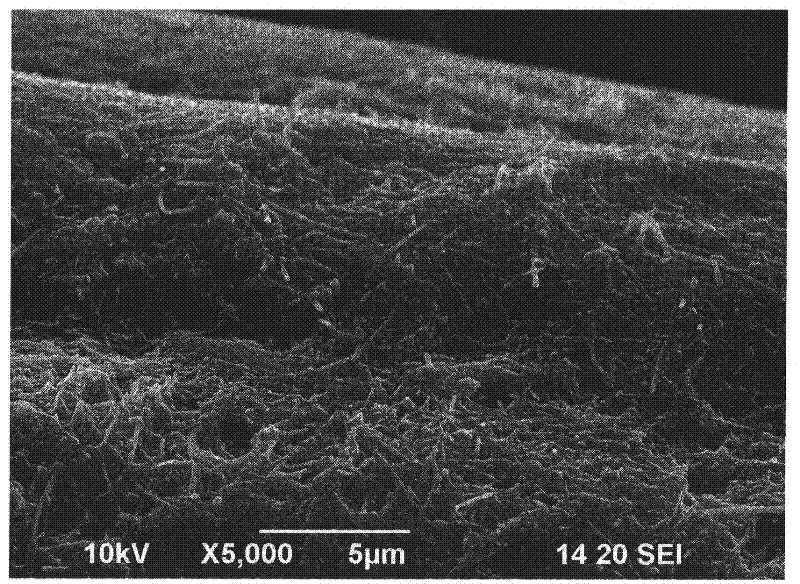

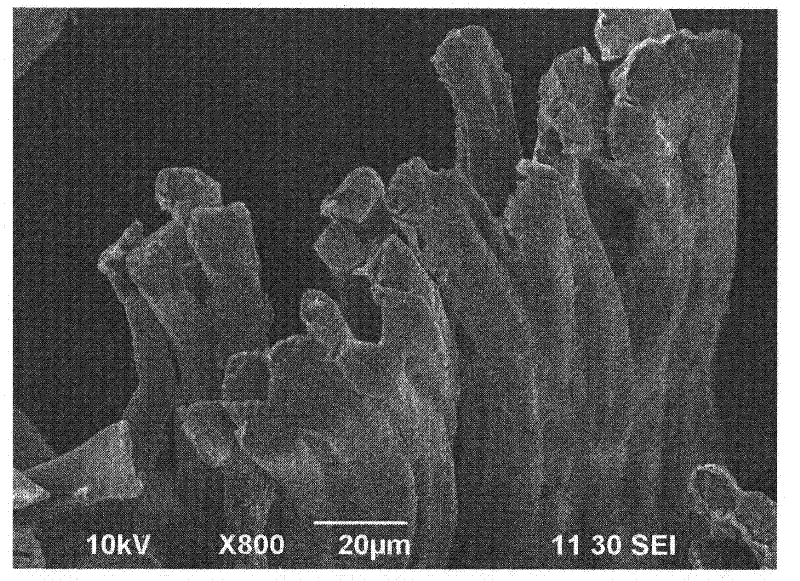

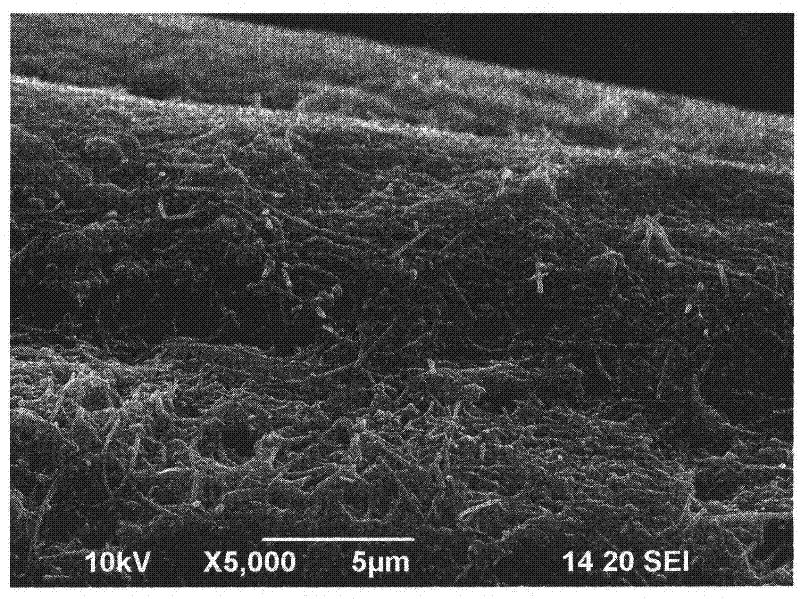

Electroconductive fibers with carbon nanotubes deposited thereon, electroconductive threads, fiber structure, and process for producing same

一种导电纤维、碳纳米管的技术,应用在纤维处理、纤维类型、纺织品和造纸等方向,能够解决没有记载合成纤维合成纤维制造方法等问题,达到优异柔软性、便于处理、优异导电性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0115] The preparation method of the dispersion liquid is not particularly limited to a specific one, and any method can be used as long as a dispersion liquid in which carbon nanotubes are stably and finely dispersed in a liquid medium (such as water) can be prepared without causing carbon nanotubes to Agglomeration (or aggregation), or formation of bundles.

[0116] In particular, according to the present invention, the preferred preparation method comprises: in the presence of surfactants (especially zwitterionic surfactants), the pH of the aqueous medium is kept at 4.0-8.0, preferably 4.5-7.5, more preferably at At the same time as 5.0 to 7.0, dispersing treatment of dispersing carbon nanotubes in an aqueous medium (water). For the dispersion treatment in this production method, a mill (media mill) using a medium (a solid medium for pulverization, such as beads or balls) is preferably used as a dispersing device. Specific examples of the media mill include bead mills usin...

Embodiment 1

[0143] (1) Preparation of aqueous carbon nanotube dispersion:

[0144] (i) Prepare an aqueous solution of surfactant by mixing 2.0 g of 3-(dimethylstearyl ammonium) propane sulfonate (zwitterionic surfactant), 5 ml of glycerin (hydration stabilizer), and 495 ml of deionized water (pH6.5).

[0145] (ii) 500ml of the aqueous surfactant solution obtained in the above step (i) and 15.2g of carbon nanotubes (manufactured by "MWCNT-7" Nano Carbon Technologies Co., Ltd.) are put into the ball mill body (cylindrical type, internal volume = 1800ml, ball diameter = 150mm, ball loading = 3200g), and the mixture was stirred by hand to obtain a paste product. The ball mill body was then placed on a rotary table (manufactured by "AS ONE" ASAHI RIKA SEISAKUSYO, Co., Ltd.), and the paste product was stirred for 1 hour to obtain a liquid product containing carbon nanotubes.

[0146] (iii) taking out all the liquid products containing carbon nanotubes prepared in the above step (ii) from the ...

Embodiment 2

[0155] (1) Preparation of aqueous carbon nanotube dispersion:

[0156] (i) Prepare an aqueous solution of surfactant by mixing 2.0 g of 3-(dimethylstearyl ammonium) propane sulfonate (zwitterionic surfactant), 5 ml of glycerin (hydration stabilizer), and 495 ml of deionized water ( pH6.5).

[0157] (ii) 500ml of the aqueous surfactant solution obtained in the above step (i) and 30.4g of carbon nanotubes (Baytube, manufactured by Bayer) are put into the ball mill body (cylindrical type, internal volume = 1800ml, ball diameter = 150mm, the filling of the ball amount = 3200 g), and stirred by hand to obtain a paste product, and then put the ball mill body on a rotary table (manufactured by "AS ONE" ASAHI RIKA SEISAKUSYO, Co., Ltd.) and stirred the paste product for 1 hour to obtain A liquid product containing carbon nanotubes.

[0158] (iii) taking out all the liquid products containing carbon nanotubes prepared in the above step (ii) from the ball mill body. To this liquid pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com