Method of controlling crimp shrinkage of fine-denier polyester by adjusting content of pentaerythritol

A technology of pentaerythritol and fine denier polyester is applied in the field of polyester to achieve the effects of improving stability, increasing strength and simplifying process changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] PER-PET copolymers can be prepared by the following process.

[0046] In this example, PER and commercially available PET chips were used as raw materials to carry out copolymerization in a polymerization tank to obtain a PER-PET copolymer. The mass ratio of PER to PET is 1:99, tetrabutyl titanate is used as a catalyst, and the dosage is 0.5% of the mass sum of PER and PET. During the polymerization, the reaction temperature is 280°C, the vacuum is strictly dehydrated, and the vacuum degree is less than 50Pa. The reaction time is 6h.

[0047] The PER content in the PER-PET copolymer obtained in this example is 1%, the number average molecular weight is 25500, the molecular weight distribution is 2.4, and the intrinsic viscosity is 0.53. It can be used as spinning masterbatch completely.

Embodiment 2

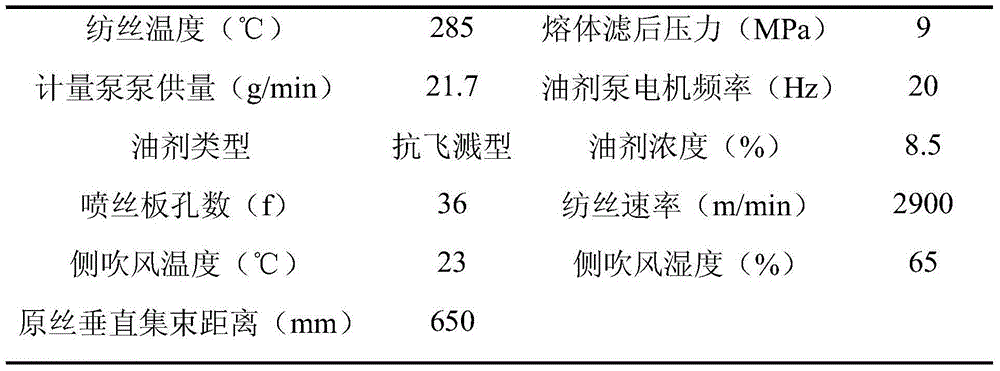

[0049] In this example, after in-line blending, the PER content in the PER-PET copolymer and pure PET mixture is 200ppm. The specific spinning process is shown in the table below:

[0050]

[0051] The total fineness of the polyester filament prepared by the above process is 74.9dtex, the tensile strength is 3.0cN / dtex, the elongation at break is 140%, and the monofilament linear density is 2.08dtex; The linear density of fiber monofilament is reduced to 0.50dtex, the strength is increased to 4.3cN / dtex, and the crimp shrinkage rate is 45%.

Embodiment 3

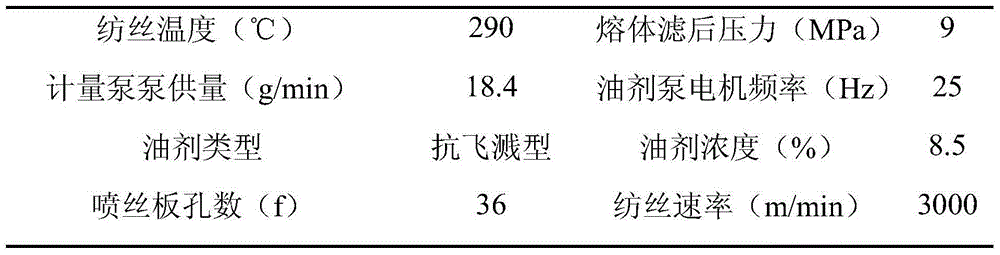

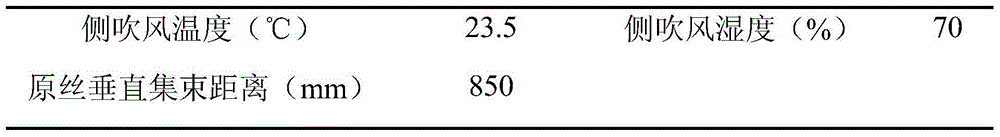

[0053] After online blending in this example, the PER content in the PER-PET copolymer and pure PET mixture is 90ppm. The specific spinning process is shown in the table below:

[0054]

[0055]

[0056] The total fineness of the polyester filament prepared by the above process is 61.2dtex, the tensile strength is 2.4cN / dtex, the elongation at break is 150%, and the monofilament linear density is 1.7dtex; The linear density of fiber monofilament is reduced to 1.04dtex, the strength is increased to 3.8cN / dtex, and the crimp shrinkage rate is 41%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com