Condensing unit used for modular wet process sulfuric acid production

A condensing device and modular technology, applied in chemical instruments and methods, inorganic chemistry, sulfur compounds, etc., can solve the problems of difficult to apply to various working conditions and high cost, to ensure the overall smooth operation, reduce maintenance costs, avoid Effects of acid gas leaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] To make the objectives, technical solutions, and advantages of the present invention clearer, the technical solutions of the exemplary embodiments of the present invention will be further described below.

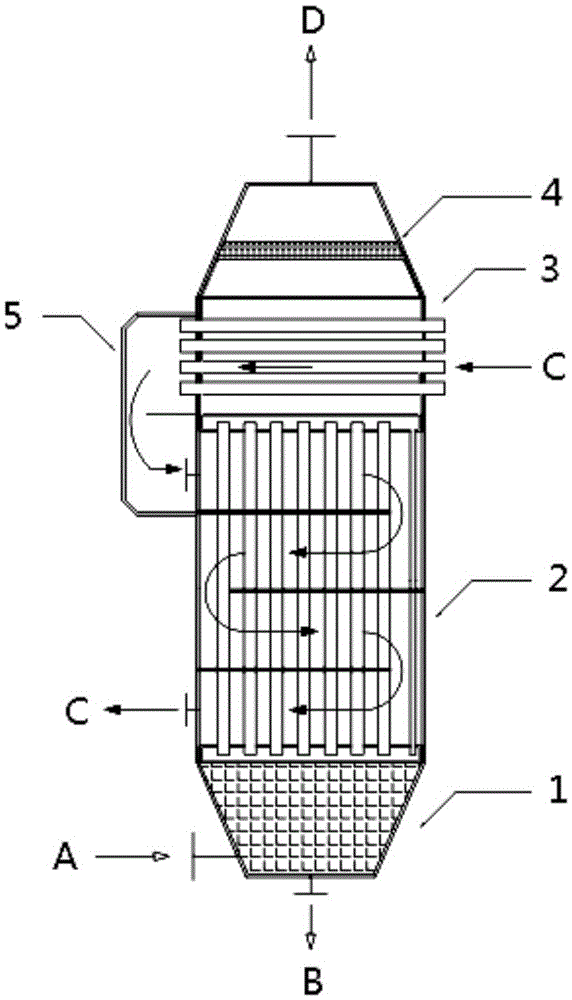

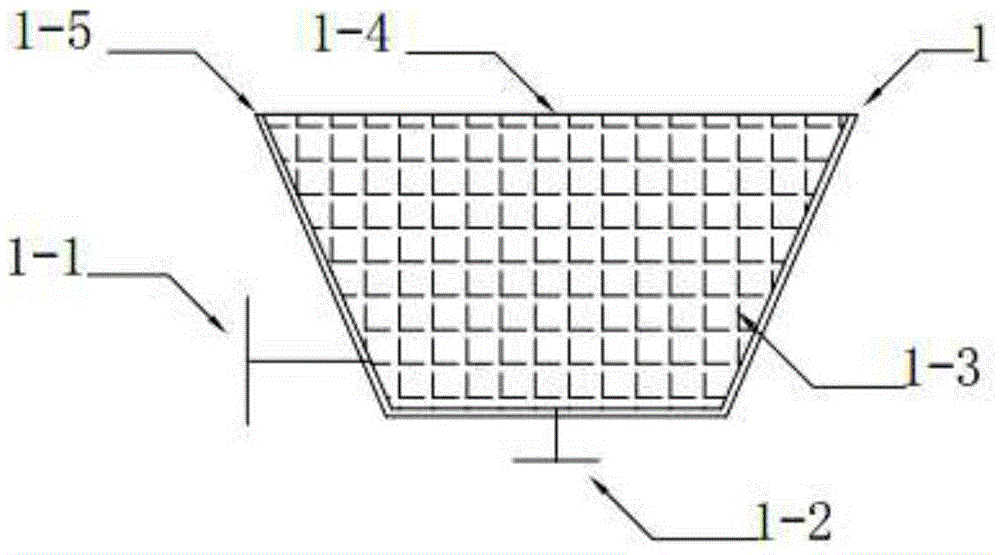

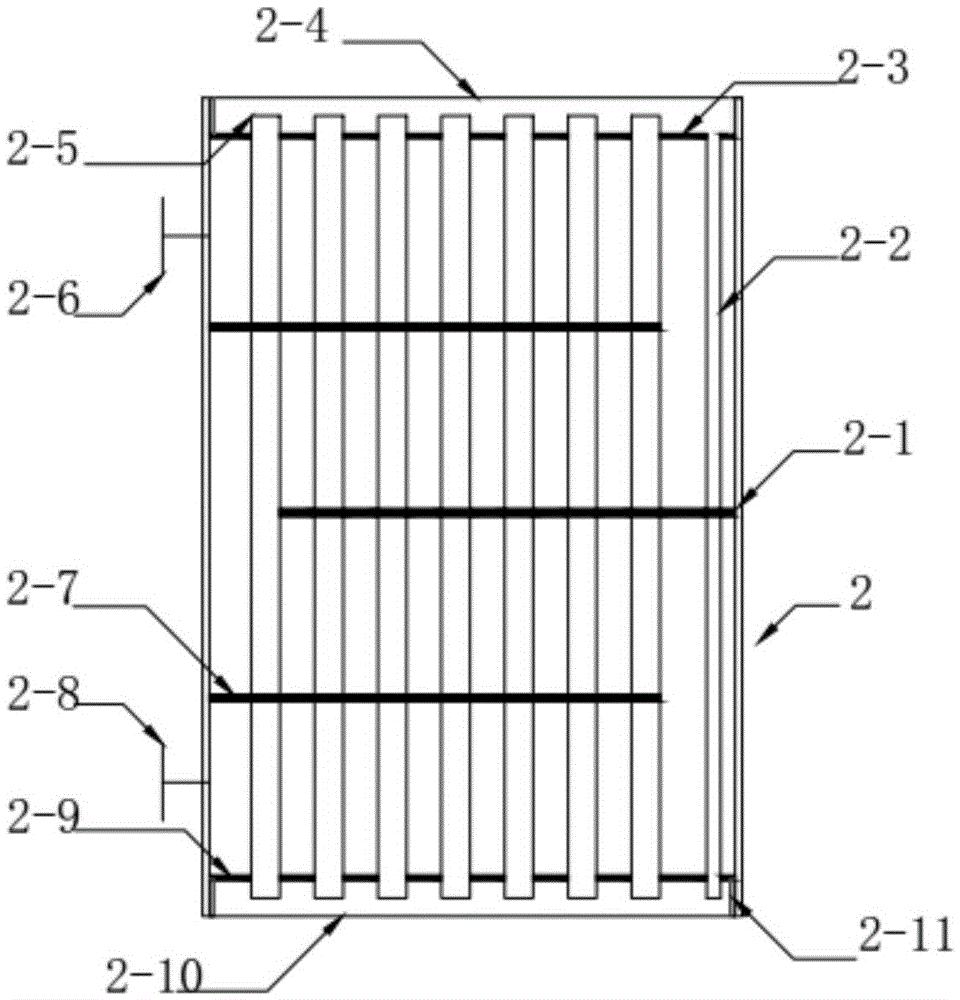

[0048] The present invention provides a modular condensation device for wet-process sulfuric acid production, comprising: a bottom tank module, a plurality of condensation modules, a demister module, and a gas circuit connection module, wherein the bottom tank module is located at the bottom of the condensation device and has a funnel shape. The side is provided with an acid gas inlet, and the bottom is provided with a sulfuric acid drain; a plurality of condensing modules are located above the bottom tank module, including at least one vertical condensing module and at least one horizontal condensing module; the demisting module is located in the multiple condensing modules The upper part is trapezoidal, with a mist removal unit inside, and a tail gas outlet at the top;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com