Improved type cloth winder

A rolling machine, an improved technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of reducing production efficiency, not neatly rolling cloth, wasting time, etc., to achieve high production efficiency and work efficiency. High efficiency and simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution and structure of the present invention will be described below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

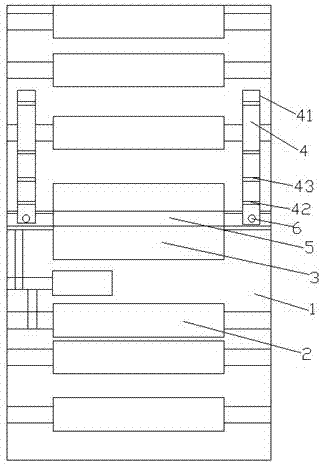

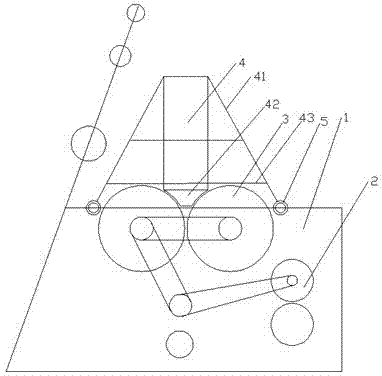

[0014] Such as figure 1 As shown, an improved cloth rolling machine includes a frame 1, a cloth loading device 2 and a rolling device 3 are arranged on the frame 1, and a width adjusting device 4 is arranged at both ends of the rolling device 3, and the width adjustment The device 4 includes an adjusting frame 41, the adjusting frame 41 is provided with a stopper 42, the bottom of the stopper 42 extends to the upper position between the first rolling wheel and the second rolling wheel of the rolling device 3, and the bottom of the stopper 42 is arranged as an inverted triangle , in order to adapt to the shape between the first rolling wheel and the second rolling wheel of the rolling device 3, guide rods 5 are arranged on both sides of the rolling device 3 on the frame 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com