Laser beam coupling output device for high-power semiconductor

A laser beam, coupled output technology, applied in the direction of optics, optical components, instruments, etc., can solve the problems of increasing the difficulty of machining laser parts, affecting the quality of the output beam beam, increasing the cost of the laser system, etc., to reduce the difficulty of machining , reduced volume and weight, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

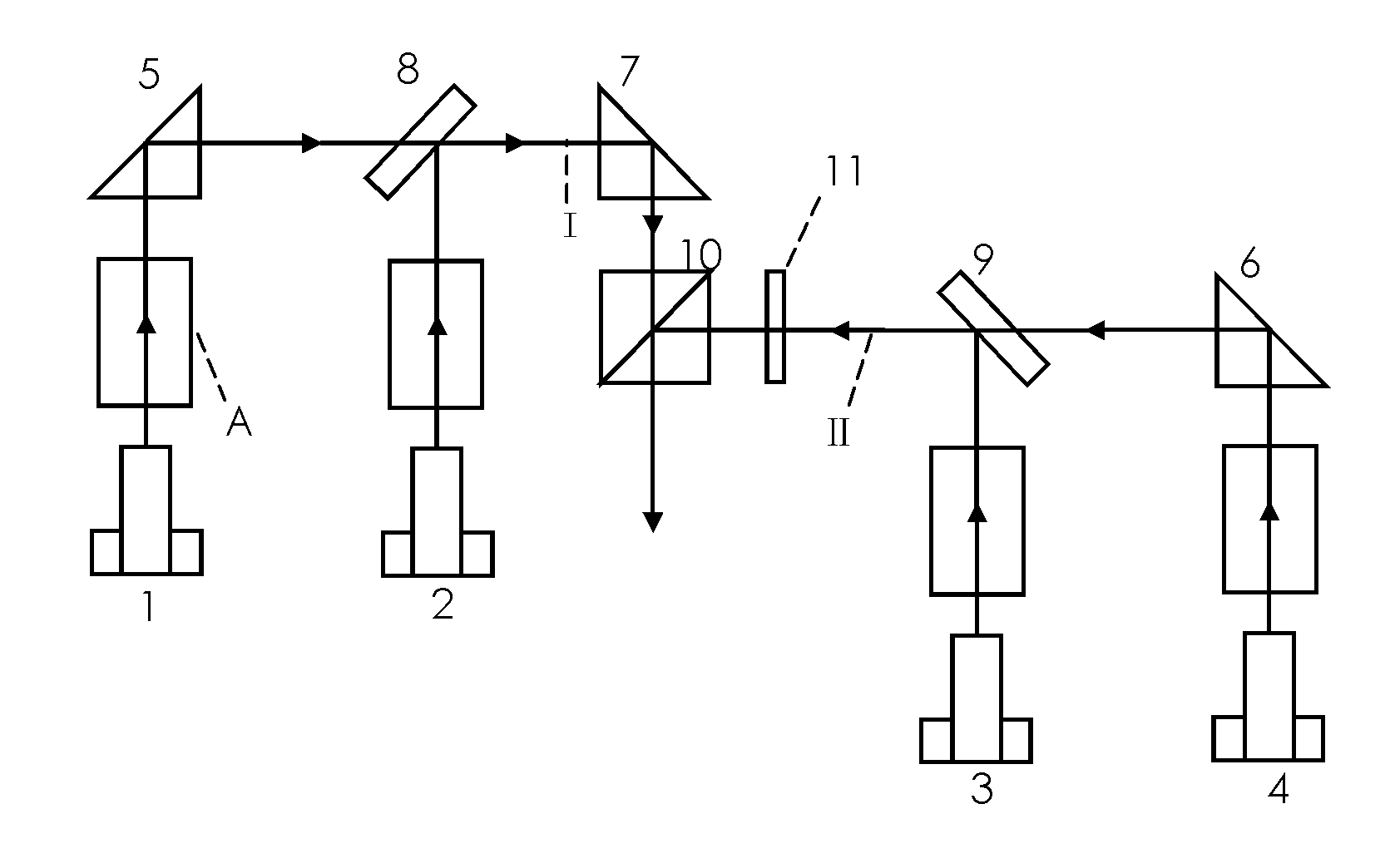

[0031] Such as figure 1 As shown, a high-power semiconductor laser beam coupling output device consists of the first semiconductor laser array 1, the second semiconductor laser array 2, the third semiconductor laser array 3, the fourth semiconductor laser array 4, the first rectangular prism 5, the second A rectangular prism 6, a third rectangular prism 7, a first wavelength coupler 8, a second wavelength coupler 9, a polarization coupler 10, a half-wave plate 11 and four shaping devices A. The four shaping devices A are respectively located behind the four semiconductor laser arrays, and the half-wave plate 11 is placed between the second wavelength coupler 9 and the polarization coupler 10 perpendicular to the propagation direction of the optical path. The surfaces of the first rectangular prism 5 , the second rectangular prism 6 , and the third rectangular prism 7 are coated. The first wavelength coupler 8 and the second wavelength coupler 9 are spectroscopic elements such ...

Embodiment 2

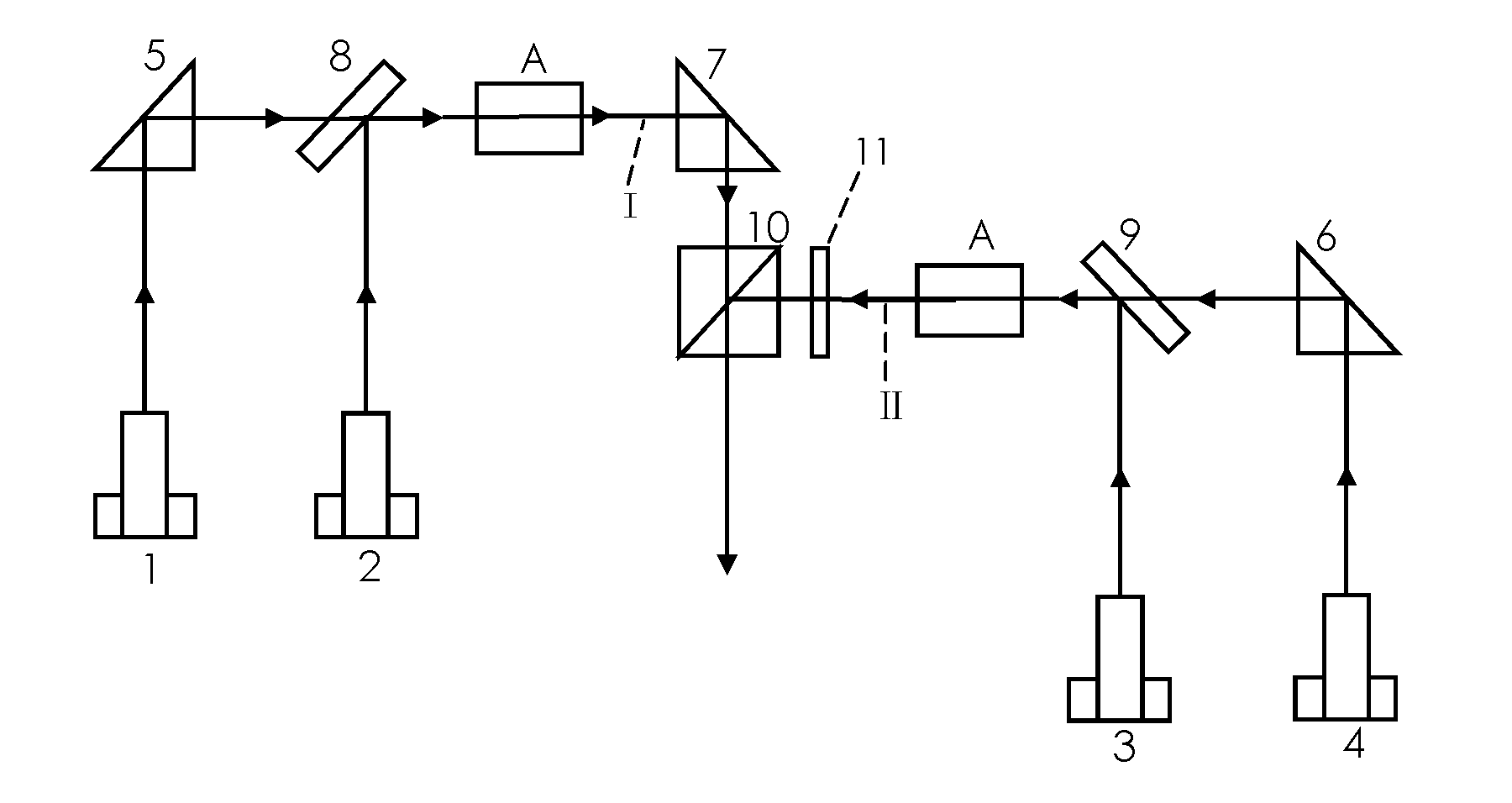

[0035] Such as figure 2 As shown, the difference between embodiment 2 and embodiment 1 is that the light emitted by the semiconductor laser array in embodiment 2 is firstly subjected to wavelength coupling, and then undergoes beam shaping. That is, the four beam shaping devices located behind the semiconductor laser array are canceled, and only two beam shaping devices are placed after the first wavelength coupler 8 and after the second wavelength coupler 9 .

Embodiment 3

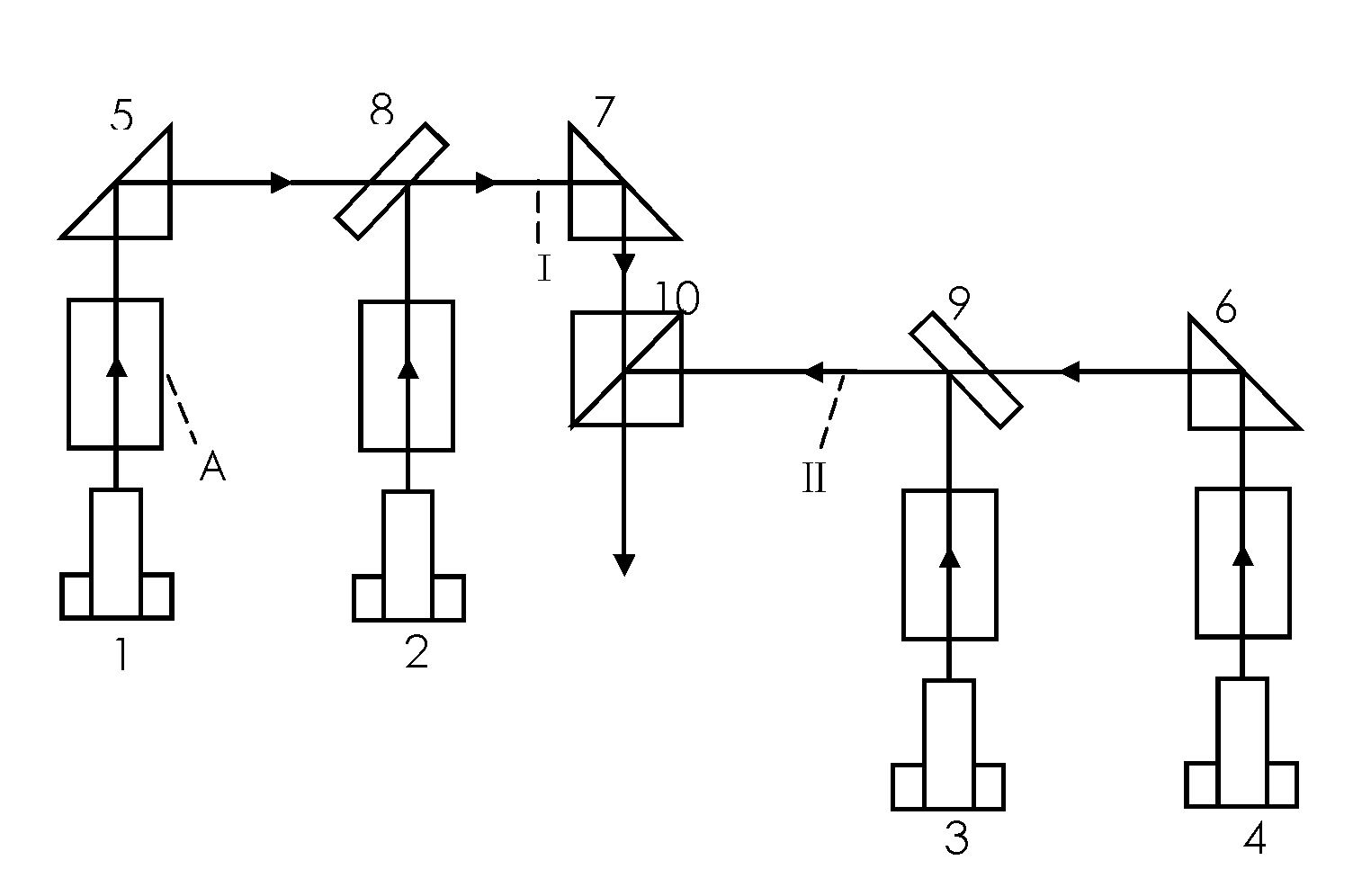

[0037] Such as image 3 As shown, a high-power semiconductor laser beam coupling output device consists of the first semiconductor laser array 1, the second semiconductor laser array 2, the third semiconductor laser array 3, the fourth semiconductor laser array 4, the first rectangular prism 5, the second A rectangular prism 6, a third rectangular prism 7, a first wavelength coupler 8, a second wavelength coupler 9, a polarization coupler 10 and four shaping devices A. The four shaping devices A are respectively located behind the four semiconductor laser arrays. The surfaces of the first rectangular prism 5 , the second rectangular prism 6 , and the third rectangular prism 7 are coated. The first wavelength coupler 8 and the second wavelength coupler 9 are spectroscopic elements such as prisms, gratings, and interferometers. The polarizing coupler 10 is a Glan-Taylor prism, a thin-film polarizing device, a film with polarizing effect or a natural birefringent crystal.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com