Patents

Literature

102results about How to "Improve the accuracy of assembly and adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

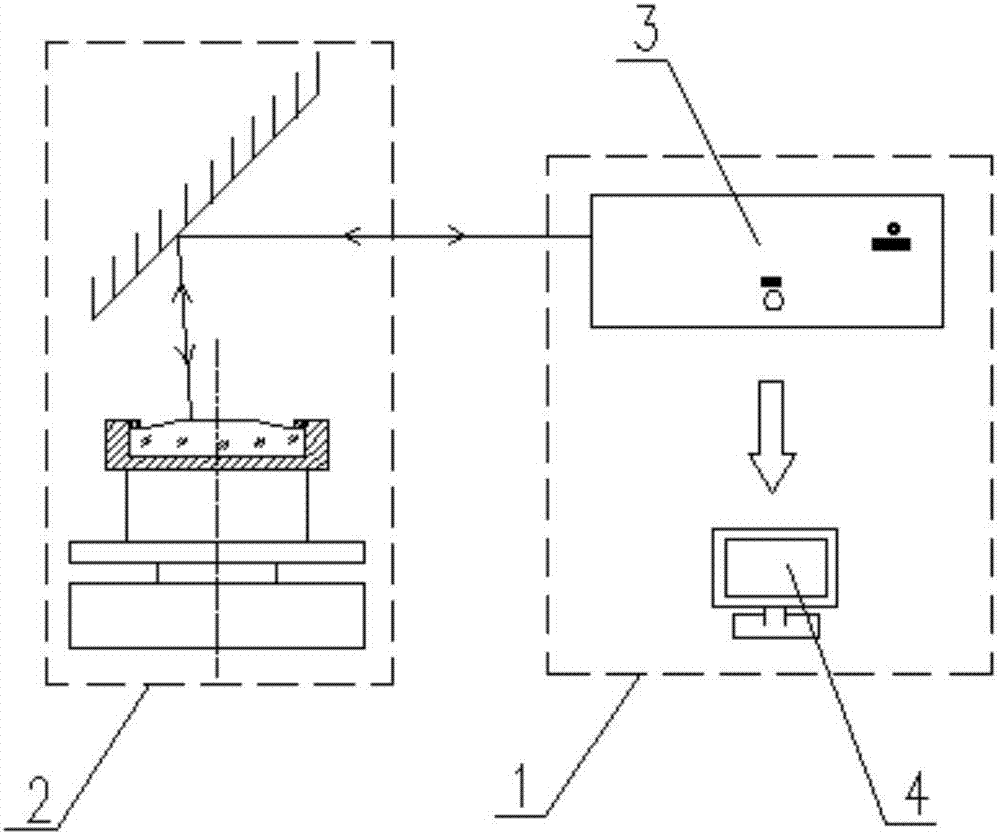

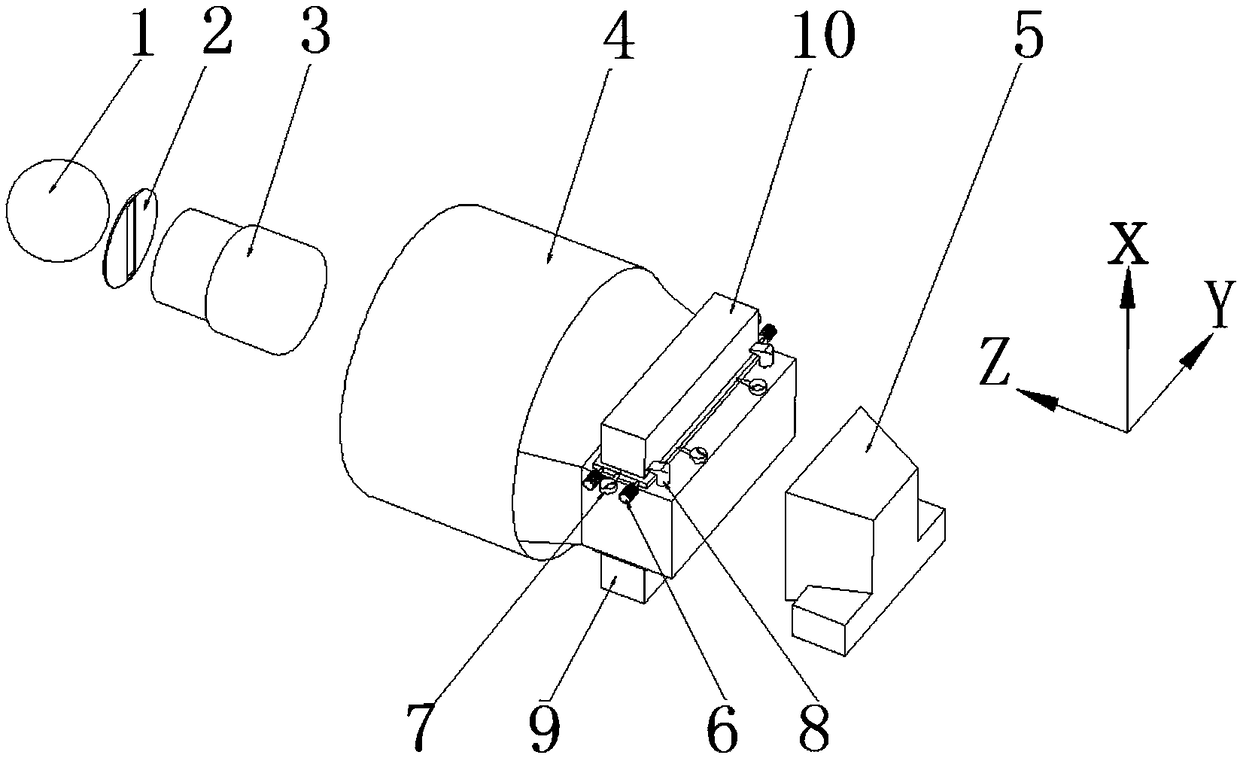

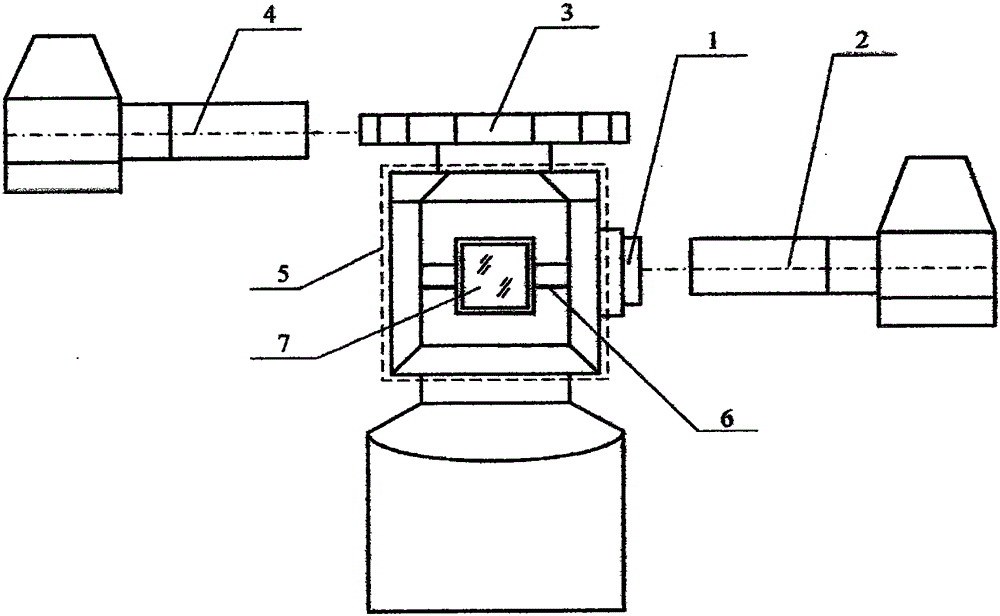

Auxiliary adjustment device for optical lenses

InactiveCN104007560AImprove the accuracy of assembly and adjustmentSimplify the assembly processUsing optical meansOptical elementsCamera lensPhotovoltaic detectors

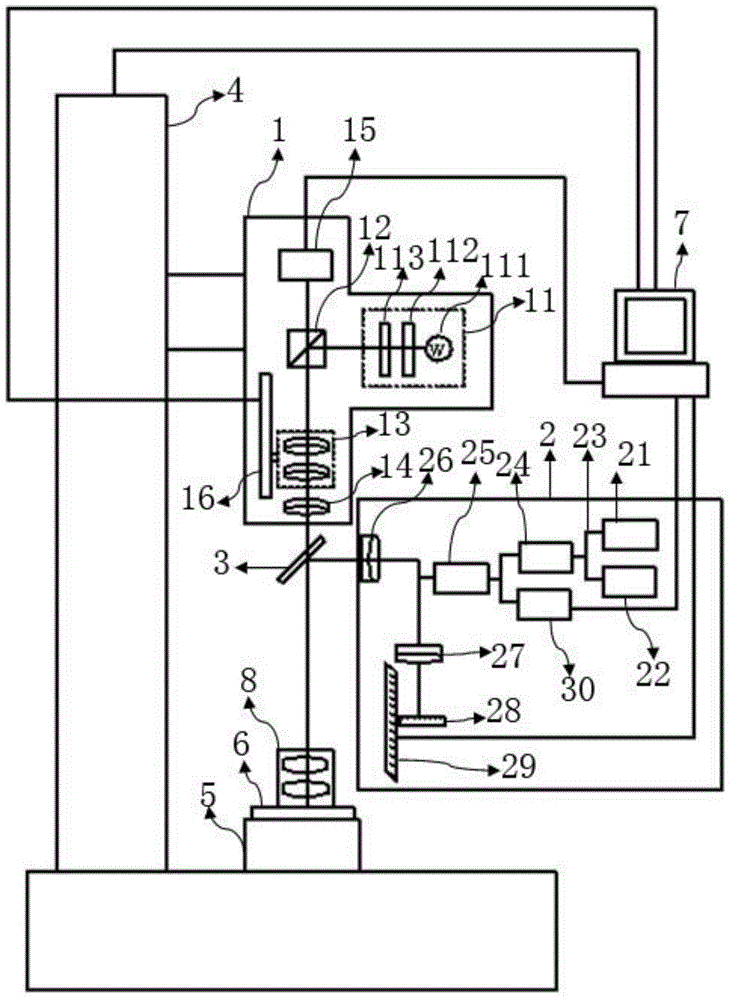

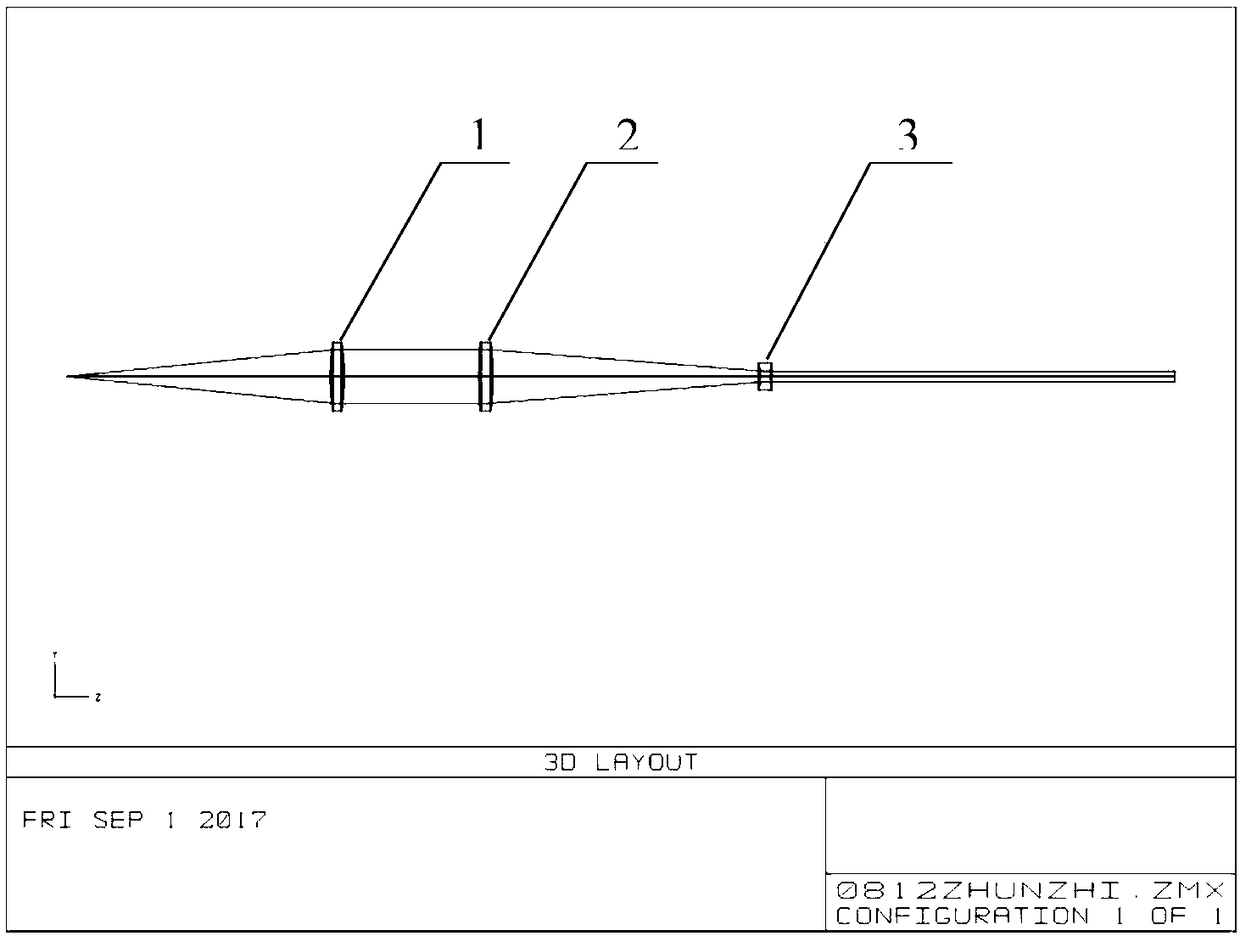

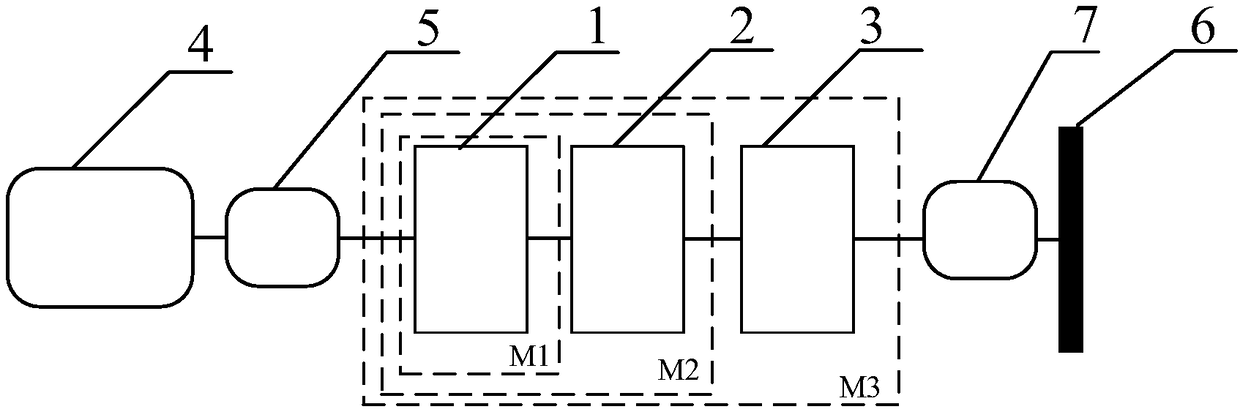

The invention relates to an auxiliary adjustment device for optical lenses and belongs to the field of optical systems. The auxiliary adjustment device for optical lenses solves the technical problems that as the center deviation and the lens interval of optical lenses are detected separately in the prior art, the measurement accuracy is low and cost is high. The auxiliary adjustment device for optical lenses comprises a center deviation measurement module, a lens interval measurement module, a reflector, a linear guide rail, a precision turn table, a mechanical adjustment platform and a main control computer, wherein the center deviation measurement module comprises an optical lighting module, a beam splitter, a collimating lens set, a focus lens set, a photoelectric detector and a linear displacement sensor. The auxiliary adjustment device for optical lenses integrates the center deviation measurement function and the lens interval measurement function for optical lenses, not only is the manufacturing cost low, but also it is ensured that the same reference axis is adopted in the adjustment process of optical lenses, the adjustment accuracy of optical lenses can be improved, the adjustment process of optical lenses is simplified, and consequently the adjustment efficiency of optical lenses is improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

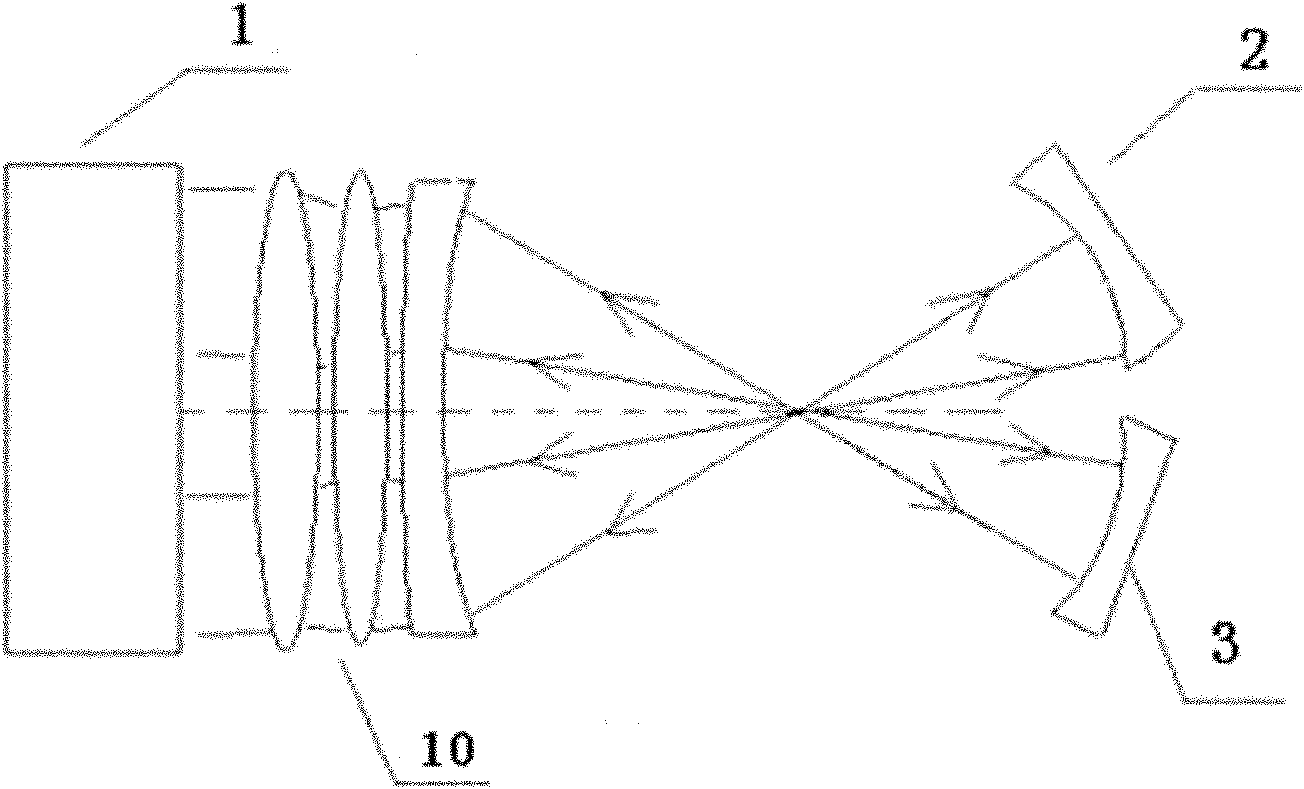

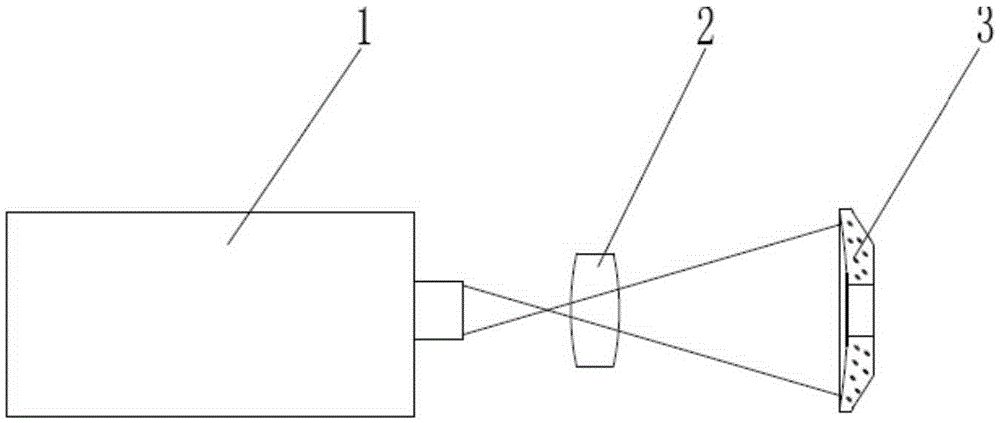

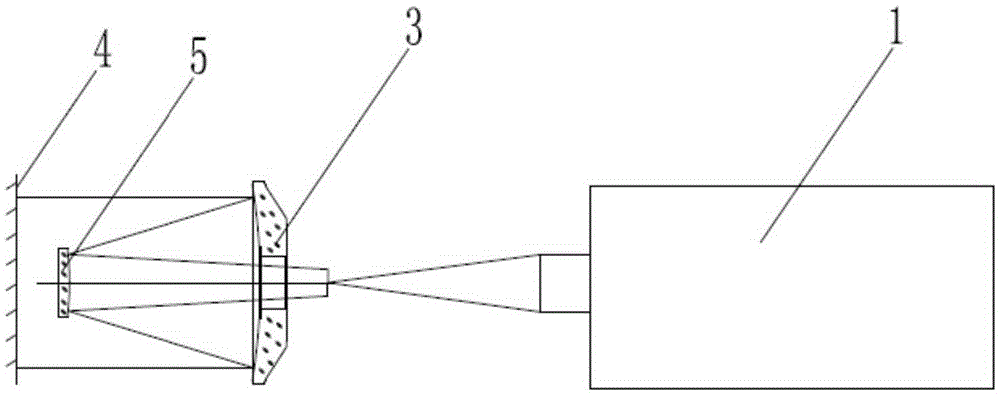

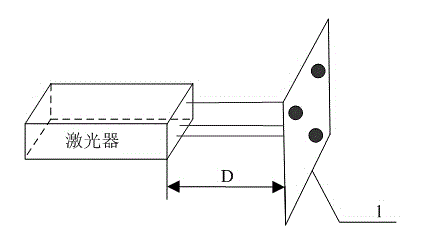

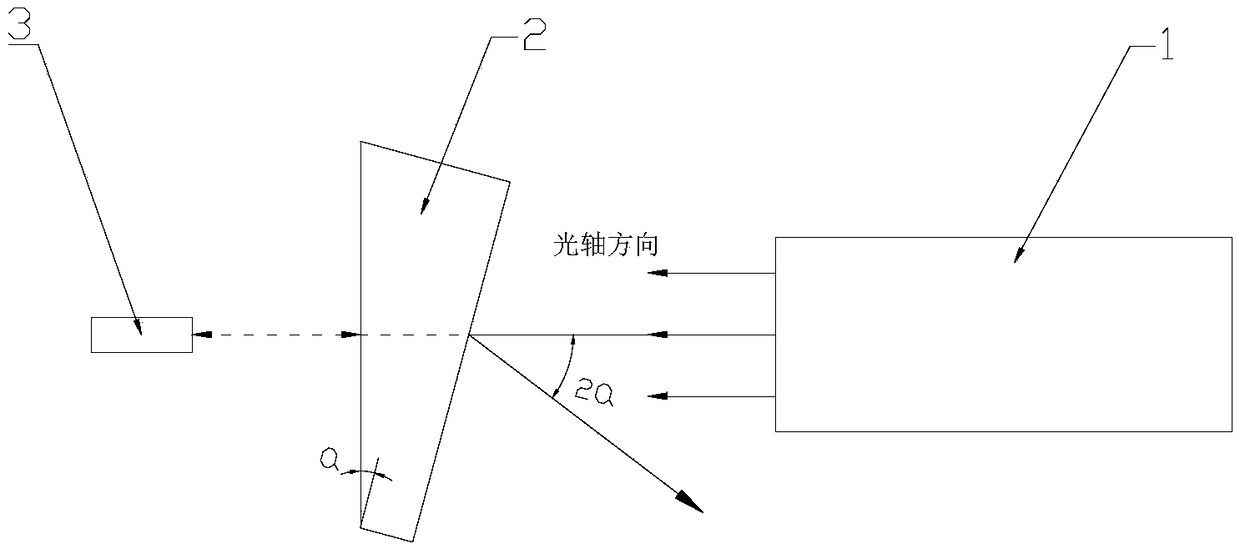

Adjustment and installation device for optical antenna of semiconductor laser range instrument

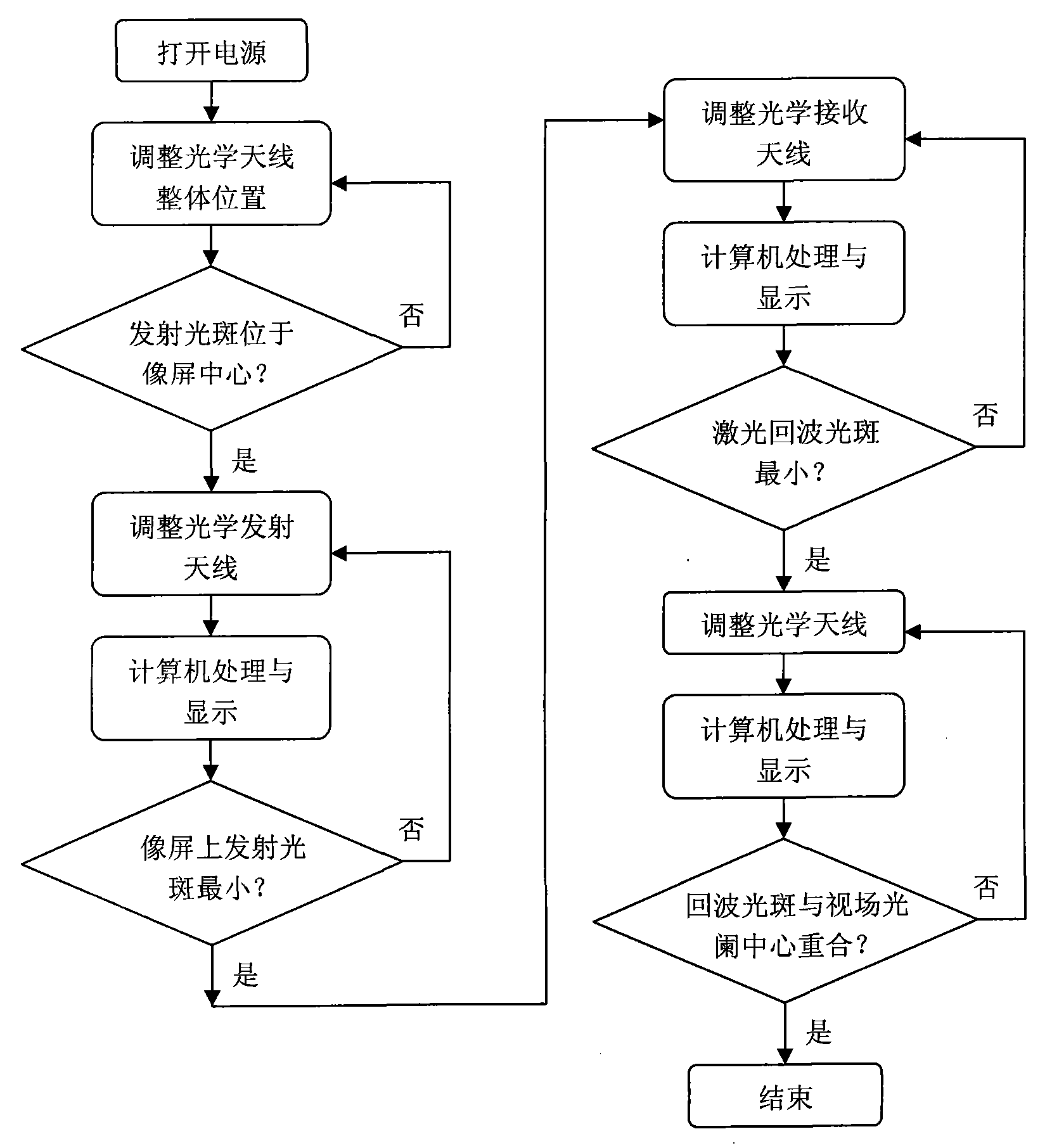

ActiveCN101551451ASimple installationImprove the accuracy of assembly and adjustmentElectromagnetic wave reradiationPhysicsCcd camera

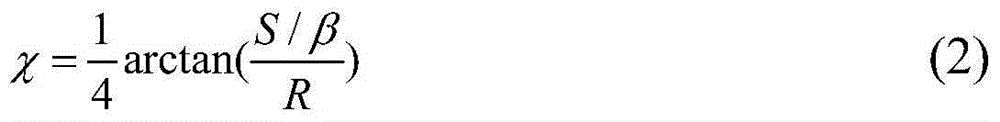

The invention discloses an adjustment and installation device for an optical antenna of a semiconductor laser range instrument. A parallel light tube is arranged behind the adjusted optical antenna; an image screen is arranged on a focus surface of the parallel light tube; a rear end area array camera is arranged behind the image screen; the rear end area array camera is connected with a computer; a reading microscope is arranged before the adjusted optical antenna; the reading microscope is connected with a front end area array CCD camera which is connected with the computer; the adjusted optical antenna comprises a transmitting antenna and a receiving antenna; and a semiconductor laser is arranged on the transmitting antenna and connected with a driving power. The adjustment and installing device can achieve integrated and visualized accurate optical antenna adjustment and installing with laser shot, viewing filed receiving and optical axle parallelity, has the advantages of simple structure, high optical antenna installation and adjustment precision and efficiency, no influence by subjective factors, and the like, and can be widely applied to the adjustment and the installation of the optical antenna of the semiconductor laser range instrument.

Owner:NANJING UNIV OF SCI & TECH

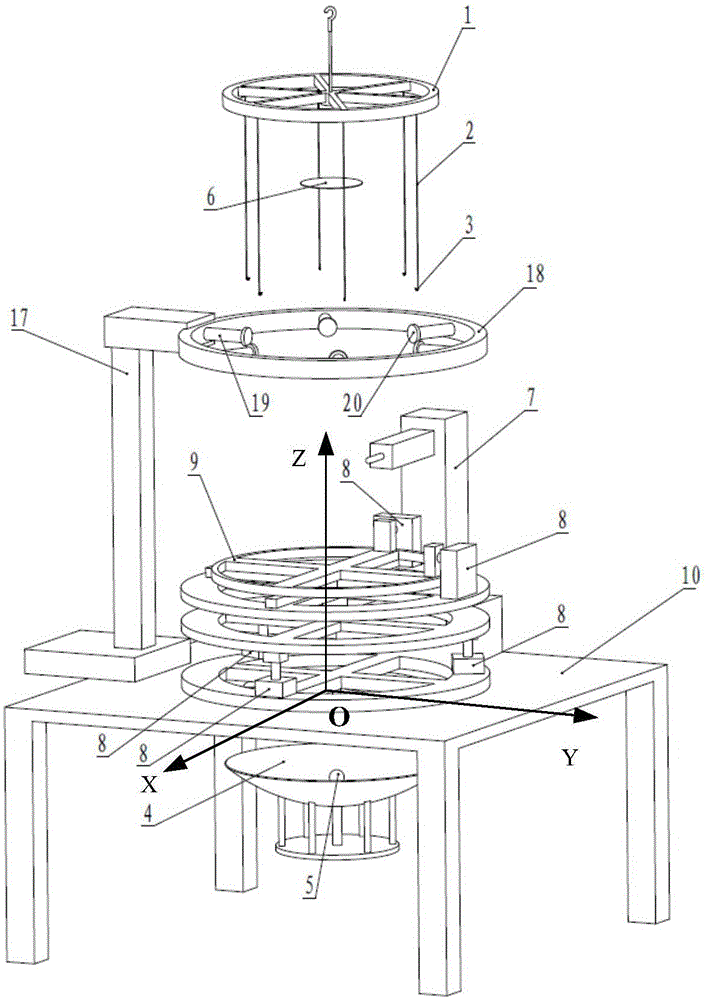

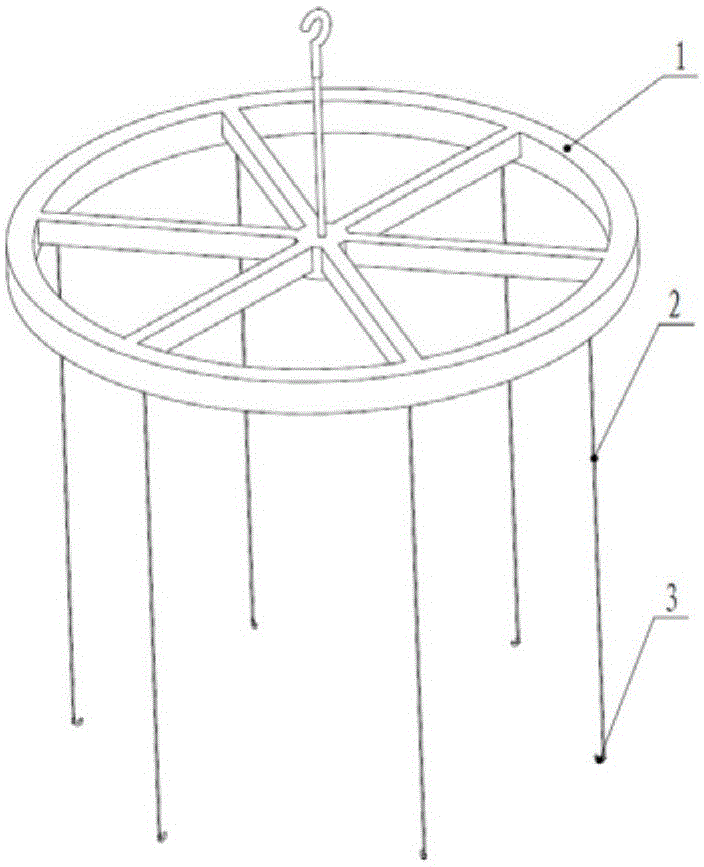

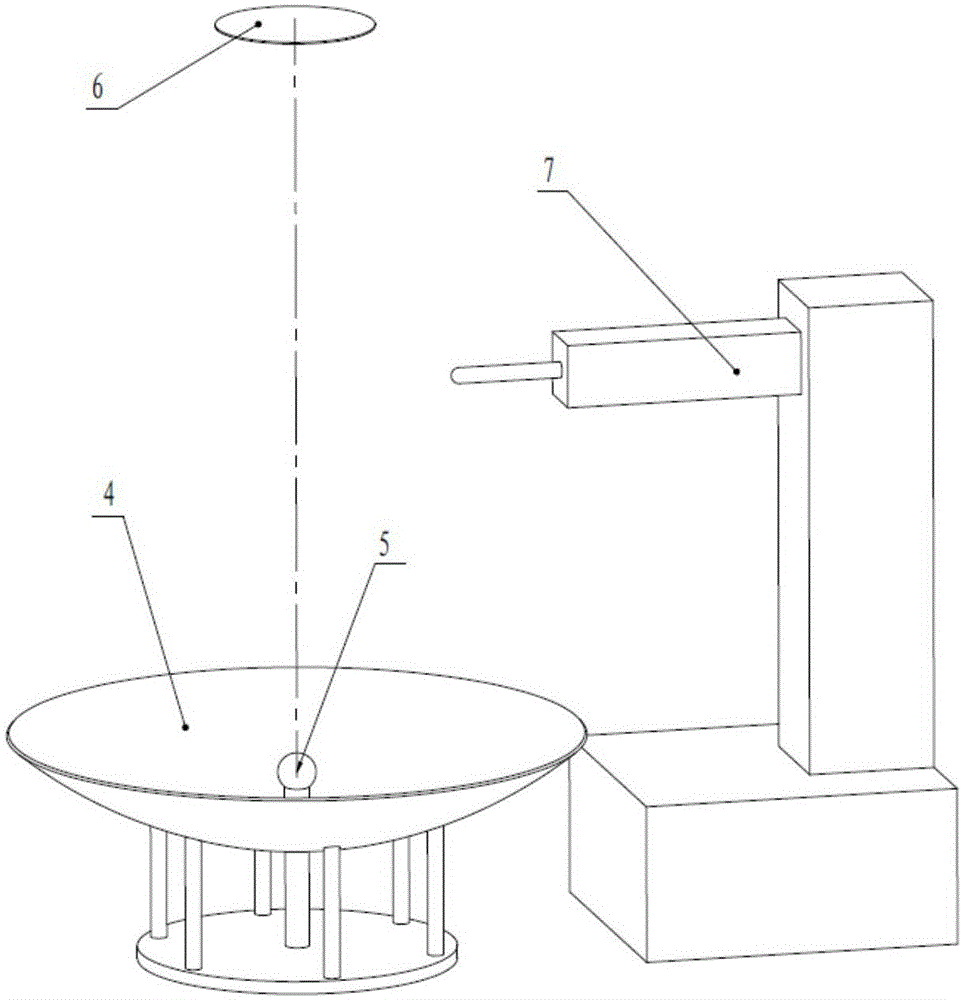

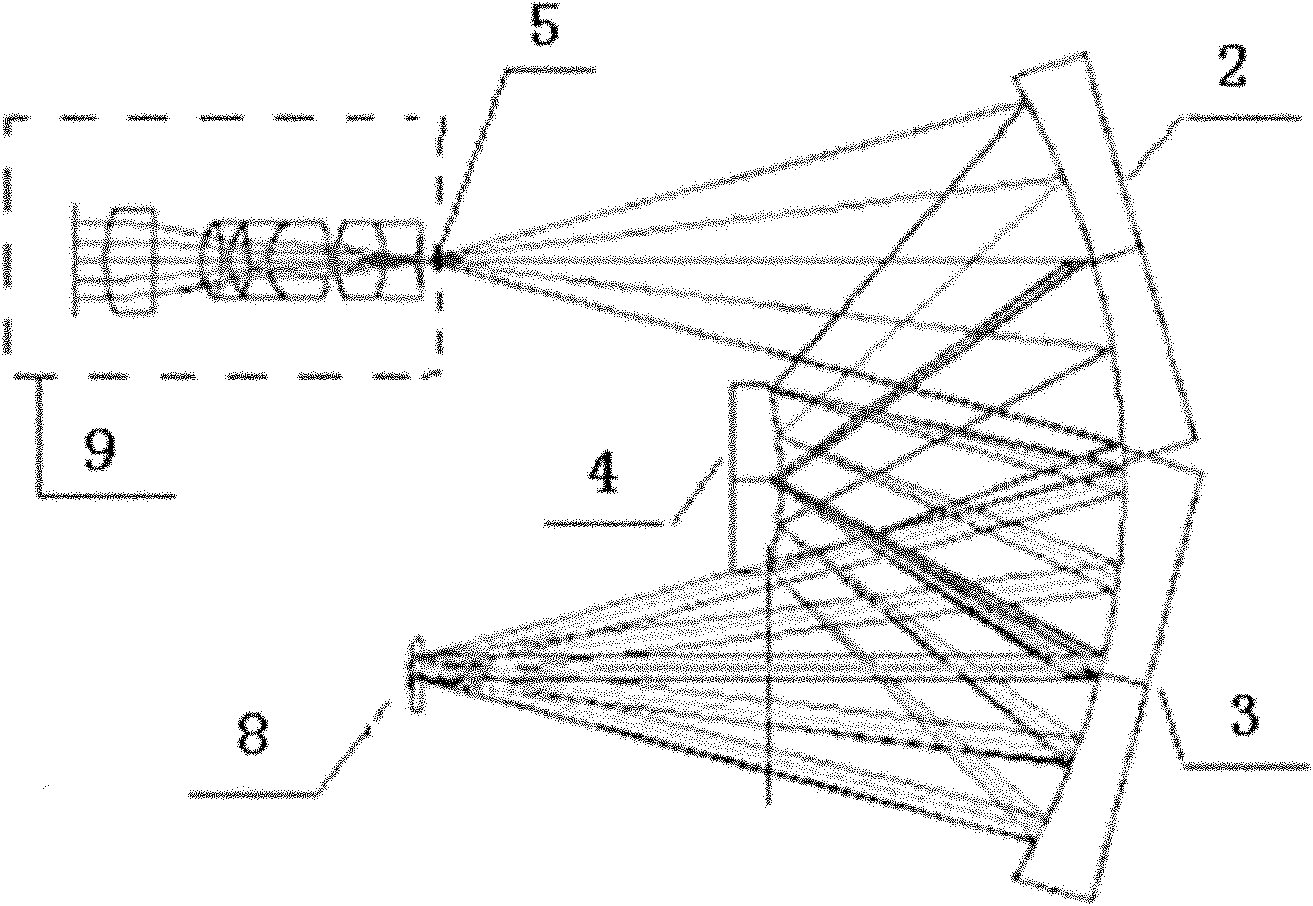

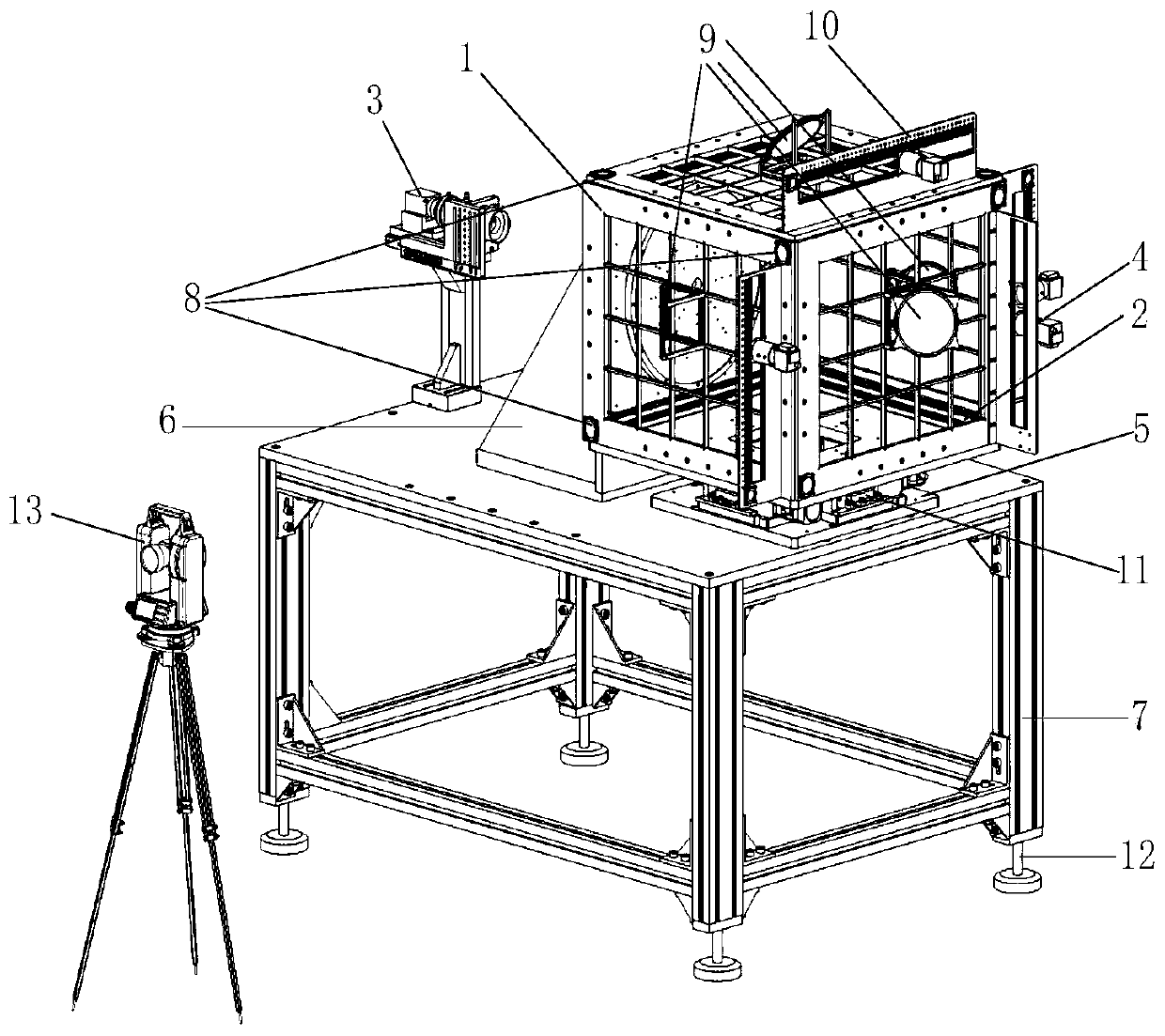

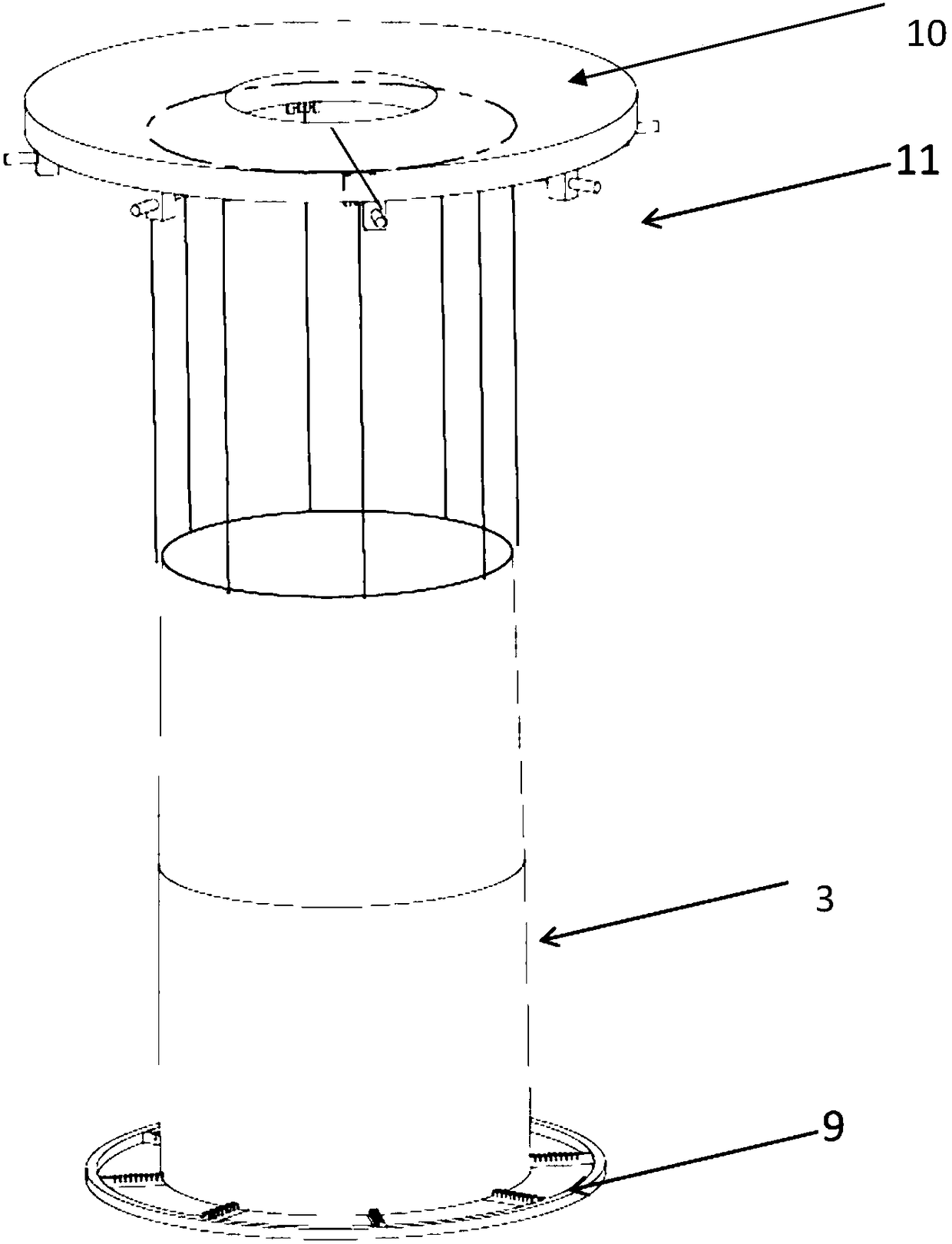

Installation and adjustment system and method for multi-layer nested X-ray grazing incidence optical lens

ActiveCN105068208AGuarantee the accuracy of the initial surface shapeAvoid damageMountingsCamera lensX-ray

The invention proposes an installation and adjustment system and method for a multi-layer nested X-ray grazing incidence optical lens, and the system comprises a suspension subsystem, a measurement subsystem, a displacement subsystem, a pre-installation supporting device, an optical supporting platform, and a focal plane receiving screen. The method comprises seven steps: preparation, suspension, pre-installation, alignment, measurement, binding, and supporting structure installation. The system and method can greatly improve the installation and adjustment precision, speed and yield of the multi-layer nested X-ray grazing incidence optical lens, achieve no-stress installation and adjustment, improve the optical performance, are easy to implement, is high in universality, is high in installation and adjustment precision, and is high in installation and adjustment efficiency.

Owner:BEIJING INST OF CONTROL ENG

Method for assembling convex grating imaging spectrometer

InactiveCN102141439ATroubleshoot assembly methodsHigh implementabilitySpectrum investigationTelephoto lensGrating

The invention discloses a method for assembling a convex grating imaging spectrometer, and the method provided by the invention belongs to the field of optical instruments, and is used for solving the problems that the existing convex grating concentric beam-splitting system is difficult to install and adjust, so that the concentric accuracy of the system is low and the practical applicability of the system is poor. The method disclosed by the invention comprises the following steps: configuring an interferometer and a standard compensating mirror; arranging a primary mirror and a triangular mirror of a convex grating beam splitting system in front of the interferometer, adjusting the positions of the primary mirror and the triangular mirror, so that an interference fringe occurs to the interferometer; arranging a mercury lamp in front of a slit, arranging a grating between the primary mirror and the triangular mirror, arranging a reading microscope at the image surface of the convex grating beam splitting system, and then adjusting the grating, so that the reading microscope can read out the zero-level and minus-one-level spectrums of the mercury lamp; and arranging a detector and a telephoto lens, and then adjusting the detector and the telephoto lens, so that the detector can accept an ideal spectral image of a detected target. In the method disclosed by the invention, because the assembling of the grating and the detector are realized by using a spectrogram direct-reading method, the method is strong in practicability and high in accuracy.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Device and method for centering assembling adjustment of large-calibre aspheric-surface reflector

ActiveCN106873122AHigh measurement accuracyImprove the accuracy of assembly and adjustmentMountingsOptical axisDisplay device

The invention, which belongs to the technical field of optical machine assembling adjustment, discloses a device and method for centering mounting adjustment of a large-calibre aspheric-surface reflector. The method is characterized in that a to-be-adjusted aspheric-surface reflector is fixed at a rotary adjusting mechanism of a centering device; deviation between an optical axis of the aspheric-surface reflector and a reference axis is measured in real time by using an eccentricity measuring system in the device and the position and direction of the deviation are displayed at a display device; and the position attitude of the aspheric-surface reflector is adjusted, so that the overlapping error between the reflector optical axis and the reference axis is smaller than a designed allowance value and thus centering assembling adjustment of the aspheric-surface reflector is completed. With the device and method, a centering problem of a large-calibre rotary symmetric aspheric-surface reflector can be solved. The device and method have characteristics of simple instrument erecting, great convenience in operation, and high centering precision and the like.

Owner:西安应用光学研究所

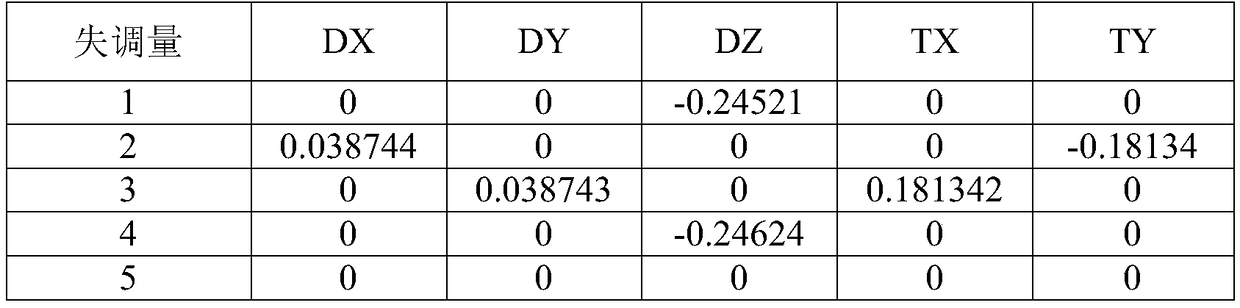

Computer-aided installation and adjustment method of coaxial optical system

ActiveCN109031659AAvoid position mutual compensation problemsSolve the problem that cannot be adjustedDesign optimisation/simulationSpecial data processing applicationsComputer-aidedComputer aid

The invention discloses a computer-aided installation and adjustment method of a coaxial optical system. The computer-aided installation and adjustment method comprises the following steps of S1, establishing an optical model of an optical system to be installed and adjusted, and separately establishing n optical sub-systems along the optical path direction, wherein the n optical sub-system comprises optical elements 1-n; S2, selecting the image plane positions of each optical sub-system and obtaining an ideal wavefront aberration through simulation analysis; S3, introducing a position deviation amount to the optical element n in the n optical sub-system to obtain a simulated wavefront aberration; S4, solving a sensitivity matrix corresponding to each optical sub-system by adoptinga sensitivity matrix formula; and S5, solving the actual position deviation of the optical element n in the n optical sub-system by utilizing the sensitivity matrix and the actual wavefront aberration, and adjusting the optical element, so as to successively complete the installation and adjustment of the n optical sub-systems. By adoption of the method, the problem of mutual compensation ofpositions of all the optical elements in the adjusting process can be avoided, so that the convergence speed in the assembling and adjusting process is accelerated, and the assembling and adjusting precision and the assembling and adjusting efficiency are improved.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

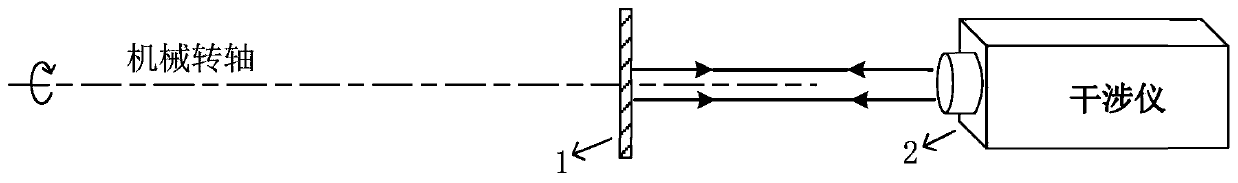

Method and device for precisely determining optical system focus surface by interferometer

InactiveCN1858632AHigh positioning accuracyAvoid blindnessRadiation pyrometrySpectrometry/spectrophotometry/monochromatorsComputational physicsOptic system

This invention discloses a method and a device for applying an interferometer to determine focusing faces of an optical system accurately, in which, the working principle is that the standard light emitted by a laser interferometer is reflected back to the interferometer after passing through a tested optical system and the focusing face of an optical system is determined by the principle that it is easy for it to get interference fringes at the cat-eye position so as to increase the location accuracy of the focusing faces of an optical system.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Optical machine adjusting method of R-C reflection and refraction system

ActiveCN105353494AReduce difficultyReduce the number of loading and unloadingMountingsOptoelectronicsInterferometry

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Optical axis consistency adjustment and detection device and method for space laser communication terminal

ActiveCN110487220AAccurate displayEfficient and intuitive assembly processUsing optical meansOptical axisComputer terminal

The invention belongs to the technical field of optical detection, and particularly relates to an optical axis consistency adjustment and detection device and method for a space laser communication terminal. According to the device, the offset of an optical axis is detected through a CCD detection camera, the CCD detection camera collects an image and can display the offset of a laser spot, the direction and the size of the optical axis are adjusted according to the displayed offset, the actual spot position is enabled to be coincide with the center of the theoretical spot position by adjusting the attitude of a to-be-detected optical system lens of the to-be-adjusted laser communication terminal, and the adjustment and detection process of the optical axis consistency is completed. The device is convenient and efficient to install and operate, high in adjustment precision and small in size, and the cost is greatly reduced.

Owner:CHANGCHUN UNIV OF SCI & TECH

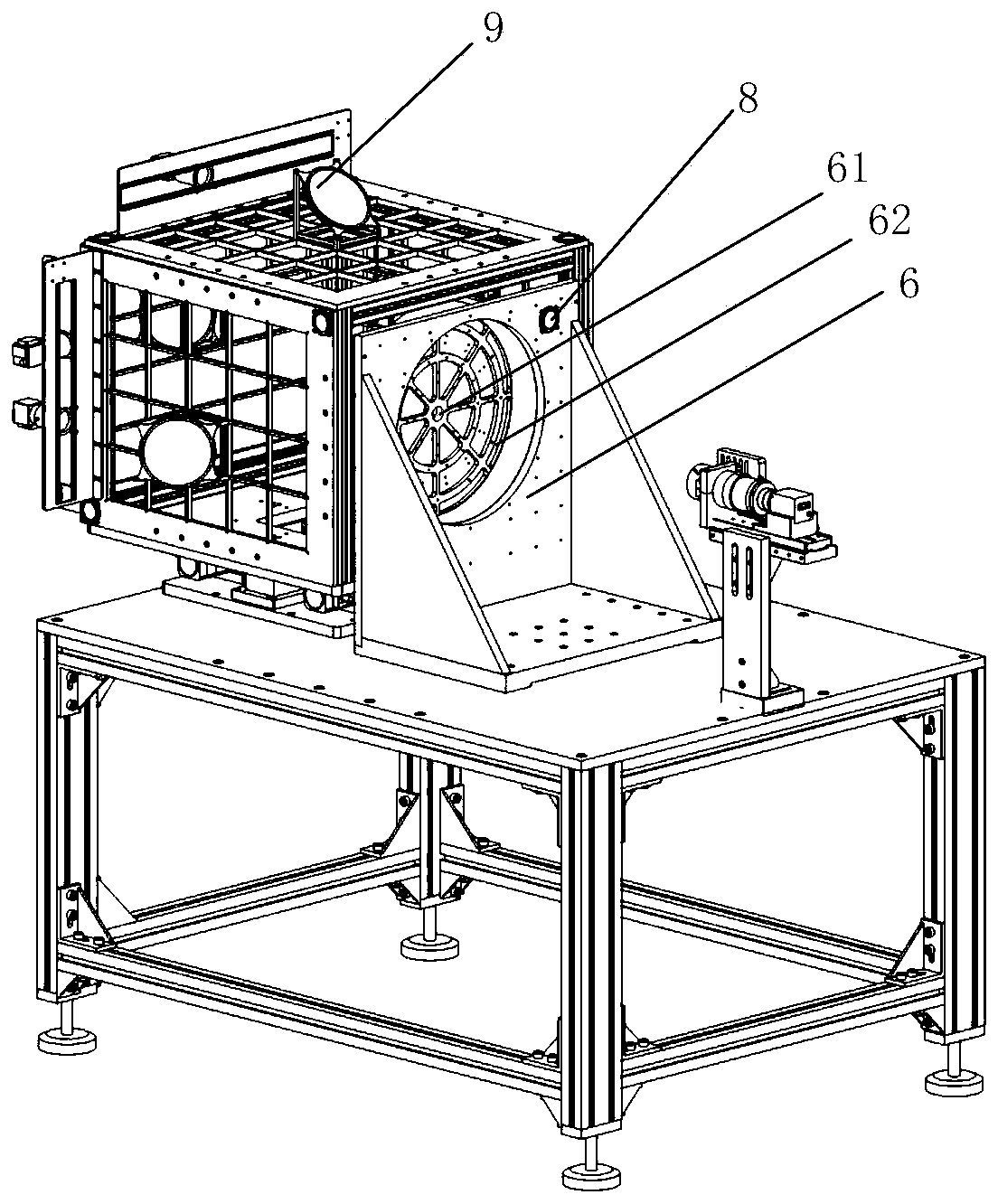

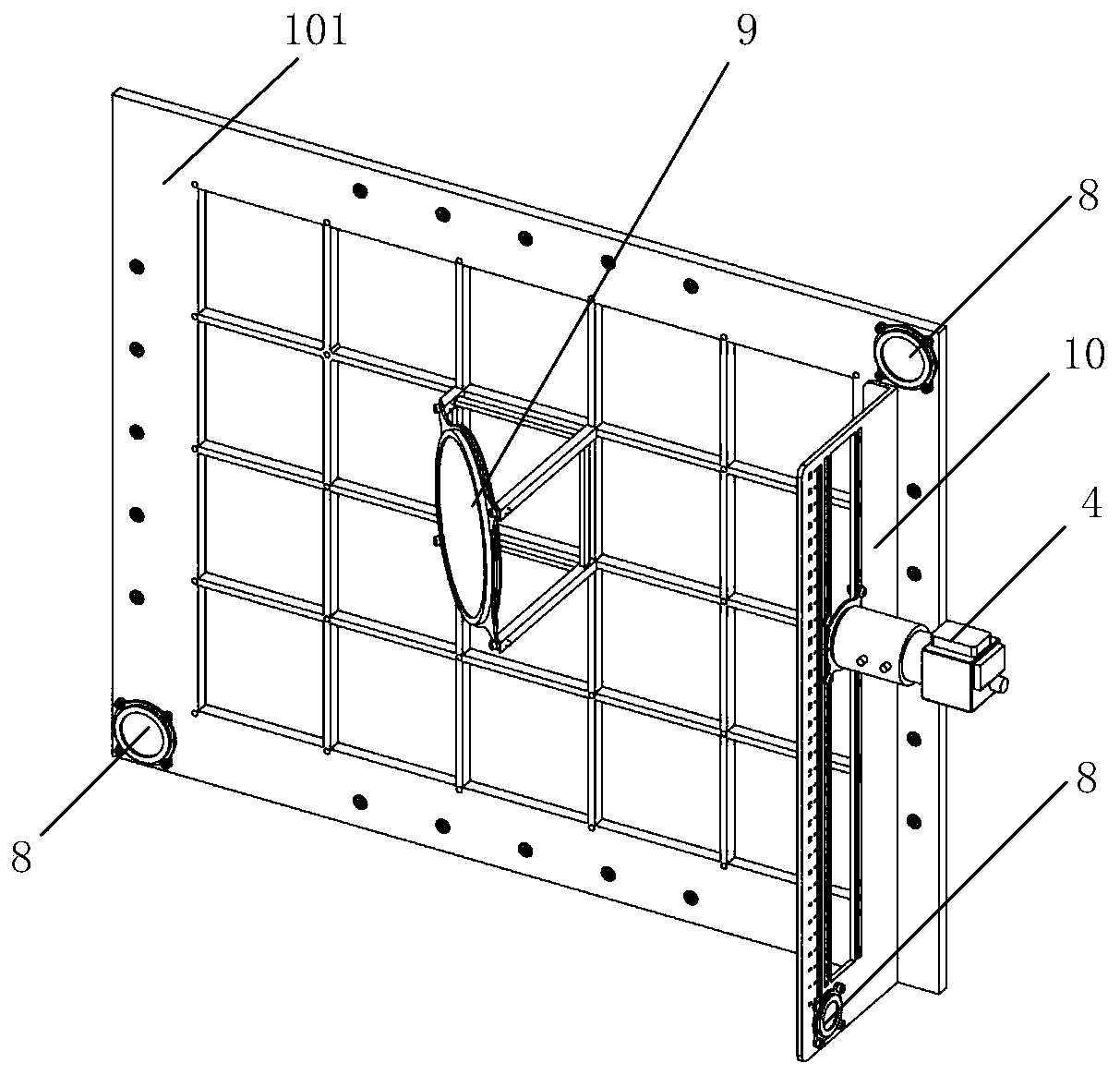

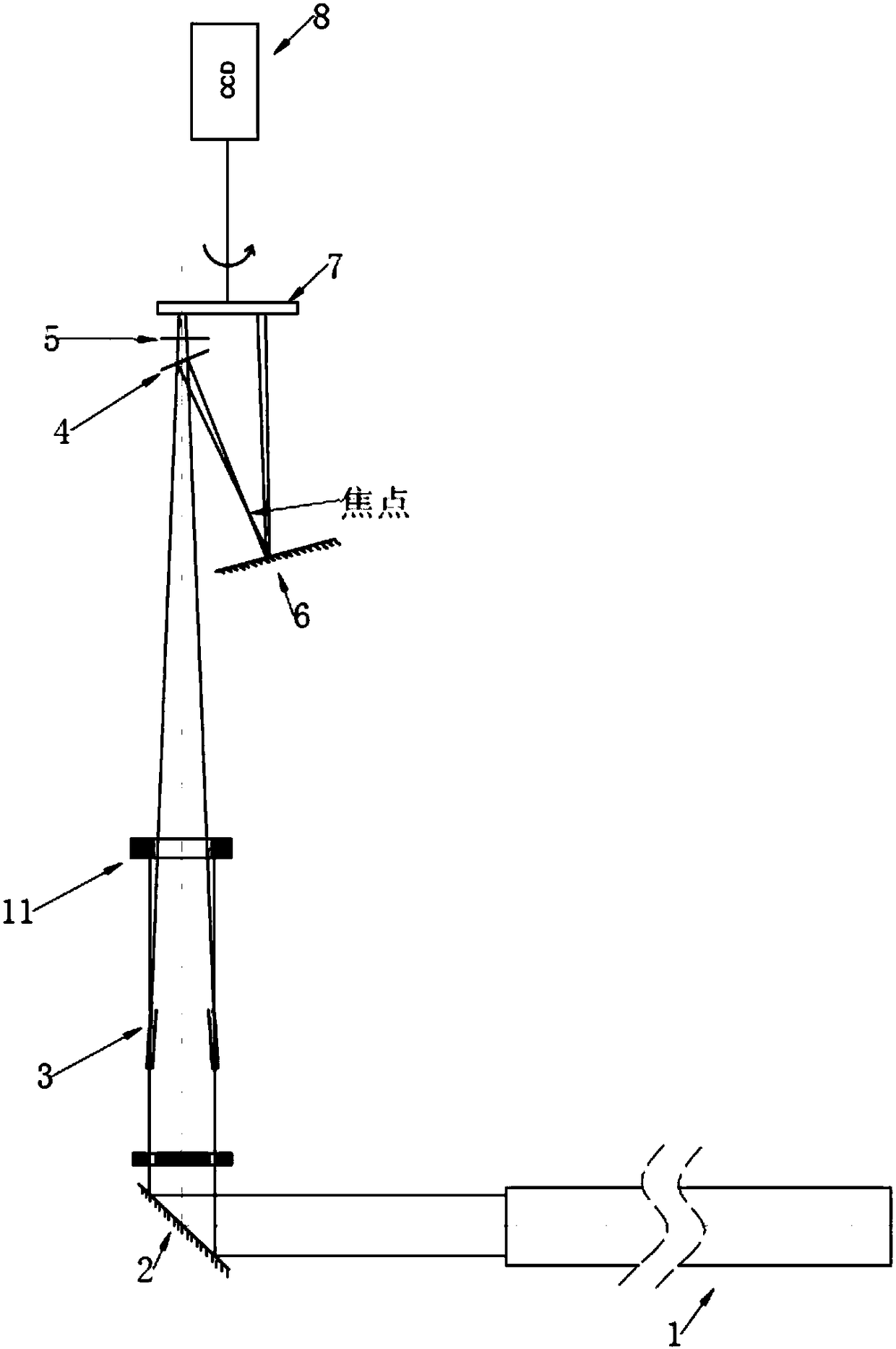

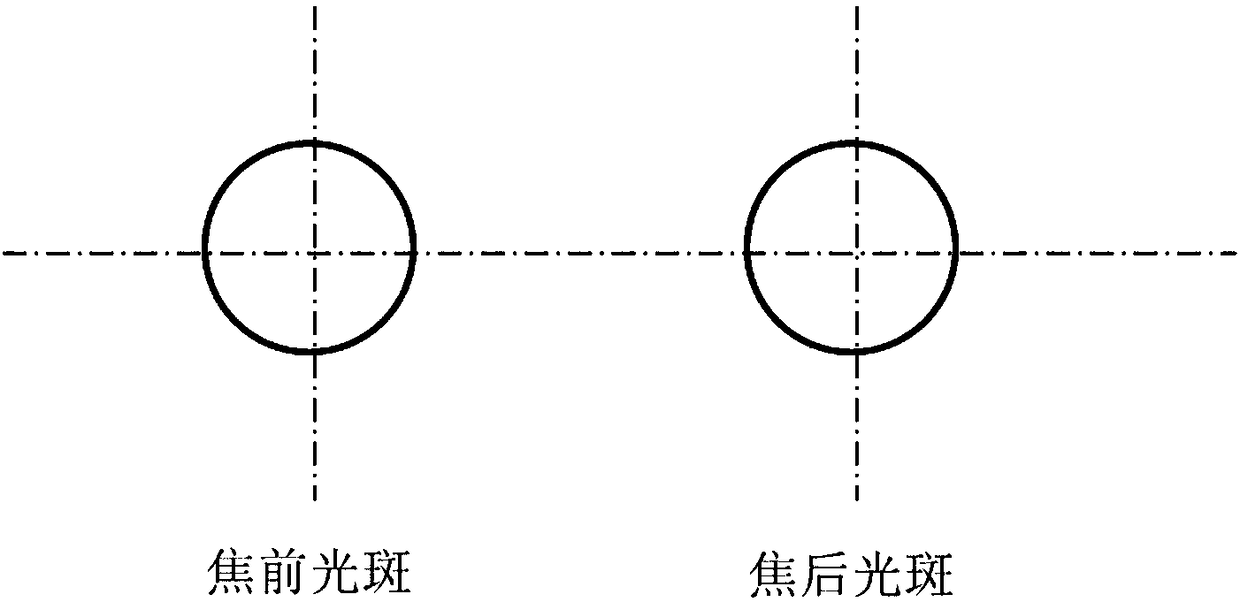

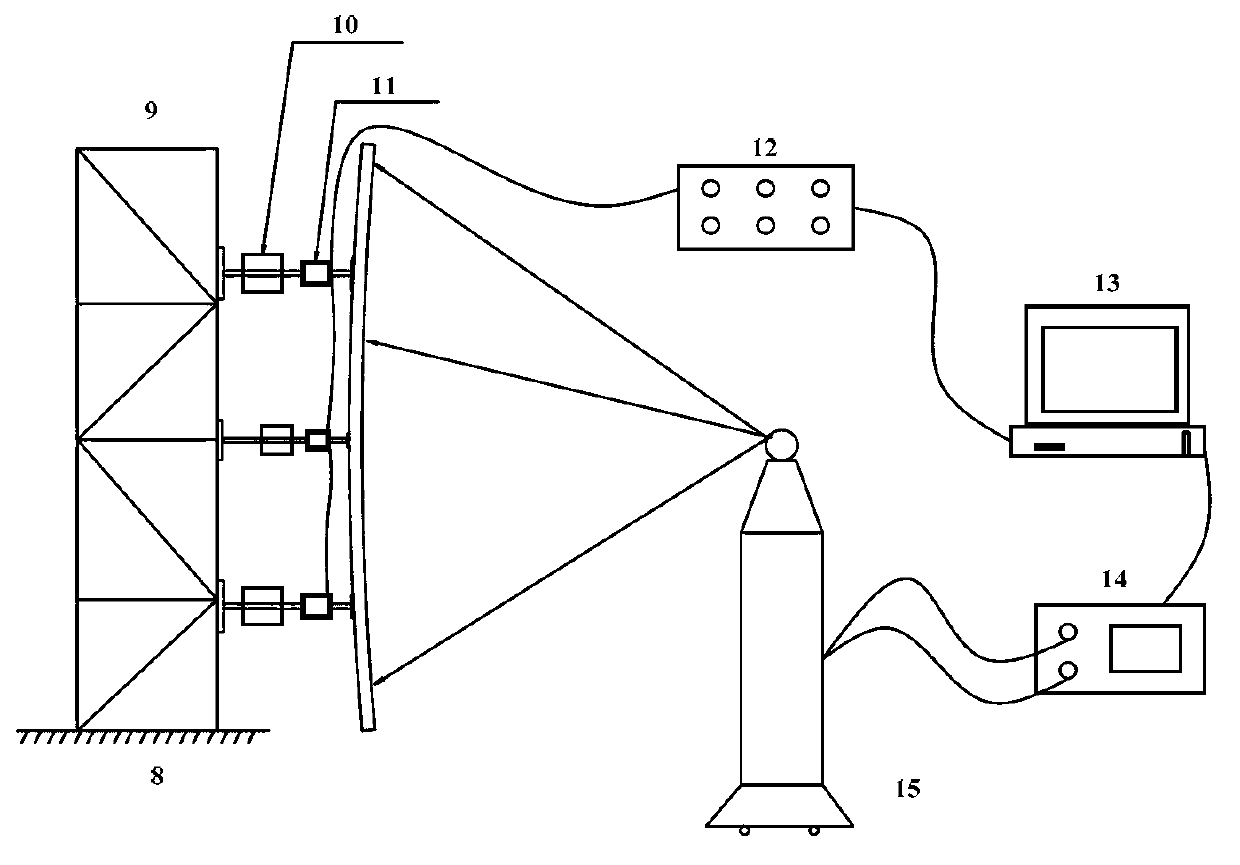

X-ray focus lens vertical installation and adjustment system and method

PendingCN108375453AQuick SetupPrecise adjustmentStatic/dynamic balance measurementBeam deviation/focusing by electric/magnetic meansMicrometerX-ray

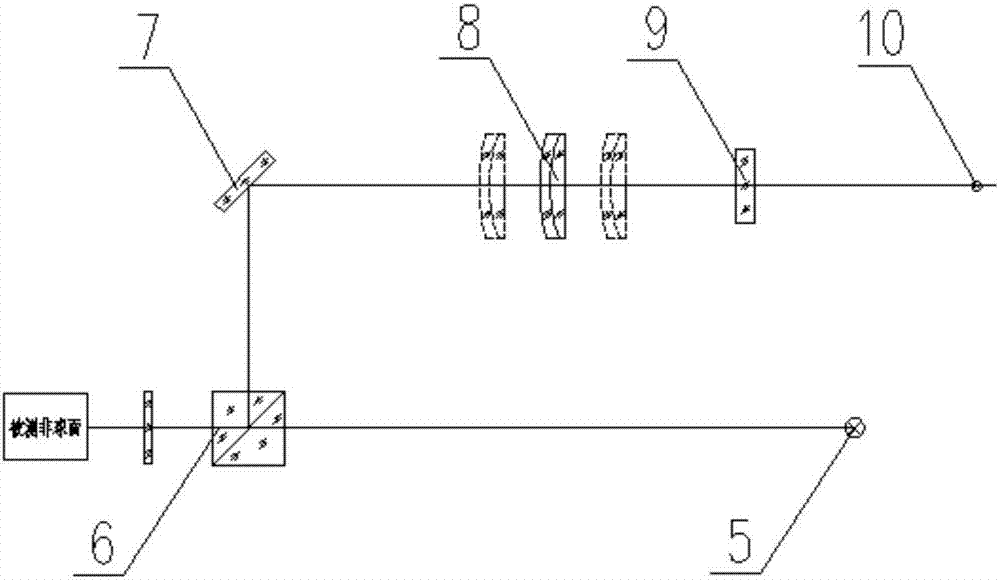

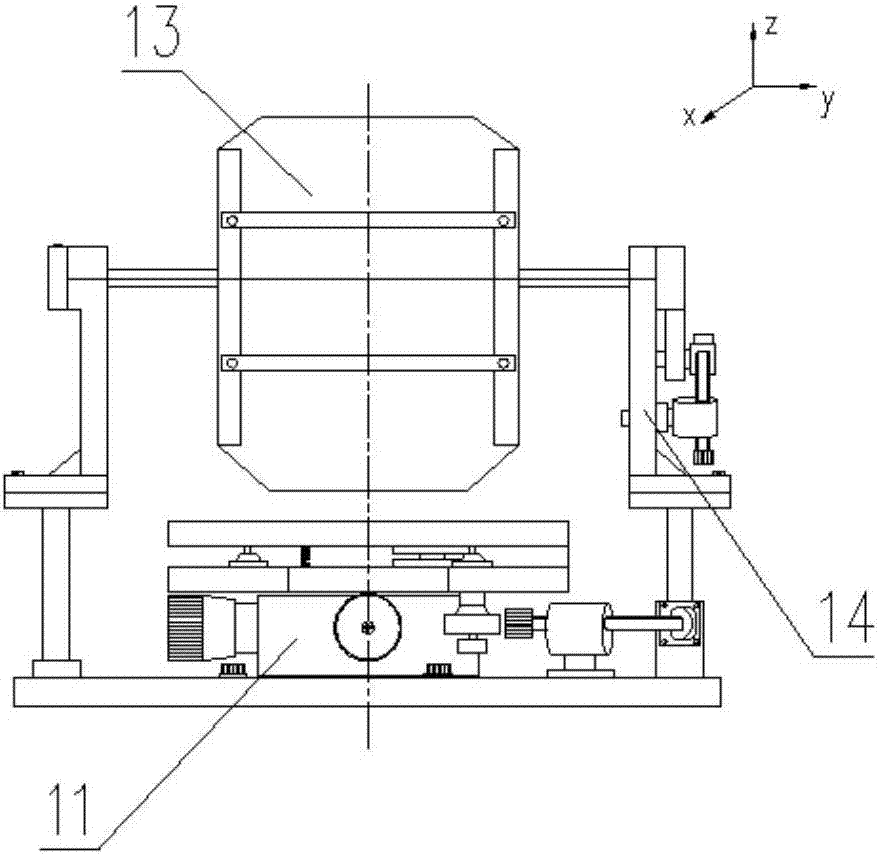

The invention relates to an X-ray focus lens vertical installation and adjustment system and method, which solves the problems that the gravity introduced in the assembling process of a focus lens tube influences a facial form and the assembling precision is relatively low. The X-ray focus lens vertical installation and adjustment system comprises a parallel light tube, a focus lens tube, a focuslens installation and adjustmentassembling system, a semitransparent semi-reflective mirror, a reflection mirror, a receiving screen, a CCD camera and a computer; the focus lens installation and adjustmentassembling system comprises a fixed disc, a micrometer head, a suspension rope and a pulley, the pulley is fixedly arranged on the fixed disc, one end of the suspension rope is connected with themicrometer head, and the other end is connected with the focus lens tube; and the outgoing light of the parallel light tube perpendicularly enters the focus lens tube, the outgoing light of the focuslens tube is divided into two beams by virtue of the semitransparent semi-reflective mirror, one beam directly enters the receiving screen, the other beam is reflected by the reflection mirror to receiving the screen, the two beams of light form the centroid of focal spot in front of and behind a focus, and the CCD camera records and transfers the centroid of focal spot to the computer. The invention also provides an installation and adjustmentassembling method based on the system.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

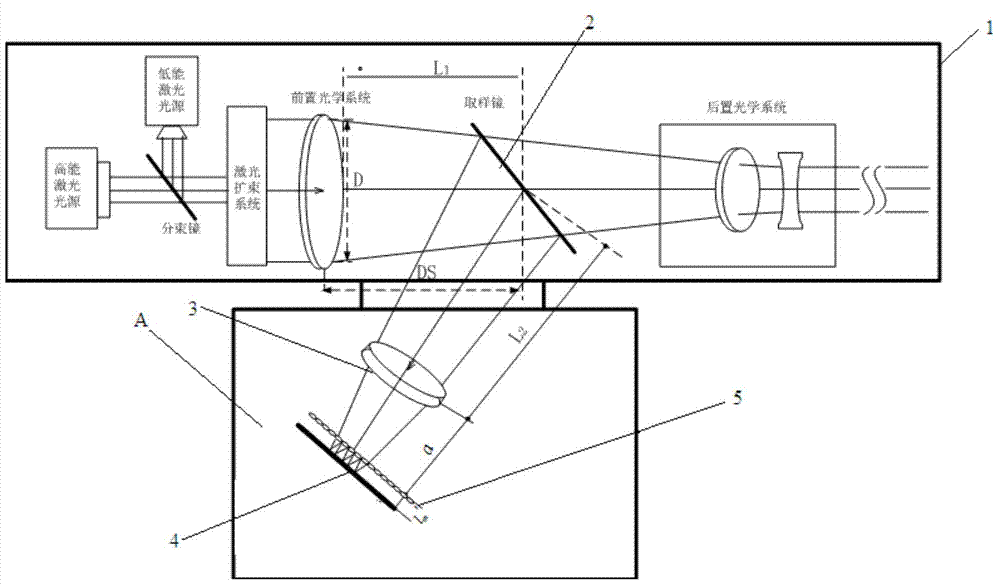

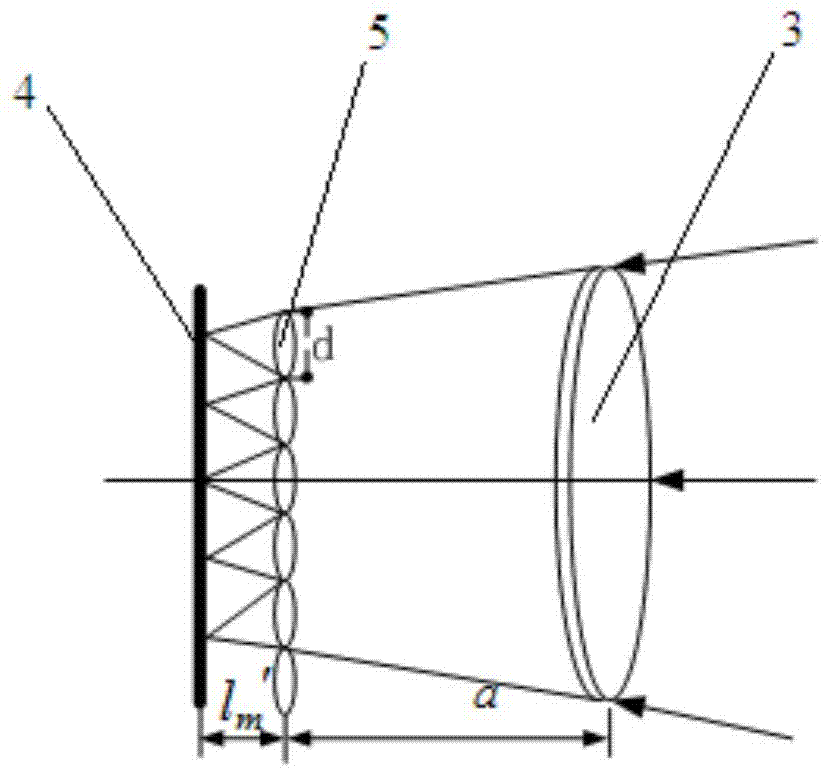

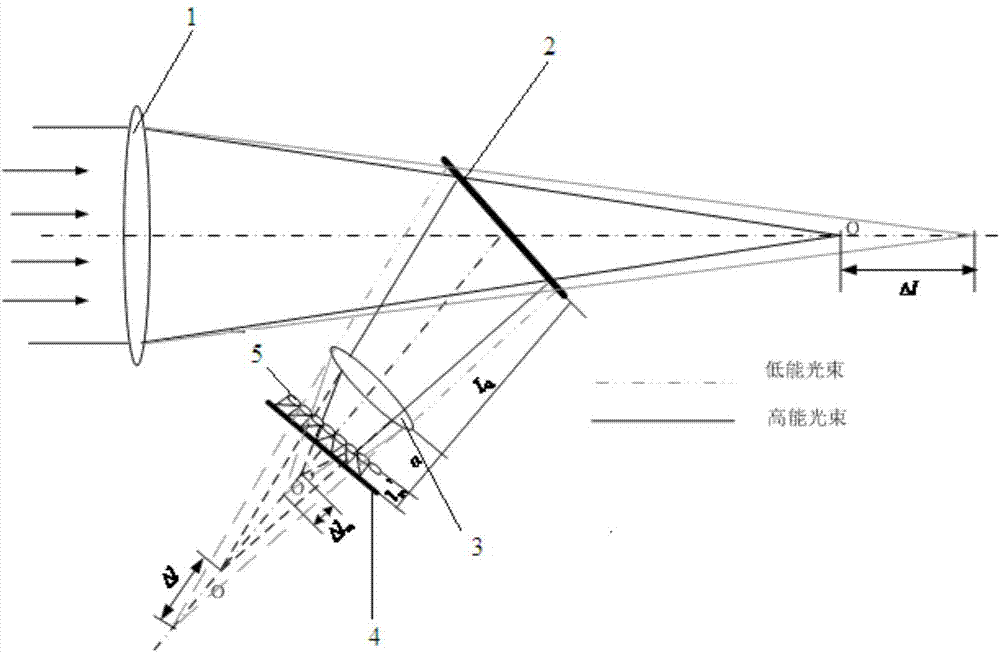

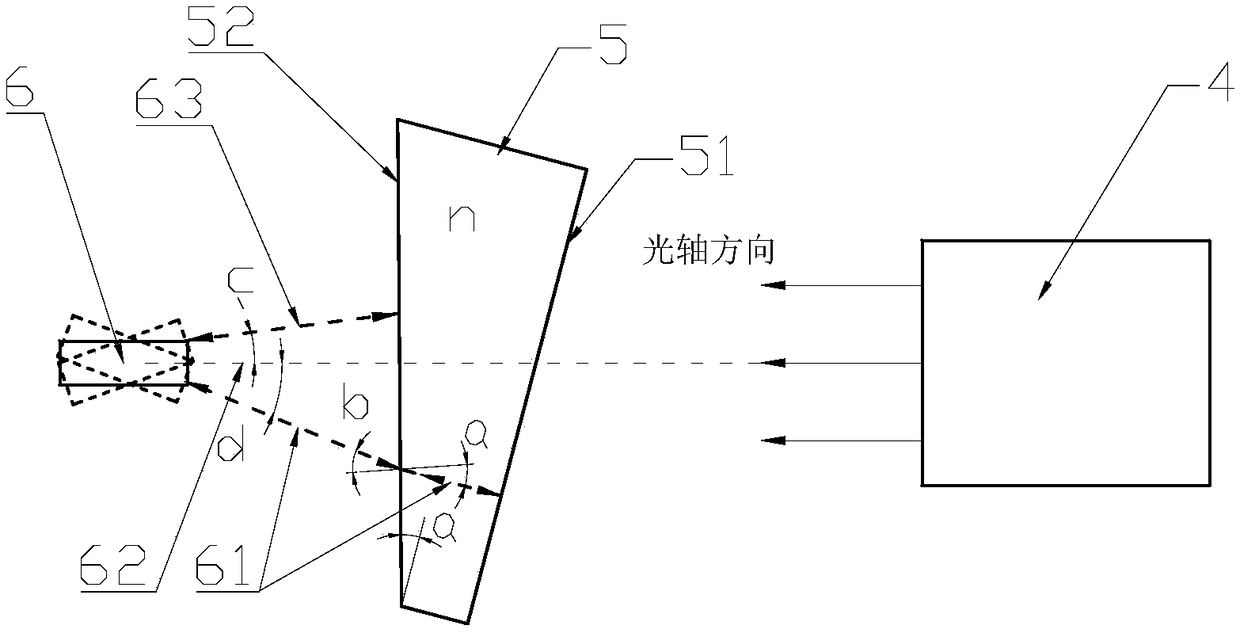

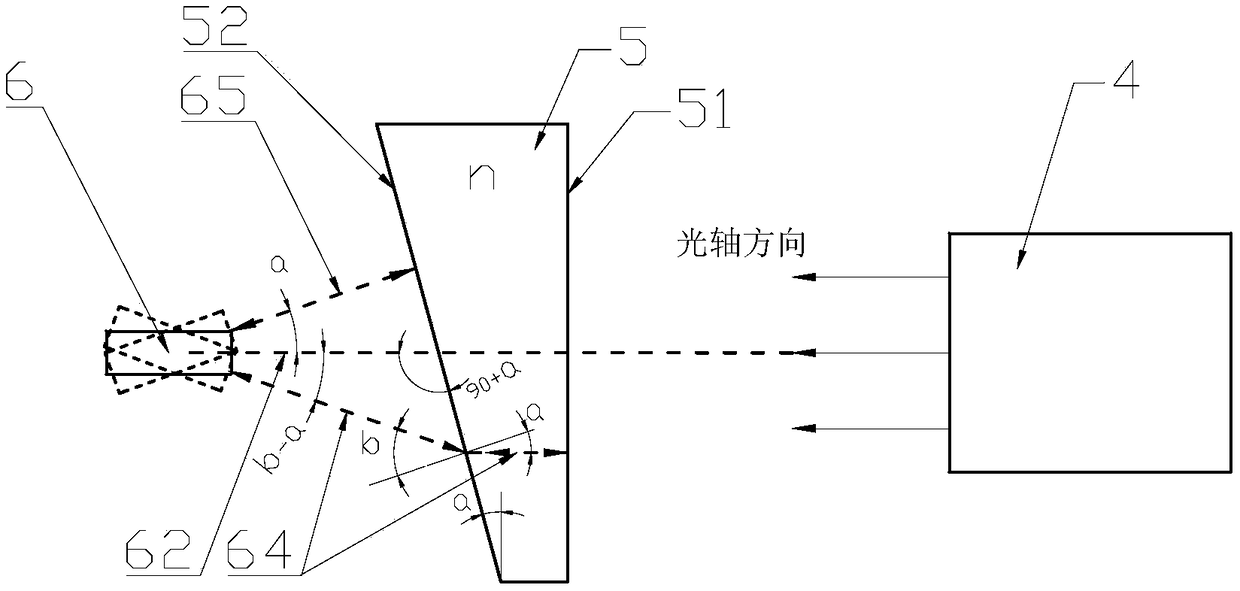

Single-pulse laser dynamic focal spot position measuring device and method

InactiveCN104764588AShorten the lengthLow cost controlOptical apparatus testingMeasurement deviceLight beam

The invention relates to a single-pulse laser dynamic focal spot position measuring device and method. The device comprises an optical system to be measured, a sampling mirror, a standard convergence lens, a microlens array, a CCD detector and a shell. The optical system to be measured provides a light beam to be measured. The sampling mirror samples the light beam to be measured and obtains a sampled light beam. The standard convergence lens carries out convergence processing on the sampled light beam to obtain a convergent light beam and transmits the convergent light beam to the microlens array. The microlens array is used for enabling the convergent light beam to converge again and imaging the convergent light beam on the CCD detector. The sampling mirror, the standard convergence lens, the microlens array and the CCD detector are sequentially packaged in the shell in the light path transmission direction. The technical problem that an existing focal spot measuring method is small in measuring range and not high in stability is solved, and the measuring precision and range of the whole system are high in adjustability.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

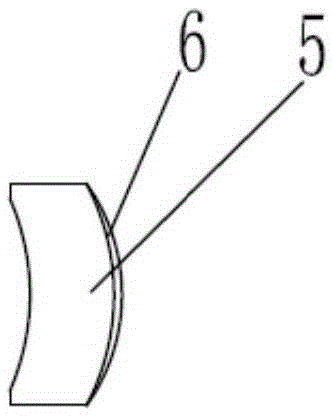

Measuring method for optical interval of refraction and reflection system with hollow main lens

ActiveCN105674934ASolve problems that cannot be quantifiedObjectiveGeometric properties/aberration measurementMeasuring instrumentPhysics

The invention provides a measuring method for the optical interval of a refraction and reflection system with a hollow main lens. A glued seat of the main lens is measured by a coordinate measuring instrument, the spatial position of a central axis of the main lens is obtained by taking the external circle of the main lens as the reference, certain point is measured in the surface of the main lens, the size of the top point of the main lens is obtained, the size of the top point is compared with the size of an installation surface of the seat of the main lens to obtain the distance between the top point of the main lens and the installation surface of the seat of the main lens, and the optical interval between the main lens and an auxiliary lens is obtained quantitatively and accurately by combining the distance between the installation surface of the seat of the main lens and the top point of the auxiliary lens. Precise adjustment of the system is further guided, the measuring method is objective, the problem that the optical interval of the refraction and reflection system with the hollow main lens cannot be measured is solved, and compared with a present adjustment method, the adjustment precision is improved, and the measuring method is suitable for precise adjustment of the optical interval of different types of refraction and reflection systems with hollow main lenes.

Owner:西安应用光学研究所

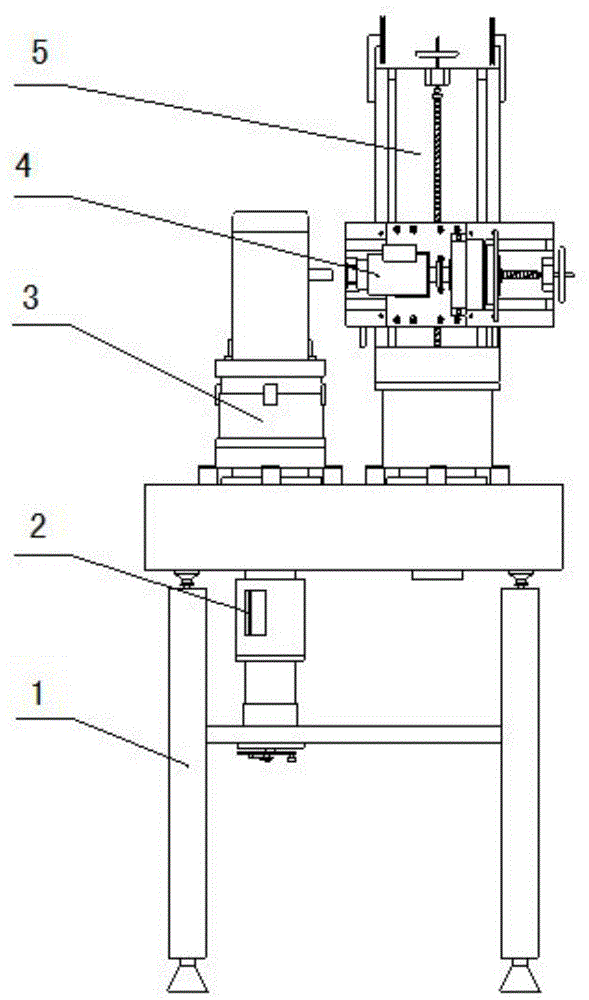

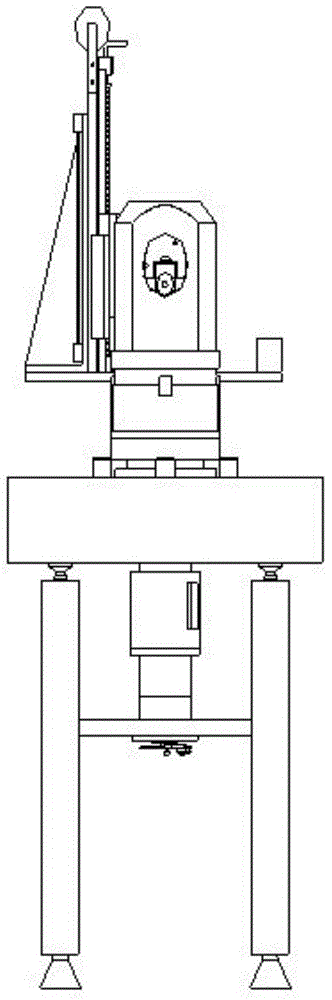

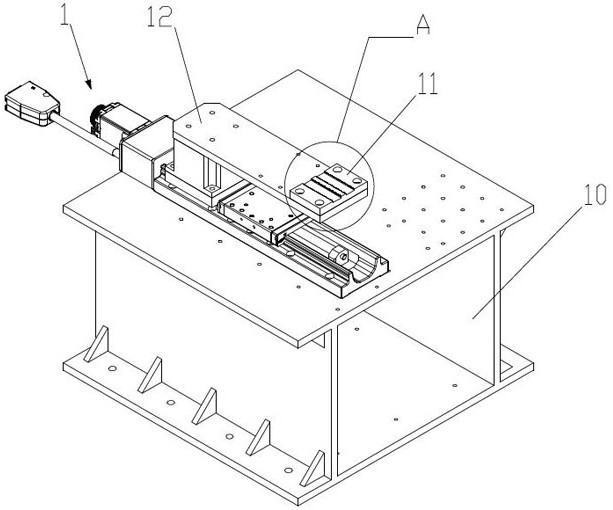

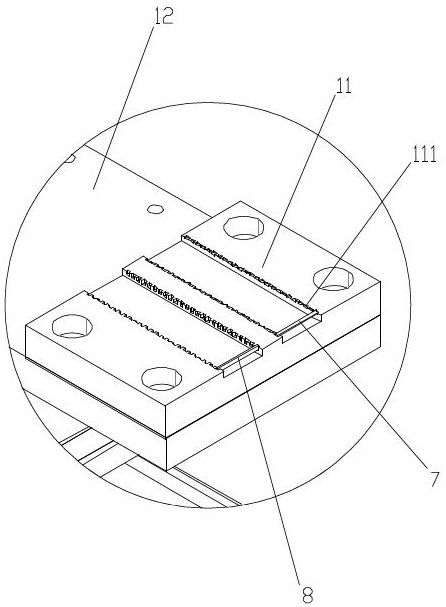

Precise shaft dynamic torque measuring instrument

ActiveCN104977112AAddress reliabilityFix stability issuesApparatus for force/torque/work measurementFriction torqueCoupling

A precise shaft dynamic torque measuring instrument relates to a shaft measurement technology and solves the problem that shaft friction torque can not be accurately measured and the test scope is small. The precise shaft dynamic torque measuring instrument comprises a structure adjusting subsystem, a pitching and yaw detection shaft subsystem, a positioning installation subsystem, a lateral roller detection shaft subsystem and a support and detection platform subsystem and measures friction torque of a fake load on vertical shaft direction. A torque motor drives a torque sensor to rotate through a toothed shaft, the displacement is adjusted on the vertical and horizontal direction, and a handwheel is rotated to move a leading screw nut mechanism vertically or horizontally along a linear guide rail. A rotary table drives a vertical sliding bench fixed together with a connection board to realize rotation of changing angle at certain level. A counterweight block is added on a fixed pulley on the vertical sliding bench to prevent extra torque, and verticality precision is ensured.

Owner:CHANGCHUN UNIV OF SCI & TECH

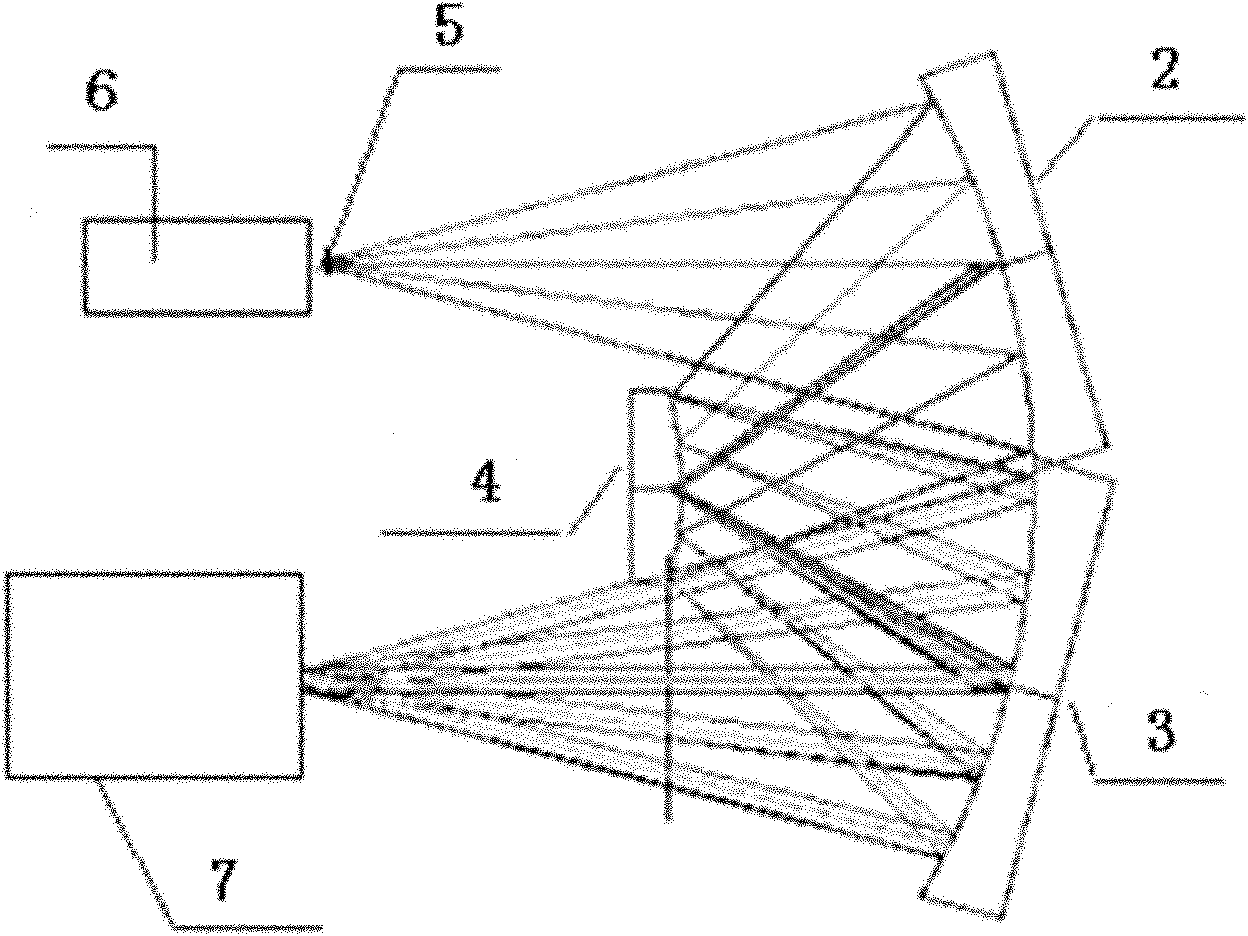

Dual-channel focal plane registering adjusting device and method

ActiveCN108833909AImplementing Band Registration ProblemsEnsure limitTelevision systemsSpectral bandsComputer science

The invention relates to a dual-channel focal plane registering adjusting device and method, specially relates to the multi-channel focal plane camera inter-channel high precision registering and adjusting, and belongs to the space optical remote sensor technical field. The method solves the sub-channel focal plane camera inter-channel spectral band registering problem, thus possibly realizing remote sensing camera multi-spectral band detection in a multi-channel mode, and providing important meanings for application and development of resource exploration remote sensing cameras.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

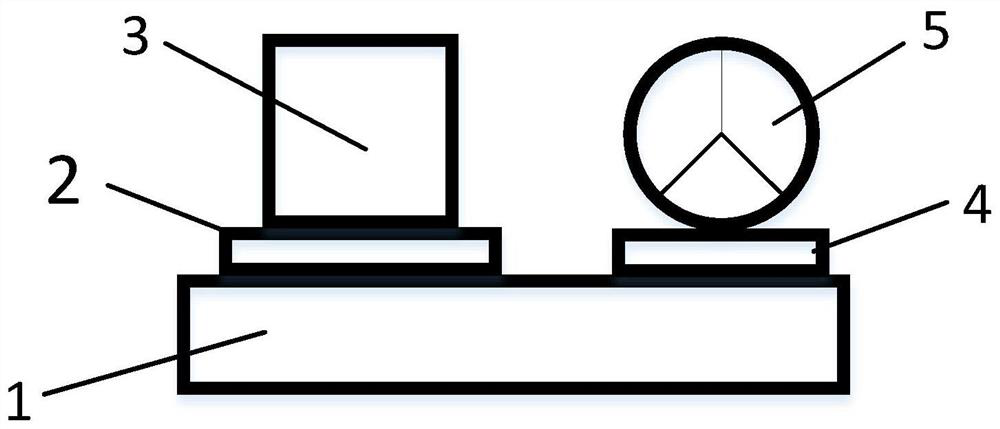

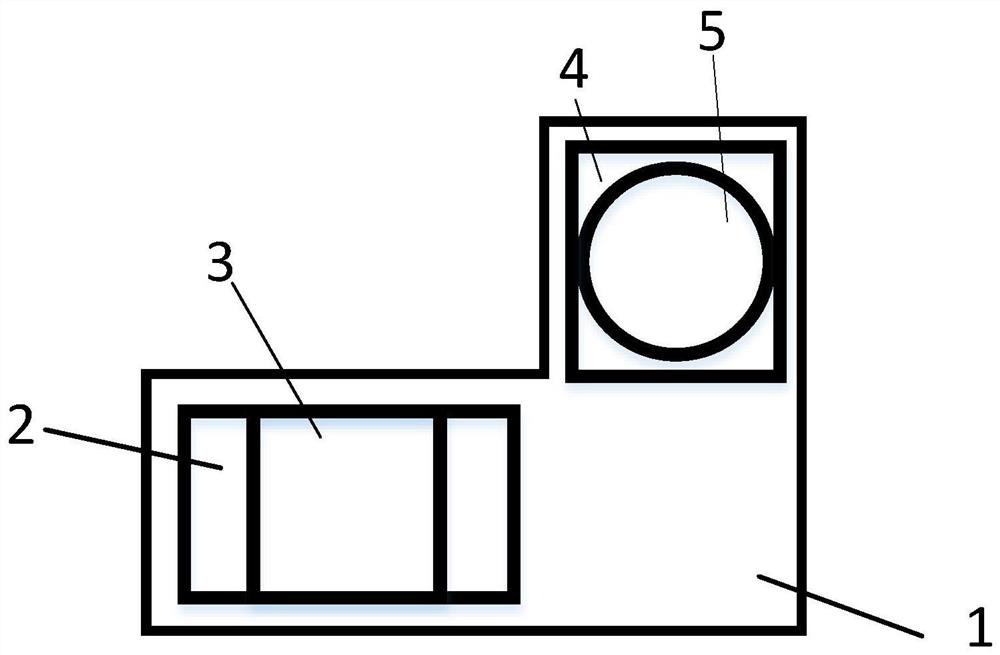

Measurement reference device capable of being used for establishing a coordinate system

ActiveCN111854713AAvoid relative pose changesReal-time monitoring of spatial poseReference line/planes/sectorsTheodolitesTheodoliteEngineering

The invention discloses a measurement reference device capable of being used for establishing a coordinate system, belongs to the technical field of optical and precision machinery adjustment, and solves the problems of low efficiency, inconvenience in operation, insufficient precision and the like in establishing a cubic prism measurement coordinate system. The reference device comprises a modulebase, a cubic prism mounting base, a cubic prism, a pyramid prism mounting base and a pyramid prism, the cubic prism is mounted on the module base through the cubic prism mounting base; the pyramidprism is installed on the module base through the pyramid prism mounting base, the cubic prism and the pyramid prism are arranged at the two ends of the module base, the relative pose relation betweenthe cubic prism and the pyramid prism is kept constant, and the normal of the surface, except the installation surface, of the cubic prism is not shielded; a theodolite and a laser tracker are used for aiming at the reference device, fitting and calculation are not needed, the coordinate axis orientation and the coordinate origin position can be directly obtained at the same time, then a coordinate system is established, and the installation and adjustment precision and efficiency are greatly improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

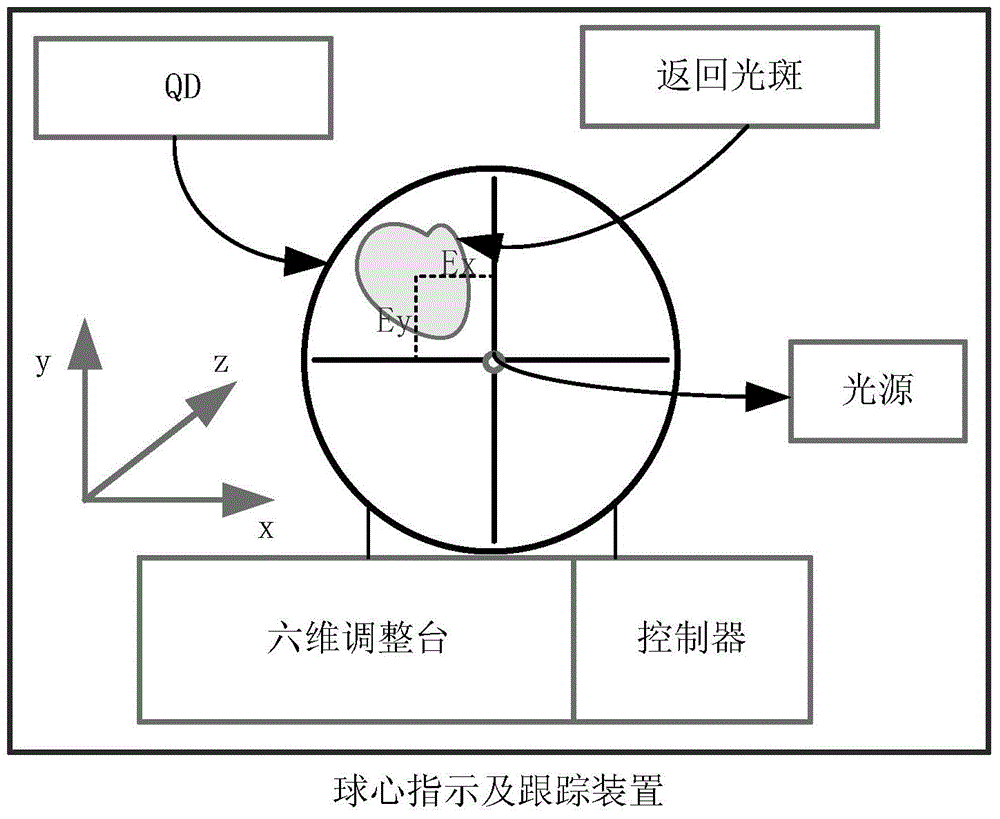

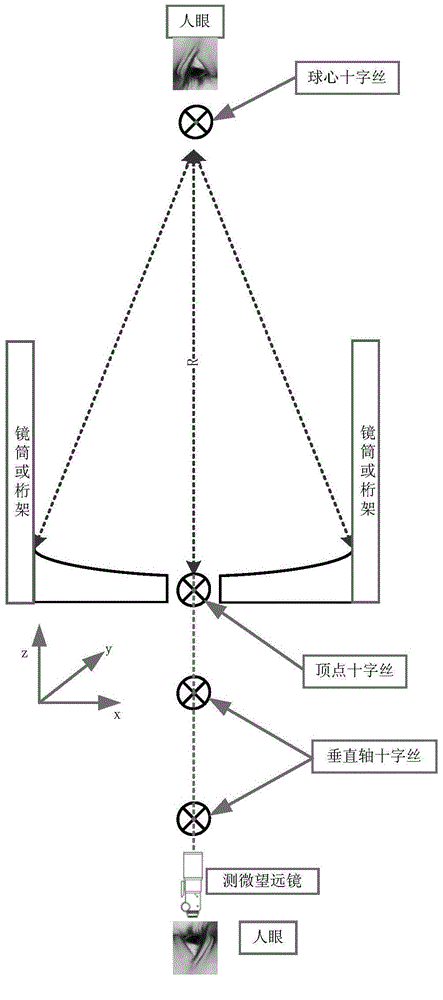

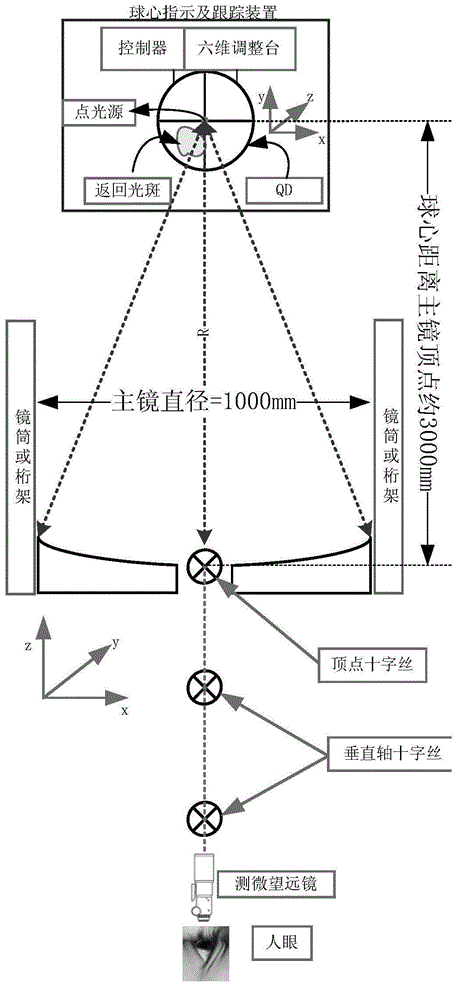

High-precision primary mirror sphere center directing and tracking device used for telescope alignment

InactiveCN104977726AImprove securityImprove the accuracy of assembly and adjustmentOptical elementsAutomatic controlPhotovoltaic detectors

The invention discloses a high-precision primary mirror sphere center directing and tracking device used for telescope alignment. The device mainly comprises a photoelectric detector with a point light source, a six-dimensional adjustment stage and a controller. When the device works, the center point light source of the photoelectric detector is arranged to be near the primary mirror sphere center. The six-dimensional adjustment stage is adjusted according to the geometrical optical principle that light emitted by the point light source of the primary mirror sphere center returns to the sphere center so that output error of the photoelectric detector is enabled to be zero and the point light source can direct the sphere center in a high-precision way. In an automatic tracking mode, an error signal is automatically adjusted to be zero by the controller and an adjustment frame; and in a manual tracking mode, the error signal is manually adjusted to be zero. The point light source emitting light actively is adopted, the characteristic of great return light spot morphology is utilized, and the focus light spot is detected by adopting the high-precision photoelectric detector so that the position of the return light spot can be detected in the high-precision way; meanwhile, high-precision real-time directing and tracking of the sphere center are completed by utilizing the automatic control technology and the six-dimensional electric adjustment stage so that the telescope alignment process is optimized.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

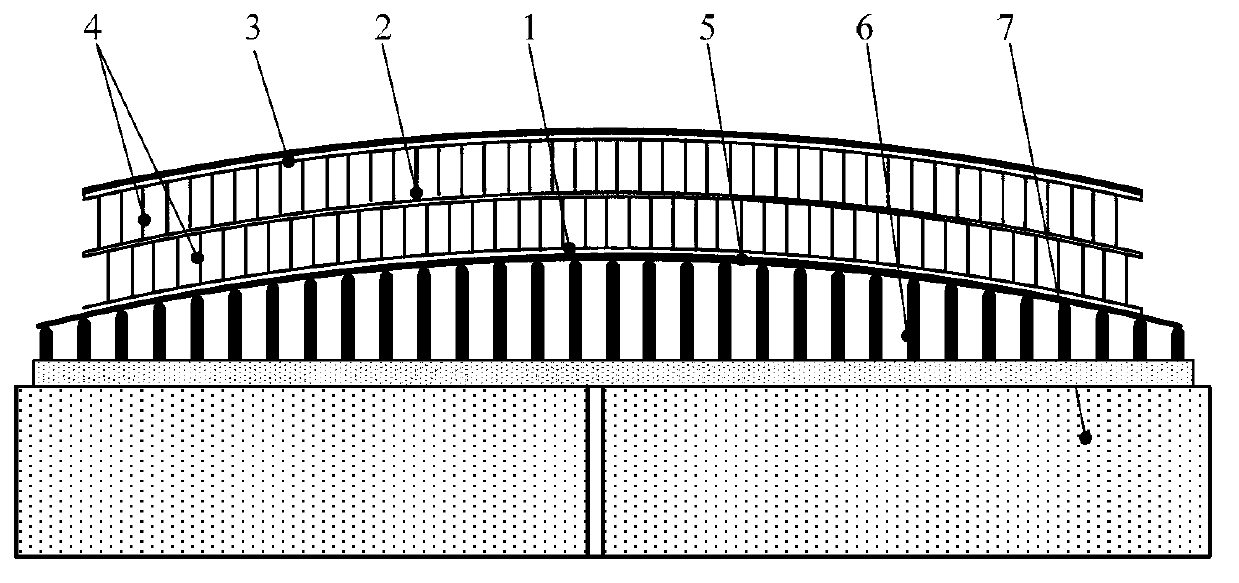

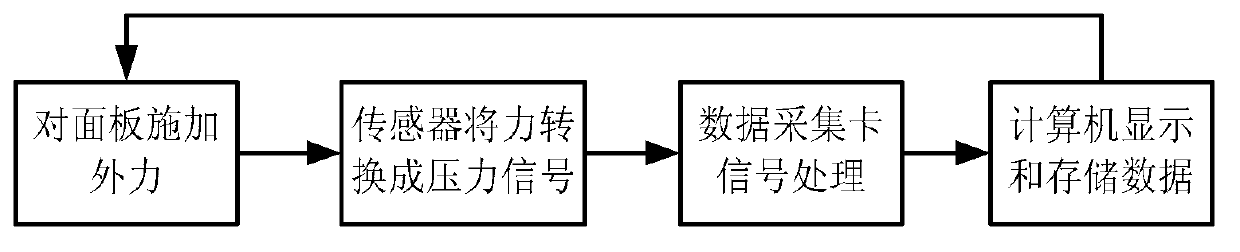

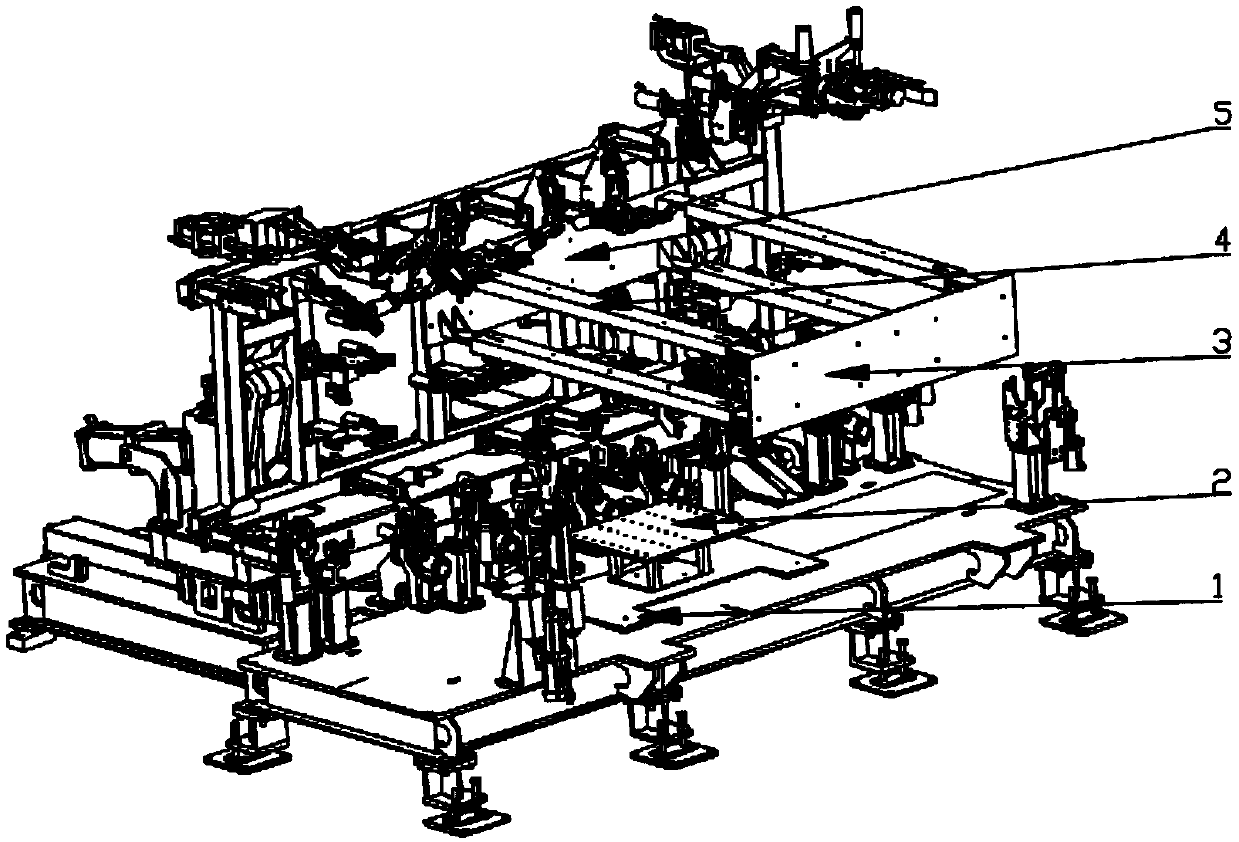

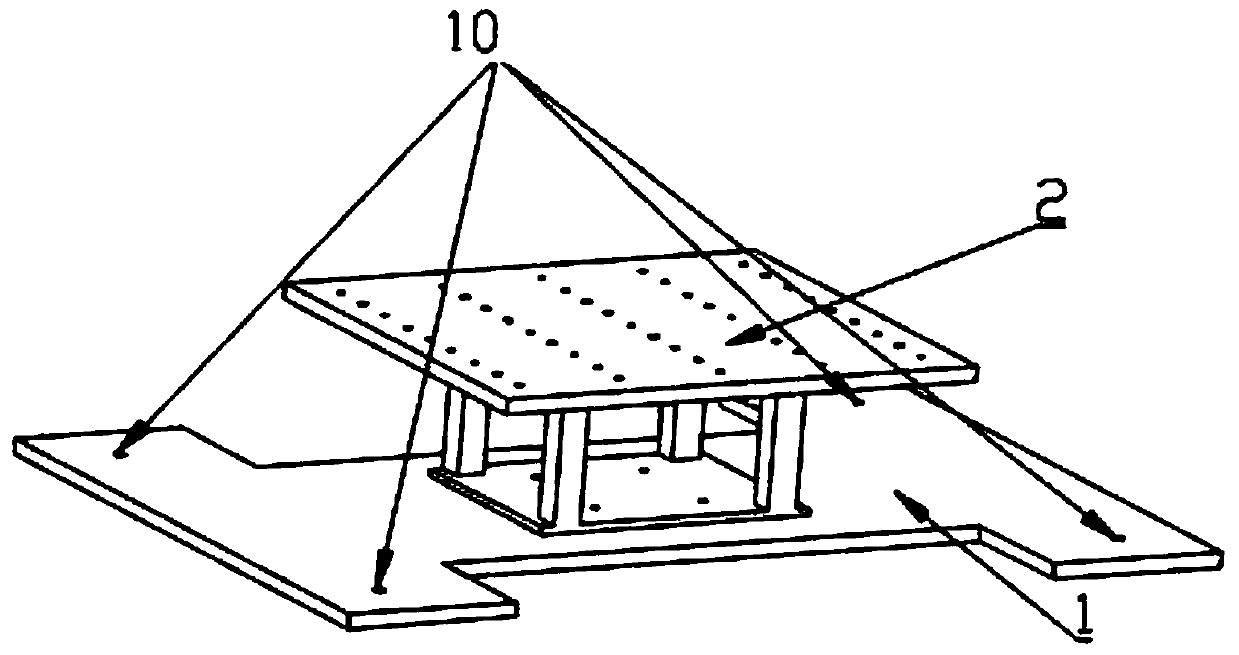

Molded surface regulating device and regulating method of honeycomb sandwich structure high-accuracy panel

ActiveCN103135616AHigh profile precisionImprove the accuracy of assembly and adjustmentControl using feedbackHoneycombEngineering

The invention discloses a molded surface regulating device of a honeycomb sandwich structure high-accuracy panel. The molded surface regulating device of the honeycomb sandwich structure high-accuracy panel comprises a mechanical system which formed by a back support and a link mechanism supporting the panel, a molded surface accuracy measuring system which is formed by a laser tracker measuring main engine, a control main engine and a notebook computer and a molded surface accuracy key parameter acquisition system which is formed by a force sensor, a parameter acquisition system and a notebook computer. A molded surface method of the honeycomb sandwich structure high-accuracy panel comprises four steps. The molded surface regulating device of the honeycomb sandwich structure high-accuracy panel is distributed according to a molded surface accuracy error produced by a high-accuracy panel, through an adjusting position which is selected reasonably, and the molded surface accuracy of the high-accuracy panel can be largely improved by the adoption of little adjusting points. The molded surface regulating device of the honeycomb sandwich structure high-accuracy panel is fully faced to an engineering application, the molded surface accuracy of the sandwich structure high-accuracy panel is very effectively improved, and adjusting accuracy of a whole reflection surface of a compact field can be effectively improved.

Owner:BEIHANG UNIV

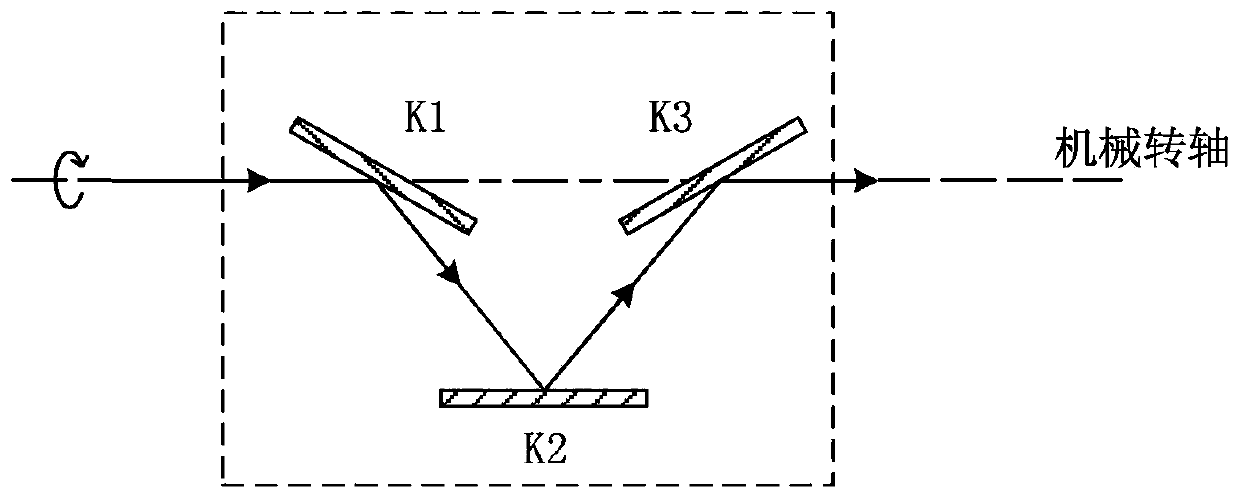

K-mirror optical system adjustment method

ActiveCN110989188AVersatilityImprove the accuracy of assembly and adjustmentOptical elementsParallel plateOptic system

The invention discloses a K-mirror optical system adjustment method, and belongs to the field of optical element adjustment. The method comprises the following steps: S1, an optical reference of a K-mirror optical system is established by using an optical parallel plate and an interferometer; S2, the position of a K2 mirror is adjusted by means of a pentaprism to make the surface of the K2 mirrorto be parallel to a mechanical rotating shaft of the K-mirror optical system; and S3, the K3 mirror is placed according to the mechanical plane position, then a K1 mirror is placed and the position ofthe K1 mirror is adjusted, so that zero-order fringes are formed in the interferometer after emergent light of the interferometer is reflected by the K1 mirror, the K2 mirror, a K3 mirror and the optical parallel plate. The method has the advantages of high adjustment precision, simple adjustment method, universality of adjustment tools and the like, and a corresponding optical reference is reserved in the adjusted K-mirror optical system to be used as an optical interface for butt joint of the K-mirror optical system and a subsequent optical system.

Owner:HUAZHONG UNIV OF SCI & TECH

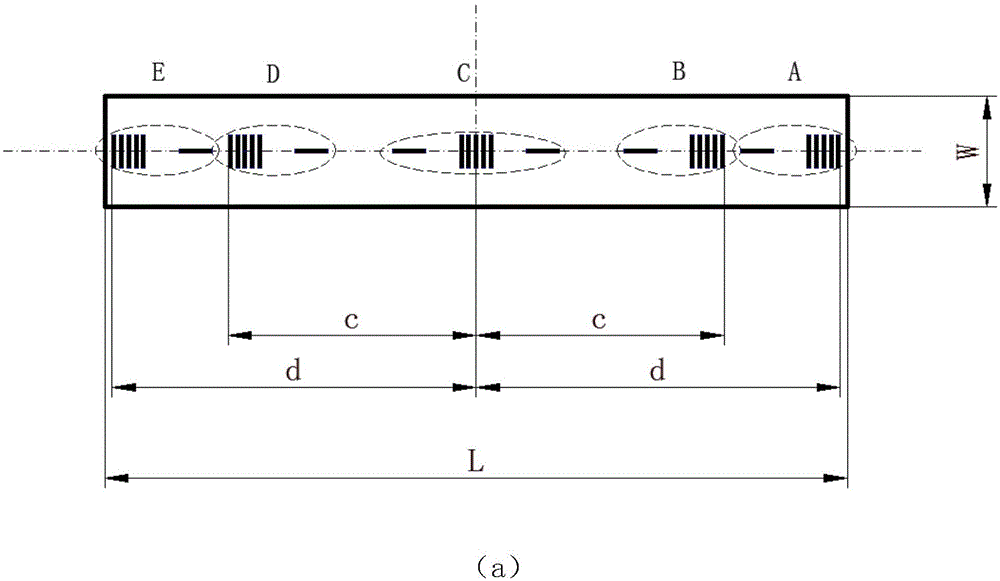

Field diaphragm assembly for spectrometer adjustment test

ActiveCN105157831ATest Space Imaging QualityEasy to observeRadiation pyrometrySpectrometry/spectrophotometry/monochromatorsGratingImaging quality

The invention discloses a field diaphragm assembly for spectrometer adjustment test, which comprises a diaphragm seat and a diaphragm substrate. One surface of the diaphragm substrate has a two-dimensional pattern; the two-dimensional pattern is a group of regularly-distributed light and shade stripes in a central field, a middle field and an edge field. When a mercury lamp light source is combined to light the field diaphragm, six-dimensional adjustment of a detector in relative to the field diaphragm can be carried out at the same time, rotation disorder of a grating in relative to the field diaphragm can be detected, and grating adjustment is carried out. When a complex color light source is combined to light the field diaphragm, the spatial imaging quality of the central field, the middle field and the edge field of the spectrometer can be tested. According to the field diaphragm assembly with the two-dimensional pattern, the problems that states of a spectral dimension and a spatial dimension on a detector array can not be observed conveniently during the traditional single-slit field diaphragm photoelectric joint adjusting process can be solved, and the adjustment efficiency and the adjusting precision can be effectively improved.

Owner:上海济物光电技术有限公司

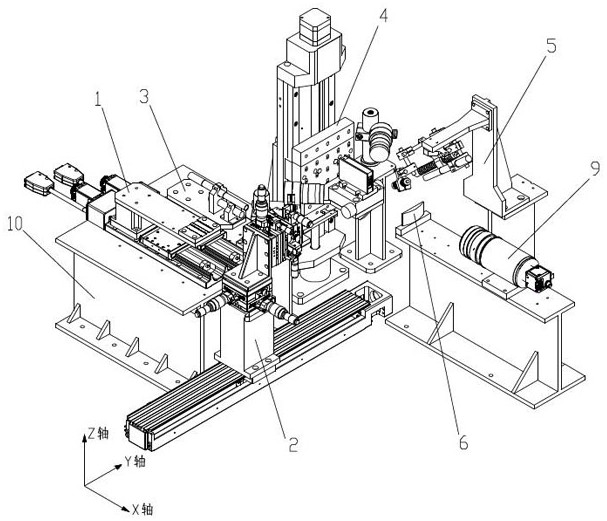

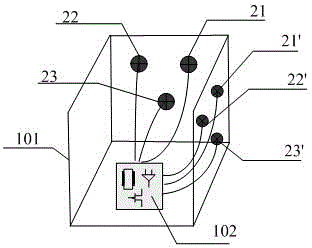

FAC mirror assembling and adjusting system and assembling and method

ActiveCN113671656AImprove the accuracy of assembly and adjustmentImprove efficiencyPretreated surfacesCoatingsLight spotLight beam

The invention discloses an FAC mirror assembling and adjusting system and method. The FAC mirror assembling and adjusting system comprises a material assembly, a transfer assembly, a dispensing assembly, a laser assembly, a curing assembly, a collimating lens and a CCD camera. The material assembly is used for placing a tray and an FAC mirror, and the transfer assembly is used for transferring the tray and the FAC mirror; the curing assembly is used for curing the glue solution of the tray and the glue solution of the FAC mirror, so that the tray is connected with a heat sink in the laser assembly through glue solution curing, and the FAC mirror is connected with the tray through glue solution curing; and the collimating lens is used for collimating light beams emitted by the bar to form light spots, the light spots are mapped on the CCD camera, the CCD camera further displays the deviation direction and the deviation distance of the light spots relative to the light-emitting central axis of the bar, and the transfer assembly adjusts the FAC mirror according to the deviation direction and the deviation distance. According to the FAC mirror assembling and adjusting device, automatic transferring and assembling and adjusting operation of the tray and the FAC mirror are achieved, so that manual assembling and adjusting operation is replaced, and the assembling and adjusting precision and efficiency of the FAC mirror are improved.

Owner:BWT BEIJING

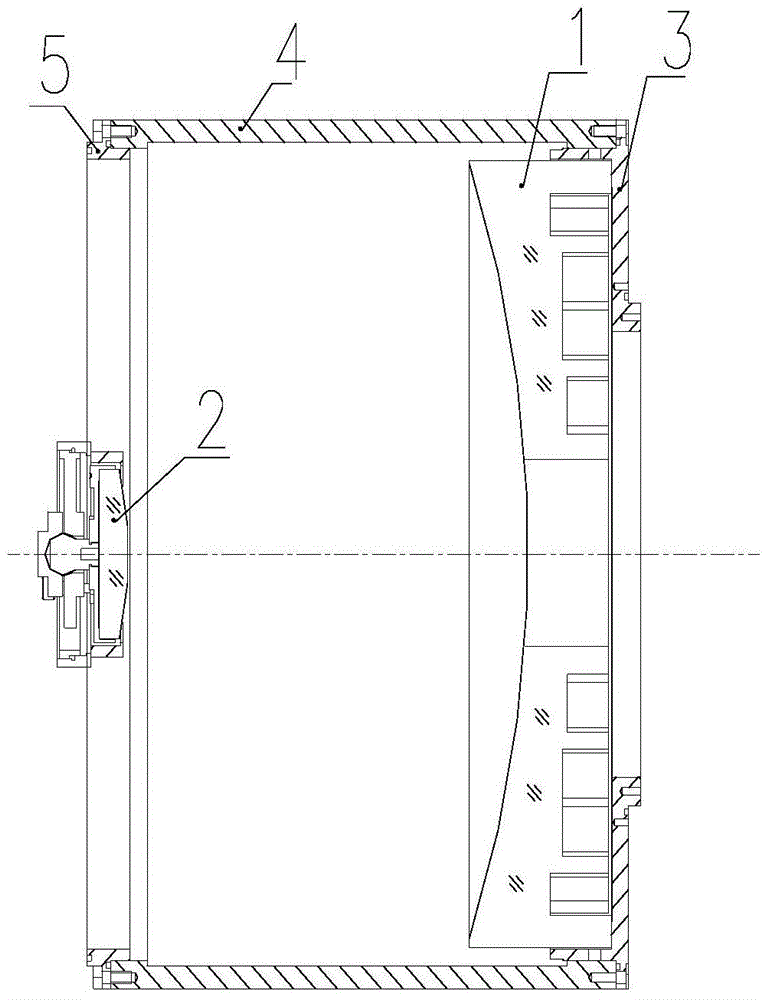

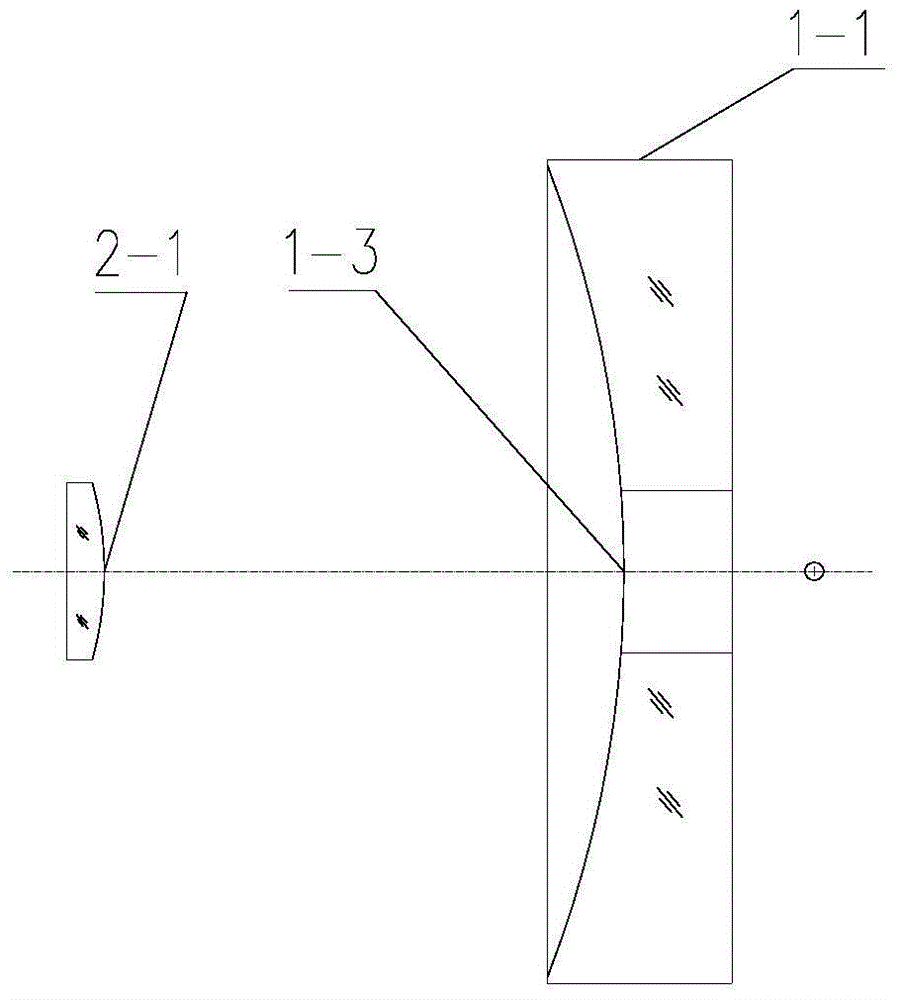

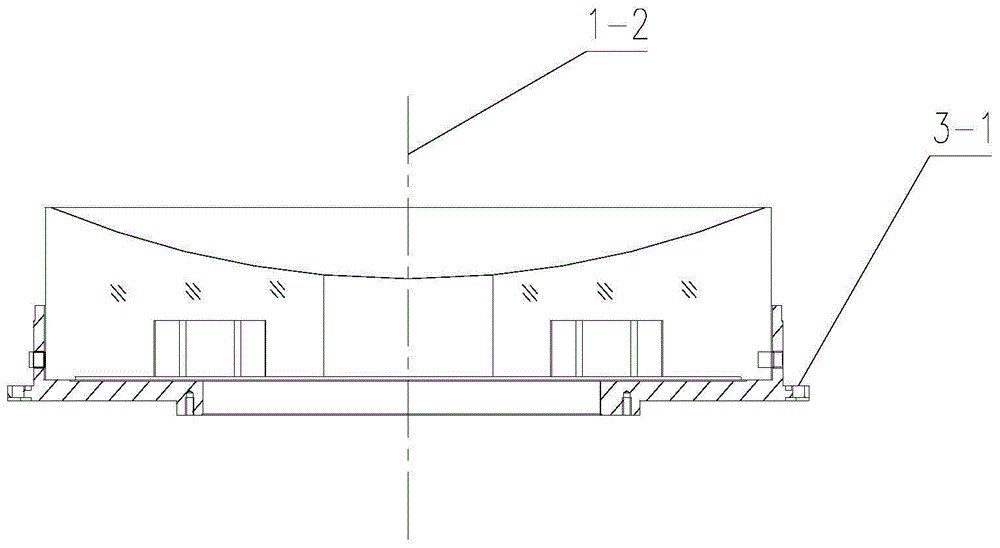

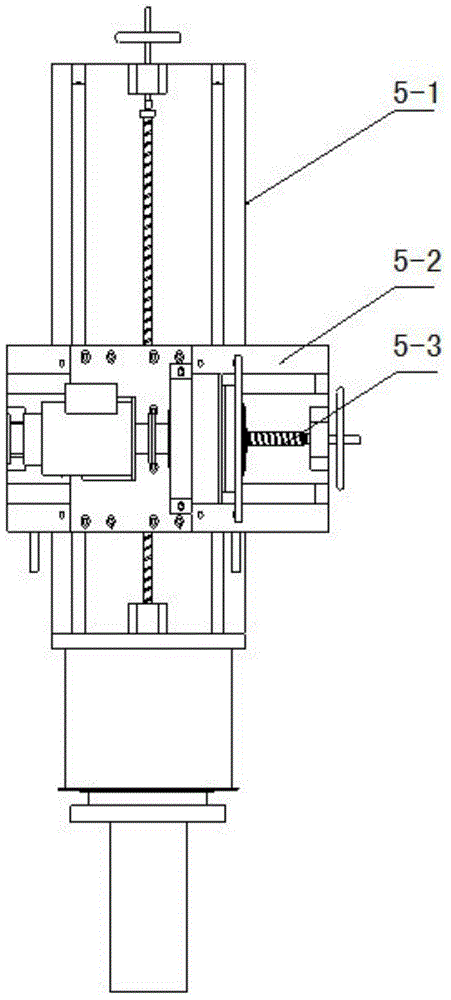

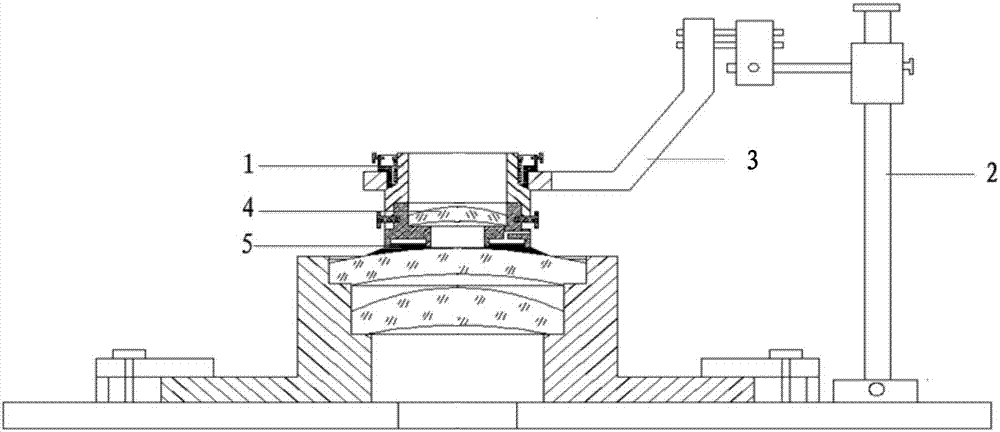

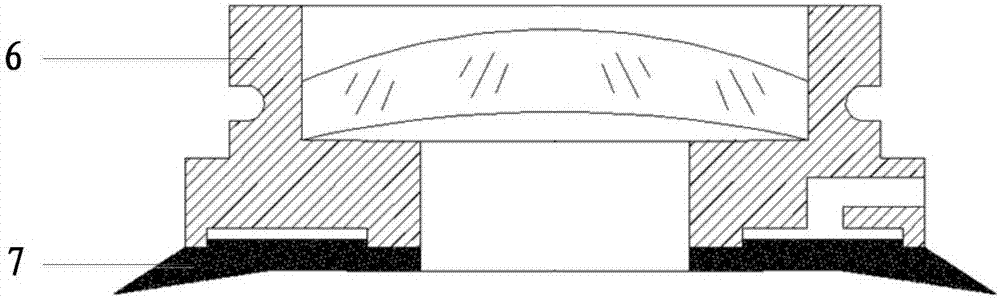

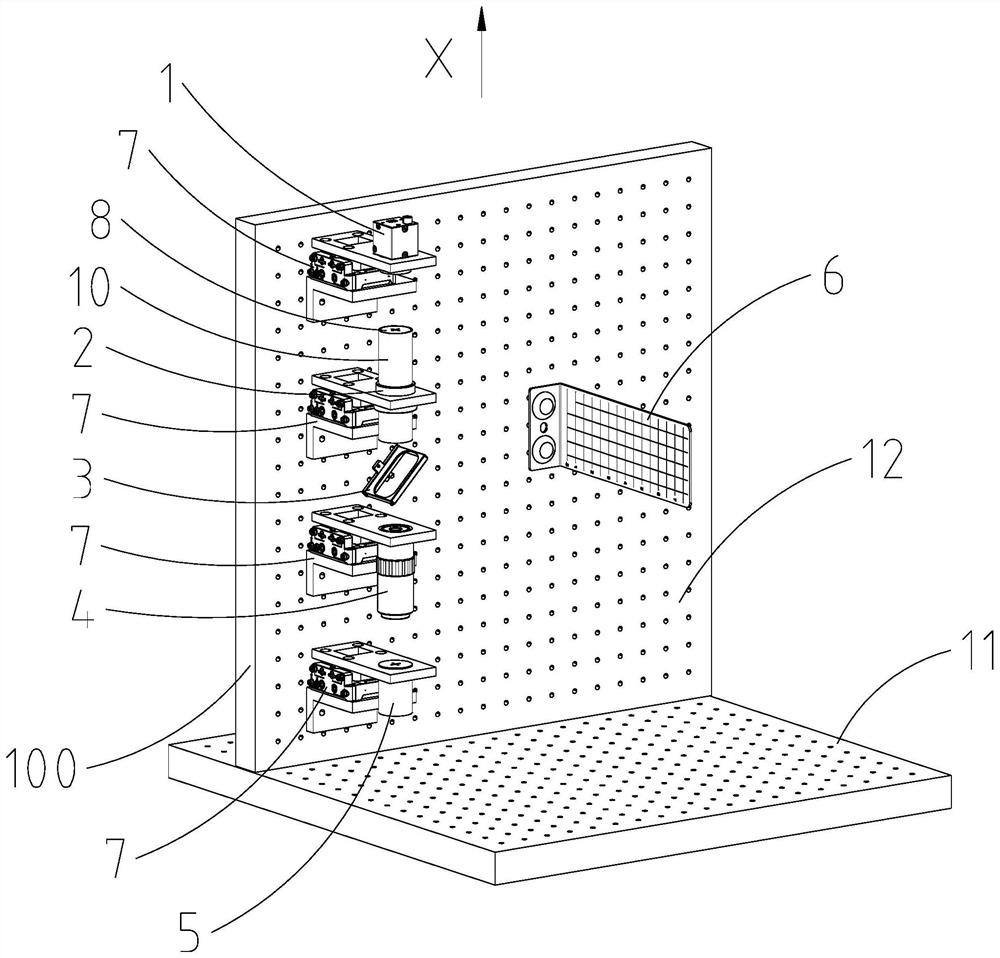

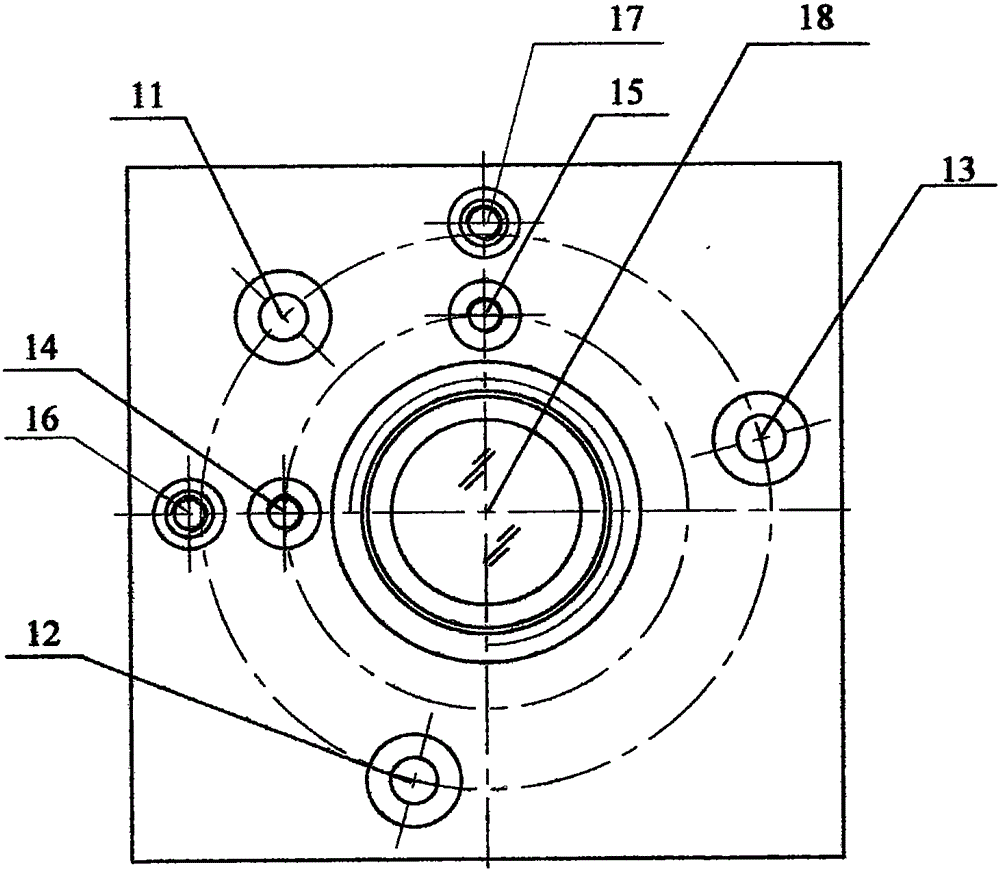

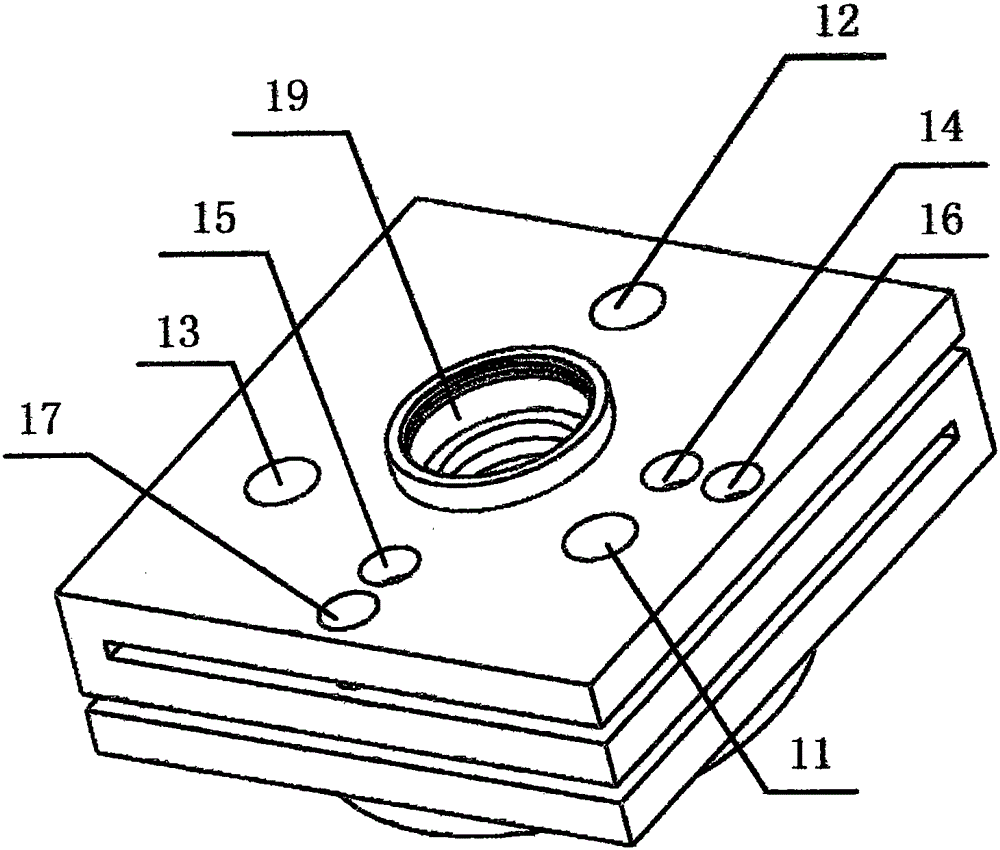

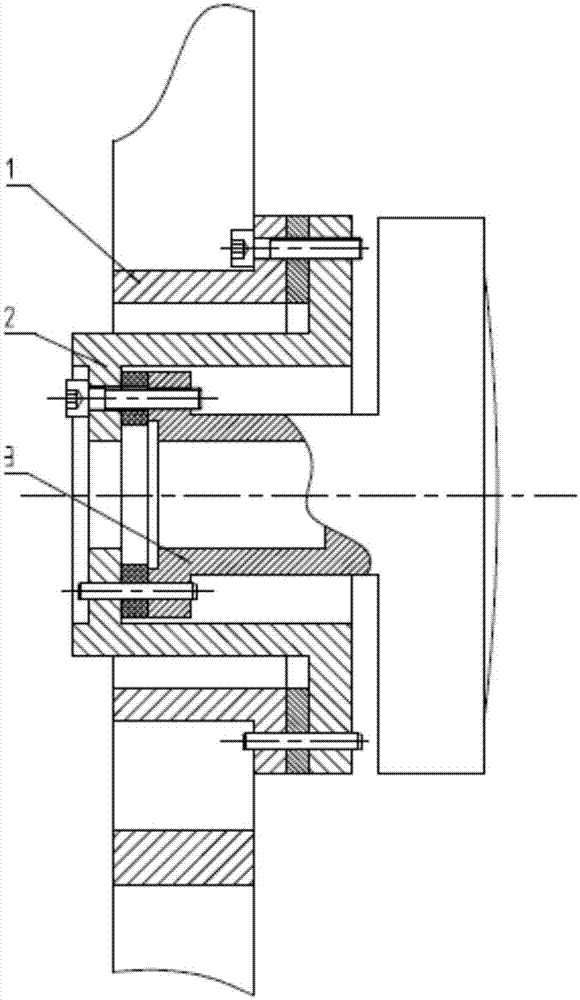

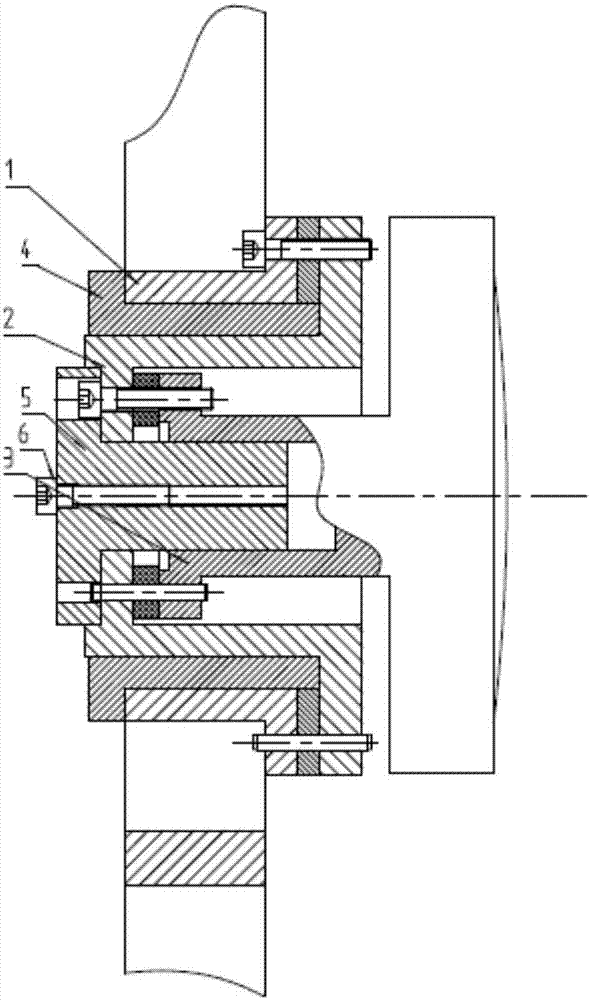

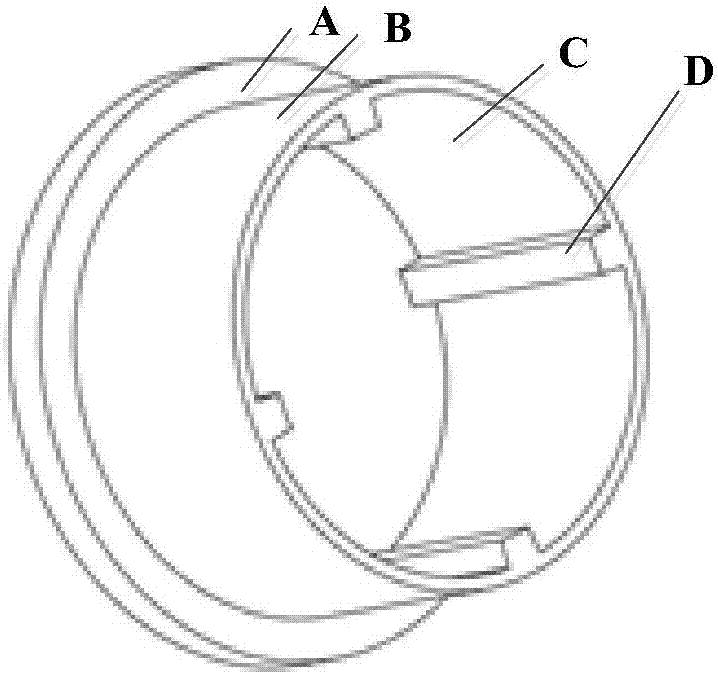

Infrared lens precision centering device and centering method on basis of low-stress clamping

ActiveCN107976767AOvercoming clothing adjustment errorImprove the accuracy of assembly and adjustmentMountingsFragilityCantilever

The invention discloses an infrared lens precision centering device and a centering method on the basis of low-stress clamping. The infrared lens precision centering device comprises a two-dimensionalrotary mechanism (1), a three-dimensional translation mechanism (2), a cantilever mechanism (3), a positioning convertible lens (4) and a micro-stress clamping positioning device (5). The micro-stress clamping positioning device (5) comprises a sucker (7) and a support (6), the two-dimensional rotary mechanism (1) is fixed to the micro-stress clamping positioning device (5) and is positioned right above the micro-stress clamping positioning device (5), the three-dimensional translation mechanism (2) is fixedly connected with the two-dimensional rotary mechanism (1) by the cantilever mechanism(3), and the positioning convertible lens (4) is adhered on an annular mounting table in a central circular hole in the support (6). The infrared lens precision centering device and the centering method have the advantages that the practical problems of inaccurate positioning of lenses mounted in later periods, fragility of clamped optical materials and the like in procedures for adjusting infrared optical systems by the aid of double-optical-path centering instruments can be solved by the aid of the infrared lens precision centering device, and infrared optical systems can be efficiently adjusted in a high-precision manner by the aid of the infrared lens precision centering device and the centering method.

Owner:BEIJING INST OF REMOTE SENSING EQUIP

Interferometer error calibrating device and method

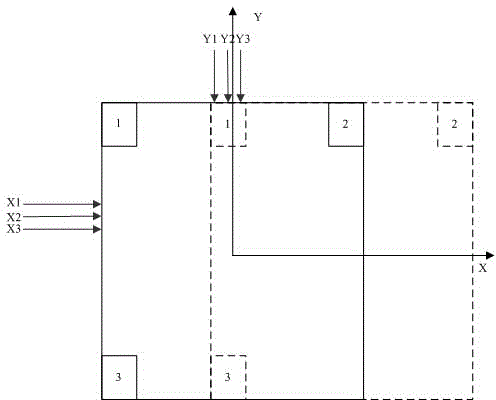

ActiveCN106154762AIndividual measurementImprove the accuracy of assembly and adjustmentPhotomechanical exposure apparatusMicrolithography exposure apparatusPosition errorPhotoelectric sensor

The invention discloses an interferometer error calibrating device for calibrating position errors of an interferometer. The interferometer error calibrating device comprises an X-direction photoelectric sensor, a Y-direction photoelectric sensor and a photoelectric sensor processing circuit. The X-direction photoelectric sensor comprises at least one photoelectric sensor located on one plane, and the Y-direction photoelectric sensor comprises at least one photoelectric sensor located on the other plane. The plane where the X-direction photoelectric sensor is located is perpendicular to the plane where the Y-direction photoelectric sensor is located. The photoelectric sensor processing circuit is used for converting photoelectric signals detected by the X-direction photoelectric sensor and the Y-direction photoelectric sensor into position information, and calculating the position errors of the interferometer according to the position information. The invention meanwhile discloses an interferometer error calibrating method.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

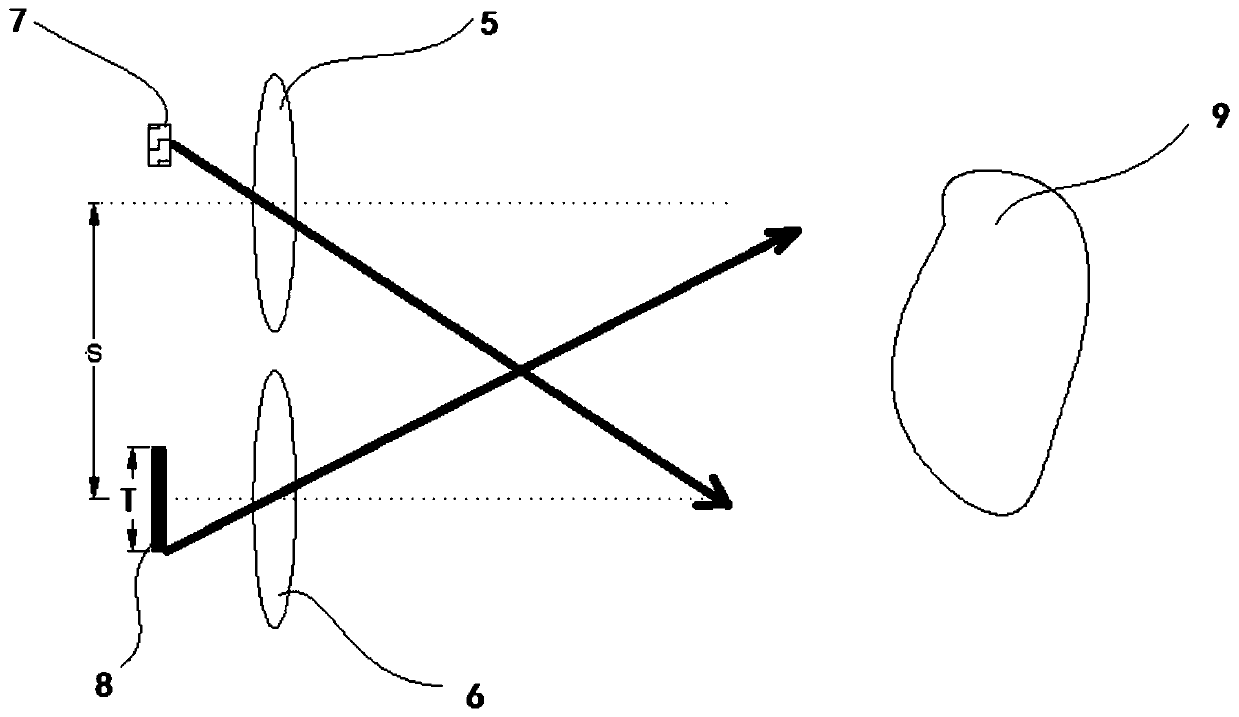

Single-line laser radar

ActiveCN111007484ASmall sizeImprove the effective detection distanceElectromagnetic wave reradiationICT adaptationGaussian beamOptical axis

The invention provides a single-line laser radar which comprises a first beam expanding collimating lens and a second beam expanding collimating lens which are adjacently arranged. A laser detector isarranged at the focal length position of the first beam expanding collimating lens, and a main detection light path of the laser detector coincides with the optical axis of the first beam expanding collimating lens. And a semiconductor laser module is arranged at the focal length position of the second beam expanding collimating lens and deviates from the optical axis of the second beam expandingcollimating lens. The semiconductor laser module integrates a fast-axis compression lens and a slow-axis compression lens and can emit a circular Gaussian beam or a near-circular Gaussian beam through reasonable design. The distance between the main light of the semiconductor laser module and the optical axis of the second beam expanding collimating lens does not exceed the radius of the detection surface of the laser detector.

Owner:UNITED MICROELECTRONICS CENT CO LTD

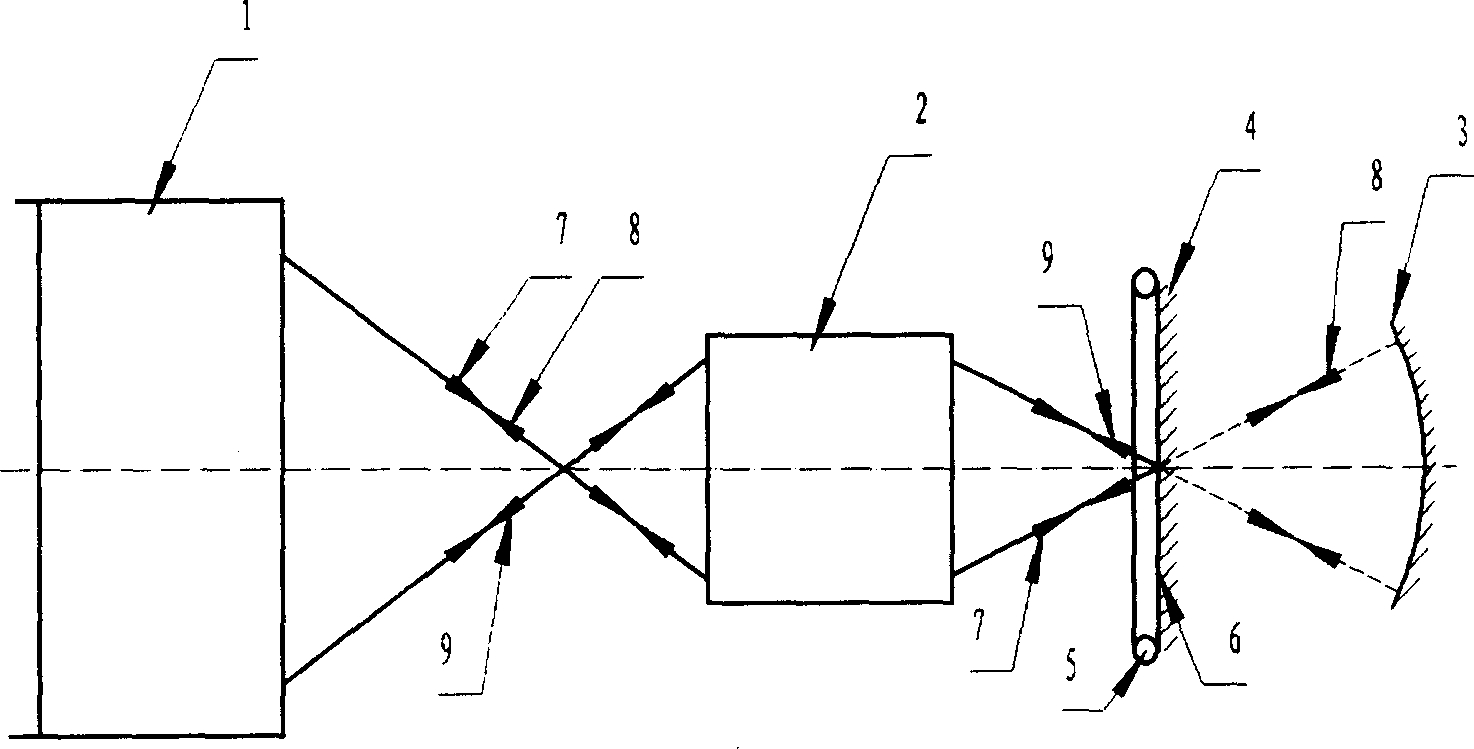

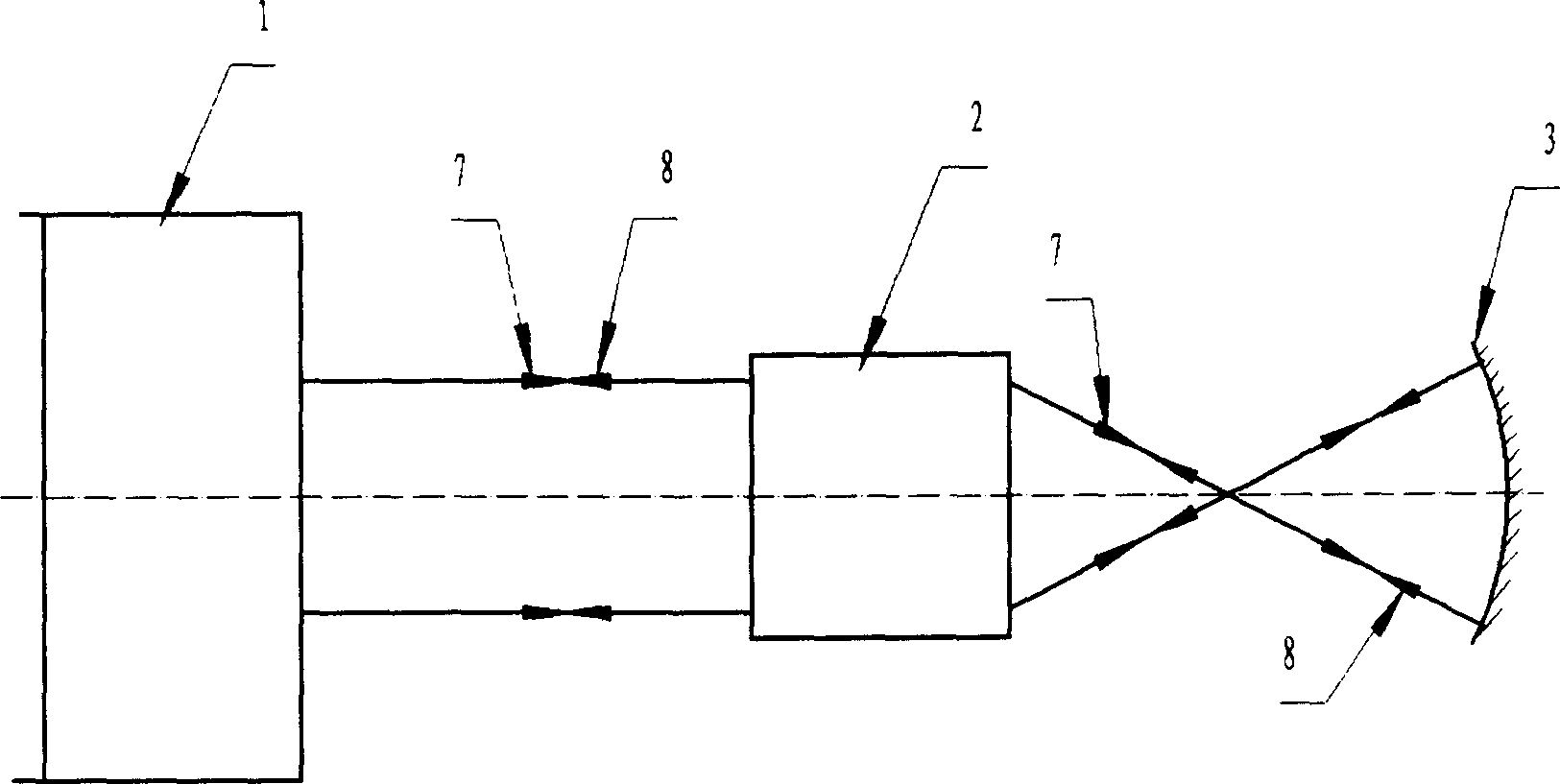

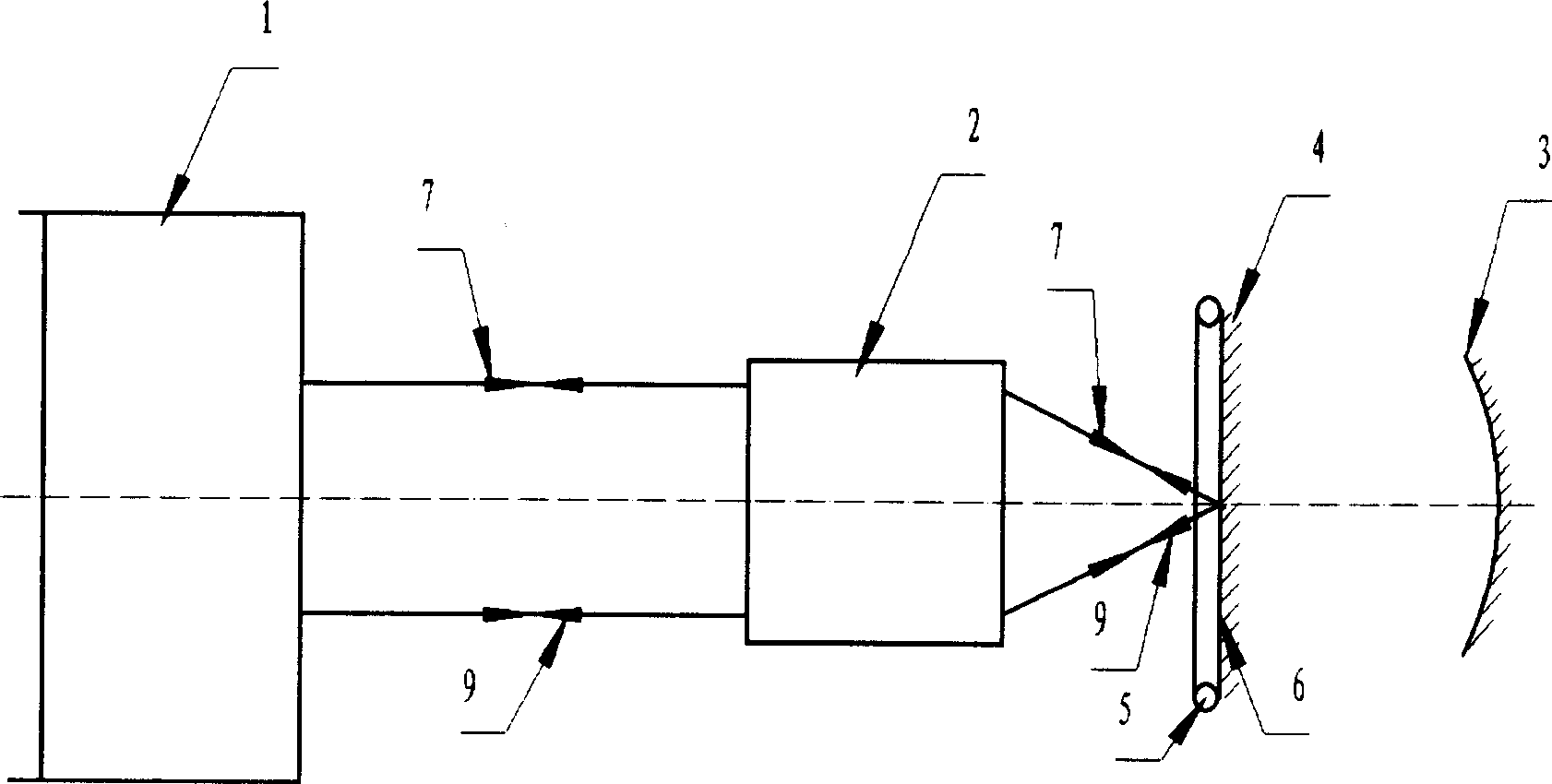

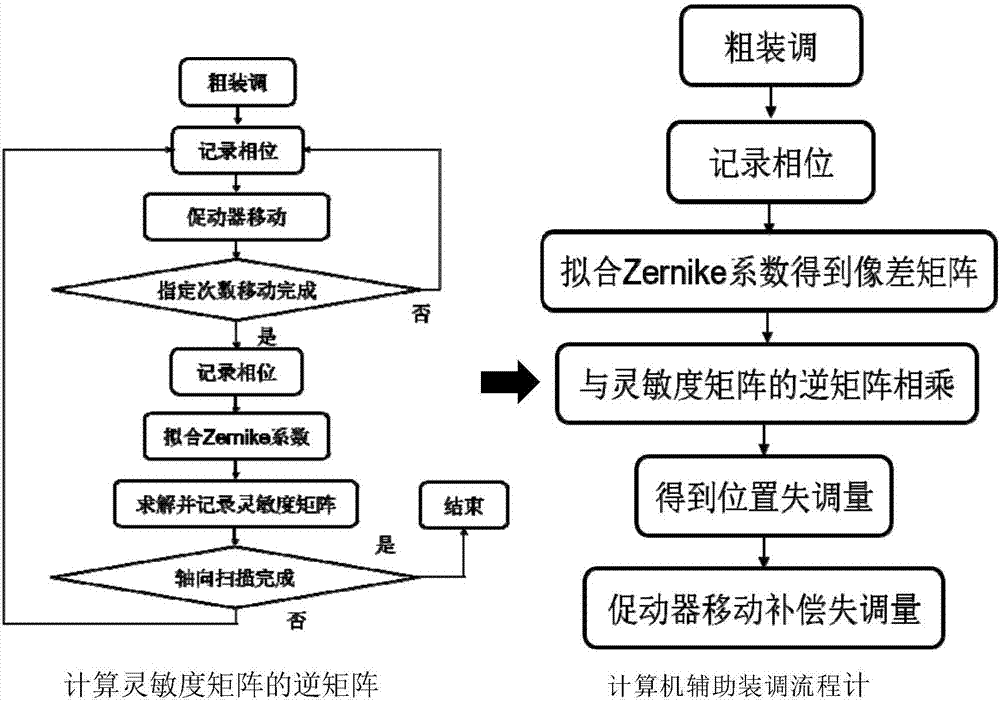

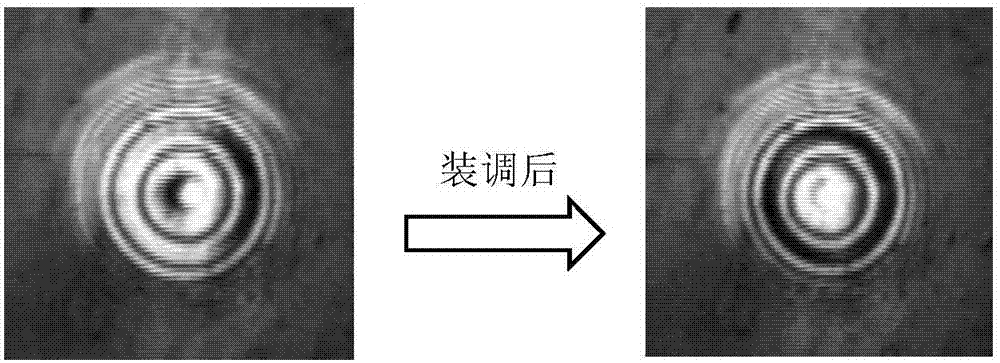

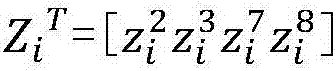

Computer-aided alignment method based on interference measurement and sensitivity matrix

ActiveCN107271150AReduce the impactReduce dependenceDesign optimisation/simulationTesting optical propertiesOptical axisComputer-aided

The invention discloses a computer-aided alignment method based on interference measurement and a sensitivity matrix; the method comprises the following steps: scanning each preset position in an optical axis direction of a tested member in the process; using a high precision displacement device to enable four misalignments of the tested member to have known variations; associating the variations with a phase position Zernike coefficient measured by an interferometer; building the sensitivity matrix of the position; using the measured phase position to calculate element misalignments, and aligning the interferometer according to the misalignments. The method can reduce the misalignment influences on calculations when an ideal model cannot comply with reality, thus effectively reducing workloads.

Owner:NANJING UNIV OF SCI & TECH

High-precision plane reflector adjusting method based on theodolite

ActiveCN109324382AImprove the accuracy of assembly and adjustmentEliminate adjustment errorsMountingsTheodoliteOptical axis

The invention discloses a high-precision plane reflector adjusting method based on a theodolite. A parallelism error of the front surface and the rear surface of a reflector is removed, so that high-precision adjustment of the reflector is realized. The method is realized through the theodolite. Firstly, the theodolite is used for leading out an optical axis of a lens; then, an included angle between the two surfaces is tested through a method for self-collimating the front surface and the rear surface of the reflector by the theodolite; angles between self-collimated images of the reflectingsurfaces and the optical axis are adjusted according to a spatial position relation; and an adjusting error caused by the included angle between the surfaces of the reflector is removed. According tothe method, the problem on the adjusting precision of the reflector is solved, and the application range of the theodolite adjusted reflector is expanded.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

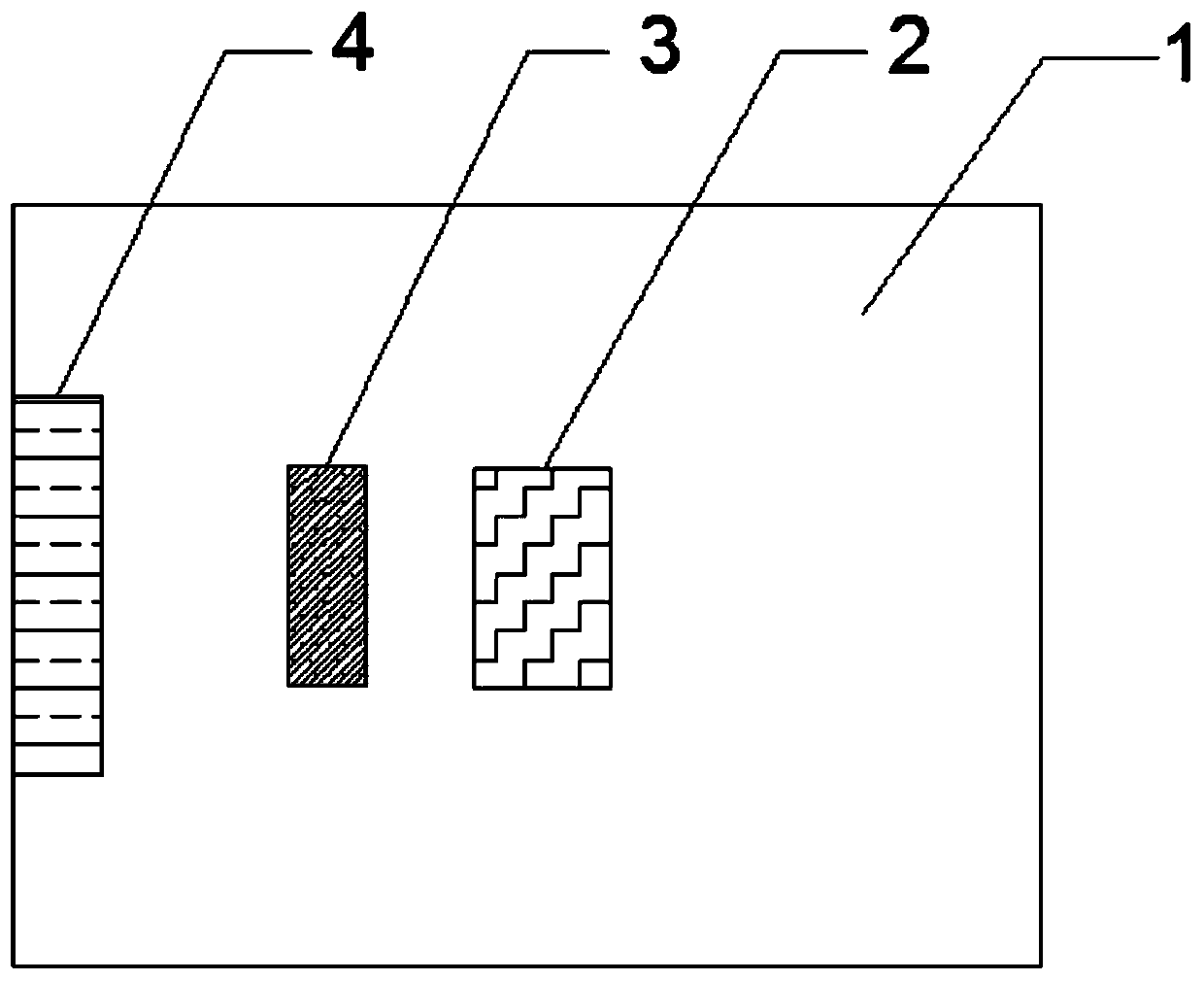

Installation and adjustment method of optical imaging system

ActiveCN112817160AHigh positioning accuracyHigh matching precisionOptical elementsBeam splitterMedicine

The invention discloses an installation and adjustment method of an optical imaging system. The optical imaging system comprises a mounting seat and an optical imaging device, the optical imaging device comprises a camera, a lens cone lens, a spectroscope and an objective lens. The method is used to complete the installation and adjustment of the optical imaging device based on a light source device and a collimating screen. The method comprises the steps of S1, adjusting the position and the angle of the light source device and the position and the angle of the camera so that the light source device emits light spots in the X direction and the emitted light spots vertically enter the camera for imaging, and the light spots have linear parts; and S2, installing the lens cone lens on the mounting seat, enabling the light spots emitted by the light source device to penetrate through the lens cone lens and then enter the camera for imaging, and adjusting the position and the angle of the lens cone lens so that the positions of the light spots in the camera can coincide with a first reference position. According to the invention, the adjustment precision can be improved, the operation is simple and fast, an adjustment speed can be improved, and the implementation cost is reduced.

Owner:常州奥创医疗科技有限公司

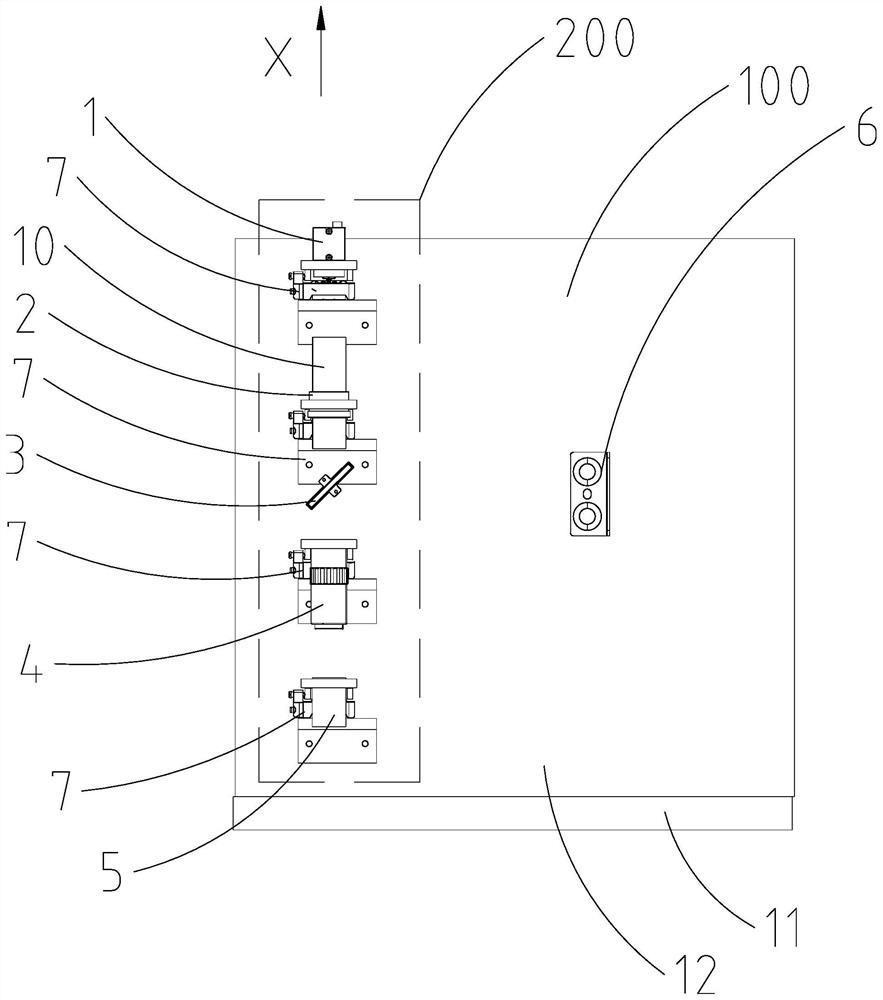

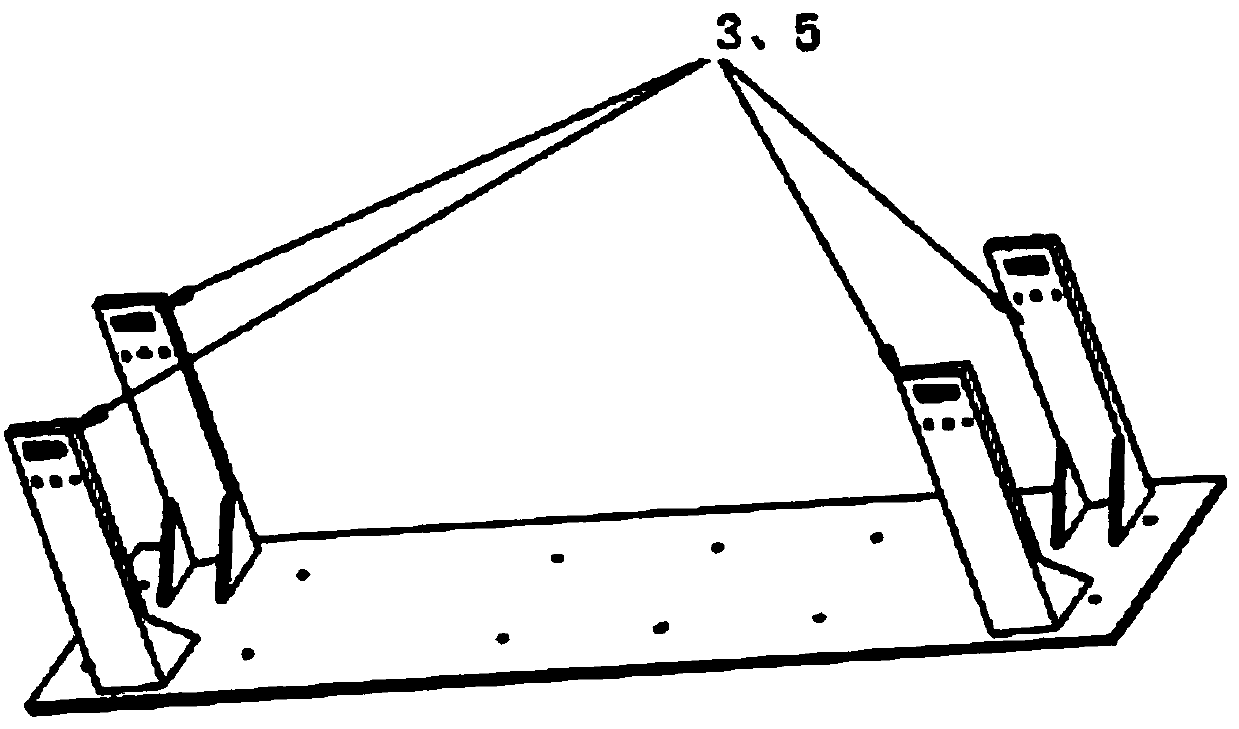

Effective measurement device for precision adjustment and control of welded vehicle body

ActiveCN109654970AAccurately installed and measuredImprove the accuracy of assembly and adjustmentMechanical measuring arrangementsMeasurement deviceEngineering

The invention discloses an effective measurement device for precision adjustment and control of a welded vehicle body. The device comprises a measuring reference base plate, a measuring base worktable, a left overturning table measuring plate, an auxiliary measuring crossbeam and a right overturning table measuring plate. The measuring base worktable is arranged above the measuring reference baseplate. Four corners of the measuring reference base plate are provided with four reference holes. Four reference holes of the measuring reference base plate are aligned with the reference holes of a clamp reference plate, the measuring reference base plate is fixedly connected with the clamp reference plate. The measuring base worktable is fixedly connected with the measuring reference base platethrough screws. The left overturning table measuring plate and the right overturning table measuring plate are fixedly connected with a clamp overturning table through screw holes arranged on the leftoverturning table measuring plate and the right overturning table measuring plate. The auxiliary measuring crossbeam is fixedly connected with the left overturning table measuring plate and the rightoverturning table measuring plate through elongated holes arranged at two ends of the auxiliary measuring crossbeam.

Owner:NANJING JINLONG NEW ENERGY AUTOMOBILE RES INST

Method for detecting included angle between tracking reflector and cross shaft of laser tracker

InactiveCN105203050AHigh measurement accuracyImprove the accuracy of assembly and adjustmentUsing optical meansLaser trackerPhysics

The invention discloses a method for detecting the included angle between a tracking reflector and a cross shaft of a laser tracker. The method is suitable for installation adjustment and error correction of the tracking reflector of the laser tracker. The method plays an important role in designing a high-accuracy adjustable end face reflector, establishing a corresponding detection mathematic model and providing high-accuracy standard angles through autocollimators and a polyhedron.

Owner:扬中中科维康智能科技有限公司

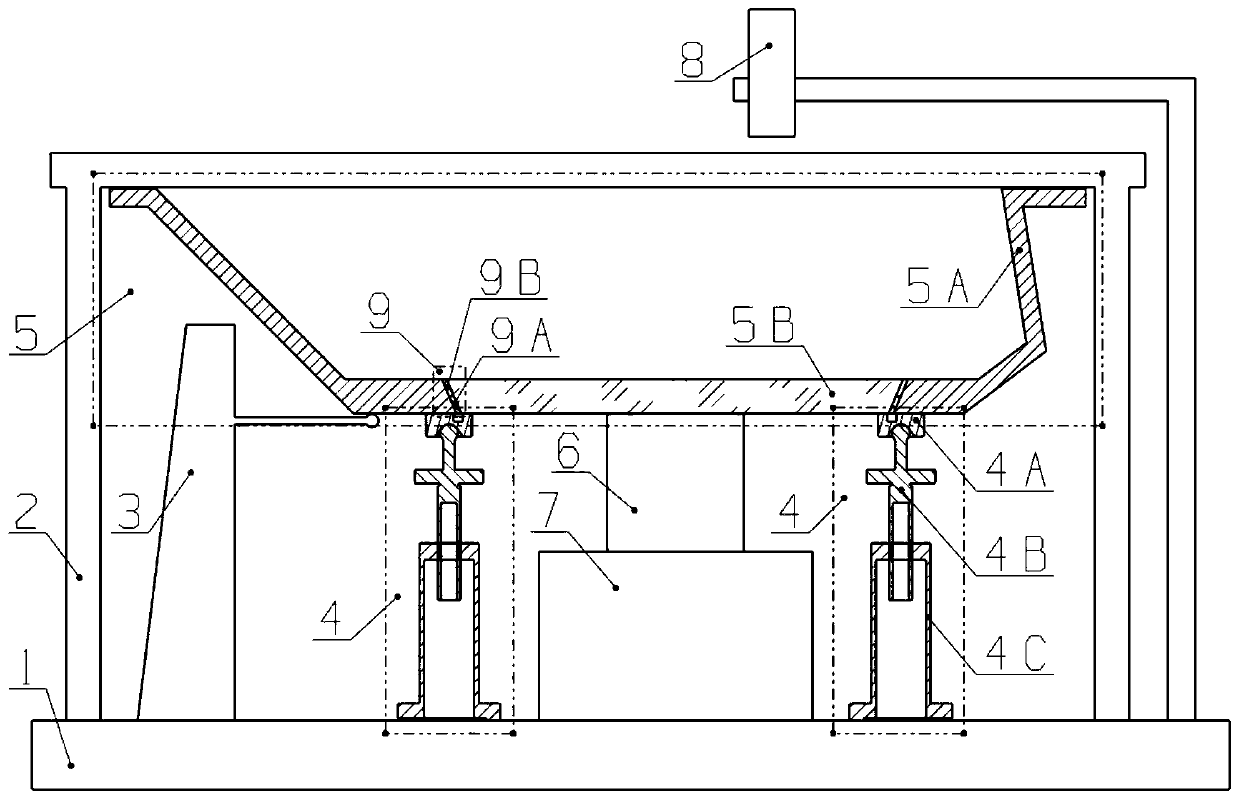

Thermal control focusing assistance adjustment device and method

ActiveCN106969754ASimple structureEasy to operatePicture taking arrangementsEngineeringService condition

The invention relates to a thermal regulator focusing assistance adjustment device and method. The device comprises a first adjustment locating ring, a second adjustment locating ring and a mounting and dismounting screw, wherein the first adjustment locating ring is mounted between an aluminum ring and a secondary mirror component of a thermal regulator focusing device; the second adjustment locating ring is mounted on the aluminum ring; the mounting and dismounting screw is located in the middle of the second adjustment locating ring; and the device is convenient to dismount after the aluminum ring and the secondary mirror component are mounted. According to the thermal regulator focusing assistance adjustment device meeting space service conditions and having stable performance, high precision and a reliable structure, and the method, the mounting precision of the thermal regulator focusing device is ensured.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

Low-stress conductive sealing adjustment device and method for aviation light window

ActiveCN110716274AImprove the accuracy of assembly and adjustmentGuaranteed tightnessScreening gaskets/sealsMountingsAviationProcess equipment

The invention relates to a low-stress conductive sealing adjustment device and method for an aviation light window. By using instruments and equipment such as a height indicator, a precise electric control adjustment table and an auto-collimation light pipe, special process equipment such as a light window adjustment reference tool and a light window supporting tool and a composite bonding layer,the adjustment reference of the aviation light window can be quickly established, the adjustment precision is improved, the clamping stress and the bonding stress are reduced, the adjustment stress isavoided, the optical performance is ensured while the sealing performance and the electromagnetic shielding performance of the aviation light window are ensured, and the adjustment efficiency and theadjustment quality of the aviation light window are greatly improved.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com