Directional heat conduction material and preparation method and application thereof

A technology of directional heat conduction and heat conduction filler, applied in the direction of heat exchange materials, chemical instruments and methods, modification through conduction heat transfer, etc., can solve the problem of low degree of orientation, achieve high thermal conductivity, and improve axial thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides an oriented thermally conductive material, which includes a polymer matrix and anisotropic thermally conductive fibers filled in the polymer matrix. The polymer matrix includes 40wt% spherical alumina and 60wt% silicone rubber, and the anisotropic thermally conductive fiber includes 5wt% carbon fiber and 95wt% paraffin. The volume fraction of the anisotropic heat-conducting fiber in the total volume of the oriented heat-conducting material is 30%. The anisotropic thermally conductive fibers are oriented within the polymer matrix, and the anisotropic thermally conductive fibers are oriented along the direction of their alignment.

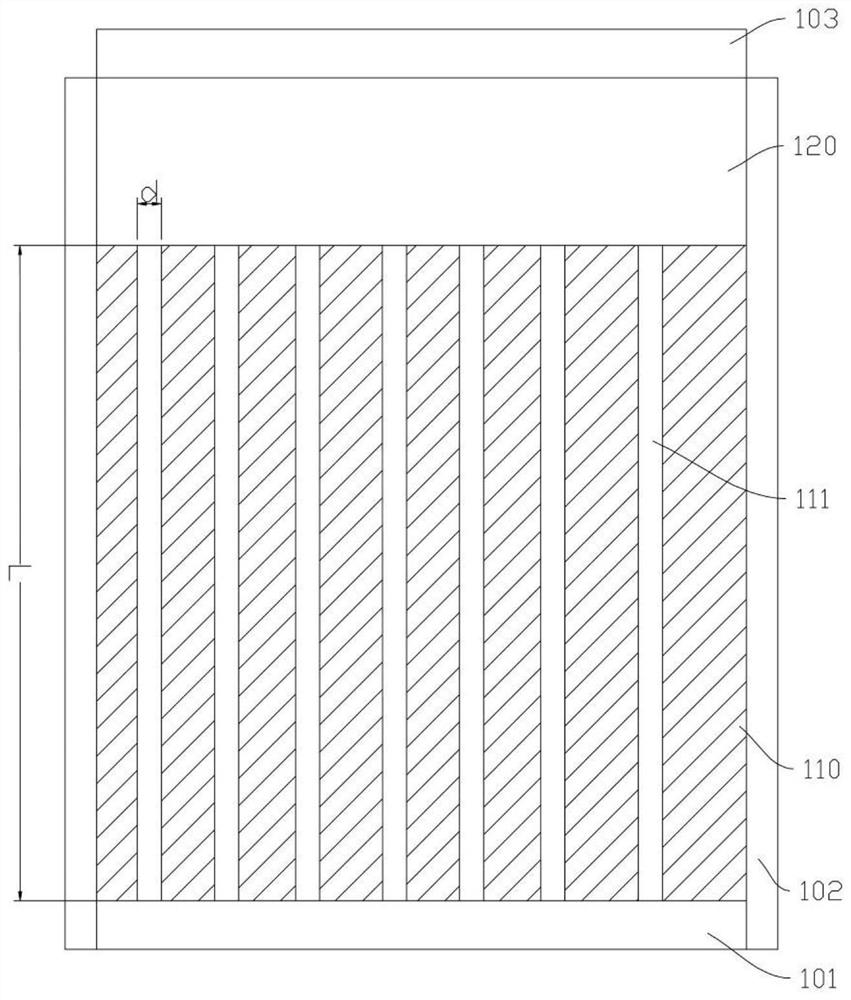

[0035] The mold used in the preparation process of the directional heat-conducting material is as follows:figure 1 shown, refer to figure 1 , is a side view of the mold of one embodiment of the present invention. The mold is a cylindrical structure, including a lower cover plate 101, and a side wall 102 is fixed alon...

Embodiment 2

[0045] This embodiment provides an oriented thermally conductive material, which includes: a polymer matrix and anisotropic thermally conductive fibers filled in the polymer matrix. The polymer matrix includes 50wt% spherical silica and 50wt% silicone rubber, and the anisotropic thermally conductive fiber includes 10wt% boron nitride and 90wt% silicone rubber. The volume fraction of the anisotropic heat-conducting fiber in the total volume of the oriented heat-conducting material is 30%. The anisotropic thermally conductive fibers are oriented within the polymer matrix, and the anisotropic thermally conductive fibers are oriented along the direction of their alignment.

[0046] The preparation method of the directional heat conducting material is as follows:

[0047] Step 1: Mix silicone rubber and boron nitride treated with coupling agent KH550 to form the first slurry, and silicone rubber and spherical silica treated with coupling agent KH550 to form the second slurry;

[...

Embodiment 3

[0064] This embodiment provides an electronic device, which includes a chip and a heat sink arranged in sequence, and a heat transfer adhesive is sandwiched between the chip and the heat sink, and the heat transfer adhesive includes the oriented thermally conductive material of Embodiment 1 . Using the directional heat-conducting material, the heat generated by the chip during operation can be quickly transferred to the heat sink for dissipation, effectively slowing down the temperature rise of the chip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com