Highly-oriented highly-heat-conducting carbon/carbon composite material and preparation method thereof

A carbon composite material and high thermal conductivity technology, which is applied in the field of highly oriented and high thermal conductivity carbon/carbon composite materials and their preparation, which can solve the problem of difficult self-bonding formability control, great influence of thermal conductivity, low density and thermal conductivity, etc. problems, to achieve the effect of shortening the preparation cycle, excellent axial thermal conductivity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

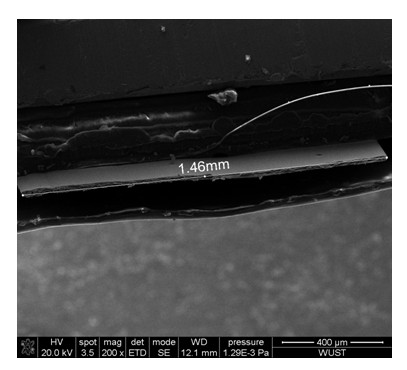

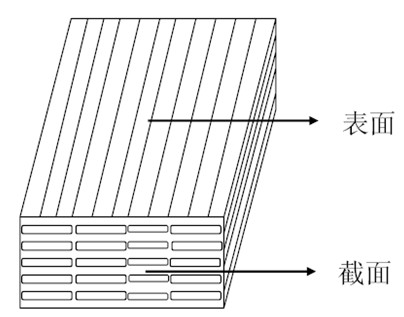

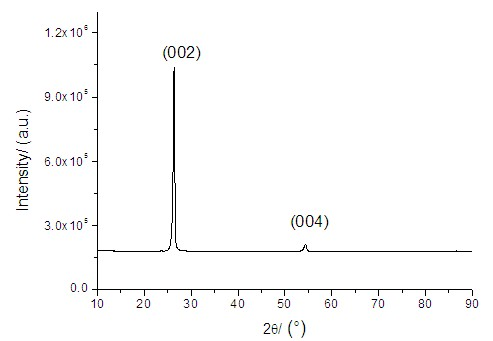

[0023] A method for preparing a carbon / carbon composite material with high orientation and high thermal conductivity. Oxidative stabilization is carried out by using large cross-section ribbon-shaped mesophase pitch fibers as raw materials; then, the surface of the large-section ribbon-shaped mesophase pitch fibers after oxidation stabilization is uniformly coated with a binder, and the binder is 15~20wt of the raw material %; then the large cross-section tape-shaped mesophase pitch fiber coated with binder is unidirectionally spread in the mold and hot-pressed; finally carry out 1000~1200 o C carbonization and 2800~2900 o C graphitization, the preparation of highly oriented and high thermal conductivity carbon / carbon composites.

[0024] In the present embodiment: described oxidation stabilization is based on 3~12 o C / min rate heating up to 200~240 o C, heat preservation 32~40h; Described binding agent is coal tar pitch; The temperature of described hot pressing is 300~500...

Embodiment 2

[0026] A method for preparing a carbon / carbon composite material with high orientation and high thermal conductivity. Oxidative stabilization is carried out by using large cross-section tape-shaped mesophase pitch fibers as raw materials; then uniformly coat the surface of the large cross-section tape-shaped mesophase pitch fibers after oxidation stabilization with a binder, the binder is 4~15wt of the raw material %; then the large cross-section tape-shaped mesophase pitch fiber coated with binder is unidirectionally tiled in the mold and hot-pressed; finally carry out 1100~1300 o C carbonization and 3000~3100 o C graphitization, the preparation of highly oriented and high thermal conductivity carbon / carbon composites.

[0027] In the present embodiment: described oxidation stabilization is based on 1~10 o C / min rate heating up to 230~260 o C, heat preservation 8 ~ 20h; The described binding agent is mesophase pitch; The temperature of the described thermoforming is 400 ~ 60...

Embodiment 3

[0029] A method for preparing a carbon / carbon composite material with high orientation and high thermal conductivity. Oxidative stabilization is carried out by using large cross-section tape-shaped mesophase pitch fibers as raw materials; then uniformly coat the surface of the large cross-section tape-shaped mesophase pitch fibers after oxidation stabilization with a binder, the binder is 10~14wt of the raw material %; then the large cross-section tape-shaped mesophase pitch fiber coated with binder is unidirectionally tiled in the mold and hot-pressed; finally carry out 1400~1600 o C carbonization and 2850~2950 o C graphitization, the preparation of highly oriented and high thermal conductivity carbon / carbon composites.

[0030] In the present embodiment: described oxidation stabilization is based on 0.1~5 o C / min rate heating up to 260~300 o C, heat preservation 5~10h; Described binding agent is phenolic resin; The temperature of described thermocompression molding is 500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com