Microchannel liquid cooling cold plate

A micro-channel and channel fluid technology, applied in the field of electronic information, can solve the problems of long manufacturing cycle, complex process, inconvenient sealing, etc., and achieve the effect of increasing the degree of turbulence, reducing the thickness of the boundary layer, and shortening the research and development cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

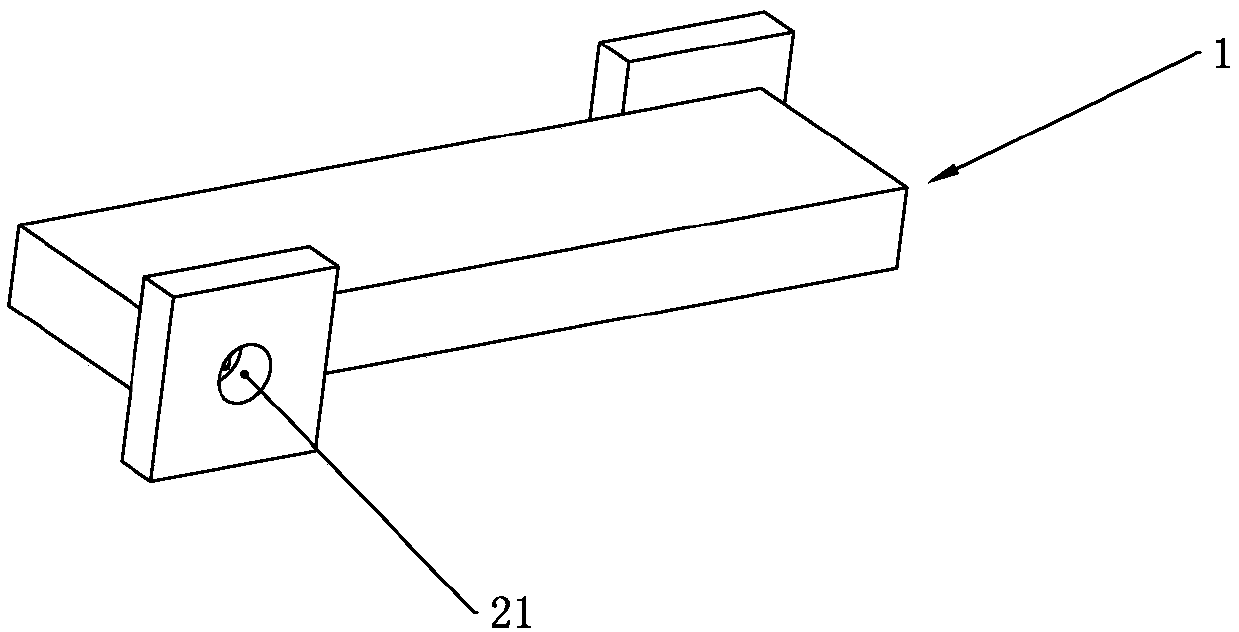

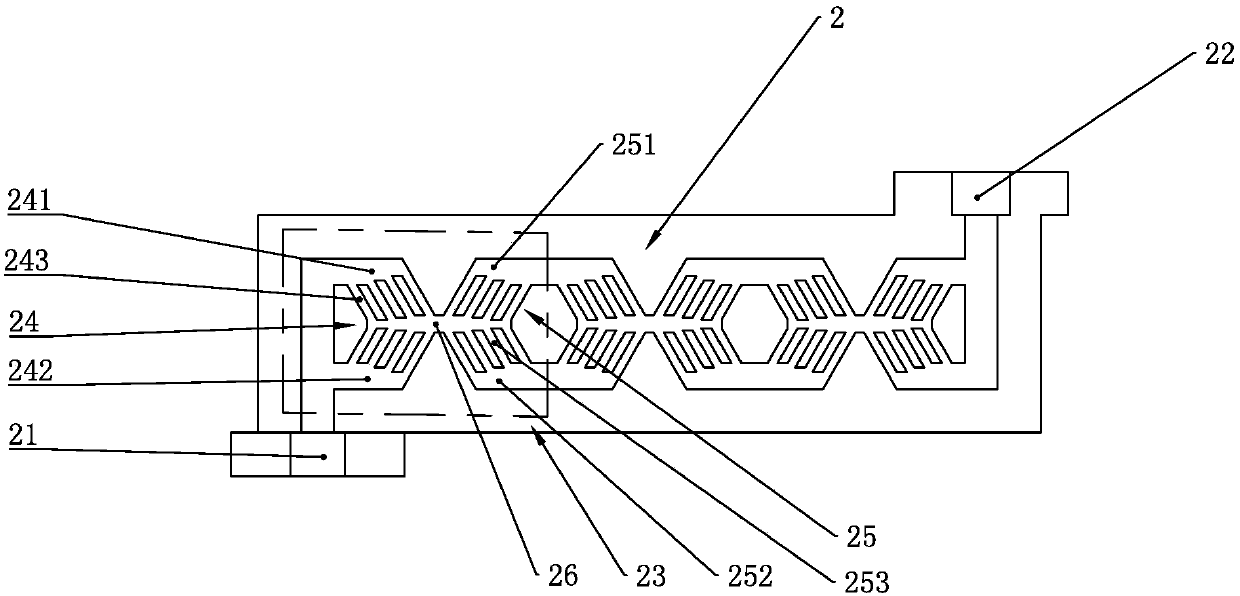

[0025] Such as figure 1 and figure 2 As shown, a kind of micro-channel liquid-cooled cold plate provided by the present invention comprises a cold plate base 1, and the inside of the cold plate base 1 is provided with an internal flow channel 2, and the internal flow channel 2 includes a flow channel inlet 21, a flow channel outlet 22 and at least A microchannel unit 23, the microchannel unit 23 communicates with the flow channel inlet 21 and the flow channel outlet 22 respectively, the cooling liquid enters from the flow channel inlet 21, and flows out from the flow channel outlet 22 after passing through the microchannel unit 23, the microchannel unit 23 The horizontal section is butterfly-shaped, and the flow channel inlet 21 and the flow channel outlet 22 communicate with the external environment respectively.

[0026] The microchannel unit 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com