Temperature-resistant pressure-resistant axial self-reinforced plastic pipe special for oil treatment

A self-reinforced plastic and oil treatment technology, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., to achieve good industrialization prospects and economic benefits, high crystallinity, and excellent product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

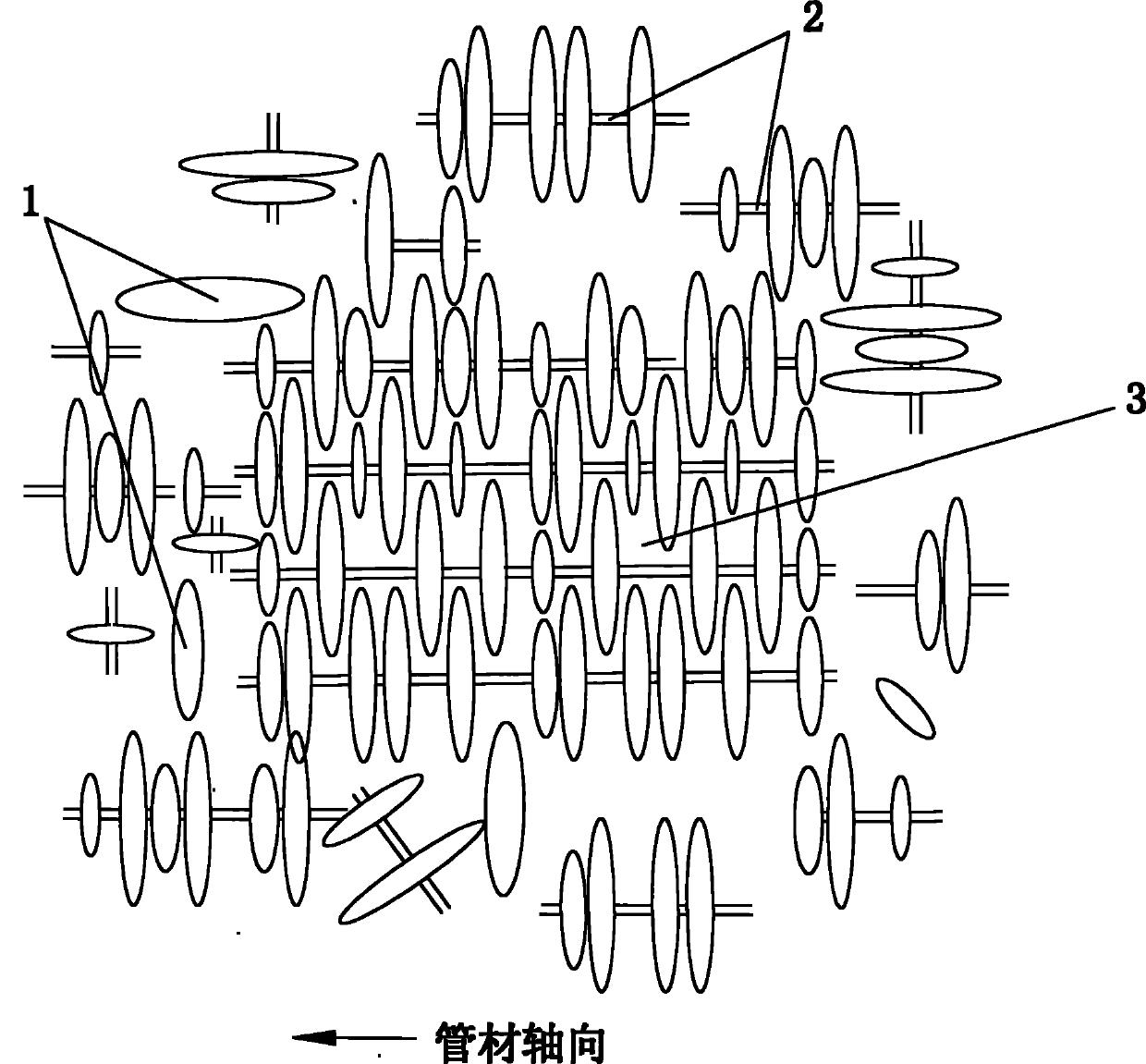

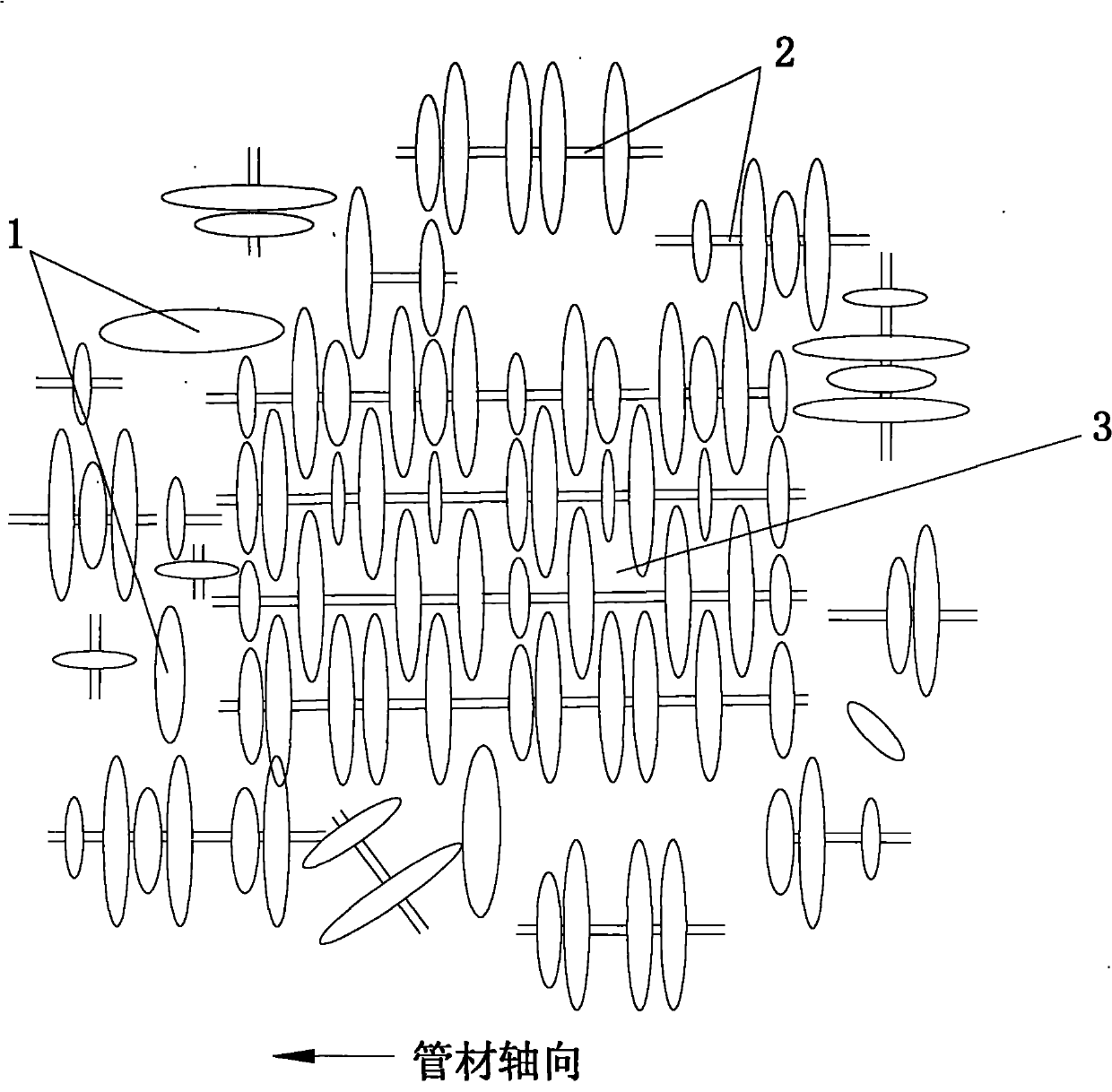

[0009] In the production process of plastic pipes, orderly high-performance condensed state structures of polymers such as macromolecules 1 oriented crystallized in the axial direction of the pipe, oriented crystallized string crystals 2, and oriented crystallized string crystal interlocking structures 3 are obtained. The formation of an ordered structure effectively enhances the axial strength, stiffness, modulus and pressure resistance of the tube; at the same time, these macromolecules 1, oriented crystallized string crystals 2, and oriented crystallized string crystals The ordering behavior of the interlocking structure 3 also improves their crystallinity, and the thickness of the wafer is also thickened, so the heat resistance of the pipe is also improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com