Pre-oxidation method for carbon fiber precursor polyacrylnitrile fiber

A technology of polyacrylonitrile fiber and precursor, applied in the direction of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of not better improving the orientation of molecular chains along the fiber axis, unfavorable cyclization process, etc., to achieve enhanced tensile strength , Improve fiber reactivity, improve the effect of orientation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

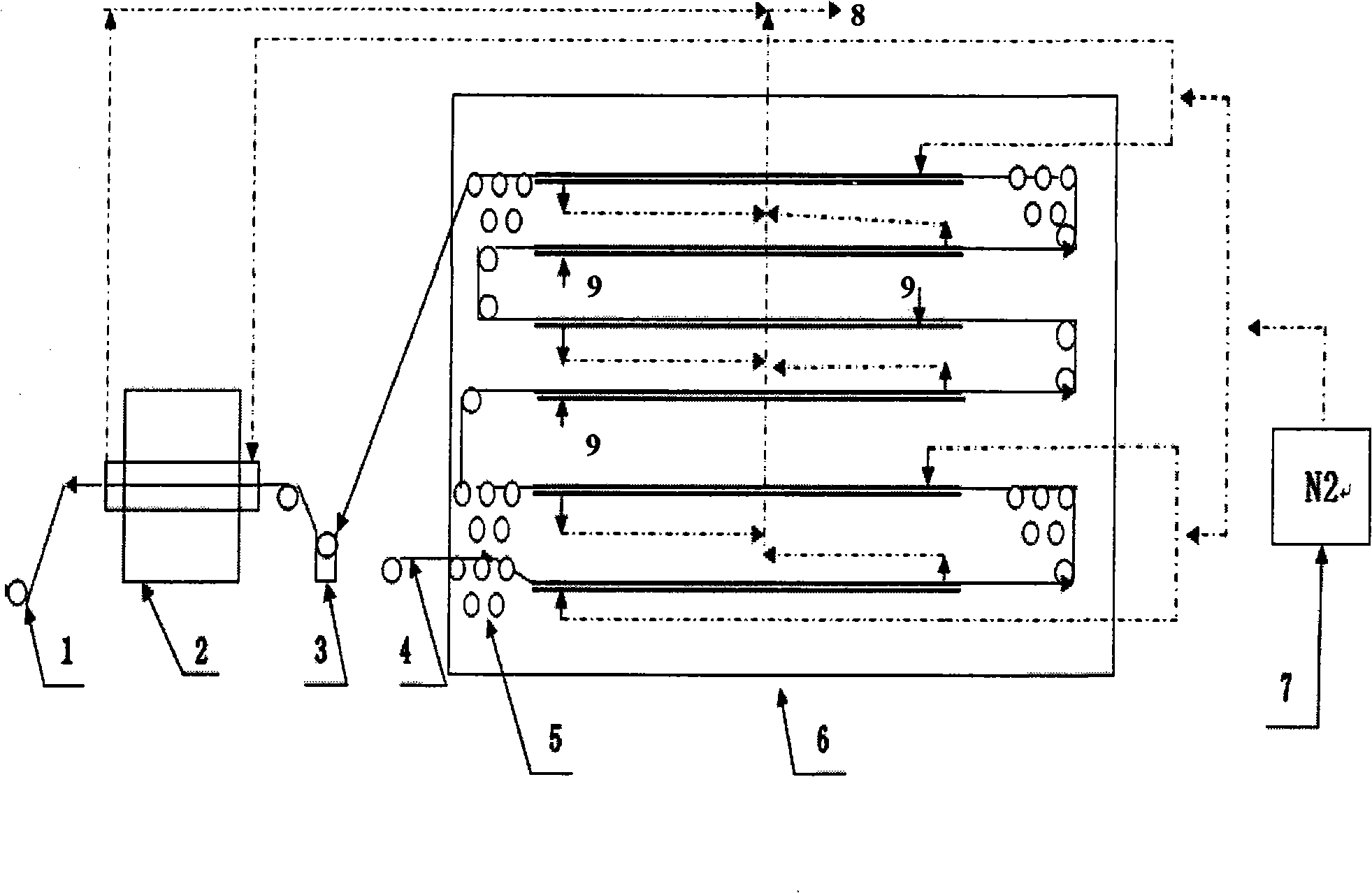

[0024] The polyacrylonitrile fiber precursors are pre-oxidized successively through five temperature sections in the continuous pre-oxidation-low temperature carbonization furnace under normal pressure conditions:

[0025] The first and second temperature sections are the cyclization process, nitrogen gas 7 is introduced, the time is controlled at 40 minutes, the temperature of the first temperature section is 180°C, the temperature of the second temperature section is 230°C, and -5% is added in the second temperature section rigid draft;

[0026] The third, fourth, and fifth temperature sections are oxidative cross-linking processes, the air 9 is introduced, and the time is controlled at 60 minutes. The temperatures of the third, fourth, and fifth temperature sections are respectively 230°C, 250°C, and 280°C;

[0027] The sixth temperature section is the low-temperature carbonization process. Nitrogen gas 7 is passed through. There are four temperature zones, the temperatures...

Embodiment 2

[0031] The polyacrylonitrile fiber precursors are pre-oxidized successively through five temperature sections in the continuous pre-oxidation-low temperature carbonization furnace under normal pressure conditions:

[0032] The first and second temperature sections are the cyclization process, nitrogen gas is introduced, and the time is controlled at 80 minutes. The temperature in the first temperature section is 150°C, and the temperature in the second temperature section is 180°C. stretch;

[0033] The third, fourth, and fifth temperature sections are oxidative cross-linking processes. Air is introduced, and the time is controlled at 120 minutes. The temperatures of the third, fourth, and fifth temperature sections are 180°C, 230°C, and 250°C respectively;

[0034] The sixth temperature section is a low-temperature carbonization process. Nitrogen gas is introduced. There are four temperature zones. The temperatures are 400°C, 530°C, 660°C, and 800°C, and the time is controlle...

Embodiment 3

[0038] The polyacrylonitrile fiber precursors are pre-oxidized successively through five temperature sections in the continuous pre-oxidation-low temperature carbonization furnace under normal pressure conditions:

[0039] The first and second temperature sections are the cyclization process. Nitrogen gas is introduced and the time is controlled at 60 minutes. The temperature in the first temperature section is 170°C, and the temperature in the second temperature section is 210°C. stretch;

[0040] The third, fourth, and fifth temperature sections are oxidative crosslinking processes, and the air is introduced, and the time is controlled at 90 minutes. The temperatures of the third, fourth, and fifth temperature sections are 210°C, 240°C, and 270°C respectively;

[0041] The sixth temperature section is the low-temperature carbonization process. Nitrogen gas is introduced. There are four temperature zones. The temperatures are 400°C, 530°C, 660°C, and 800°C, and the time is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com