Hot drawing method for aromatic polysulfonamide nascent fibre

A polyarylsulfone amide, spun fiber technology, applied in the direction of drawing spinning, single-component polyamide rayon, single-component copolyamide rayon, etc., can solve the problem of high solvent and water content in fibers, friction The problems such as large force and low ability of the primary fiber to bear the tensile tension, etc., can improve the fiber strength, improve the degree of orientation, and reduce the stretching ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

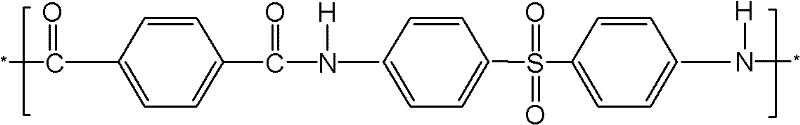

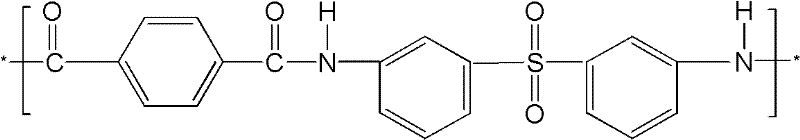

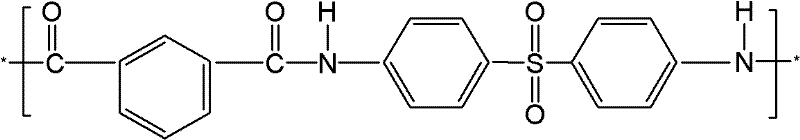

[0035] Mix polyaryl sulfone amide having a weight average molecular weight of 1,000,000 and consisting of units of structural formula (1) with solvent 1-butyl-3-methylimidazolium chloride to obtain a spinning solution with a concentration of 8 wt%.

[0036] The spinning solution is extruded through the spinneret, the extrusion temperature is 105°C, the extrusion speed is 20m / min, the aspect ratio of the spinneret hole is 1.8, passes through a section of 20mm air section, and then enters a solvent and residual solution composed of 60wt%. Measure water and coagulate in a coagulation bath at a temperature of 40° C. to obtain polyarylsulfone amide primary fibers composed of 10 wt % polyarylsulfone amide, 60 wt % solvent 1-butyl-3-yl imidazolium chloride salt and the balance of water.

[0037] The as-spun fiber was stretched 15 times under hot air at a temperature of 80° C., and the strength of the finally obtained polyarylsulfonamide fiber was 3.51 cN / dtex.

Embodiment 2

[0039] Mix the polyarylsulfone amide having a weight average molecular weight of 10000 and consisting of units of the structural formula (3) with the solvent 1-butyl-3-methylimidazolium bromide to obtain a spinning solution with a concentration of 40 wt%.

[0040] The spinning solubility is extruded through the spinneret, the extrusion temperature is 70°C, the extrusion speed is 15m / min, the aspect ratio of the spinneret hole is 1.5, passes through an 80mm air section, and then enters the composition of 10wt% solvent and The remaining amount of water is coagulated and formed in a coagulation bath at a temperature of -10° C. to obtain polyarylsulfonamide primary fibers composed of 50 wt % polyarylsulfone amide, 10 wt % solvent and the remaining amount of water.

[0041] The as-spun fiber was stretched 8 times under hot air at a temperature of 180° C., and the strength of the finally obtained polyarylsulfone amide fiber was 3.55 cN / dtex.

Embodiment 3

[0043] The weight average molecular weight is 50000, the polyaryl sulfone amide that is made up of two kinds of units of structural formula (1) and structural formula (2) (mole ratio is 1:9) and solvent 1-allyl-3-methylimidazolium bromide Mix to obtain a spinning solution with a concentration of 10 wt%.

[0044] The spinning solution is extruded through the spinneret, the extrusion temperature is 90°C, the extrusion speed is 10m / min, the aspect ratio of the spinneret hole is 1.4, passes through a section of 30mm air section, and then enters the composition of 20wt% solvent and residual Measure water, coagulate and form in a coagulation bath at a temperature of 0° C., and obtain polyarylsulfonamide primary fibers composed of 15 wt % polyarylsulfone amide, 20 wt % solvent and the balance of water.

[0045] The as-spun fiber was stretched 10 times under hot air at a temperature of 90°C, and the strength of the finally obtained polyarylsulfonamide fiber was 3.63cN / dtex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com