SLA (Stereo Lithography Apparatus) 3D printer

A technology of printers and racks, applied in the field of SLA-based 3D printers, which can solve problems such as unsightly appearance, increased cost, and difficulty in entering and leaving the room for equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

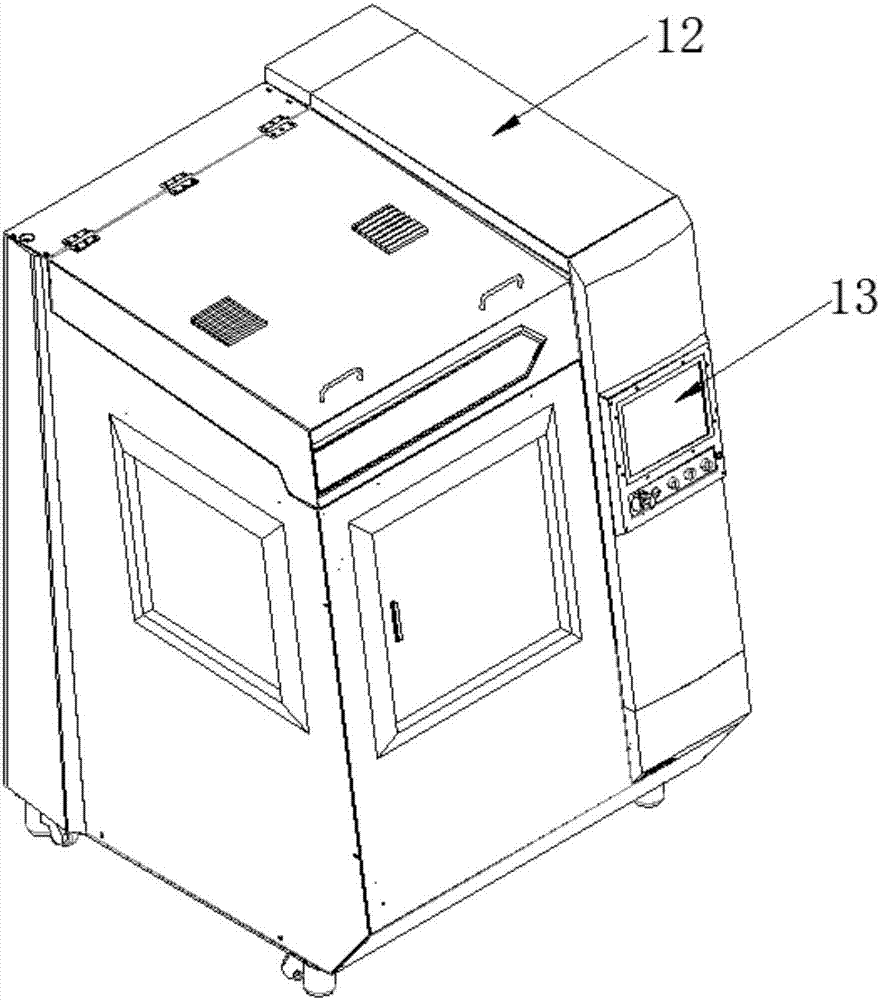

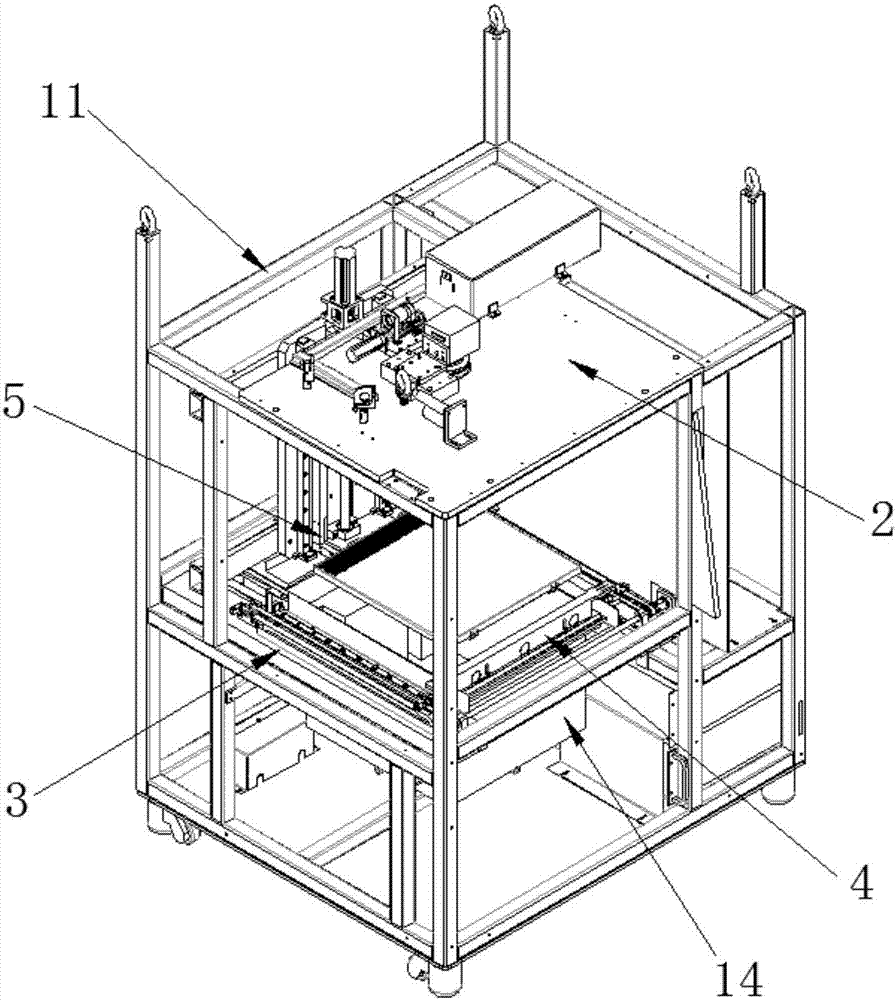

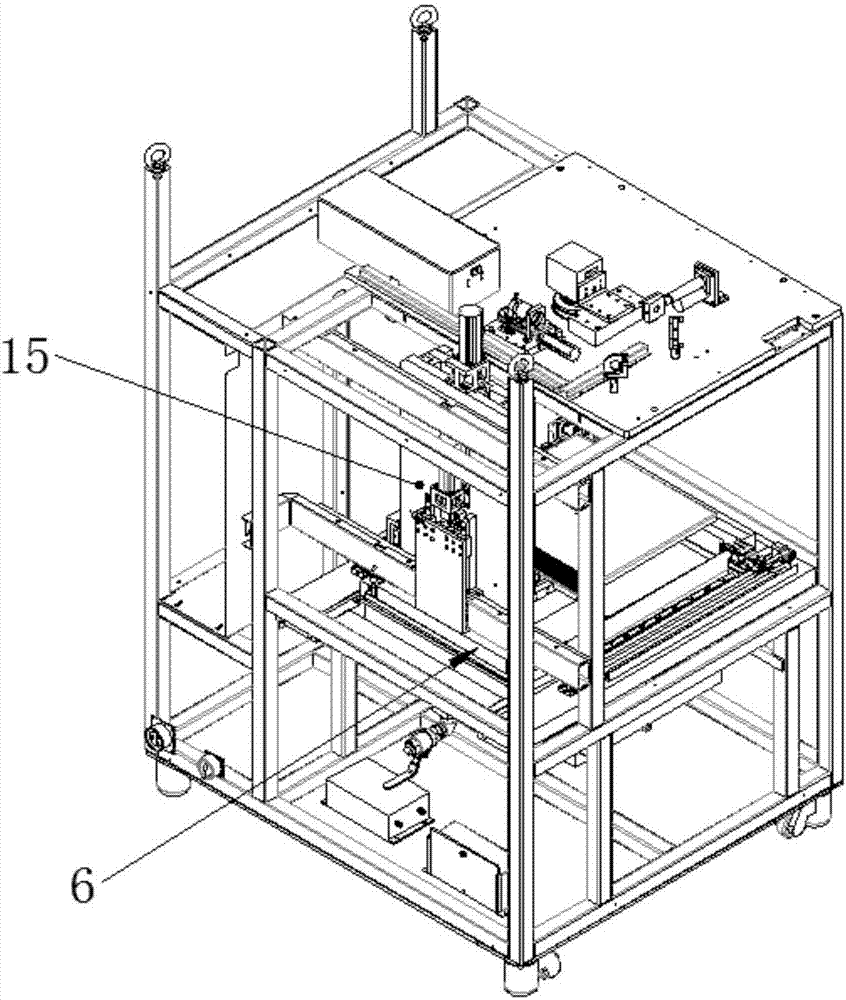

[0066] Such as figure 1 , figure 2 and image 3 As shown, the present invention discloses a SLA 3D printer. The structure of the printer mainly includes a frame 11, a housing 12, a display screen 13 for displaying printing progress and system parameters, and an optical path adjustment for generating laser light and controlling the printing path. Module 2, a trough 14 for holding liquid photosensitive resin materials, a scraper module 4 for scraping the slice layer, a bottom plate 31 for driving the scraper to work, a fixed component 3, and a device for controlling the change of the liquid level by lifting and lowering the sinker The sinker module 6, the L-shaped support platform 5 used to drive the screen plate to move up and down, the back plate 15 used to support the sinker module 6 and the L-shaped support platform 5, and the shell 12 and used to control the coordination of various execution components working controller.

[0067] Specifically, the frame 11 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com