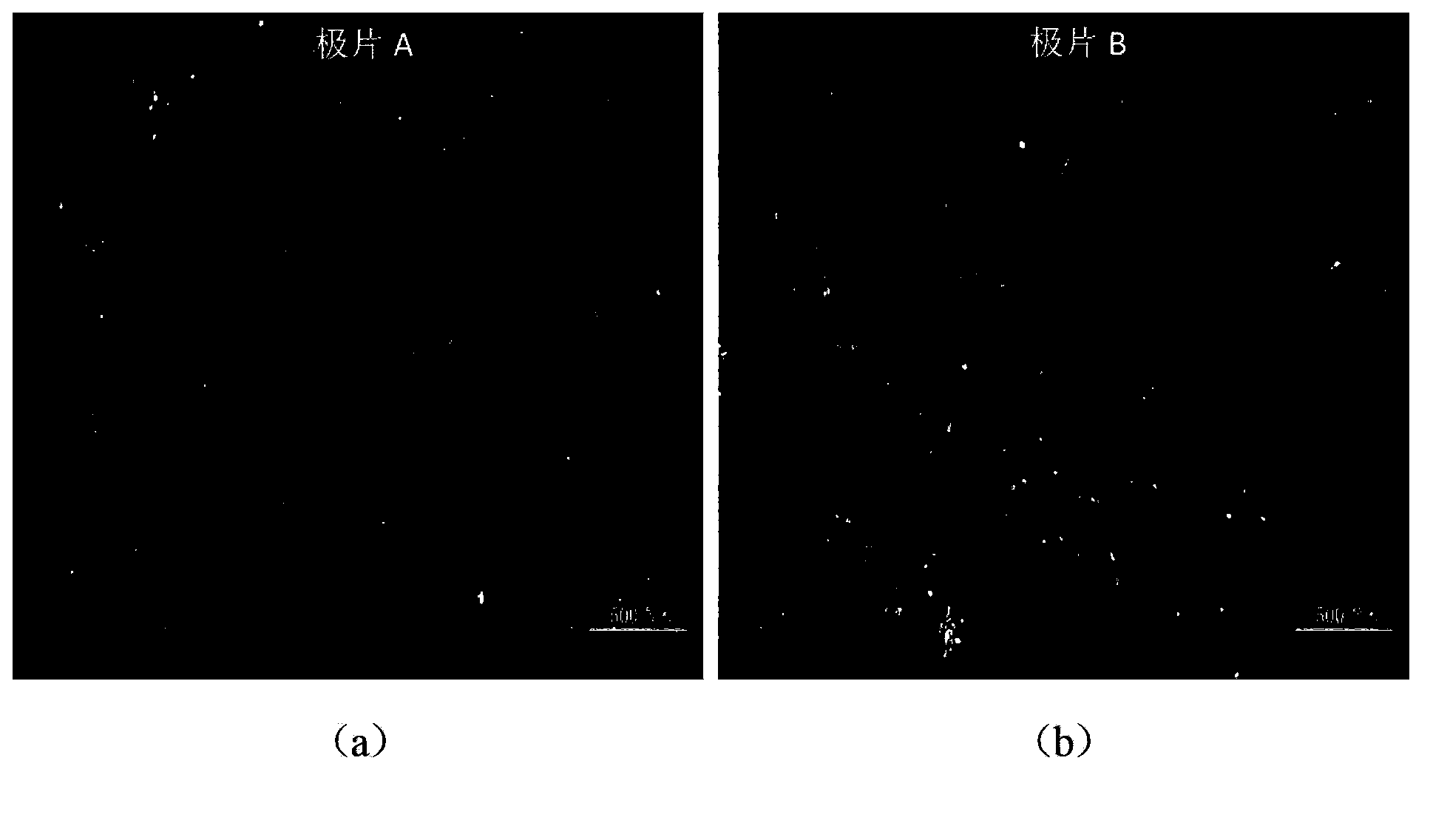

Method for using carbon nano conductive agent in lithium ion battery aqueous slurry

InactiveCN103840164AEffective dispersionEasy to smoothImpregnation manufacturingSlurrySurface-active agents

The invention discloses a method for using a carbon nano conductive agent in lithium ion battery aqueous slurry, and belongs to the technical fields of conductive agents and lithium ion batteries. According to the method disclosed by the invention, the carbon nano conductive agent is directly added into the lithium ion battery anode / cathode aqueous slurry (free from a surface active agent) and then is subjected to ball milling at a high speed after being stirred; the hydrophobic carbon nano conductive agent is effectively dispersed by utilizing shearing force generated during ball-milling at the high speed, so that various constituent materials in the lithium ion battery anode / cathode aqueous slurry can be uniformly dispersed, and therefore, the hydrophobic carbon nano conductive agent can also be applied in the lithium ion battery aqueous slurry in the absence of the surface active agent. The method disclosed by the invention is simple in process and low in cost; the current process is not changed; after being coated, the slurry prepared by utilizing the method disclosed by the invention is assembled to form a lithium ion battery, and therefore, the rate capability can be effectively increased.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

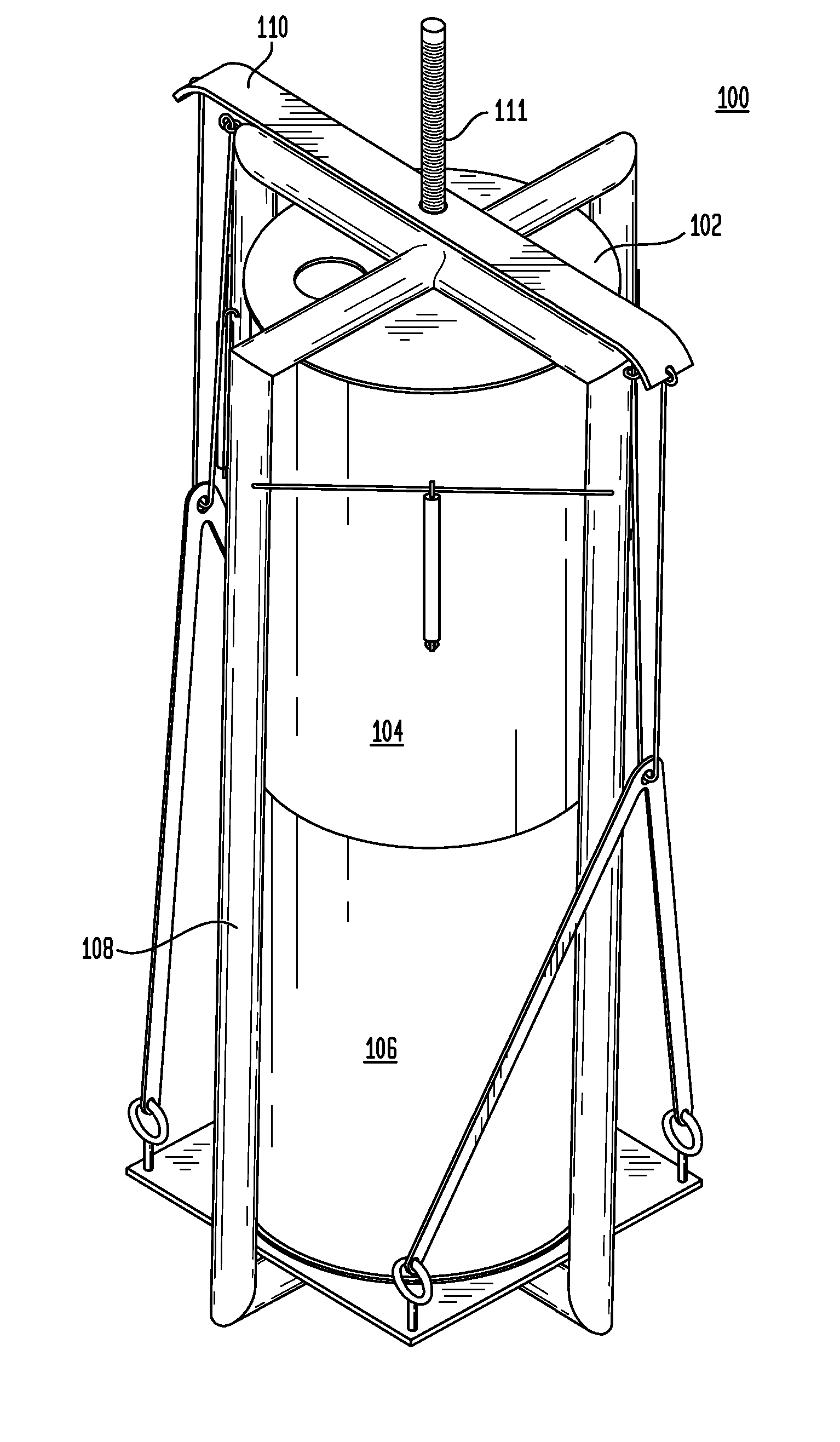

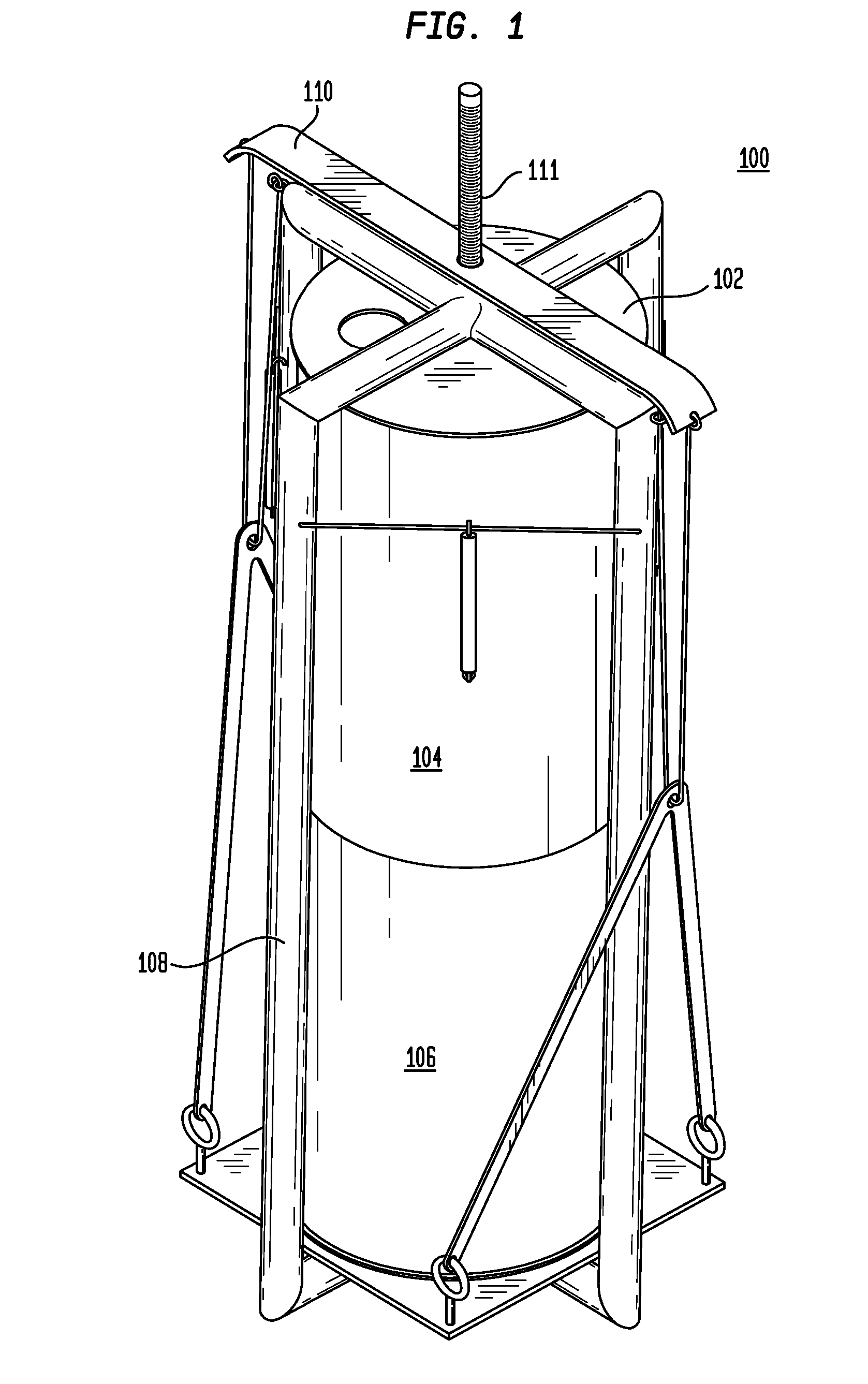

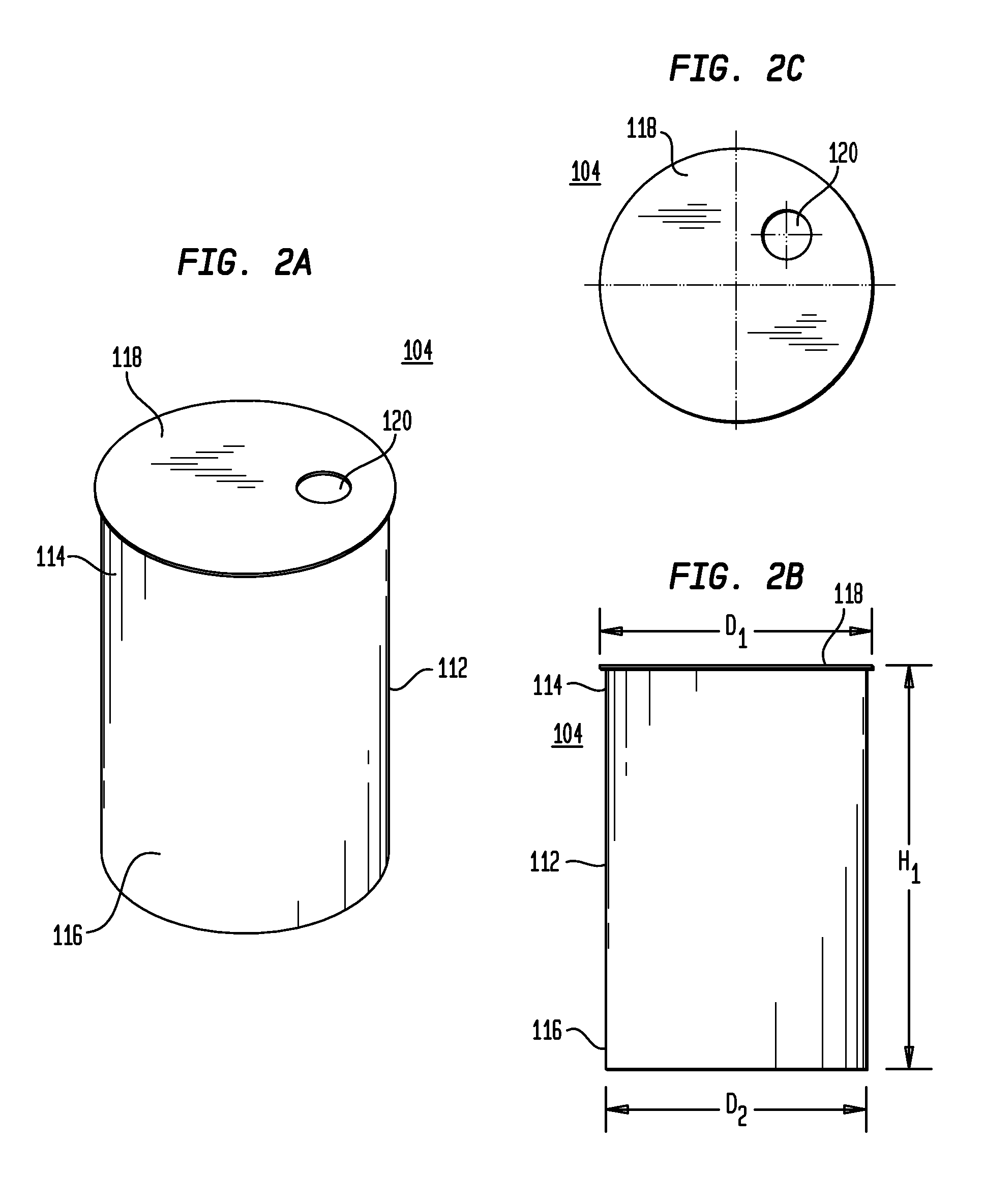

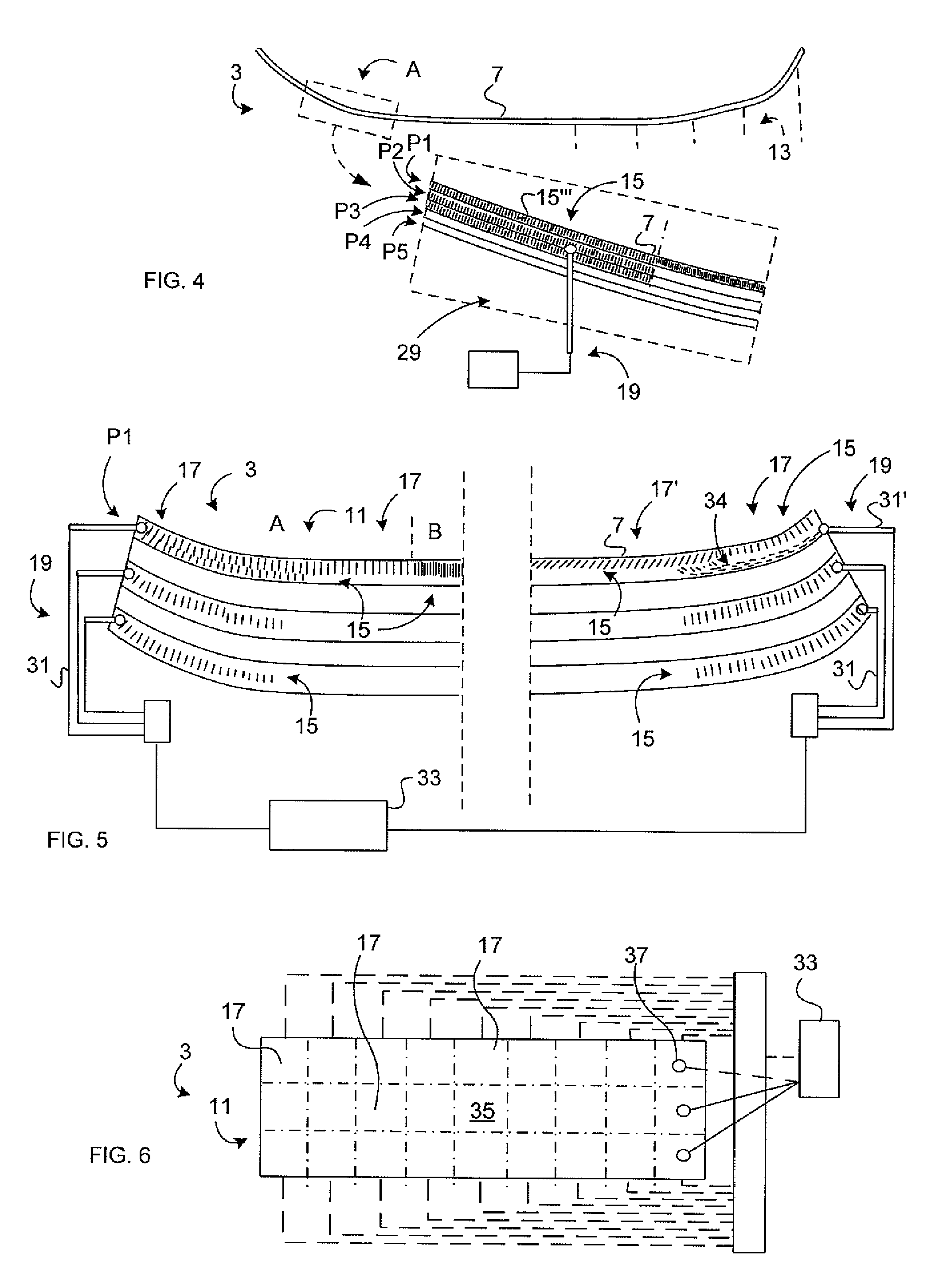

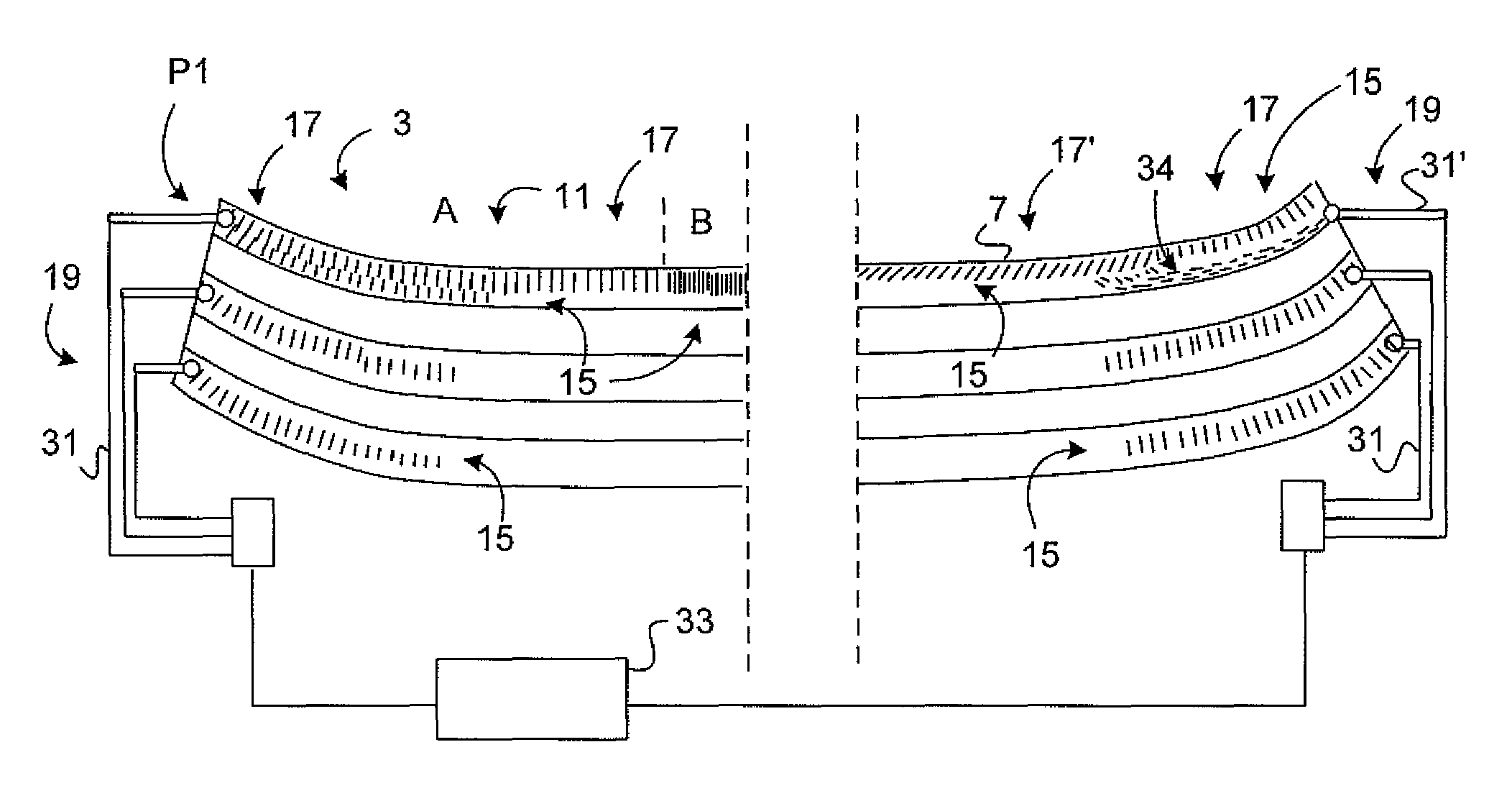

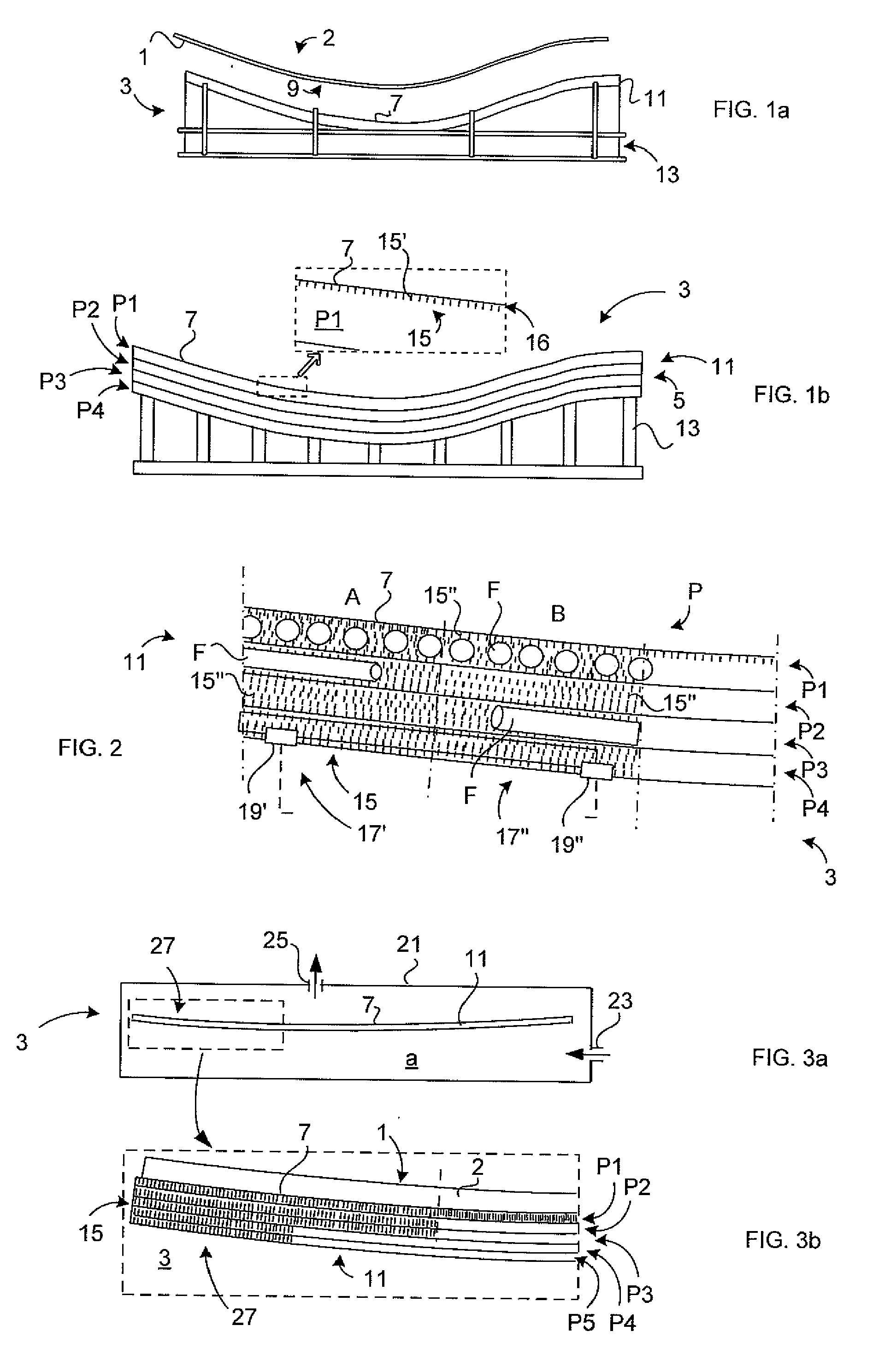

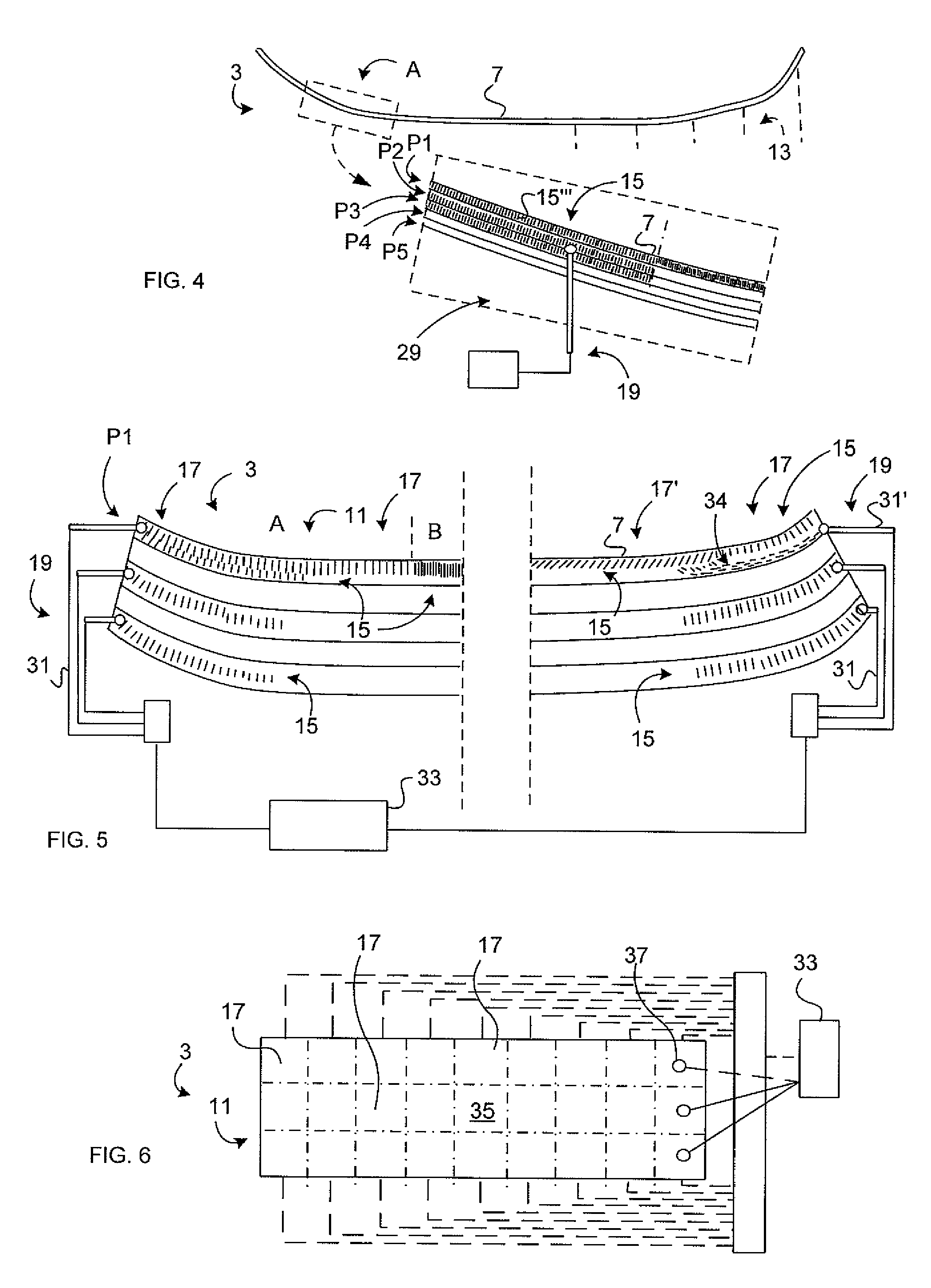

Systems and methods using gravity and buoyancy for producing energy

InactiveUS20080092535A1Sufficient buoyancy forceIncrease in sizeHydro energy generationMachines/enginesEngineeringGravitational force

A system for producing energy includes expandable vessels that are submerged in a liquid. The vessels are collapsible for sinking in the liquid due to gravitational forces and are expandable for rising in the liquid due to buoyancy forces. As the vessels sink in the liquid, the vessels rotate a shaft for generating energy. In one embodiment, the system includes a tank holding a liquid, an air-tight, expandable vessel disposed within the liquid and being adapted to move reciprocally between upper and lower ends of the tank, a conduit attached to the vessel for passing gas into and out of the vessel, and a linkage for selectively coupling the vessel with a rotatable shaft. The vessel is moveable between a collapsed state in which the vessel sinks in the liquid due to gravitational forces and an expanded state in which the vessel rises in the liquid due to buoyancy forces.

Owner:PASSIVE ENERGY

Individual package of absorbent article

InactiveUS20080276570A1High bonding strengthStay softContainers for flexible articlesWrapper folding/bending apparatusEngineeringUltimate tensile strength

An individual package of an absorbent article permits a base end of a tape to be bonded with sufficiently large bonding strength without complicating packaging process and increasing manufacturing cost. The absorbent article is wrapped by a package sheet having side edge portions and end edges, and one end edge is overlapped over the other end edge. The package sheet is sealed along the side edge portions, a base end of a tape is fixed on the surface of the package sheet located outside in an overlapping portion, and a free end of the tape extends across one end edge and is releasably adhered on the outer surface of the package sheet adjacent one end edge. The package sheet has a surface, on which the base end of the tape is fixed, the surface being smoothed by a smoothing process.

Owner:UNI CHARM CORP

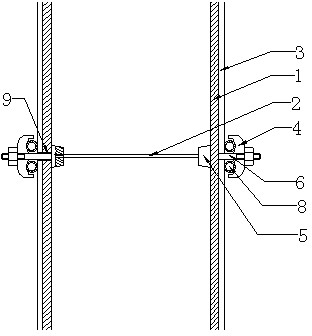

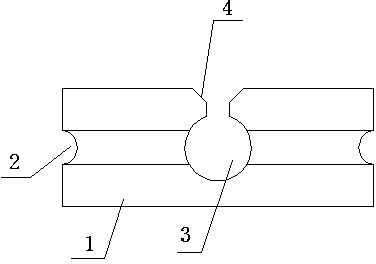

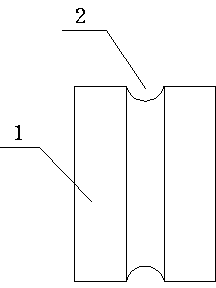

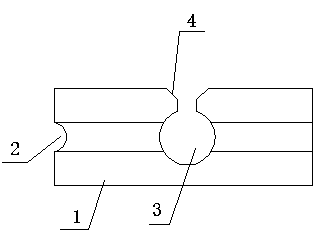

Building formwork forming structure, fasteners and construction method of building formwork

InactiveCN102296812AReduce wasteDensely packedAuxillary members of forms/shuttering/falseworksBuilding material handlingArchitectural engineeringScrew thread

The invention relates to a building formwork forming structure, a fastener used for the structure and a construction method, belonging to the formwork technology for concrete pouring in the construction industry. Its building formwork forming structure includes templates, tensioning screws, reinforcing ribs and clamps. The templates are arranged on both sides of the concrete filling cavity in parallel. There are one pair of tensioning bolt holes set opposite to each other on the formwork. The two ends of the pull bolts are matched, and the two ends of the pull bolts are threaded to connect a pair of frustum-shaped fasteners; the frustum-shaped fasteners are arranged on the inside of the two templates, and the large end faces of the frustum-shaped fasteners facing the outside are arranged There is an extended screw that can pass through the hole of the pull bolt on the template; the protruding part of the extended screw passes through the column on the outside of the template and is tightened and fixed by a conventional clamp. The structure and method of the invention reduce the waste caused by cutting the ends of the pull bolts in the traditional structure, and simultaneously simplify the construction and improve the efficiency.

Owner:黄学贵

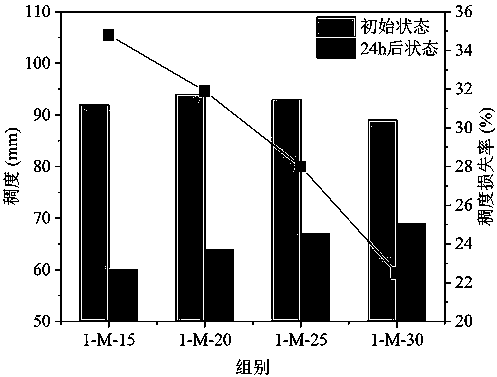

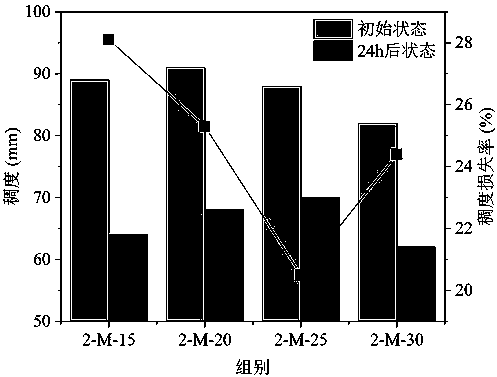

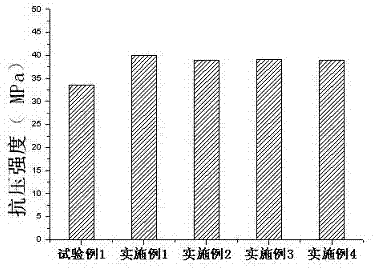

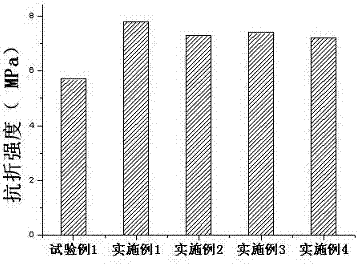

Mixed sand wet mixed mortar and preparation method thereof

InactiveCN110117173AImprove consistencyIncreased durabilityFineness modulusUltimate tensile strength

The invention discloses mixed sand wet mixed mortar and a preparation method thereof, and belongs to the field of building materials. The mortar is prepared from, by weight, 5-15 parts of cement, 2-6parts of coal ash, 40-100 parts of mixed sand, 0.1-0.2 part of a water reducing agent, 0.1-0.5 part of a thickening agent, 0.2-0.8 part of a retarder and 10-15 parts of water; the mixed sand is composed of machine-made sand and tailing sand. The industrial by-product tailing sand and abundant machine-made sand are sufficiently utilized, the fineness modulus of the mixed sand and the compact stacking state of a mortar mixture are regulated by regulating the mixing ratio of the mixed sand and the consumption of a binding material, and the mixed sand wet mixed mortar with the advantages of the machine-made sand and the tailing sand, the good working performance, convenient construction, excellent mechanical performance and outstanding durability is obtained. The wet mixed mortar is good in hardened compressive strength and good in durability.

Owner:CNBM ZHONGYAN TECH

Skin beautifying cosmetic for whitening, moisture preserving, anti-wrinkling and pore shrinking

InactiveCN105640862AEasy to smoothIncrease moist feelingCosmetic preparationsToilet preparationsVitamin CMelanin

The invention provides a skin beautifying cosmetic for whitening, moisture preserving, anti-wrinkling and pore shrinking. The skin beautifying cosmetic is prepared from the following raw materials in percentage by mass: 3 percent of hyaluronic acid, 6.7 percent of vitamin C (VC) and 90.3 percent of collagen. The hyaluronic acid can form a layer of film on the surface, so that the skin generates good smooth and moist feelings. Through self antioxidant activity, the VC can inhibit melanin formation, can inhibit peroxidase activity and can also directly reduce melanin, so that color spots on the pores are relieved, the skin becomes white, and the pores are not obvious. The skin is whitened, and water and nutrition are simultaneously supplemented; the water-oil balance of the skin is regulated; ingredients such as mild and safe corn oil extracts, moisture preserving factor hyaluronic acid, ceramide similar to skin formation structures and the like are selected; the prepared product achieves the effects of moistening and whitening the skin, improving the roughness and dullness of the skin and improving the moistening degree and the bright white degree of the skin.

Owner:王伟娜

Whitening essence

ActiveCN108498408APromote generationRestore elasticityCosmetic preparationsToilet preparationsWrinkle skinSide effect

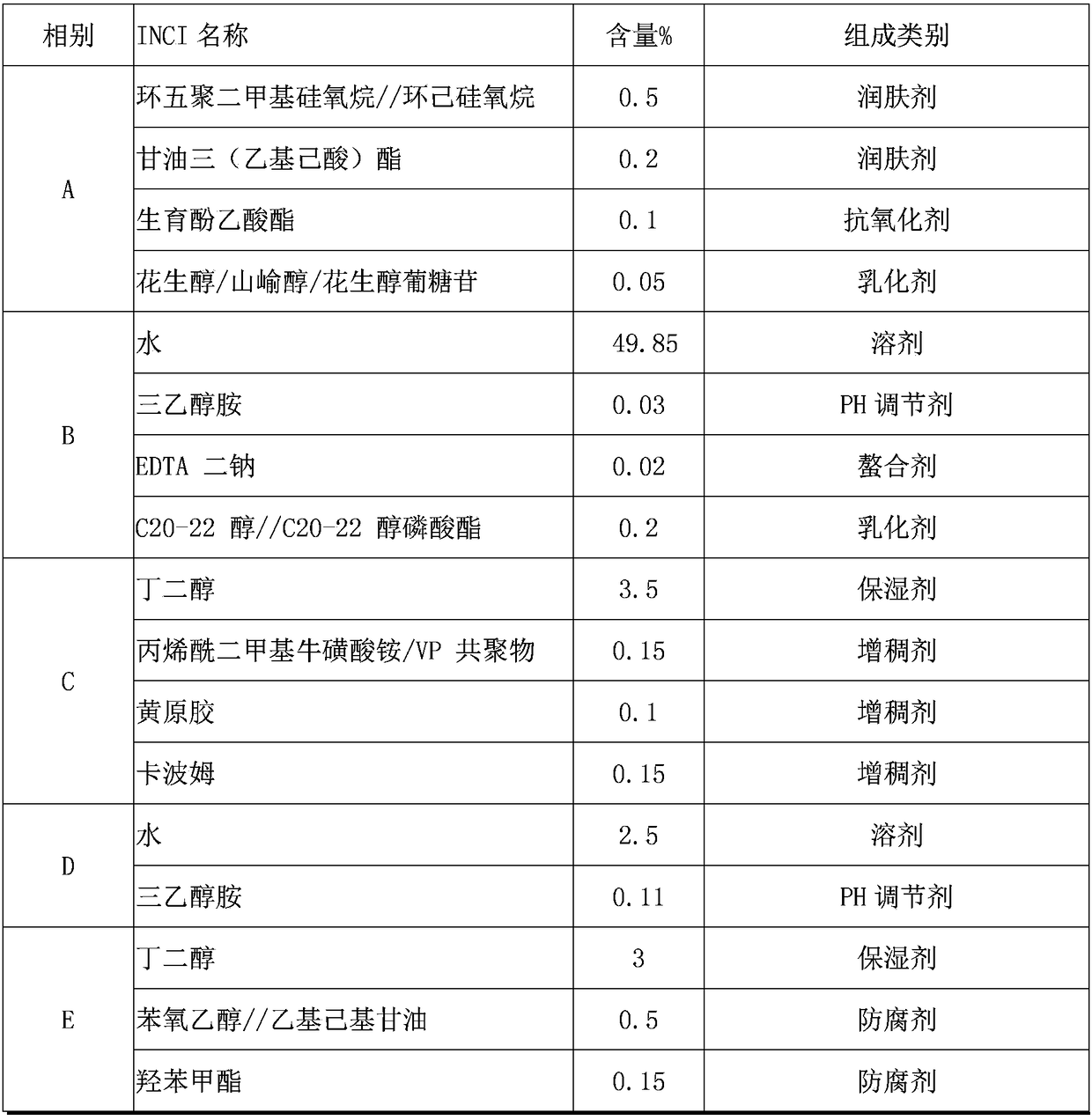

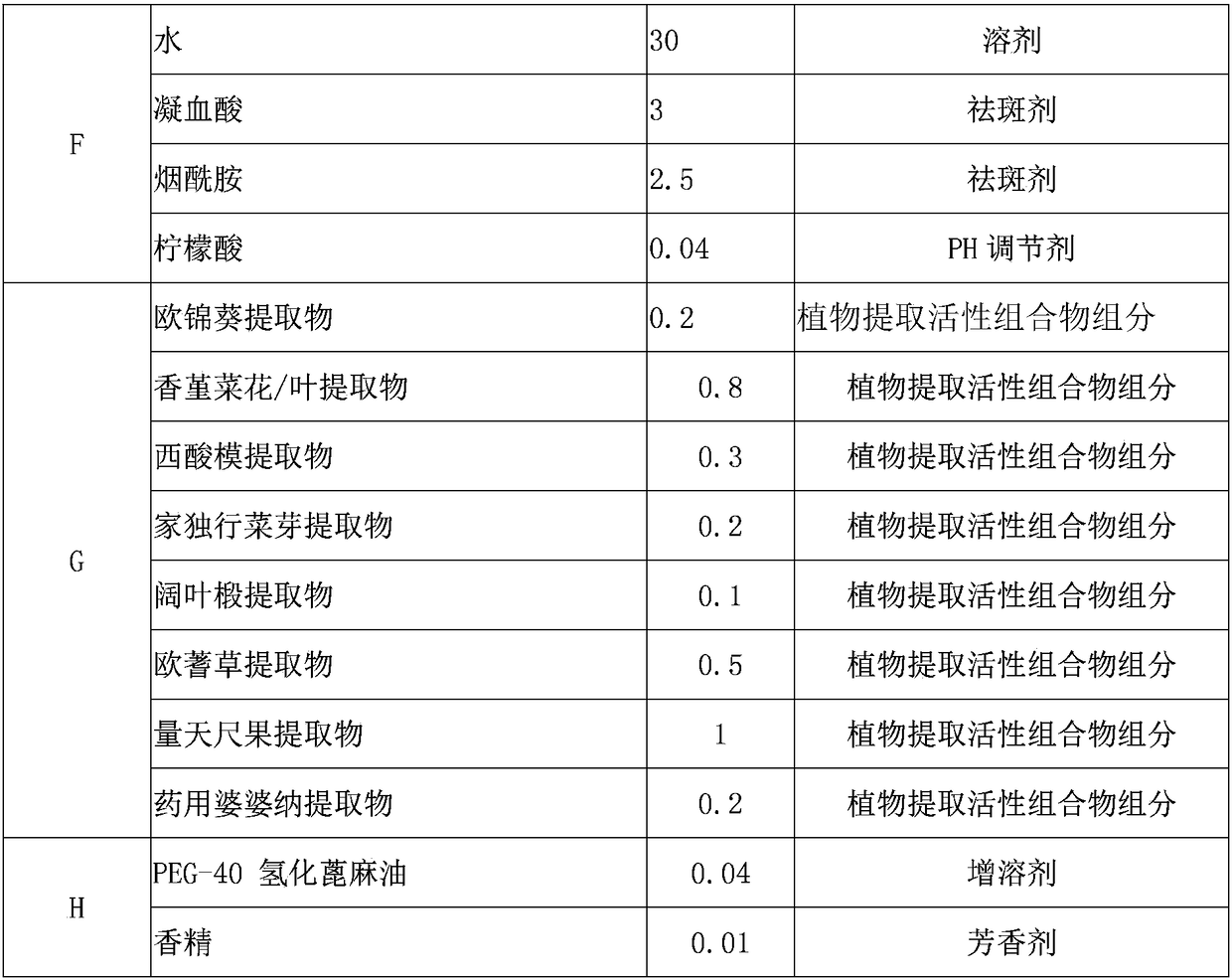

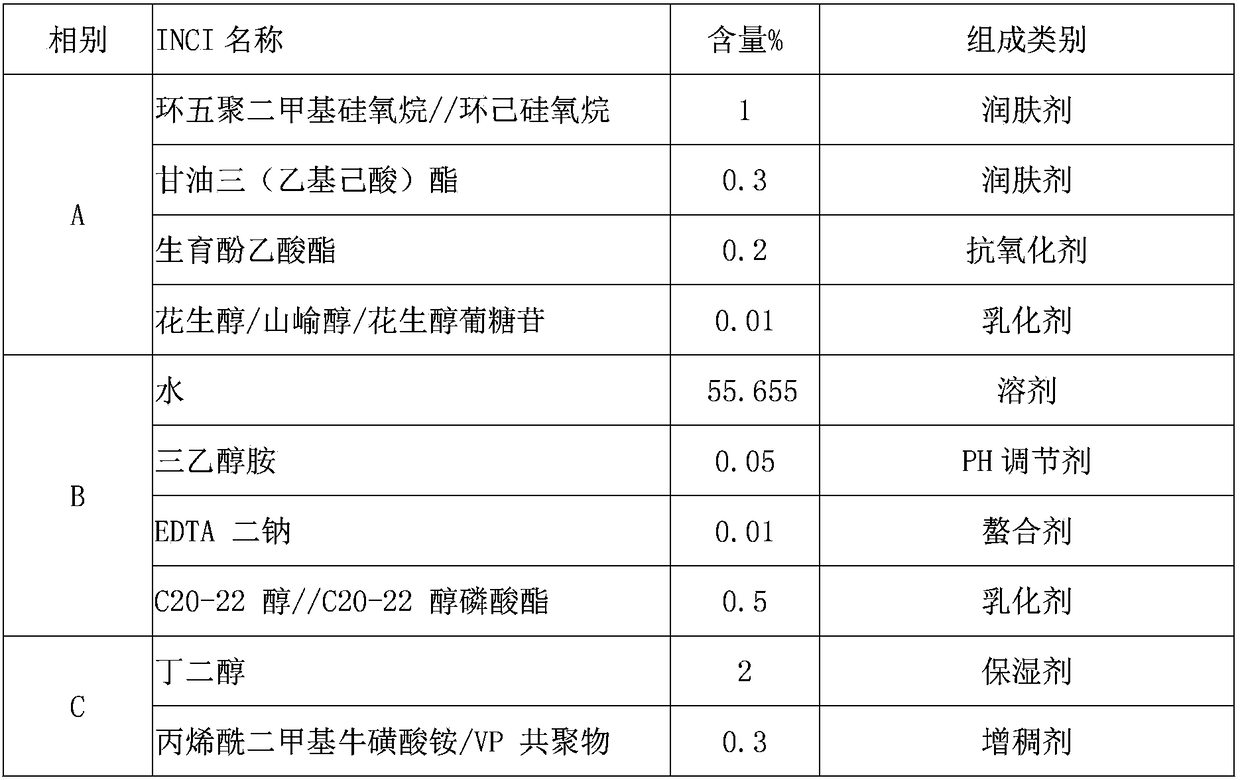

The invention discloses a whitening essence. The whitening essence has no side effect, is capable of effectively inhibiting the formation of melanin and has good efficacies of preserving moisture, resisting wrinkles and removing spots. The whitening essence mainly contains the following components in by weight percent: 0.16%-1.25% of a pH adjuster, 0.01%-0.03% of a chelating agent, 3%-9% of a humectant, 0.2%-1.3% of a preservative, 0.05%-0.2% of an antioxidant, 3%-8% of a spot removal agent, 0.11%-0.6% of an emulsifying agent, 0.4%-1.5% of an emollient, 0.25%-0.8% of a thickening agent, 1%-8%of a plant extract active composition and a proper amount of water. The whitening essence belongs to the technical field of cosmetics.

Owner:GUANGDONG BAWEI BIOLOGICAL TECH CO LTD

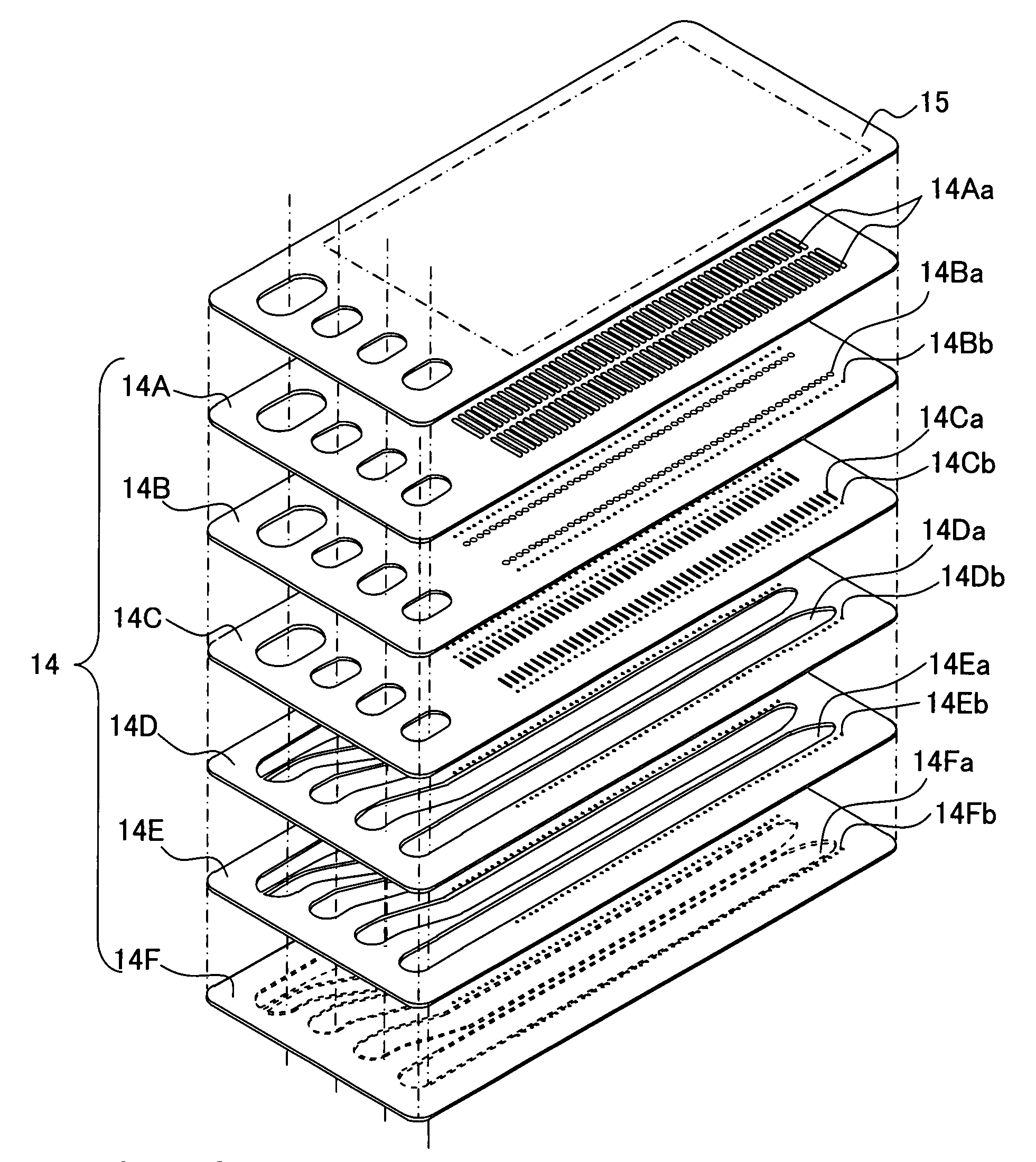

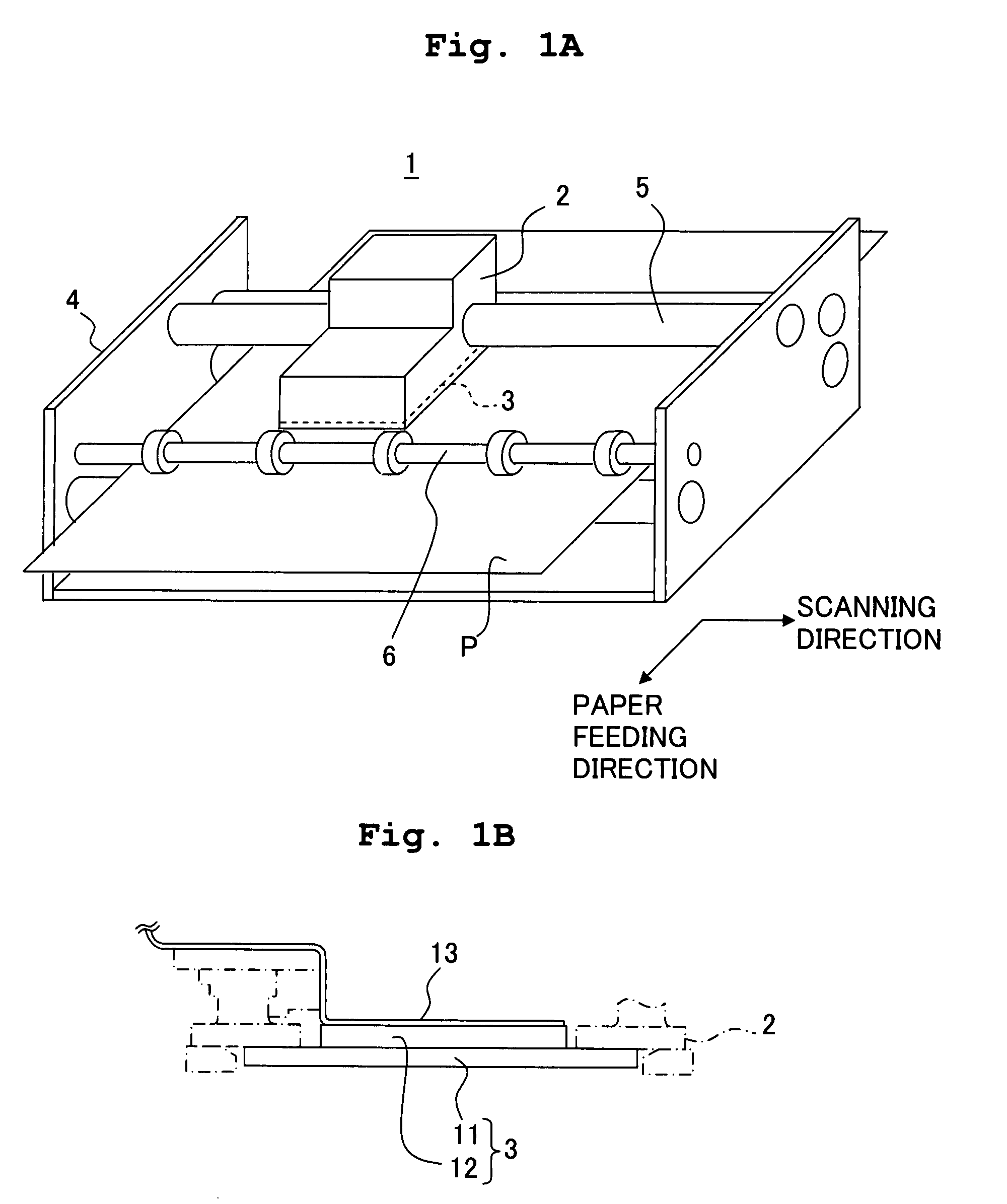

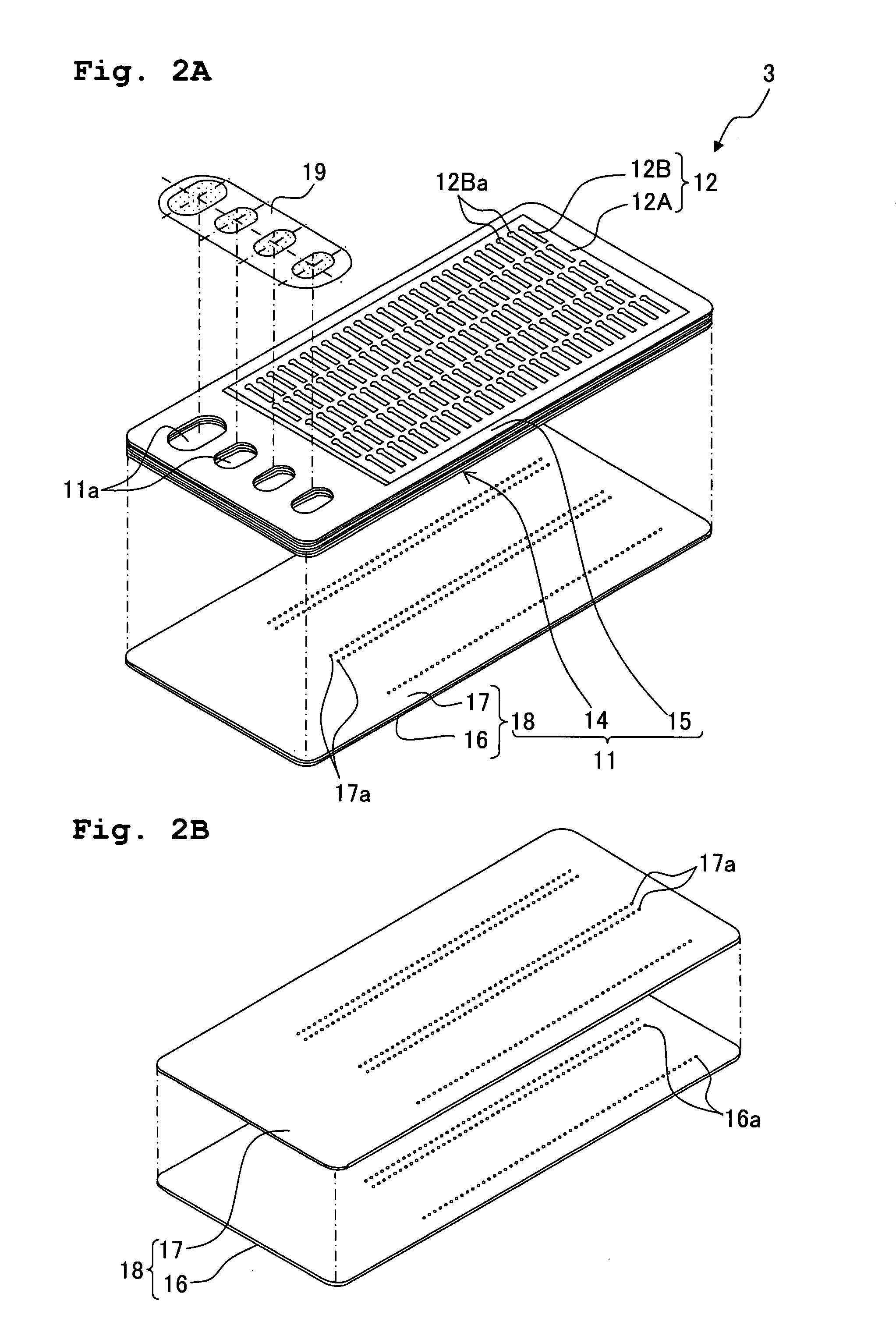

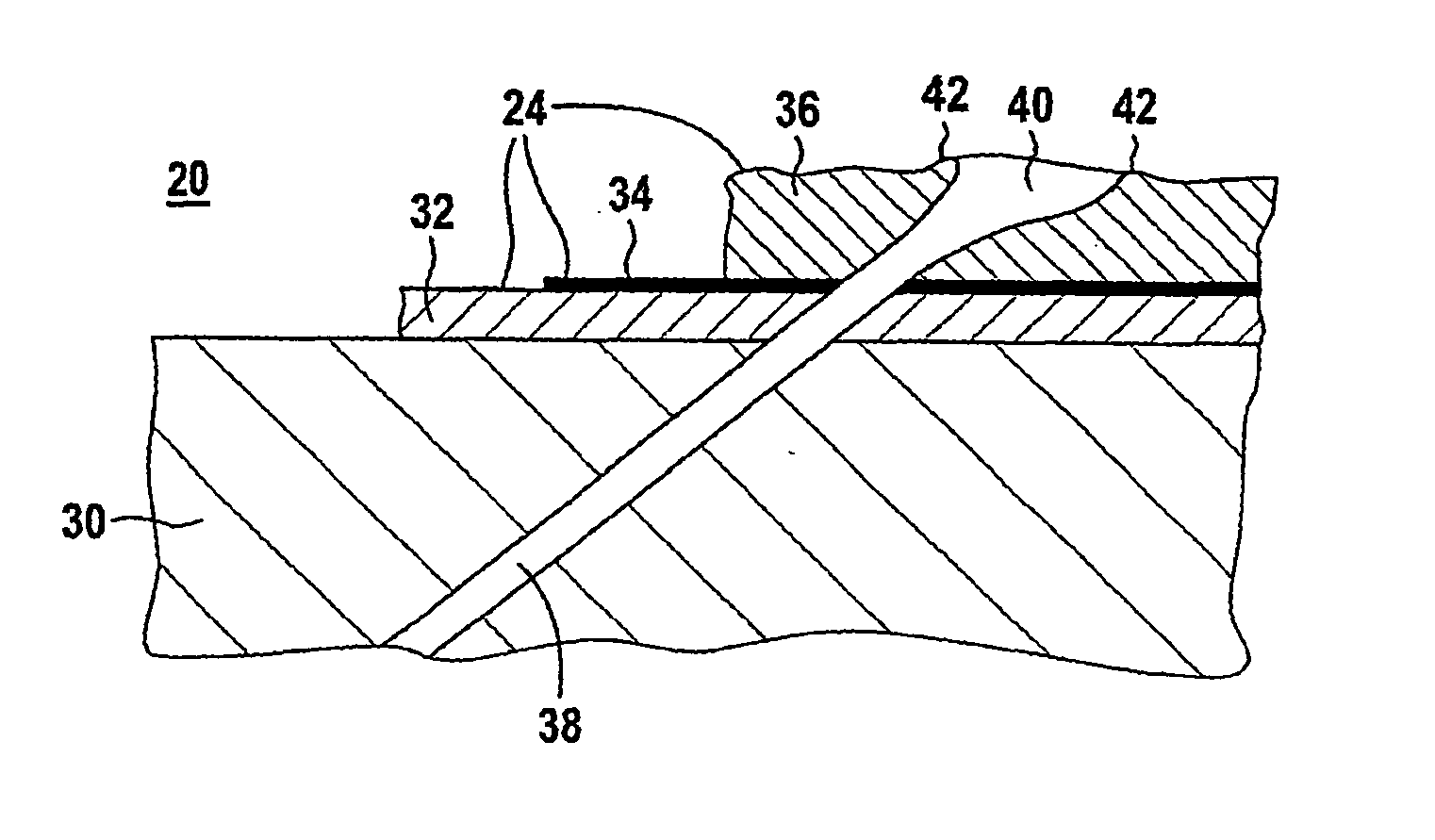

Liquid discharging head and method for producing the liquid discharging head

InactiveUS20080180469A1Residual bubbles are reducedImprove discharge performanceSoldering apparatusPrintingUltrasound attenuationEngineering

A liquid discharging head includes a channel unit formed of a plurality of stacked plates having openings and a liquid channel formed of the openings of the stacked plates. A curing material is filled in a step formed due to shift of the openings provided in the adjacent plates respectively, and the curing material forms part of an inner surface of the liquid channel. Consequently, the channel inner surface becomes smooth, and a liquid discharging head with little residual bubbles and with excellent bubble discharging capability is provided. Further, the attenuation of a pressure wave due to the step can be prevented.

Owner:BROTHER KOGYO KK

Tableting method for sampler wafer with boric acid substrate applied to XRFS analysis

ActiveCN110470685AEasy to smoothImprove tableting efficiencyMaterial analysis using wave/particle radiationProduction rateBoric acid

The invention relates to a tableting method for a sampler wafer with a boric acid substrate applied to XRFS analysis. The technical scheme of the method comprises the steps of putting 2.5-3.5g boric acid into the bottom of a material cavity of a tableting machine, and spreading out to acquire a substrate layer; preparing a thin film material with the thickness of 0.5-1mm into a wafer with a diameter d that is equal to d0-(3-5mm), and thus acquiring a liner film, wherein d0 is the diameter of the material cavity of the tableting machine, mm; then tiling the liner film on the substrate layer, and uniformly spreading 0.5-3g sample powder onto the liner film; and at last floating the sample powder by using a sample spoon, installing a press head of the tableting machine, pressurizing, keepingthe pressure and demolding to acquire the sampler wafer with the boric acid substrate applied to XRFS analysis. The method has the characteristics of being high in efficiency, not prone to generate astripping layer, small in consumption of sample powder, and high in production rate.

Owner:WUHAN UNIV OF SCI & TECH +2

Modified basalt fiber reinforced scoria lightweight aggregate concrete and preparation method thereof

Owner:JILIN JIANZHU UNIVERSITY

Cast-in-site rigid bone self-heat-preservation wall body, building blocks and wall building method

InactiveCN104047392AEasy to smoothGuaranteed smoothConstruction materialWallsArchitectural engineeringBuilding construction

Owner:SHANDONG CHUNTIAN BUILDING MATERIAL SCI & TECH

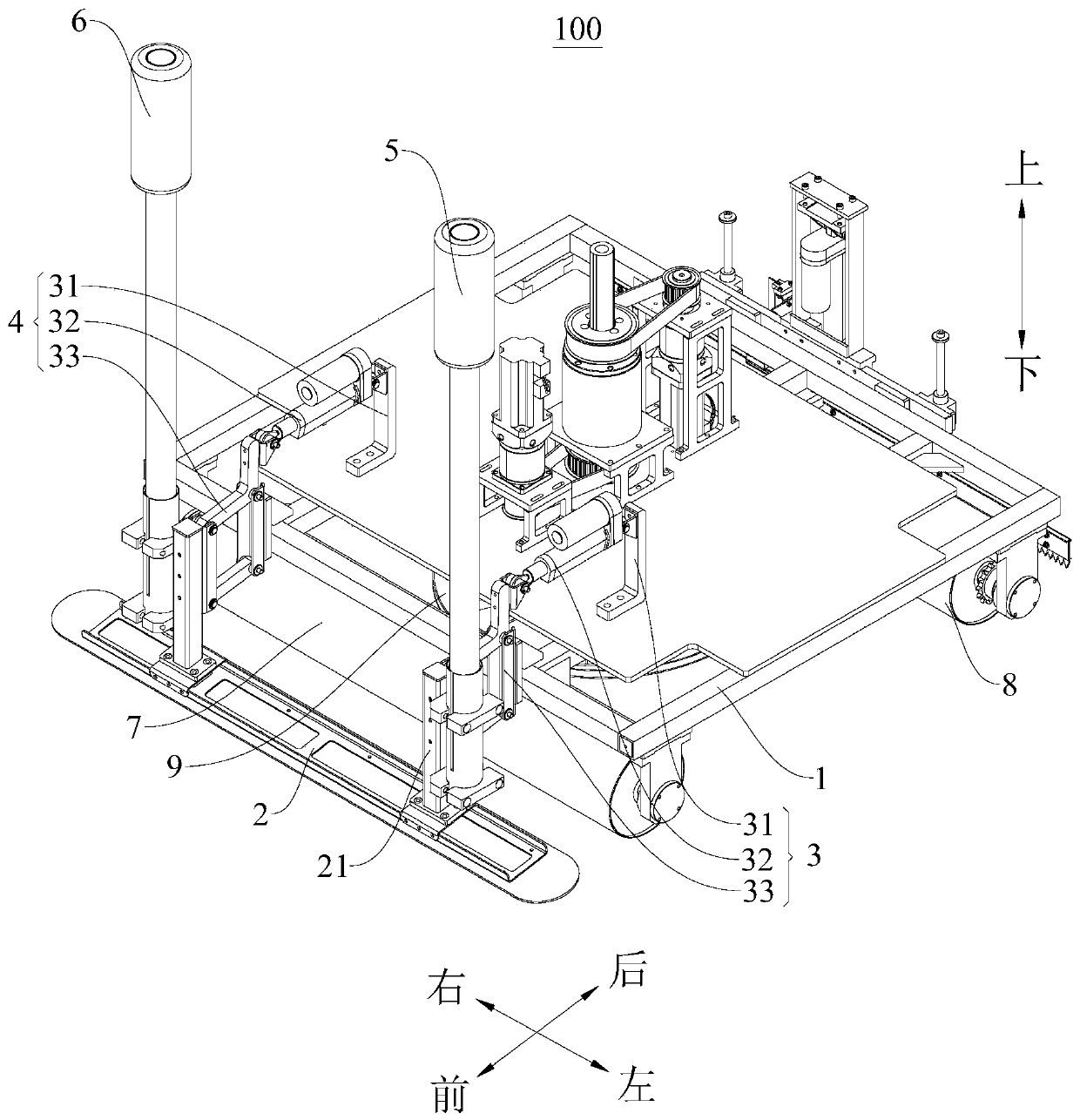

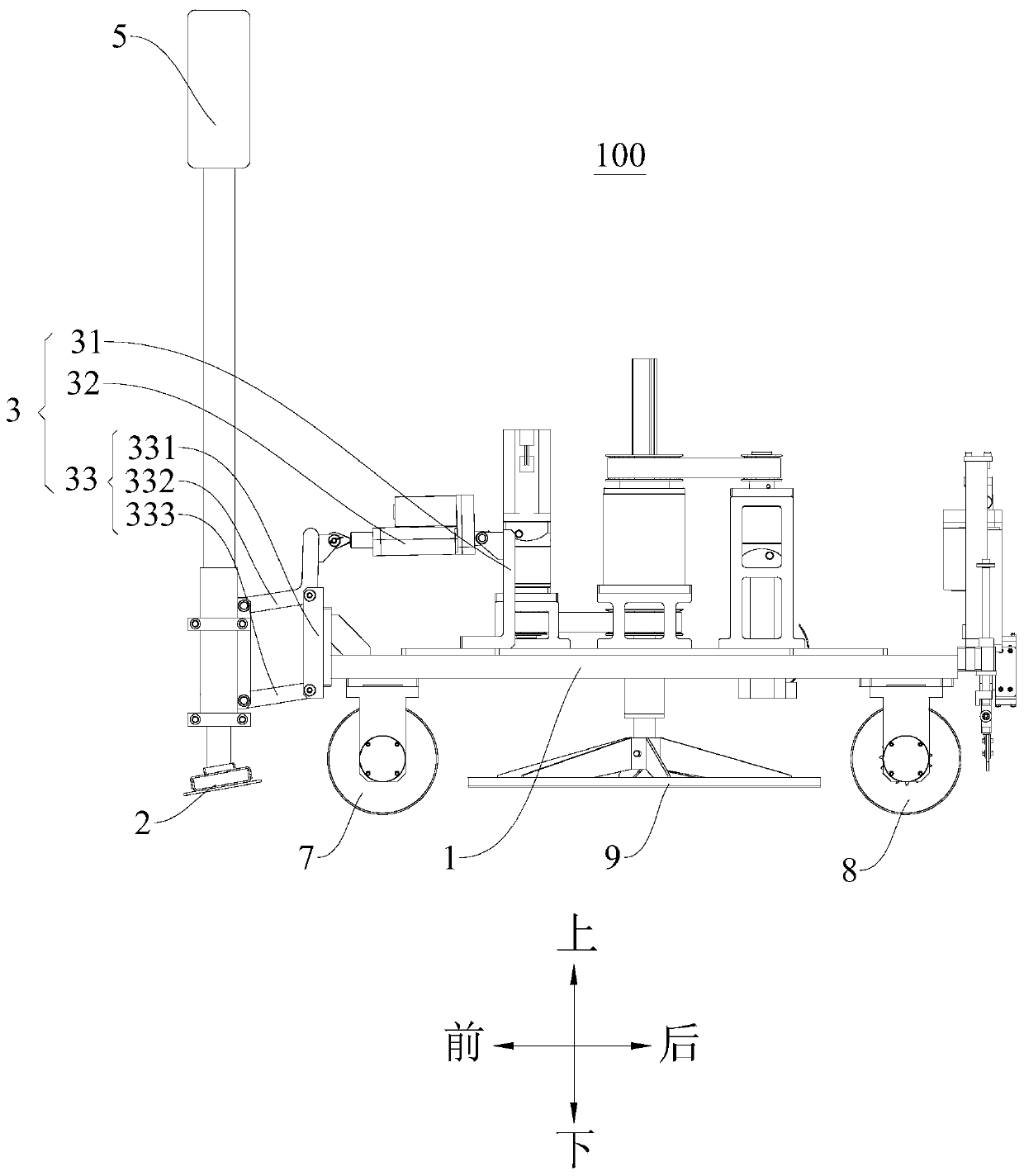

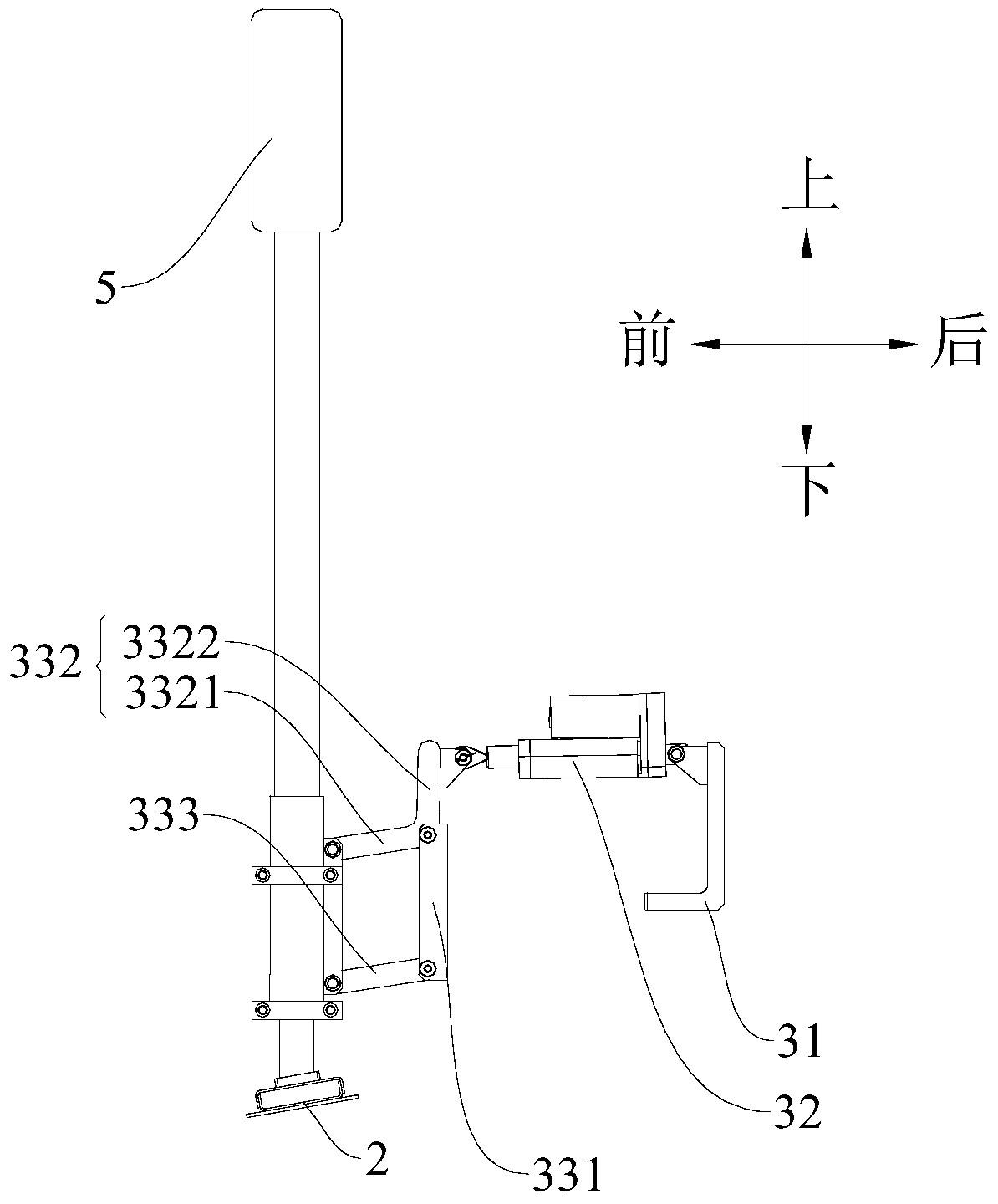

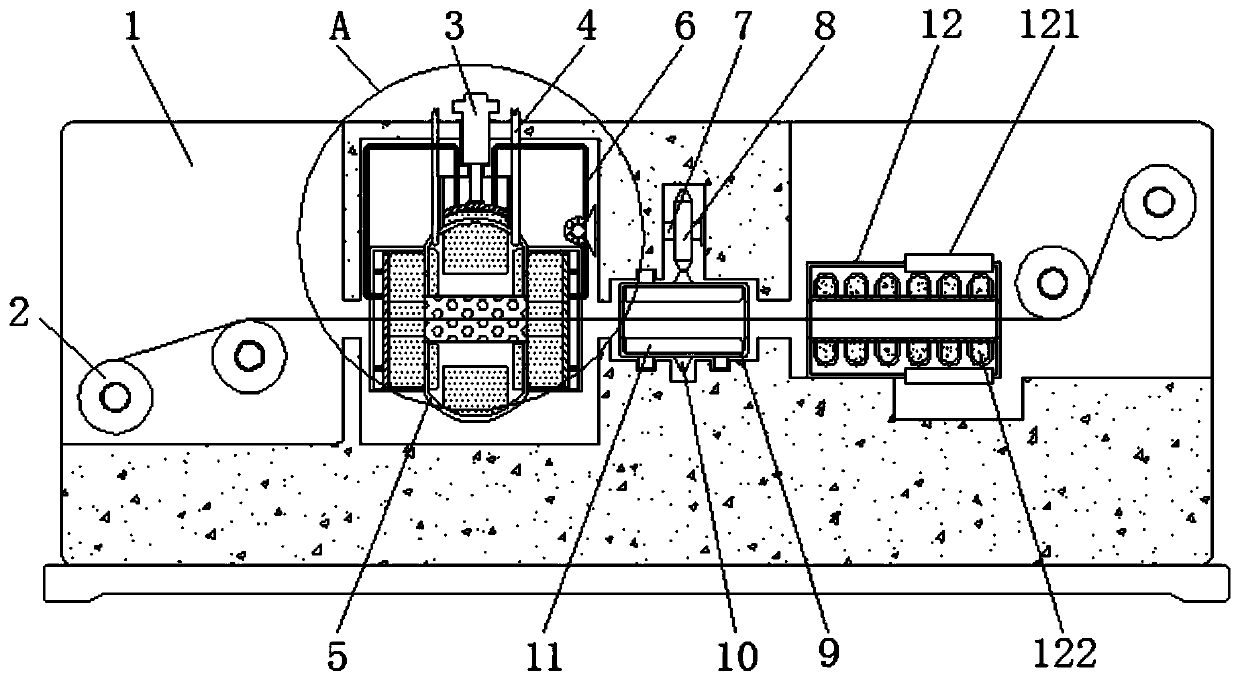

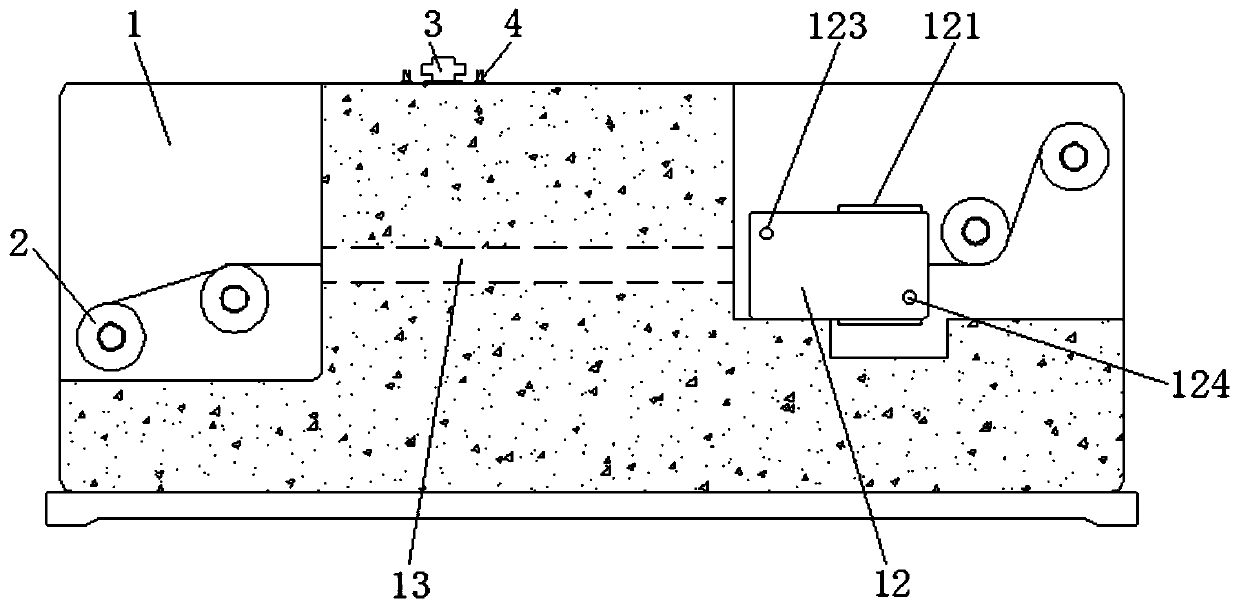

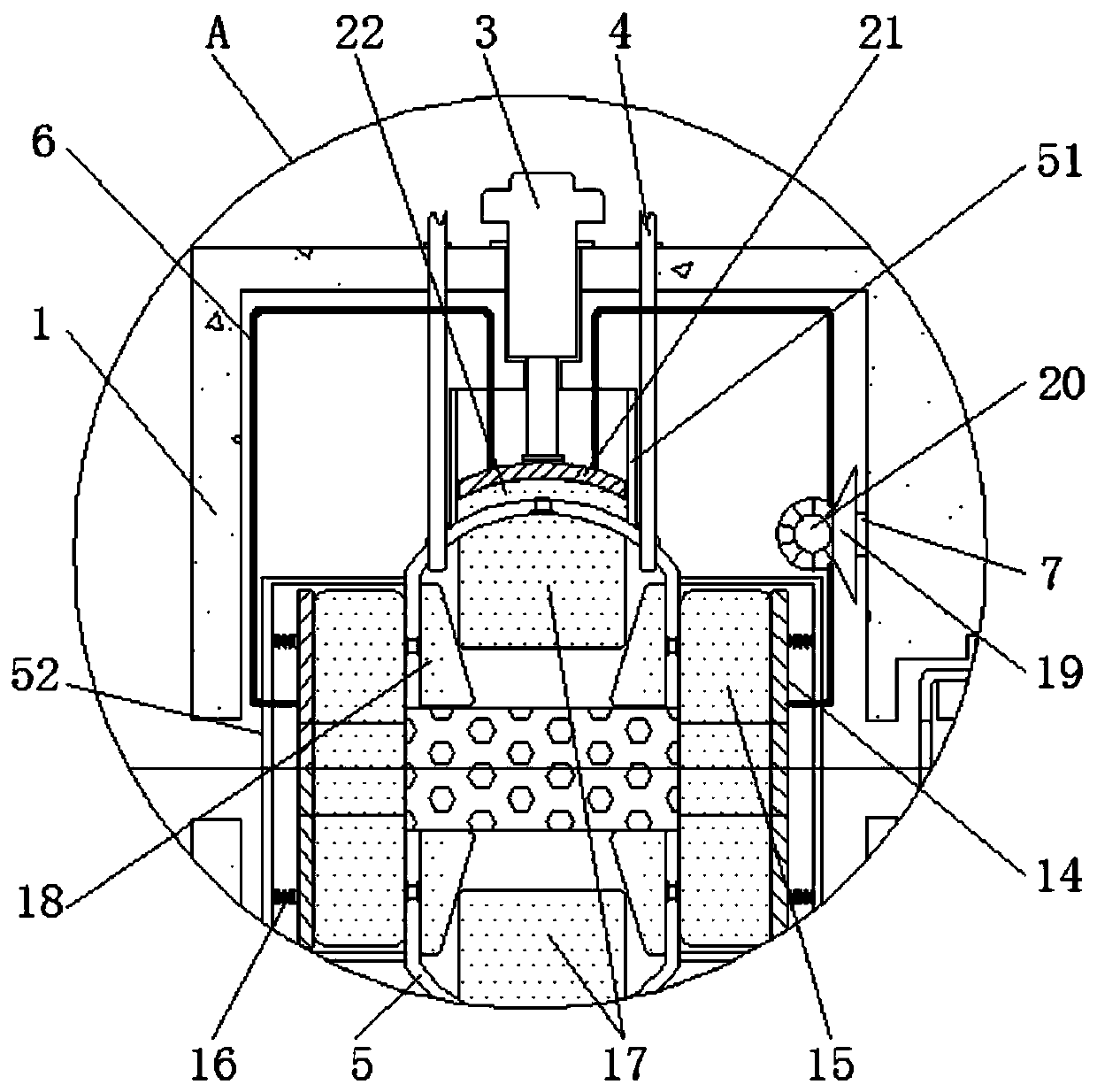

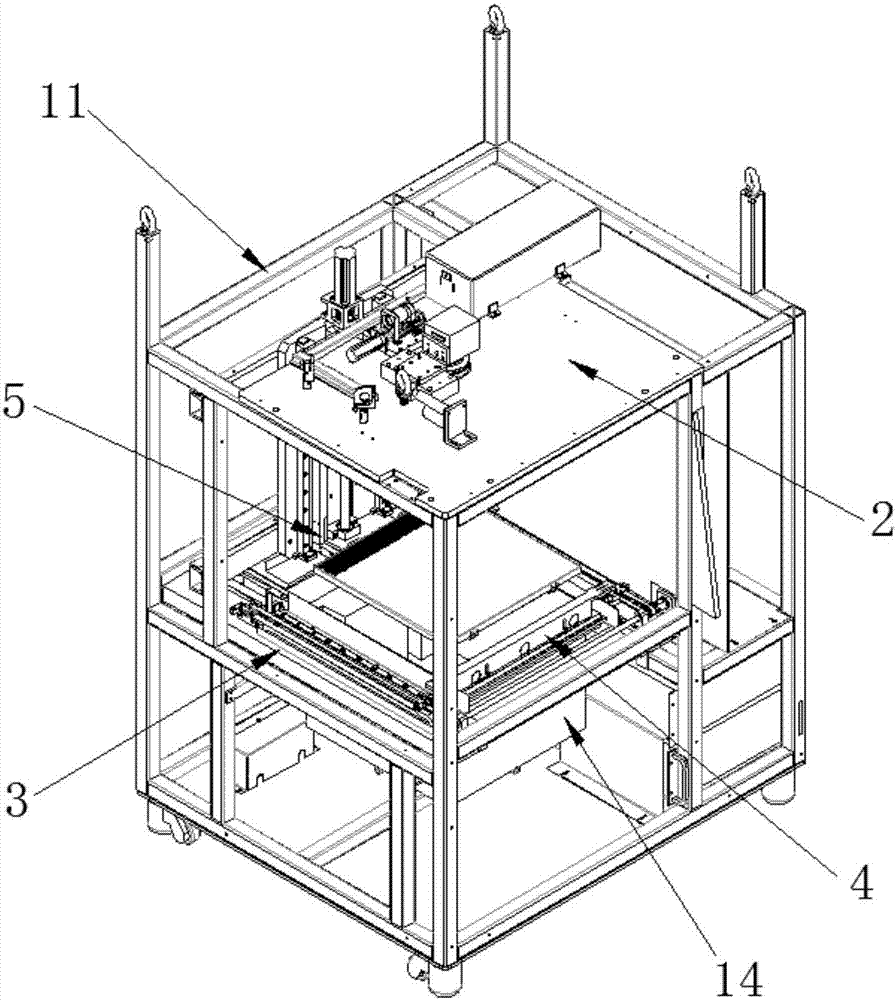

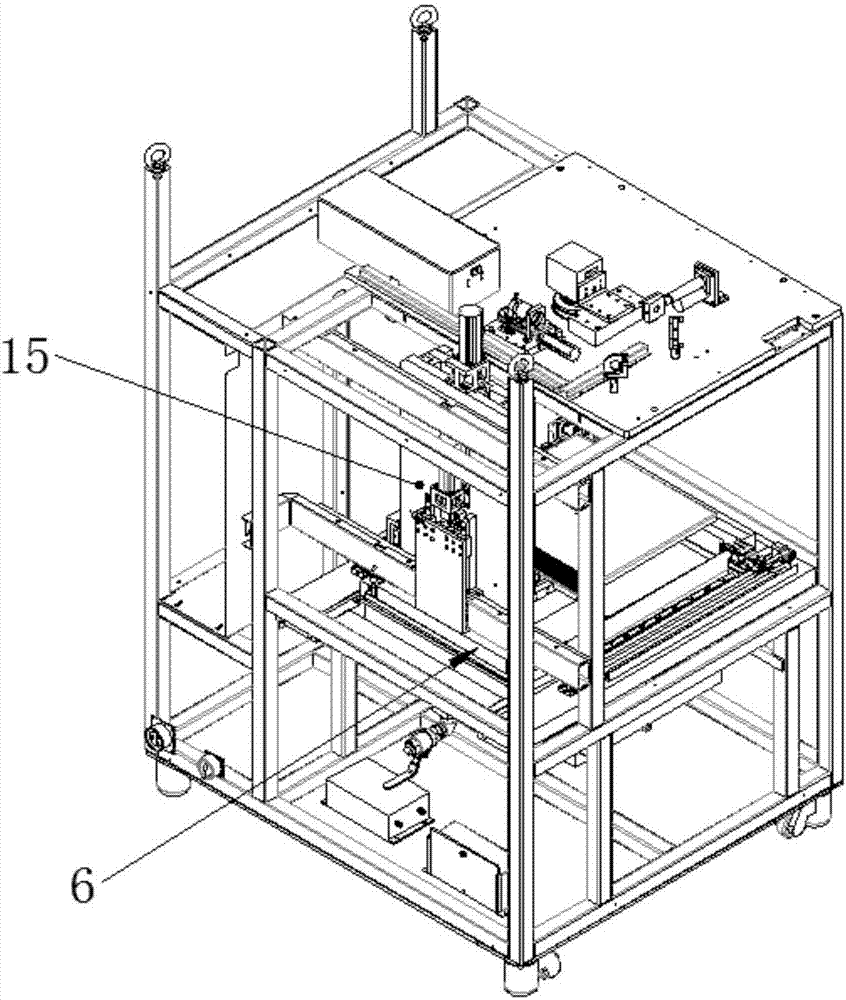

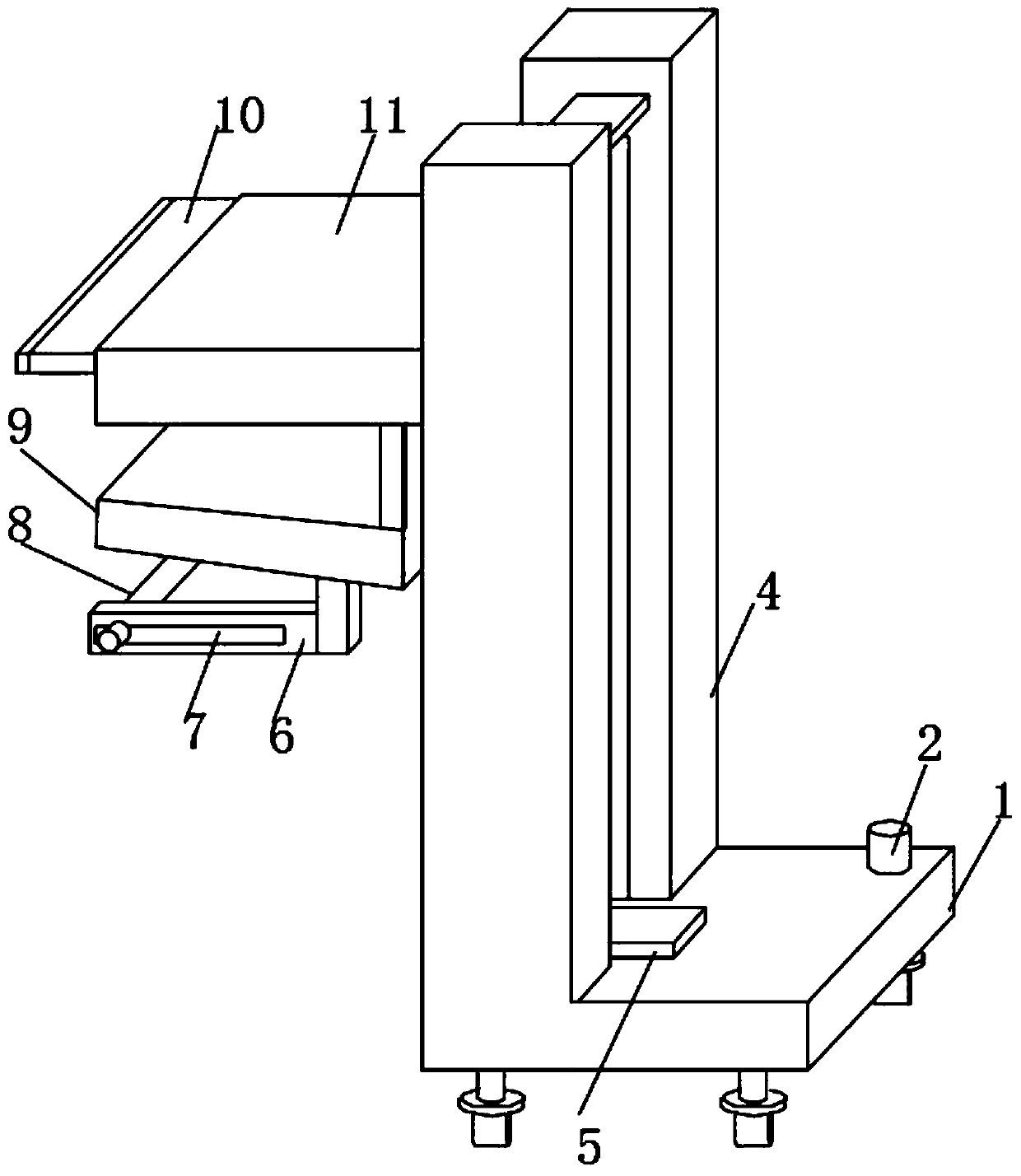

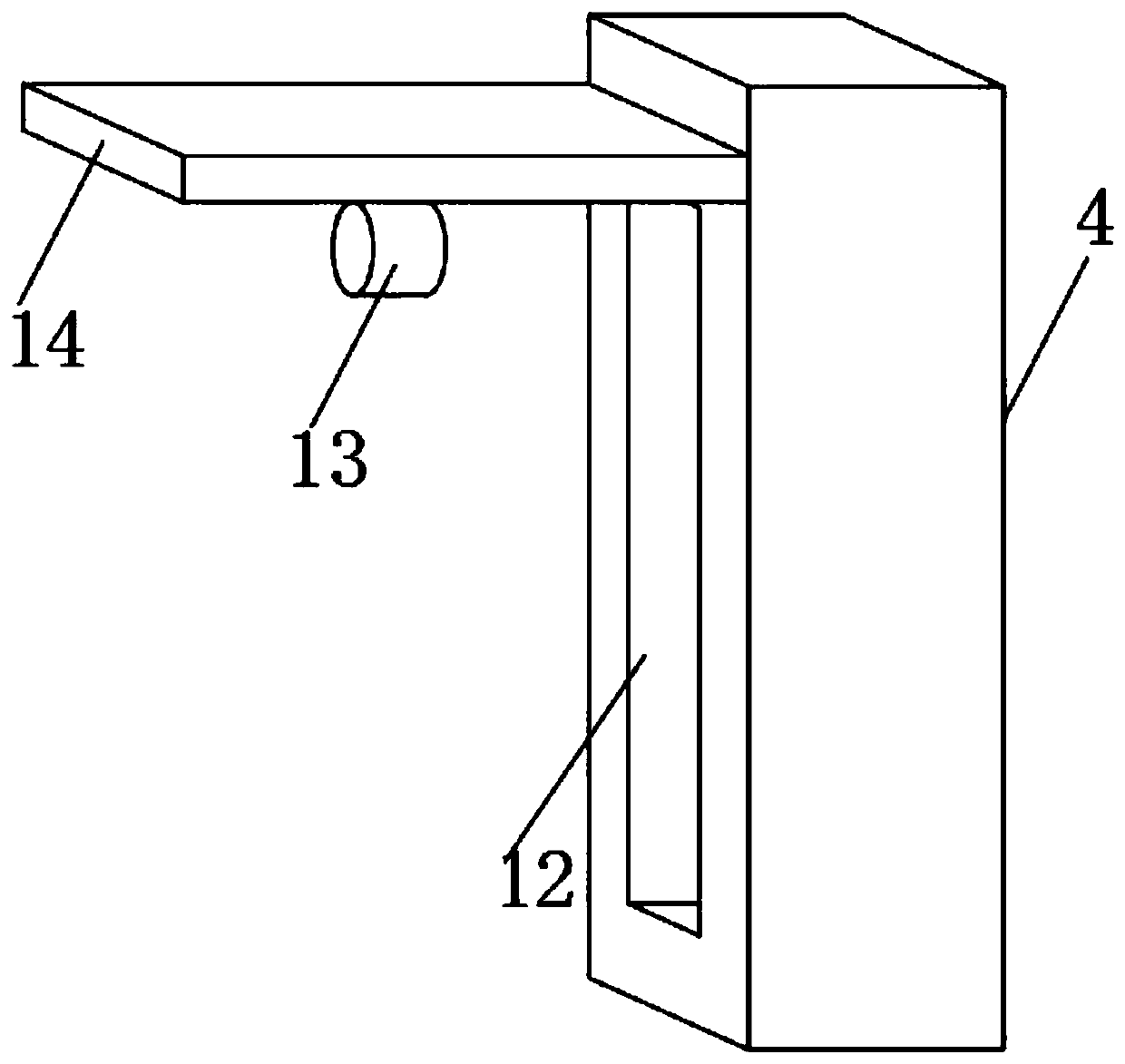

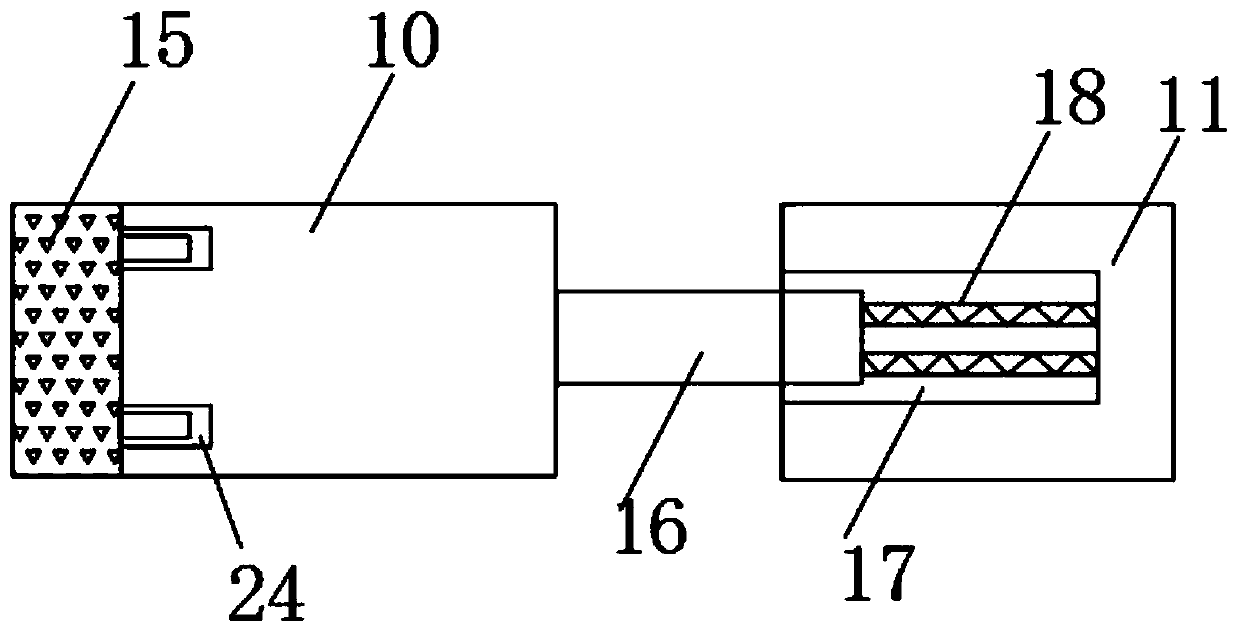

Leveling robot and working system thereof

The invention discloses a leveling robot and a working system thereof, The leveling robot comprises a rack, a spatula device, a first adjusting device, a second adjusting device, a first signal receiving device, a second signal receiving device and a controller, the spatula device is arranged on the rack, the first adjusting device is arranged between the left end of the spatula device and the rack to adjust the distance between the left end of the spatula device and an operating basal surface, the second adjusting device is arranged between the right end of the spatula device and the rack toadjust the distance between the right end of the spatula device and the operating basal surface, and the first signal receiving device is arranged at the left end of the spatula device. According to the leveling robot, the leveling operation is high in efficiency and good in effect.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

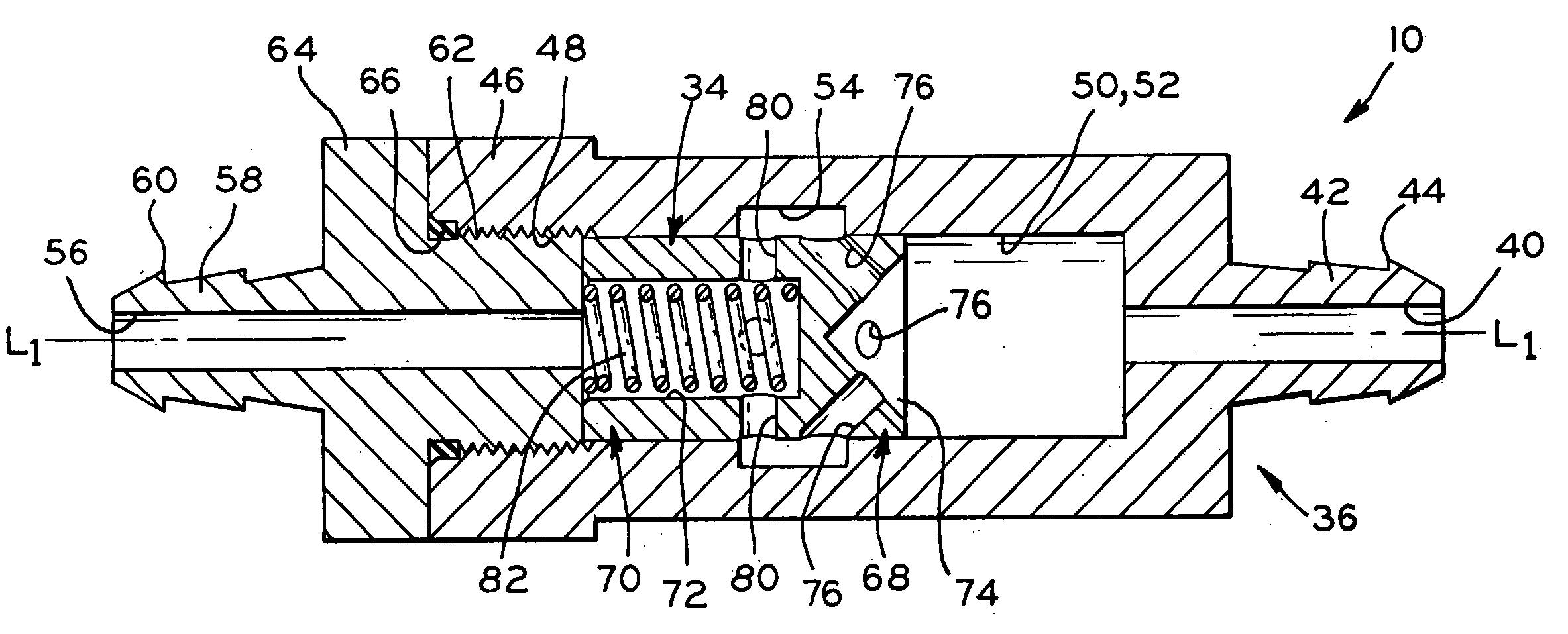

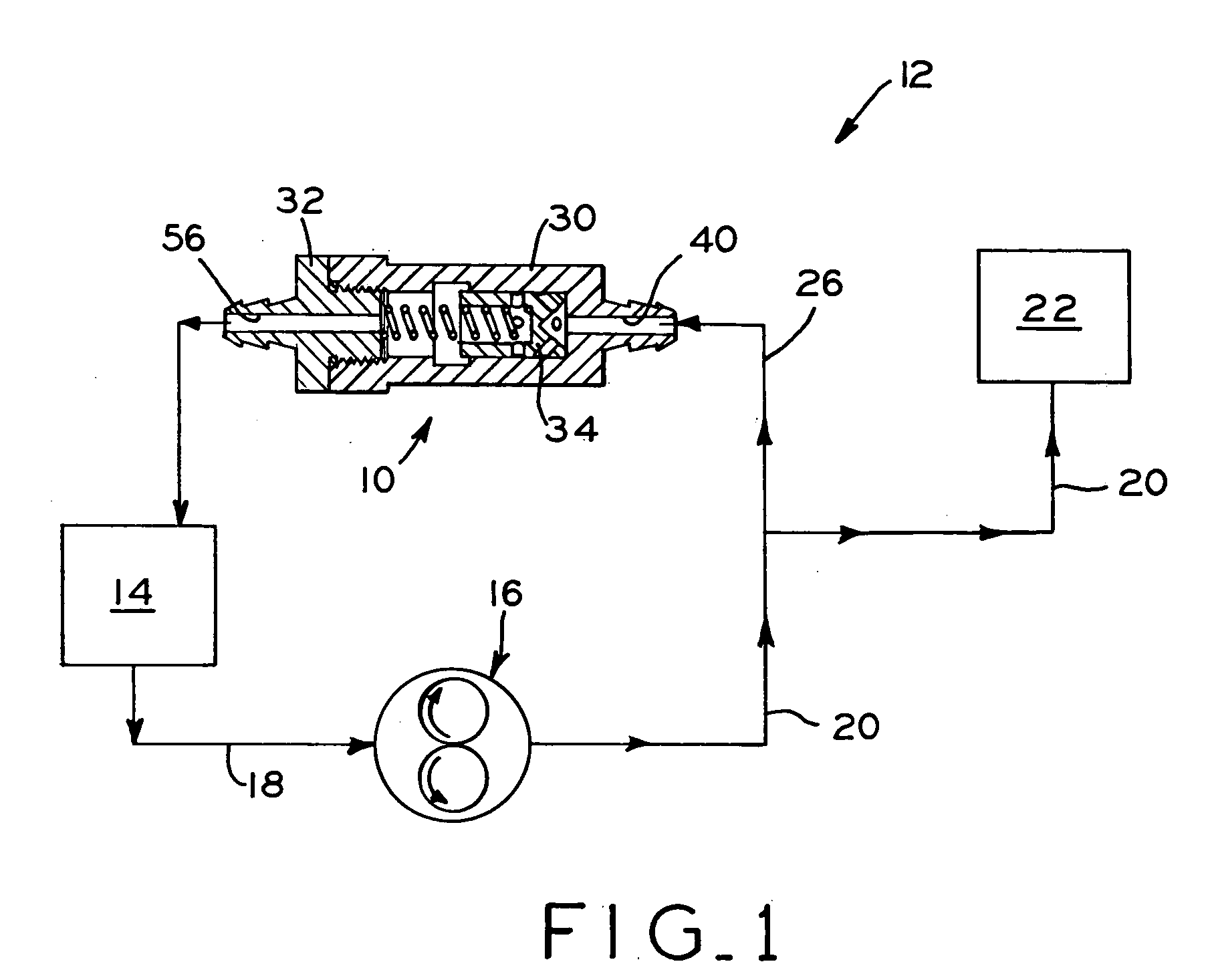

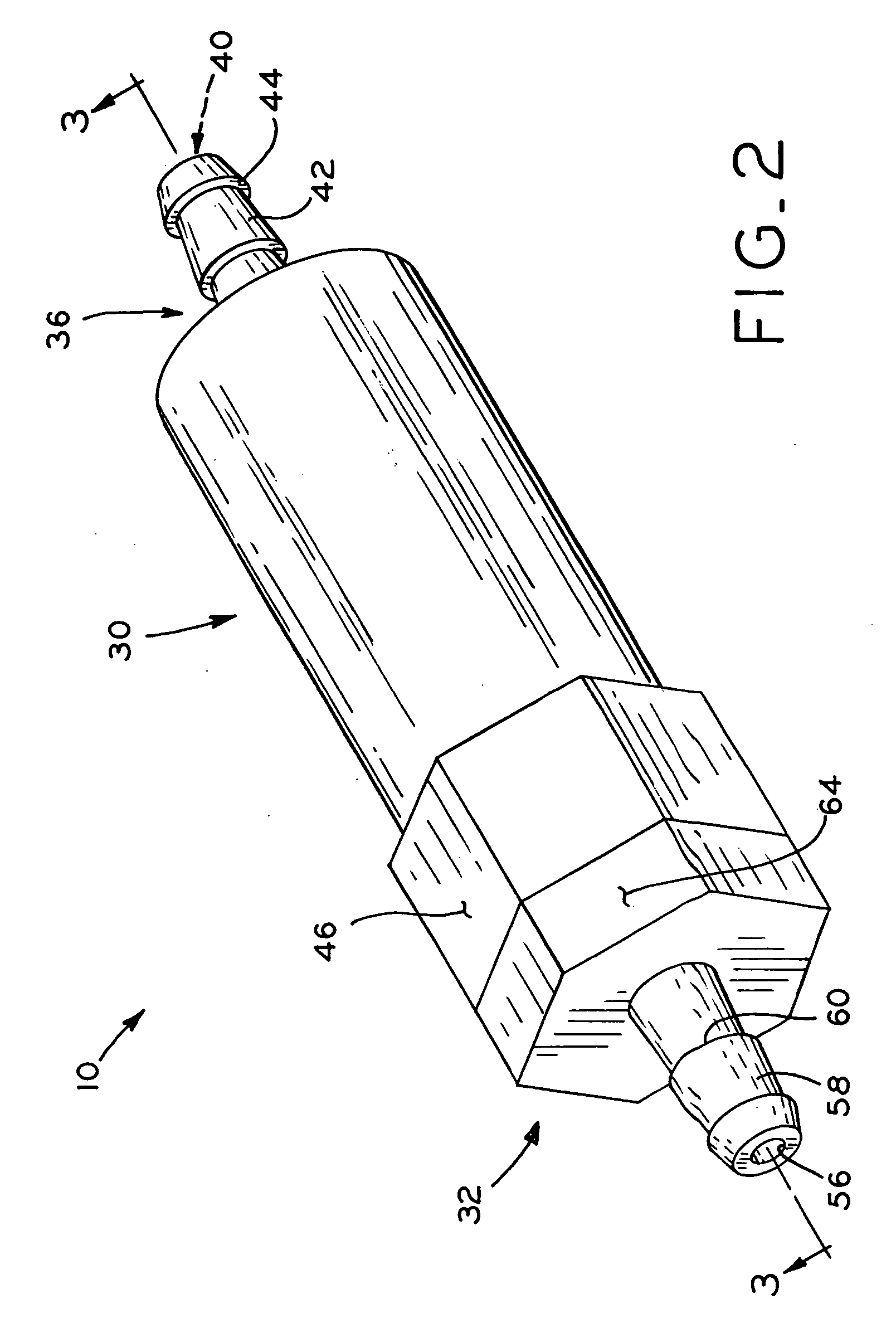

By-pass pressure regulator

InactiveUS20050034766A1Easy to smoothFacilitate accurate operationCheck valvesEqualizing valvesPressure thresholdFluid system

A pressure regulating valve which is responsive to pressure within a fluid system and operable to relieve pressure within the fluid system if same exceeds a predetermined pressure threshold, allowing the regulated pressure in the system to be held to a very accurate level. In particular, the valve includes a valve body having an inlet, an outlet, and a valve chamber which includes a recessed portion. A valve member is movable within the valve chamber, and includes at least one first passage in fluid communication with the inlet at least one second passage in fluid communication with the outlet. The valve member is movable within the valve body responsive to fluid pressure between first and second positions. In the first position, at least one of the first and second passages is not aligned with the recessed portion, such that fluid cannot flow through the valve. In the second position, at least a portion of each of the first and second passages is aligned with the recessed portion, such that fluid may flow from the inlet to the outlet through the first passage, the recessed portion, and the second passage.

Owner:TECUMSEH PROD CO

Coating equipment used for cable production and capable of rapidly reducing temperature for reducing bubbles

ActiveCN110504069ARapid coolingEasy squeezeInsulating conductors/cablesBiochemical engineeringEquipment use

The invention discloses coating equipment used for cable production and capable of rapidly reducing temperature for reducing bubbles. The coating equipment comprises a frame main body, guide rollers,an electric push rod and liquid injection pipes; the guide rollers are arranged at the left end and the right end of the frame main body; the electric push rod is fixed in the upper part of the framemain body; the liquid injection pipes are arranged on the left side and the right side of the electric push rod; a second squeezing plate is fixed at the bottom end of the electric push rod; and connecting ropes are fixed at the left end and the right end of the upper part of the second squeezing plate. The coating equipment used for cable production and capable of rapidly reducing the temperaturefor reducing the bubbles is provided with a first inner air bag and a first outer air bag; the first outer air bag is squeezed by a first squeezing plate, so that gas inside the first outer air bag enters the first inner air bag through a connecting pipe; and the inner side wall of the first inner air bag is in contact with the inner side wall of a coating sleeve ring firstly to close a discharging hole in the inner side wall of the coating sleeve ring, so that raw materials in the coating sleeve ring can be squeezed conveniently, and the bubbles in the raw materials are broken.

Owner:吉林省鑫联达电缆制造有限公司

Tea beverage for treating gout

InactiveCN105560481AGood curative effectSmall side effectsDispersion deliveryPre-extraction tea treatmentTreatment effectSide effect

The invention discloses a tea beverage for treating gout. The tea beverage is prepared from the following raw materials in parts by weight: 15-25 parts of pomegranate seeds, 15-25 parts of radix sanguisorbae, 15-25 parts of herba lycopodii, 30-50 parts of semen plantaginis and 7-13 parts of rhizoma corydalis. The tea beverage for treating gout is prepared from just five raw materials; the pomegranate seeds are capable of relieving gout; the radix sanguisorbae is capable of stopping bleeding, cooling blood and diminishing swelling; all the herba lycopodii, the semen plantaginis and the rhizoma corydalis are capable of diminishing swelling; the rhizoma corydalis also has the effect of relieving pain; the semen plantaginis also has the effect of inducing diuresi and facilitating removal of toxins. The tea beverage for treating gout has an excellent treatment effect on the gout, is few in toxic and side effects, is capable of quickly relieving symptom, and has an excellent effect of preventing relapse of the gout.

Owner:叶国生

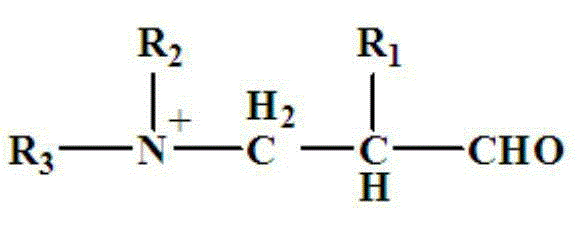

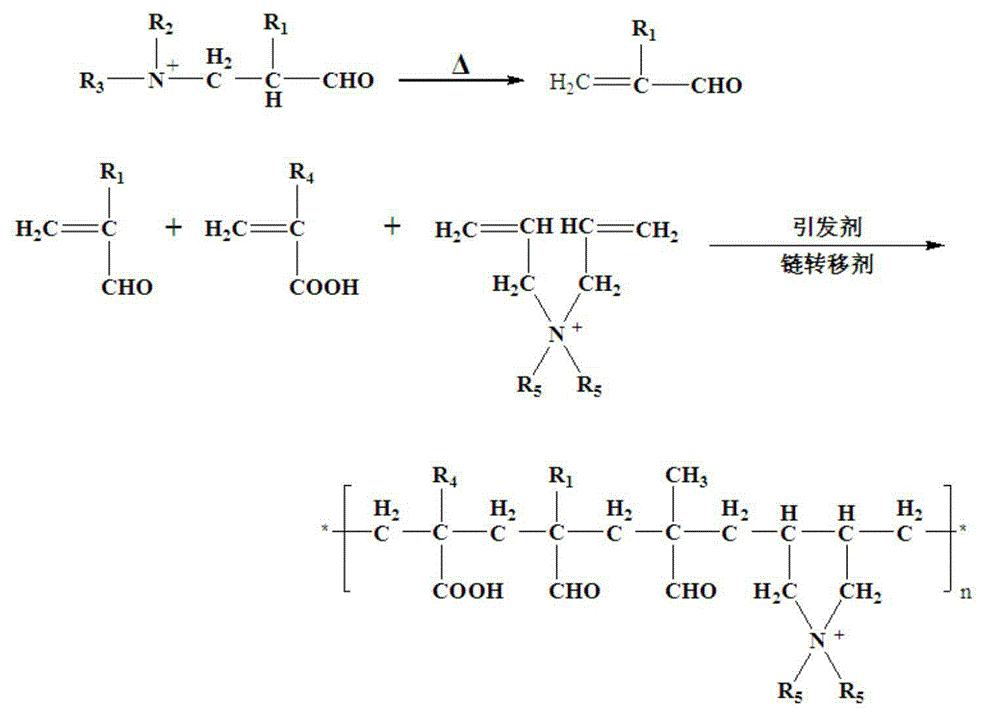

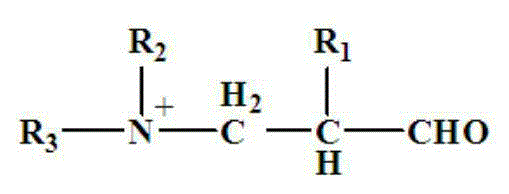

Salt-free pickling-free amphoteric polymer chrome-free tanning agent

The invention discloses a salt-free pickling-free amphoteric polymer chrome-free tanning agent which is characterized in that according to the salt-free pickling-free amphoteric polymer chrome-free tanning agent, firstly, organic amine and fatty aldehyde with active alpha-H undergo Mannich reaction, a Mannich base midbody with a formyl group is obtained, and then, after an allyl monomer with the formyl group is generated in the original position of the midbody, the midbody, the allyl monomer with a cation and allyl acid undergo free radical polymerization, and the salt-free pickling-free amphoteric polymer chrome-free agent is obtained. The salt-free pickling-free amphoteric polymer chrome-free tanning agent is a polymer tanning agent containing the formyl group and has certain filling capacity, tanning properties of the salt-free pickling-free amphoteric polymer chrome-free tanning agent are rival with the properties of an existing aldehydes tanning agent, molecular weight is large, when the salt-free pickling-free amphoteric polymer chrome-free tanning agent is in use, a leather blank is free of pickling, salt pollution in the follow-up processes can be eliminated, carboxyl and amino contained by the agent can further prompt absorption to follow-up finishing materials by the leather blank, and the whole quality of a leather is improved. According to preparation of the salt-free pickling-free amphoteric polymer chrome-free tanning agent, air pollution due to raw materials is avoided, chrome and NaCl pollution of a traditional tanning agent is avoided, processes are reduced, silicate consumption is reduced, and cost is reduced.

Owner:SICHUAN UNIV +1

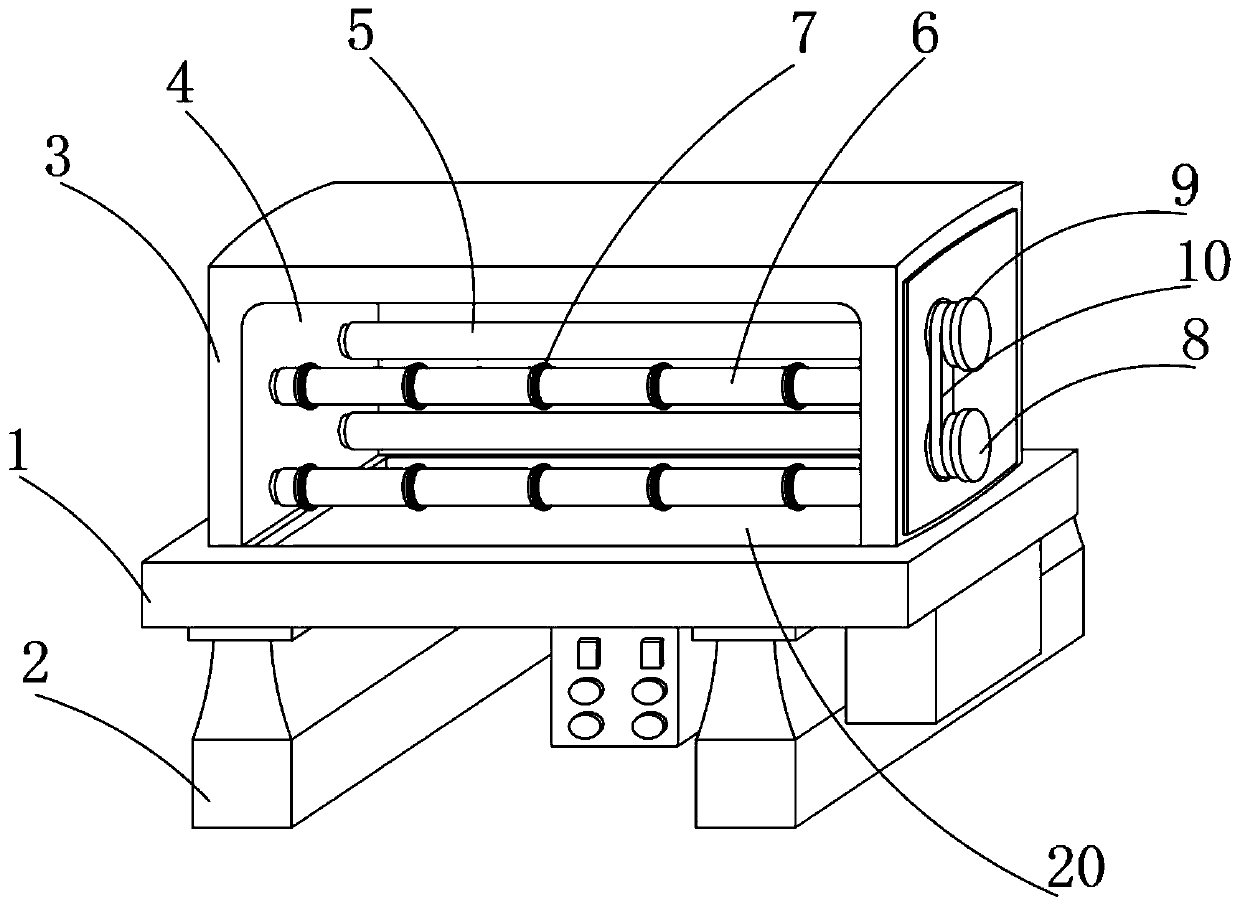

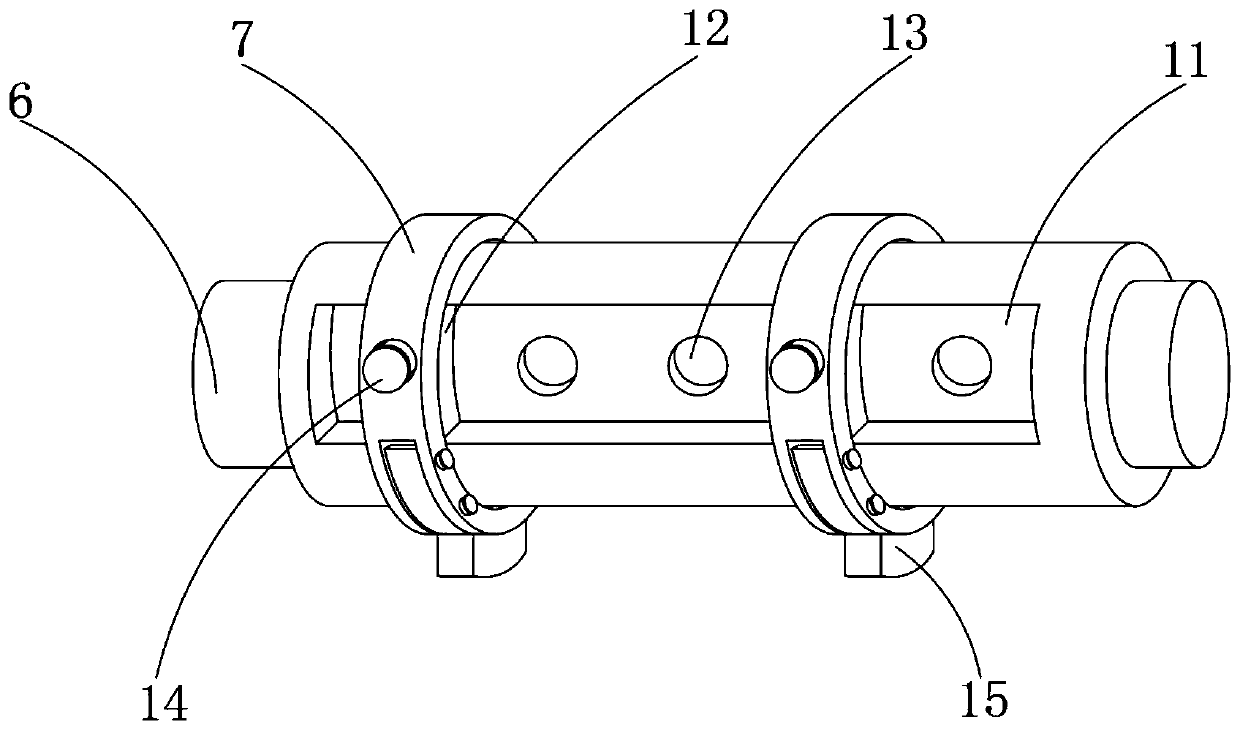

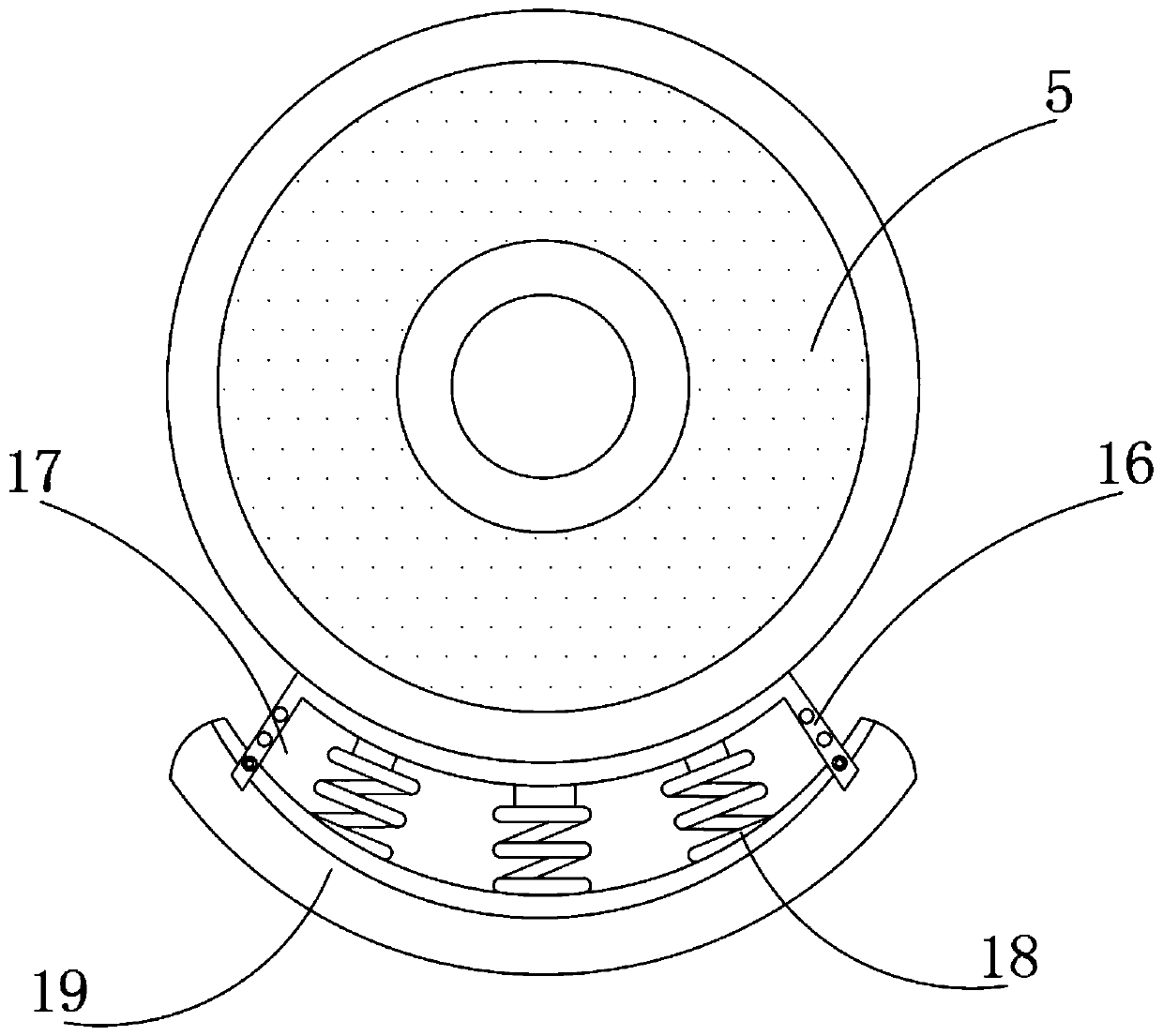

High-efficiency slitting machine for mixing rubber

InactiveCN110065173AScientific and reasonable structureEasy to useMetal working apparatusEngineeringSilica gel

The invention discloses a high-efficiency slitting machine for mixing rubber. The high-efficiency slitting machine comprises a fixing table; a slitting bracket is arranged at the top end of the fixingtable; pressing rollers are arranged on one side in the slitting bracket; direction adjusting rollers are arranged on one sides of the pressing rollers; sliding grooves are formed in the direction adjusting rollers; silica gel gaskets are mounted at the bottom ends of the pressing rollers through fixing rods; and collecting grooves are formed in the middle of the fixing table. The high-efficiencyslitting machine is scientific and reasonable in structure and safe and convenient to use; with the arrangement of the direction adjusting rollers and the sliding grooves, the slitting machine can conveniently adjust and fix the spacing between splitting cutters inside the guide rollers according to the actual production requirements of the mixing rubber; with the arrangement of the fixing rods and silica gel backing plates, the problem that the cutting quality of mixing rubber is affected since the position of the mixing rubber is easy to shift during material conveying is solved; and with the arrangement of the collecting grooves, the cleanliness of an internal environment of the slitting machine is ensured, and dust and impurities are prevented from falling into the slitting machine tocause a failure of the slitting machine.

Owner:浙江柏冠精密机械制造有限公司

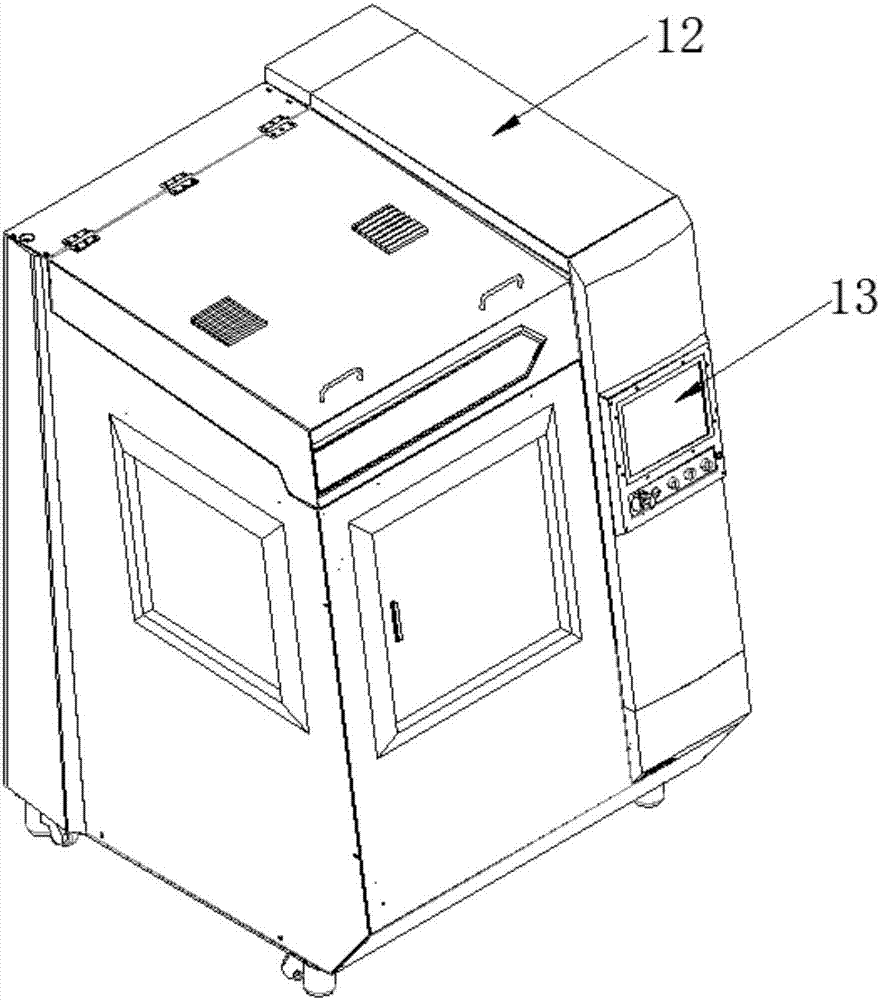

SLA (Stereo Lithography Apparatus) 3D printer

PendingCN107443730AChange distanceAutomatic adjustment of beam expansion magnificationAdditive manufacturing apparatus3D object support structuresLithographyComputer printing

The invention discloses an SLA (Stereo Lithography Apparatus) 3D printer. The SLA 3D printer comprises a rack, a housing, a display screen, a light path adjustment module, a trough, a scraper module, a bottom plate fixing assembly, a heavy block module, an L-shaped support platform, a backing plate and a controller. According to SLA 3D printer, the light path adjustment module is controlled by the controller, so that laser is perpendicularly emitted to the liquid level of the trough from top to bottom, and liquid photosensitive resin is cured and formed under the action of laser; the scraper module is installed on the bottom plate fixing assembly, and a scraper is driven to do a reciprocating motion in the trough by the bottom plate fixing assembly, so that layer-by-layer printing is realized, and an ideal printing effect is obtained; the L-shaped support platform is fixedly connected with a screen plate, and the screen plate is driven to perpendicularly move up and down in the trough by a motor, so that the distance of one layer is reduced per layer which is printed; and the liquid level of the trough is changed by lifting a heavy block of the heavy block module, so that the height of the liquid level in the trough is kept after the screen plate descends, and the fluctuation of the liquid level is reduced during printing, thereby obtaining a good printing effect.

Owner:佛山吗卡工程技术有限公司

Improved-hardness heat-radiation aqueous coating for glass doors, and its preparation method

The invention discloses an improved-hardness heat-radiation aqueous coating for glass doors. The coating is prepared by using the following raw materials, by weight, 30-34 parts of aqueous hydroxy acrylic resin, 7-9 parts of an aqueous film forming assistant, 2-4 parts of hexamethyldisiloxane, 18-22 parts of aqueous gadoleic acid resin, 1-2 parts of nanometer sericite powder, 1-2 parts of a pigment, 4-7 parts of inorganic nanometer ceramic resin, 1-2 parts of magnesium dialkyl sulfosuccinate, 0.3-0.4 parts of octadecanamide, 0.2-0.4 parts of polyether modified polysiloxane, 0.3-0.4 parts of azodiisobutyronitrile, 0.4-0.7 parts of sodium phytate, 0.5-1.0 part of a silane coupling agent KH792, 1-2 parts of triethanolamine borate, 0.6-1.2 parts of magnesium tungstate, 2-3 parts of nanometer charcoal powder, 1-2 parts of flake graphene, 0.3-0.6 parts of urea, 2-3 parts of diethylenetriamine and 13-16 parts of deionized water. The coating has the advantages of ageing resistance, strong adhesion, corrosion resistance, pollution resistance, fouling resistance, mutual coordination of the added nanopowders, good filling property, increase of the smoothness and the flatness of a coating film of the coating, and good heat radiation property.

Owner:MAANSHAN HENGYI MACHINERY MFG

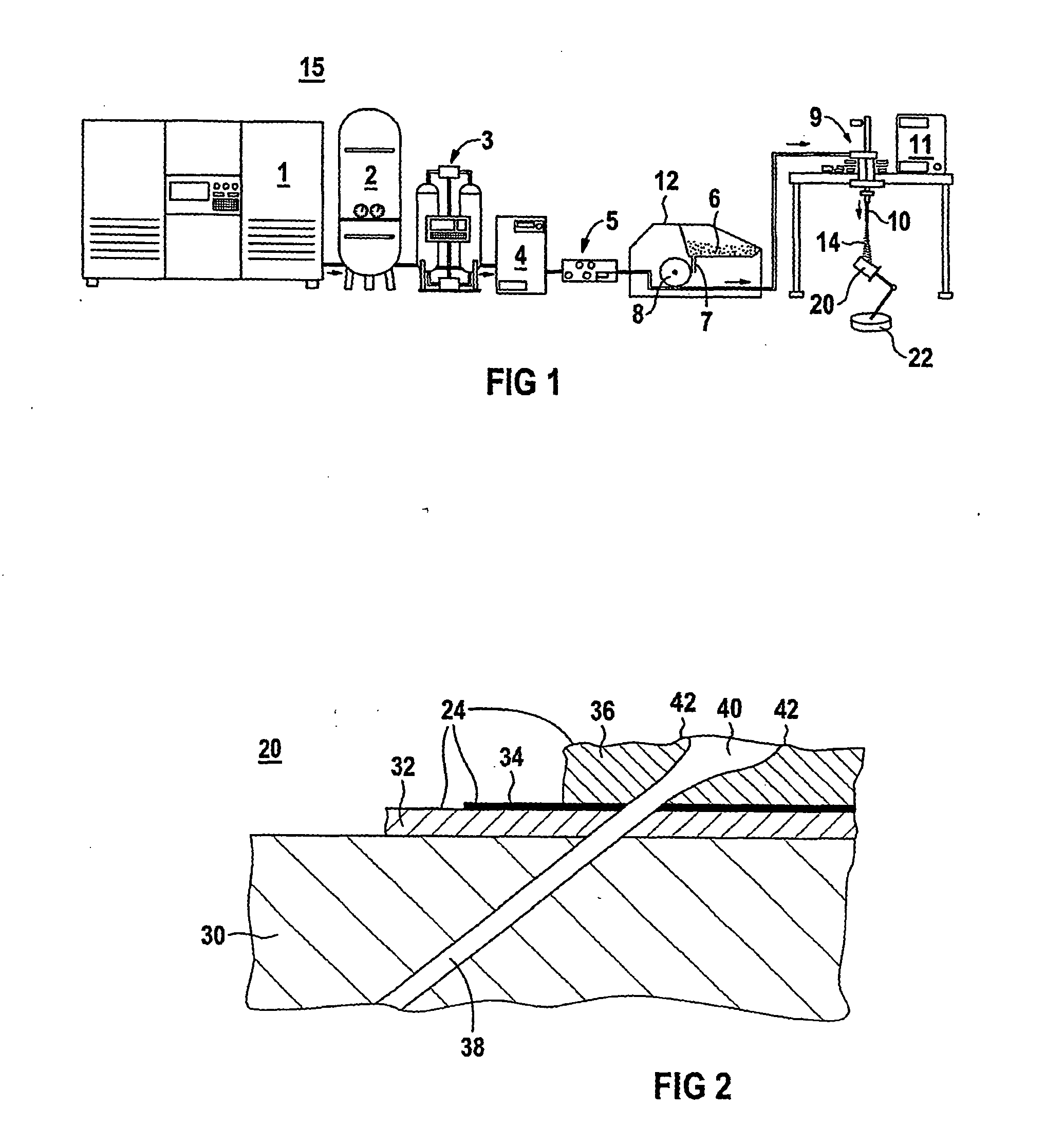

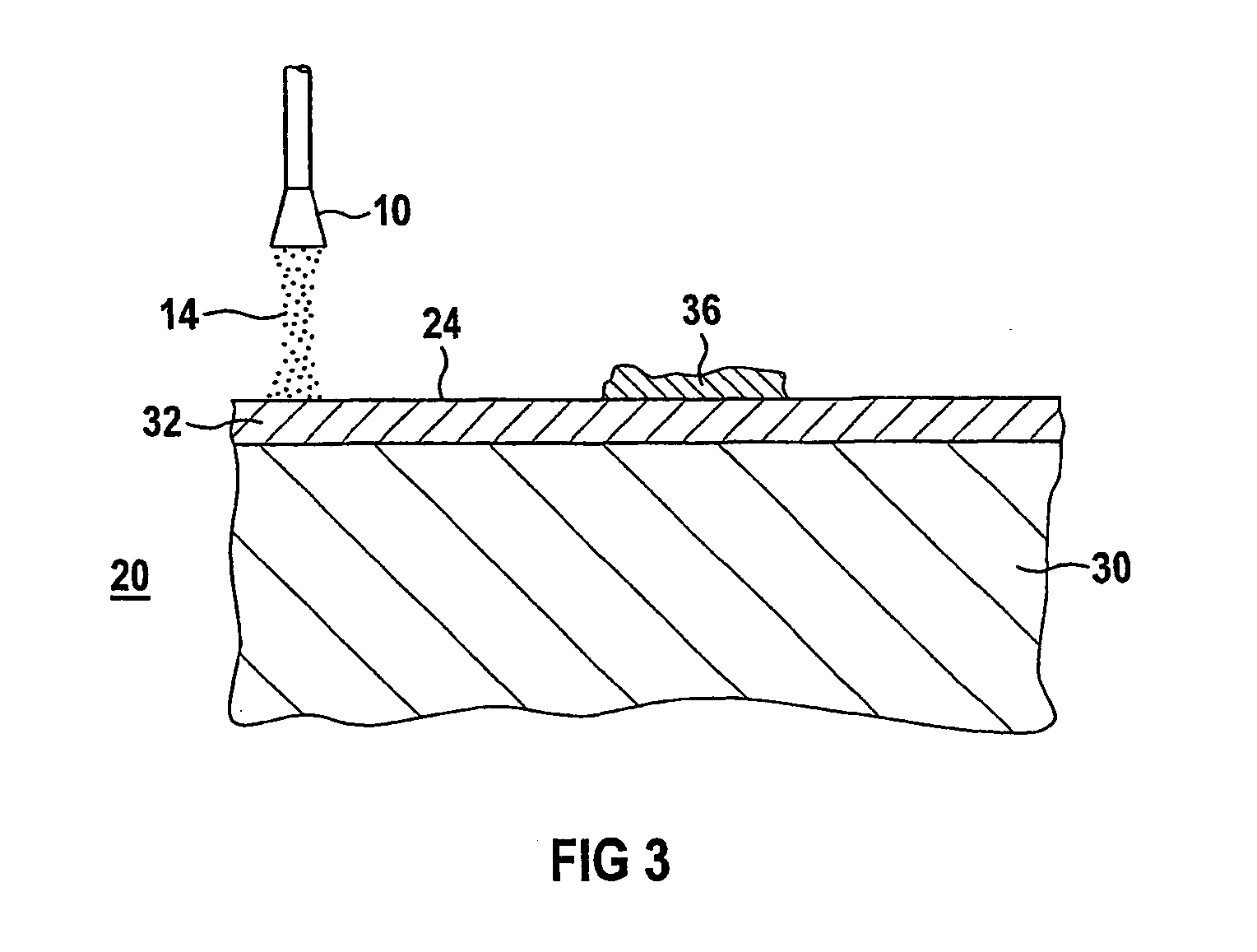

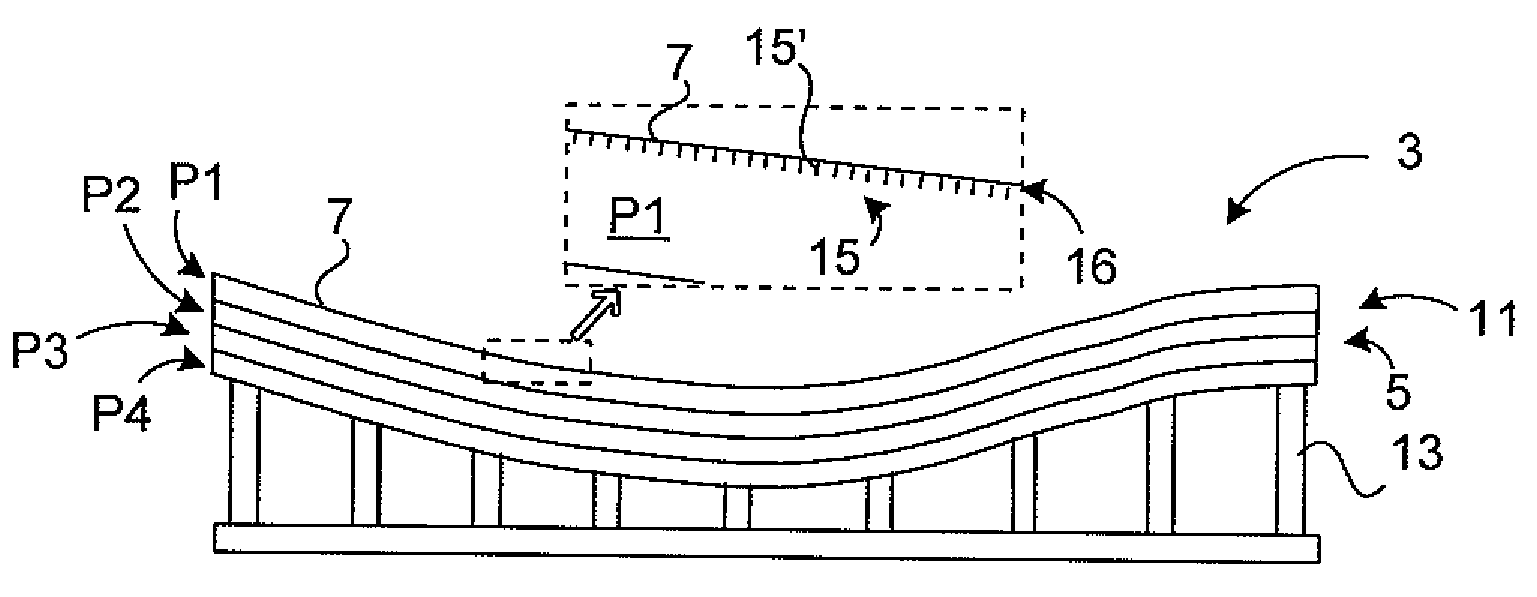

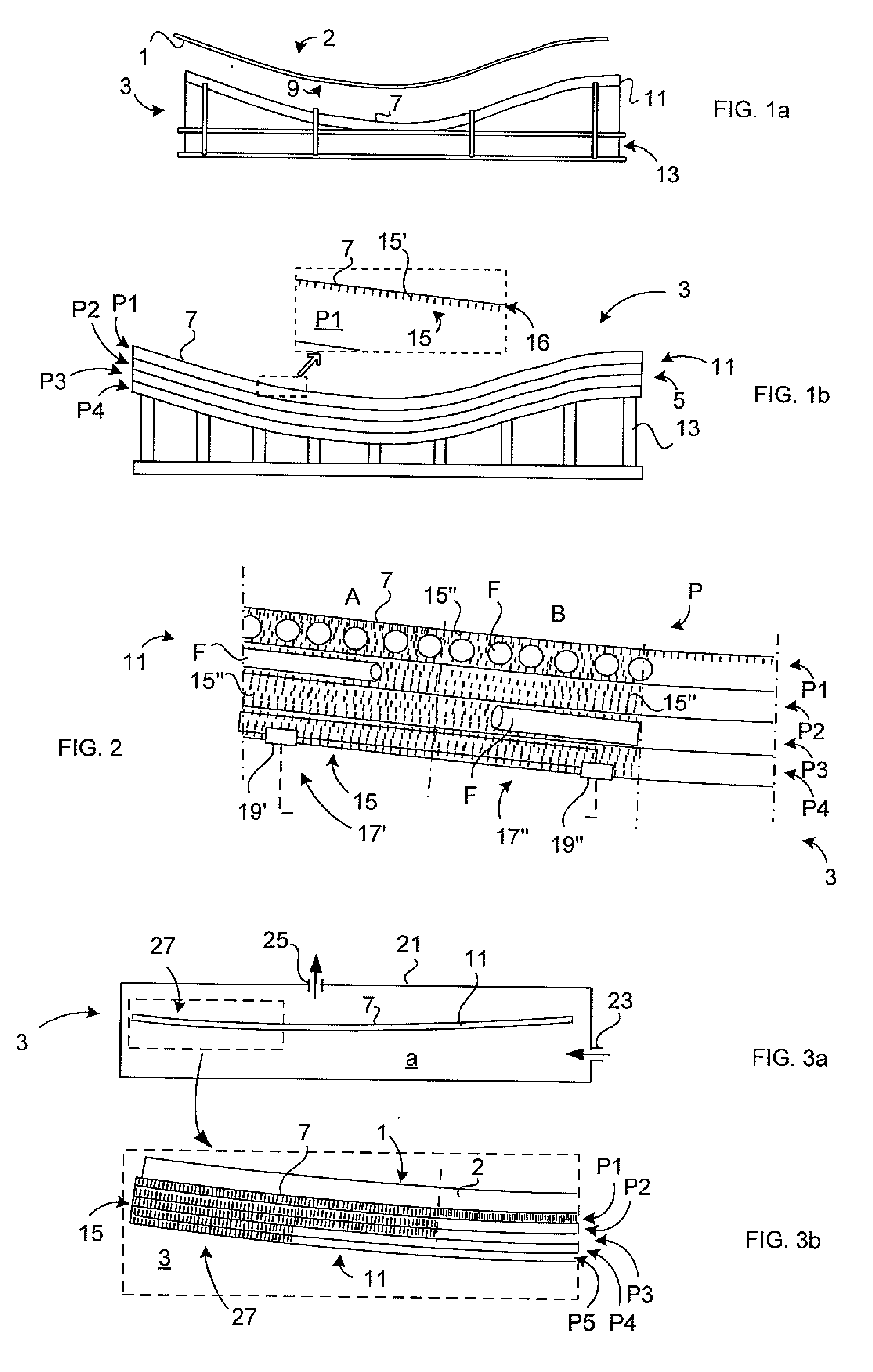

Smooth surface forming tool and manufacture thereof

ActiveUS20130240110A1Promotes hardEasy to smoothMaterial nanotechnologyMechanical working/deformationStructural engineeringMechanical engineering

An aircraft article composite forming tool and a method for producing the tool. The aircraft article to be formed includes a composite material including an outer surface. The aircraft article composite forming tool includes a matrix laminate made of at least an upper ply including a forming surface for forming the aircraft article and outer surface. The upper ply includes a nano filament structure embedded therein.

Owner:SAAB AB

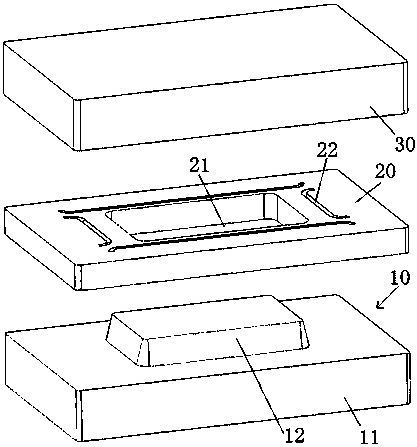

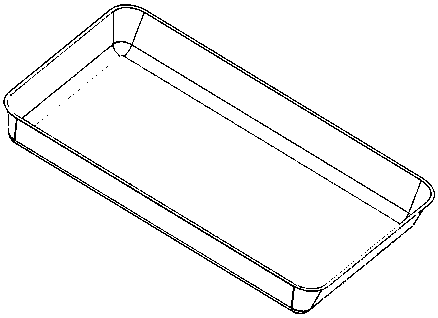

Punching method of new energy vehicle battery aluminum box

The invention relates to a punching method of a new energy vehicle battery aluminum box. The punching method includes the following steps that firstly, material selection is conducted, wherein an Al-Fe series aluminum alloy plate is used as a raw material, the plate elongation is larger than or equal to 35%, the plate width ranges from 800 mm to 900 mm, length ranges from 1000 mm to 1300 mm, and thickness is larger than or equal to 0.6 mm; secondly, film pasting is conducted, wherein the two faces of the aluminum alloy plate are covered with deep-draw protection films correspondingly; thirdly,chamfering is conducted, wherein the four corners of the aluminum alloy plate covered with the films are chamfered to form 1 / 4 circles correspondingly; fourthly, placement on a die is conducted, wherein the chamfered aluminum alloy plate is placed on the surface of a male die of the punching die, and stretching oil is sprayed on the four edges of the aluminum alloy plate or the punching die; fifthly, punching is conducted, punching is conducted with a female die of the punching die facing downwards and the male die of the punching die facing upwards, the blank holder force of the aluminum alloy plate ranges from 20 t to 40 t, the punching speed is smaller than or equal to 60 mm / s, and the punching depth is larger than or equal to 100 mm; and sixthly, shaping is conducted, wherein shaping,edge trimming, flanging and assembling are conducted after punching, and finally the new energy vehicle battery aluminum box is formed. The method is simple and convenient, steel is replaced with aluminum, and the aim of decreasing the weight of the battery aluminum box is achieved.

Owner:中铝东南材料院(福建)科技有限公司 +1

Processing method of high-elasticity cloud flannelette

InactiveCN108660793AGood crepe effectGood shape retention for pleatsBiochemical fibre treatmentLiquid/gas/vapor removalProduct inspectionProcessing cost

The invention discloses a processing method of high-elasticity cloud flannelette, which comprises the following steps of: S1, preparing raw materials, and pretreating processing flannelette, S2, sufficiently dyeing the flannelette, S3, drying the dyed flannelette, S4, preparing an elasticity improvement solution, and spraying the solution onto the surface of the flannelette to improve elasticity,S5, gigging and sufficiently carding the soaked flannelette, and S6, conveying the gigged flannelette into a setting machine for setting, and then performing finished product inspection, rolling and package. The flannelette prepared by the method is soft, thick and breathable, keeps warm, has a good creping effect, an excellent pleat preservation effect, a good textile shape and structural stability, is easy to flatten, soft in hand feeling, bright in color and has a strong stereoscopic effect and perfect elasticity; in addition, the overall processing cost is low; a production procedure is simple; and the method is suitable for massive processing.

Owner:常熟市兆佳针纺织有限公司

Automatic-controlled wall mud screeding device and using method thereof

ActiveCN109853914AWell mixedGood effect in useGrinding carriagesGrinding drivesAutomatic controlStructural engineering

Owner:浙江飞锐科技有限公司

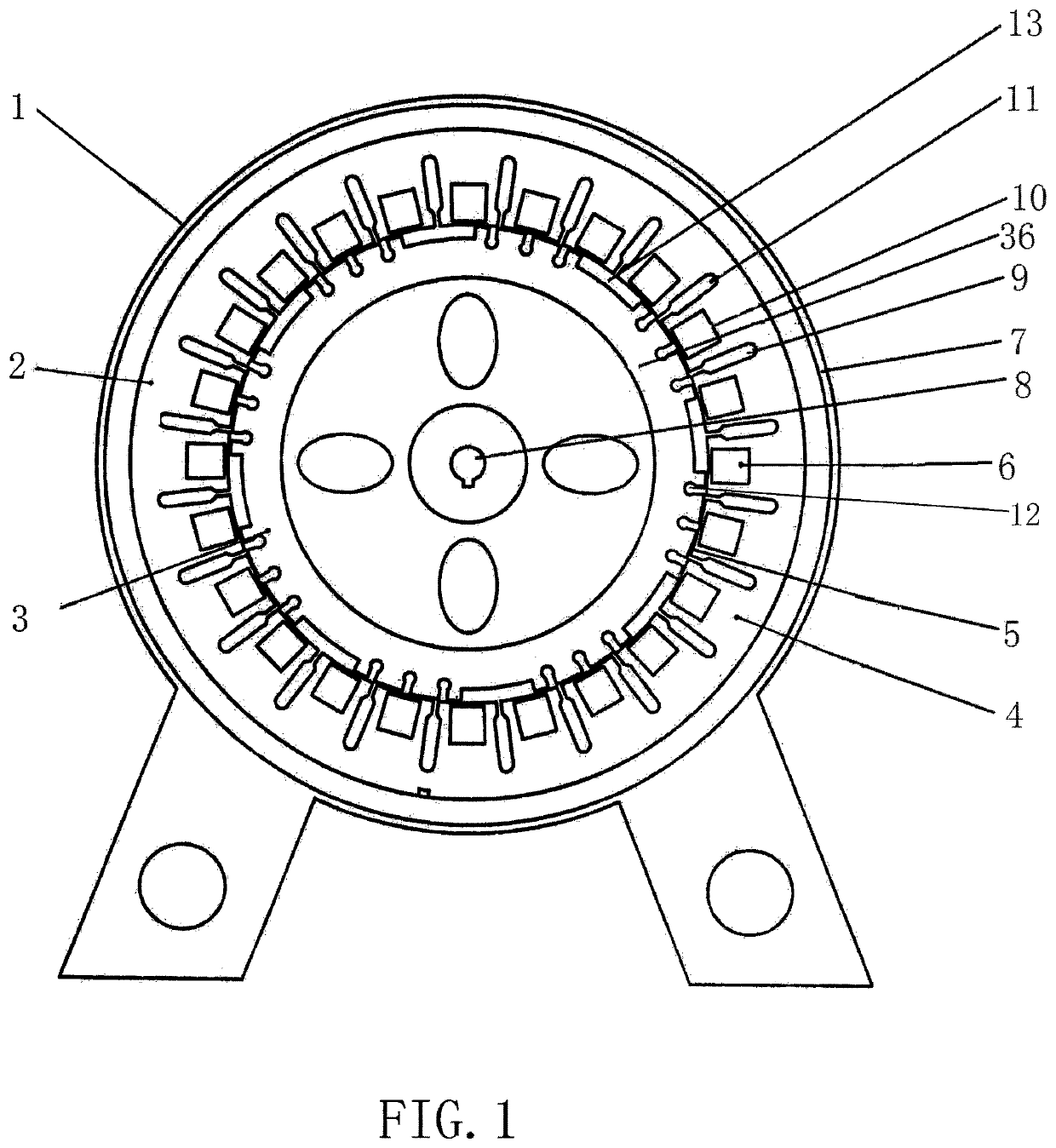

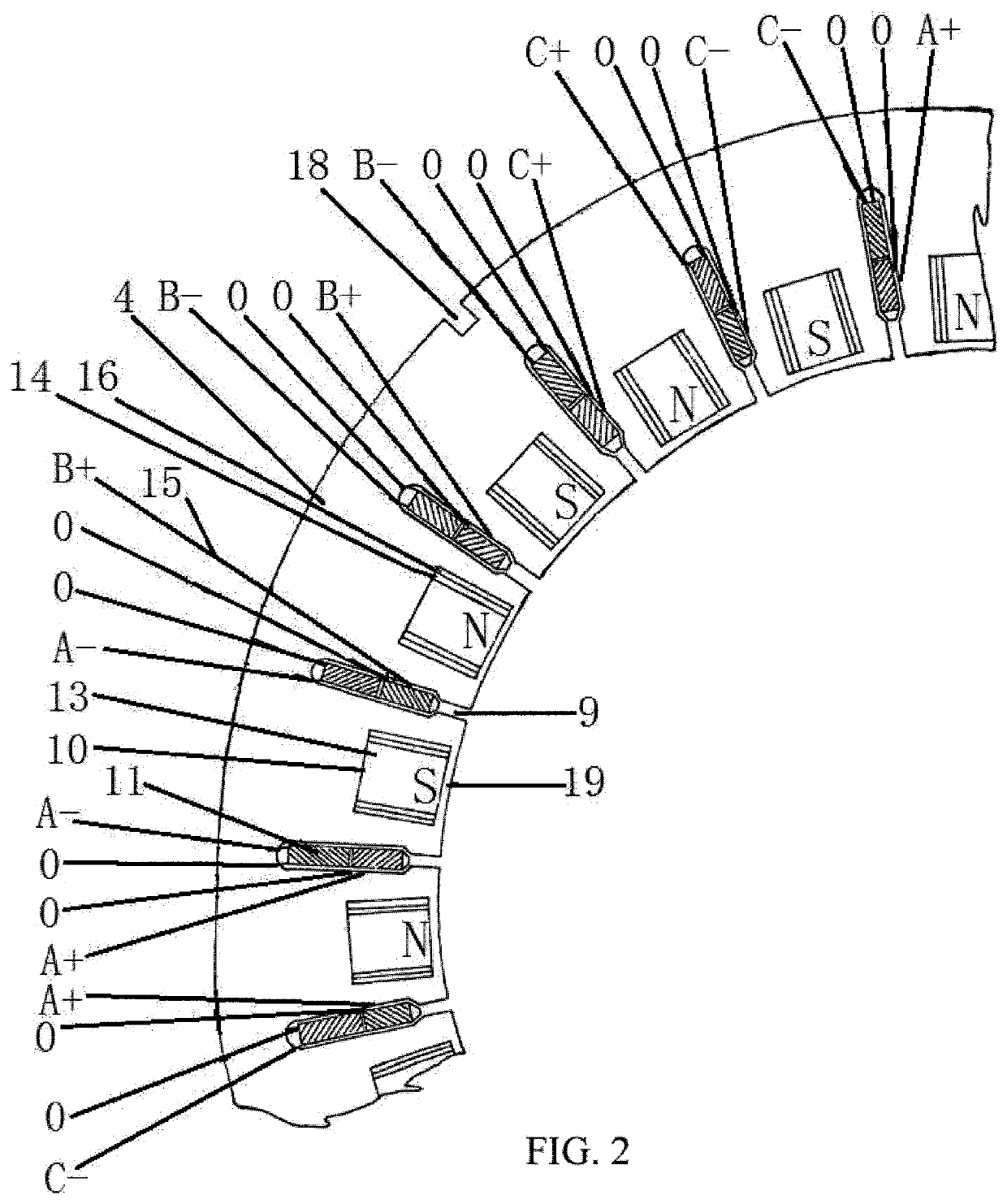

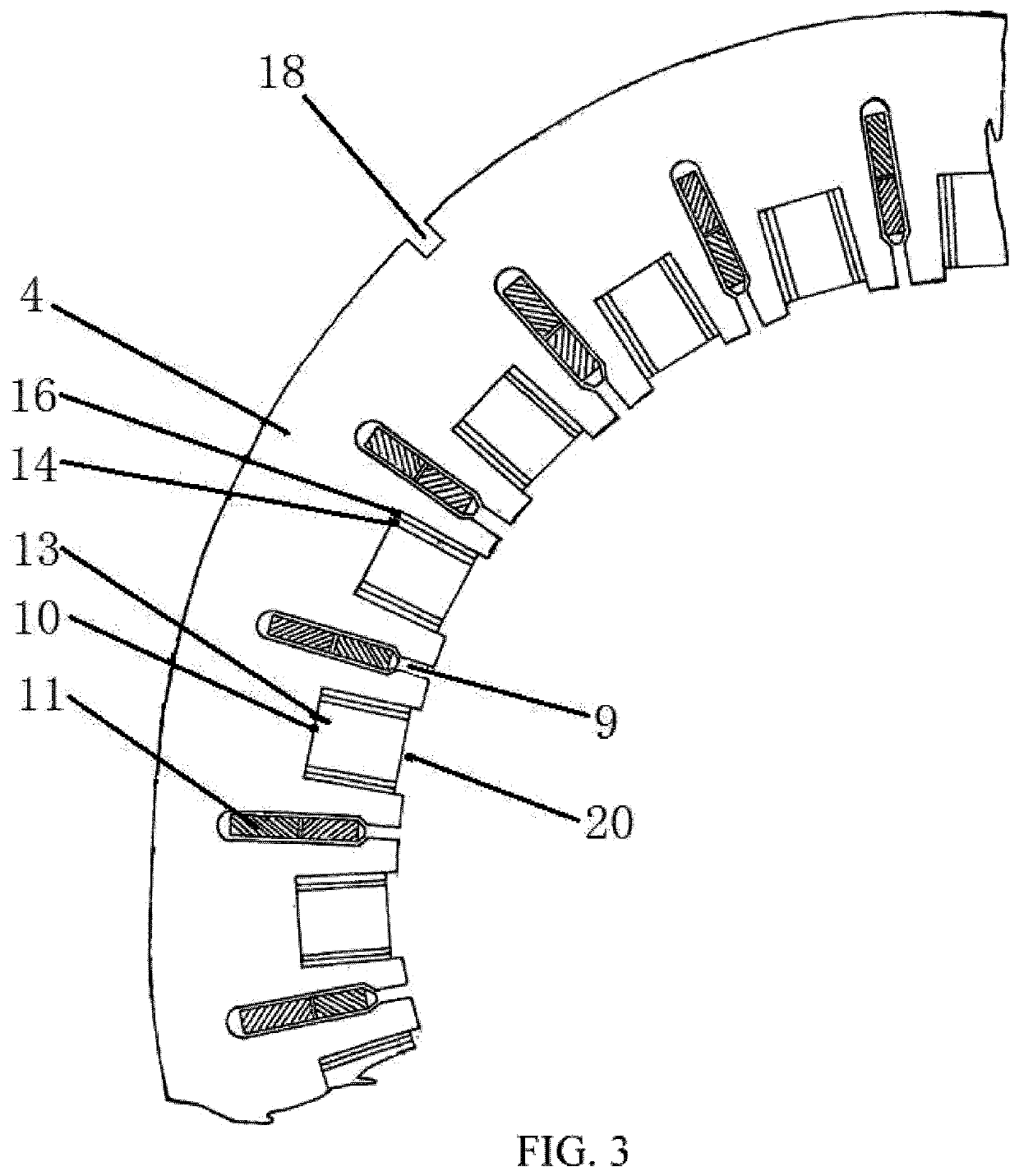

AC permanent magnet motor

ActiveUS10566856B2Improve compoundEasy to operateMagnetic circuit rotating partsAsynchronous induction motorsAC - Alternating currentElectric machine

The present invention discloses an alternating current (AC) permanent magnet motor, including a stator, a rotor, and a controller. Cable troughs and some same coil windings exist on a silicon steel sheet of a stator core. Grooves exist on the stator core, and stator permanent magnets are mounted in the grooves. The groove includes two types of grooves, namely, open grooves and enclosed grooves, and the two types of grooves are alternately laminated to form the stator core. A coil unit of the stator includes stator permanent magnets mounted in grooves of two stator cores and four same coils, and some same coil units form a three-phase stator coil. The rotor includes rotor cores, enclosed squirrel cages and rotor permanent magnets. The controller outputs a three-phase power source having a same positive and negative half sine-wave or step-wave pulse.

Owner:ZHANG XIAN

Smooth surface forming tool and manufacture thereof

ActiveUS9180979B2Promotes hardEasy to smoothMaterial nanotechnologyMechanical working/deformationEngineeringAirplane

Owner:SAAB AB

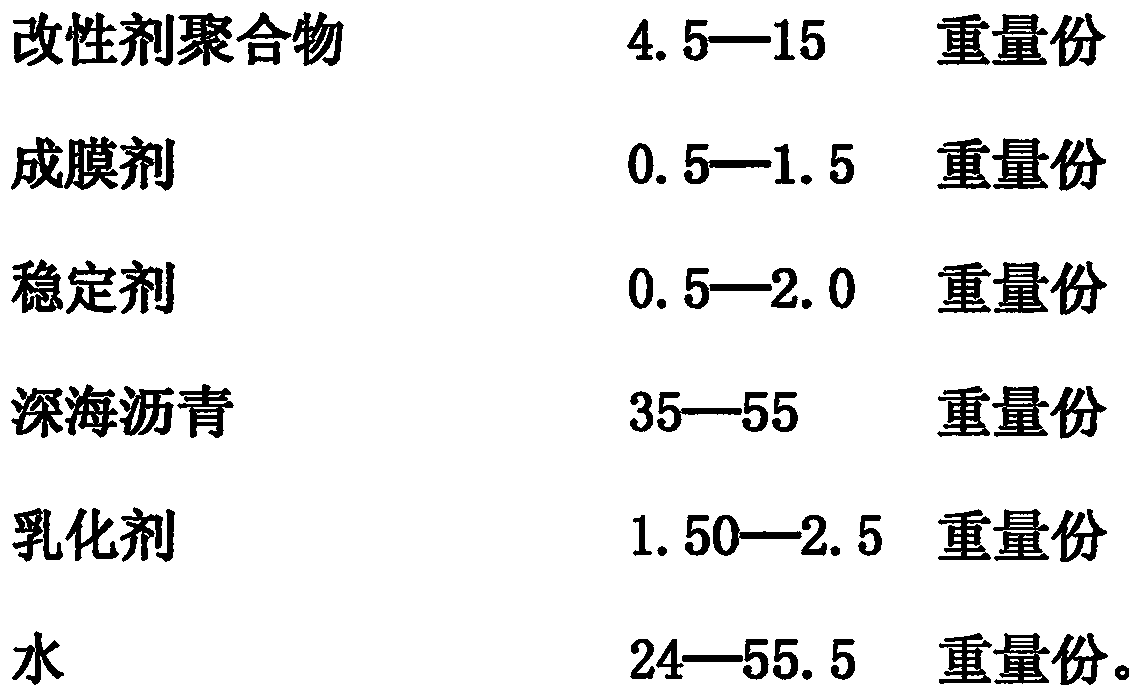

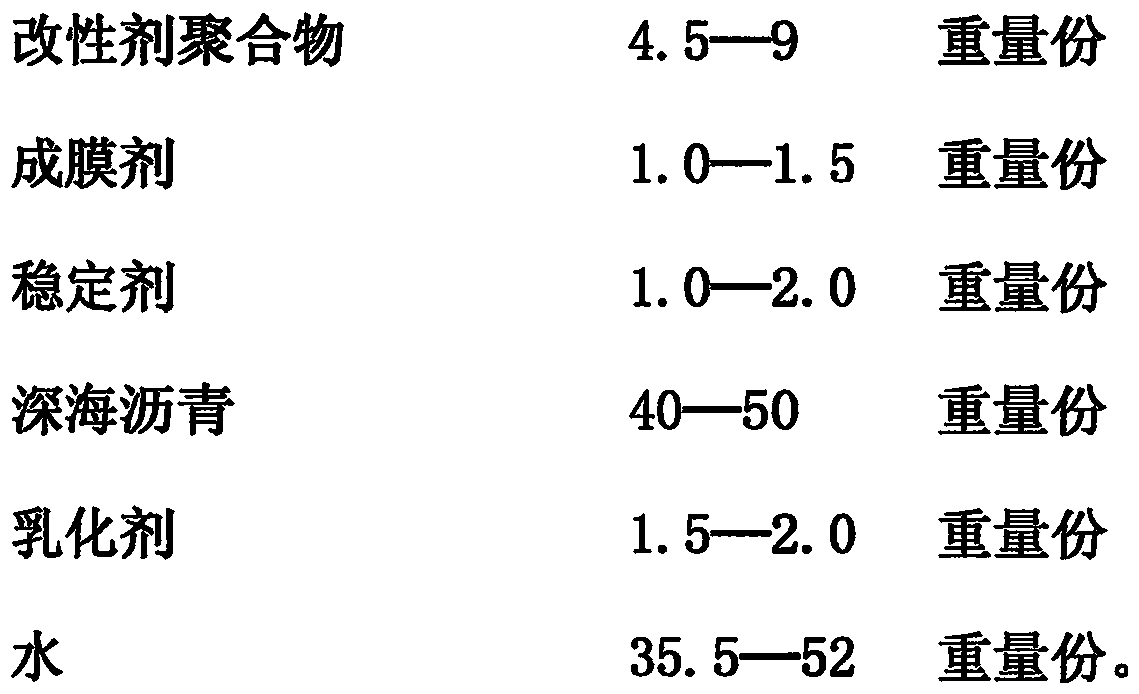

Polymer aqueous asphalt colloid and preparation method thereof

InactiveCN108165030AImprove aging performanceImprove high temperature performanceBuilding insulationsPolymer scienceRoad surface

The invention relates to a polymer aqueous asphalt colloid and a preparation method thereof, wherein the polymer aqueous asphalt colloid comprises, by weight, 4.5-15 parts of a modified polymer, 0.5-1.5 parts of a film forming agent, 0.5-2.0 parts of a stabilizer, 35-55 parts of deep sea asphalt, 1.0-2.5 parts of an emulsifier, and 25-56 parts of water, and mixing, emulsifying, shearing and colloid milling are performed to obtain the polymer aqueous asphalt colloid. According to the present invention, the polymer aqueous asphalt colloid has advantages of simple and reliable preparation, excellent performance, good film forming property, excellent high-temperature resistance and excellent low-temperature resistance, can significantly improve the water resistance, the slip resistance, the flatness and the wear resistance of pavement, and can be widely used in the micro-surface positions of urban and rural traffic heavy-duty high-grade pavements, or the sealing layer cover surfaces of newroads, and the like.

Owner:江苏荣成路桥材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com