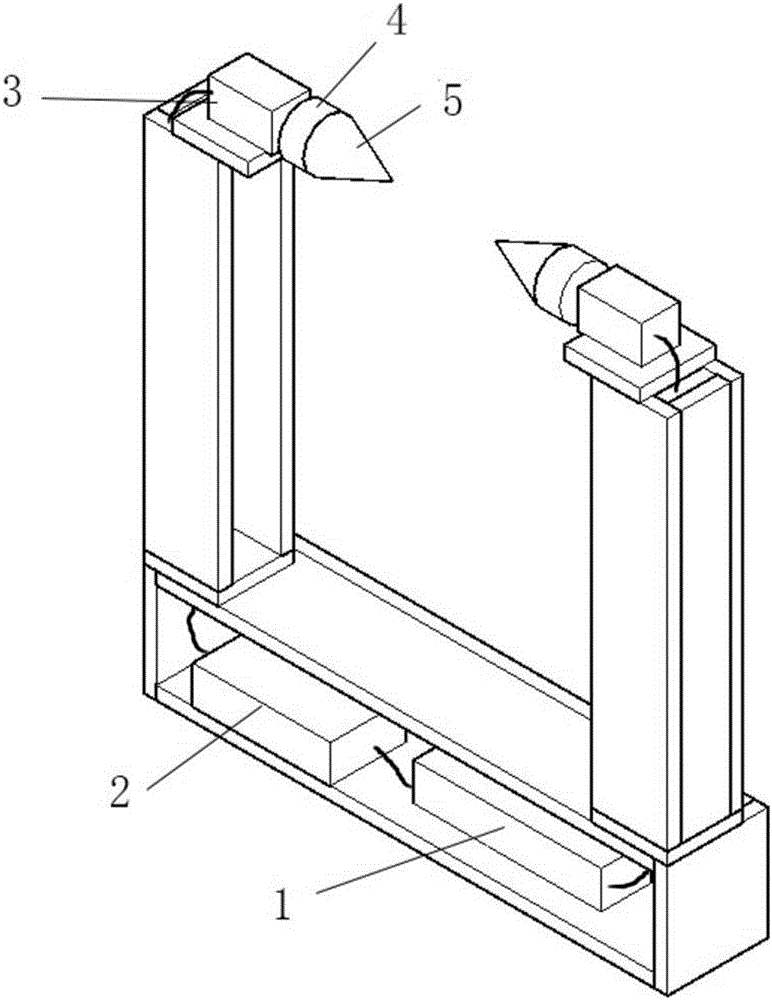

Electrostatic spinning collecting device and preparation method of nanofiber adopting gradient-oriented structure

A collection device and electrospinning technology, applied in fiber processing, fiber chemical characteristics, filament/line forming, etc., can solve the problem of irregular nanofiber arrangement, and achieve the effects of easy assembly, excellent mechanical properties, and simple parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

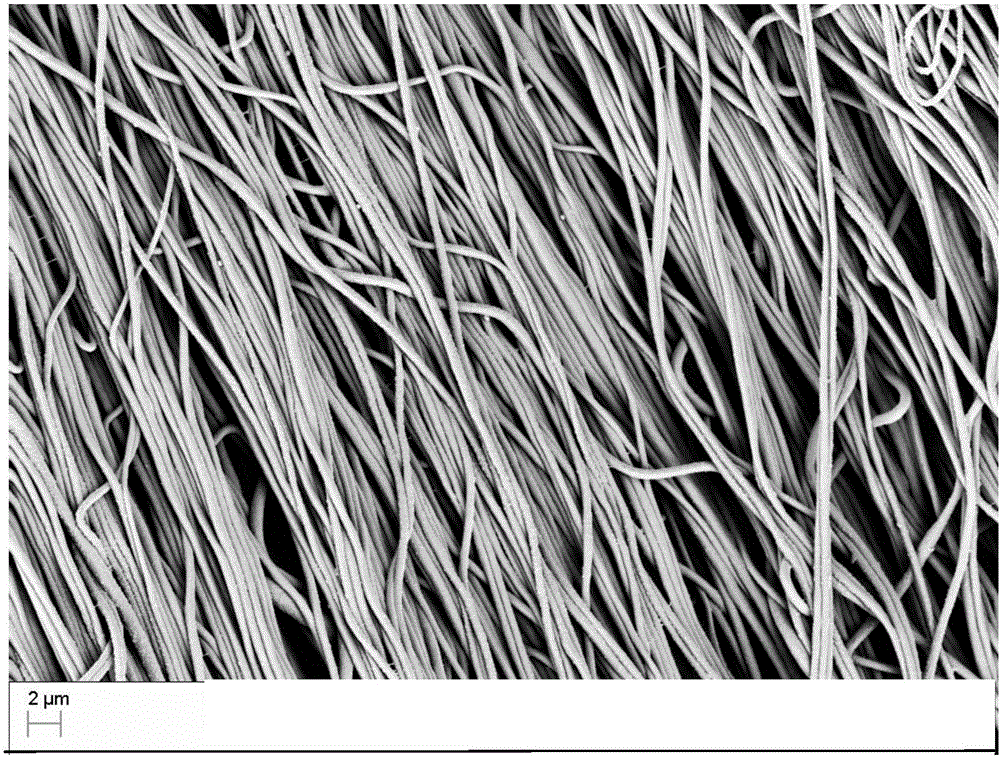

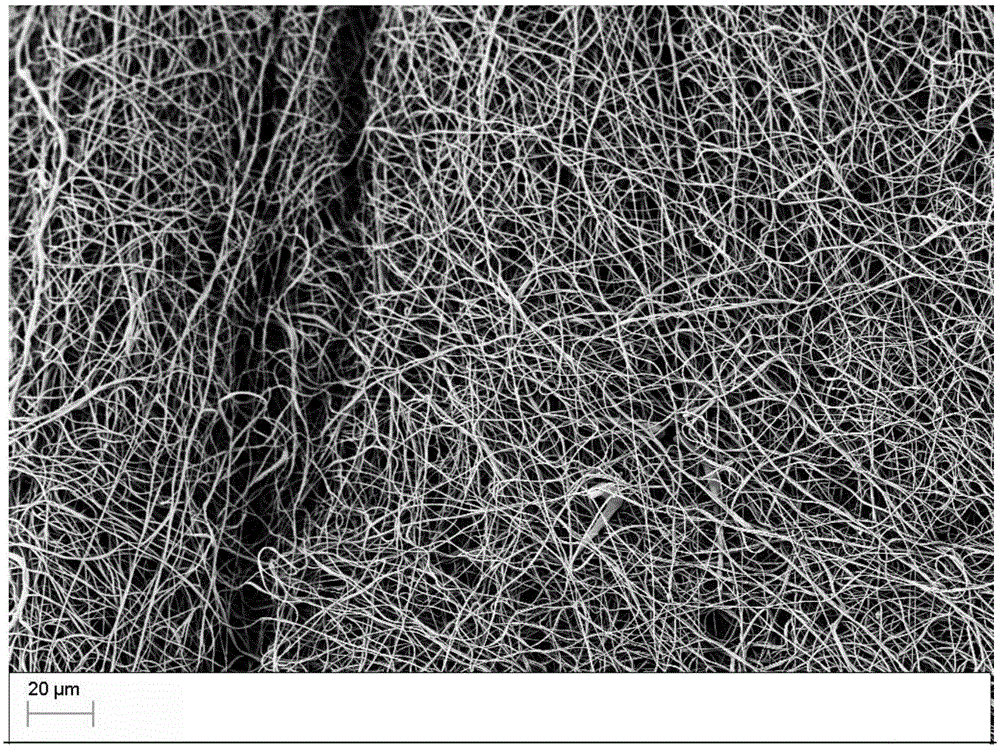

[0040] Weigh 1.2 g of polycaprolactone, add 10 mL of a mixed solution of dichloromethane and N-N dimethylformamide with a volume ratio of 4:1, and stir for 12 hours. Use a 10mL syringe to absorb the above-prepared spinning solution, and connect it to a needle through a polyethylene catheter. The needle is a 20G needle, connected to a 15kV high-voltage positive voltage, and the conical receiving head of the electrospinning receiving device is connected to a 5kV negative voltage. The magnet connecting the receiving head is a cylindrical magnet with a diameter of 5 mm. The electrospinning collection device was placed under the needle with a distance of 18 cm, and the distance between the two receiving heads was 0.5 cm. The flow rate of the spinning solution was 1.0 mL / h, and the total spinning time was 3 h. The prepared scaffolds were vacuum-dried. figure 2 Parallel-oriented sections of polycaprolactone nanofibrous scaffolds are shown. image 3 The randomly oriented sections...

Embodiment 2

[0042] Weigh 0.012 g of carbon nanotubes, add 10 mL of trifluoroethanol solution to disperse evenly, add 1.2 g of polycaprolactone and stir for 12 hours. Use a 10mL syringe to absorb the above-prepared spinning solution, and connect it to a needle through a polyethylene catheter. The needle is a 20G needle, connected to 15kV high voltage positive electricity. The electrospinning collection device was placed under the needle with a distance of 20 cm, and the distance between the two receiving heads was 7 cm. The conical receiving head of the electrospinning receiving device was connected to a negative voltage of 0 kV. The magnet connecting the receiving head is a cylindrical magnet with a diameter of 15mm. The flow rate of the spinning solution was 1.0 mL / h, and the total spinning time was 2 h. The prepared scaffolds were vacuum-dried. The average diameter of the obtained nanofibers is 242 nm, the standard deviation is 49 nm, and the ultimate tensile strength is as high as ...

Embodiment 3

[0044] Weigh 2 g of polylactic acid-glycolic acid copolymer, dissolve in hexafluoroisopropanol, and stir for 24 hours. Use a 10mL syringe to absorb the above-prepared spinning solution, and connect it to a needle through a polyethylene catheter. The needle is 18G needle, connected to 10kV high voltage positive electricity. The electrospinning collection device was placed under the needle with a distance of 10 cm, and the distance between the two receiving heads was 3 cm. The conical receiving head of the electrospinning receiving device was connected to a negative voltage of 3 kV. The magnet connecting the receiving head is a cylindrical magnet with a diameter of 10mm. The flow rate of the spinning solution was 1.0 mL / h, and the total spinning time was 1 h. The prepared scaffolds were vacuum-dried. The obtained nanofibers have good morphology, the average diameter is 352nm, the standard deviation is 72nm, the angle distribution is between -25°~20°, the degree of orientatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com