Multilayer insulation thermal interface material and preparation method thereof

A technology of thermal interface material and insulating heat-conducting layer, which is applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problems that the heat dissipation effect cannot meet the actual application, poor thermal conductivity, etc., and achieve favorable thermal conductivity , Excellent thermal conductivity, simple equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

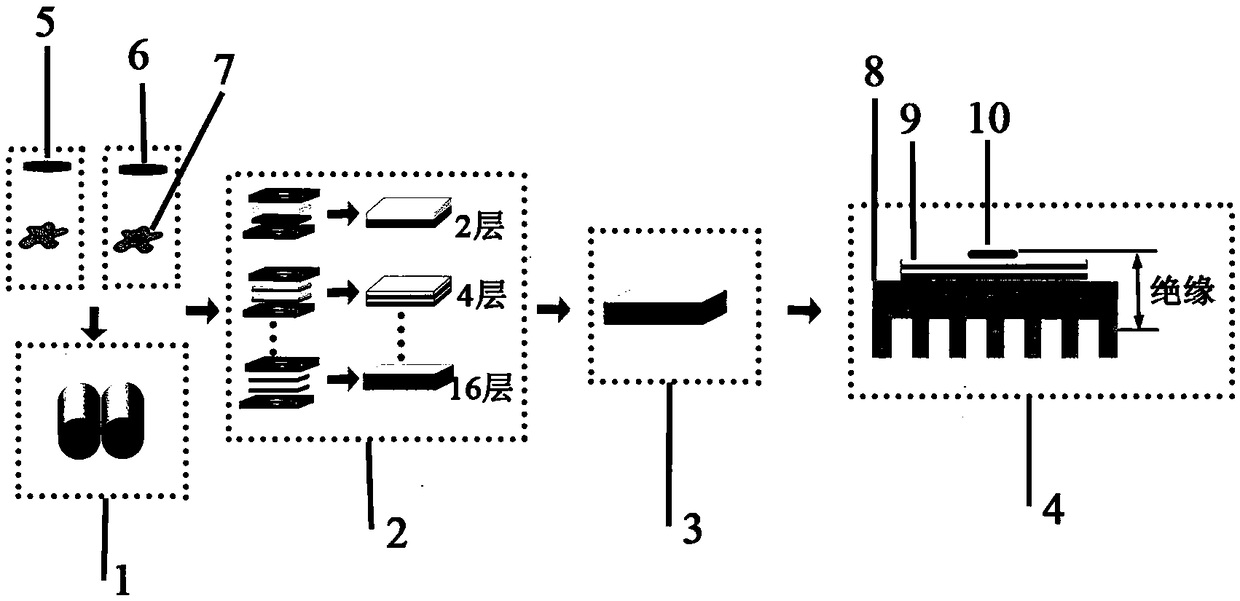

[0038] A multi-layer insulating silica gel / boron nitride / graphene nanosheet insulating thermal interface material, which is prepared according to the following steps:

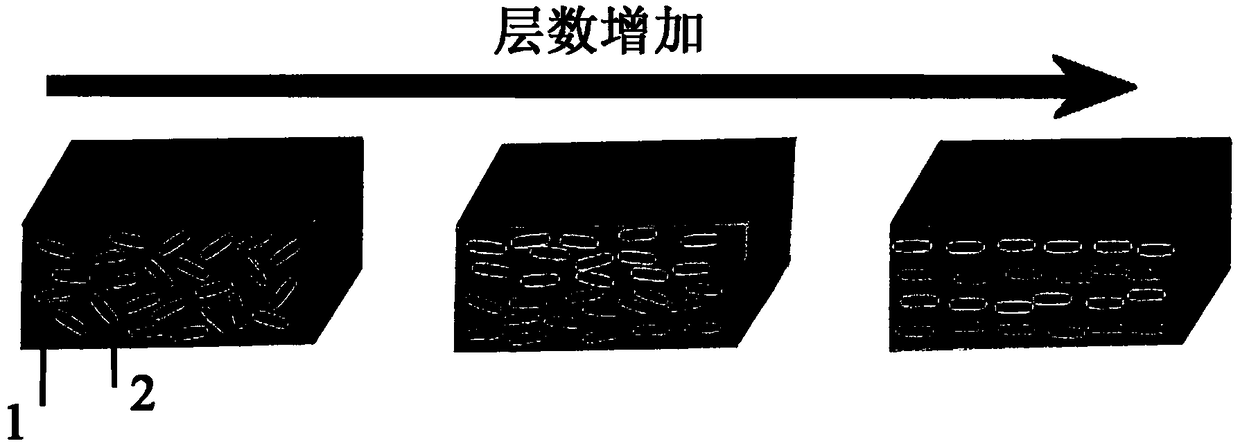

[0039] (1) 100g silicone rubber and 2g diisopropylaniline peroxide, 5g fumed silica and 2g dimethylsiloxane oligomer are uniformly mixed at room temperature by a two-roll mill to obtain a rubber compound, wherein The silicone rubber is made of low compression set silicone rubber with a vinyl molar fraction of 0.25%; then weigh 50g of boron nitride and 50g of graphene nanosheets and add them to the mixed rubber to prepare the blended rubber white material and the blended rubber black material;

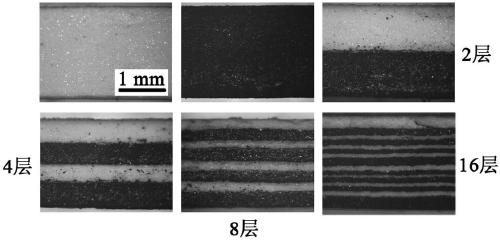

[0040] (2) According to the size of the mold, take an appropriate amount of mixed rubber on the mold and put it into a flat vulcanizing machine, first cold press it at room temperature 10MPa for 1 minute, and exhaust it three times to avoid air bubbles inside the sample; use figure 1 The preparation process of the multi...

Embodiment 5~10

[0048] A kind of multi-layer insulating silica gel / aluminum oxide / graphite thermal interface material, its preparation is carried out according to the following steps:

[0049] (1) 100g of silicone rubber, 1g of 2,5-dimethyl-2,5-bis(tert-butyl peroxide) hexane and 5g of dimethylsiloxane oligomer were passed through a double-roller mill Mix evenly under room temperature; Wherein silicon rubber selects the low hardness methyl vinyl silicone rubber of 0.10% vinyl molar fraction for use; Then take 50g aluminum oxide or 100g graphite and join in the mixed rubber to make mixed rubber white material and Mixed rubber black material;

[0050] (2) Take an appropriate amount of mixed rubber on the mold and put it into a flat vulcanizing machine, first cold press it at room temperature 10MPa for 1 minute, and exhaust it three times to avoid air bubbles inside the sample; use figure 1 The preparation process of the multilayer insulating thermal interface material shown in the figure produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com