Dry uniaxial stretching process of lithium-ion battery separator, lithium-ion battery separator and lithium-ion battery

A lithium-ion battery, uniaxial stretching technology, applied in the field of lithium-ion battery separators and lithium-ion batteries, to achieve the effects of uniform pore size distribution, increased strength, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

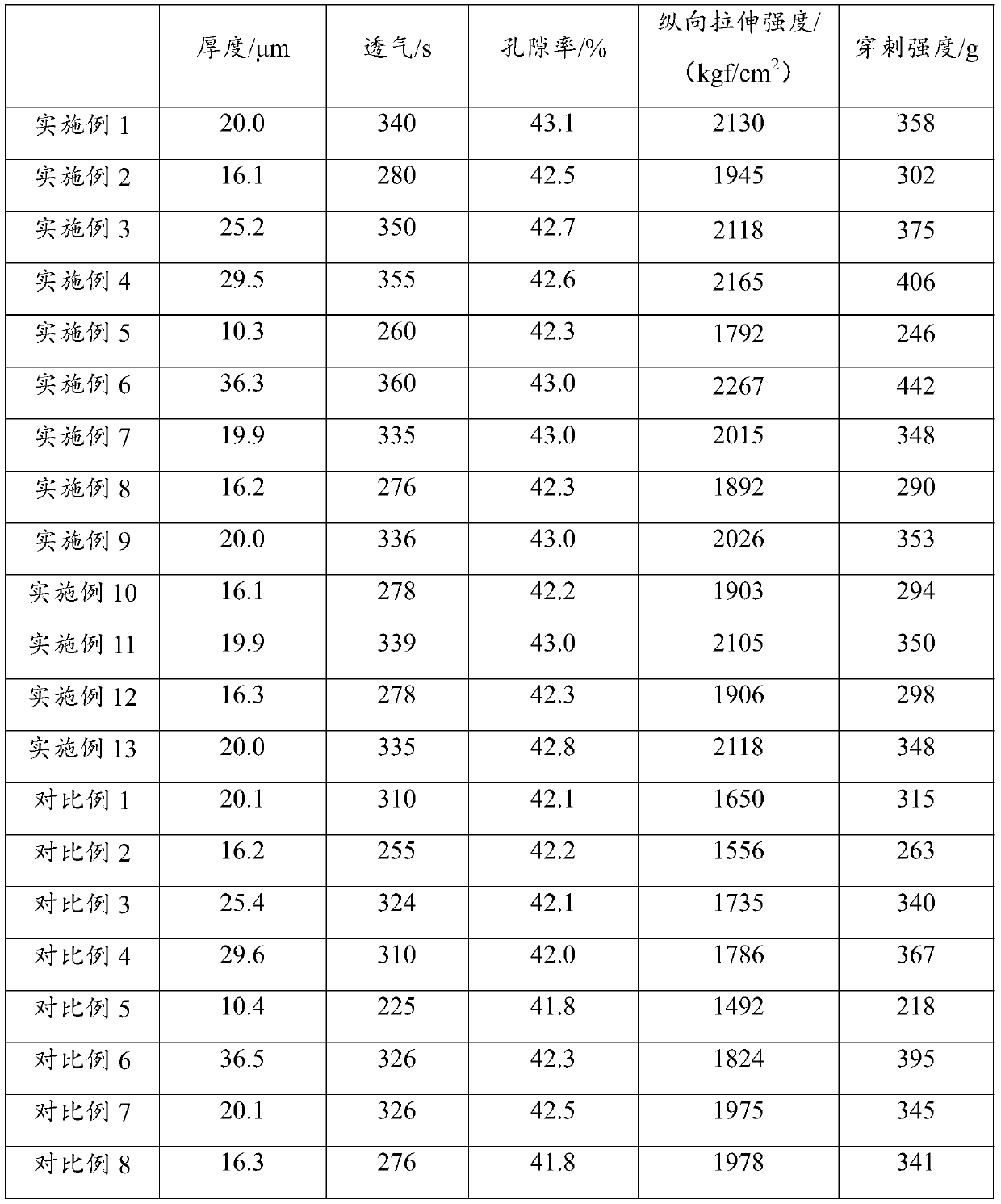

[0052] The preparation process of the traditional dry uniaxially stretched lithium battery separator is extrusion→casting→annealing→stretching. The tensile strength of the obtained uniaxially stretched separator is between 100-160MPa, and the puncture strength of the 16-20μm thick separator is In 263 ~ 315g. The present invention adopts the staged stretching method, pre-stretching before annealing and then conventional stretching, and pre-stretching at a pre-stretching ratio of 1.1 to 1.5 times and a pre-stretching temperature of 100-150°C The degree of orientation of the molecular chain is enhanced, so that the tensile strength and puncture strength of the separator are significantly improved after subsequent stretching, while other performance indicators of the separator remain at a good level. The pore size distribution of the lithium-ion battery separator obtained by the dry uniaxial stretching process of the present invention is uniform, the tensile strength is increased ...

Embodiment 1

[0118] A dry uniaxial stretching process for a lithium-ion battery diaphragm, comprising the following steps:

[0119] The polypropylene particles are plasticized by a 230°C extruder to form a polypropylene melt, and then extruded from a 210°C die, cast into a 23.8μm sheet polypropylene base film by a 70°C quenching roll, and harvested into a roll; The base film is pre-stretched at 130°C with a ratio of 1.3 and harvested into rolls; the rolled base film is pushed into an oven for heat treatment at 145°C for 8 hours; the heat-treated polyolefin base film is subjected to a single Lithium battery microporous separator can be obtained after stretching.

Embodiment 2

[0121] A dry uniaxial stretching process for a lithium-ion battery diaphragm, comprising the following steps:

[0122] The polypropylene particles are plasticized by a 228°C extruder to form a polypropylene melt, and then extruded from a 208°C die, cast into a 18.8μm sheet polypropylene base film by a 60°C quenching roll, and harvested into a roll; The base film is pre-stretched at 120°C with a ratio of 1.2 and harvested into a roll; the rolled base film is pushed into an oven for heat treatment at 140°C for 10 hours; the heat-treated polyolefin base film is subjected to a single Lithium battery microporous separator can be obtained after stretching.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com