Patents

Literature

66results about How to "Raise the degree of orientation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

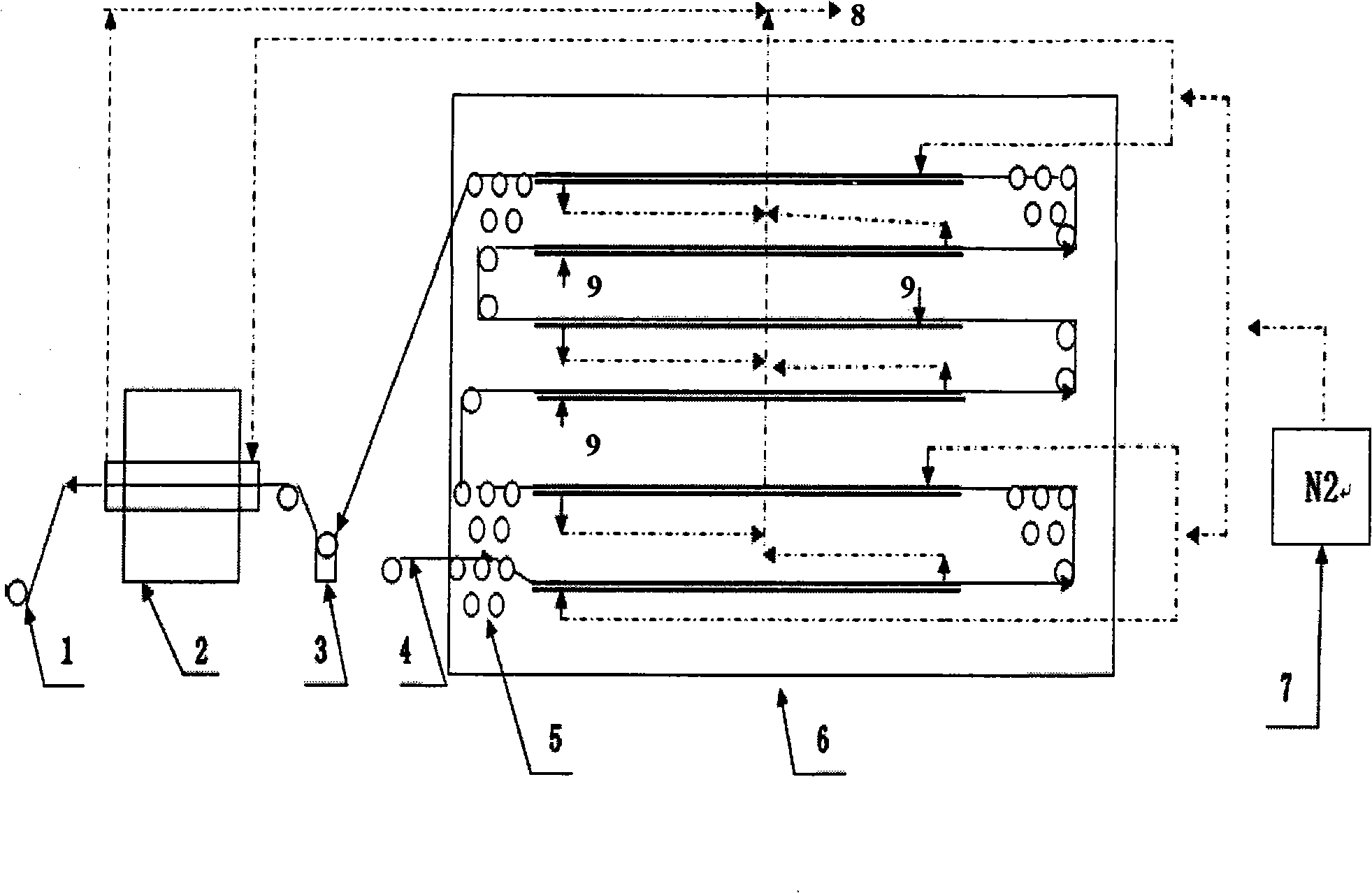

Pre-oxidation method for carbon fiber precursor polyacrylnitrile fiber

InactiveCN101260575AHigh tensile strengthGood orientationFibre chemical featuresCarbonizationNitrogen

The invention discloses a preoxidation method for a polyacrylonitrile fiber of former body of carbon fiber. The method is, under normal pressure, to subject the polyacrylonitrile fiber precursor orderly and continuously to constant preoxidation, that is, preoxidation at five temperatures in a low temperature carbonization furnace, including a cyclization process under the protection of nitrogen at a first temperature and a second temperature with rigid drawing at the second temperature, and a oxidation crosslink process with the presence of air at a third temperature, a fourth temperature and a fifth temperature; to low temperature carbonization with nitrogen passing through the furnace at a sixth temperature; and finally to high temperature carbonization under the protection of nitrogen after entering a high temperature carbonization furnace through a tension bracket. The method has the advantages that in case of the protection of nitrogen gas, the heat treatment to fiber can improve the reactivity of the fiber, is favorable for the implement of cyclization reaction, and meanwhile in the case of the protection of nitrogen gas, the applied rigid drawing can improve the orientation degree of a molecular chain along the fiber axis, and thus polyacrylonitrile carbon fiber with higher strength and higher modulus can be obtained.

Owner:DONGHUA UNIV +1

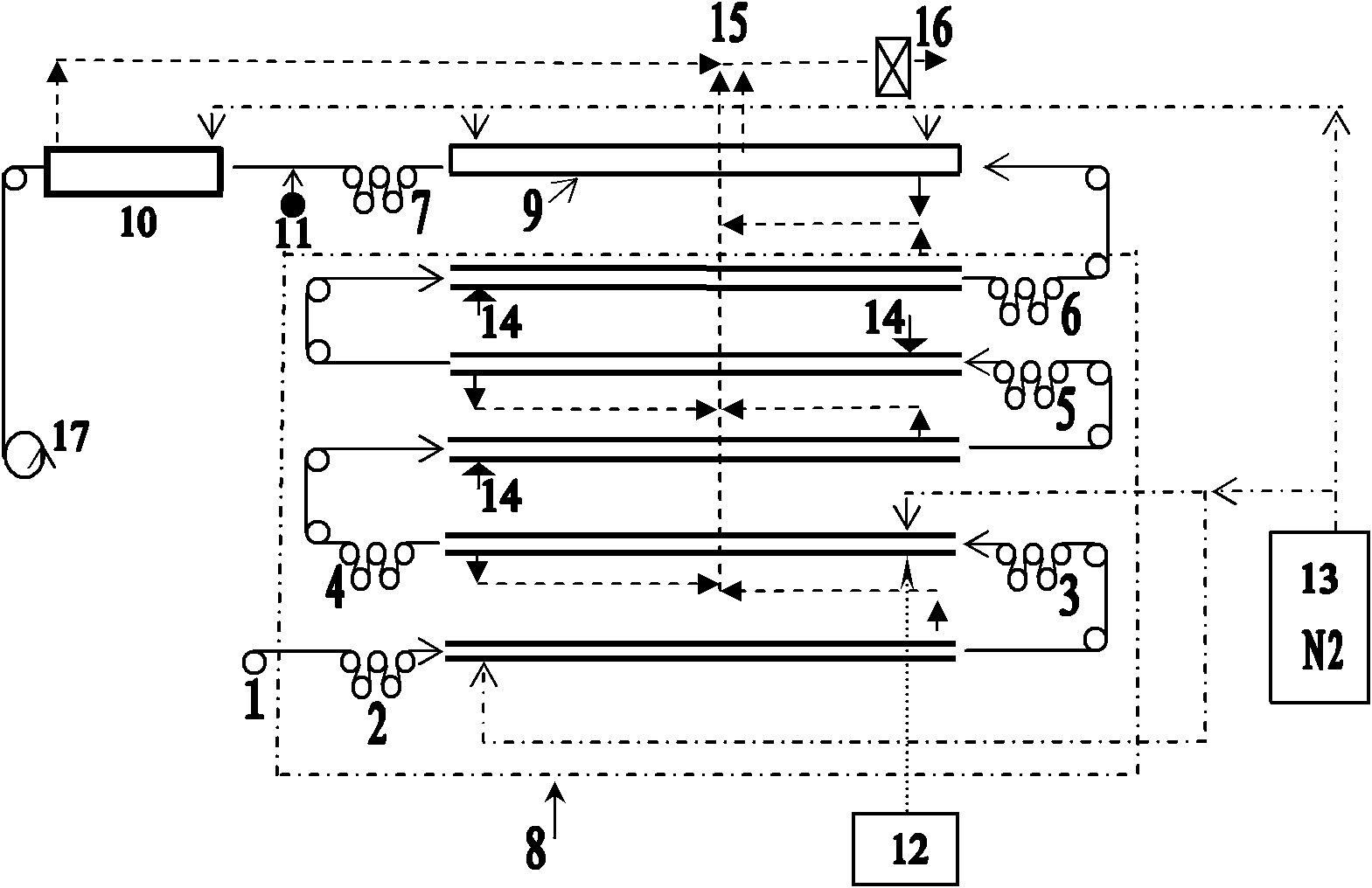

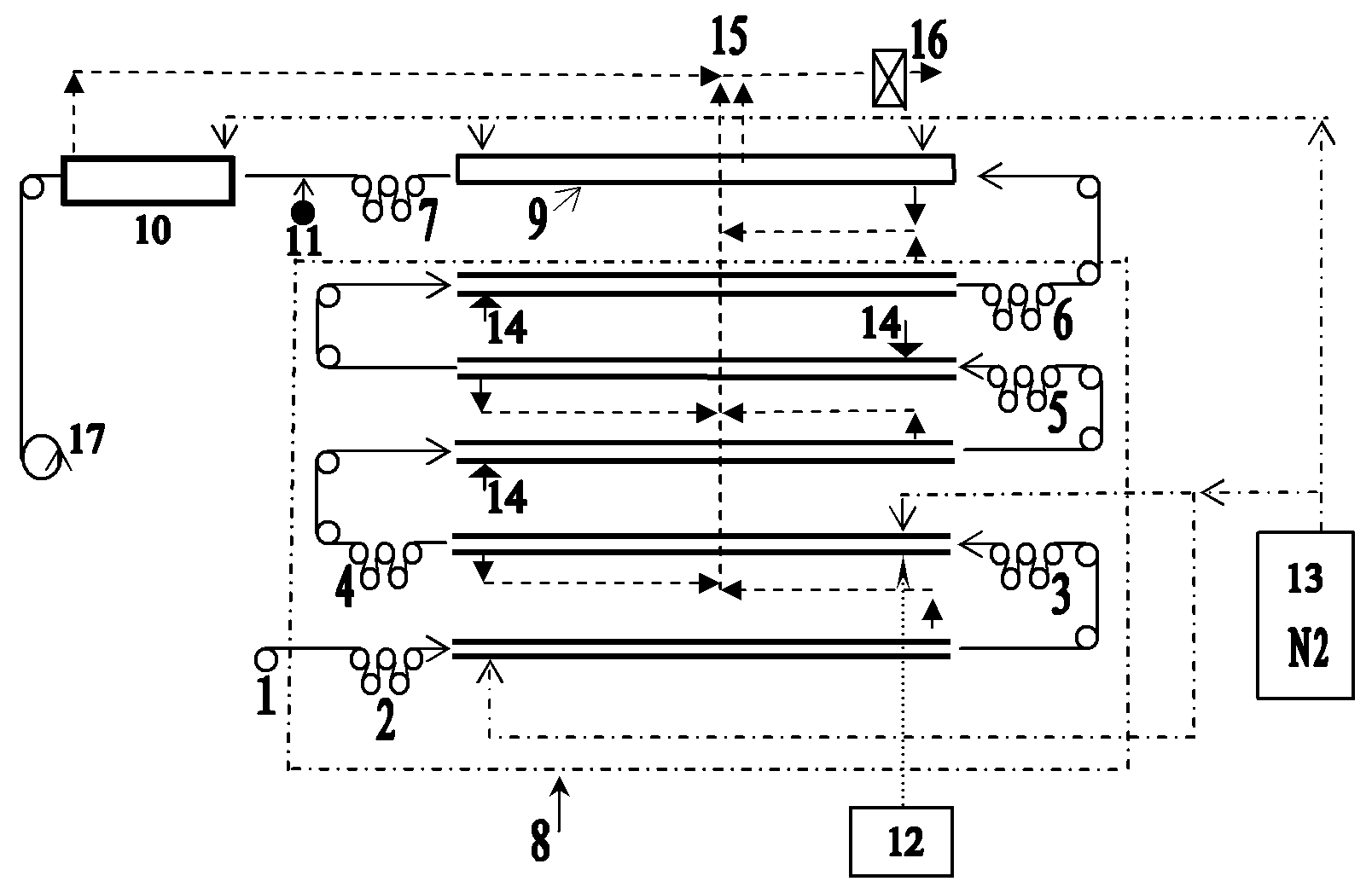

Curing treatment method of carbon fiber precursor polyacrylonitrile fiber

InactiveCN102181963AGood for cyclization reactionRaise the degree of orientationFibre chemical featuresAir atmosphereCarbon fibers

The invention relates to a curing treatment method of a carbon fiber precursor polyacrylonitrile fiber. The method comprises the following steps: pre-cyclizing the polyacrylonitrile fiber precursor in the atmosphere of inert gas; carrying out cyclizing and plastic drawing in the atmosphere of inert gas and water vapor; and carrying out oxidation crosslinking in the atmosphere of air, thus obtaining a pre-oxidized polyacrylonitrile fiber. The method has the following beneficial effects: carrying out heat treatment on the fiber in the inert atmosphere is beneficial to implementation of cyclization reaction in the molecules to form rigid ladderlike molecules with regular structure and strong heat resistance, and at the same time, a defined amount of water vapor is introduced to obtain a higher drawing ratio by enhancing the plasticity of the molecular chains in the fiber, thus improving the orientation degree of the rigid molecules along the fiber axis.

Owner:DONGHUA UNIV

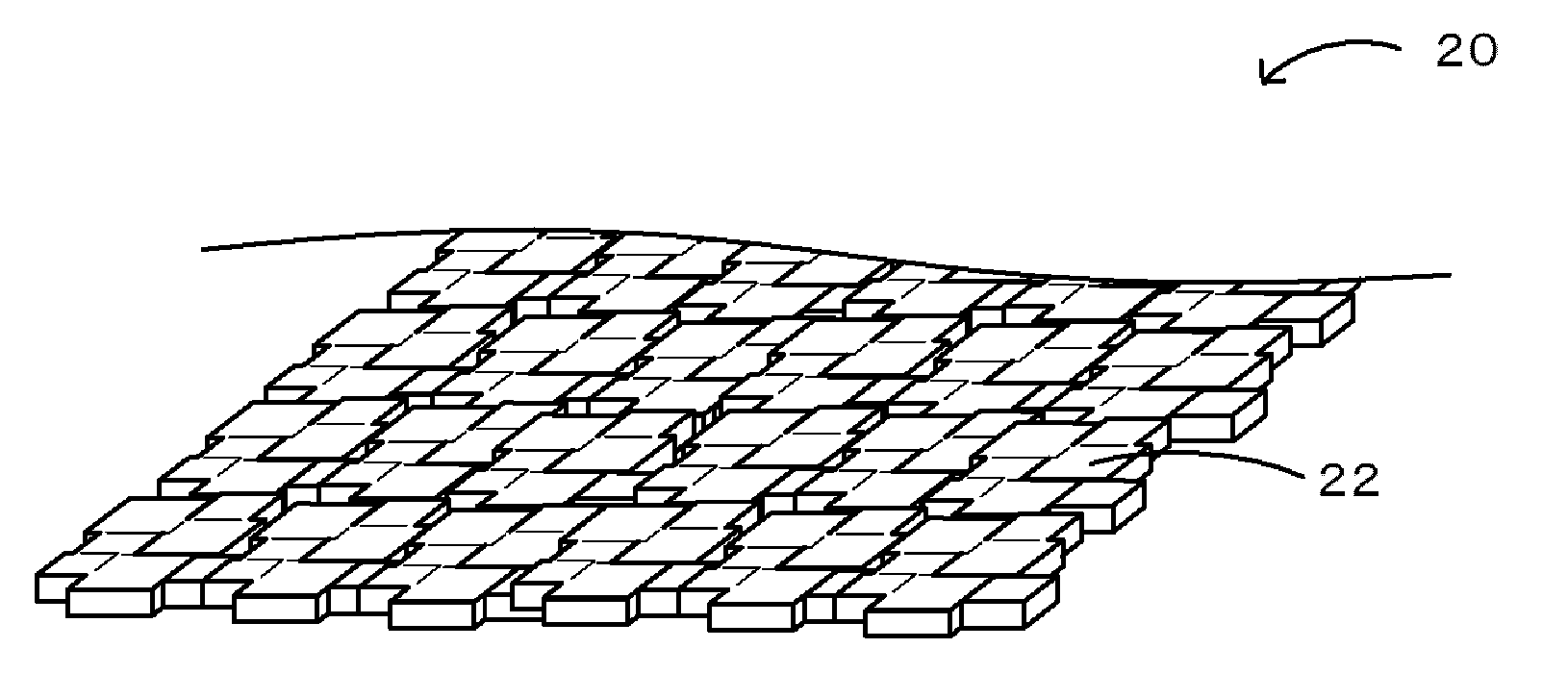

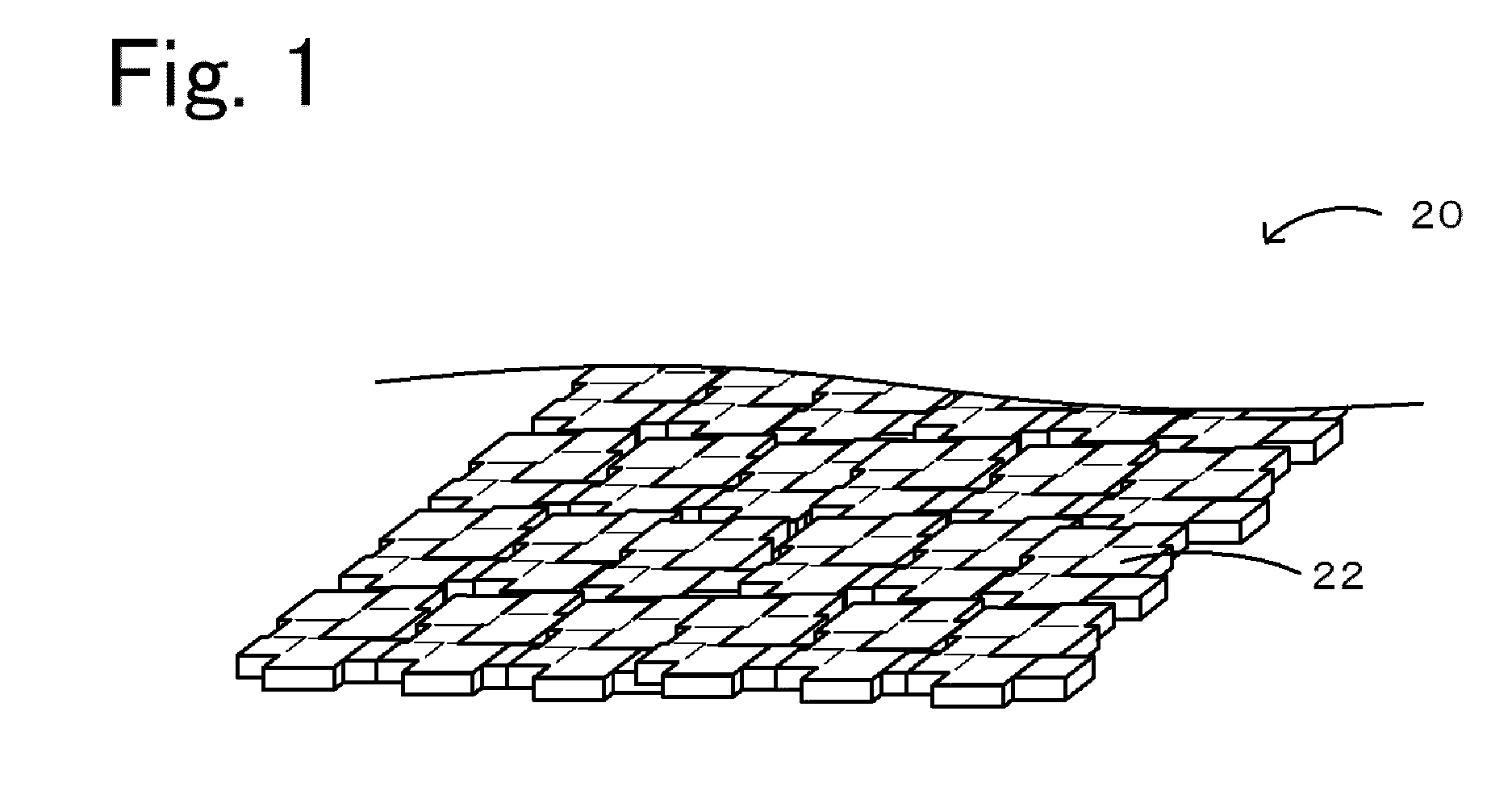

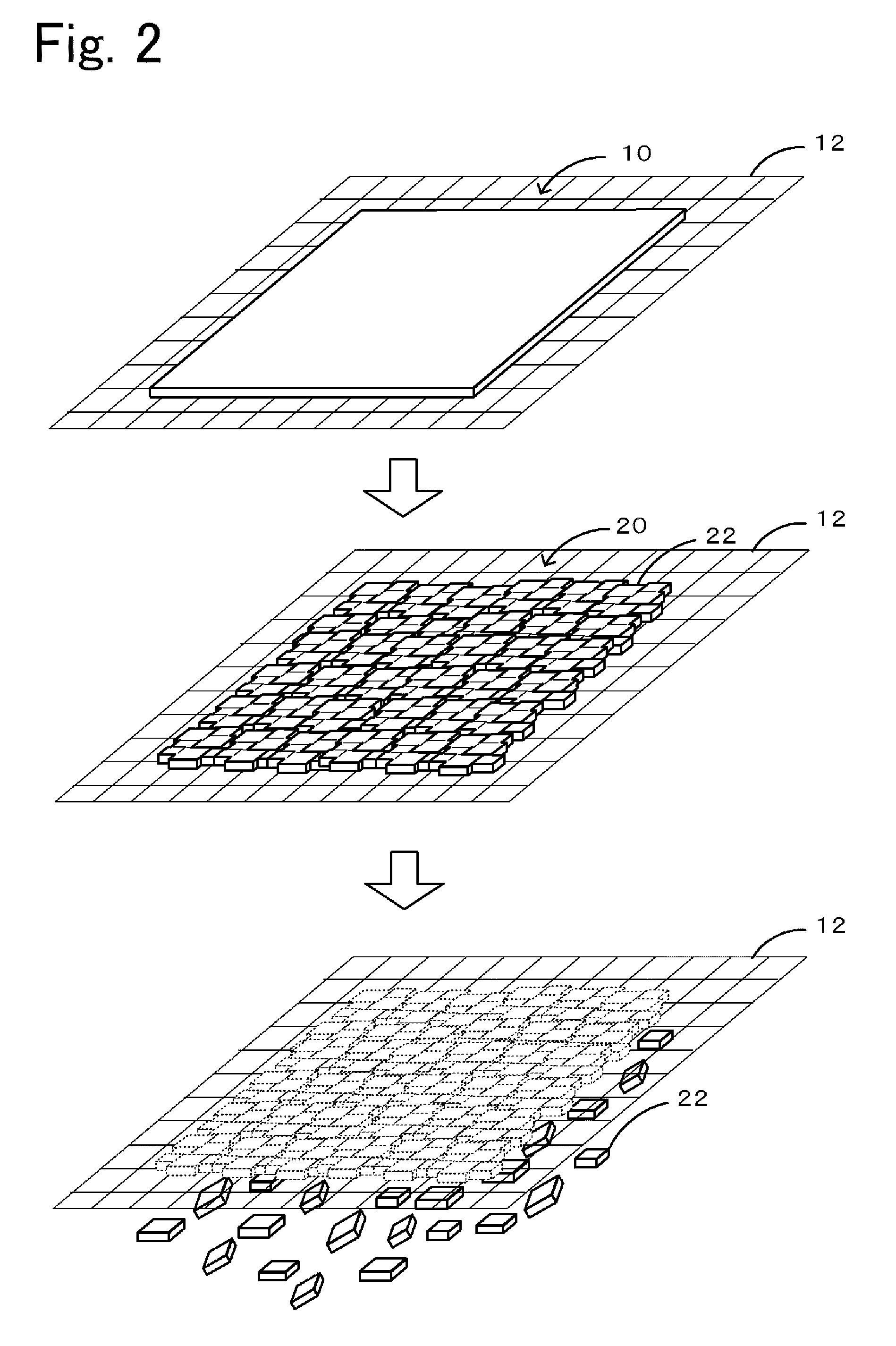

Ceramic sheet and method for producing the same

InactiveUS20100119800A1Reduce energy consumptionHigh densityPiezoelectric/electrostrictive device manufacture/assemblySynthetic resin layered productsInorganic particleInorganic particles

A ceramic sheet 20 is produced by a method in which inorganic particles including, as a main component, an oxide represented by general formula ABO3 and containing a volatile component are mixed such that the A / B ratio is 1.05 or more, the inorganic particles are formed into a self-supported planar shaped body with a thickness of 30 μm or less, and the shaped body is fired, without an inactive layer or with an inactive layer which does not substantially react with the shaped body and is disposed adjacent to the shaped body, at a temperature-rising rate of 30° C. / min or more in a temperature range which is equal to or higher than a temperature at which the volatile component is volatilized.

Owner:NGK INSULATORS LTD

Heat-conducting graphite membrane and preparation method

ActiveCN103387225AOvercoming the existence of a large number of air gapsOvercome the thicknessGrapheneHeat conductingGraphite

The invention discloses a heat-conducting graphite membrane and a preparation method. The heat-conducting graphite membrane is prepared from 90 to 99.7 wt% of a graphene nanosheet and 0.3 to 10.0 wt% of an inorganic adhesive. The preparation method comprises the following steps: 1) with the graphene nanosheet as a raw material, adding an aqueous inorganic adhesive material to wet the graphene nanosheet and carrying out uniform mixing with stirring; 2) adding a mixed wet material into a rolling unit for calendaring so as to obtain the heat-conducting graphite membrane; and 3) drying the calendared heat-conducting graphite membrane. The preparation method is a novel preparation method for the heat-conducting graphite membrane, can be carried out with a traditional rolling unit to prepare the heat-conducting graphite membrane and has low requirements for the unit, and a rolling process is simple; the prepared graphite membrane has a few air gaps, uniform compactness and high heat conduction performance at two directions respectively parallel and perpendicular to the graphite membrane.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

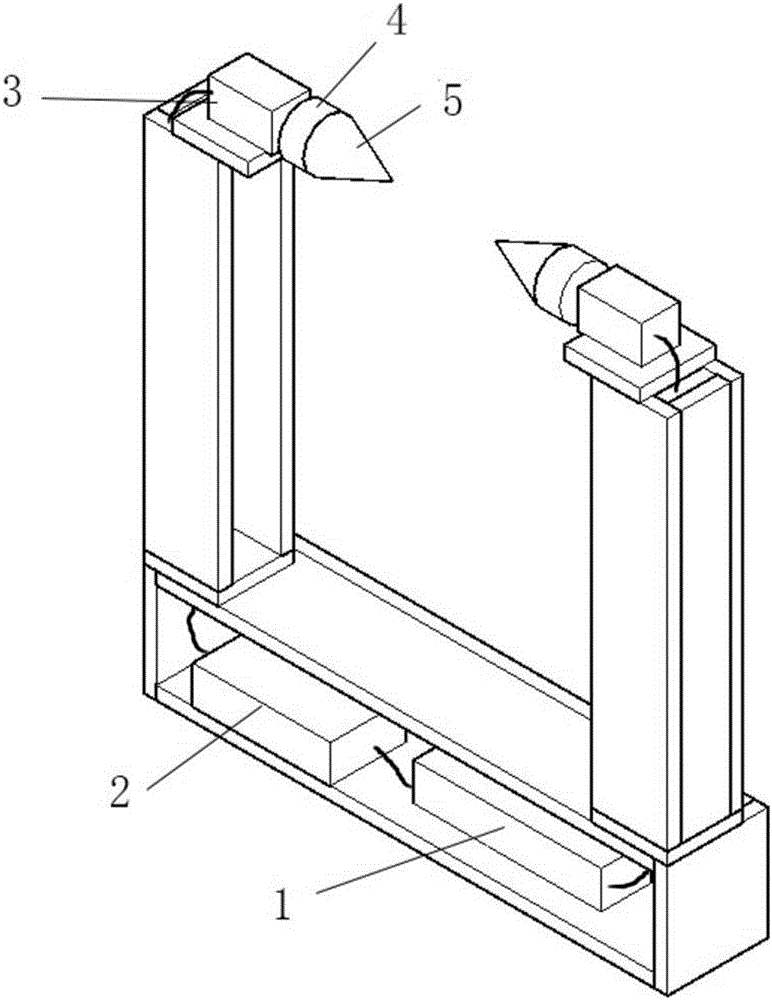

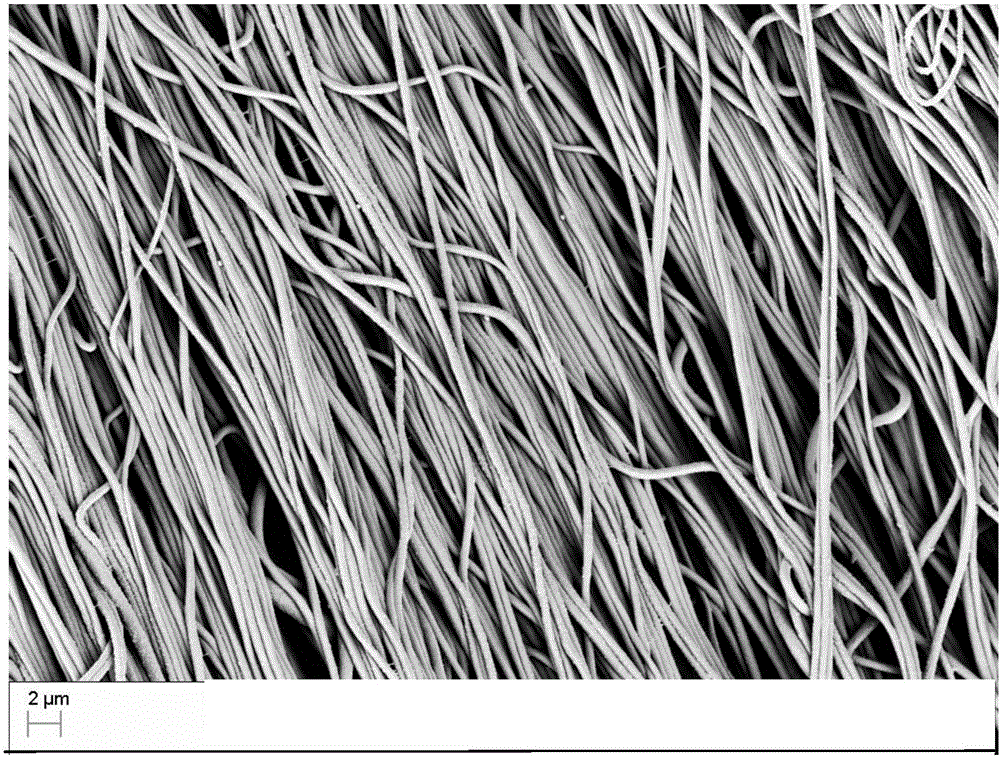

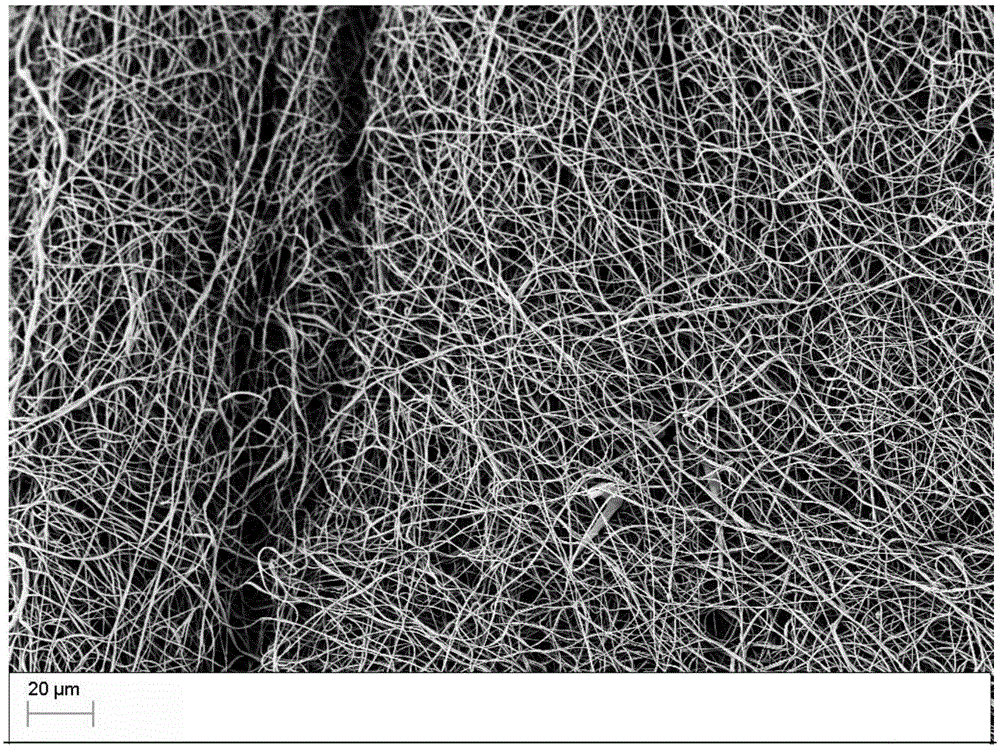

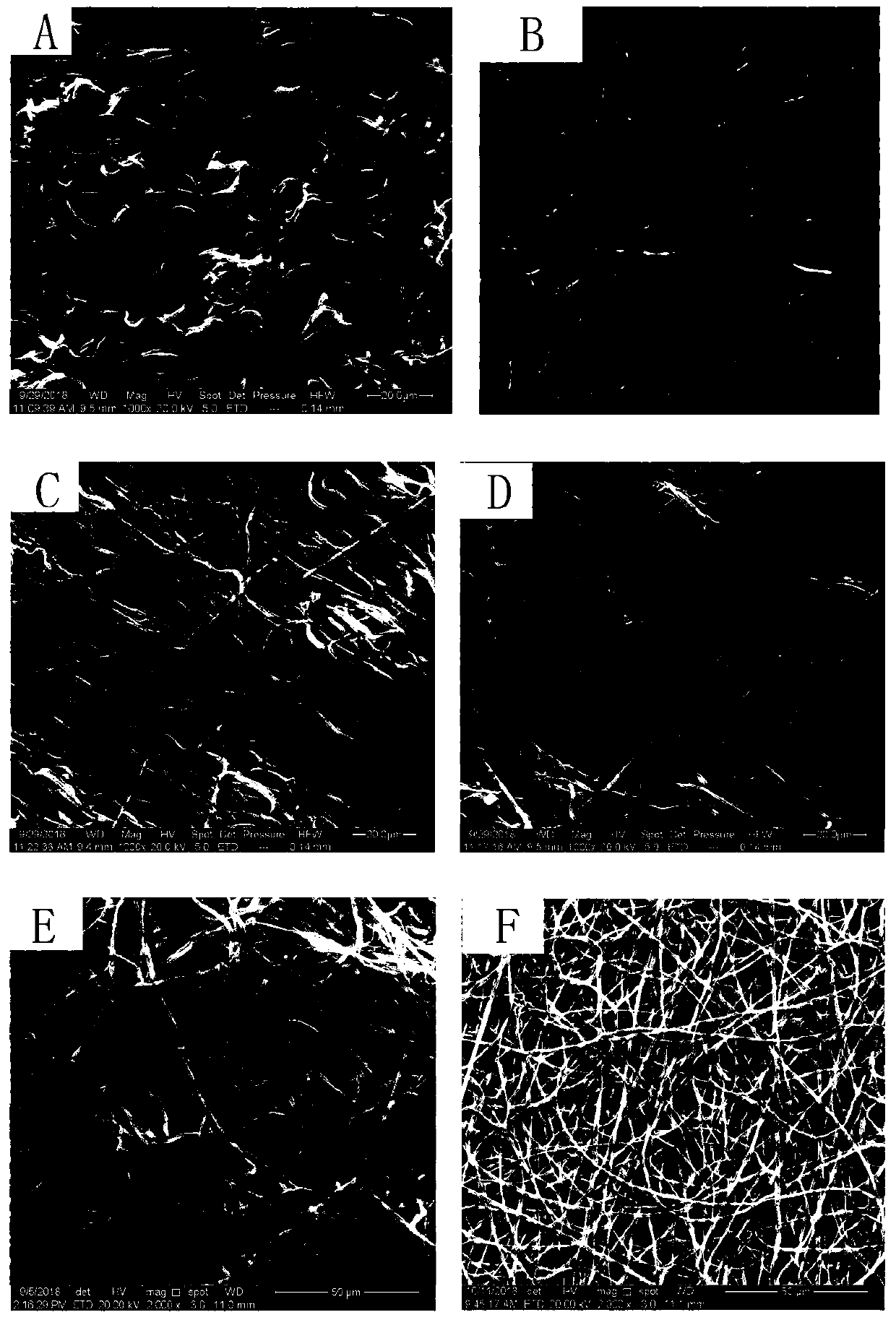

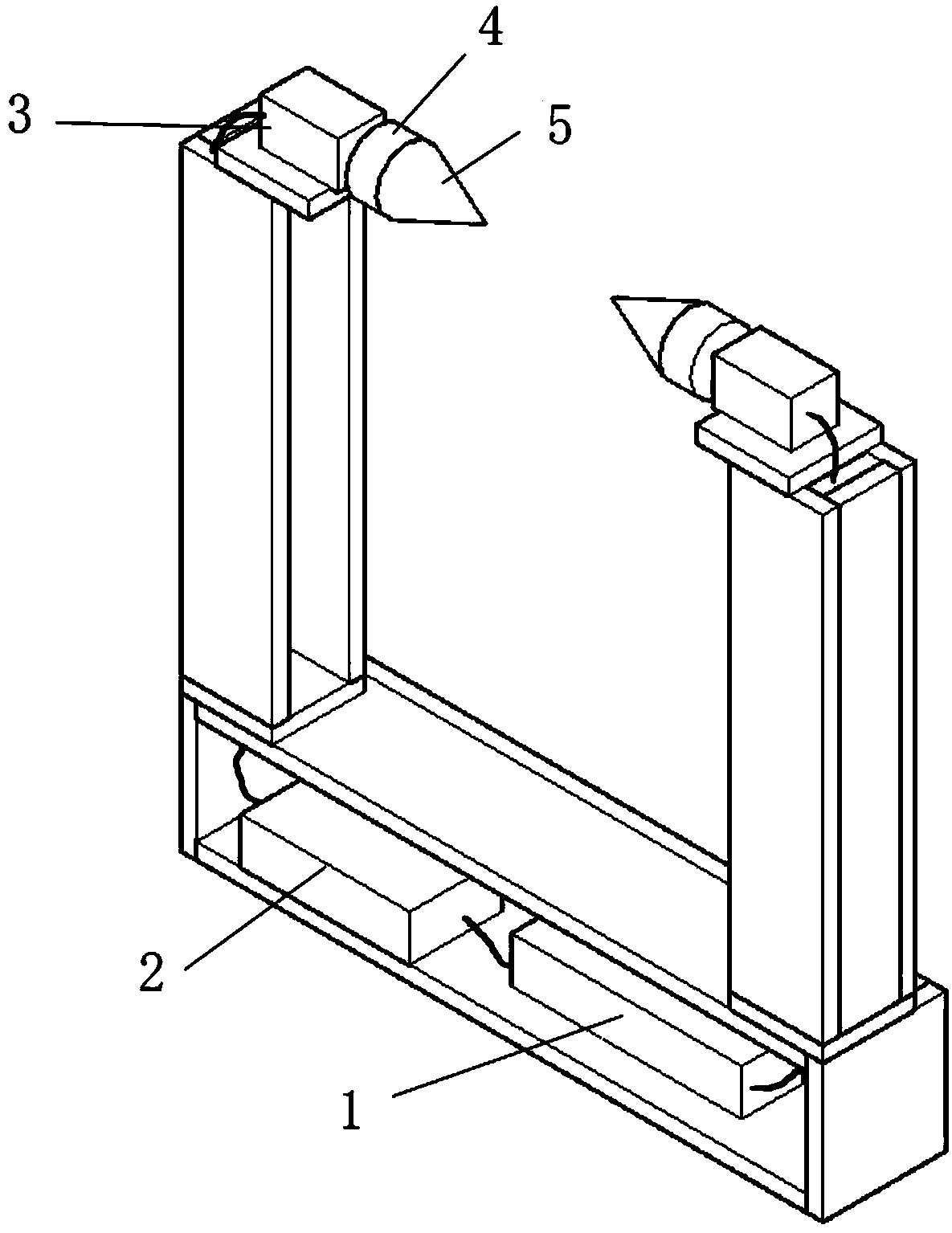

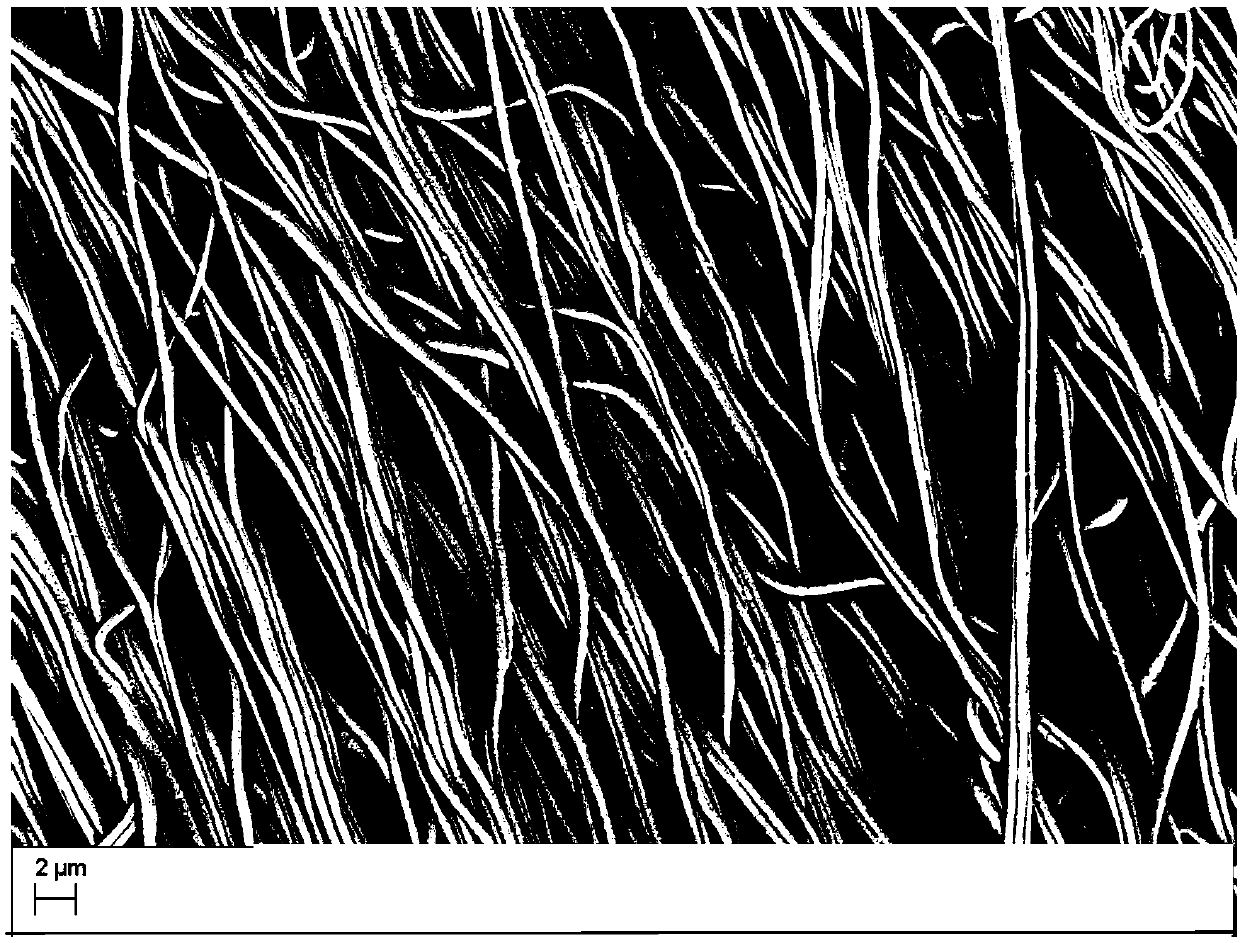

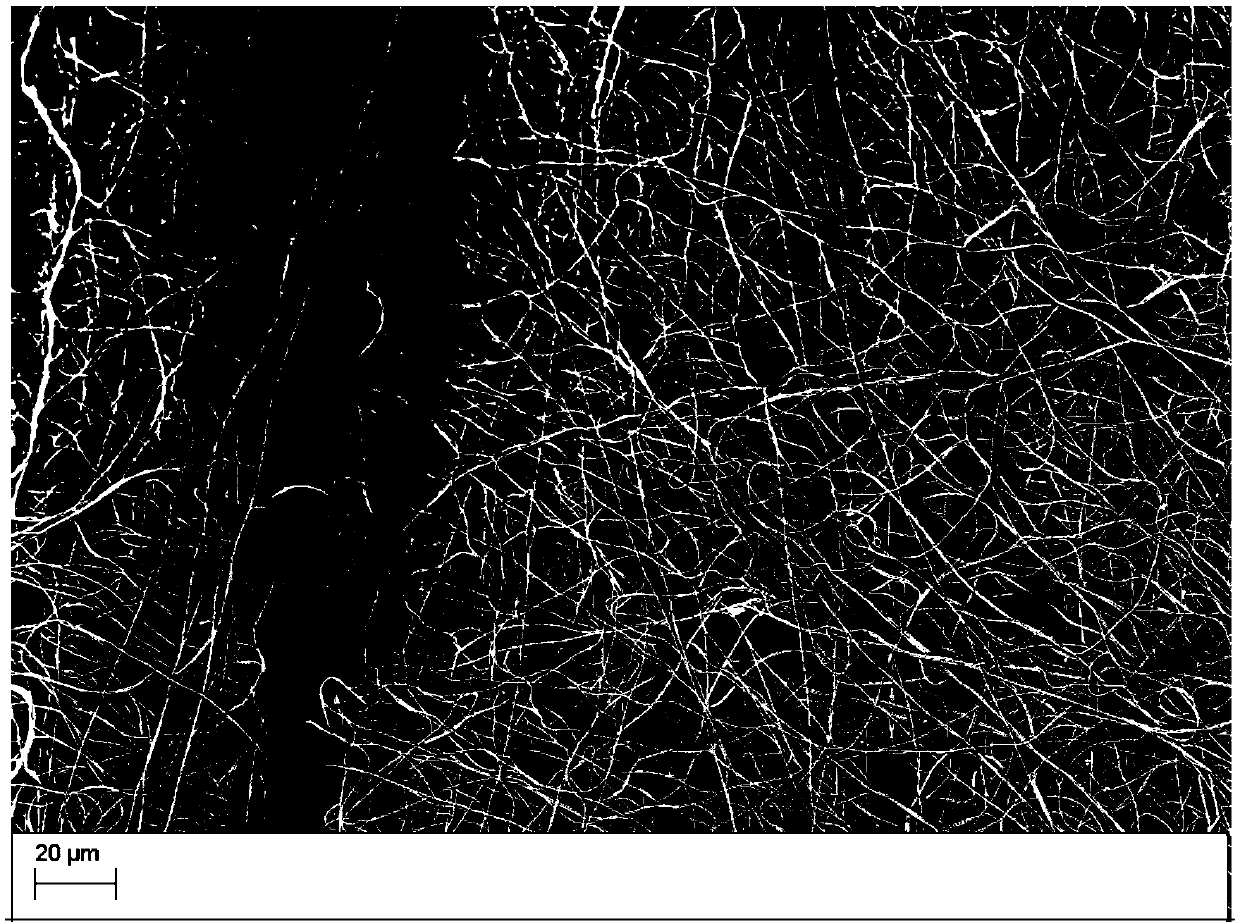

Electrostatic spinning collecting device and preparation method of nanofiber adopting gradient-oriented structure

ActiveCN106480518AHigh mechanical strengthGood mechanical propertiesMonocomponent protein artificial filamentInorganic material artificial filamentsElectrospinningTissue engineering

The invention discloses an electrostatic spinning collecting device and a preparation method of nanofiber adopting a gradient-oriented structure. The electrostatic spinning collecting device consists of a power supply, a forward and reverse rotation controller, motors, magnets and receiving heads. The preparation method comprises the following steps: dissolving a solute such as polycaprolactone into a mixed solution of dichloromethane and N-N dimethylformamide, uniformly stirring, and adjusting the spinning positive voltage to be 10-20 kV, the negative pressure to be -5 kV to 0 kV, the distance between a needle head and the electrostatic spinning collecting device to be 10-20 cm, and the distance between the two conical receiving heads to be 0.5-7 cm. In the spinning process, parallel fibers are deposited between the receiving heads, while the fibers deposited at the receiving heads are randomly oriented, and a transitional area exists in the middle. Through the electrostatic spinning collecting device and the preparation method, a nanofiber stent adopting the gradient-oriented structure can be obtained; the nanofiber stent adopting the gradient-oriented structure has relatively high mechanical strength, simulates an arrangement mode of collagen fibers in a muscle tendon and a ligament tissue, and can be applied to tissue engineering and tissue repair of the muscle tendon and the ligament.

Owner:SOUTH CHINA UNIV OF TECH

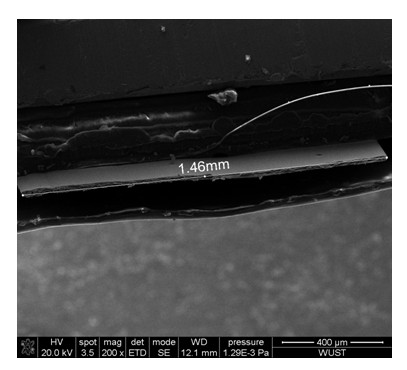

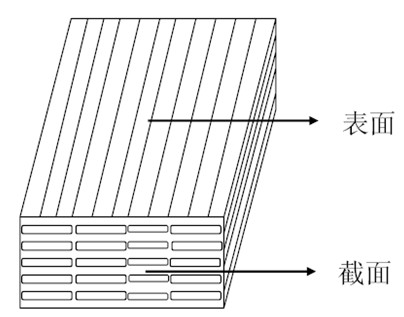

Highly-oriented highly-heat-conducting carbon/carbon composite material and preparation method thereof

The invention relates to a highly-oriented highly-heat-conducting carbon / carbon composite material and a preparation method thereof. The technical scheme is as follows: the method comprises the following steps of: oxidizing and stabilizing large-section strip-shaped intermediate phase pitch fiber which serves as a raw material; uniformly coating an adhesive on the surface of the oxidized and stabilized strip-shaped intermediate phase pitch fiber, wherein the adhesive accounts for 4 to 20wt% of raw materials; tiling the strip-shaped intermediate phase pitch fiber coated with the adhesive is coated in a mold in a unidirectional mode and performing hot-forming; and finally, carbonizing at the temperature of between 1,000 and 1,600 DEG C and graphitizing at the temperature of between 2,800 and 3,100 DEG C, so as to obtain the highly-oriented highly-heat-conducting carbon / carbon composite material. In the scheme, the cross section of the large-section strip-shaped intermediate phase pitch fiber has a shape of an approximate rectangle which has the width of 1 to 2 millimeters and the thickness of 8 to 20 microns; the hot-forming temperature is 300 to 700 DEG C; the hot-forming pressure is 5 to 20MPa, and the temperature and the pressure are kept for 1 to 24 hours. The method has the advantages of being simple in preparation process, low in cost, high in repeatability and short in production cycle, and the composite material prepared by using the method has the highly-oriented and highly-heat-conducting characteristics.

Owner:WUHAN UNIV OF SCI & TECH

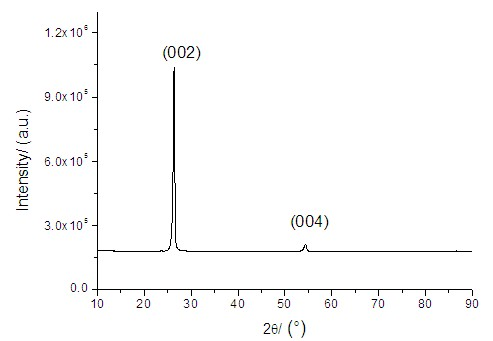

Mesophase pitch raw material used for preparing high-modulus high-thermal-conductivity carbon fiber, and preparation method thereof

The invention relates to a mesophase pitch raw mateiral for preparing high-modulus high-thermal-conductivity carbon fiber, and a preparation method thereof. With a polarizing microscope measuring method, a mesophase content of the mesophase pitch raw material is 100%. With a capillary rheometer measuring method, a softening point of the mesophase pitch raw material is 220-260 DEG C. With an X-ray diffraction measuring method, an aromatic hydrocarbon macromolecule average sheet piling thickness Lc of the mesophase pitch raw material is larger than 8nm. According to the invention, a naphthalene series compound such as methylnaphthalene is adopted as a raw material; hydrogen fluoride-boron trifluoride is adopted as a catalyst; and through controlling a catalyst dose, polymerization conditions and low-boiling-point product separation conditions, the mesophase pitch is prepared. Compared with prior arts, the mesophase pitch provided by the invention has excellent spinnability, such that spinning process controlling and operation are facilitated. The mesophase pitch has good molecular orientation, such that high-modulus high-thermal-conductivity carbon fiber with high orientation degree can be prepared under a relatively low graphitization temperature. Therefore, the production cost of high-performance carbon fiber is greatly reduced.

Owner:SHANGHAI JIAO TONG UNIV

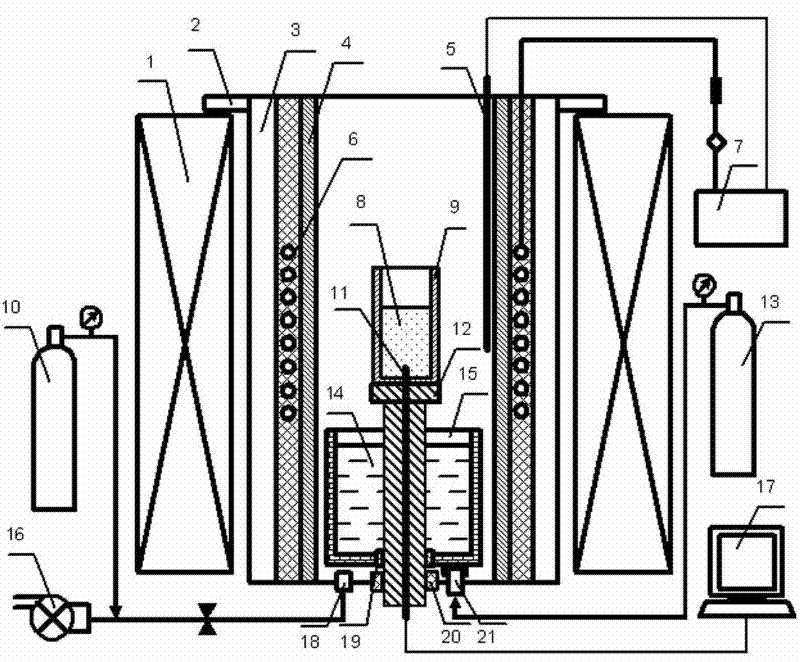

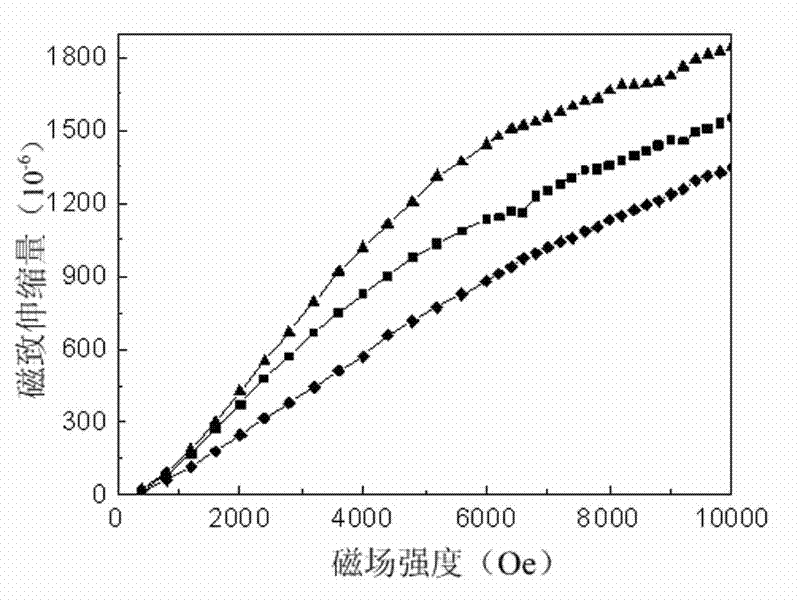

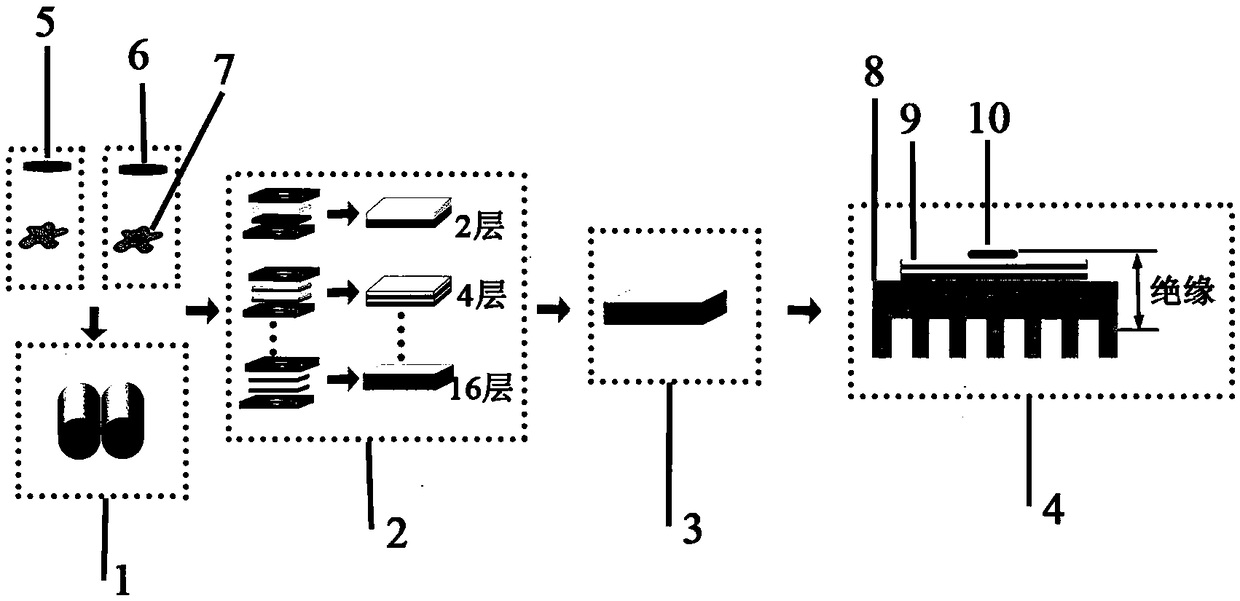

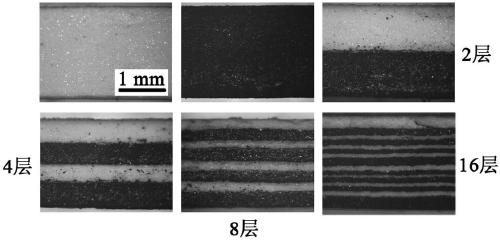

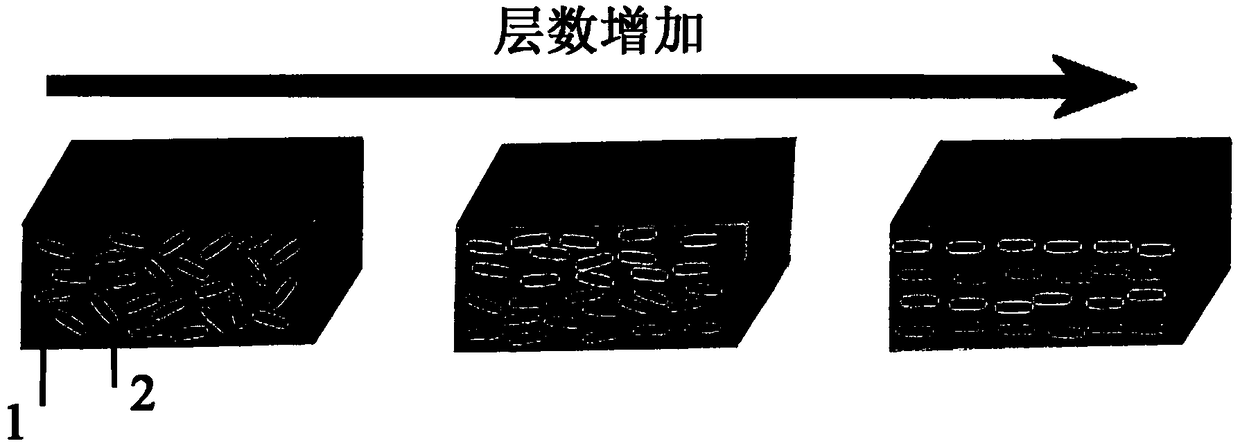

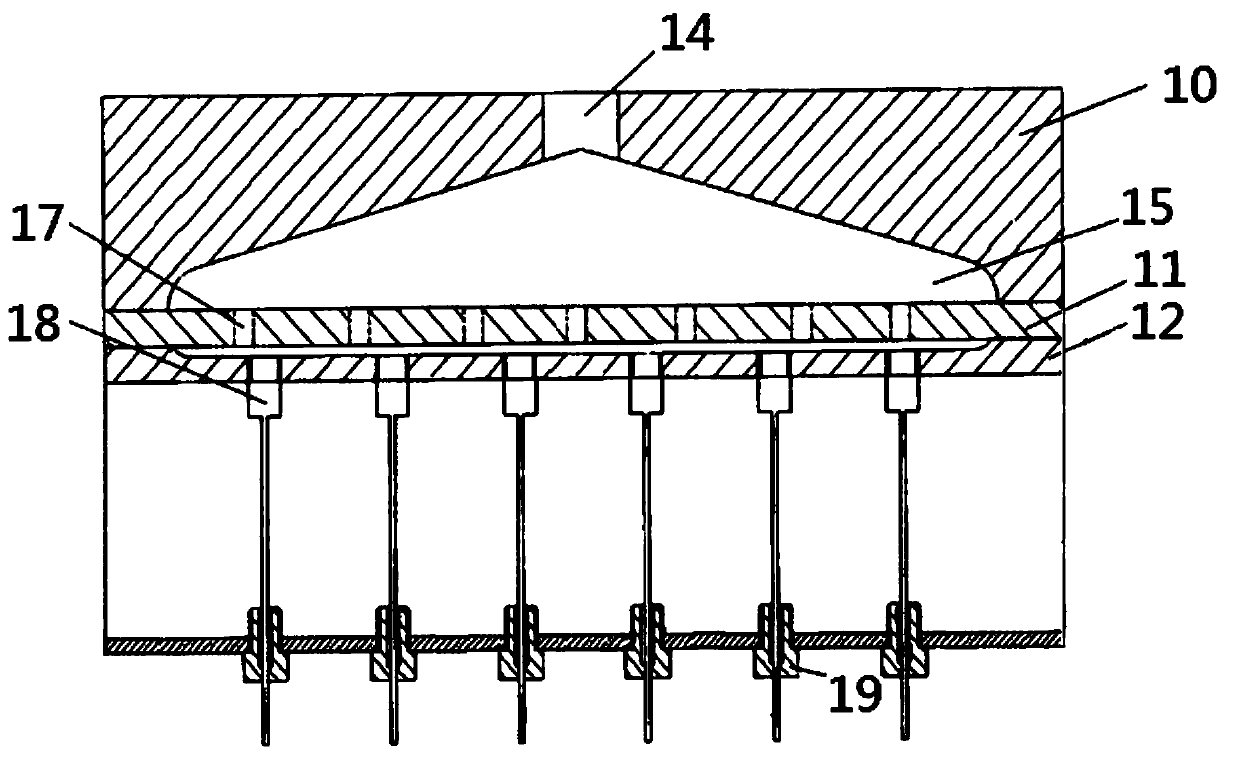

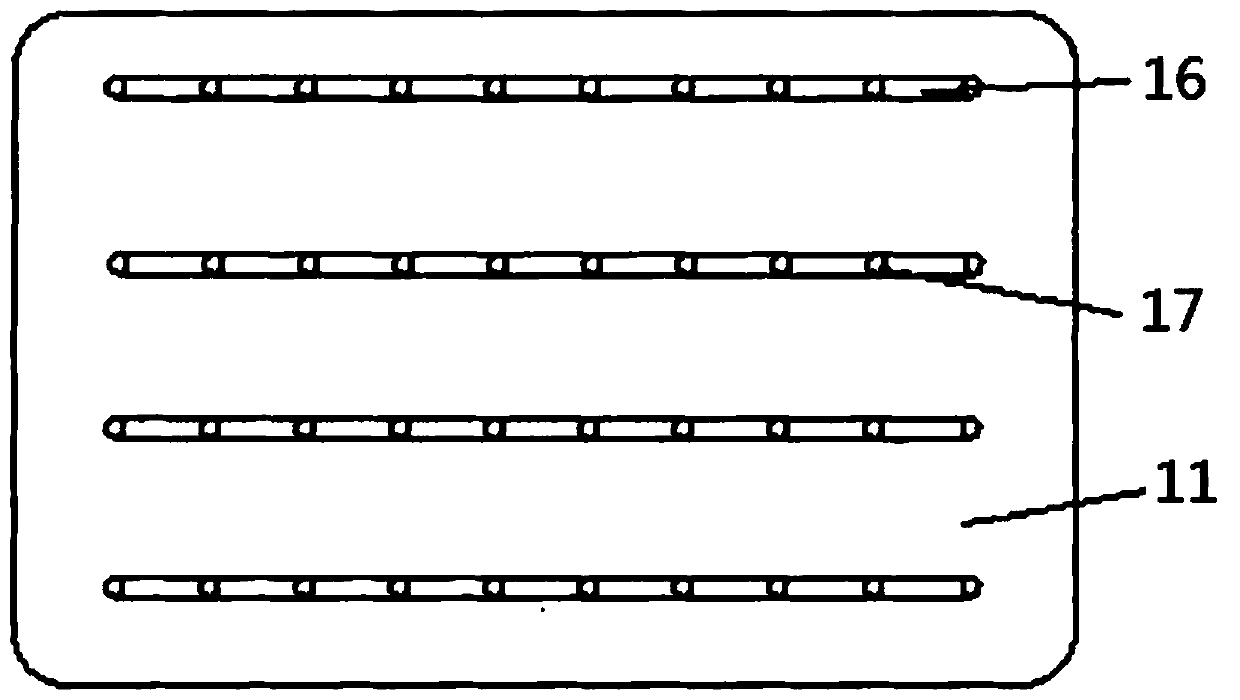

Method and device for preparing magnetostrictive material

The invention discloses a method and device for preparing magnetostrictive material, which belong to the technical field of materials. The method comprises the following steps: (1) smelting to prepare Tb-Dy-Fe master alloy or Tb-Fe master alloy; (2) putting the master alloy in a crucible in a heating furnace, applying a balanced magnetic field, and heating the master alloy to obtain semi-solid material in the presence of a magnetic field and inert gas for isothermal treatment; and (3) in the presence of inert gas, cooling to 900+ / -5DEG C; then cooling to normal temperature to obtain the Tb-Dy-Fe or Tb-Fe magnetostrictive material. The device comprises a strong magnet, a heating furnace, a crucible, a bracket and a cooling medium container, wherein the lower end of the bracket is fixed on the bottom plate of the heating furnace; the bottom plate of the cooling medium container is in slip connection with the outer wall of the bracket; the cooling medium container is positioned between the crucible and the bottom plate of the heating furnace; and the bottom surface of the cooling medium container is connected with a gas-driven lifting device. With the method disclosed by the invention, the orientation degree of TbFe2 or (Tb, Dy)Fe2 in the alloy in (111) direction can be obviously improved. The device is simple to operate.

Owner:NORTHEASTERN UNIV

Multilayer insulation thermal interface material and preparation method thereof

InactiveCN108943921AImprove insulation performanceImprove thermal conductivityLaminationLamination apparatusBreakdown strengthPolymer science

The invention belongs to the technical field of high molecular materials and particularly relates to a multilayer insulation thermal interface material and a preparation method thereof. The multilayerinsulation thermal interface material is an interface material which is formed through alternate distribution of insulation heat conduction layers and conductive heat conduction layers and is of a multilayer structure, wherein the insulation heat conduction layers are prepared by filling a ceramic-base heat conduction filler with silicone rubber, and the conductive heat conduction layers are prepared by filling a carbon-base heat conduction filler with silicone rubber; and the multilayer structure comprises 2n layers, and n is more than or equal to 1. The insulation thermal interface materialhas the multilayer structure, relatively high heat conductivity coefficient (reaching 6W / mK-11W / mK) and excellent electrical insulating property (volume resistivity reaches 10<11>ohmcm-10<13>ohmcm),disruptive strength (5KV / mm-9KV / mm) and mechanical property.

Owner:SICHUAN UNIV

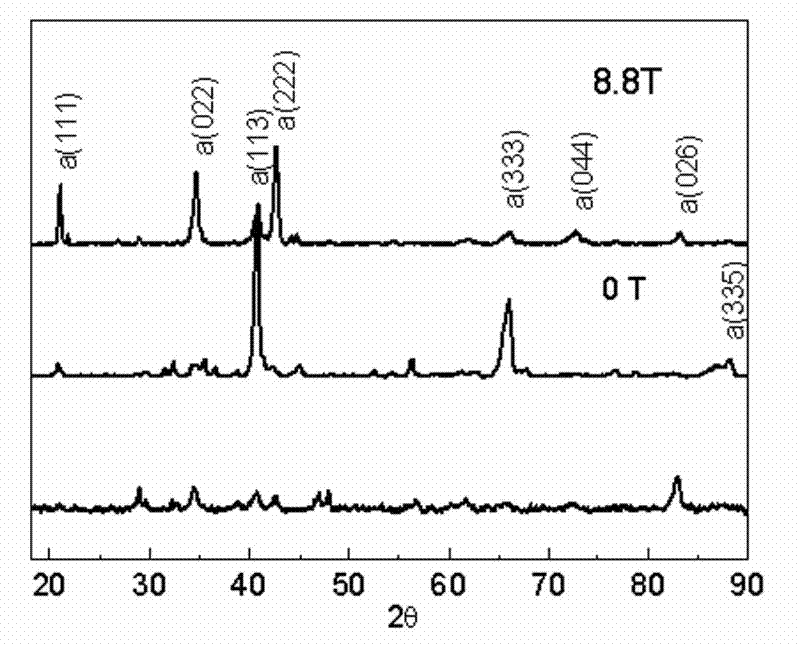

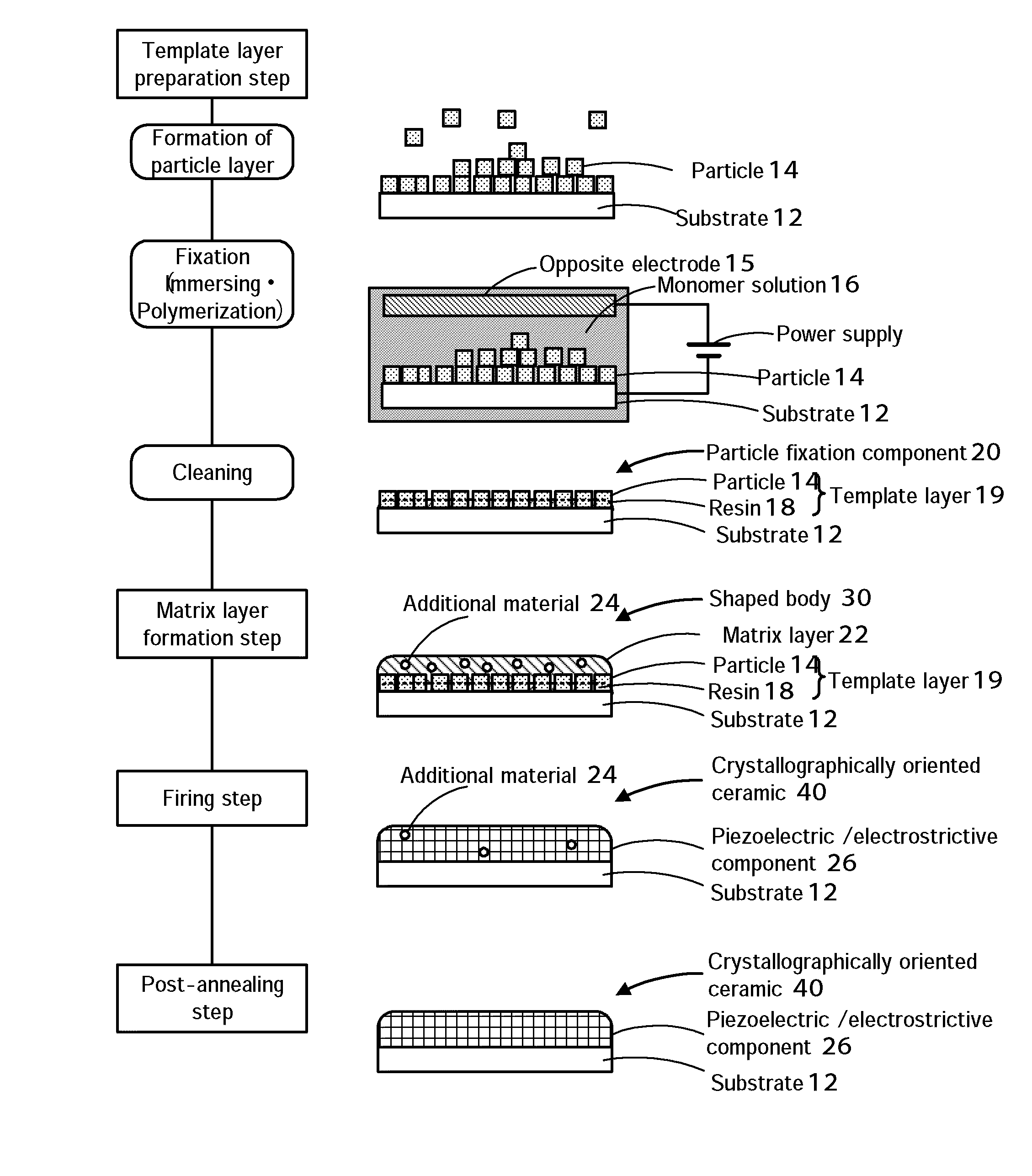

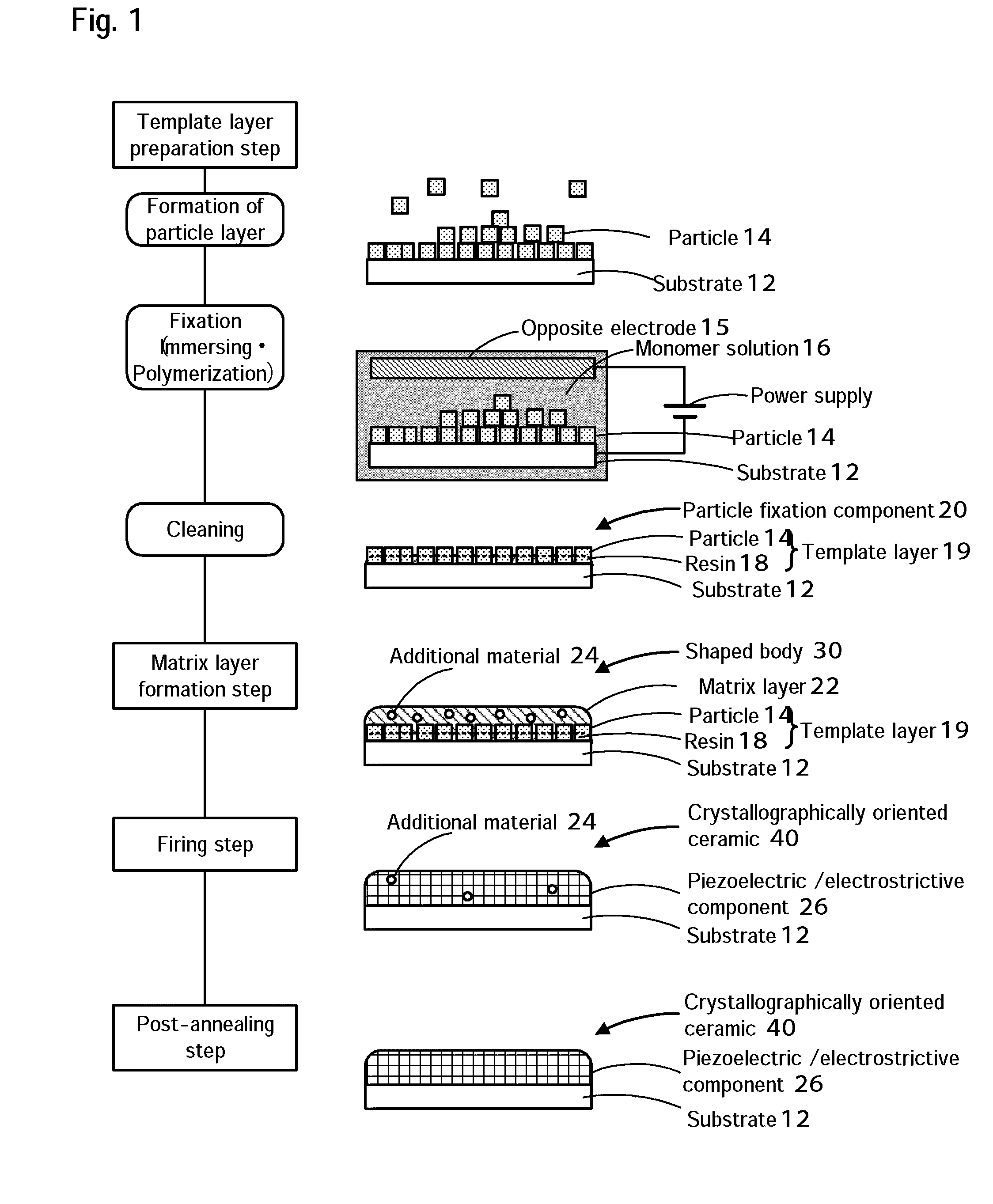

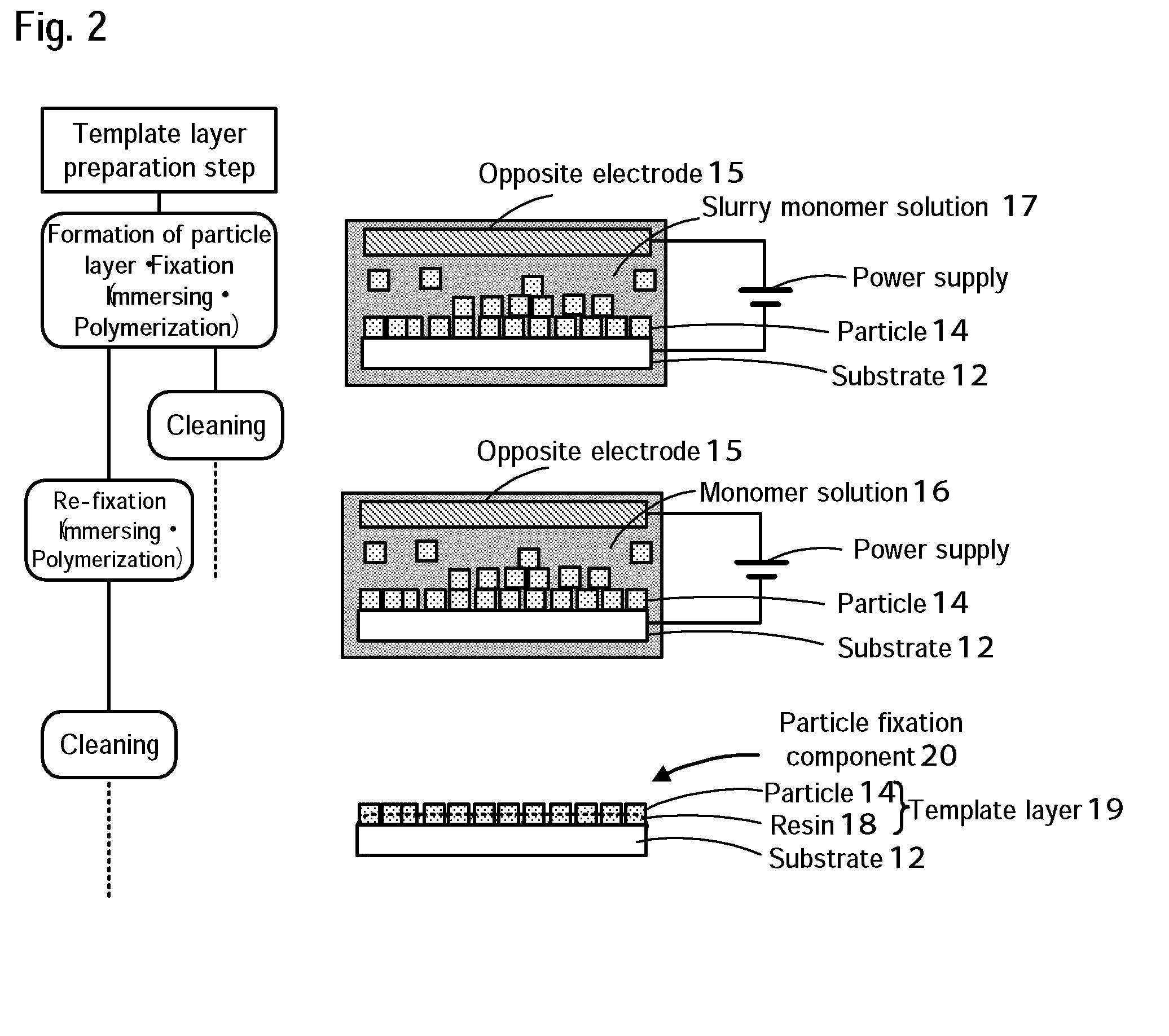

Method for producing crystallographically oriented ceramic

InactiveUS20110012049A1Raise the degree of orientationPrecise positioningPolycrystalline material growthCoatingsLithiumCrystal orientation

A method for producing a crystallographically oriented ceramic according to the present invention includes a preparation step of preparing a template layer having uniform crystal orientation in a predetermined direction, a formation step of forming a shaped body including a matrix layer arranged on the template layer, the matrix layer being composed of a mixed material that contains a lead-containing material and an additional material containing lithium and boron, and a firing step of firing the shaped body formed in the formation step at a predetermined firing temperature. Furthermore, after the firing step, a post-annealing step of heating the shaped body to remove lithium and boron may be included.

Owner:NGK INSULATORS LTD

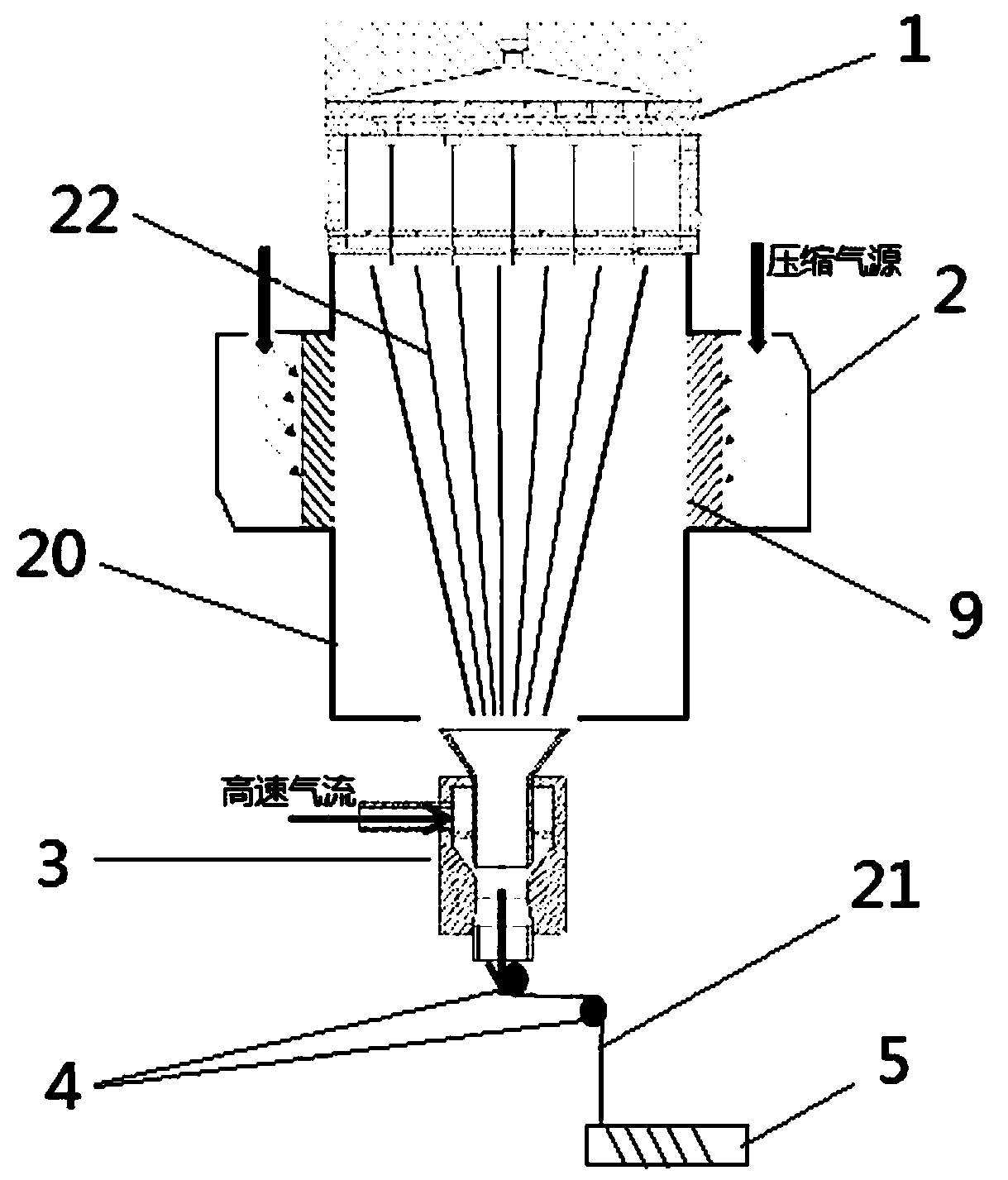

Continuous preparation device and continuous preparation method for nanofiber yarns

InactiveCN110629299ARaise the degree of orientationRealize continuous productionDry spinning methodsStretch-spinning methodsYarnFiber

The invention discloses a continuous preparation device for nanofiber yarns. The continuous preparation device comprises a solution jet spinning die head, an auxiliary air jet device, a Venturi tube receiving system, a yarn guide roller and a spool. Spinning solution is subjected to drafting, thinning and solvent evaporation under the action of the spinning die head to obtain nanofibers, the auxiliary air jet device is additionally arranged to jet obliquely downward auxiliary airflow, the oriented nanofibers can be straightened, twisted and gathered under the action of side face to form nanofiber yarn tows, and the Venturi tube receiving system is matched with the yarn guide roller and the spool to timely collect generated yarns, so that the nanofiber yarns can be continuously produced. Besides, the invention further discloses a continuous preparation method for the nanofiber yarns. Operation is safe, simple and convenient, the problem of yarn length limitation is avoided, the generated yarns are good in orientation degree and mechanical property and can meet the high requirement of current nanofiber yarn preparation, and rapid development of nanofiber yarn application can be promoted.

Owner:TIANJIN POLYTECHNIC UNIV

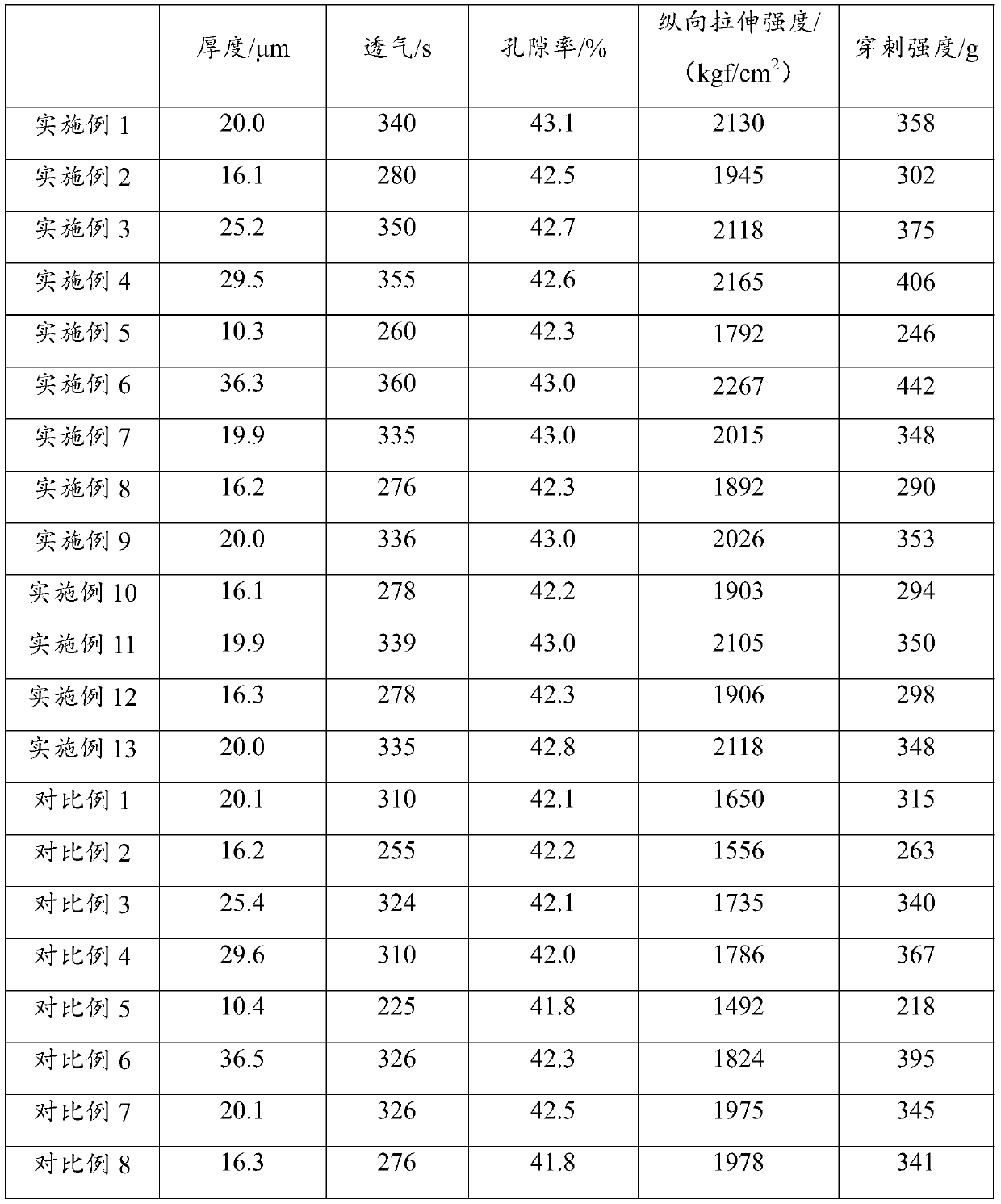

Dry unilateral-stretching production technology of lithium battery separator

InactiveCN111391267AHigh crystallinityHigh tensile strengthCell component detailsPhysical chemistryPolypropylene

The invention relates to the technical field of lithium battery separators and provides a dry unilateral-stretching production technology of a lithium battery separator. The dry unilateral-stretchingproduction technology of the lithium battery separator solves the problem that the hole size distribution of a lithium battery separator produced in the prior art is uneven. The dry method unilateralstretching production technology of the lithium battery separator comprises the following steps of (1) preparing materials, wherein polypropylene and ethylene-propylene copolymer are used as raw materials, pre-dried respectively and then put into a high-speed mixer to be stirred to uniform; (2) conducting melt extrusion, wherein the evenly mixed raw materials are fed into an extrusion machine andplastified into uniform melt, and the uniform melt is extruded from a slit die; (3) conducting tape casting film formation, wherein the melt undergoes tape casting and then forms a polypropylene basefilm, and the polypropylene base film undergoes traction and coiling; (4) conducting annealing treatment, wherein the coiled polypropylene base film is placed in a drying box to undergo annealing treatment; (5) conducting unilateral stretching, wherein the annealed polypropylene base film undergoes cold stretching and hot stretching; and (6) conducting heat setting, wherein heat setting is conducted on the polypropylene base film completing unilateral stretching, and after cooling and coiling, the lithium battery separator is obtained.

Owner:石狮申泰新材料科技有限公司

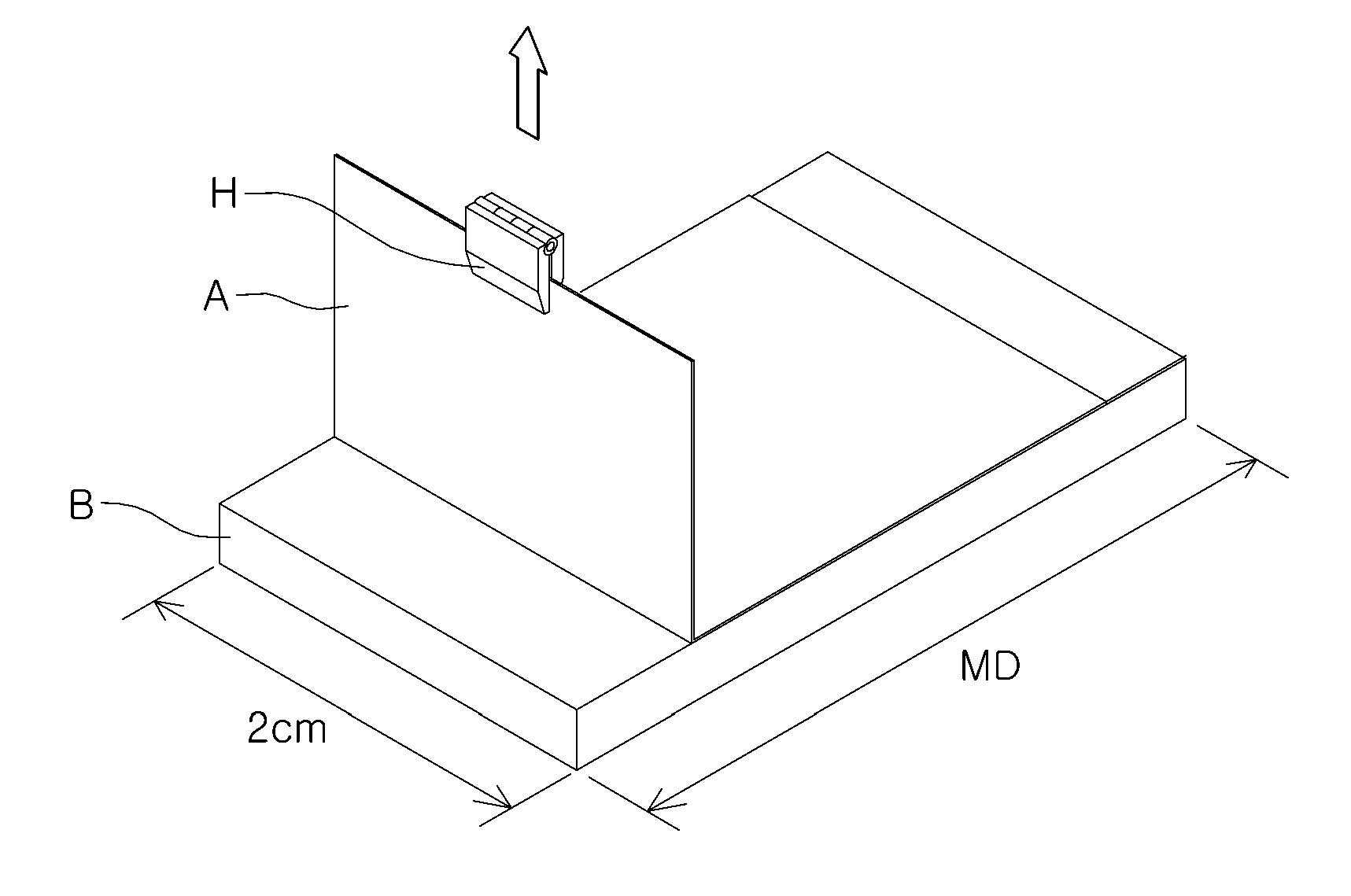

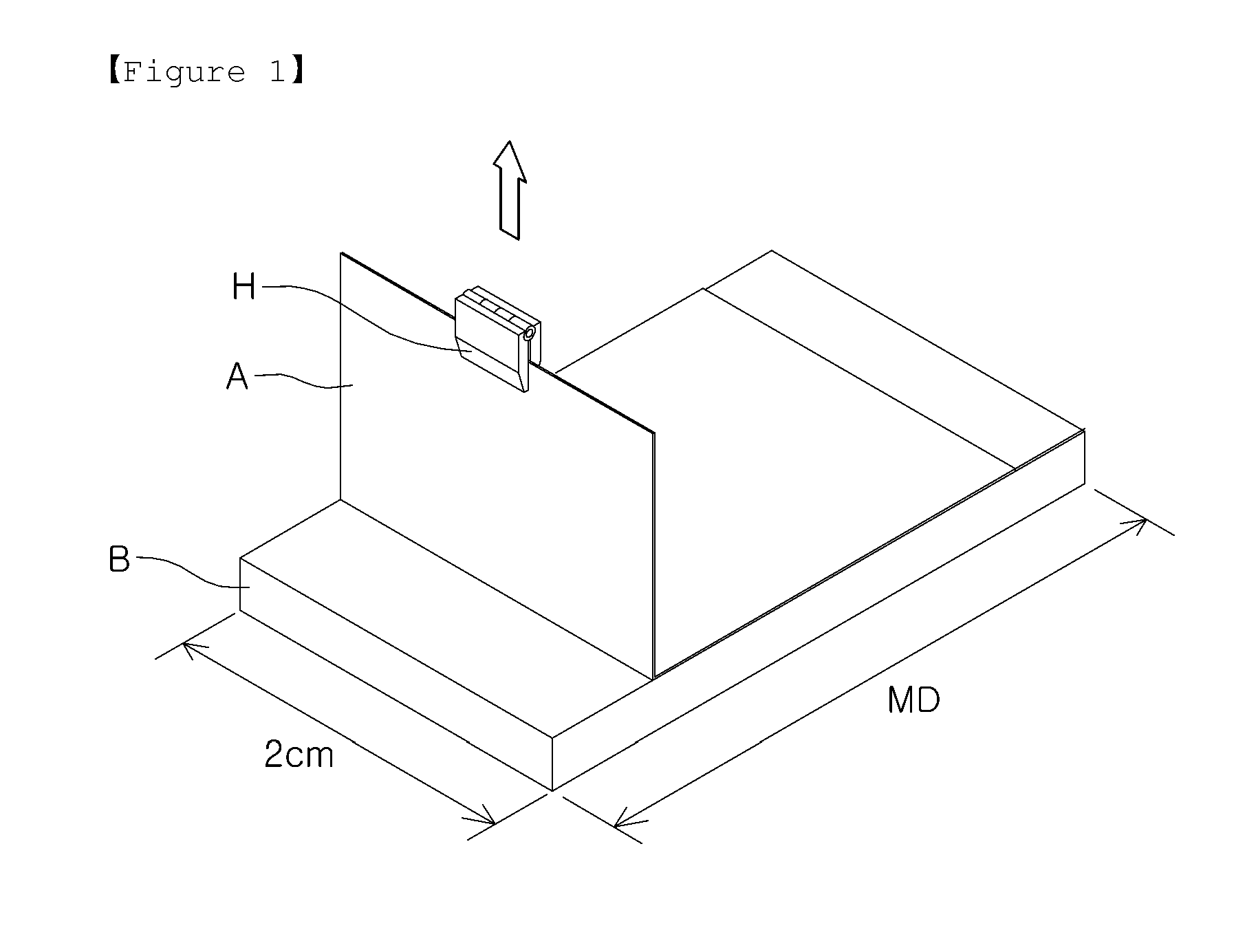

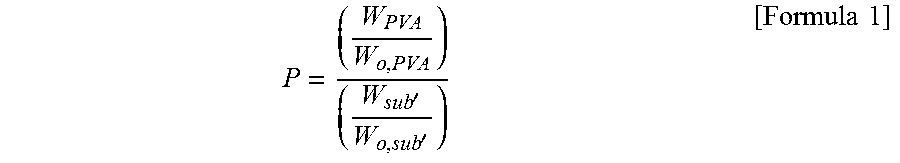

Stretched laminate, method of manufacturing thin polarizer, thin polarizer manufactured by the method, and polarizing plate including the thin polarizer

ActiveUS20150224746A1Excellent optical propertiesRaise the degree of orientationLamination ancillary operationsSynthetic resin layered productsPolarizerOptoelectronics

Provided is a stretched laminate for manufacturing a thin polarizer while increasing the degree of orientation of a polyvinyl alcohol-iodine complex without problems such as breakage. In addition, there are provided a method of manufacturing a thin polarizer having superior optical characteristics by using the stretched laminate, a thin polarizer manufactured by the method, and a polarizing plate including the thin polarizer.

Owner:SHANJIN OPTOELECTRONICS SUZHOU CO LTD

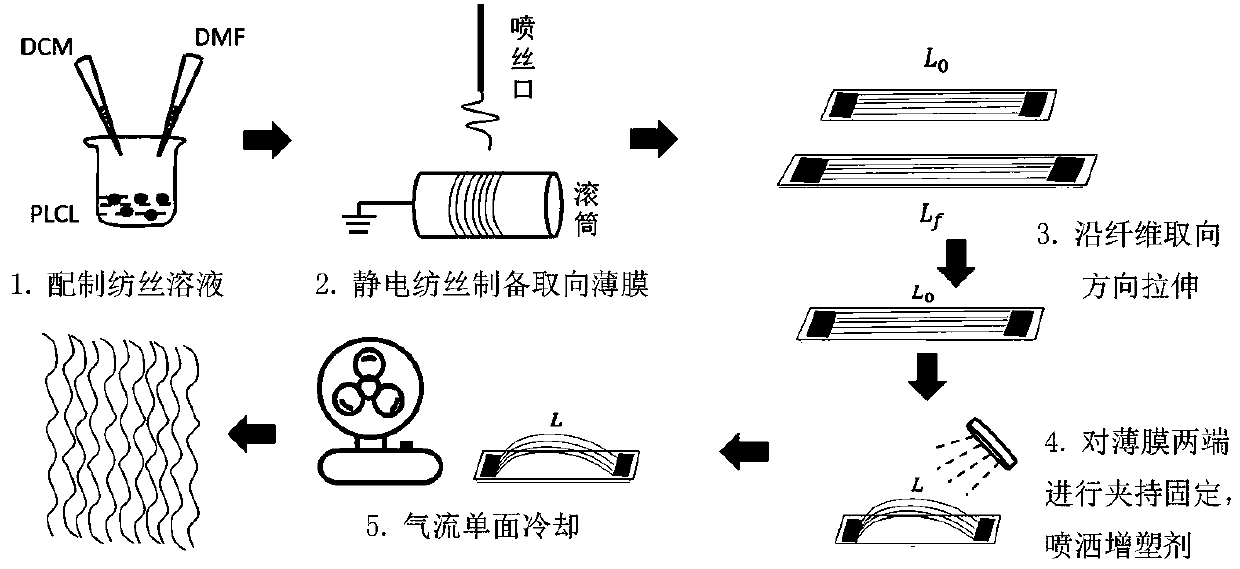

Method for imparting crimp structure to polymer micro-nano fiber

ActiveCN109811469AIncrease internal stressRaise the degree of orientationFibre typesFilament/thread formingMicro nanoPlasticizer

The invention discloses a method for imparting a crimp structure to a polymer micro-nano fiber. The method comprises the following steps that (1) a polymer is prepared into an oriented micro-nano fiber film or an oriented micro-nano fiber tube; (2) the micro-nano fiber film or the micro-nano fiber tube is stretched at least once in the fiber orientation direction to elastically deform the micro-nano fiber film or the micro-nano fiber tube, and then a tensile load is removed; (3) the surface of the micro-nano fiber film or the micro-nano fiber tube processed in the step (2) is uniformly sprayedwith a plasticizer; and (4) the micro-nano fiber film or the micro-nano fiber tube treated by the step (3) is subjected to single-side cooling treatment by gas flow to obtain a micro-nano fiber filmwith a stable fiber crimp structure or a micro-nano fiber tube with the stable fiber crimp structure. The method has a simple process, good reproducibility and high universality, and facilitates large-scale industrial application; and the prepared fiber crimp structure has good stability and can still show good mechanical nonlinearity after multiple times of force action.

Owner:ZHENGZHOU UNIV

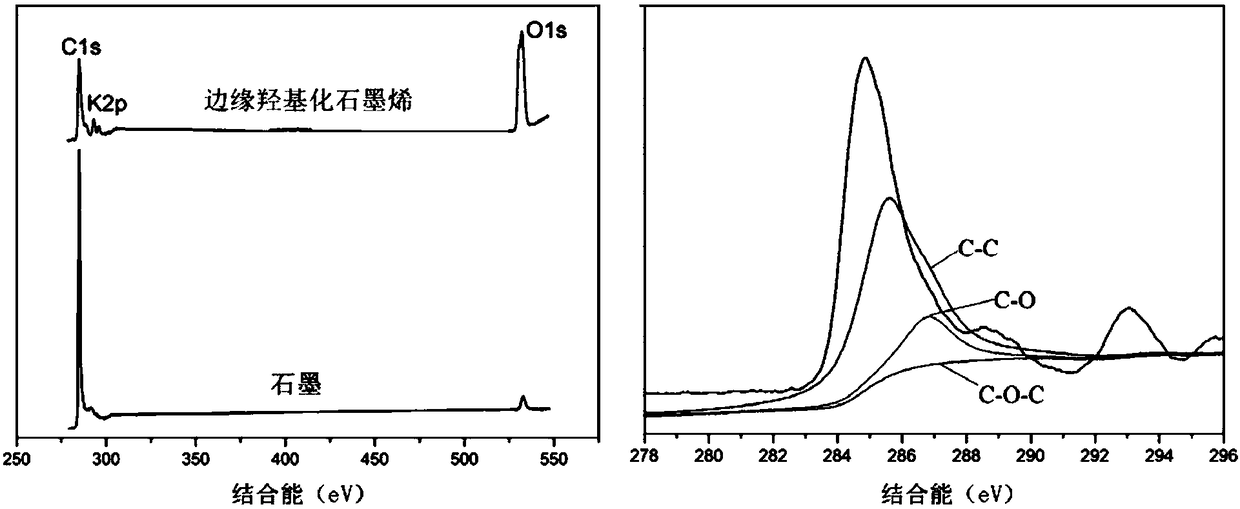

Graphitized film and preparation method and application thereof

InactiveCN108314033AHigh thermal conductivityProtect thermal conductivityCarbon compoundsComposite filmIn situ polymerization

The invention relates to the technical field of functional film materials, and in particular relates to a graphitized film and a preparation method and application thereof. The preparation method of the graphitized film comprises: (1) low temperature in-situ polymerization of a diamine monomer and a dianhydride monomer; (2) film casting of an obtained mixed solution; (3) in-sequence drawing treatment and heating imidization of an obtained graphene / polyamic acid composite film; (4) and in-sequence heating carbonization and heating graphitization of an obtained graphene / polyimide composite film.Edge-functionalized graphene is used as a filler, and the graphene / polyamic acid composite film is appropriately drawn to improve the orientation and regularity of the composite film, and so that theobtained graphitized film has high directivity, high conductivity and high thermal conductivity, and is expected to be better applied in microelectronic packaging, electromagnetic shielding, heat dissipating materials, electrode materials and other aspects.

Owner:BEIJING UNIV OF CHEM TECH

Directional heat conduction material and preparation method and application thereof

ActiveCN112111153AIncreased axial thermal conductivityImprove thermal conductivityHeat-exchange elementsModifications by conduction heat transferPolymer chemistryFiber

The invention provides a directional heat conduction material as well as a preparation method and application thereof. The directional heat conduction material comprises a polymer matrix and anisotropic heat conduction fibers filled in the polymer matrix, the anisotropic heat conduction fibers are directionally arranged in the polymer matrix, and the anisotropic heat conduction fibers are orientedalong the directional arrangement direction. The directional heat conduction material at least has the following beneficial effects: the directional heat conduction material utilizes the anisotropicheat conduction fillers to form directionally arranged heat conduction fibers, and the heat conduction fibers are also oriented along the arrangement direction of the heat conduction fibers on the microscale, so that the heat conduction material can utilize the anisotropy of the fillers to the greatest extent; the orientation degree of the fillers is greatly improved, the high heat conduction performance can be achieved with the low proportion of the anisotropic heat conduction fillers, and the heat dissipation requirement brought by high-speed development of electronic devices is further met.

Owner:佛山(华南)新材料研究院

Dry uniaxial stretching process of lithium-ion battery separator, lithium-ion battery separator and lithium-ion battery

The invention discloses a dry one-way drawing process of a lithium-ion battery separator, the lithium-ion battery separator and a lithium-ion battery and relates to the technical field of preparation of the lithium-ion battery separator. The dry one-way drawing process of the lithium-ion battery separator comprises the following steps that a polyolefin base film is subjected to pre-drawing before annealing treatment and subjected to secondary drawing after annealing treatment, wherein the drawing multiplying power of pre-drawing is 1.1-1.5 and the drawing temperature is 100-150 DEG C. The problems that as for traditional dry one-way drawing, the lithium-ion battery separator drawing strength and puncture strength are low, the drawing strength is 170-180 MPa at most, and the separator strength requirement cannot be met are solved. According to the separator dry one-way drawing process provided by the invention, as pre-drawing is performed before annealing, the drawing process is performed stage by stage; and by means of the process, the strengths of the lithium-ion battery separator subjected to dry one-way drawing can be improved, specifically, the drawing strength of the separator subjected to dry one-way drawing can be improved by 20-30%, and the puncture strength of the separator subjected to dry one-way drawing can be improved by 10-20%.

Owner:SHENZHEN SENIOR TECH MATERIAL

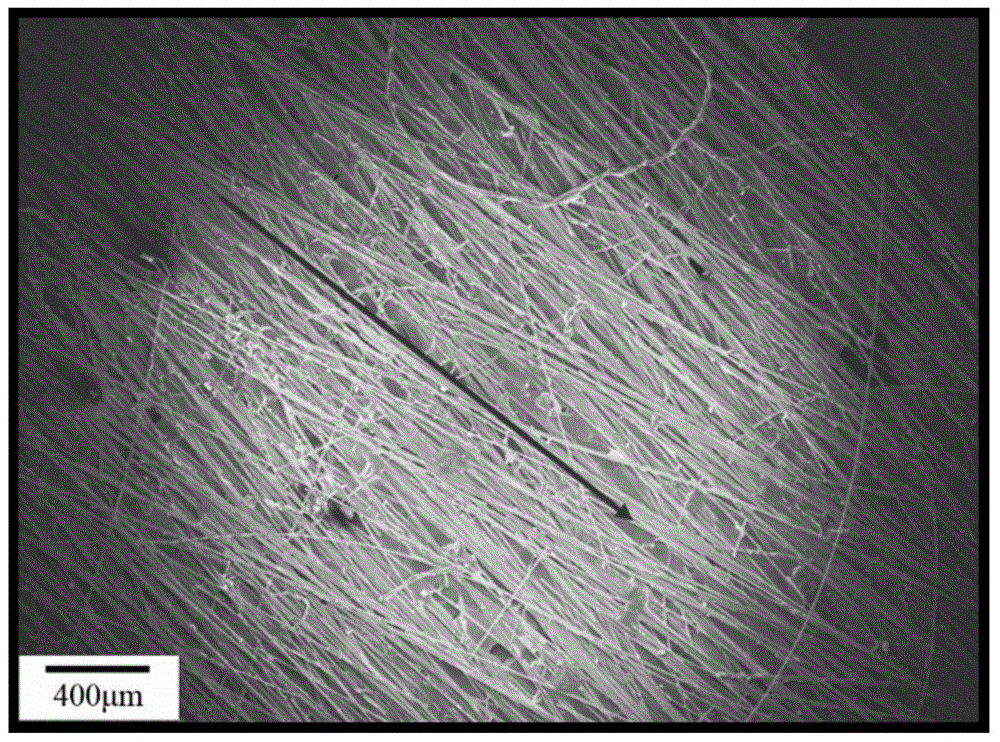

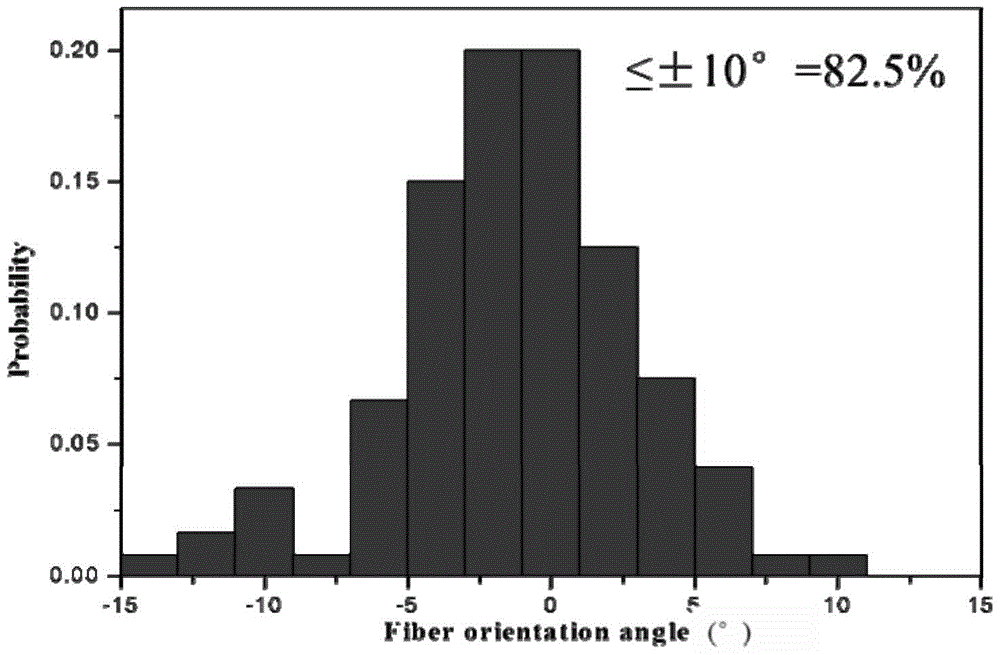

A kind of preparation method of chopped fiber oriented mat

ActiveCN105178090BRaise the degree of orientationSimple preparation processSynthetic cellulose/non-cellulose material pulp/paperFiberState of art

The invention belongs to the field of fiber fabric materials, and particularly relates to a preparation method of a chopped-fiber oriented felt. The method comprises the following steps: with water as a main dispersion medium and methylcellulose as an auxiliary dispersion medium, adding a chopped fiber to the dispersion mediums, and stirring and dispersing the mediums to prepare an evenly dispersed chopped-fiber suspension liquid, wherein the length of the chopped fiber is 3-12mm; and treating the obtained evenly dispersed chopped-fiber suspension liquid through a reducing orientation nozzle, orienting the chopped fiber by a reducing liquid, and preparing the chopped-fiber oriented felt through a separating procedure and a drying procedure. According to the method, the problem of environmental pollution caused by an organic solvent dispersion medium in the prior art is solved; and meanwhile, through specific preparation technology and device, the problems of relatively low orientation degree of the chopped fiber, complicated orientation device, low production efficiency and the like in the chopped-fiber oriented felt obtained by the prior art are further solved.

Owner:BEIJING UNIV OF CHEM TECH +1

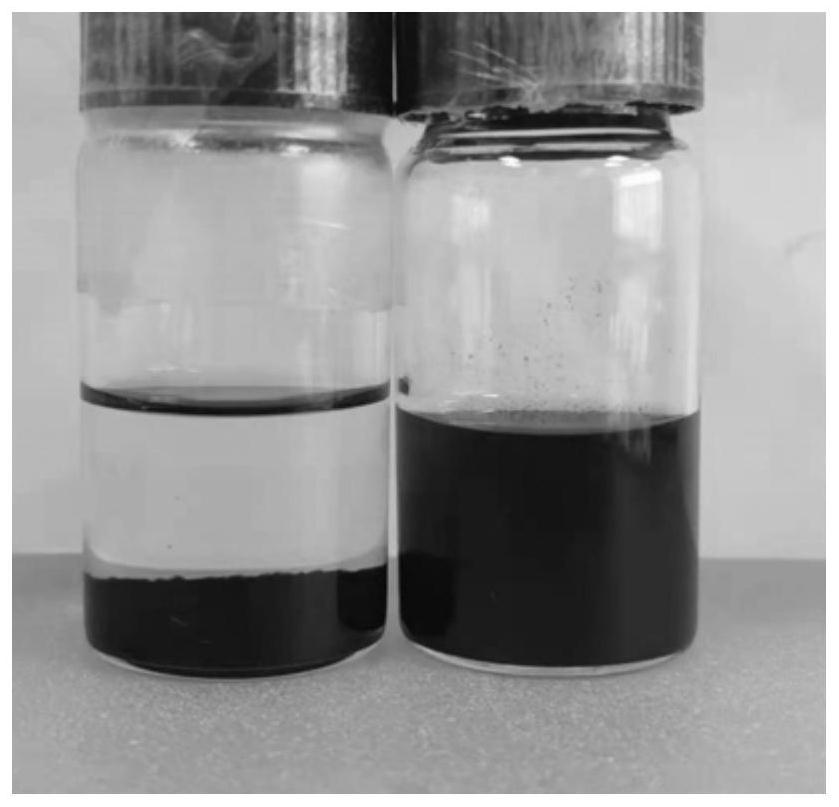

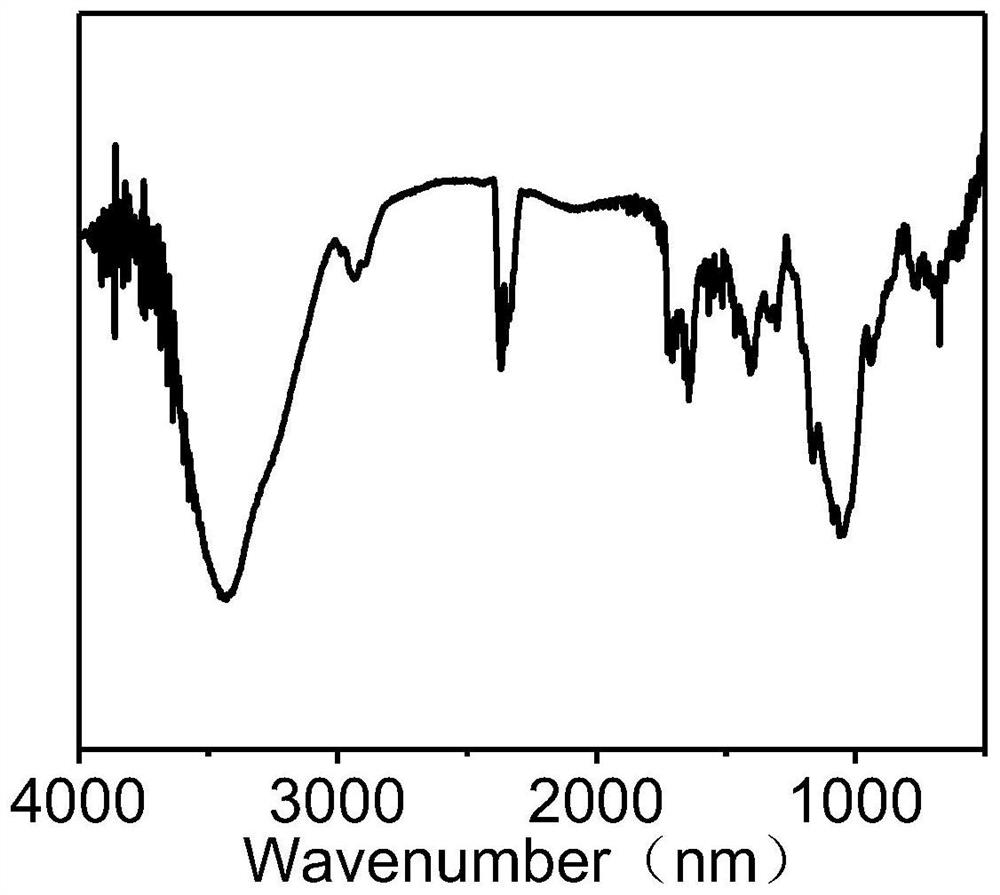

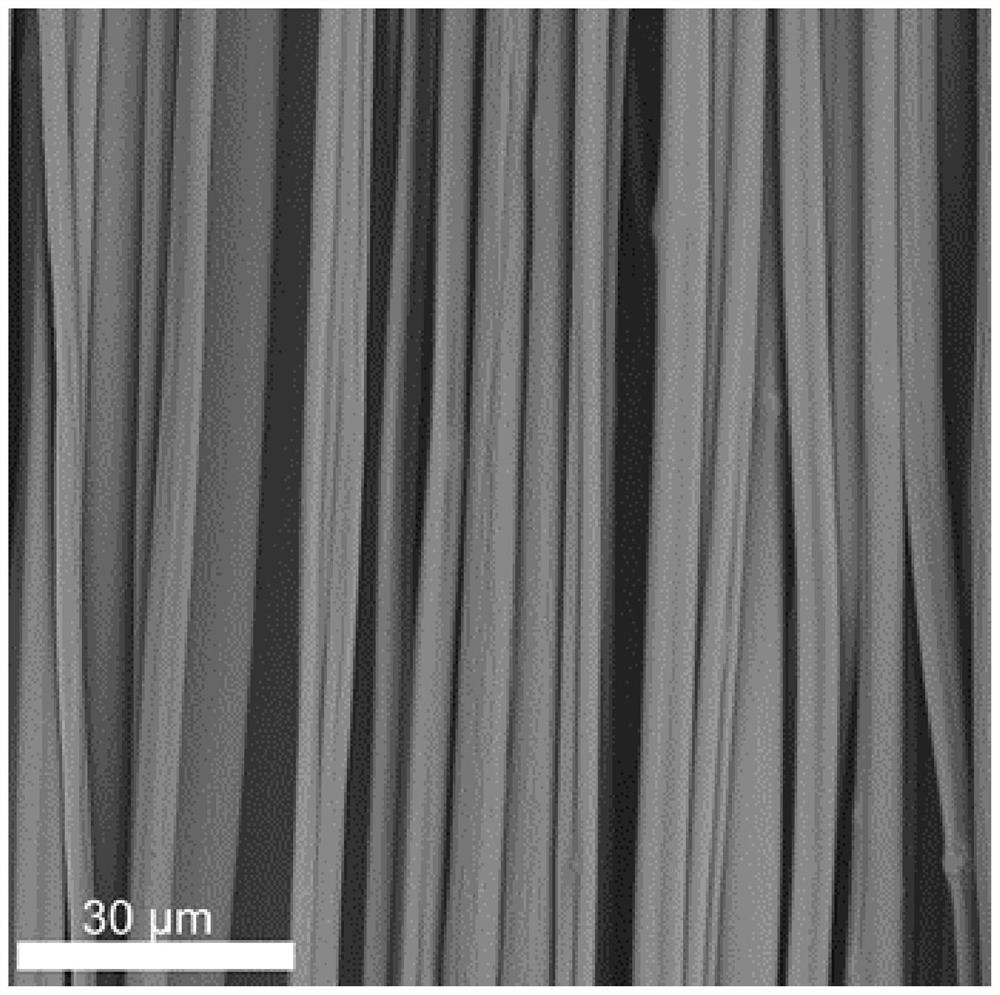

Preparation method and application of composite film

PendingCN113235227ARaise the degree of orientationRich varietyFilament/thread formingNon-woven fabricsFiberComposite film

The invention belongs to the technical field of composite material optics, and discloses a preparation method and application of a composite film. The composite film provided by the invention mainly comprises a polymer and a carbon nanotube. The method comprises the steps of carrying out surface modification on the carbon nanotube; uniformly mixing the polymer, the modified carbon nanotube and a solvent to obtain a mixed solution; obtaining an oriented polymer / carbon nanotube composite fiber film through an electrostatic spinning method; and annealing and setting the dried composite fiber film through the solvent to form a film, and then carrying out stretching and secondary orientation to obtain the product. The oriented carbon nanotube composite film provided by the invention has the advantages of various selectable raw material types, simple process and large-scale preparation, thereby having very good application prospects in the fields of liquid crystal display, imaging and the like.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing longitudinal high-thermal-conductivity gasket by orienting carbon fibers through controllable compression deformation method

The invention provides a method for preparing a longitudinal high-thermal-conductivity gasket by orienting carbon fibers through a controllable compression deformation method, which is characterized in that the carbon fibers are orientated and arranged through the controllable compression deformation method, and the carbon fiber silica gel gasket with the thermal conductivity of 30W / mK in the thickness direction is prepared through the subsequent processes of defoaming, vulcanizing, cutting, surface treatment and the like. The carbon fiber gasket with the length-width ratio of 20: 1 can be prepared, the production efficiency is improved, and meanwhile waste materials are reduced.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA +1

Heat-conducting composite material as well as preparation method and application thereof

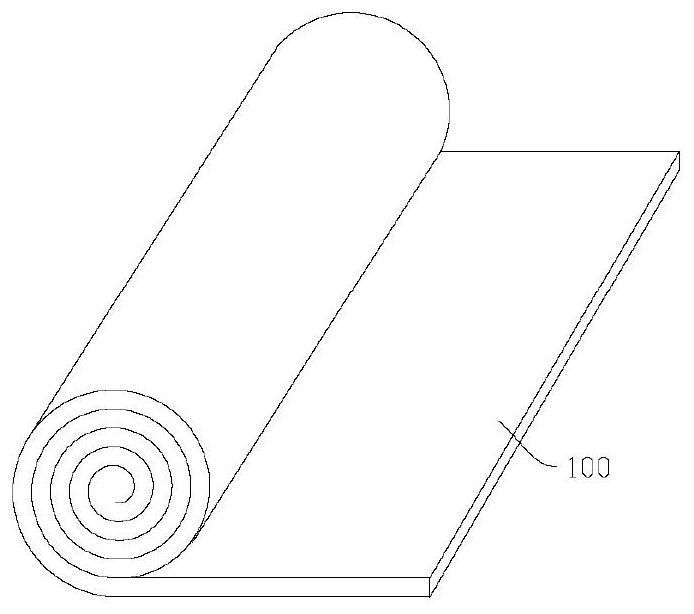

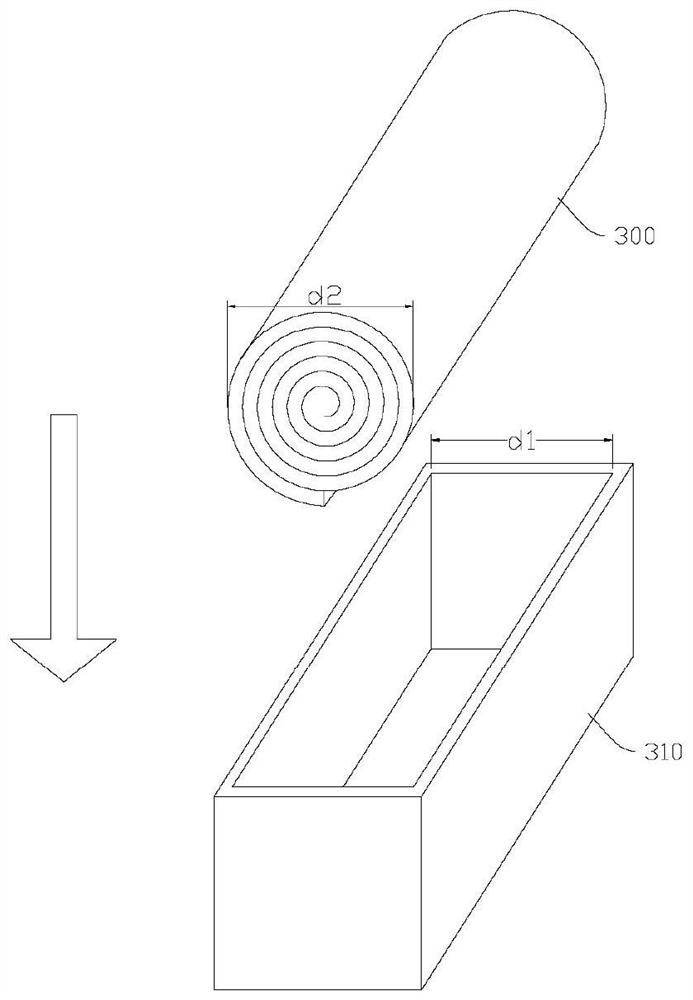

ActiveCN112297469ARaise the degree of orientationHigh thermal conductivityHeat-exchange elementsFlat articlesThin membraneSlurry

The invention provides a heat-conducting composite material as well as a preparation method and application thereof. The preparation method of the heat-conducting composite material comprises the following steps of S1, mixing a filler and a polymer matrix to obtain slurry; S2, forming a first composite film from the slurry by a thin film forming process; S3, winding the first composite film to form a first cylinder; S4, enabling the first cylinder to form a second composite film by the thin film forming process, and winding to subsequently form a second cylinder; and S5, pressurizing and curing the second cylinder, wherein the filler comprises a two-dimensional heat-conducting sheet. According to the preparation method, a high-heat-conducting composite material is prepared in the manner that a thin film is curled and then pressurized for forming; the two-dimensional heat-conducting sheet adopted in the course of forming the thin film is arranged in the plane direction of the thin filmunder the action of pressure and / or shearing force; a pressure influence caused by pressurization is enhanced by repeating a curling step and an extrusion step; the two-dimensional heat-conducting sheet is oriented as much as possible; the anisotropic heat conduction performance of the two-dimensional heat-conducting sheet is fully utilized; and a higher heat conductivity is obtained.

Owner:佛山(华南)新材料研究院

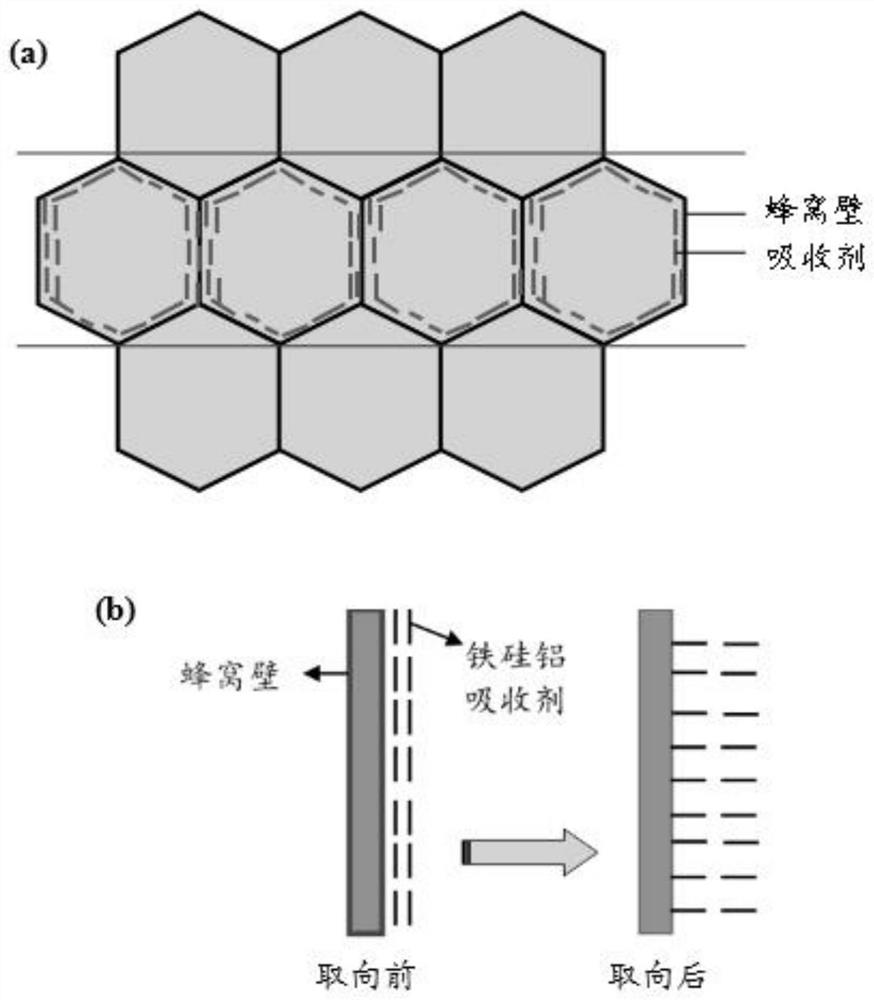

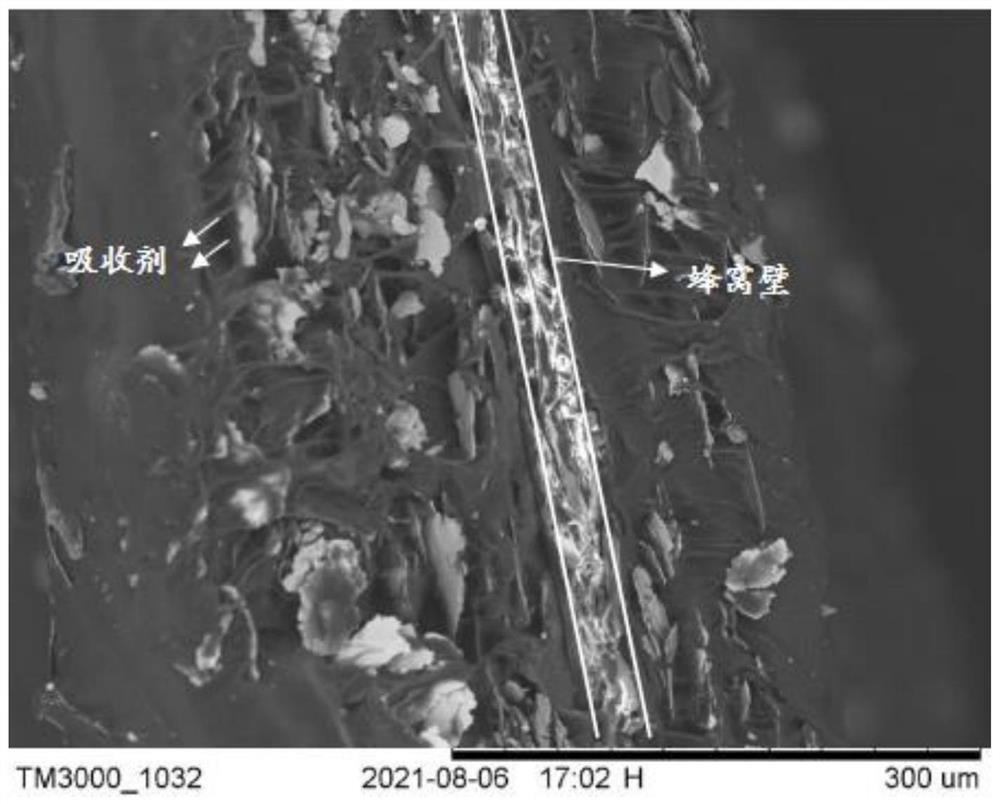

Oriented honeycomb wave-absorbing material and preparation method thereof

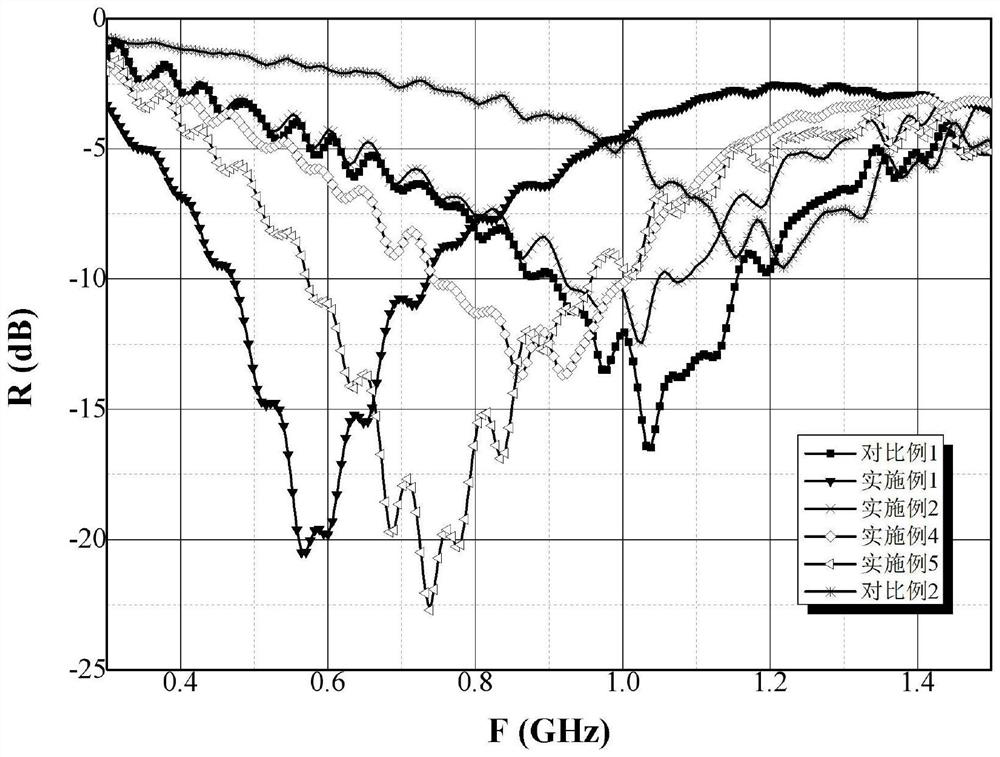

ActiveCN114069251ARaise the degree of orientationEnhanced magnetic lossMagnetic/electric field screeningAntennasPolymer scienceSlurry

The invention discloses an oriented honeycomb wave-absorbing material and a preparation method thereof, and belongs to the technical field of electromagnetic wave functional materials. The preparation method comprises the following steps: (1) dipping treatment of a honeycomb base material: dipping the honeycomb base material in magnetic absorbent slurry to obtain a honeycomb material coated with a magnetic wave-absorbing coating; and (2) orientation and molding of the honeycomb material: rotating the honeycomb material coated with the magnetic wave-absorbing coating in a magnetic field for 6-12 hours, and then heating and curing to obtain the oriented honeycomb wave-absorbing material. An impregnation method and a magnetic field induction method are combined, on the basis of an existing honeycomb structure wave-absorbing material, the spatial arrangement of the absorbent on the honeycomb wall is changed by applying a magnetic field, the orientation degree of the absorbent is improved, the obtained honeycomb material has remarkably improved magnetic loss, and especially in a P frequency band, and the low-frequency absorption performance of the wave-absorbing material is effectively improved.

Owner:NANJING UNIV

Preparation method of neodymium iron boron magnetic material and magnetic material prepared by adopting method

PendingCN113223847ALow costImprove performanceInductances/transformers/magnets manufactureMagnetic materialsSpinningCerium

The invention relates to the field of magnetic materials, in particular to a preparation method of a neodymium iron boron magnetic material and the magnetic material prepared by adopting the method. The preparation method of the neodymium iron boron magnetic material comprises the following steps of: weighing raw materials; smelting the raw materials, pre-cooling the smelting liquid, preserving the heat, and performing melt-spinning to obtain a melt-spunning sheet; carrying out hydrogen demolishing, powdering and molding orientation on the melt-spinning sheet to obtain a blank; and sintering and tempering the blank to obtain the neodymium iron boron magnetic material. The neodymium iron boron magnetic material is prepared by adopting the preparation method. The magnet is made of the neodymium iron boron magnetic material. According to the preparation method, praseodymium-neodymium alloy is partially replaced by metal cerium and gadolinium-iron alloy, and meanwhile, the smelting liquid is pre-cooled and subjected to heat preservation before melt-spinning. Through cooperative implementation of the measures, the cost of the neodymium iron boron magnetic material is reduced, meanwhile, thereby guaranteeing that the neodymium iron boron magnetic material has good performance, and the requirements of actual use can be met.

Owner:慈溪市兴发磁业科技有限公司

Oriented Silicon Steel and Method for Manufacturing Same

ActiveUS20150302962A1Low production costHigh potential benefitConductive/insulating/magnetic material on magnetic film applicationInorganic material magnetismWell controlSilicon

The invention discloses an oriented silicon steel with excellent magnetic properties and a manufacturing method thereof. The present invention obtains the oriented silicon steel with excellent magnetic properties by controlling the area ratio of small crystal grains of D<5 mm in an oriented silicon steel finished product to be not more than 3%, and controlling the ratio μ17 / μ15 of the magnetic conductivity under the magnetic induction of 1.7 T and 1.5 T in the oriented silicon steel finished product to be 0.50 or more. In addition, by using a slab of the oriented silicon steel with suitable components and an optimized cold rolling step, the present invention effectively decreases the heating temperature of the slab and the production cost thereof, and simultaneously better controls the size and ratio of the crystal grains in the oriented silicon steel finished product and the magnetic conductivity in a certain range of magnetic induction, ensures that secondary recrystallization has good Goss texture orientation and finally, stably obtains the oriented silicon steel product with excellent magnetic properties.

Owner:BAOSHAN IRON & STEEL CO LTD

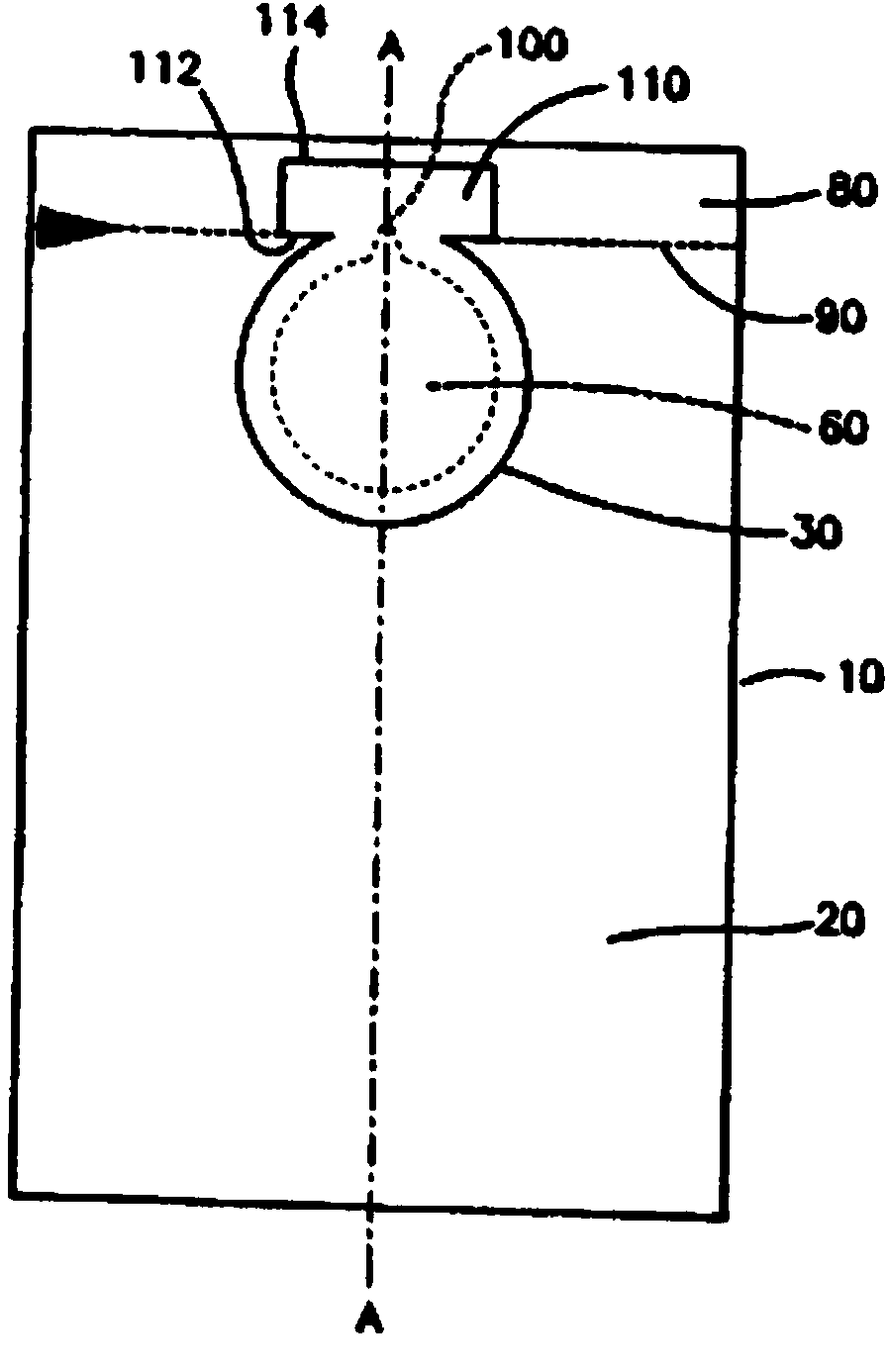

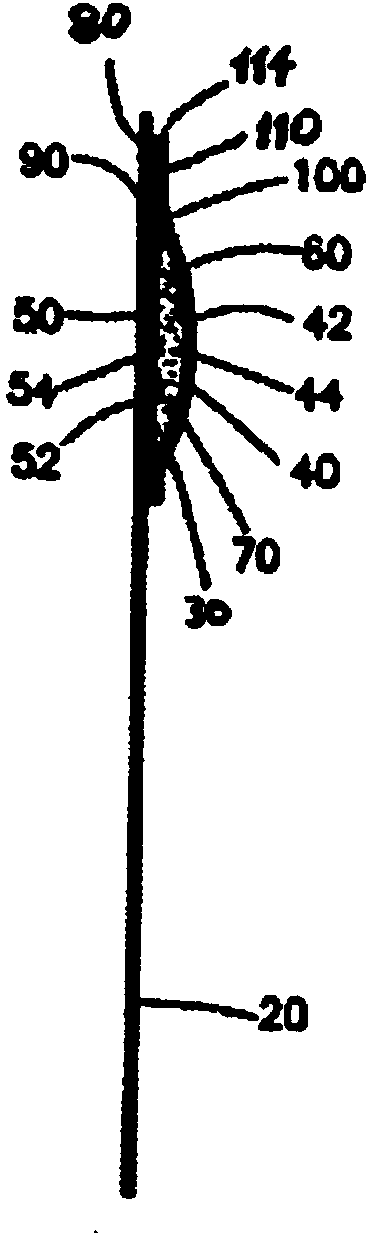

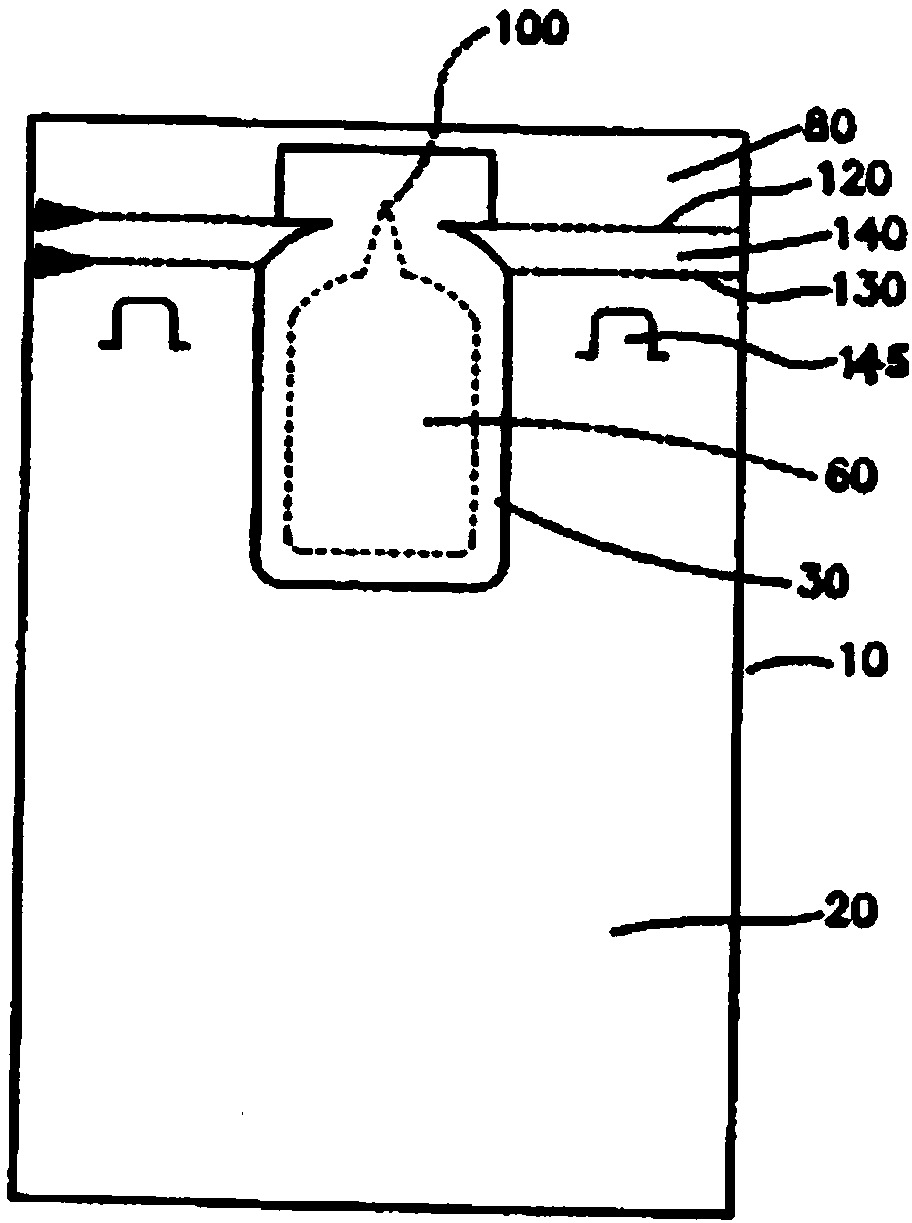

Unitized package and method of making same

InactiveCN104220344ARaise the degree of orientationIncreased resistance to deformationSuccessive articlesProduct gasEngineering

The invention generally relates to unitized packages for containing and dispensing a product material. In particular, the unitized packages comprise a printed base card and a fluid vessel permanently bonded to the printed base card. The fluid vessel comprises a first laminate barrier layer comprising at least one layer of a biaxially oriented thermoplastic polymer, a portion of which is formed into a modified dome shape, and a planar second laminate barrier layer. The first and second laminate barrier layers are sealed together to form a fluid-tight enclosure, wherein the product material substantially fills the enclosure and the modified dome shape is resiliently sustainable. A method of manufacturing the unitized packages as described above is also provided. In particular, the method includes forming a portion of the first laminate barrier layer comprising the biaxially oriented polymer into the modified dome shape using a force such as pressurized gas.

Owner:AKI INC

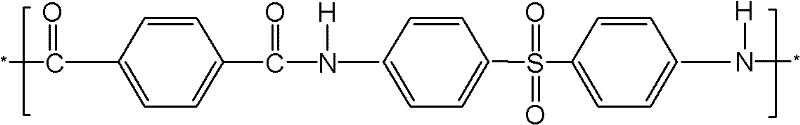

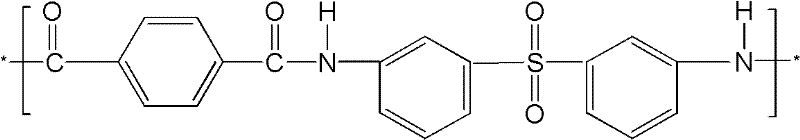

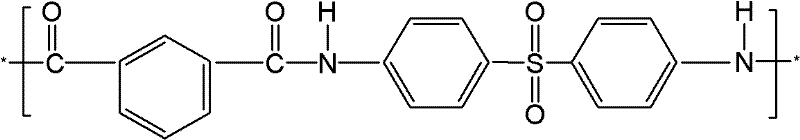

Hot drawing method for aromatic polysulfonamide nascent fibre

InactiveCN102337600AGood orientationHigh strengthMonocomponent copolyamides artificial filamentStretch-spinning methodsState of artPolymer science

The invention relates to a hot drawing method for aromatic polysulfonamide nascent fibres, which is a method different from the drawing technology adopted for preparing the aromatic polysulfonamide nascent fibres in the prior art. The hot drawing method for aromatic polysulfonamide nascent fibres, which is disclosed by the invention, comprises the following steps: the nascent fibres obtained through extruding, solidifying and shaping aromatic polysulfonamide spinning solution is drawn in hot air, wherein the temperature of the hot air is 80-180DEG C, and the drawing multiple is 2-16; and the aromatic polysulfonamide nascent fibre comprises 10-50wt% of aromatic polysulfonamide, 10-60wt% of solvent and the balance of water. According to the hot drawing method for aromatic polysulfonamide nascent fibres, which is disclosed by the invention, a molecular orientation degree is improved, thereby being favorable to crystallization in the follow-up high-temperature heat setting process and improvement of fibre strength.

Owner:DONGHUA UNIV

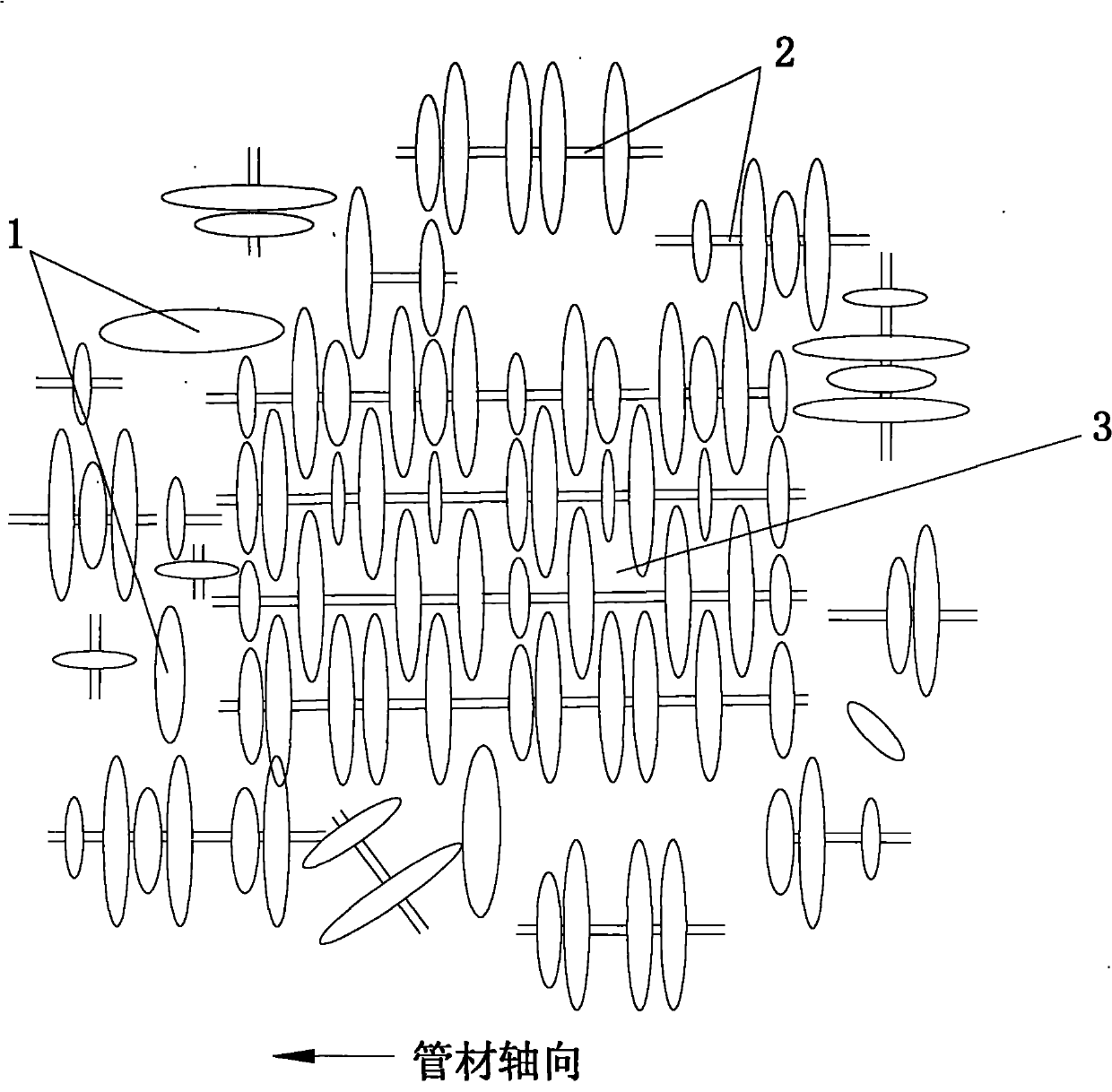

Method of controlling crimp shrinkage of fine-denier polyester by adjusting content of pentaerythritol

ActiveCN104060347ASolve the adjustmentSolve control problemsMelt spinning methodsConjugated synthetic polymer artificial filamentsPentaerythritolPolyethylene terephthalate

The invention relates to a method of controlling the crimp shrinkage of a fine-denier polyester by adjusting the content of pentaerythritol. The method is characterized by comprising the following steps: adjusting the irregularity of molecular chains of polyester fibers by means of a branching effect of the pentaerythritol to a molecular chain of PET (Polyethylene Terephthalate) so as to change the flexibility of the molecular chains of the fibers; and finally, controlling the crimp shrinkage of the fine-denier polyester. On one hand, the method provided by the invention can greatly increase the crimp shrinkage of polyester filament yarns (from 25-38% to 40-46.7%), and on the other hand, the method can adjusts the crimp shrinkage of the fibers according to the filament number of the fibers by means of adjusting the content of the pentaerythritol, so that the fibers with different filament numbers are close in crimp shrinkage under a same draw texturing process condition, and thus, technical changes caused by switching production are simplified and the stability of fiber production is improved.

Owner:ZHEJIANG YINYU NEW MATERIAL CO LTD

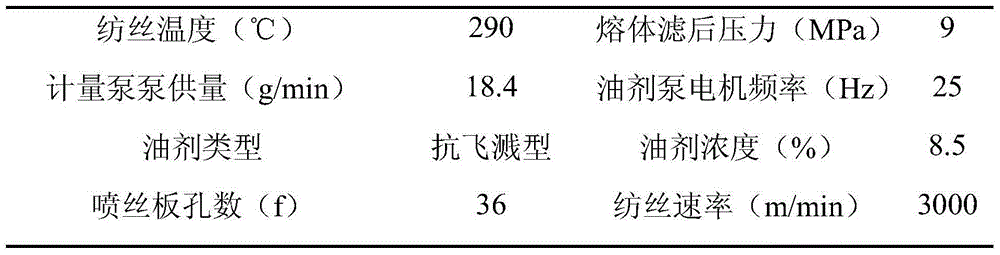

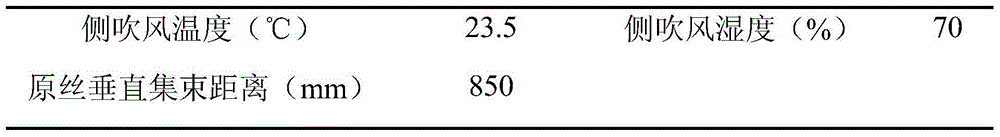

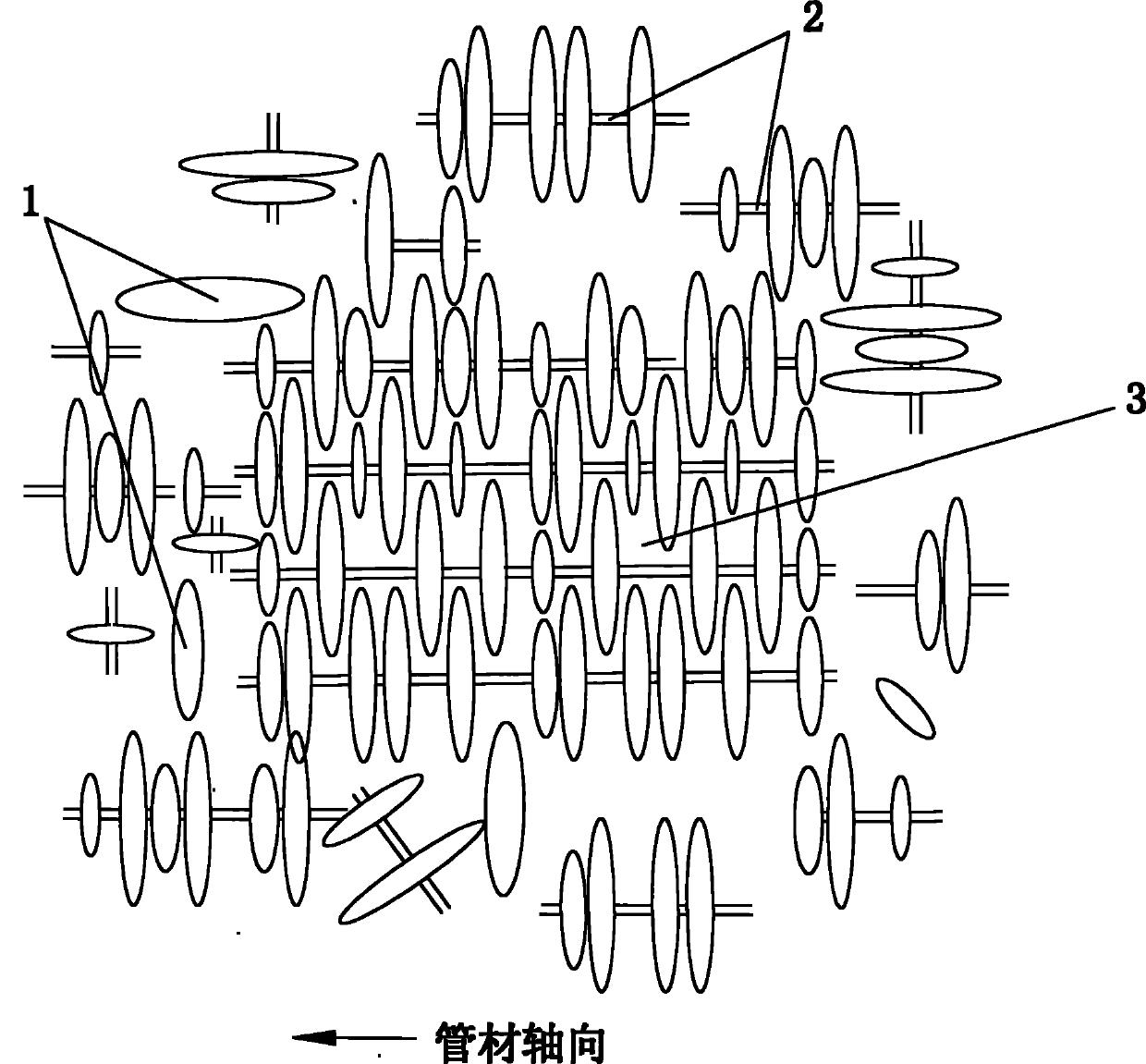

Temperature-resistant pressure-resistant axial self-reinforced plastic pipe special for oil treatment

InactiveCN102086951ARaise the degree of orientationHigh crystallinityRigid pipesSelf reinforcedEconomic benefits

The invention relates to a structural composition of various plastic pipe parts. The structural composition is characterized in that: a plastic pipe has temperature-resistant pressure-resistant performance due to a high-performance condensed-state structure which has a self-reinforcing function and comprises polymers such as macromolecules, shish-kebab, interlocking shish-kebab and the like on the premise of not comprising any other extra reinforcing agent, wherein the polymers are oriented and crystallized along the axial direction of the pipe. When the strength and the modulus of the pipe are simultaneously reinforced in the axial direction, the actual demand of the pipe on material performance is met better. After reinforcement, the orientation degree of the pipe in the axial direction is also higher than that of the conventional pipe, the wafer of the reinforced pipe is thicker, and the crystallization degree is higher, so that the temperature resistance is also obviously improved compared with that of the conventional pipe, and the pipe is particularly suitable for a pipeline special for oil treatment. The pipe has the advantages of high production efficiency, small equipment investment, low raw material cost, low production cost and high product performance, can accord with the industrial production conditions and has better industrial prospect and economic benefit.

Owner:CHONGQING TECH & BUSINESS UNIV

An electrospinning collection device and a method for preparing nanofibers with a gradient orientation structure

ActiveCN106480518BIncreasing the thicknessRaise the degree of orientationMonocomponent protein artificial filamentInorganic material artificial filamentsFiberN dimethylformamide

The invention discloses an electrostatic spinning collecting device and a preparation method of nanofiber adopting a gradient-oriented structure. The electrostatic spinning collecting device consists of a power supply, a forward and reverse rotation controller, motors, magnets and receiving heads. The preparation method comprises the following steps: dissolving a solute such as polycaprolactone into a mixed solution of dichloromethane and N-N dimethylformamide, uniformly stirring, and adjusting the spinning positive voltage to be 10-20 kV, the negative pressure to be -5 kV to 0 kV, the distance between a needle head and the electrostatic spinning collecting device to be 10-20 cm, and the distance between the two conical receiving heads to be 0.5-7 cm. In the spinning process, parallel fibers are deposited between the receiving heads, while the fibers deposited at the receiving heads are randomly oriented, and a transitional area exists in the middle. Through the electrostatic spinning collecting device and the preparation method, a nanofiber stent adopting the gradient-oriented structure can be obtained; the nanofiber stent adopting the gradient-oriented structure has relatively high mechanical strength, simulates an arrangement mode of collagen fibers in a muscle tendon and a ligament tissue, and can be applied to tissue engineering and tissue repair of the muscle tendon and the ligament.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of longitudinal high thermal conductivity gasket prepared by oriented carbon fiber by controllable compression deformation method

The invention provides a method for preparing longitudinal high thermal conductivity gaskets from oriented carbon fibers by a controllable compression deformation method. The carbon fibers are oriented and arranged by the controllable compression deformation method, and the subsequent defoaming, vulcanization, cutting, surface treatment, etc. The carbon fiber silicone gasket with a thermal conductivity of 30W / mK in the thickness direction is prepared by the process. This patent can prepare carbon fiber gaskets with an aspect ratio of 20:1, which improves production efficiency and reduces waste.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com