Heat-conducting composite material as well as preparation method and application thereof

A technology of thermally conductive composite materials and composite films, which can be used in heat exchange materials, applications, other household appliances, etc., can solve problems such as restricting the application of two-dimensional materials, and achieve the effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a thermally conductive composite material and a preparation method thereof, Figure 1 ~ Figure 4 It is a schematic flow chart of the preparation method of the thermally conductive composite material in Example 1 of the present invention. refer to Figure 1 ~ Figure 4 , the preparation method of the heat-conducting composite material comprises the following steps:

[0038] Filler pretreatment: 15 parts by mass of graphene and 60 parts by mass of spherical alumina powder are mixed and modified with coupling agent KH550 to obtain modified fillers.

[0039] S1: uniformly mix the modified filler with 25 parts by mass of polyvinyl alcohol to form a slurry.

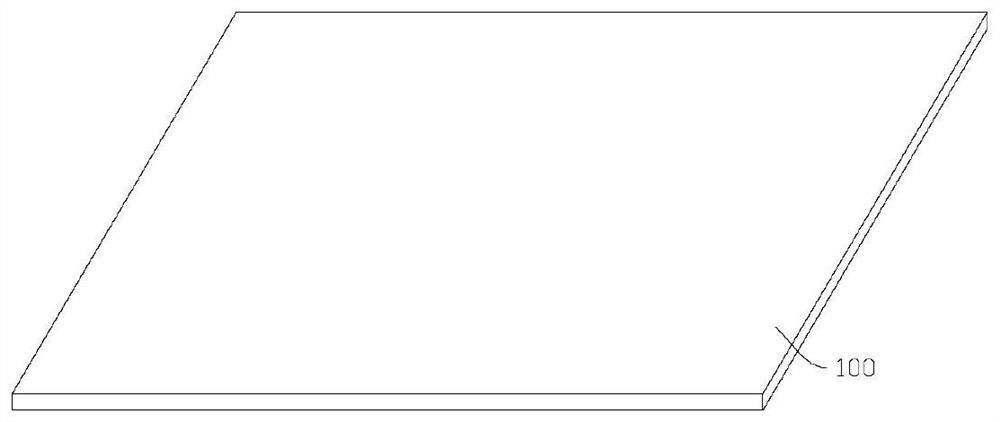

[0040] S2: Reference figure 1 , the slurry is formed by calendering process such as figure 1 The first composite membrane 100.

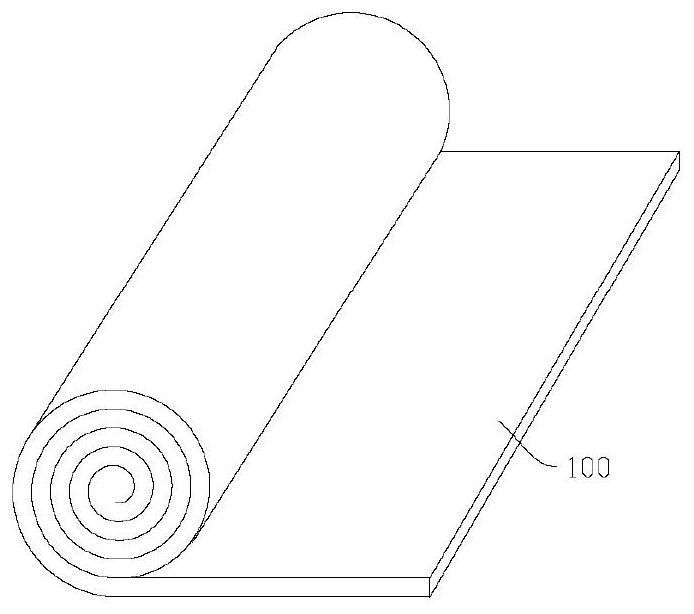

[0041]S3: Reference figure 2 , the first composite film 100 is wound along the side to form a closely attached first cylinder.

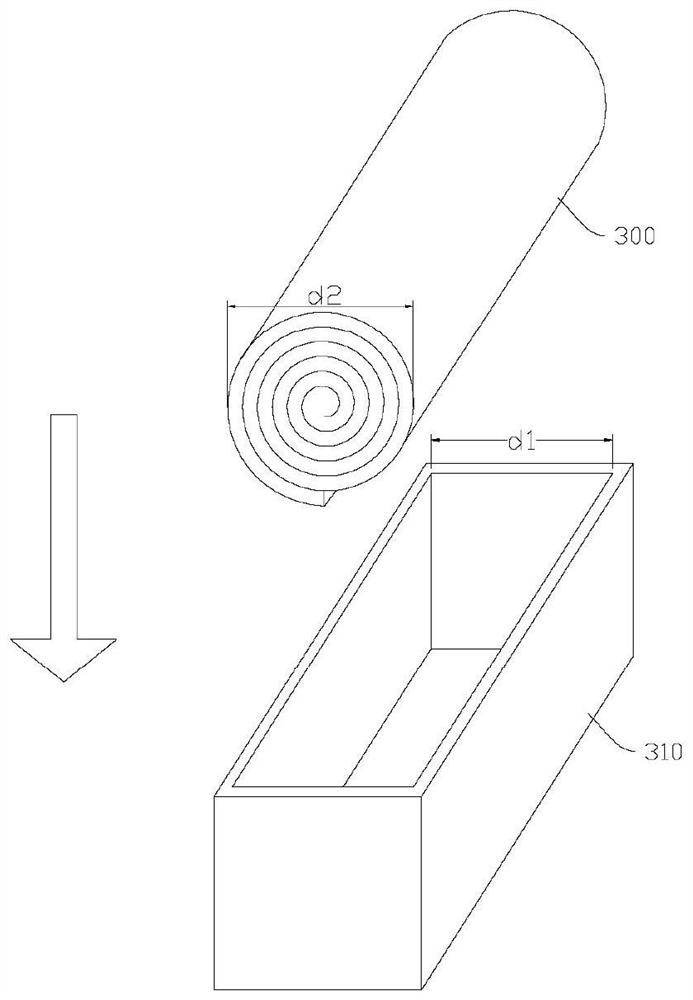

[0042] S4: Form the second compo...

Embodiment 2

[0046] This embodiment provides a heat-conducting composite material. The difference from Embodiment 1 is that 20 parts by mass of hexagonal boron nitride and 60 parts by mass of spherical alumina powder treated with ultrasound and coupling agent KH560 are used as fillers, and 20 parts by mass of spherical alumina powder are used as fillers. Silicone oil in parts by mass is used as a polymer matrix. The preparation method of the heat-conducting composite material is the same as that of Example 1.

Embodiment 3

[0048] This embodiment provides a thermally conductive composite material. The difference from Embodiment 1 is that 20 parts by mass of lamellar graphite and 70 parts by mass of spherical alumina powder chemically grafted with aminopolysiloxane are used as fillers to 10 parts by mass of silicone oil as a polymer matrix. The material preparation steps are the same as in Example 1.

[0049] Comparative Experiment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com