Heat-conducting graphite membrane and preparation method

A heat-conducting graphite film, graphene micro-sheet technology, applied in graphene, nano-carbon and other directions, can solve problems such as uneven distribution of film, plane thermal conductivity of graphite film needs to be further improved, etc. Good thermal diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

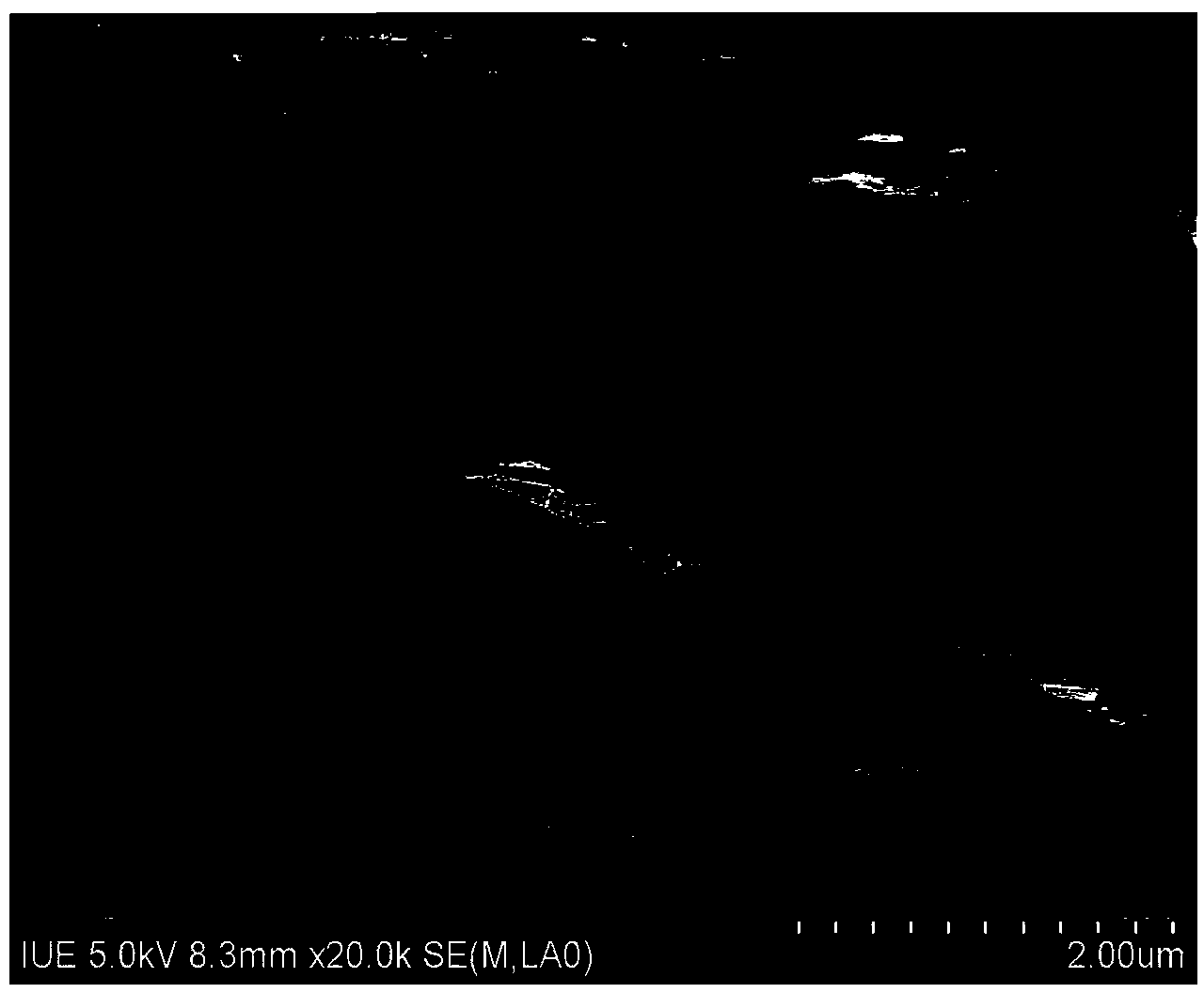

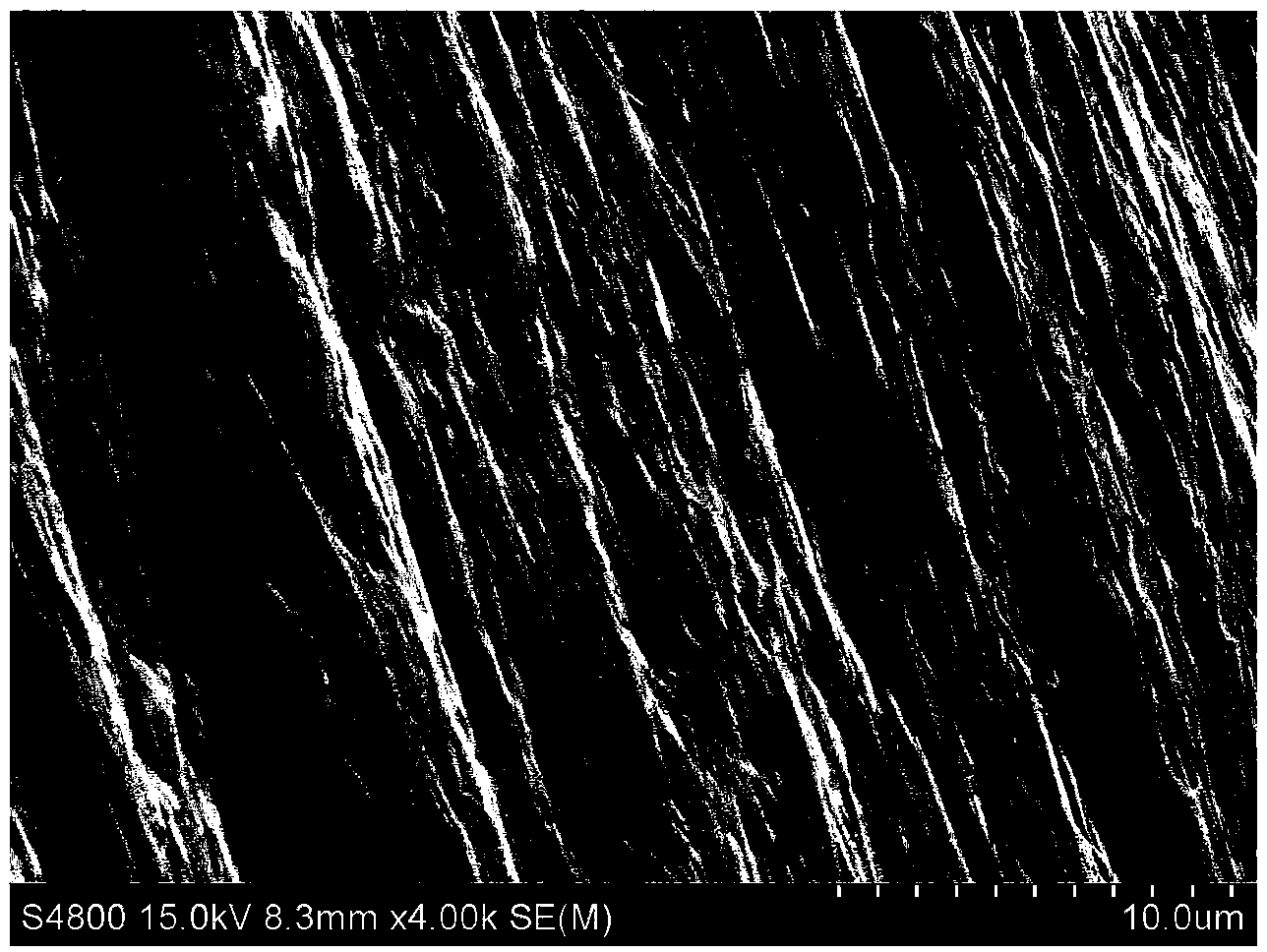

Image

Examples

Embodiment 1

[0028] Take graphene microchip 5kg, join in high-speed mixer, be 99.7:0.3 ratio according to graphene microchip and sodium silicate weight percentage, adopt the method for spraying while stirring to add sodium silicate water glass solution to graphene microchip The sheet is wetted, mixed and stirred evenly, and the mixed and wetted material is added to the rolling equipment and rolled into a film.

[0029] By adjusting the parameters such as feeding speed, roll pressure, and roll pitch, a thermally conductive graphite film with a thickness of 0.01mm can be obtained, and then the calendered thermally conductive graphite film is dried at high temperature.

[0030] The thermal conductivity was tested by laser method. The thermal conductivity of the thermal graphite film in the plane is 1500W / mk, and the thermal conductivity in the thickness direction is 30W / mk.

Embodiment 2

[0032] Take graphene microchip 5kg, join in high-speed mixer, be 99.5:0.5 ratio according to graphene microchip and sodium silicate weight percentage, adopt the method for spraying while stirring to add sodium silicate water glass solution to graphene microchip The sheet is wetted, mixed and stirred evenly, and the mixed and wetted material is added to the rolling equipment and rolled into a film.

[0033] By adjusting parameters such as feeding speed, roll pressure, and roll pitch, a thermally conductive graphite film with a thickness of 0.03mm can be obtained, and then the calendered thermally conductive graphite film is dried at high temperature.

[0034] The thermal conductivity was tested by laser method. The thermal conductivity of the thermal graphite film in the plane is 1470W / mk, and the thermal conductivity in the thickness direction is 29W / mk.

Embodiment 3

[0036] Get Graphene microchip 5kg, join in high-speed mixer, be 99:1 ratio according to Graphene microchip and aluminum phosphate weight percentage, adopt the method for spraying while stirring to add aluminum phosphate aqueous solution and graphene microchip is wetted, And mix and stir evenly, put the mixed and wetted material into the rolling equipment and roll it into a film shape.

[0037] By adjusting parameters such as feeding speed, roll pressure, and roll distance, a thermally conductive graphite film with a thickness of 0.05mm can be obtained, and then the calendered thermally conductive graphite film is dried at high temperature.

[0038] The thermal conductivity was tested by laser method. The thermal conductivity of the thermal graphite film in the plane is 1480W / mk, and the thermal conductivity in the thickness direction is 26W / mk.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com