Intelligent clamping and fixing equipment for circuit board welding

A technology for clamping and fixing the circuit board, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of simple structure, only considering the circuit board, inconvenient flipping, etc., so as to improve welding efficiency and reduce The effect of fixed steps and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

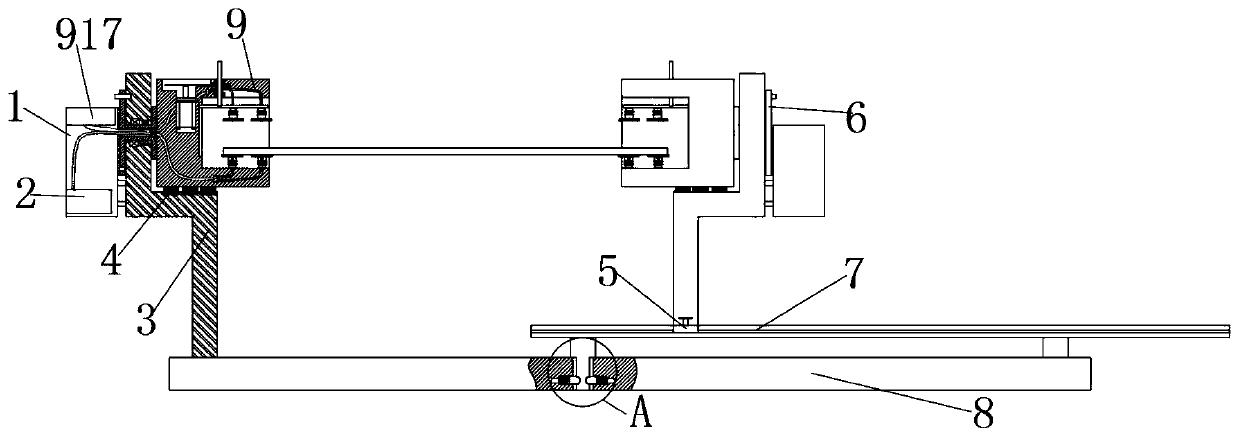

[0024] Example: see Figure 1-5 , the present invention provides a technical solution: an intelligent clamping and fixing device for circuit board welding, which is characterized in that it includes a fixed clamping assembly, a moving clamping assembly and an angle adjustment device, and the moving clamping assembly is used to adjust The distance from the fixed clamping assembly and together with the fixed clamping assembly clamp the circuit board; the fixed clamping assembly and the moving clamping assembly both include a fixed suction device and a mobile pressure applying device; the angle adjustment device is used to adjust the circuit The angle between the plate and the horizontal plane.

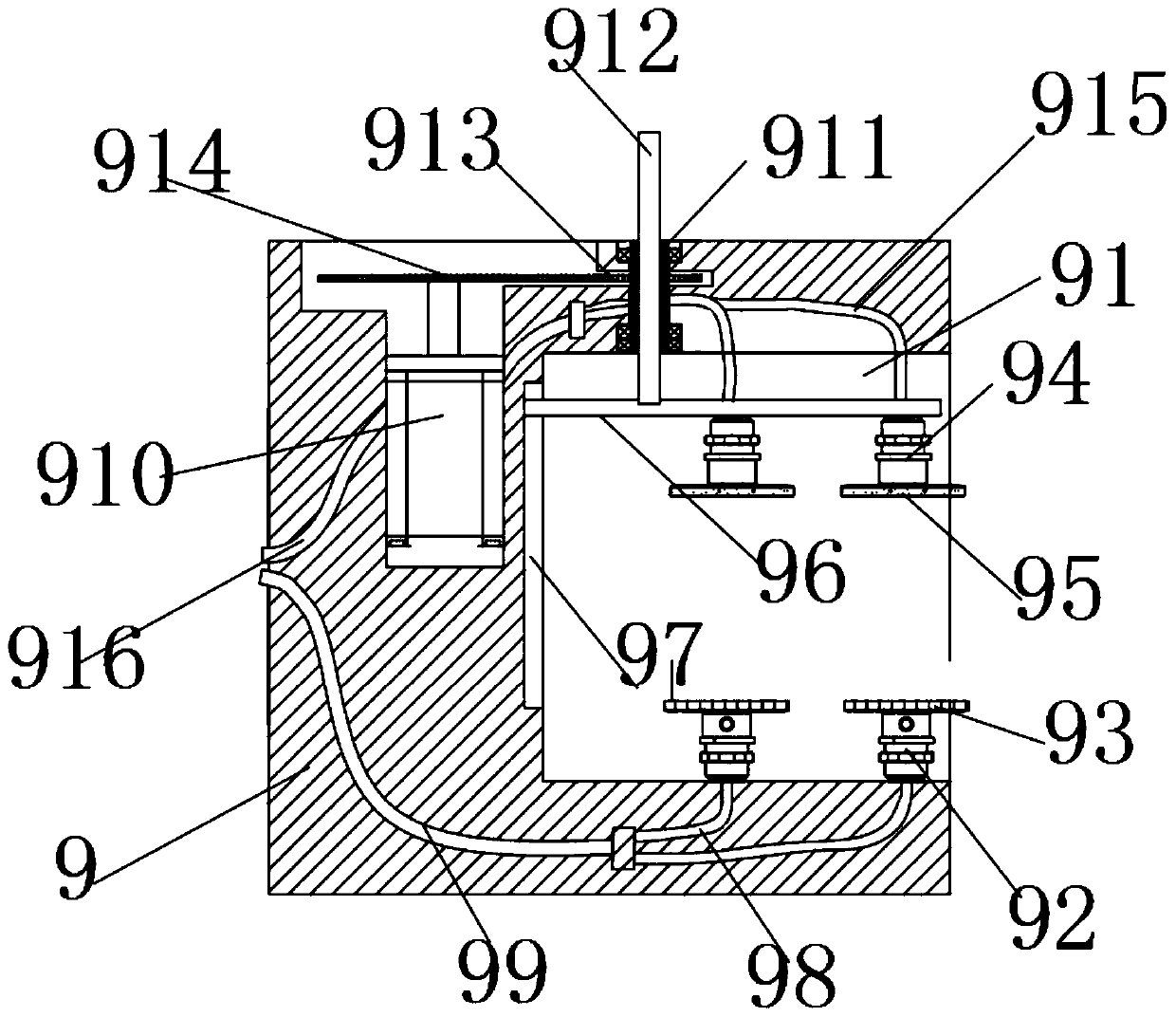

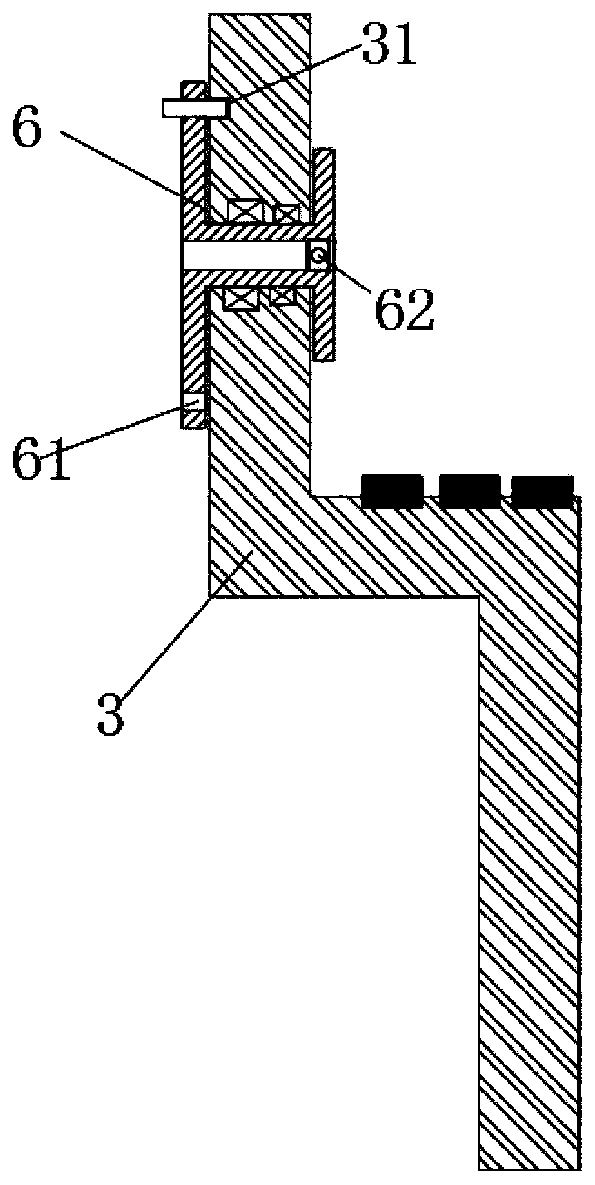

[0025] Wherein, the fixed clamping assembly includes a clamping seat body 9, a turntable 6, a vacuum base 1 and a fixed seat 3, and the fixed clamping assembly is fixed on the mounting seat 8 through the fixed seat 3, and the fixed seat 3 A plurality of support rollers 4 are embedded an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com