Patents

Literature

39results about How to "Overcome fragile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of reduction graphene oxide heat-conducting film

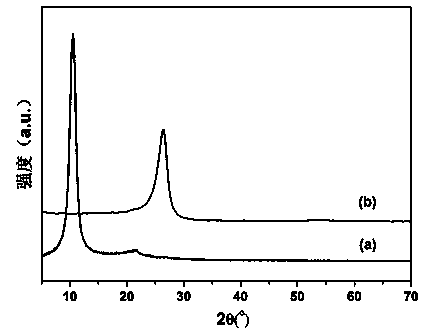

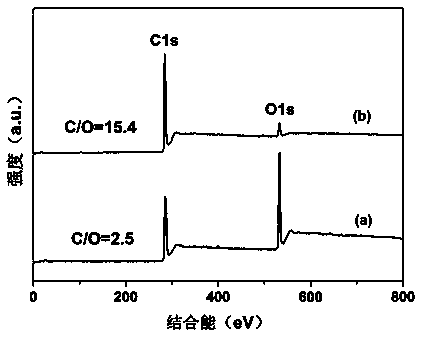

InactiveCN104030275AHigh thermal conductivityOvercome fragileGraphenePhysical chemistryThin membrane

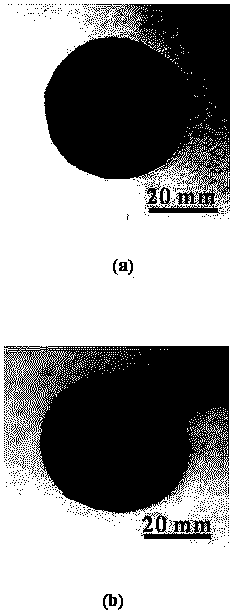

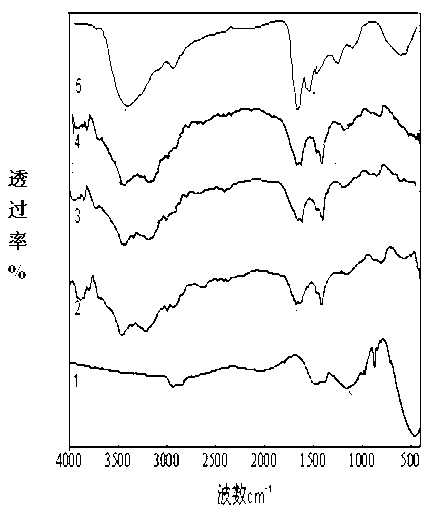

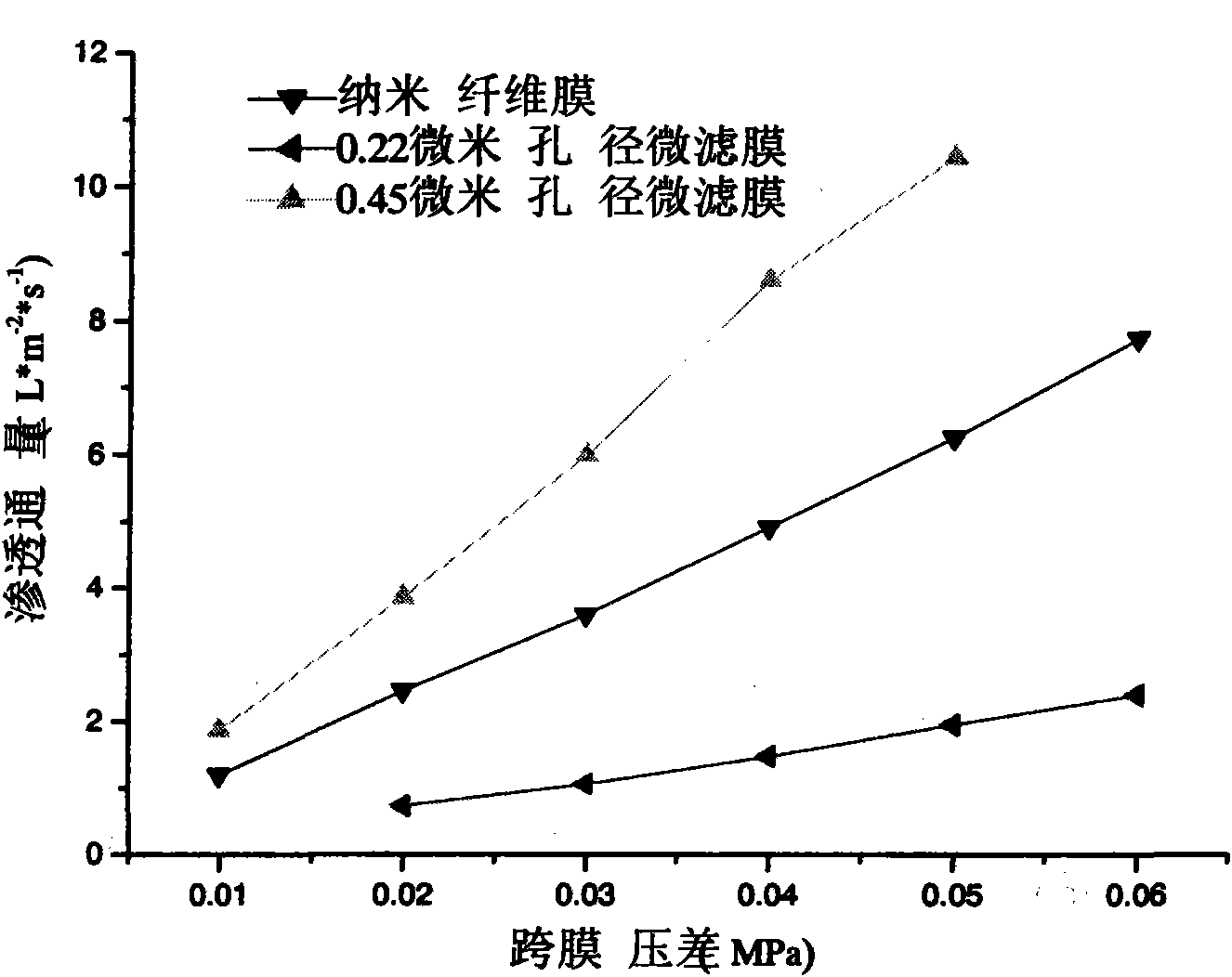

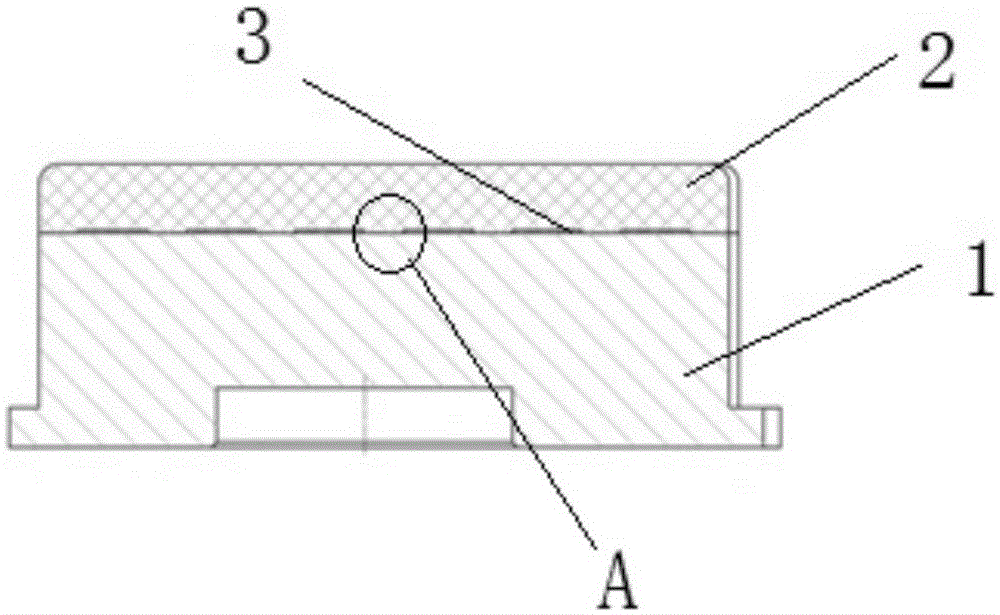

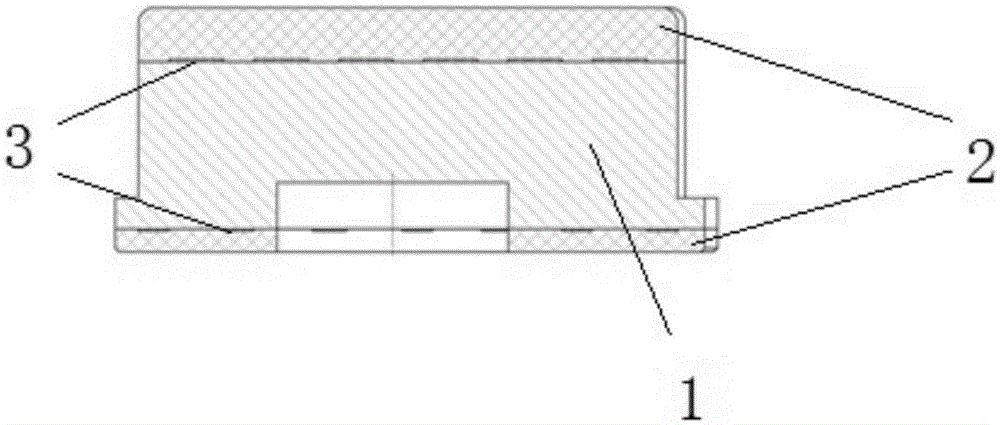

The invention relates to a preparation method of a reduction graphene oxide heat-conducting film. The preparation method comprises the following steps of: firstly weighing graphite oxide, adding the graphite oxide to deionized water, and carrying out ultrasonography, centrifugalizing at low speed for impurity removal, drying and grinding to obtain graphene oxide; dissolving the graphene oxide into a solvent, and carrying out the ultrasonography to prepare a graphene oxide dispersion solution; carrying out vacuum filtration on the graphene oxide dispersion solution by adopting a microporous filtering film, drying an obtained filter cake and the filtering film together, and then stripping the filter cake from the filtering film to obtain a graphene oxide film; acquiring the reduction graphene oxide heat-conducting film by adopting a high-temperature heat treatment or hydriodic acid reduction method in a restricted space. The preparation method disclosed by the invention effectively solves the technical problems of easiness for breakage and difficulty in large-area integrity keeping in preparing the reduction graphene oxide heat-conducting film from the graphene oxide film and is simple and higher in film heat conductivity; the prepared reduction graphene oxide heat-conducting film achieves potential practical application value in the field of heat radiation of a microelectronic device.

Owner:SHANGHAI INST OF TECH

Vegetable gum based on modified starch, preparation method thereof and application of vegetable gum

The invention discloses vegetable gum based on modified starch. The vegetable gum is prepared from the following raw materials in parts by weight, 40-90 parts of modified starch, 3-30 parts of gelatinizing agents, 2-20 parts of plasticizers, 2-20 parts of polymer, 2-20 parts of plant fibers, 10-50 parts of deionized water and 1-15 parts of cross-linking agents. The raw materials are mixed and subjected to reaction at the temperature ranging from 20 DEG C to 120 DEG C for 10-200 minutes, and the vegetable gum is prepared by kneading, extruding and cutting procedures. The starch and the polymer or macro-molecules are compounded and mixed or grafted and copolymerized, the vegetable gum overcomes the shortcomings of poor plasticity, low tensile strength and frangibility of original starch and difficulty in degradation and non-renewable performance of the macro-molecules, the vegetable gum is degradable, renewable, low in cost, good in plasticity, stable on heat and resistant to aging, and a preparation method of the vegetable gum controls extrusion temperature, screw rotation speed, cutter rotation speed and granule cooling, so that granules cannot be adhered and are uniform in size and good in plasticity. The vegetable gum is applied to related products such as degradable plastics, capsules and food and drug packing materials.

Owner:安顺济世科技有限公司

Material of non-woven fabric surface heavy nitrogen coupling gelatin adsorbing material and preparation method thereof

InactiveCN103263898AEasy to captureImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionPolymer scienceTannin

The invention discloses a non-woven fabric surface heavy nitrogen coupling gelatin adsorbing material and a preparation method thereof. The method comprises the following steps of: grafting an unsaturated monomer with carboxy to the surface of a macromolecule non-woven fabric base material by using an ultraviolet induction technique so as to introduce the carboxy; furthermore introducing aromatic amine through catalytic condensation of aroma diamine and carboxy; subsequently, converting the aromatic amine into diazo salt; coupling and immobilizing the gelatin on the surface of the non-woven fabric through diazo coupling reaction; and finally, soaking in hot water and eliminating the uncoupled gelatin so as to prepare the non-woven fabric surface diazo coupling gelatin absorbing material. The absorbing material is good in hydrophilicity, namely, the water absorption rate is greater than 292.3%; the solid load and the absorption rate of the gelatin can be adjusted in a large range, the absorbing material has high absorption capability for tannin; and when the tannin concentration is 200-400mg / L, the balance absorption capacity is within 16.8-53.2mg / g, and the absorption balance can be achieved within 3 hours.

Owner:KUNMING UNIV OF SCI & TECH

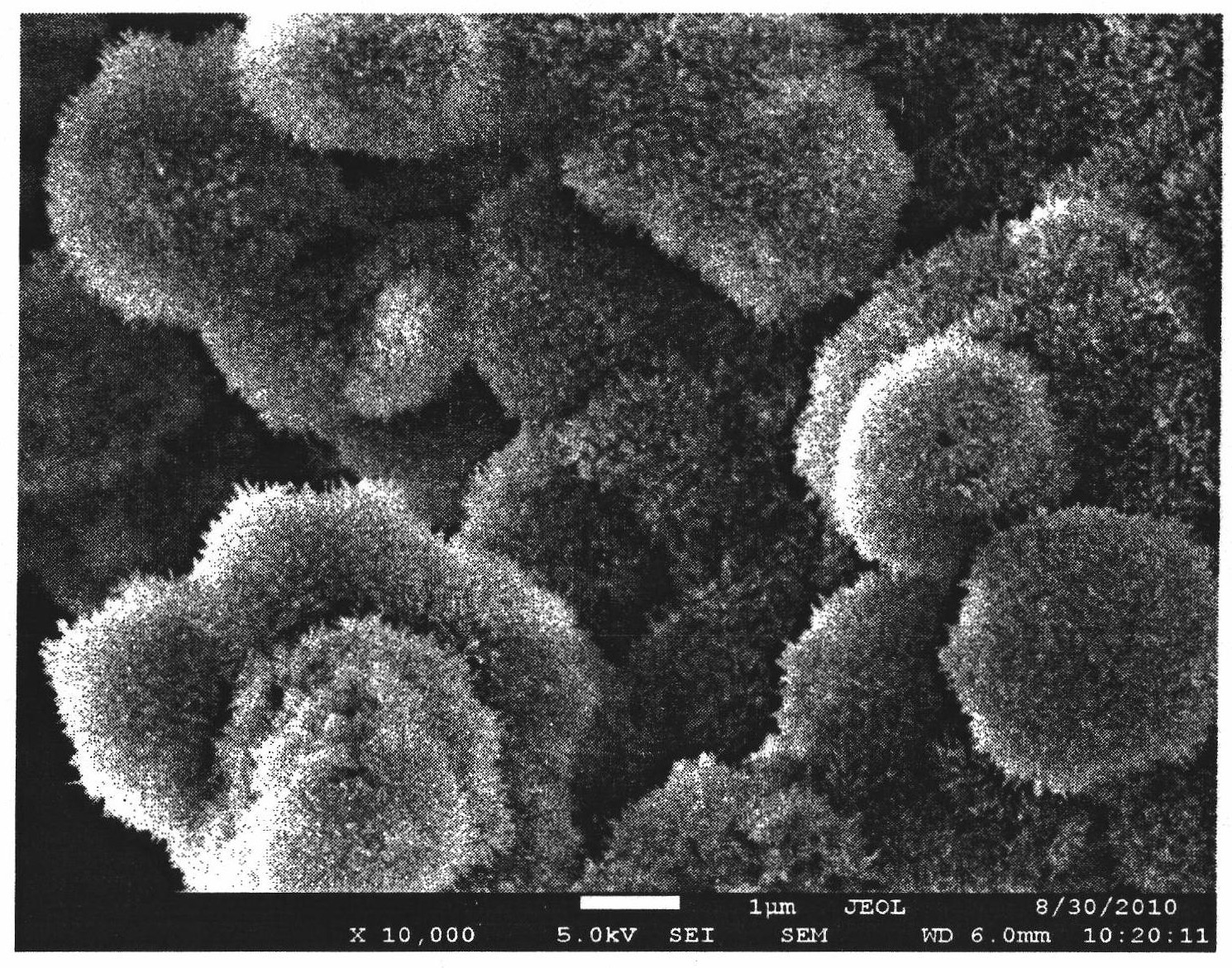

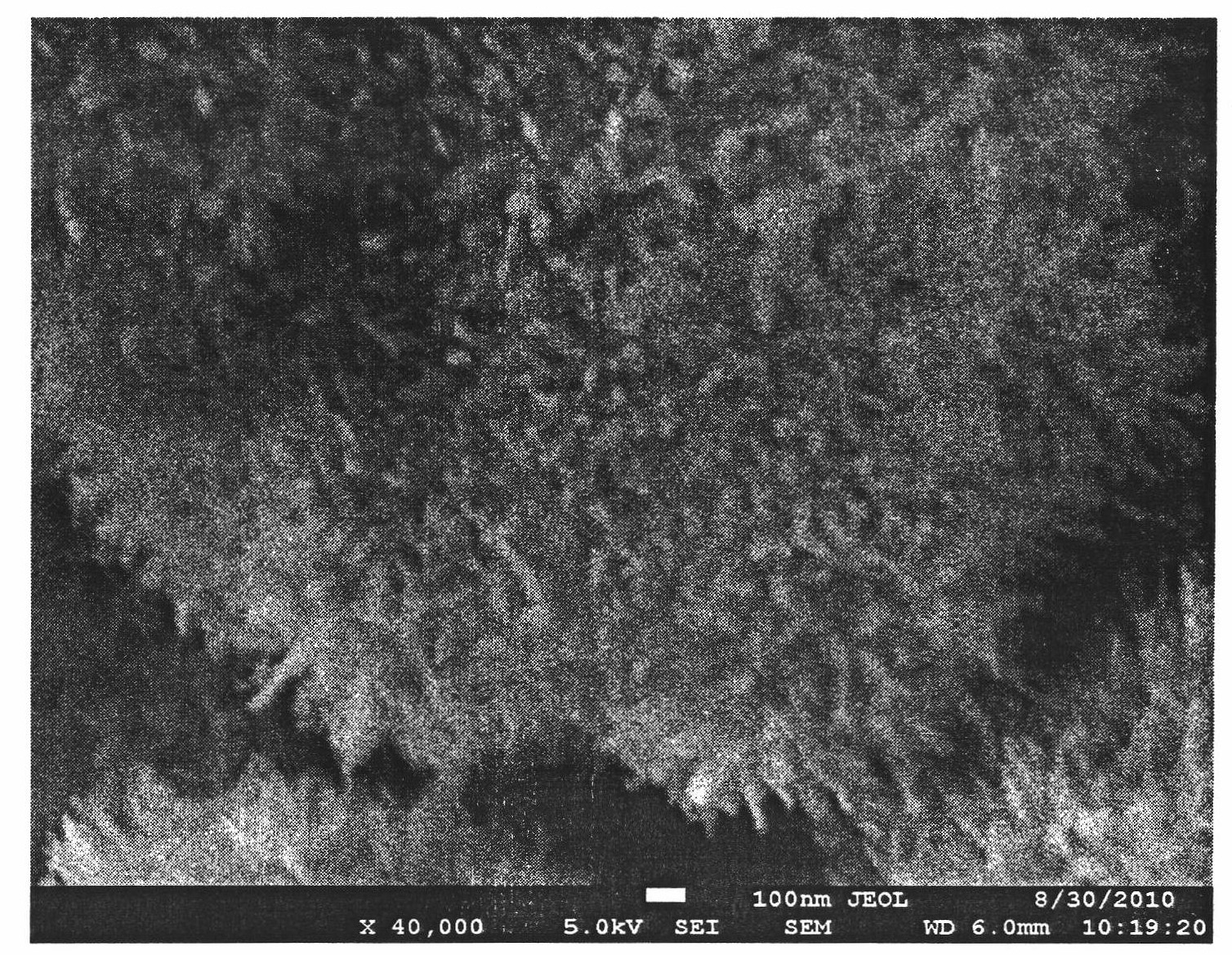

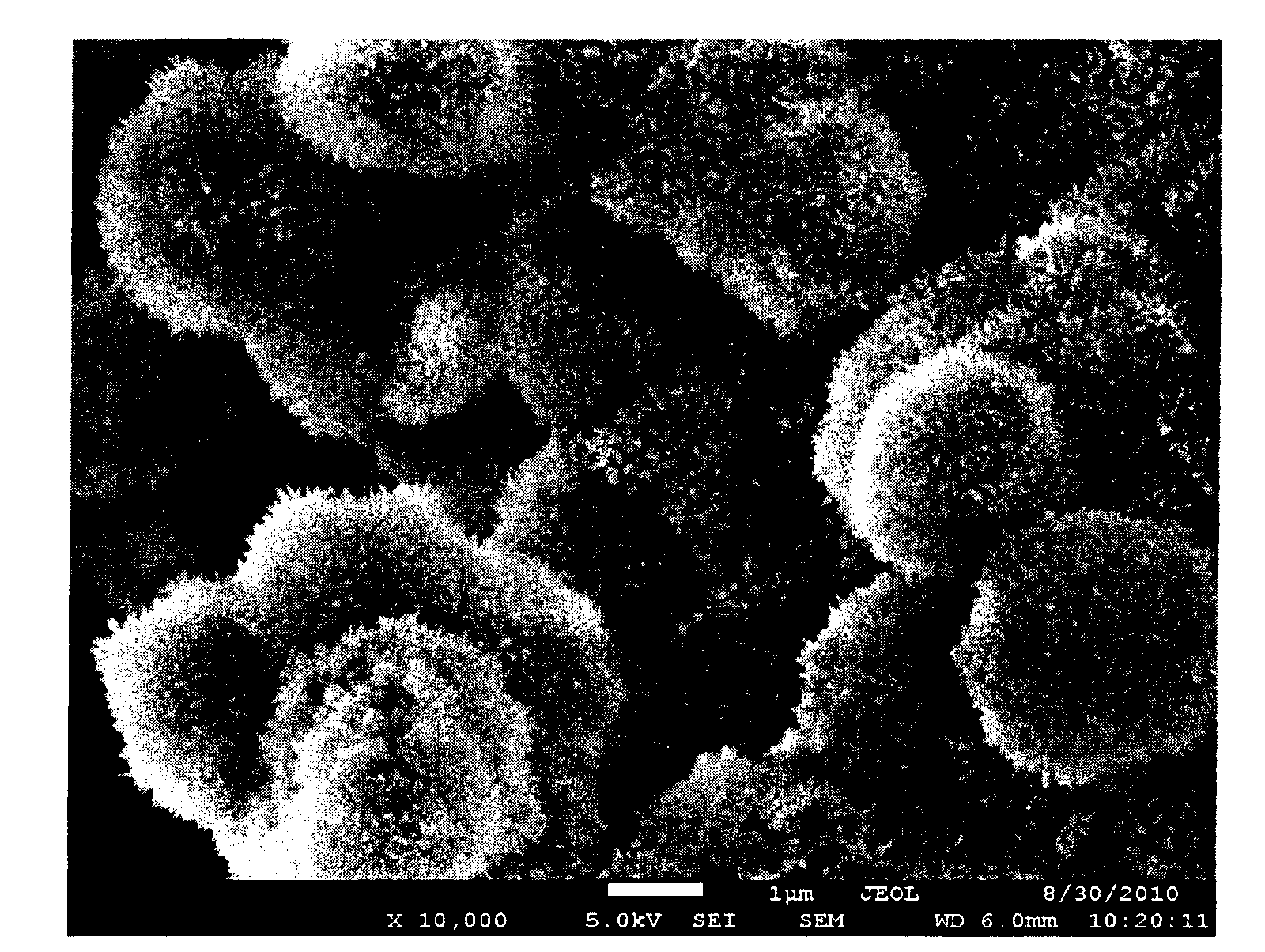

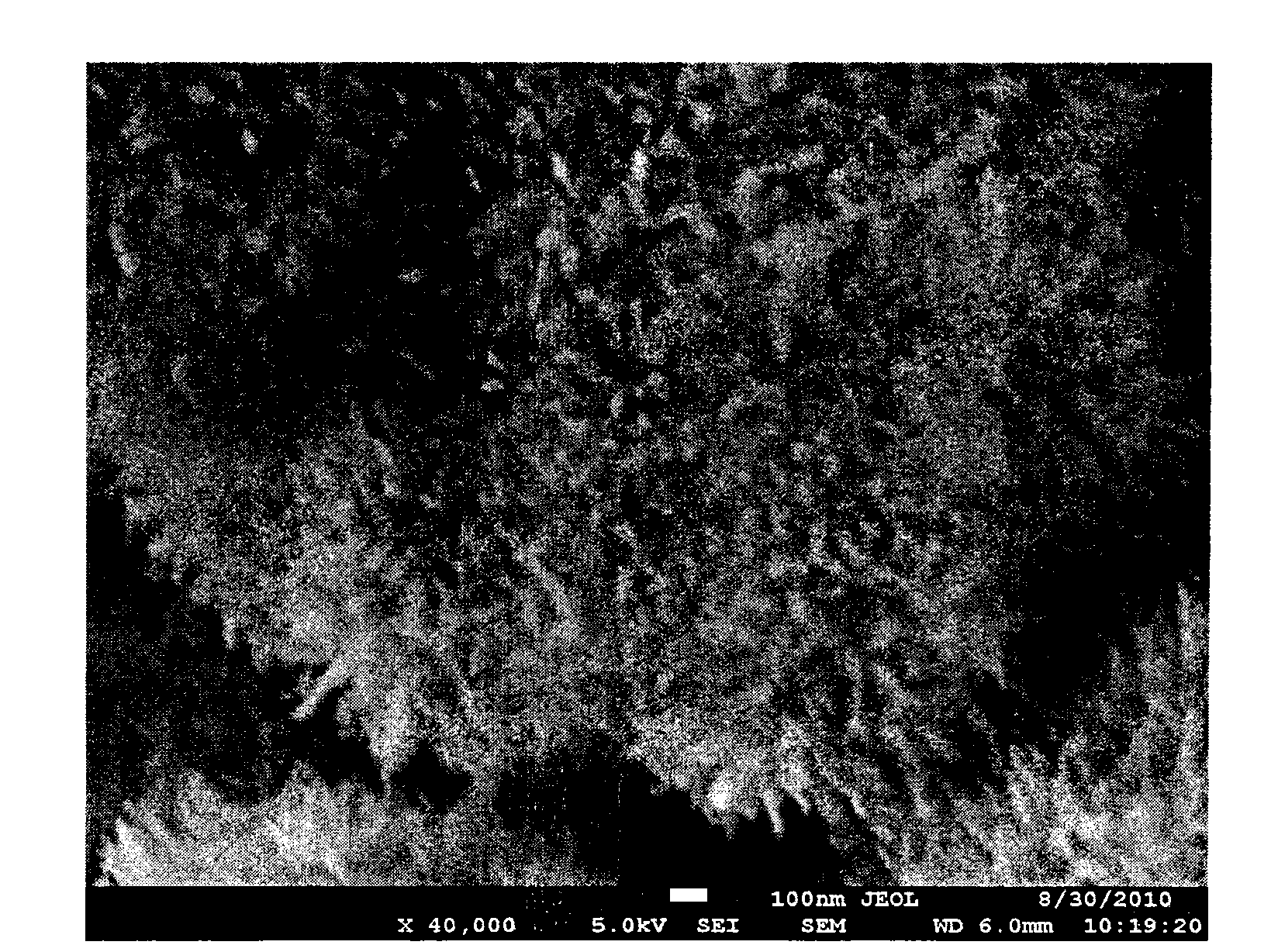

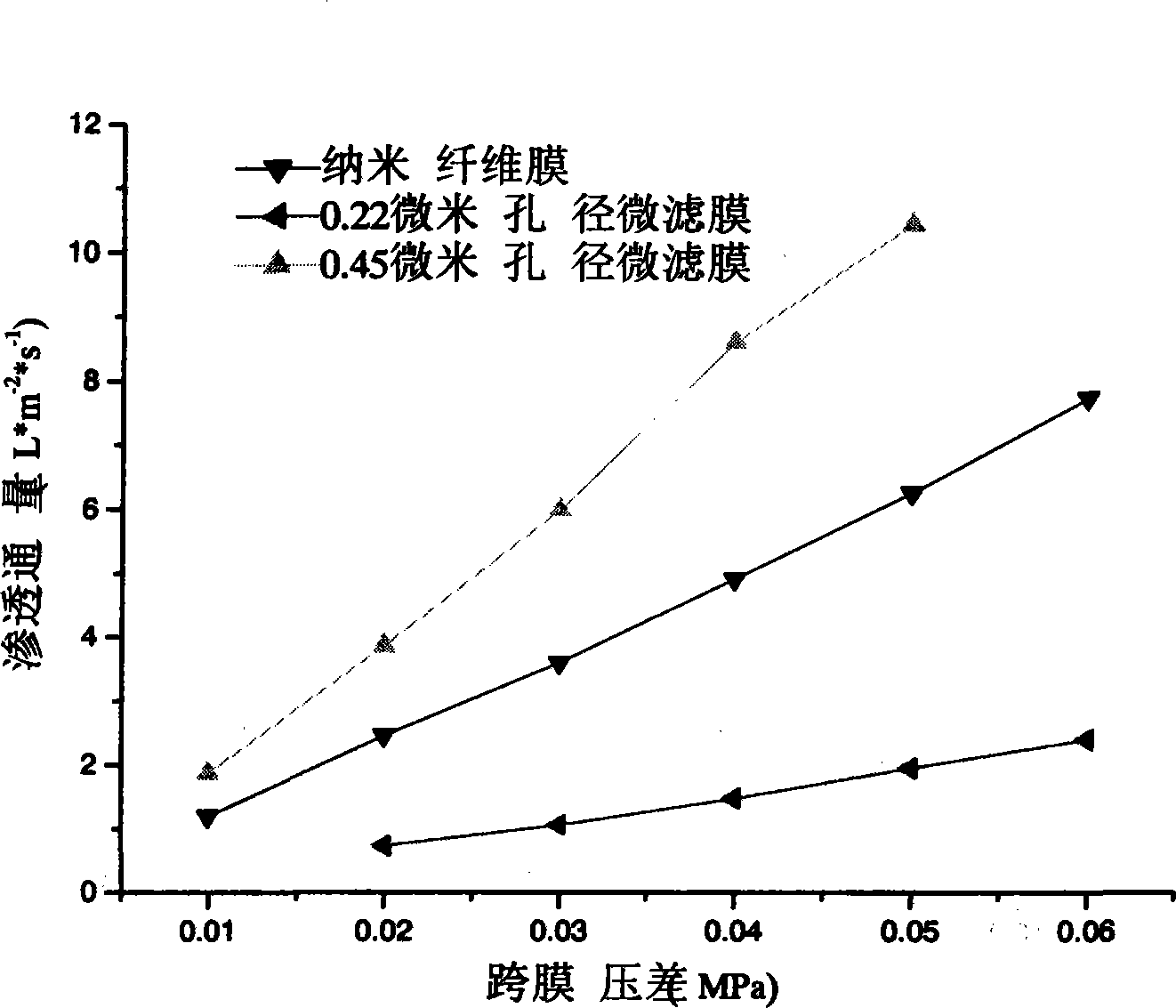

Preparation method for positively charged three-dimensional nanofibre membrane

The invention relates to a preparation method for a positively charged three-dimensional nanofiber membrane. The preparation method comprises the following steps of: 1, preparing a meshed ceramic fiber framework; 2, synthesizing a rodlike or sheet-type nanoparticle on the surface of the framework obtained in the step 1 by a hydrothermal method or a steam-thermal method; and 3, obtaining a needlelike nanofiber on the nanoparticle by a soft template precipitation method. By a wet chemical method, the flexible meshed ceramic fiber framework which is capable of automatic adhesion to form a membrane and has small elastic modulus is synthesized, and a three-dimensional nano charged gamma-Al2O3 fiber is self-assembled and synthesized in situ on the surface of the framework, so a branch shaped three-dimensional structure extends from the surface of the framework, and an inorganic charged fiber membrane which can be used at high temperature and has large specific surface area and high charged electric quantity is prepared.

Owner:BEIJING KANGJIE ZHICHEN WATER TREATMENT

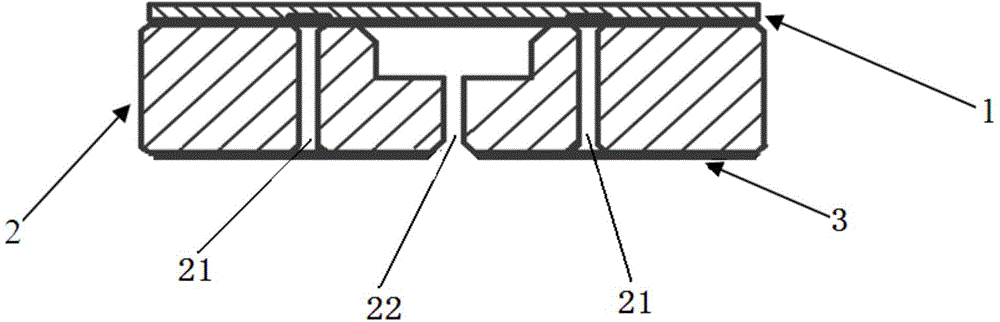

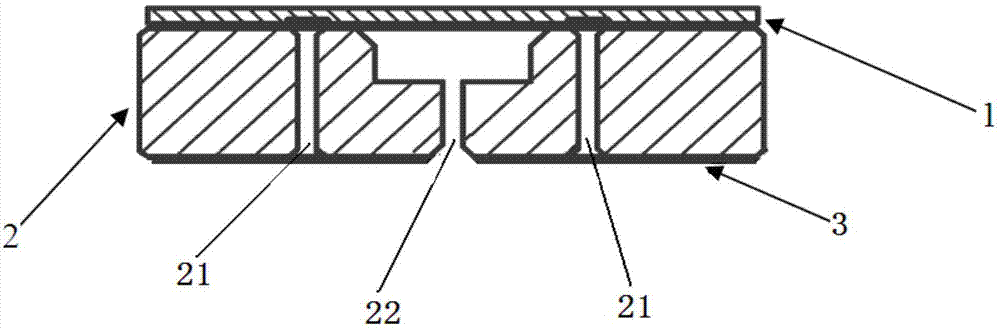

Water lubrication composite thrust bearing of nuclear main pump

ActiveCN105020267AGood impact resistance and complianceOvercome fragilePump componentsPumpsLubricationThermoplastic

The invention discloses a water lubrication composite thrust bearing of a nuclear main pump. The water lubrication composite thrust bearing comprises a stainless steel tile base and an engineering plastic layer. The stainless steel tile base is provided with a concave-convex face connected with the engineering plastic layer. The concave-convex face and the engineering plastic layer are compositely molded through thermoplastic mould pressing. The specific value of the area of the concave-convex face to the area of the orthographic projection of the concave-convex face on the stainless steel tile base ranges from 1.2 to 2. The concave-convex face and the engineering plastic layer are combined through a concave face and a convex face of the concave-convex face and the specific bonding property obtained after fusion of a rough face and the engineering plastic layer, and the composite thrust bearing capable of being physically connected into a whole is formed. Respective advantages of metal and nonmetal can be brought into play, so that the thickness of the engineering plastic layer can be greatly reduced, and the bearing capability is improved; the size of the bearing still has good stability under the effect of pressure and temperature during running; a stable safety lubrication water film can be easily built; and the water lubrication composite thrust bearing is a novel water lubrication composite thrust bearing resistant to nuclear radiation, safe and reliable.

Owner:DALIAN SANHUAN COMPOSITE MATERIAL TECH DEV

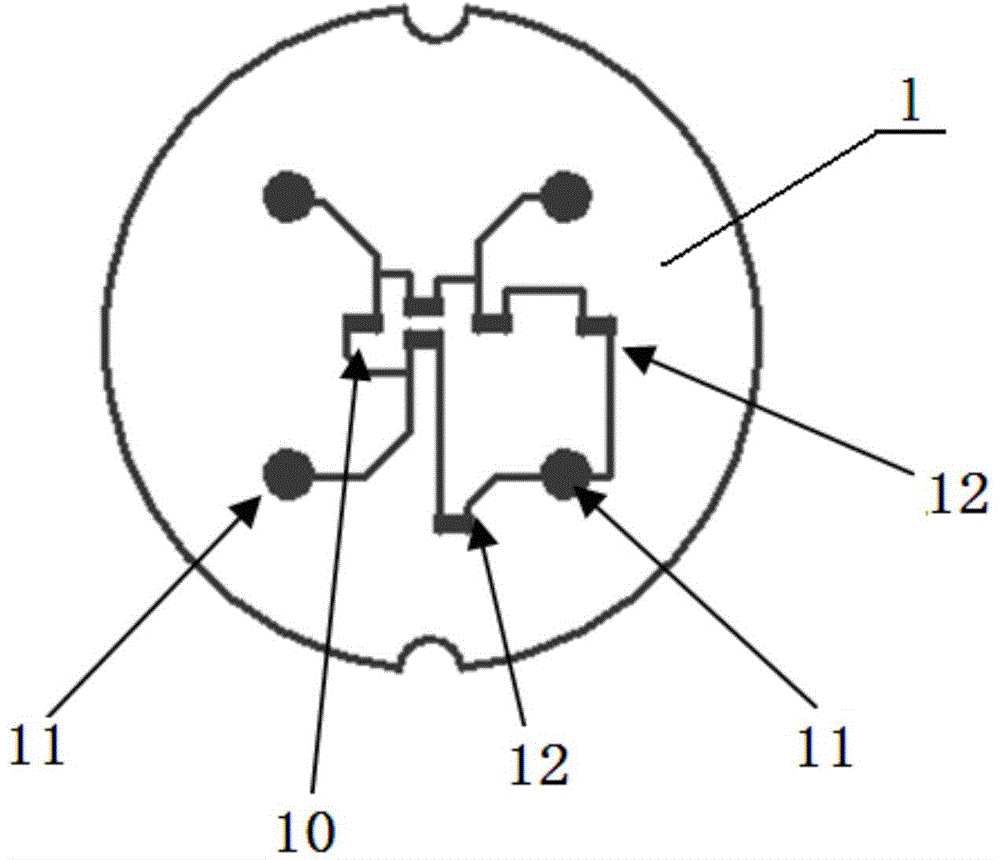

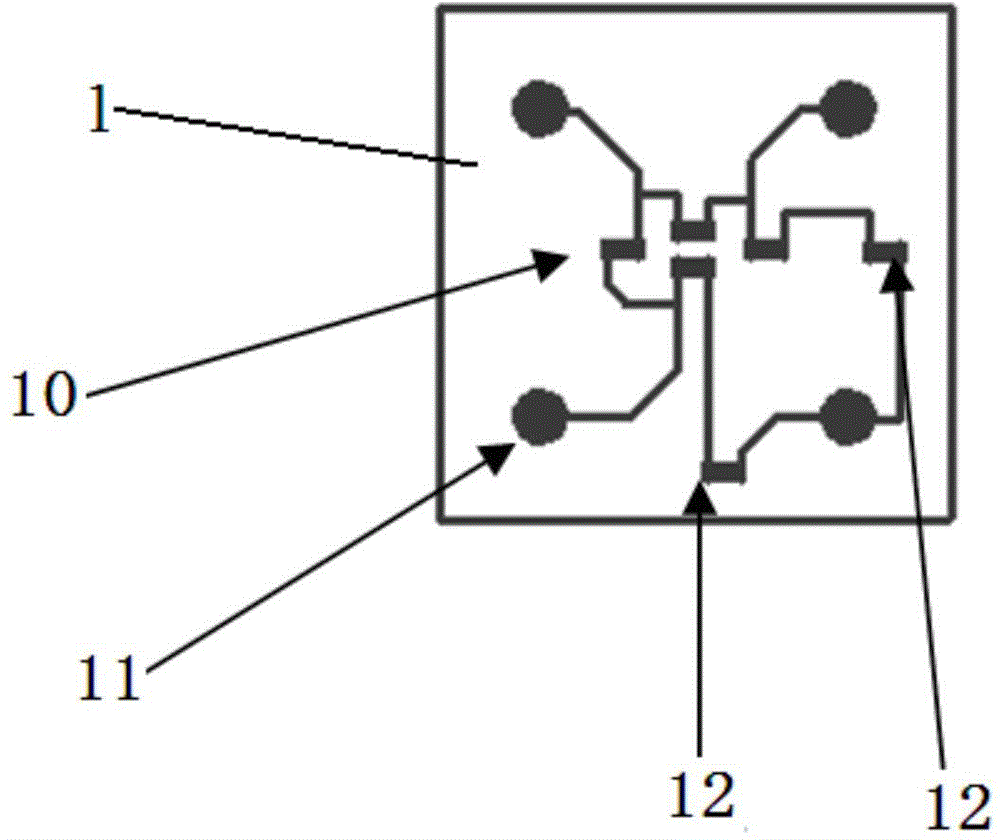

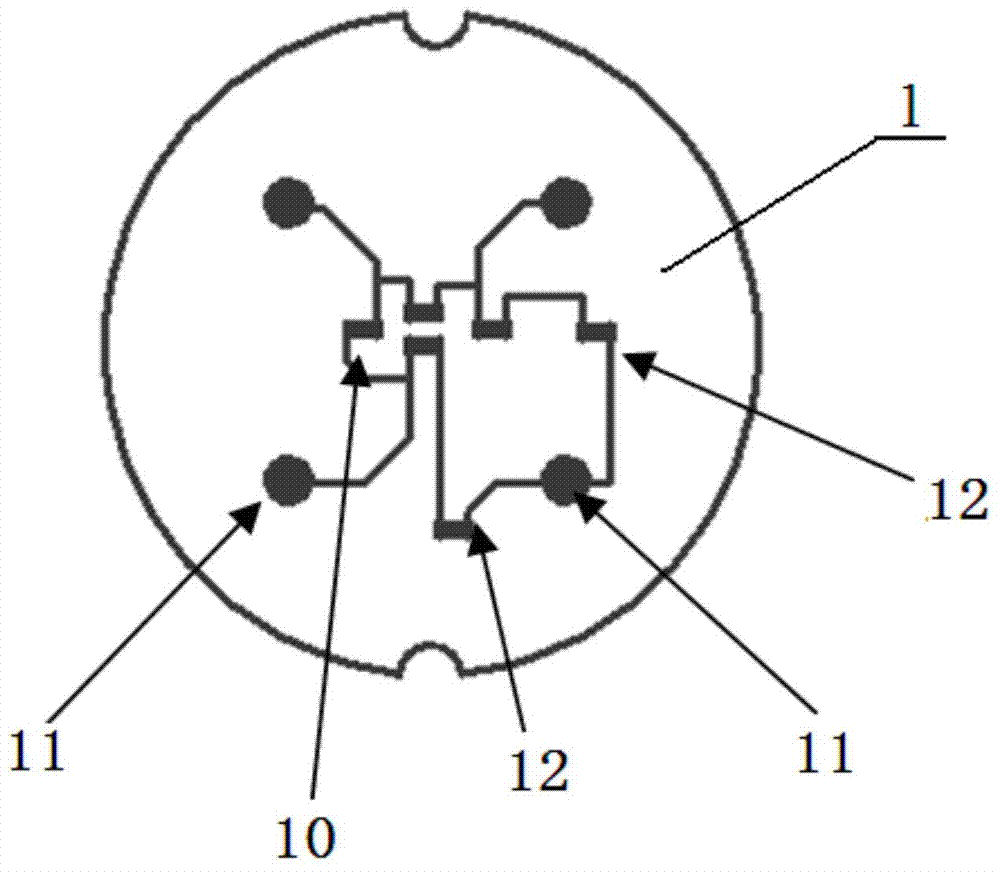

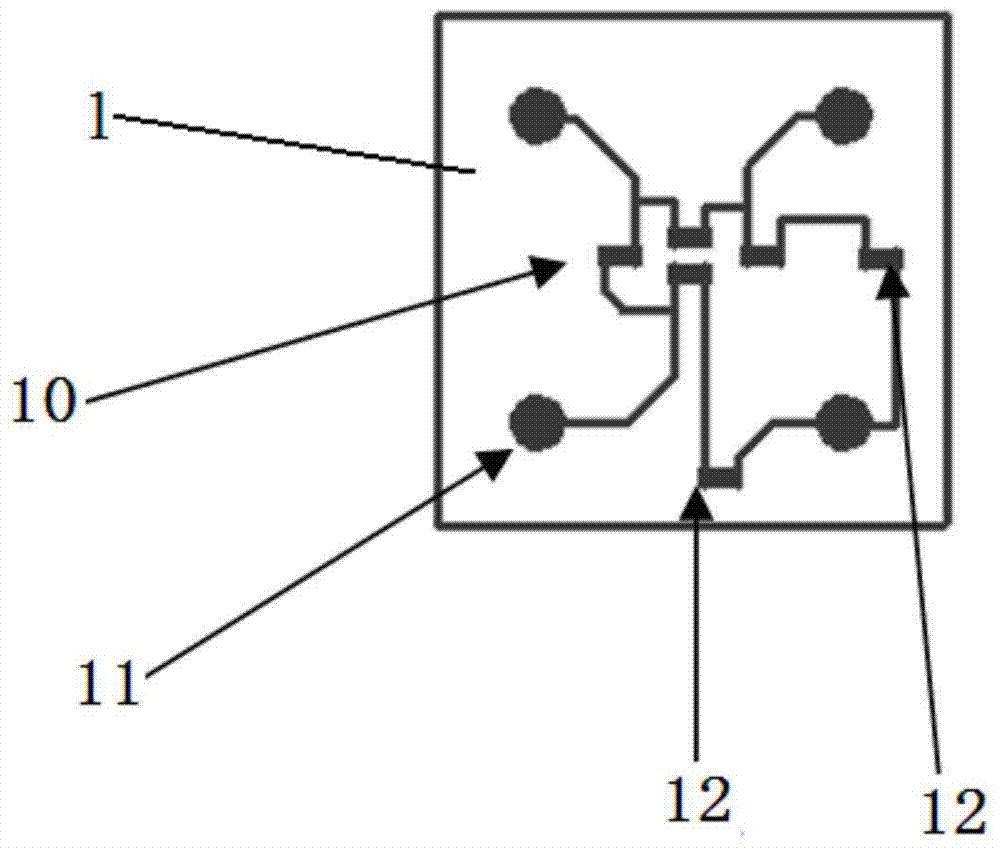

Level-membrane piezoresistive ceramic pressure sensor

ActiveCN104359596AOvercome fragileHigh mechanical strengthForce measurement using piezo-resistive materialsBridge circuitPressure sensor

The invention discloses a level-membrane piezoresistive ceramic pressure sensor comprising a ceramic ring, a ceramic elastic membrane and a signal conditioning circuit. The ceramic elastic membrane is printed and sintered over the ceramic ring through glass glaze paste; the signal conditioning circuit is printed and sintered under the ceramic ring through conducting paste. Four pads connected with four through holes of the ceramic ring respectively are evenly disposed on the ceramic elastic membrane; four bridge resistors connected with the pads to form a Wheatstone bridge are also disposed on the ceramic elastic membrane; a bridge circuit trimming resistor is provided between any two of the pads and any tow of the bridge resistors. The ceramic elastic membrane is printed and sintered to the ceramic ring through the glass glaze paste, the problem that the ceramic elastic membrane easily breaks is solved, and reliability of the mechanical structure of the sensor is ensured; the signal conditioning circuit is printed and sintered to the ceramic ring through the conducting paste, so that the sensor is higher in overall precision and better in stability.

Owner:无锡盛赛传感科技有限公司

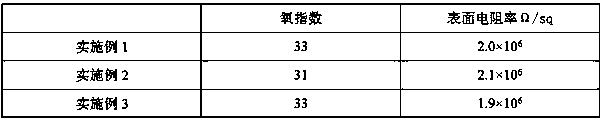

Anti-static/flame-retardant XPE environment-friendly foam material for vehicle and preparation method of XPE environment-friendly foam material

The invention provides an XPE environment-friendly foam material for an anti-static / flame-retardant vehicle and a preparation method of the XPE environment-friendly foam material. The XPE environment-friendly foam material is mainly prepared from, by weight, 60-80 parts of PE resin, 4-8 parts of anti-static agent, 20-30 parts of self-made composite flame retardant, 5-20 parts of foaming agent, 2-5 parts of cross-linking agent and 3-5 parts of blowing promoter. The material is prepared through extrusion of an XPE master slice in a single-screw extruder, calendaring, continuous normal-pressure foaming in a foaming furnace, cooling and shaping, and trimming and coiling. Anti-static and flame-retardant performance is integrated in the XPE foam material, the formulation is simple and scientific, the material has the anti-static performance and the flame-retardant performance, chemical and physical performance is stable, electrostatic induction and inflammability are completely eliminated, and the foam material is safe, free of toxins and smells and environmentally friendly, and saves energy.

Owner:FUJIAN SANSHENG IND

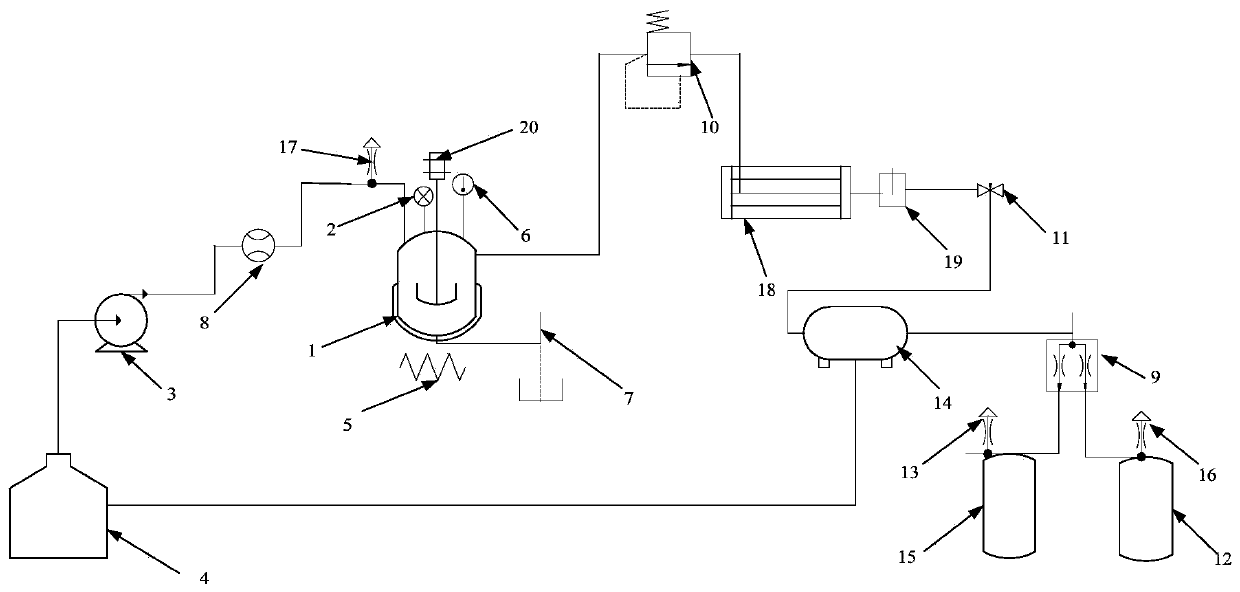

Method and equipment for improving latent heat utilization rate in seawater desalination

InactiveCN103449543AReduce volumeStrong pressure and shock resistanceThermo-electric condensationGeneral water supply conservationEngineeringLatent heat

The present invention relates to a method and equipment for improving latent heat utilization rate in seawater desalination and provides a method for improving latent heat utilization rate in seawater desalination. The method comprises the following steps: providing a thermoelectric device and electrifying the thermoelectric device. The invention further discloses equipment for improving latent heat utilization rate in seawater desalination.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation technique for thermal spraying nano-microcrystalline enamel

InactiveCN105463457AImprove corrosion resistanceDense coatingMolten spray coatingThermal sprayingFrit

The invention relates to a preparation technique for thermal spraying nano-microcrystalline enamel. The process comprises the steps that 1, an enamel glaze block is prepared, specifically, a raw material prepared according to a formula and mixed uniformly is fed into a high-temperature furnace to be melted sufficiently at the temperature of 1300-1500 DEG C and is subjected to water quenching to obtain the homogeneous enamel melted glaze block; 2, thermal spraying powder is prepared, specifically, the melted glaze block is smashed and ground, enamel pre-grinding powder is obtained, 5-30% of nano-silica is added into the pre-grinding powder, mixing granulation is carried out, and the nano-microcrystalline enamel powder for thermal spraying is obtained; and 3, thermal spraying and overall crystallization are conducted, specifically, the enamel powder is uniformly sprayed on the surface of a workpiece through a thermal spraying gun, and the powder is melted and liquefied in the process of being spayed out from the spraying gun and is cooled and solidified after being sprayed on the surface of the workpiece; the obtained enamel layer is a multiphase composite material with nanocrystallines, microlite and glass being interwoven together. The enamel layer has the characteristics of being good in corrosion resistance, high in density, good in toughness, high in impact resistance, capable of being formed at a time and low in manufacturing cost.

Owner:李训竹

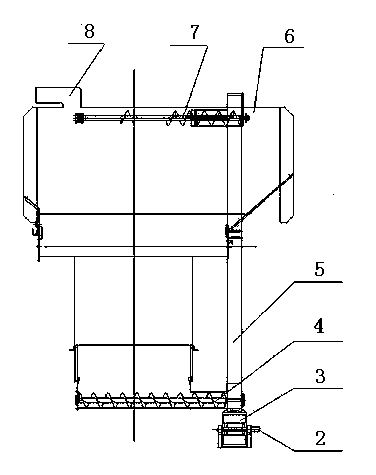

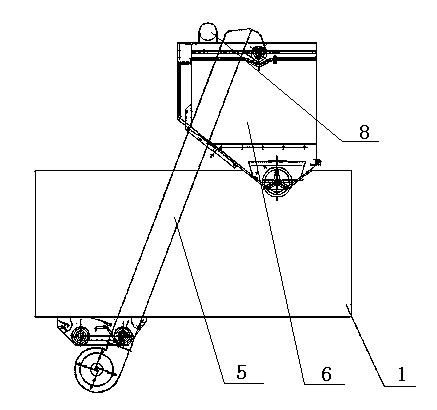

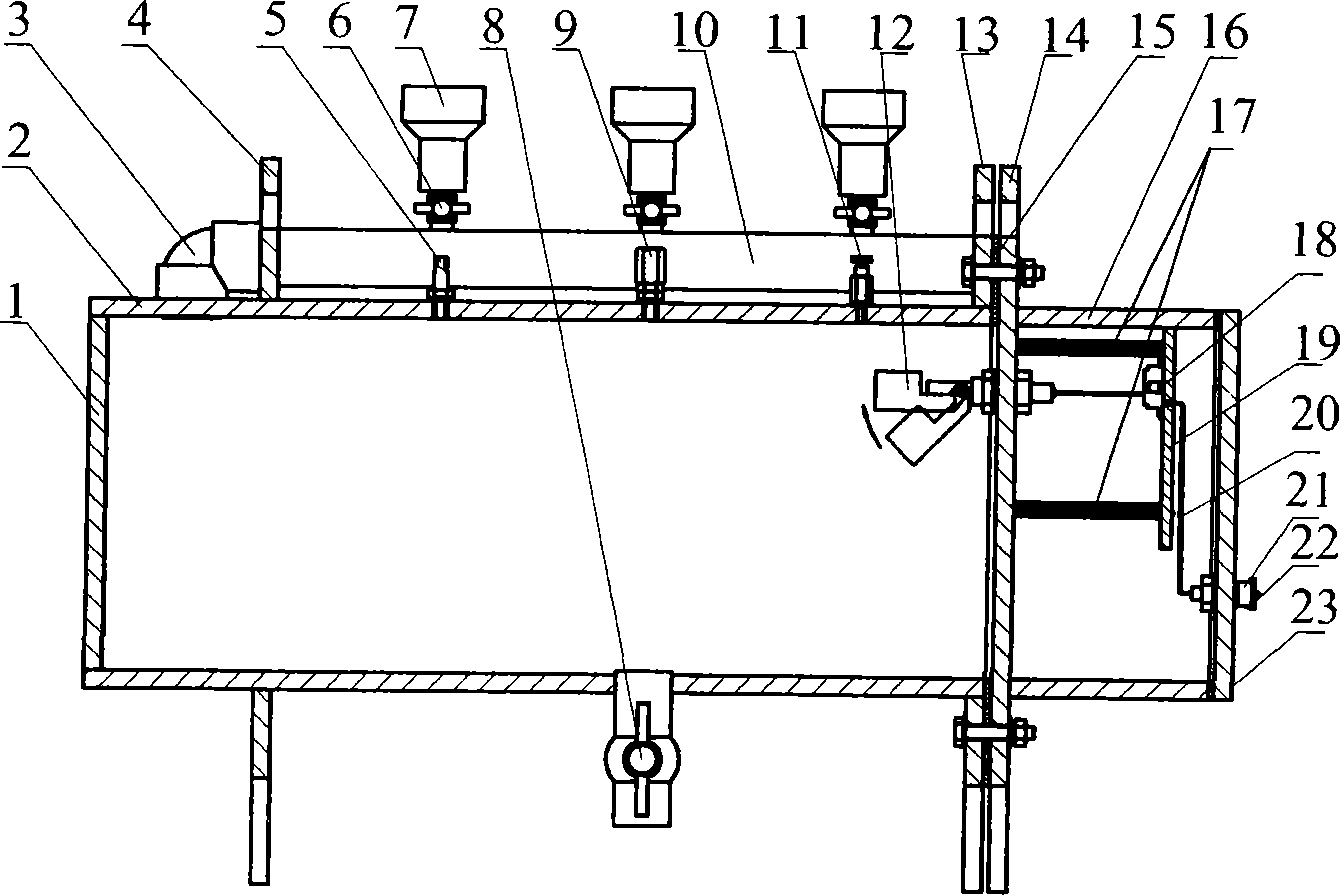

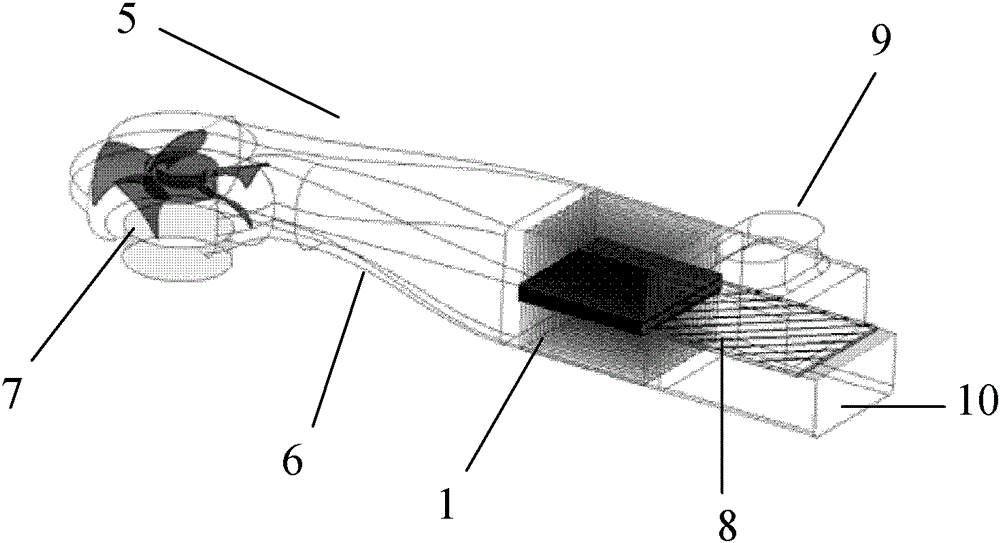

Grain warehousing device for combine harvester

InactiveCN104094742AOvercome fragileOvercoming the disadvantages caused by low harvest rateThreshersHydraulic motorPropeller

The invention discloses a grain warehousing device for a combine harvester, and belongs to the field of farm machines. The grain warehousing device comprises a grain distribution propeller in a barn, and a grain conveyer at the bottom of a frame outside the barn, wherein an oblique grain lifter is arranged between the grain conveyer and the grain distribution propeller; a fan driven by a hydraulic motor is arranged at the outlet of the grain conveyer corresponding to the grain lifter; moreover, a dust outlet is formed in the top of the barn. By adopting the grain warehousing device, grains at the outlet of the grain conveyer can be blown into the grain distribution propeller under the action of wind power, so that the process of feeding grains through wind is realized, the conventional conveying mode is changed, and the defects of easiness in breaking the grains and low harvesting efficiency in the conventional warehousing method are overcome effectively. Meanwhile, fine cereals such as dust and awn of wheat included in the grains are discharged from the dust outlet formed in the top of the barn in a floating state after entering the barn. The purity of the grains is increased remarkably. Furthermore, the grain warehousing device further has the advantages of simple and reasonable structure, stability and reliability in running, low cost, high efficiency, high economical efficiency, high practicability, suitability for industrial popularization and the like.

Owner:吉林省东风机械装备有限公司

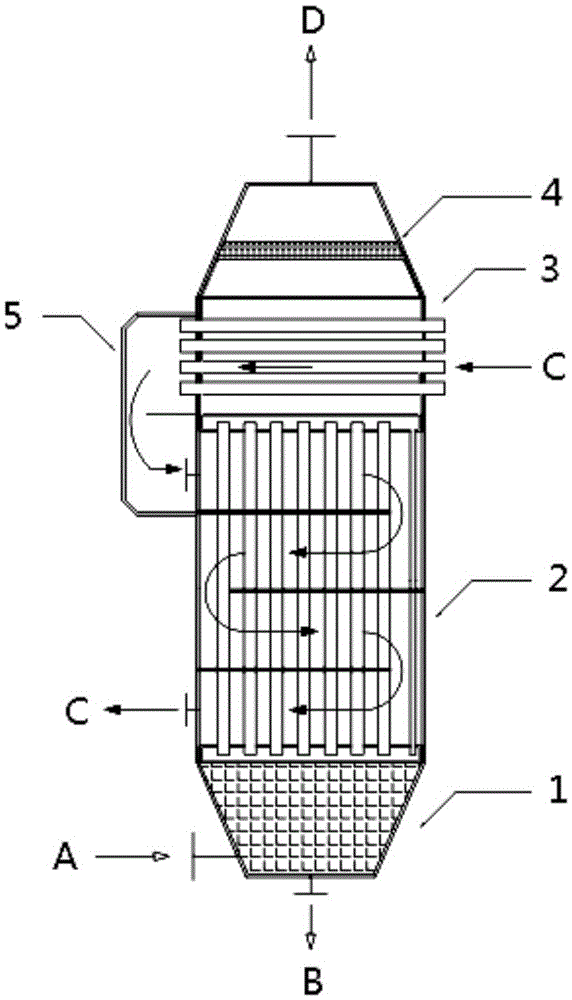

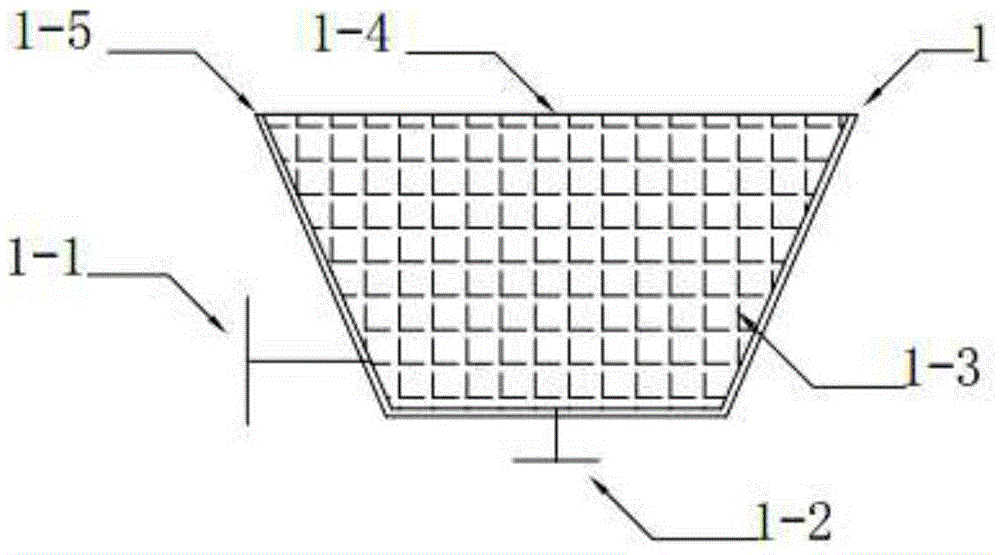

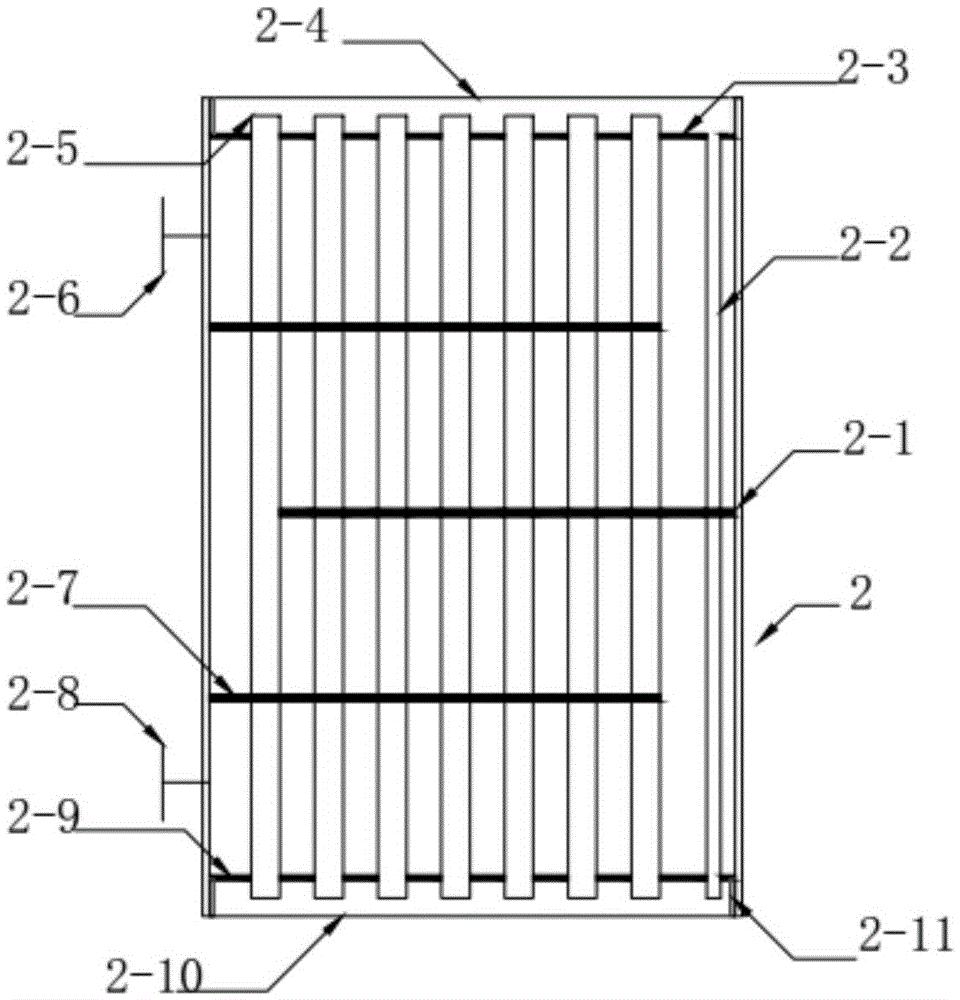

Condensing unit used for modular wet process sulfuric acid production

ActiveCN105600757AIncrease or decrease quantityMeet the conditions of useSulfur compoundsManufacturing cost reductionComputer module

The invention provides a condensing unit used for modular wet process sulfuric acid production. The condensing unit used for the modular wet process sulfuric acid production comprises a bottom kerf module, multiple condensation modules, a mist eliminating module and a gas circuit connecting module. The condensing unit used for the modular wet process sulfuric acid production adopts modular design, standardization of manufacturing of the condensing unit can be realized by increasing or decreasing quantity of related condensation modules according to different requirements, further manufacturing cost is reduced, parts among the modules are sealed by adopting dual sealing structures, sealing property among the modules can be effectively guaranteed, acid gas leakage is avoided, safety of the condensing unit is improved, vertical link between upper and lower modules is also facilitated, and overall smooth running of the condensing unit is guaranteed.

Owner:美景(北京)环保科技有限公司

Freeze-dried grain food product

InactiveCN109105729ALong-term retention of nutrientsExtended shelf lifeFood freezingFood homogenisationCarrageenanAdditive ingredient

The invention relates to a freeze-dried grain food product. Grains are taken as the main food raw materials of the freeze-dried grain food product. A preparation method comprises following steps: material supply, crushing, slurry preparation, mould injection, freezing, and drying, or material supply, pulp grinding, mould injection, freezing, and drying. The crushed raw materials are subjected to freeze drying, so that the nutrients in grains are maintained for a long term, the self life is prolonged, it is convneeint for storage, carrying, and eating, no additive is added, the freeze-dried grain food product is natural and is good for health. Auxiliary food raw materials are added into a slurry, so that nutrient components are increased, and the mouthfeel is improved; and in addition, foodcolloids such as guar gum, xanthan gum, carrageenan, konjac glucomannan, pectin, Arabic gum, and locust bean gum are added into the slurry, so that product surface lubricity is improved, demoulding from a mould is convenient, product cohesive force is increased, and a problem in the prior art that cracking of freeze-dried food is easily caused is solved.

Owner:WINNER MEDICAL CO LTD

Circulation box used for machining circulation of engine blade

ActiveCN109353649AAvoid deformationEffectively absorb shock energyPackaging vehiclesContainers for machinesFilling materialsEngineering

The invention discloses a circulation box used for machining circulation of an engine blade. The circulation box comprises a box body (1). A filling material (2) is arranged in an inner cavity of thebox body (1). The upper end of the box body (1) is opened, and a hole is formed in the lower end face of the box body (1). The filling material (2) is a whole piece of EPE pearl wool, and a blade containing groove penetrating the upper end face and the lower end face of the EPE pearl wool is formed in the EPE pearl wool. The depth of the blade containing groove is larger than the height of a bladebody. By means of the circulation box, the EPE pearl wool which is high in buffering and vibration resisting capability is used as a carrier for carrying a blade, the rectangular groove containing the blade body is used for limiting wobbling of the blade, circulation, transportation and storage of the blade between the machining processes can be achieved, and the blade is not greatly wobbled, impacted, scratched and deformed in the process.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

A Flush Membrane Piezoresistive Ceramic Pressure Sensor

ActiveCN104359596BOvercome fragileHigh mechanical strengthForce measurement using piezo-resistive materialsConductive pasteSignal conditioning circuits

The invention discloses a flush membrane piezoresistive ceramic pressure sensor, which includes a ceramic ring, a ceramic elastic diaphragm printed and sintered on the upper part of the ceramic ring by glass glaze paste, and a ceramic elastic diaphragm printed and sintered on the lower part of the ceramic ring by conductive paste The signal conditioning circuit; wherein, the ceramic elastic diaphragm is uniformly provided with four pads respectively connected to the four ceramic ring through holes on the ceramic ring, and connected to the pads to form a Wheat Four bridge resistors of the Dayton bridge; a bridge trimming resistor is arranged between the pad and the bridge resistors. In the present invention, the ceramic elastic diaphragm is printed and sintered on the ceramic ring through glass glaze paste, which overcomes the fragile problem of the ceramic diaphragm and ensures the reliability of the mechanical structure of the sensor; at the same time, the signal conditioning circuit is also printed and sintered through conductive paste On the ceramic ring, the overall accuracy of the sensor is higher and the stability is better.

Owner:无锡盛赛传感科技有限公司

Self control type pumping filter

InactiveCN101249340AOvercome fragileOvercoming scattered partsStationary filtering element filtersExhaust valveBiochemical engineering

The invention provides a self-control filter, which is characterized in that a filtration container is a filtration tank which is made of metal or PVC material, a filter holder is arranged above the filtration tank, the outlet of the filter holder is connected into the filtration tank by a switch valve, a vacuum pump connector, a vacuum degree automatic regulating valve and an exhaust valve are arranged on the filtration tank, the extraction port of a vacuum pump is connected with the vacuum pump connector on the filtration tank, the lower part of the filtration tank is provided with a water drainage valve, a liquid level switch is arranged on the upper part of the inner side wall of the filtration tank, and the liquid level switch is connected in a control circuit of the vacuum pump by a cable. When the liquid level in the filtration tank is increased to drive the liquid level switch to act, the vacuum pump stops the operation so as to prevent the filtered liquid from entering the vacuum pump, the vacuum degree can be adjusted automatically, the whole filter is an integrated structure, the filtration tank is made of metal or PVC material, the filter is difficult to be crushed and has simple operation, convenient carrying and maintenance.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Lightweight imitation ceramic composite material and preparation method thereof

The invention discloses a lightweight imitation ceramic composite material. The lightweight imitation ceramic composite material is composed of, by mass, 25% of polyamide, 60 to 75% of nanosized ceramic powder, 0.2 to 0.6% of a coupling agent, 0.5 to 1% of an anti-oxidant, 2 to 5% of zinc stearate, and 0.5 to 5% of aluminium powder. According to a preparation method, the raw materials above are subjected to mixing, fusion, extrusion, and granulation under certain conditions so as to obtain the lightweight imitation ceramic composite material. The lightweight imitation ceramic composite material is light, excellent in mechanical properties, thermal insulation performance and comprehensive properties, and low in heat conductivity coefficient.

Owner:WUJIANG HUACHENG COMPOSITE MATERIAL SCI & TECH

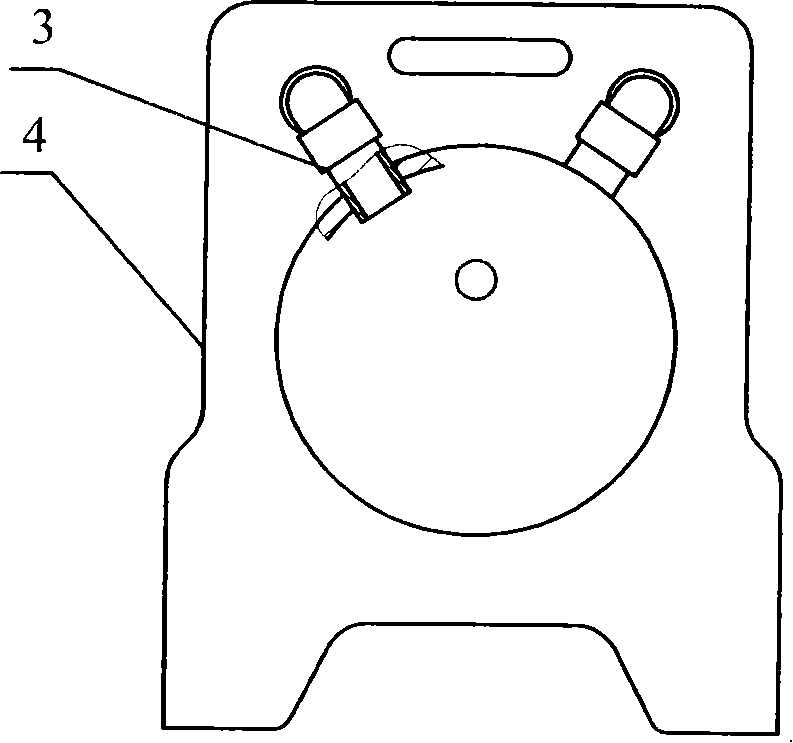

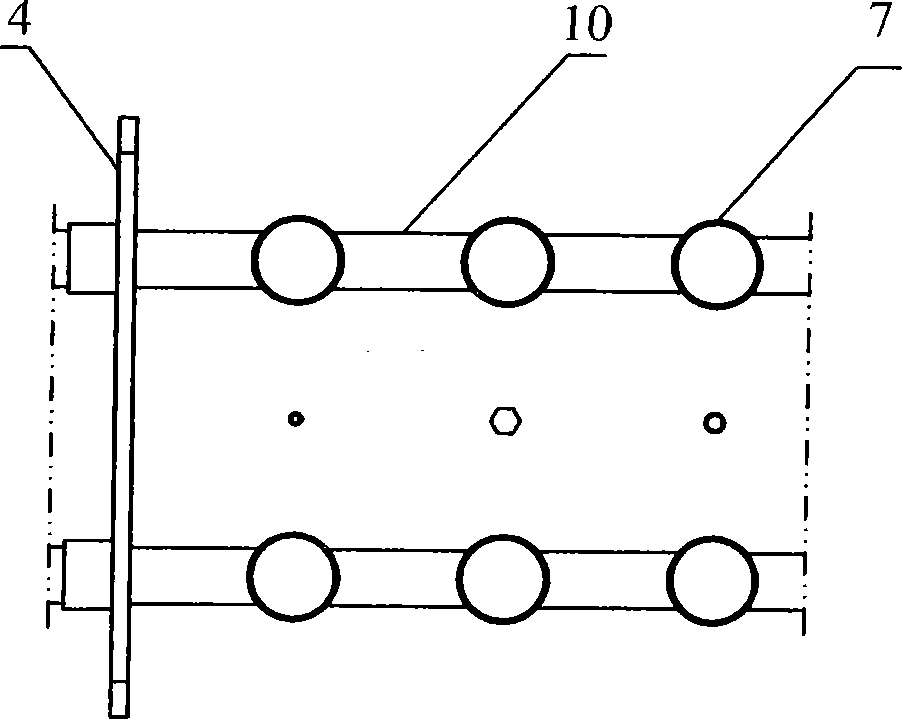

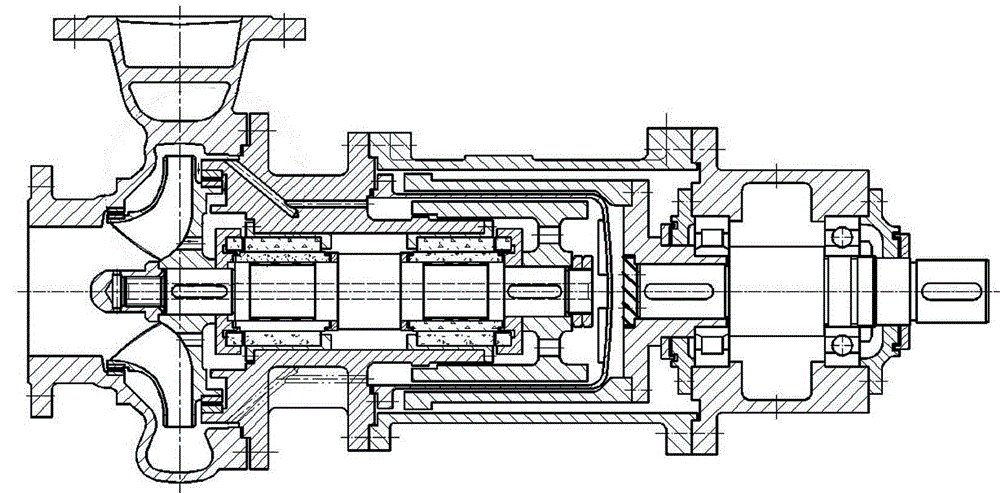

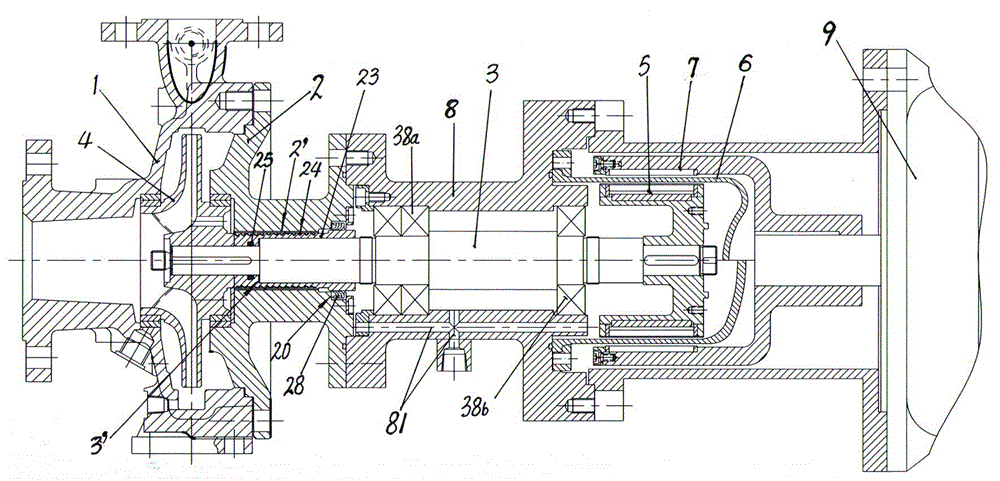

Spindle dry-type-running magnetic drive pump

InactiveCN103603825AOvercome fragileSimple structureSpecific fluid pumpsPump componentsImpellerRing device

The invention relates to a spindle dry-type-running magnetic drive pump which comprises a pump body (1), a pump cover (2), a spindle (3), an impeller (4), an inner magnetic rotor (5), an isolating sleeve (6), an outer magnetic rotor (7) and a connecting frame (8). The spindle dry-type-running magnetic drive pump is characterized in that a shutoff sleeve (23) and a closed sealing ring device (28) are arranged between a shaft hole (2') of the pump cover and a pump shaft (3) for sealing, the pump shaft (3) and the connecting frame (8) are connected through rolling bearing devices (38a and 38b), an inert gas incoming hole (81) is formed in the connecting frame (8), and the isolating sleeve (6) is made of glass steel. The spindle dry-type-running magnetic drive pump is simple in structure and convenient to process, mount and maintain, application range of the pump is effectively widened, safety of the pump is effectively improved, and service life of the pump is effectively prolonged.

Owner:丹东克隆先锋泵业有限公司

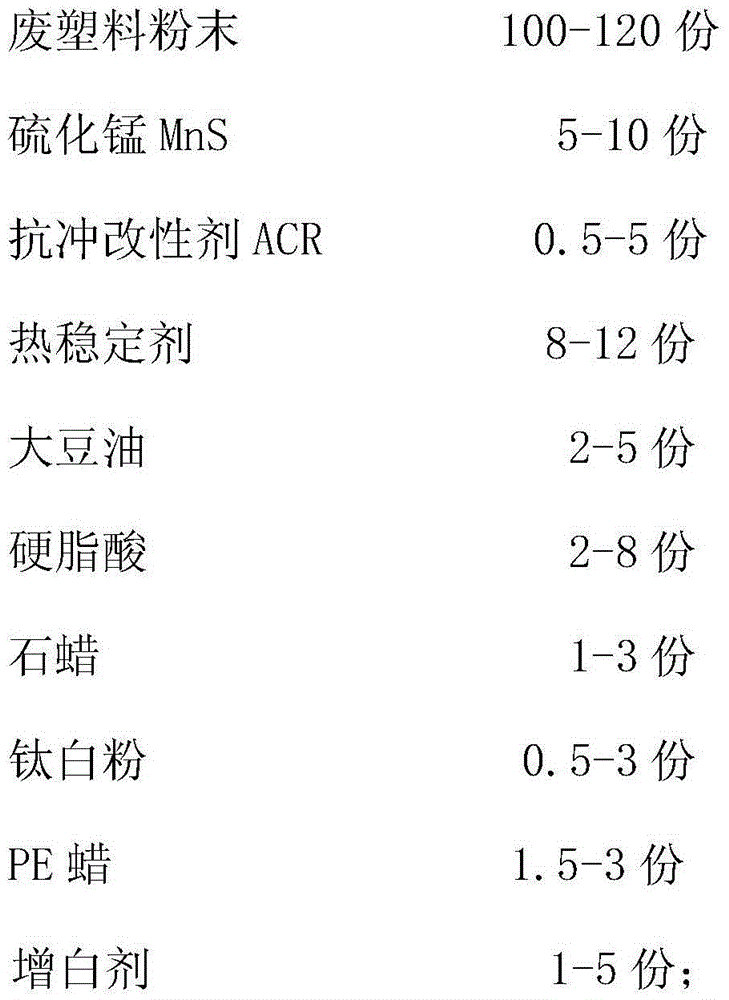

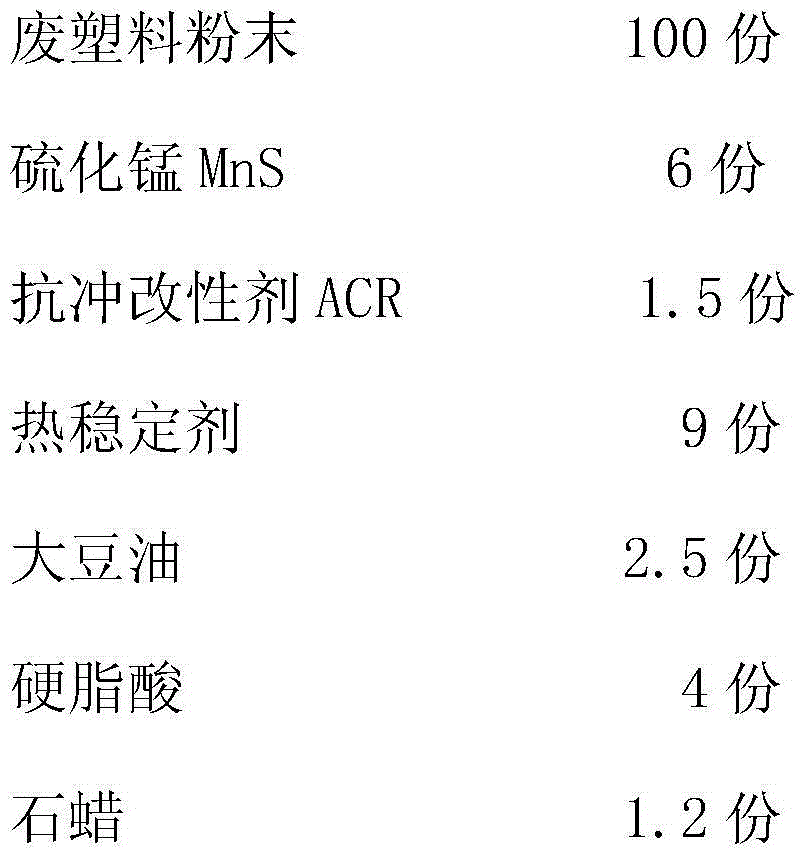

Method for manufacturing hard plastic bridge frame with waste plastic

The invention relates to a method for manufacturing a hard plastic bridge frame with waste plastic. The method for manufacturing a hard plastic bridge frame with waste plastic comprises the steps of (1) washing waste plastic with a plastic cleaning agent, then filtering the waste plastic for 10-15 minutes by putting into clear water, subsequently drying the filtered waste plastic by putting into a drying machine for 5-10 minutes; (2) cutting the waste plastic washed and purified in the step (1) into small pieces by using a cutting machine, then breaking the pieces into waste plastic particles by adding into a crushing machine, subsequently grinding the waste plastic particles into waste plastic powder by adding the waste plastic particles into a grinder; (3) mixing components of the hard plastic bridge frame in a mixing machine; and (4) adding the raw materials mixed uniformly in the step (3) into an extruder which squeezes and molds the targeted product. According to the method, the relevant performances of the hard bridge frame manufactured such as strength, and resistance to water, acid, alkali and salt meet the relevant requirements, is energy-saving and environment-friendly, and has no pollution and good flame retardancy.

Owner:江苏华坤电气有限公司

Electronic tag used for metal

InactiveCN102184444AOvercome fragileOvercoming complexityRecord carriers used with machinesPolyethylene terephthalateElectronic tagging

The invention relates to an electronic tag used for metal, belonging to the technical field of the electronic tag. The electronic tag is characterized in that the structure of a ceramic metal tag in the existing metal resistance field is changed, a UHF (Ultra High Frequency) aluminum antenna metal tag successively composed of a PET (Polyethylene terephthalate) film, an aluminum antenna connected with the chip, a foam material and release paper is designed. The PET film and the foam material in the electronic tag are light, have small possibility of breaking, have simple production process and are easy to debug, thereby overcoming the defects that the existing ceramic metal tag is always broken and is complex to process and debug. The electronic tag is not only suitable for metal surface but also suitable for the human body as well as objects carried by people. The central point 3Db bandwidth of frequency is 5-20MHz. According to the electronic tag, different requirements of various nations can be satisfied by finely adjusting antenna shape, and the electronic tag is favourable for widening the application field of the metal tag and has strong practicality.

Owner:ARIZON RFID TECH YANGZHOU

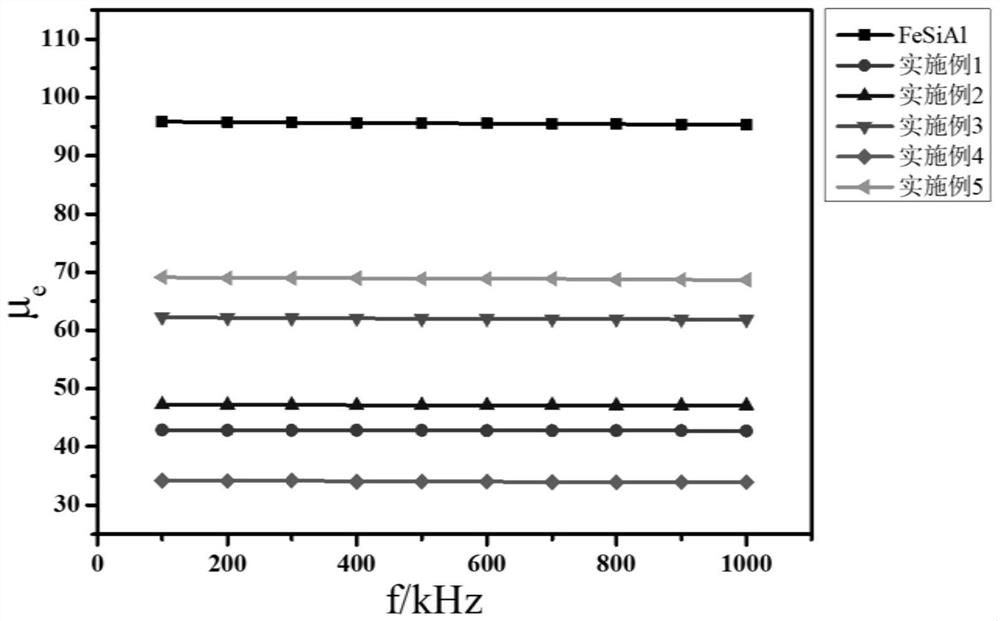

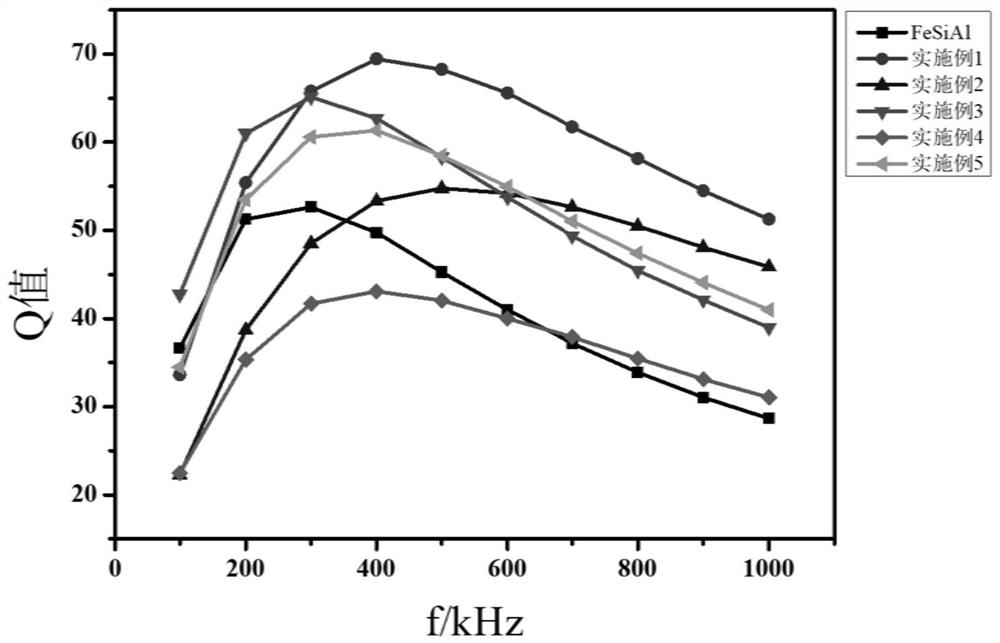

High-frequency high-Q-value FeSiAl@MnZn ferrite soft magnetic composite magnetic powder core and preparation method thereof

PendingCN113658769AHigh resistivityOvercome fragileInorganic material magnetismInductances/transformers/magnets manufactureCompression moldingCoprecipitation

The invention discloses a high-frequency high-Q-value FeSiAl@MnZn ferrite soft magnetic composite magnetic powder core and a preparation method thereof. The preparation method mainly comprises the steps of powder size screening, MnZn ferrite shell layer coating through a chemical coprecipitation method, composite magnetic powder pre-sintering, compression molding, annealing and the like. According to the method, flattening and phosphating treatment is not carried out on FeSiAl powder, the experimental process is simplified, environmental pollution is reduced, a better coating effect can be achieved, electric contact among metal magnetic powder particles is effectively isolated, the magnetic conductivity and the quality factor of the composite magnetic powder core are improved, and the application frequency range of the FeSiAl magnetic powder core is widened. The method is simple in implementation process, short in reaction time and easy for large-scale production and industrial application.

Owner:西安锐磁电子科技有限公司

Preparation method for positively charged three-dimensional nanofibre membrane

The invention relates to a preparation method for a positively charged three-dimensional nanofiber membrane. The preparation method comprises the following steps of: 1, preparing a meshed ceramic fiber framework; 2, synthesizing a rodlike or sheet-type nanoparticle on the surface of the framework obtained in the step 1 by a hydrothermal method or a steam-thermal method; and 3, obtaining a needlelike nanofiber on the nanoparticle by a soft template precipitation method. By a wet chemical method, the flexible meshed ceramic fiber framework which is capable of automatic adhesion to form a membrane and has small elastic modulus is synthesized, and a three-dimensional nano charged gamma-Al2O3 fiber is self-assembled and synthesized in situ on the surface of the framework, so a branch shaped three-dimensional structure extends from the surface of the framework, and an inorganic charged fiber membrane which can be used at high temperature and has large specific surface area and high charged electric quantity is prepared.

Owner:BEIJING KANGJIE ZHICHEN WATER TREATMENT

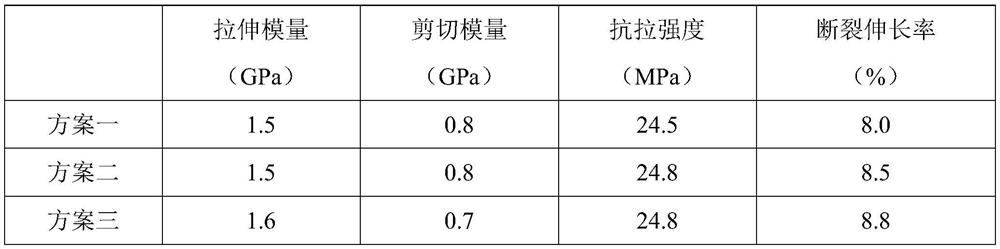

Steel rail milling and grinding vehicle grinding wheel unbalance amount adjusting hole filling glue and using method thereof

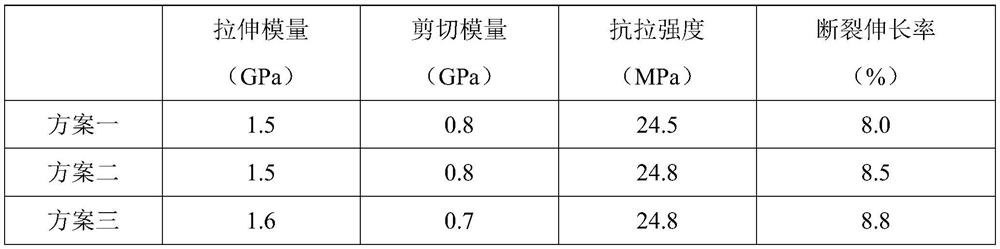

ActiveCN112757177ASolve the problem of static balance adjustmentOvercome fragileGrinding machine componentsGrinding devicesShear modulusPtru catalyst

The invention discloses steel rail milling and grinding vehicle grinding wheel unbalance amount adjusting hole filling glue and using method thereof. The hole filling glue is formed by mixing mixed resin, a curing agent and a catalyst according to the proportion of (81.5%-82.9%): (9.8%-11.3%): (5.8%-8.7%). The tensile modulus of the cured hole filling glue is 1.5GPa, the shear modulus is 0.8GPa, the tensile strength is 24.5MPa, the elongation at break is 8.0%, and the hole filling glue is suitable for the ceramic bond steel rail milling and grinding vehicle grinding wheel which is large in outer diameter, heavy in mass and free of a base body. The steel rail milling and grinding vehicle grinding wheel unbalance amount adjusting hole filling glue can solve the problems that daub is prone to falling off, the appearance of a grinding wheel is influenced by de-weight drilling, and the grinding wheel is prone to breaking, and solves the problem of static balance adjustment of the grinding wheel of a steel rail milling and grinding vehicle.

Owner:CHINA RAILWAY LONGCHANG MATERIALS +1

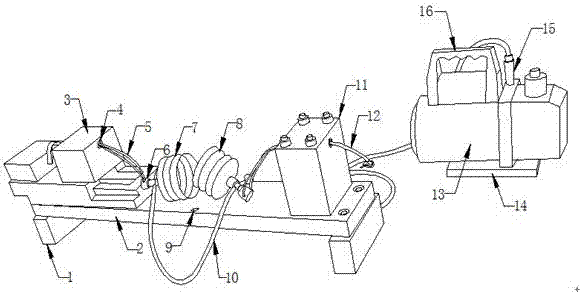

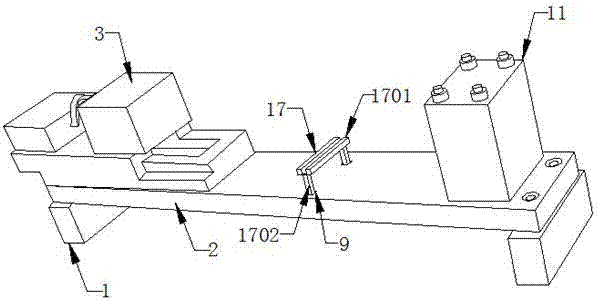

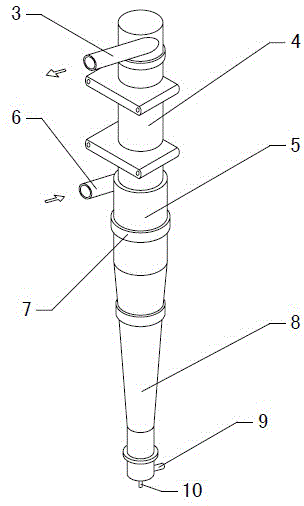

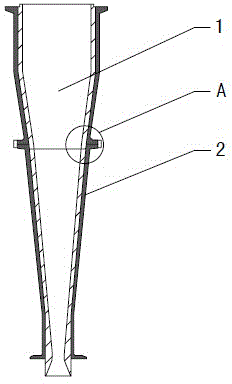

Tensile-resistant test device for digital display missile antenna

InactiveCN107036889AOvercome fragileEasy to placeMaterial strength using tensile/compressive forcesVacuum pumpIndustrial engineering

The invention discloses a tensile-resistant test device for a digital display missile antenna. The tensile-resistant test device comprises a supporting block, a working table, a first test table, a through hole, a drawing wire, a connector, a first plastic sucker, a second plastic sucker, an inserting hole, an air pipe, a second test table, a connecting wire, a vacuum pump, a base, an air pipe connecting end, a handle, a product placing part, a groove block and a fine column. The tensile-resistant test device has the advantages that products to be tested are conveniently placed by the product placing part of tensile-resistant test device of thin products for high-end devices, the product placing part is formed by the groove block and the fine column, inserting products to be tested can be effectively clamped by the groove block, so that the products to be tested can be conveniently and effectively adsorbed by the first plastic sucker and the second plastic sucker, and the product placing part can be conveniently taken out from the inserting hole of the working table and the products after the products to be tested are adsorbed, so that subsequent operations are performed.

Owner:KUNSHAN SHANSHAN PLASTIC TECH CO LTD

Composite slag remover and manufacturing process thereof

ActiveCN103480185BHigh strengthOvercoming the disadvantage of being fragileSedimentation settling tanksVulcanizationSlag

Owner:ZIBO BEICHEN CERAMICS EQUIP

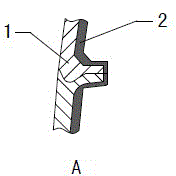

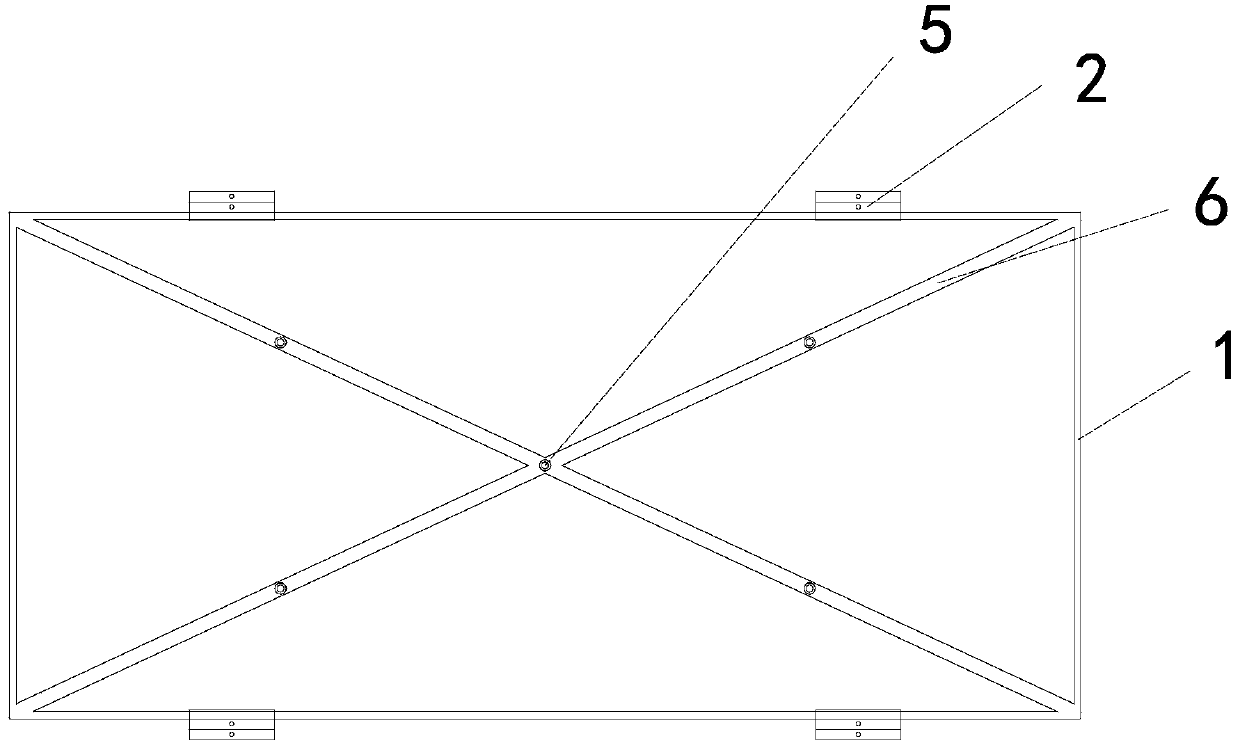

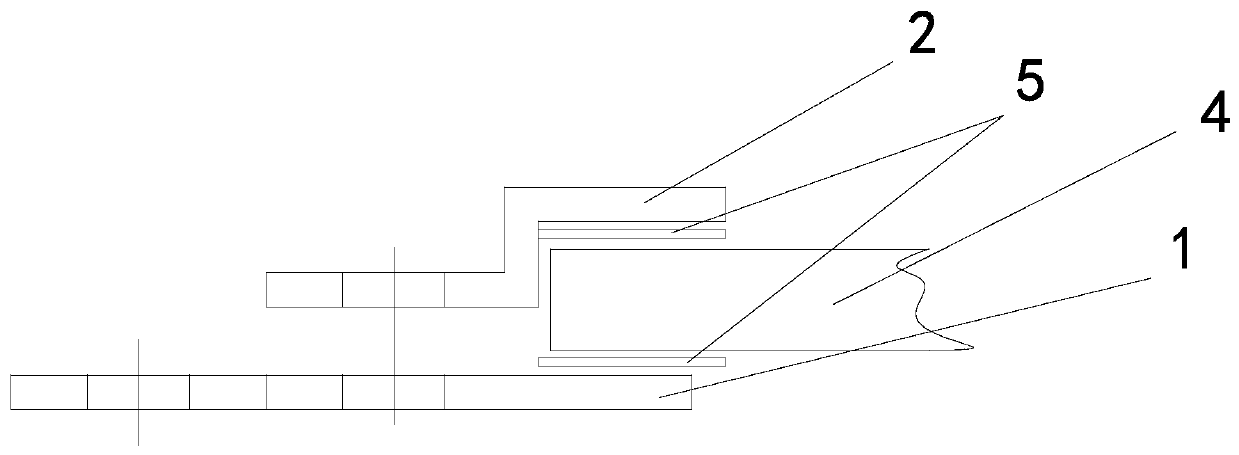

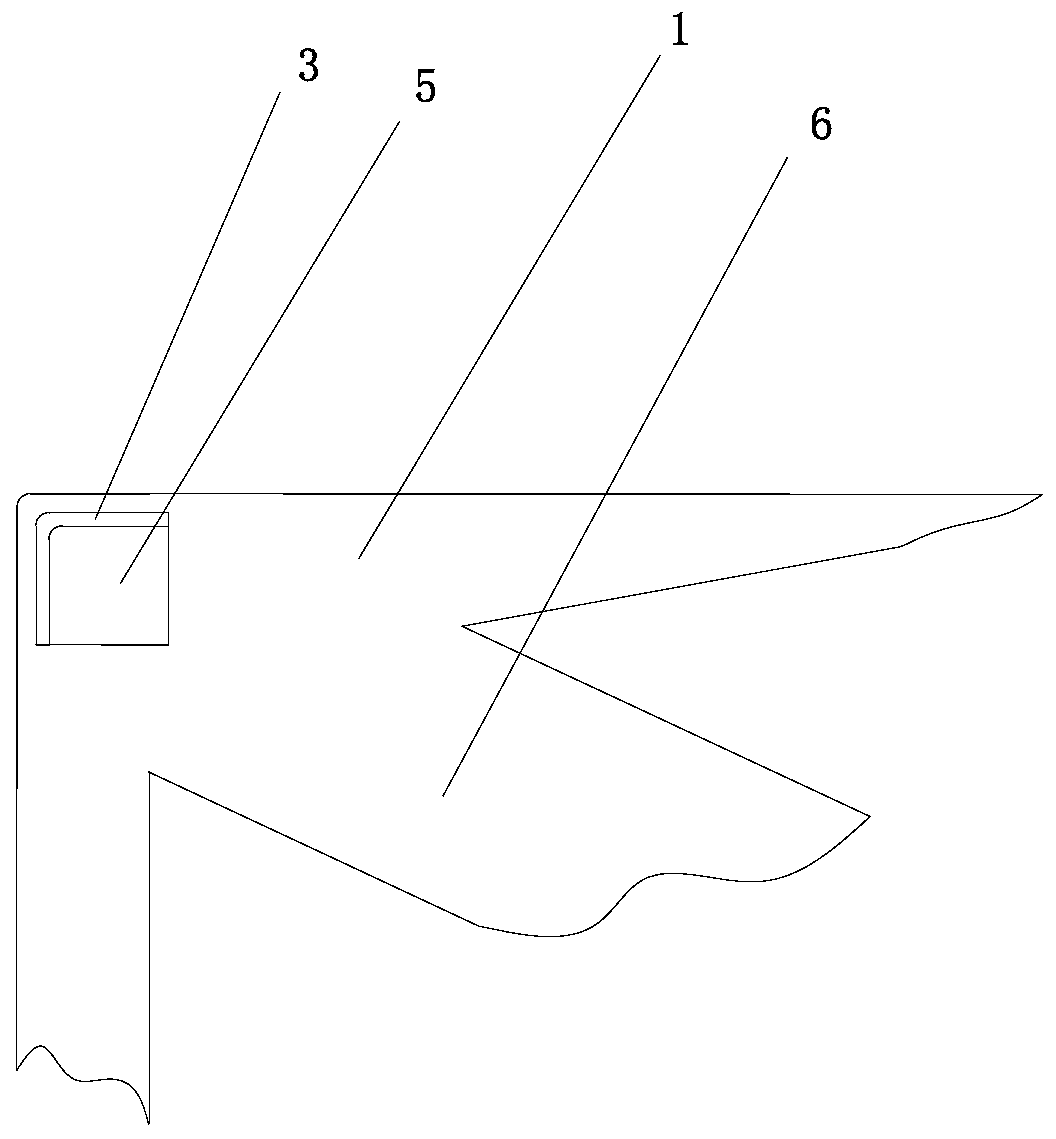

Double-glazing component mounting structure with protection function and double-glazing component array

InactiveCN110445460AAchieve protectionRealize the protection functionPhotovoltaicsPhotovoltaic energy generationEngineeringMechanical engineering

The invention provides a double-glazing component mounting structure with a protection function and a double-glazing component array. The double-glazing component mounting structure comprises a framebody, pressing blocks and corner armors, wherein the pressing blocks are detachably arranged on the frame body; double-glazing components are arranged between the pressing blocks and the frame body; and the corner armors are fixedly arranged on the frame body, and coated or semi-coated at the corners of the double-glazing components. According to the double-glazing component mounting structure with the protection function and the double-glazing component array, the corner armors are arranged at the corners of the double-glazing components for rigid supporting, so that protection and limiting of the double-glazing components are realized; the problem of friableness or easy sliding of the double-glazing components in the prior art is overcome; the frame body can ensure the attractiveness during arrangement of the array; auxiliary protection strips are arranged for supporting middle positions of the double-glazing components, so that the problem of hot spot formation due to sinking of thecenters of the double-glazing components under gravity action is overcome; and the safety and the attractiveness of the double-glazing components are improved.

Owner:GREE ELECTRIC APPLIANCES INC

Fractionating device and fractionating method for organic chemical experiment

InactiveCN110613948AOvercoming fragile glassOvercome fragileFractional distillationCentrifugal pumpOrganic chemicals

The invention discloses a fractionating device for an organic chemical experiment. The fractionating device comprises a pressure-resistant tank, a centrifugal pump, a stock solution storage tank, a resistor, a condenser and a buffer tank, a stock solution in the stock solution storage box enters the pressure-resistant tank through the centrifugal pump, the resistor is arranged at the bottom of thepressure-resistant tank and used for heating the stock solution in the pressure-resistant tank, the heated stock solution becomes steam and enters the condenser, and after heat exchange is repeatedlyconducted in the condenser pipe, fractions enter the buffer tank. The device solves the problems of complicated operation process and impure fraction components of the existing organic chemical experiment fractionating device. The invention discloses a fractionating method of a fractionating device for an organic chemical experiment, which can meet the requirements of fractionation of fractions with different boiling points, sampling and circulation in the flow division process and cleaning of a pressure-resistant tank, and is convenient to operate.

Owner:YULIN UNIV

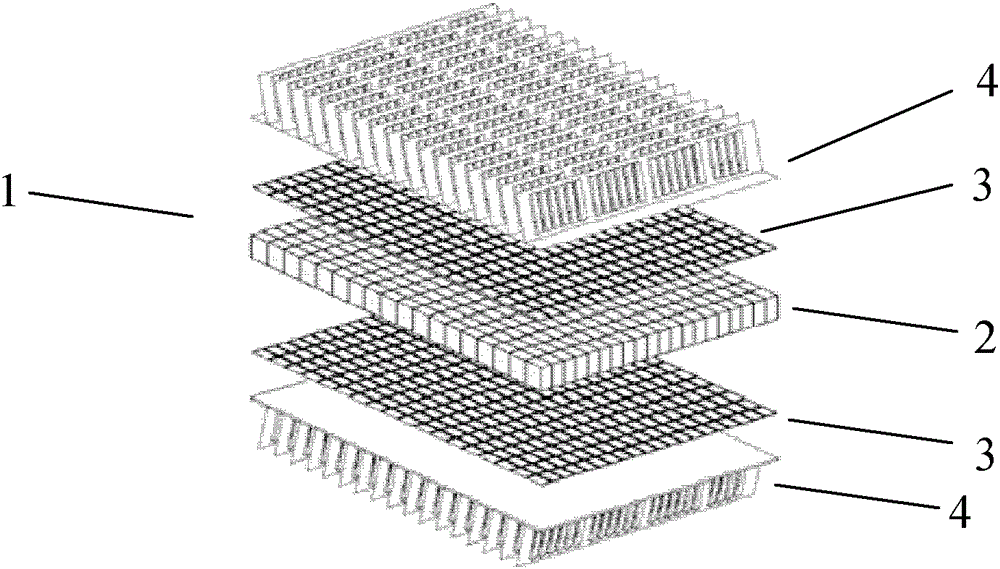

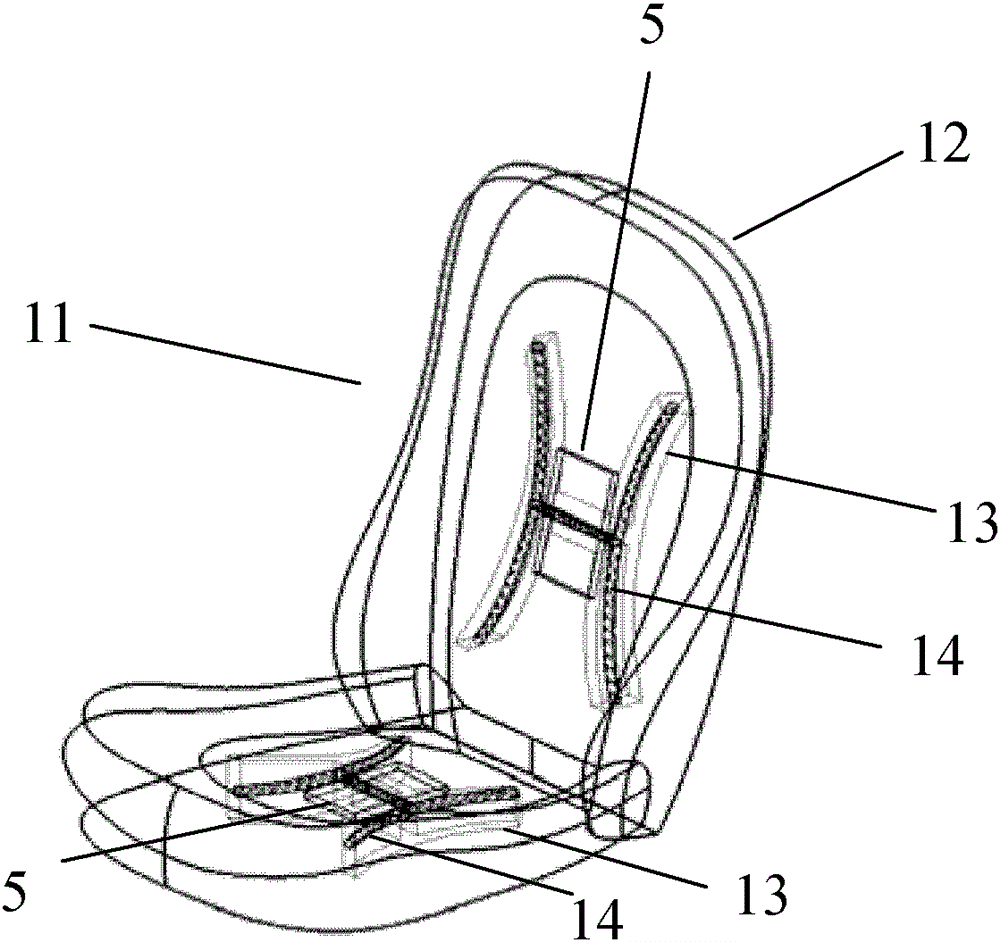

Thermoelectric air-conditioning unit and car air-conditioning seat with the thermoelectric air-conditioning unit

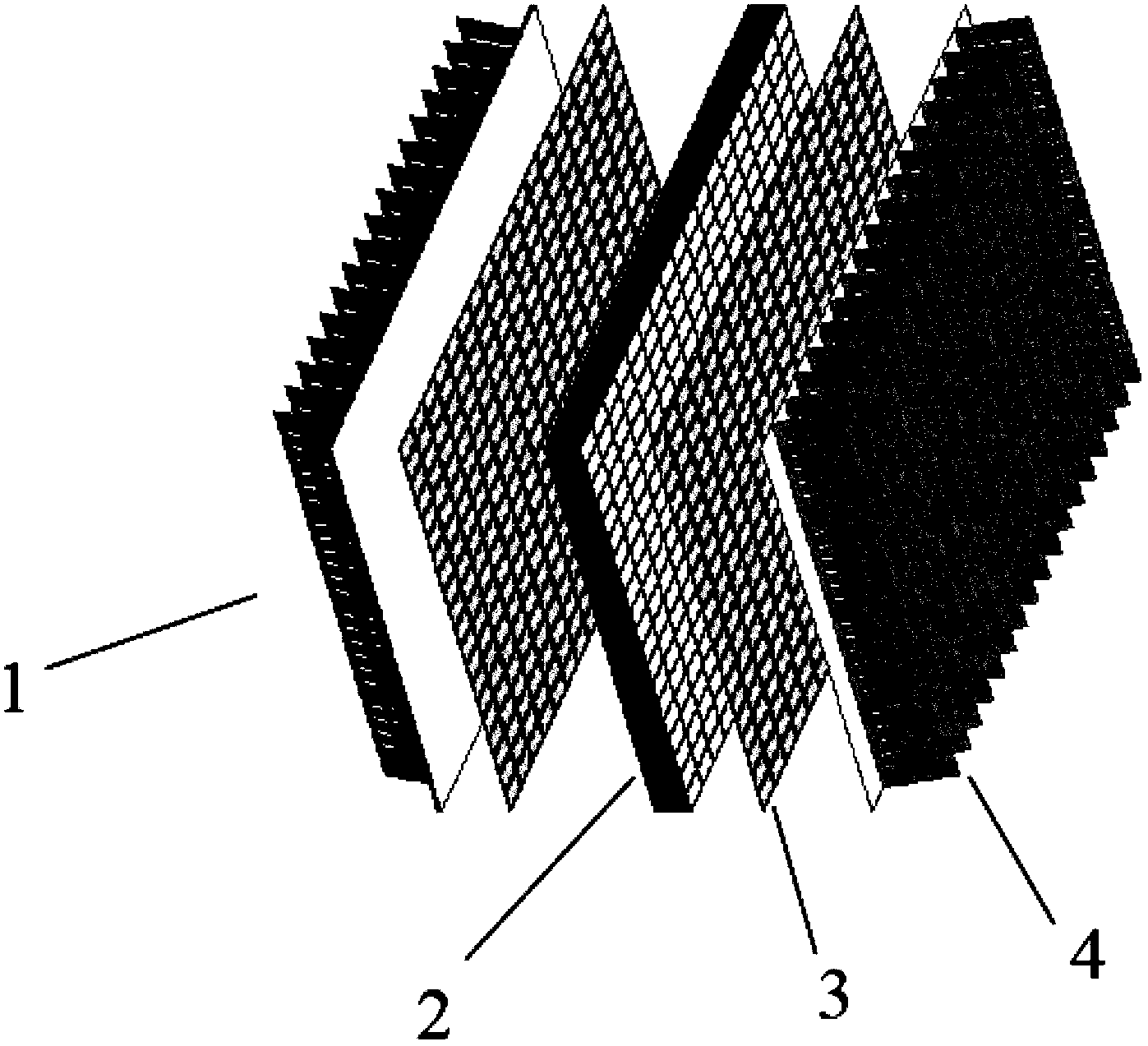

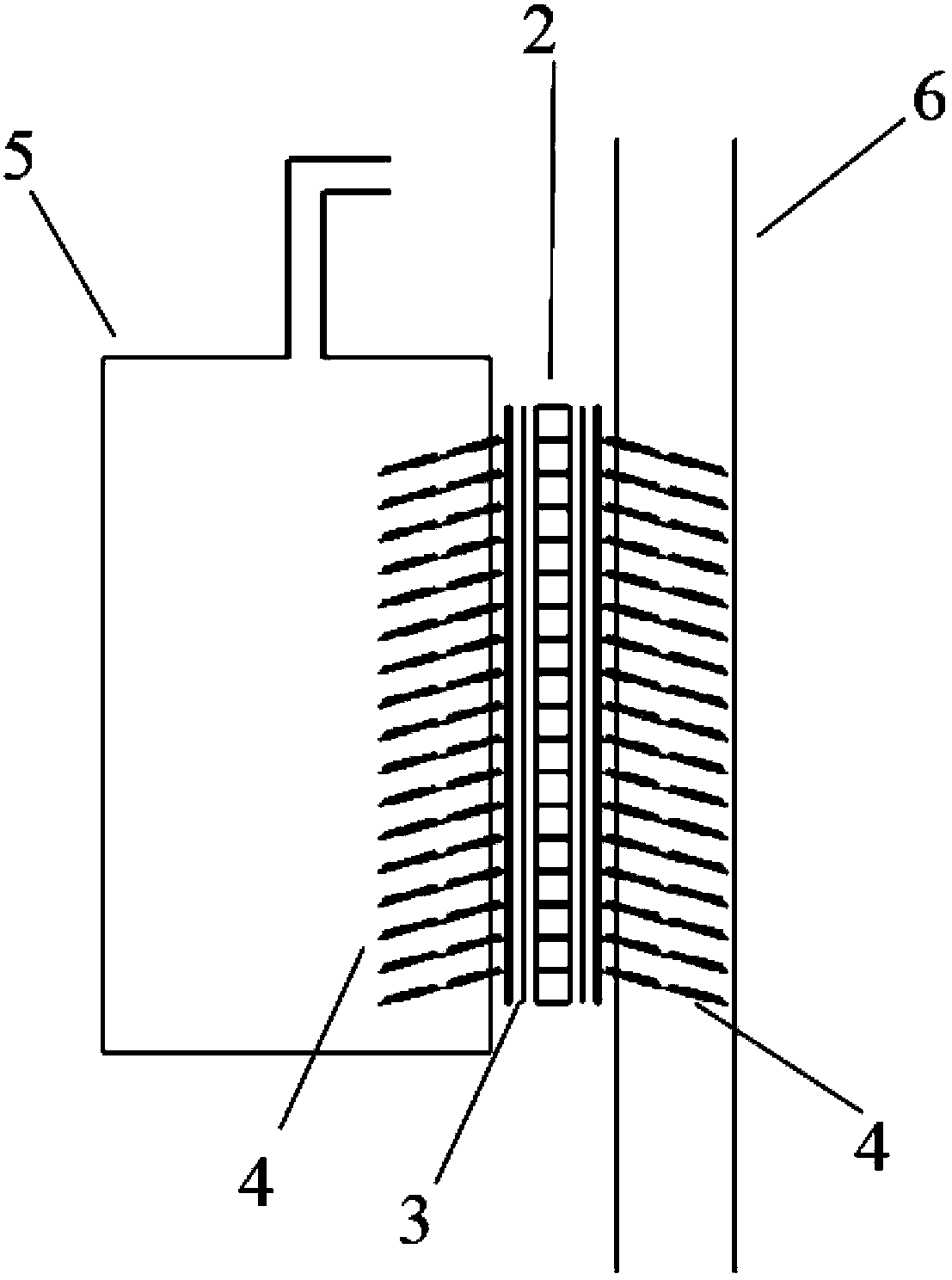

ActiveCN103057449BOvercome fragileWeld tightlySeat heating/ventillating devicesAutomobile air conditioningEngineering

The invention aims to provide a thermoelectric air conditioning unit and a car air conditioning seat with the same. The car air conditioning seat with the thermoelectric air conditioning unit is suitable for a car and energy efficiency ratio is improved. The thermoelectric air conditioning unit comprises thermoelectric devices, copper-clad films and cooling fins. The copper-clad films are arranged on the upper and lower sides of the thermoelectric devices, and the cooling fins are arranged on the sides of the copper-clad films in a laminating mode, opposite to the thermoelectric devices.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

A hole-filling glue for adjusting the unbalance amount of the grinding wheel of rail milling and grinding vehicles and its application method

ActiveCN112757177BSolve the problem of static balance adjustmentOvercome fragileGrinding machine componentsGrinding devicesShear modulusFirming agent

The invention discloses a hole-filling glue for adjusting the unbalance amount of a grinding wheel of a rail milling and grinding vehicle and a method for using the hole-filling glue. (5.8% ~ 8.7%) by mixing the proportion. After curing, the tensile modulus of the potting glue is 1.5GPa, the shear modulus is 0.8GPa, the tensile strength is 24.5MPa, and the elongation at break is 8.0%. It is suitable for ceramic bonding with large outer diameter, heavy mass and no matrix. Grinding wheels for rail milling and grinding vehicles. The hole-filling glue for adjusting the unbalance amount of the grinding wheel of the rail milling and grinding vehicle provided by the invention can overcome the problems that the cement is easy to fall off, the appearance of the grinding wheel is affected by the heavy-duty drilling, and the grinding wheel is easily broken, and the problem of the static balance adjustment of the grinding wheel of the rail milling and grinding vehicle is solved.

Owner:CHINA RAILWAY LONGCHANG MATERIALS +1

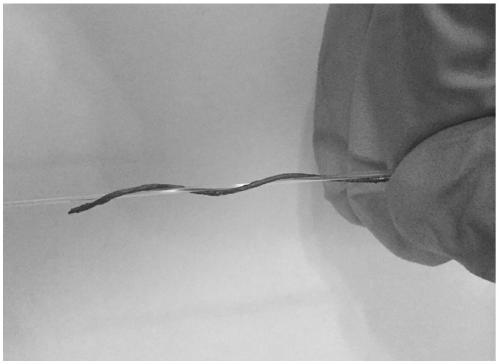

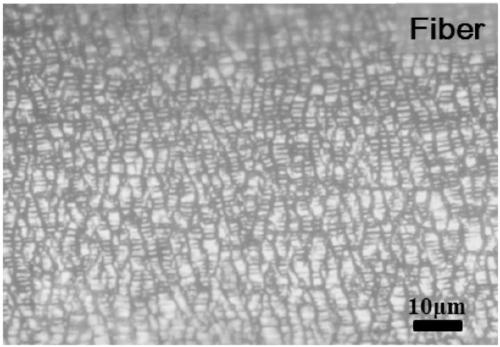

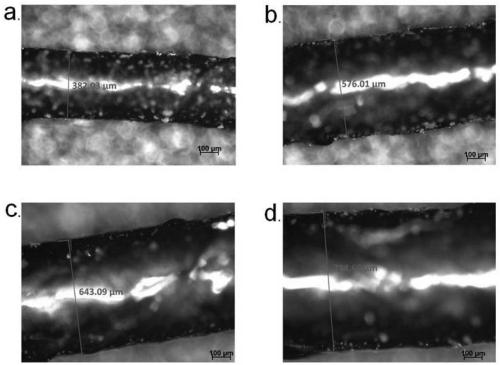

A kind of preparation method of conductive fiber with stretchable and low resistance change

ActiveCN108053946BOvercome fragileInhibition of microcracksElectroconductive/antistatic filament manufactureVacuum evaporation coatingElectrical resistance and conductanceFiber

The invention discloses a preparation method of a stretchable conductive fiber with low resistance change. According to the method, polydimethylsiloxane is added dropwise to the surface of the water,heat treatment is performed, and a polydimethylsiloxane film is stripped off from the surface of the water to prepare the polydimethylsiloxane film; a metal evaporator is utilized, and a metal film isvapor-deposited on the polydimethylsiloxane film and is taken as a conductive layer; the polydimethylsiloxane film loaded with the metal film is laid on a substrate and curled to prepare the conductive fiber. The method is advantaged in that the conductive fiber is stretchable and has low resistance change, the preparation method is simple, the preparation condition is mild, and the method has far-reaching significance for further development and promotion of flexible electrodes and flexible electronics.

Owner:NANJING TECH UNIV

Method for preparing green tea from summer tea leaves

InactiveCN108684840AEfficient hydrolysisImprove qualityPre-extraction tea treatmentMicrowaveAspergillus oryzae

The invention relates to a method for preparing green tea from summer tea leaves. The method comprises the following steps of selecting picked summer tea leaves; withering the selected summer tea leaves; performing fixation on the withered summer tea leaves; spreading the summer tea leaves after fixation for cooling, lowering the temperature, and performing spraying with binary probiotic metabolism liquid of aspergillus oryzae and rhizopus oryzae; and rolling the summer tea leaves sprayed with the binary probiotic metabolism liquid, performing drying, and performing spreading for cooling, so as to obtain finished products of the green tea. According to the technical scheme provided by the invention, viscosity materials in the rolling process of the summer tea leaves can be notably reduced,regiment-shaped adhesive leaf balls or leaf blocks can be prevented, and the problems that the summer tea leaves are easy to break and difficult to shape during rolling and processing, and the dry tea is bitter, are solved. A microwave vacuum drying technique is combined, so that the dry tea products are light and grayish green in color, durable in fragrance, and clear in soup color. Through adoption of the method, the summer tea leaves are used as raw materials for making superior green tea.

Owner:贵州三福生物科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com