Patents

Literature

48results about How to "Reduce the number of loading and unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recovering coin protein sugar dregs and preparing protein nitrogen sources and nitrogen-containing syrup

The invention discloses a method for recovering coin protein sugar dregs and preparing protein nitrogen sources and nitrogen-containing syrup in the production of enzymatic corn starch sugar, comprising the steps of size mixing, liquefying, saccharifying, standing separation, centrifugal separation, proteolysis, concentration, drying, compounding, and the like. In the invention, protein is condensed under the heat flash of liquefying, the protein sugar dregs concentrate and float upwards in saccharifying, the sugar dregs are recovered through the steps of standing separation and centrifugal separation, the sugar dregs are dried into protein, or the sugar dregs are hydrolyzed to prepare protein nitrogen sources, and the nitrogen sources can be compounded with syrup to form nitrogen-containing starch syrup for fermenting. Clarified saccharification liquid after centrifugal separation is decolored, filtered, refined and concentrated, and starch syrup products are obtained. The majority of lentous sugar dregs in the saccharification liquid are removed before the treatment of decoloring and filtering, and the decoloring and filtering performance of the material is better. The use level of active carbon, and the like can be properly reduced, the production capability of filtering equipment is improved, and the frequency of the loading and unloading of filters as well as the consumption of washing waste water and various kinds of loss are greatly reduced.

Owner:广州双桥(重庆)有限公司

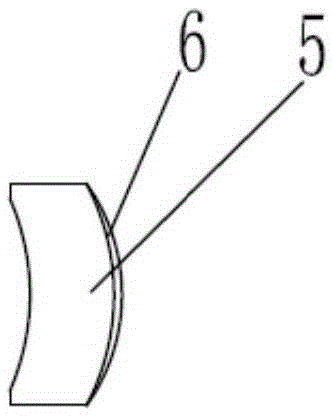

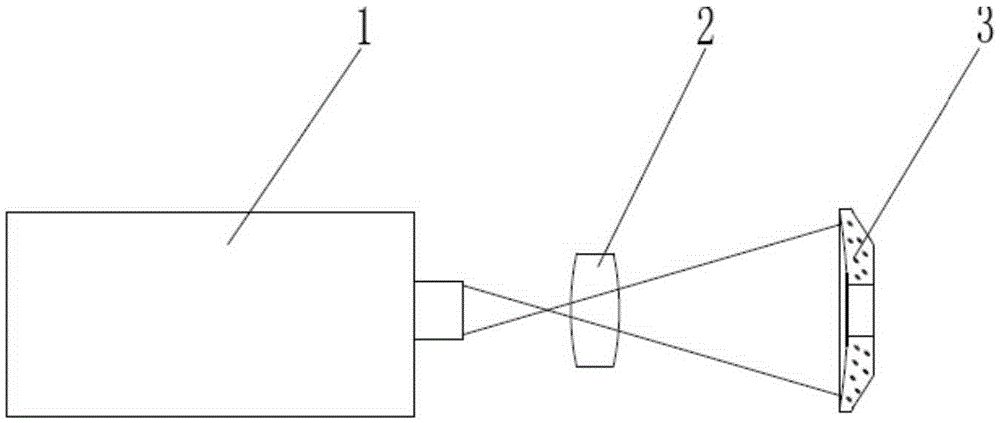

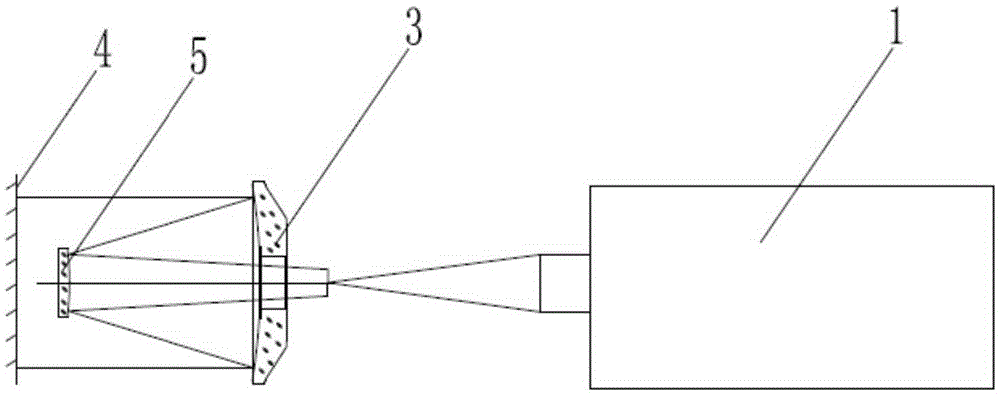

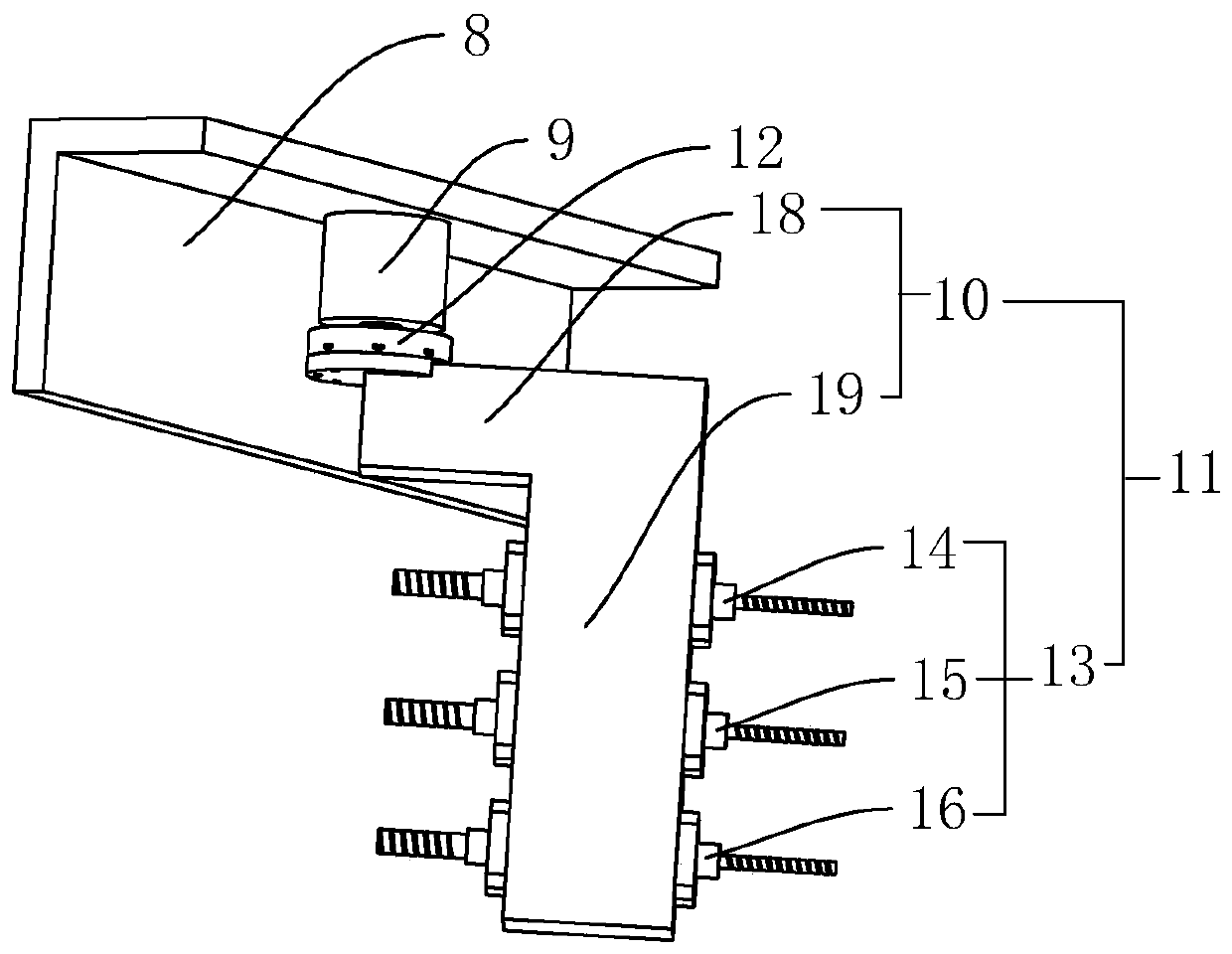

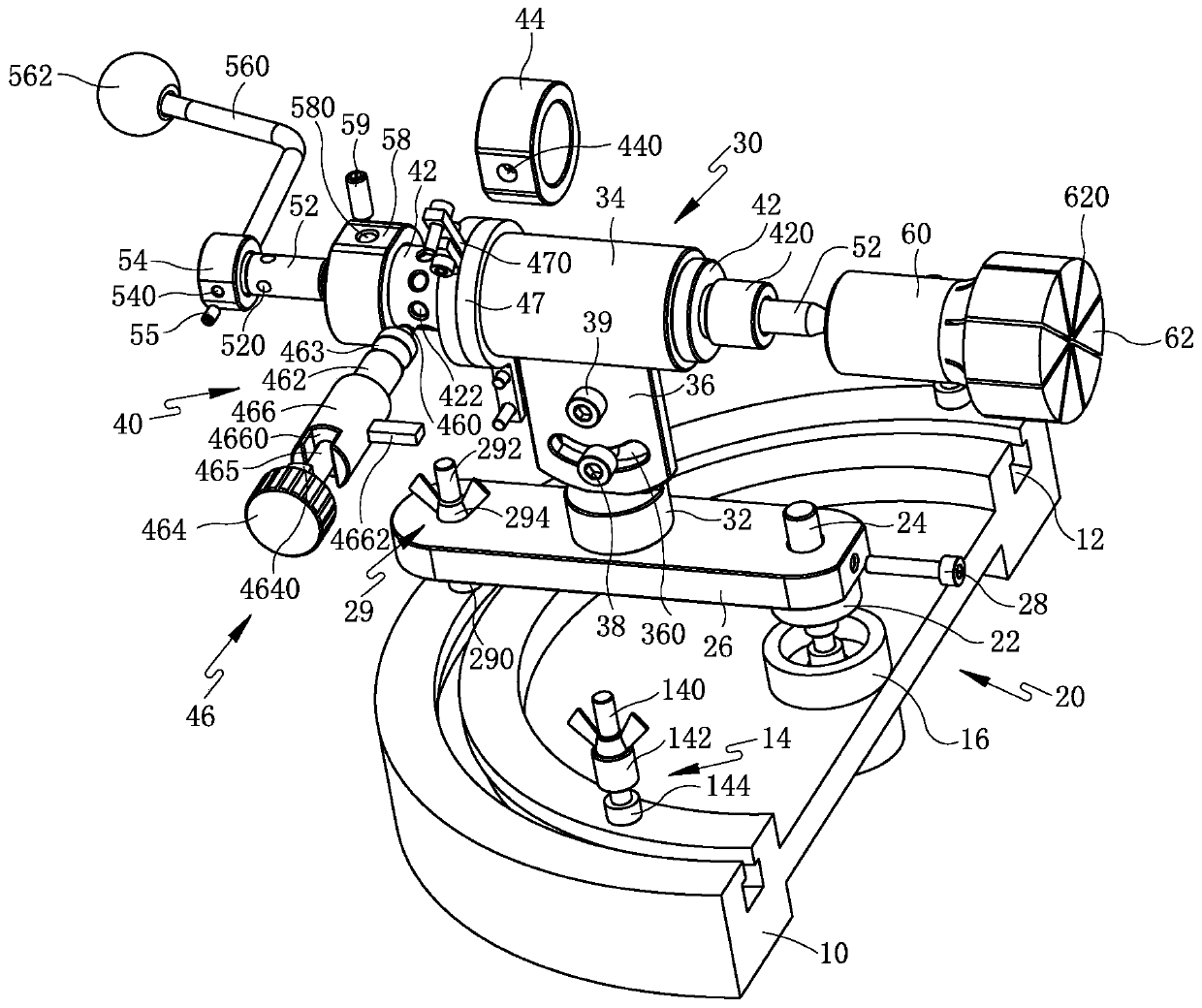

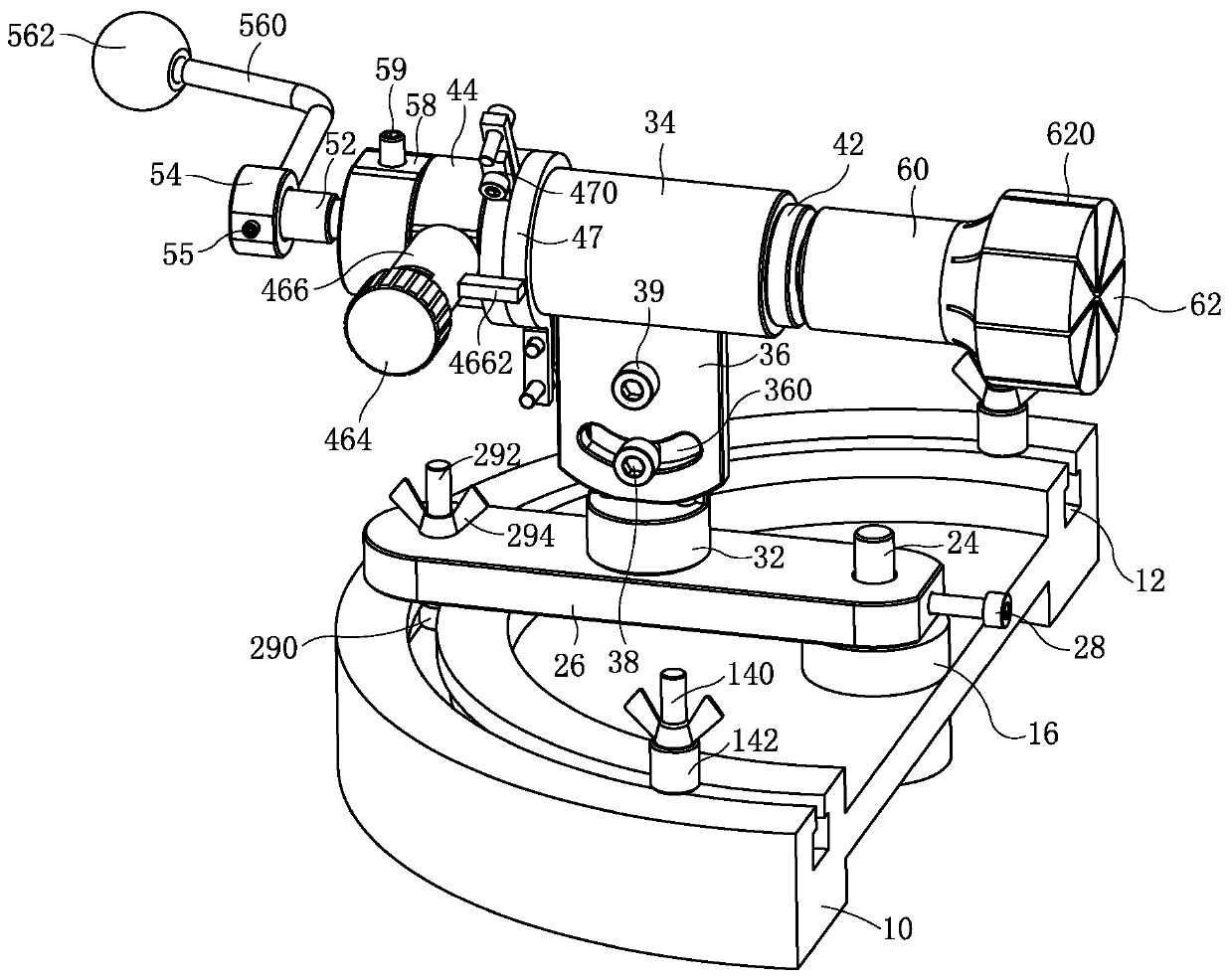

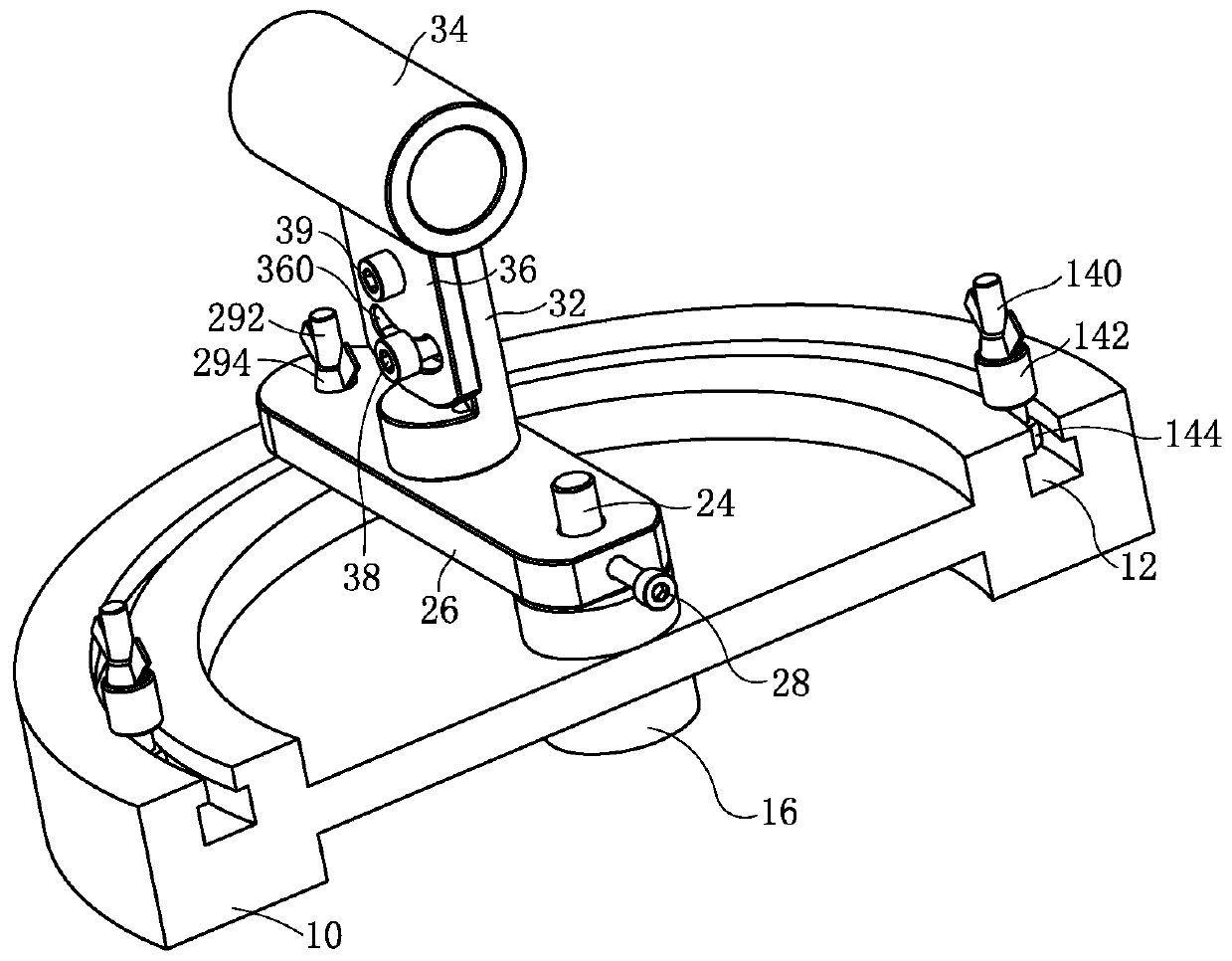

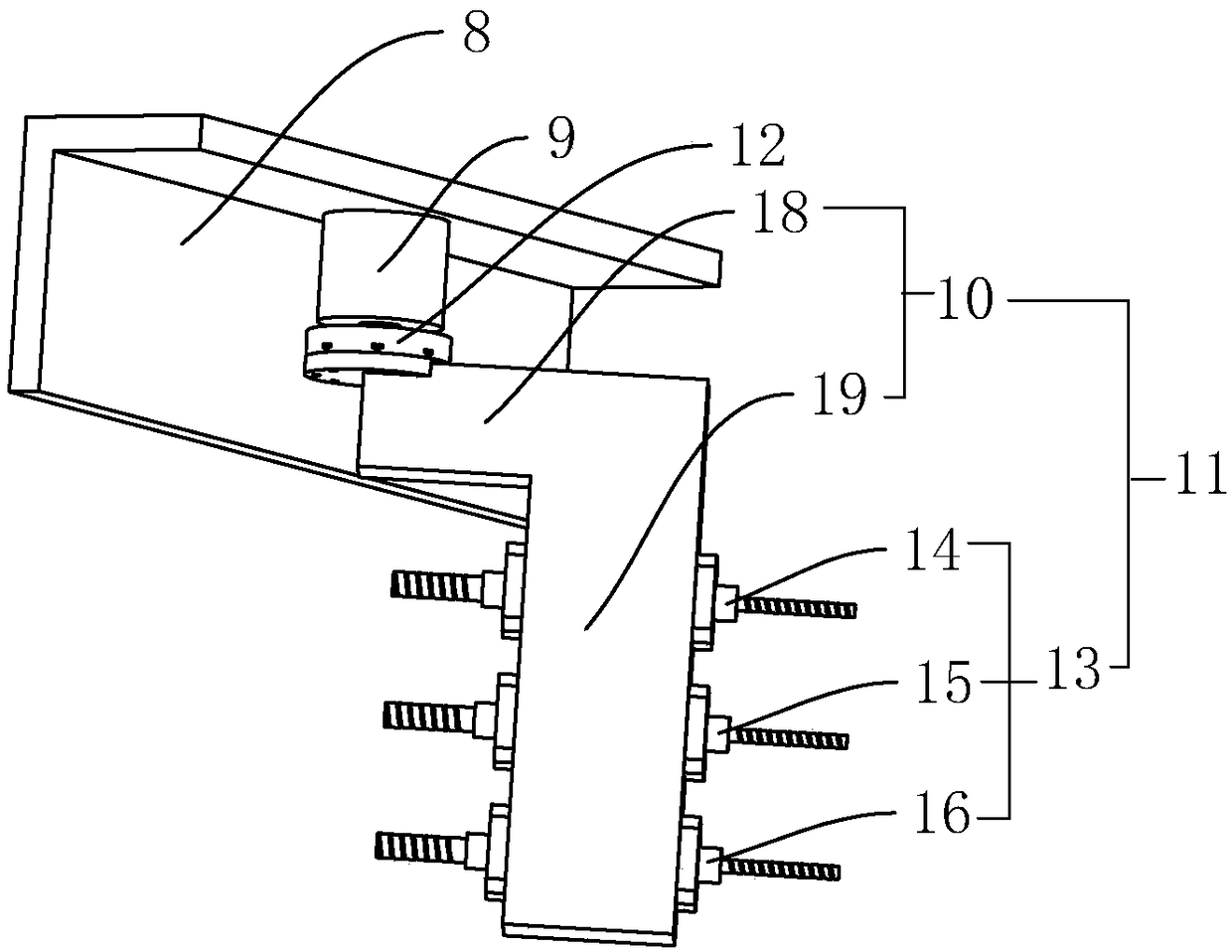

Optical machine adjusting method of R-C reflection and refraction system

ActiveCN105353494AReduce difficultyReduce the number of loading and unloadingMountingsOptoelectronicsInterferometry

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

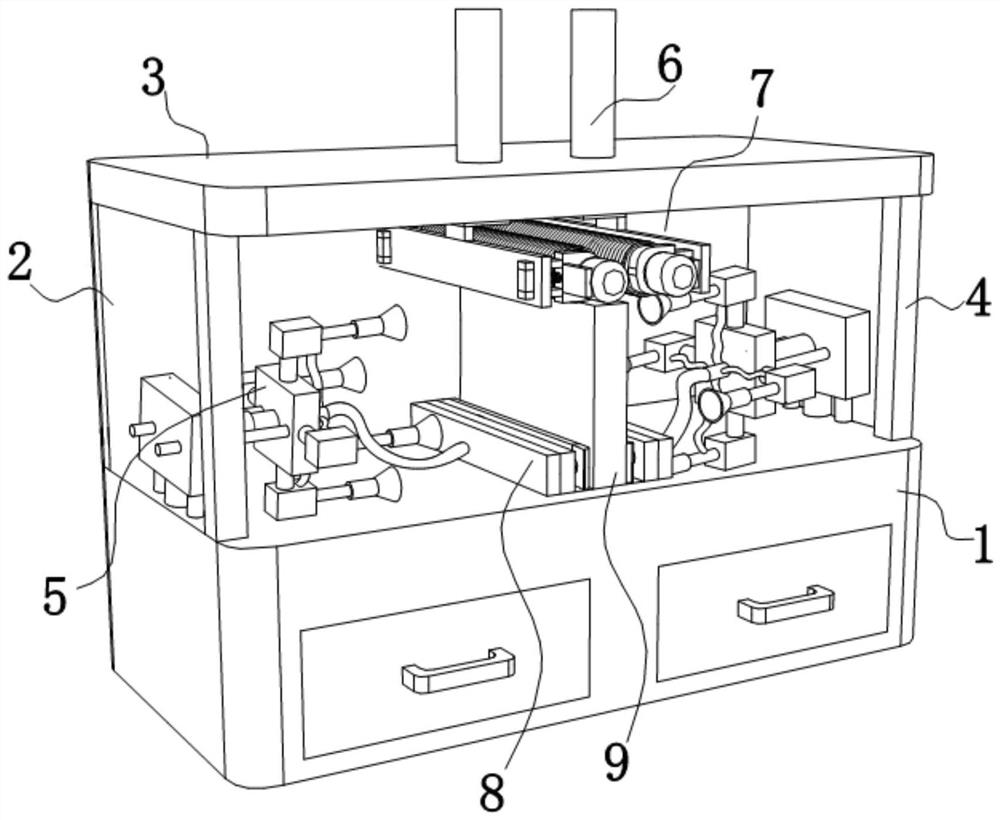

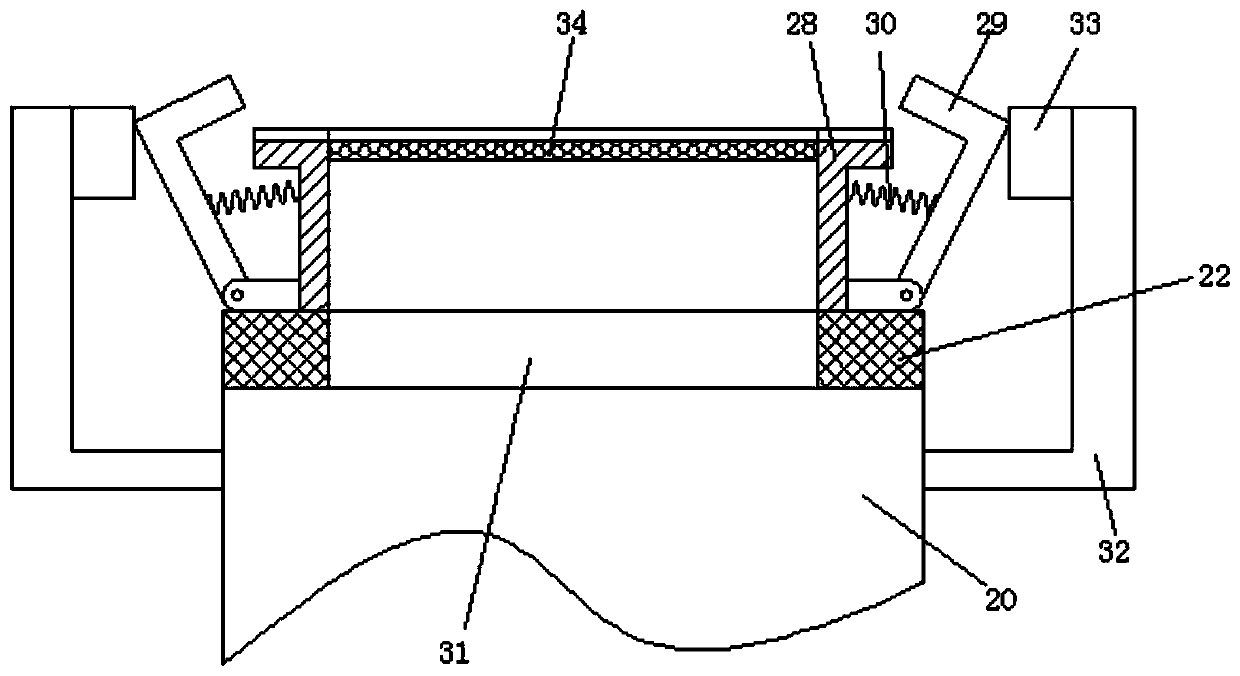

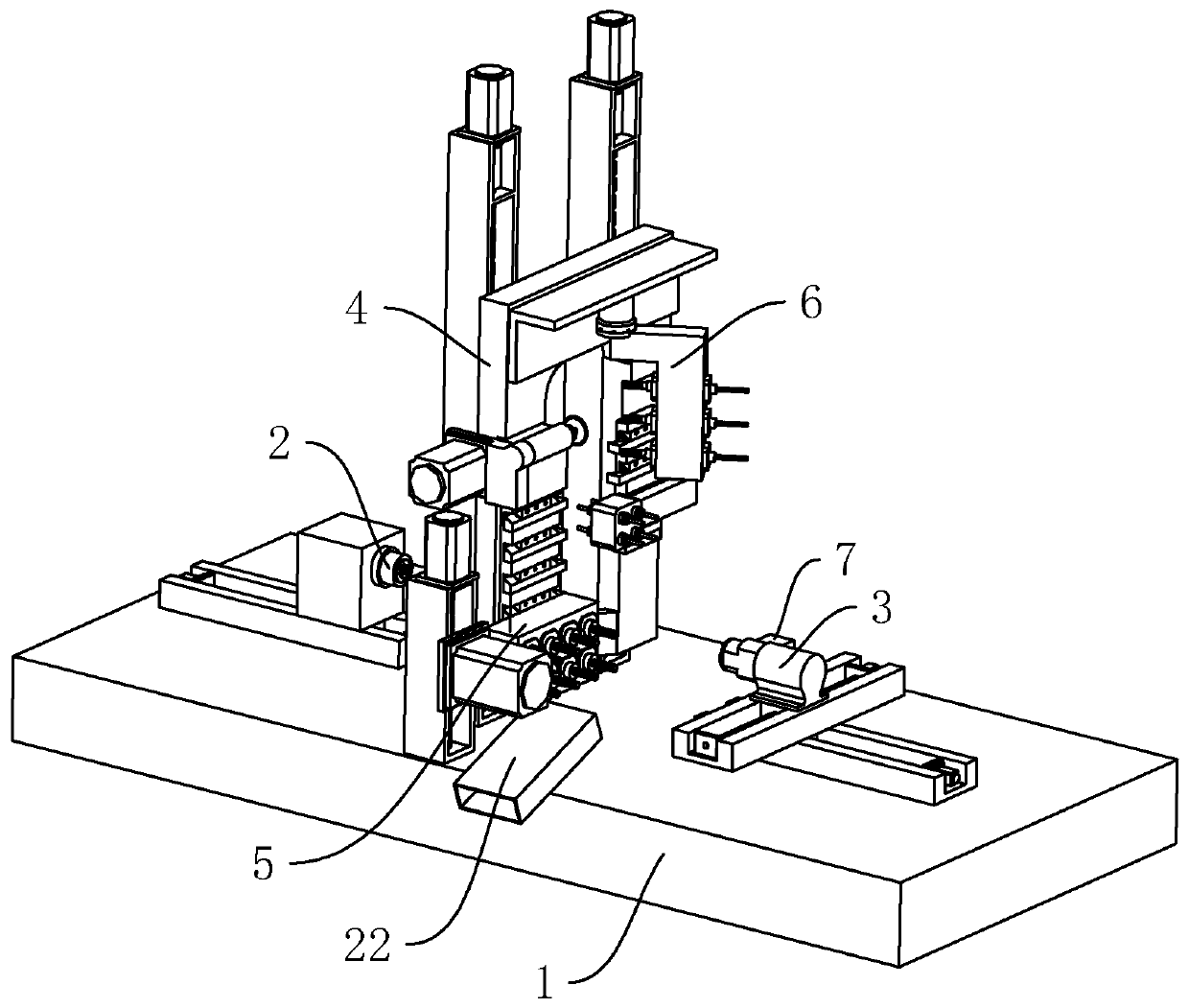

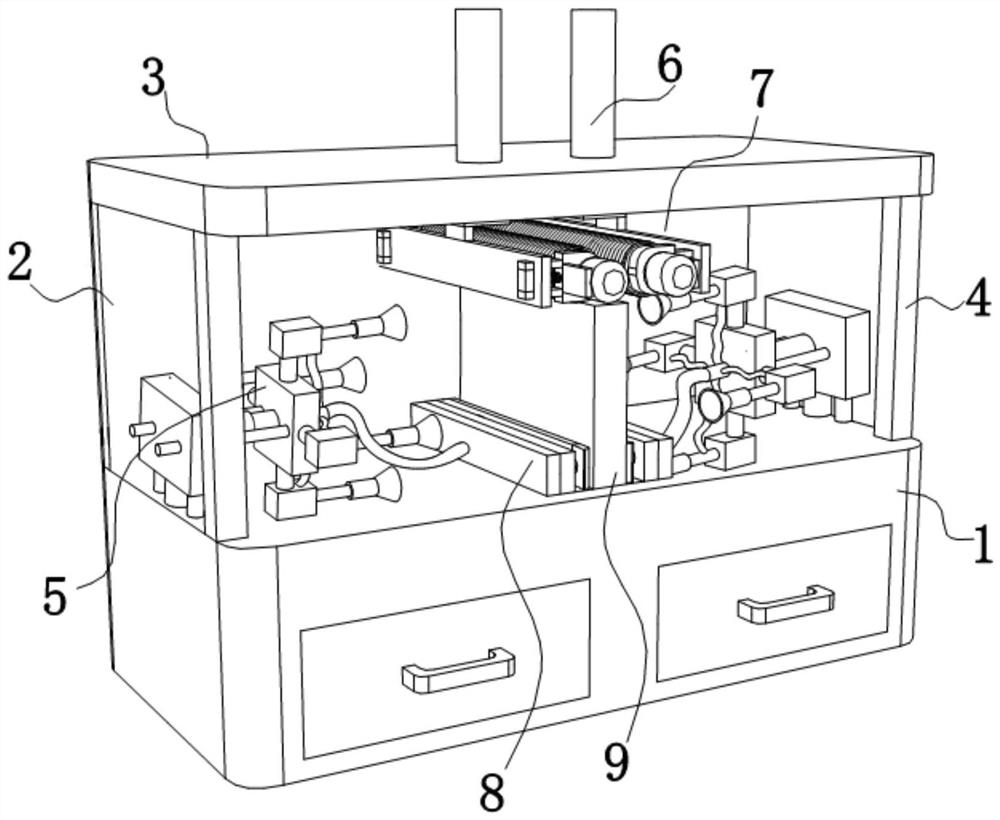

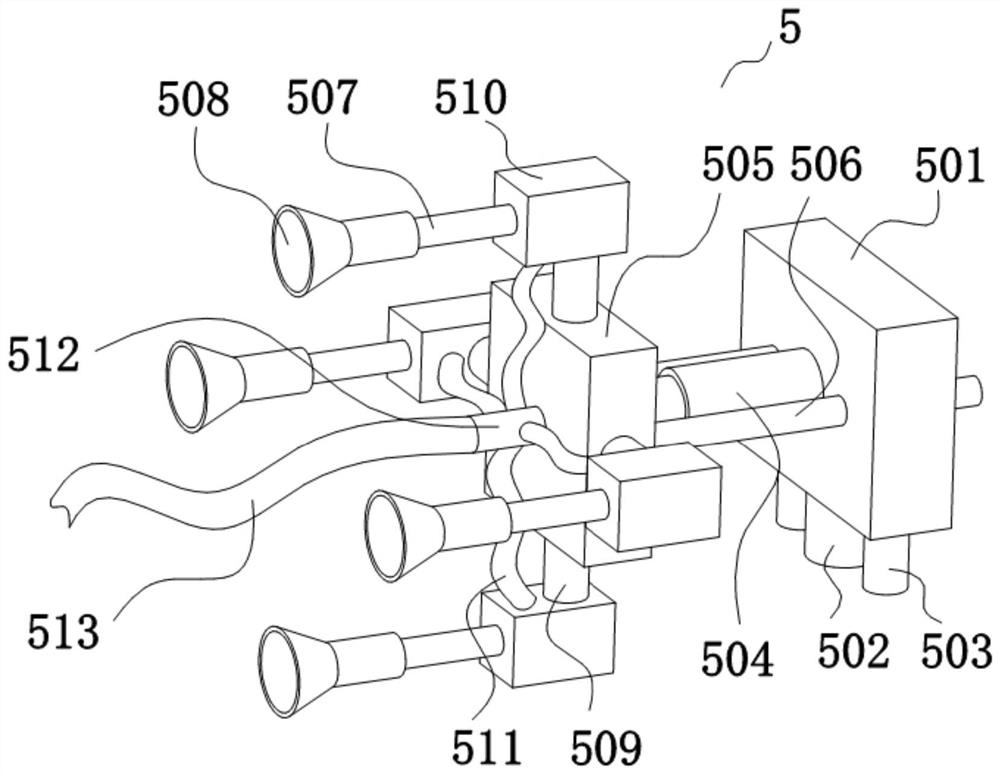

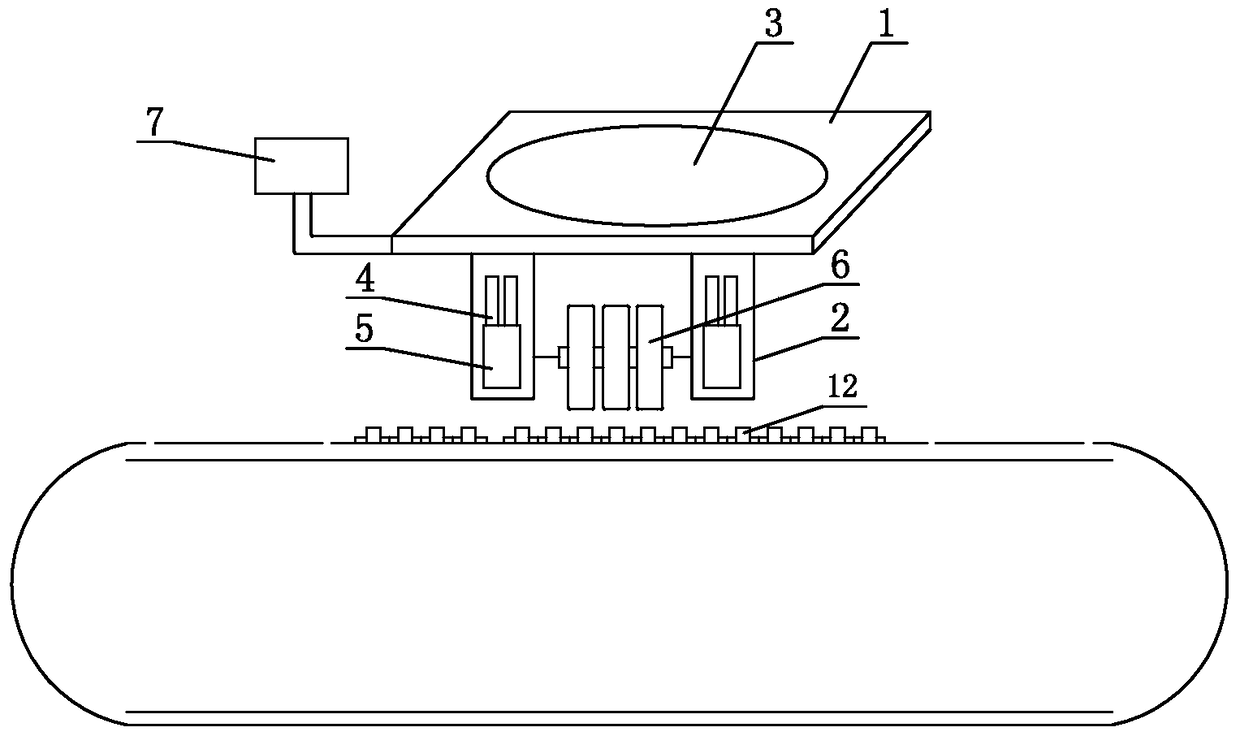

Aluminum alloy metal part grinding and polishing device

ActiveCN112775777AEffectively fixedEasy to polishGrinding carriagesGrinding drivesStructural engineeringMechanical engineering

The invention belongs to the technical field of aluminum alloy machining equipment, and discloses an aluminum alloy metal part grinding and polishing device which comprises a grinding table and an aluminum alloy plate. Two symmetrically-distributed fixing assemblies are arranged at the top of the grinding table. Each fixing assembly comprises a first hydraulic rod, wherein the mounting end of the first hydraulic rod is arranged at the top of the grinding table, a fixing plate is arranged at the output end of the first hydraulic rod, a first electric telescopic rod is arranged on one side of the fixing plate, a first moving plate is arranged at the output end of the first electric telescopic rod, second electric telescopic rods are arranged on the end face of the periphery of the first moving plate, second moving plates are arranged at the other ends of the second electric telescopic rods, first air guide pipes are arranged at one ends of the second moving plates, and suckers are arranged at the other ends of the first air guide pipes. According to the aluminum alloy plate polishing device, through the arrangement of a polishing assembly, the fixing assemblies and a containing plate, the two side faces of an aluminum alloy plate can be ground at a time, the aluminum alloy plate can be ground and pre-cleaned, and the grinding precision is controlled.

Owner:JIANGXI DONGYANG ALUMINUM CO LTD

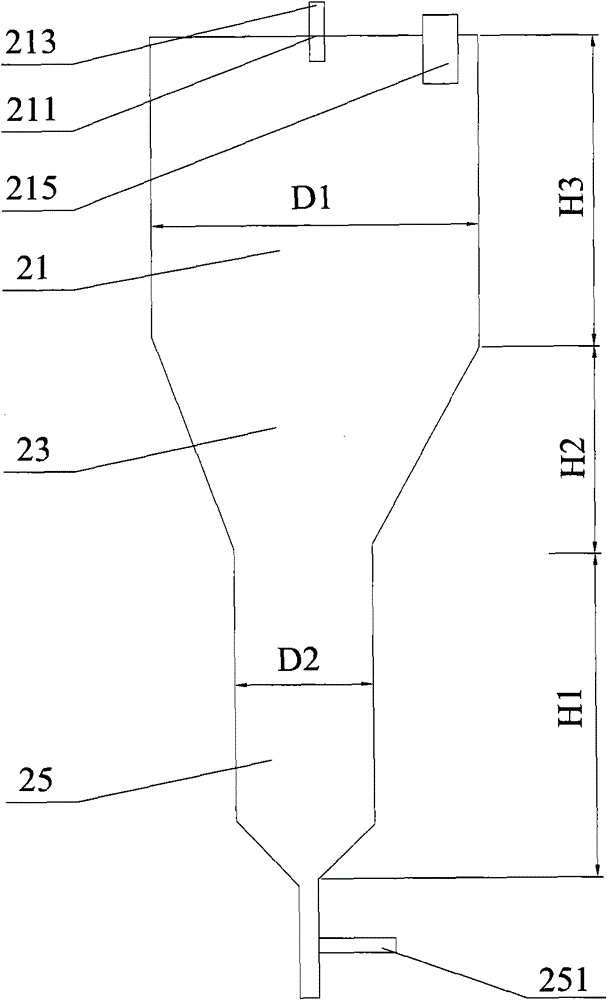

Tempering and transshipment tank for processed grains

InactiveCN103444865AGuarantee quality and safetyImprove logistics efficiencyEdible seed preservationDistributorMoisture

The invention belongs to the field of storage and transportation of grains and particularly relates to a tempering and transshipment tank for processed grains. The transshipment tank comprises a tank body comprising a base plate, side plates and a top plate; a temperature control system outside machine, an ultrasonic humidifier, an ozone generator, a temperature and humidity monitoring and wireless transmission system and an integrated displaying and monitoring system are arranged in an external space in the tank body; an air distributor, a draught fan and a temperature control system inside machine are arranged in an internal space in the tank body; a steel plate, a partition board, grids, an anemograph, a moisture transducer, steel tubes with grooves and steel plates with vent holes are further arranged in the tank body. According to the tempering and transshipment tank for the processed grains, the problem that grains dew or crack due to the high temperature of the new processed grains and the larger differences between the temperature and the humidity of the grains and the environmental temperature and humidity during entering-exiting processes is effectively solved; the tempering and the transshipment are integrated, the tempering and transshipment operations of the grains can be finished in batches as required before the transportation, during the transportation or after reaching a transportation destination, and the problem that the grains dew due to the change of environmental conditions when the grains are transported from the north to the south of China is effectively solved.

Owner:SHANDONG INST OF COMMERCE & TECH

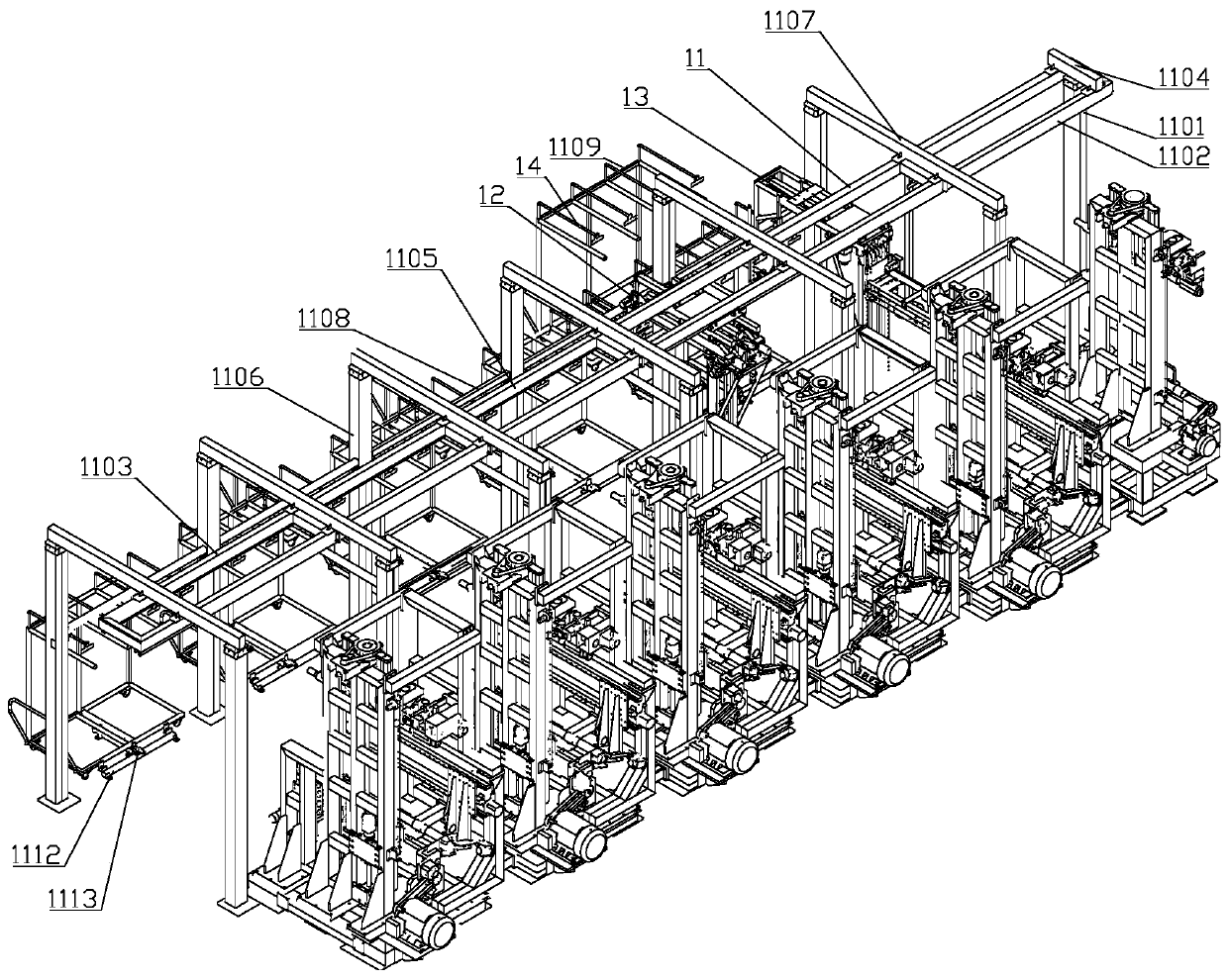

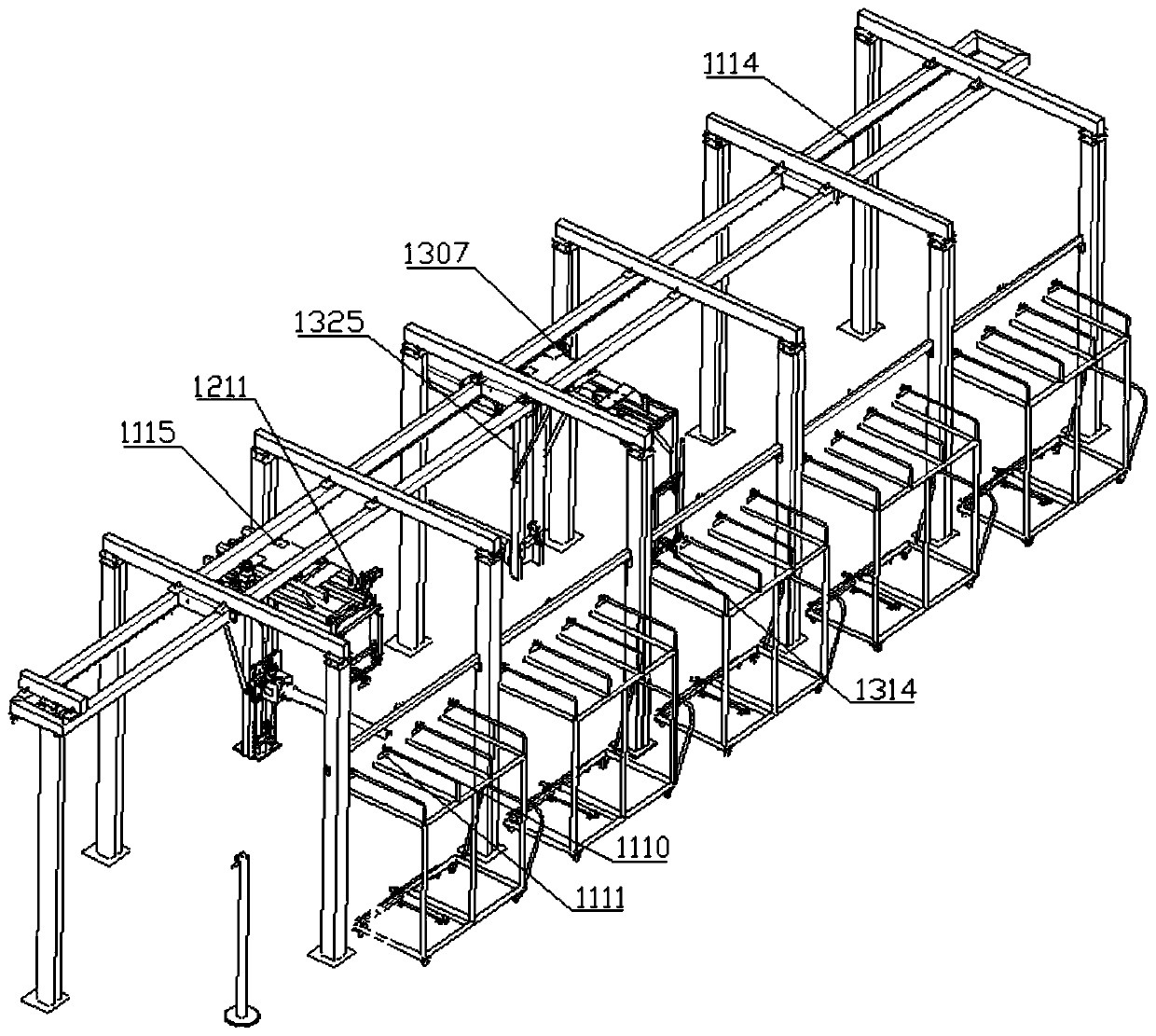

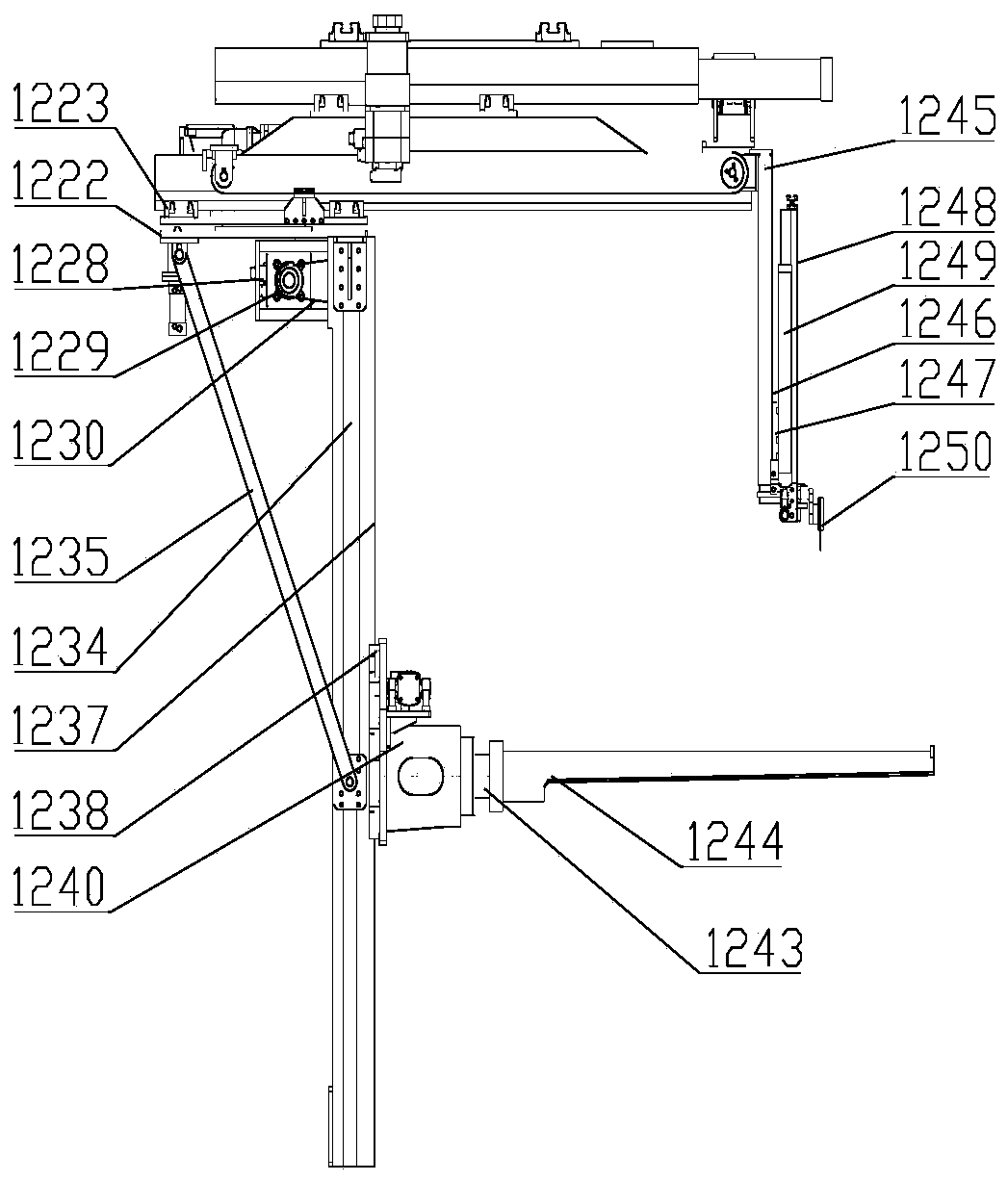

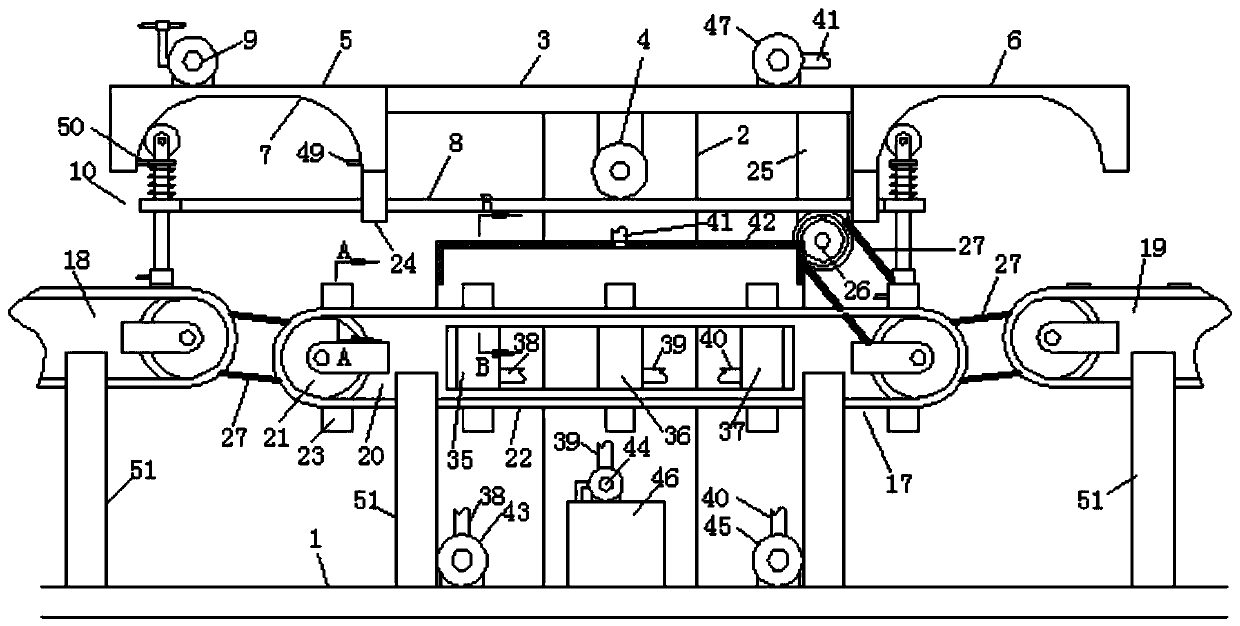

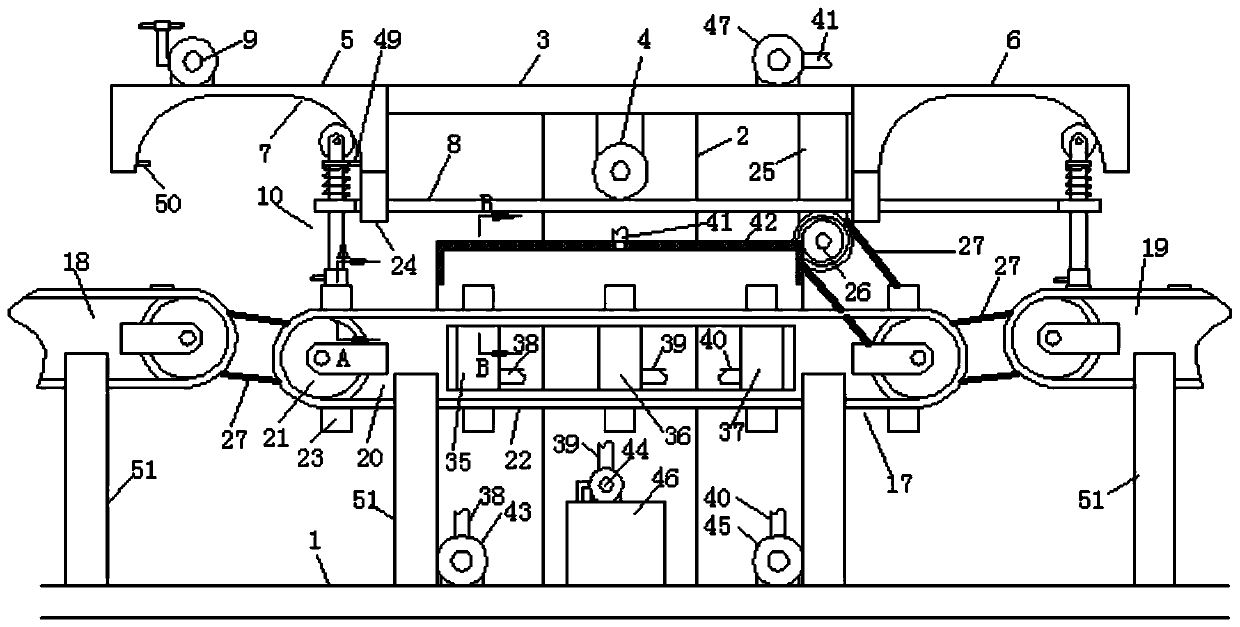

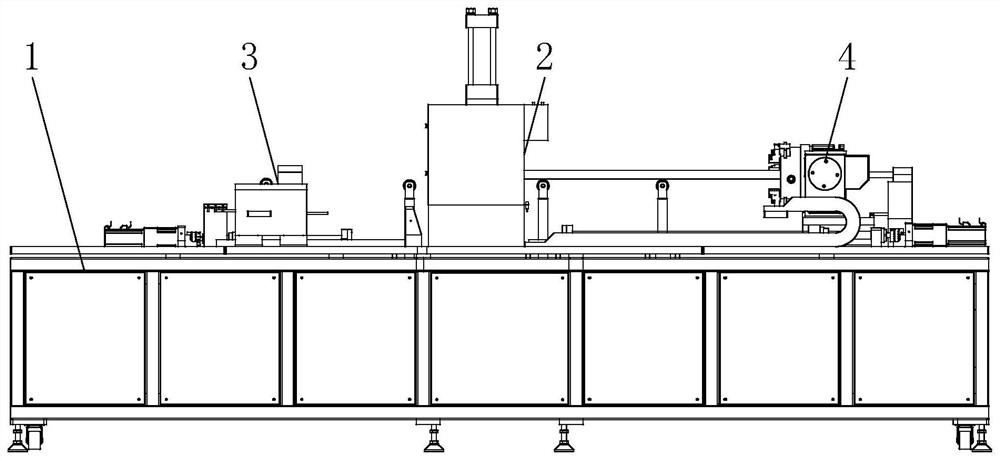

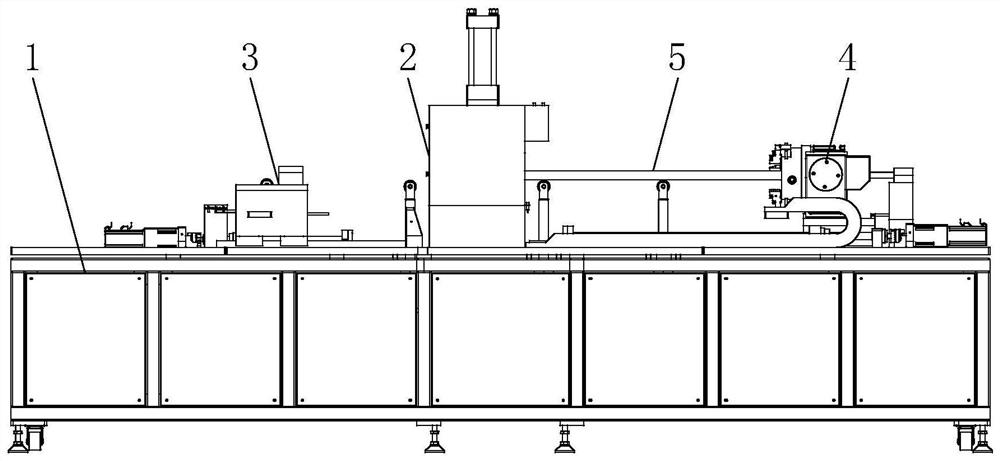

Automatic multi-function rubber belt grinding and cutting assembly line

PendingCN111390994AReduce lossReduce the number of loading and unloadingBelt grinding machinesMetal working apparatusConstant powerElectric machinery

The invention relates to an automatic multi-function rubber belt grinding and cutting assembly line. The automatic multi-function rubber belt grinding and cutting assembly line aims to shorten the time of multiple clamping of a conventional rubber belt in production by arranging a plurality of grinding devices and cutting devices and carts in a assembly line, the processing efficiency is improved, at the same time, the error caused by multiple disassembly and clamping is reduced, and the machining accuracy is improved. Before grinding and cutting, a deviation correction device provided corrects the deviation of a rubber belt, a rubber detector detects the thickness of the rubber belt, during grinding and cutting, a grinding roller can move horizontally during processing and further can reduce the processing stress caused by the uneven thickness of the rubber belt, and a constant power motor can save energy and overcome the disadvantages of traditional processing; and after the rubberbelt automatically unloads the belt and transports to the carts after grinding and cutting are completed, the order of the rubber belt remains unchanged to realize the accurate positioning of the whole processing process, so that the working efficiency of a rubber belt grinding and cutting machine is greatly improved.

Owner:QINGDAO UNIV OF SCI & TECH

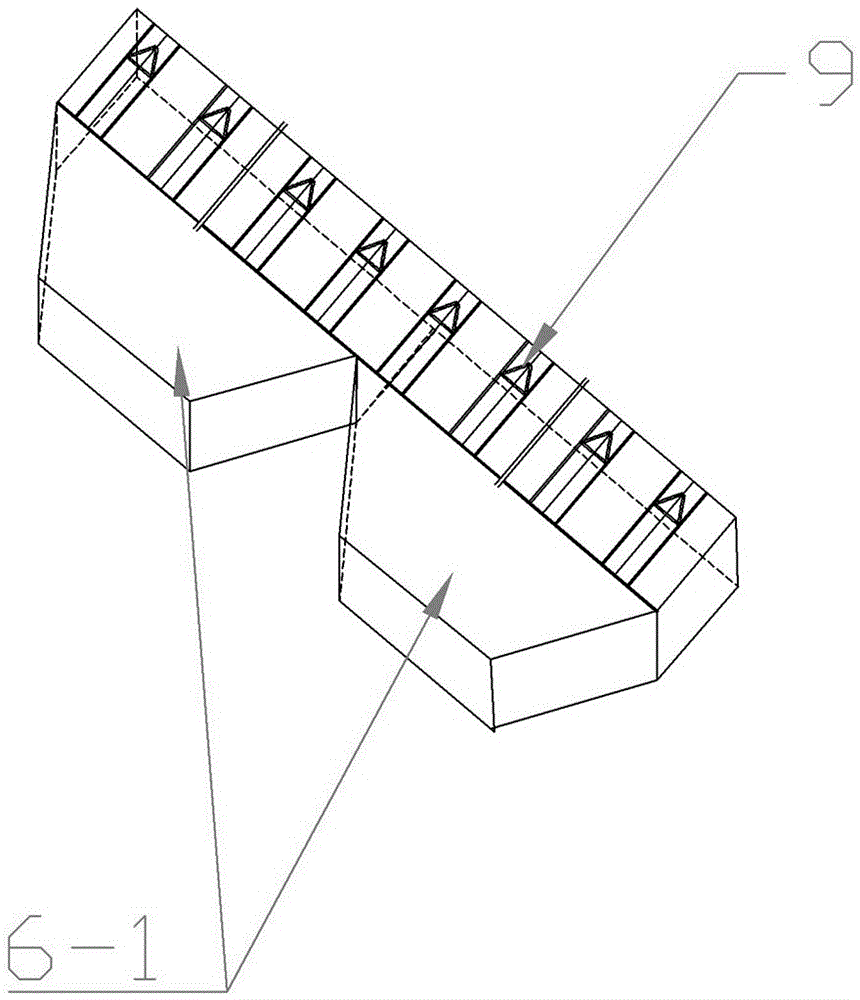

Die-cutting and splitting integrated pole piece manufacturing cutting die and method

ActiveCN106827059AReduce slitting processReduce the number of loading and unloadingElectrode manufacturing processesMetal working apparatusSmall footprintEngineering

The invention discloses a die-cutting and splitting integrated pole piece manufacturing cutting die. The cutting die comprises a die body and a die core used for cutting a pole piece. The die core is fixed to the die body and comprises a set of parallel horizontal cutting parts, two sets of parallel oblique cutting parts and two rectangular cutting ends. The width a of each rectangular cutting end is the distance between an upper side pole lug and a lower side pole lug. The distance b between the horizontal cutting parts is the width (c+2d) of middle blank foil, wherein d is the width of a cut-off upper slurry area or a cut-off lower slurry area. The invention further discloses a manufacturing method for the pole piece. The die-cutting and splitting integrated pole piece manufacturing cutting die and method have the advantages that the pole piece is formed at a time in a die-cutting and splitting integrated mode, a splitting procedure is omitted, the number of feeding and discharging of the pole piece is decreased, the production efficiency is high, equipment input is low, energy consumption is reduced, input of manpower and material resources is reduced, the production cost is effectively lowered, the occupied area is small, the space utilization rate is high, the well-cut edge of the pole piece is trim and free of steps, and the dimensional precision is high.

Owner:利信(江苏)能源科技有限责任公司

Automatic mask processing machine and using method thereof

InactiveCN111332689AReduce labor intensityReduce the number of loading and unloadingConveyorsProcess engineeringTransfer mechanism

The invention relates to the field of mask circulation recovery processing equipment, in particular to an automatic mask processing machine and a using method thereof. The automatic mask processing machine comprises a base, wherein a first stand column is fixed on the base, a material picking mechanism used for loading and unloading masks is fixed on the first stand column, a plurality of second stand columns are fixed on the base, a transfer mechanism used for shifting masks is fixed at the upper ends of the second stand columns, the material picking mechanism is in transmission connection with the transfer mechanism, a plurality of clamping mechanisms for clamping the masks are arranged on the transfer mechanism, and processing equipment for cleaning, disinfecting and drying the masks isarranged on the transfer mechanism. According to the automatic mask processing machine and the using method thereof, the masks are cleaned, disinfected and dried in the transfer process, the labor intensity of transfer personnel is reduced, the loading and unloading times are reduced, and the whole processing process is synchronously carried out, so that the production efficiency is improved.

Owner:姜依辰

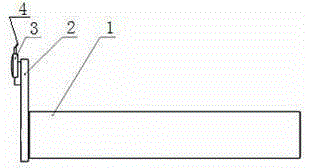

Coaxiality alignment method

InactiveCN105318815ASimple structureEasy to manufactureMechanical measuring arrangementsBiochemical engineeringProcessing cost

The invention relates to a coaxiality alignment method which is characterized by comprising the following steps: manufacturing a tool which consists of a standard core bar, a dial gauge stand and a lever indicator which are connected together; feeding the standard core bar into a standard hole of a combined workpiece, adhering the support end of the dial gauge stand on the end surface of a bracket of the standard core bar; rotating the standard core bar, moving the dial gauge stand to an inner hole to be detected; aligning the center of the combined workpiece with a processing hole to be just aligned to the center of the standard core bar, namely, the center of the combined workpiece with the processing hole is concentric with the standard hole; and roughly boring the hole to be processed, and finely boring the hole to be processed till the design size. By adopting the coaxiality alignment method provided by the invention, the alignment tool is simple in structure, easy to manufacture and simple and convenient to use and operate; due to the dial gauge and a fine tuning coordinate system, high alignment accuracy and precision can be achieved, the assembling and disassembling times of the combined workpiece can be reduced, the assembling and disassembling working intensity can be alleviated, the processing efficiency and the processing quality of the combined workpiece can be improved, the reliability is good, the processing cost is lowered, the economical efficiency is high; influence of artificial factors is reduced, and the processed combined workpiece is good in quality stability consistency.

Owner:HUNAN NANFANG AVIATION HIGH ACCURATE DRIVE

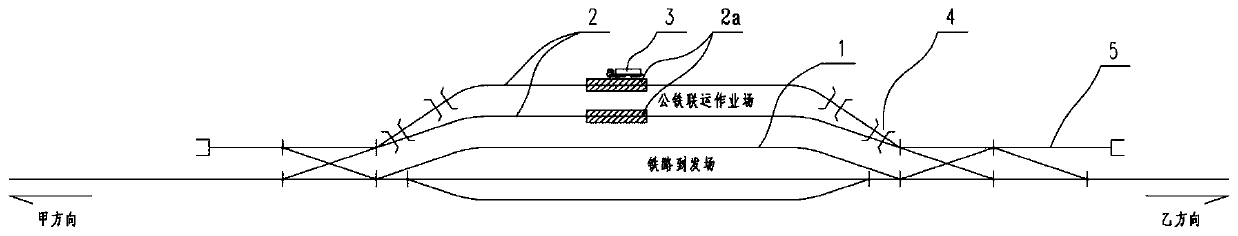

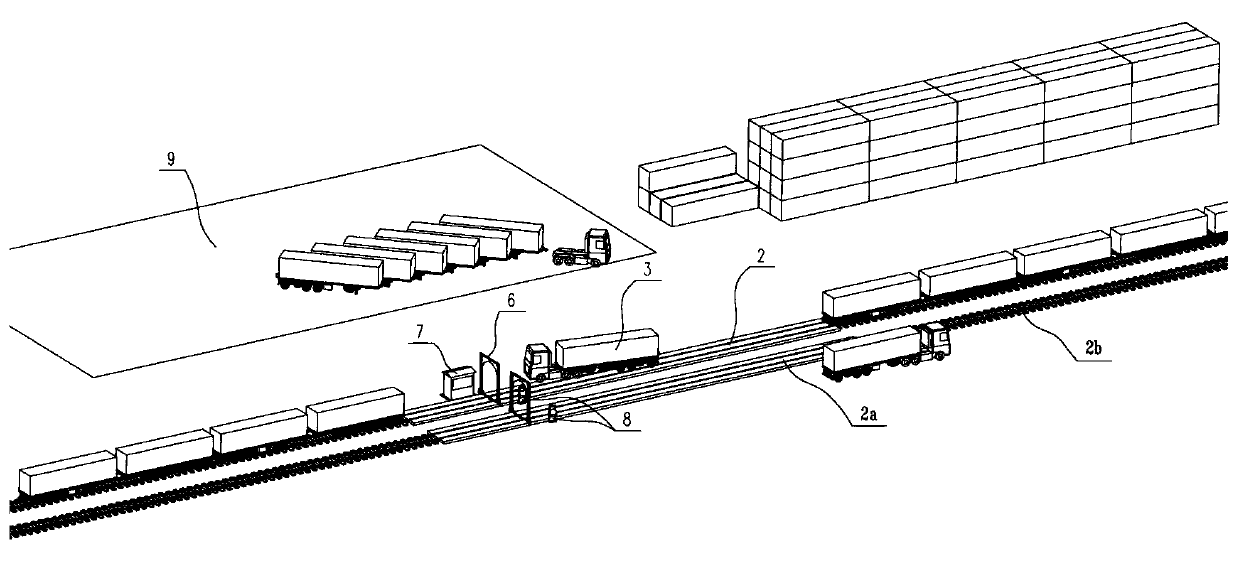

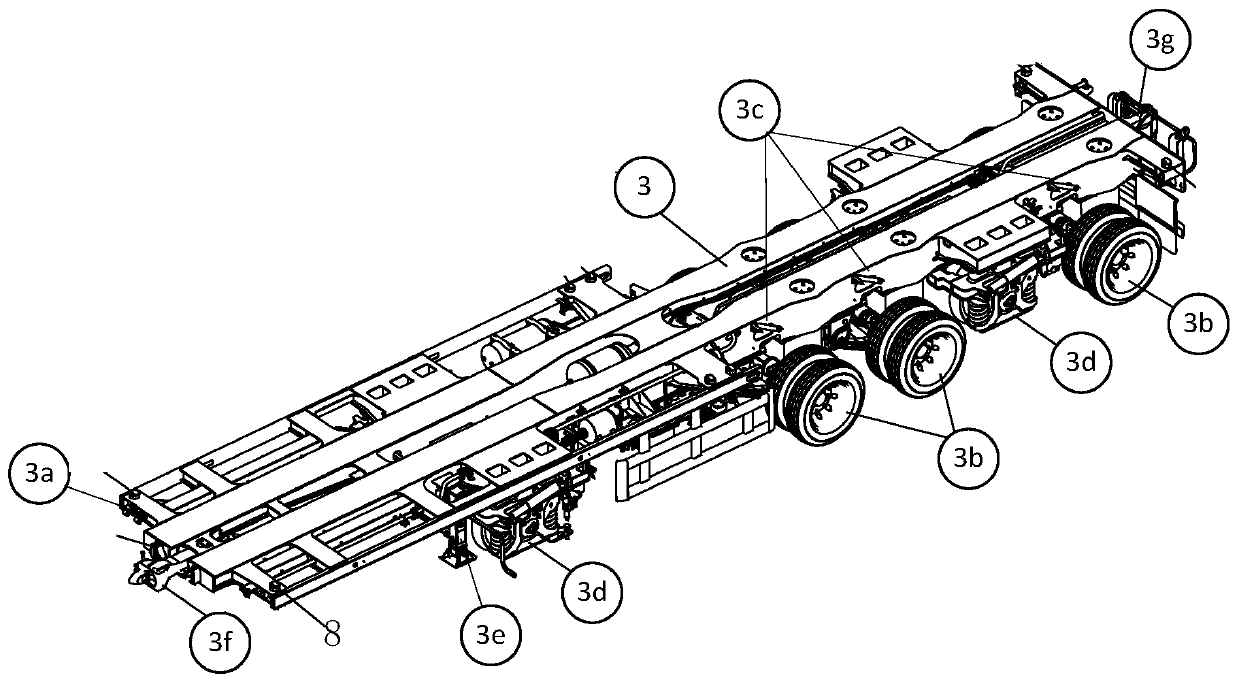

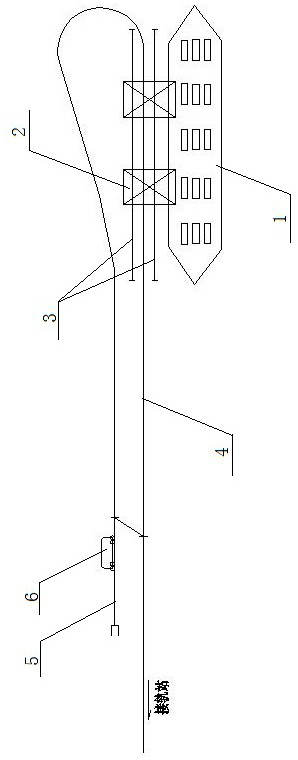

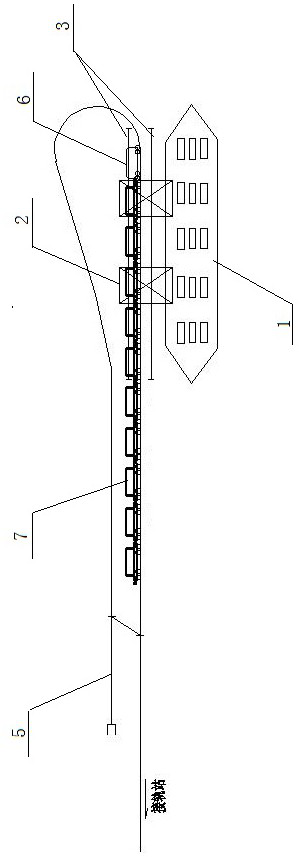

Operation method and method for rail-road intermodal transport mode conversion of railway station and yard

ActiveCN111453448AAchieve seamless connectionSimplify the flip-chip operation processConveyorsLogisticsControl roomTransfer operation

The invention discloses an operation method and method for rail-road intermodal transport mode conversion of a railway station and yard. The operation system comprises a railway receiving-departure yard, a rail-road intermodal transport operation yard which is adjacent to the rail receiving-departure yard, and a control room; transfer operation strategies and process are prepared through the control room according to relevant information of vehicles; the railway receiving-departure yard is provided with at least one receiving-departure line for the vehicles to stop and be on standby; the rail-road intermodal transport operation yard is provided with one or more conversion lines which are parallel with the receiving-departure line, and a plurality of road-railers can run on each conversionline; each conversion line comprises a flat running channel and a stop line, wherein the stop line is used for the road-railers to stop; and the road-railers are pulled by trucks to run on the flat running channels, and the rail-road mode conversion operation is finished according to the transfer operation strategies and process.

Owner:CRRC YANGTZE CO LTD

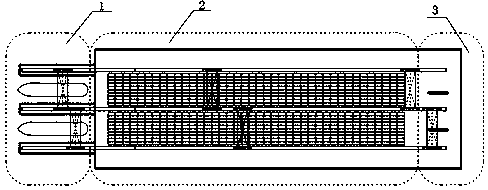

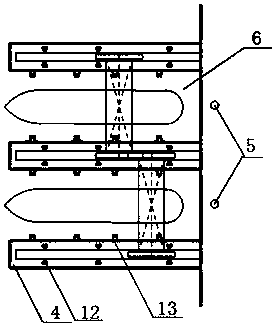

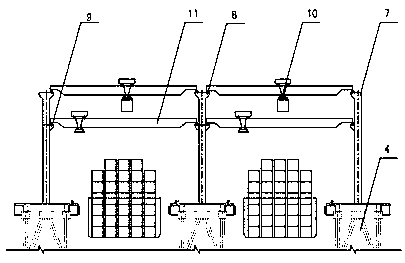

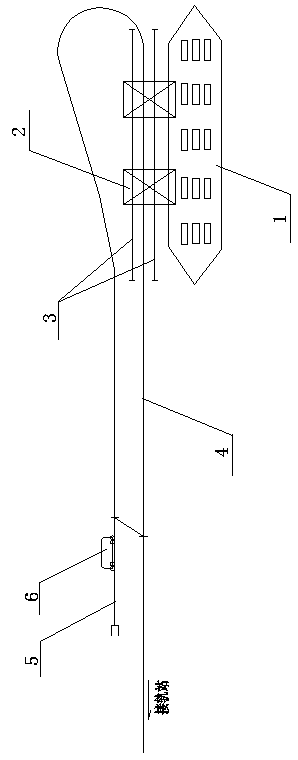

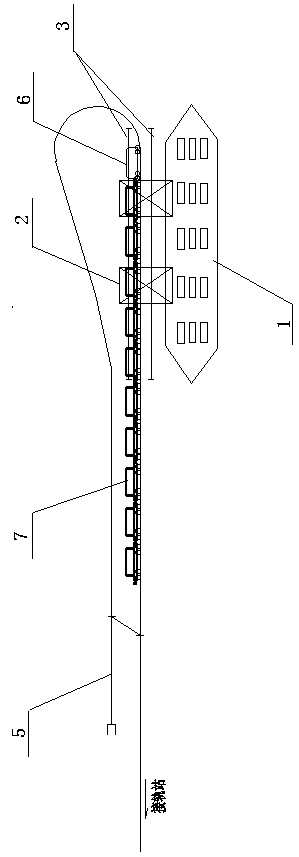

Plane-arranged small and medium-sized wharf and loading and unloading method thereof

PendingCN110467008AReduce pollutionReduce labor intensityStorage devicesLoading/unloadingTraction systemHydraulic structure

The invention discloses a plane-arranged small and medium-sized wharf and a loading and unloading method thereof, and relates to the technical field of wharf loading and unloading. The plane-arrangedsmall and medium-sized wharf comprises a front-edge wharf area, a storage yard area and a land-side handover area which are sequentially connected; the front-edge wharf area comprises a plurality of hydraulic structures and a plurality of ship traction systems, the plurality of hydraulic structures are fixed on one side of the storage yard area in a comb-shaped mode, a ship stopping area is formedbetween the two hydraulic structures, and the plurality of ship traction systems are fixed on one side of the storage yard area and are opposite to the position of the ship stopping area. Due to thefact that a comb type wharf layout is adopted at the front edge of the wharf, the length of the shoreline of the wharf can be increased, the loading and unloading system can complete loading and unloading processes of vehicles at front edge of the wharf to the storage yard and even directly to the outside of a port through a double-layer bridge crane, the loading and unloading frequency is reduced, the double-layer bridge crane can move in opposite directions, and the problem that the loading and unloading efficiency of an existing small and medium-sized wharf is low is solved.

Owner:CCCC FHDI ENG

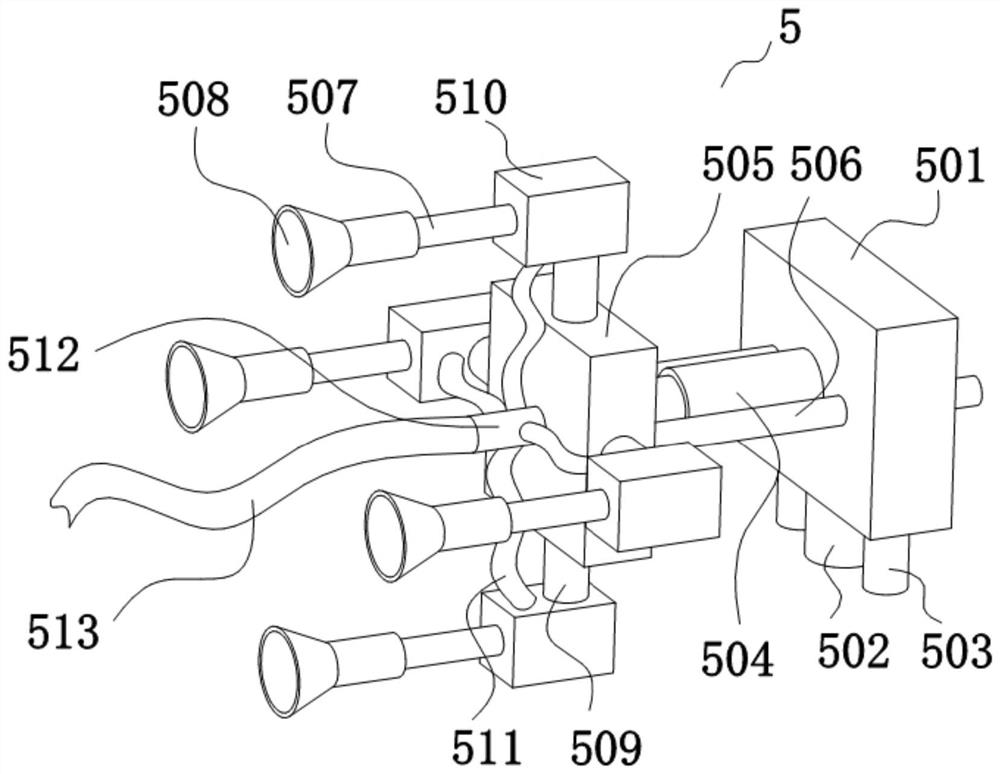

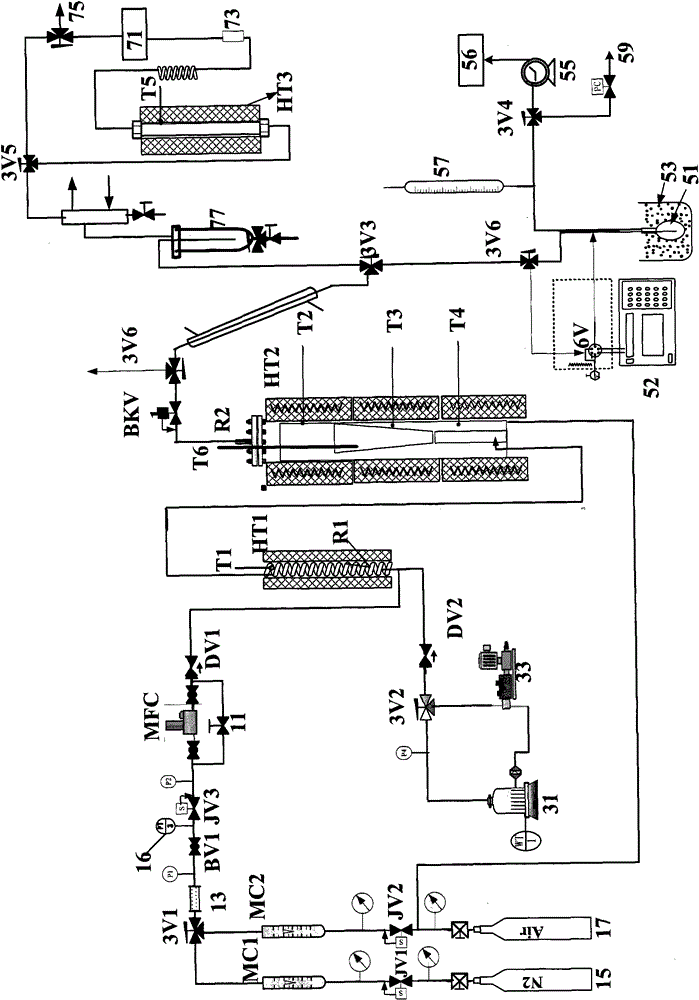

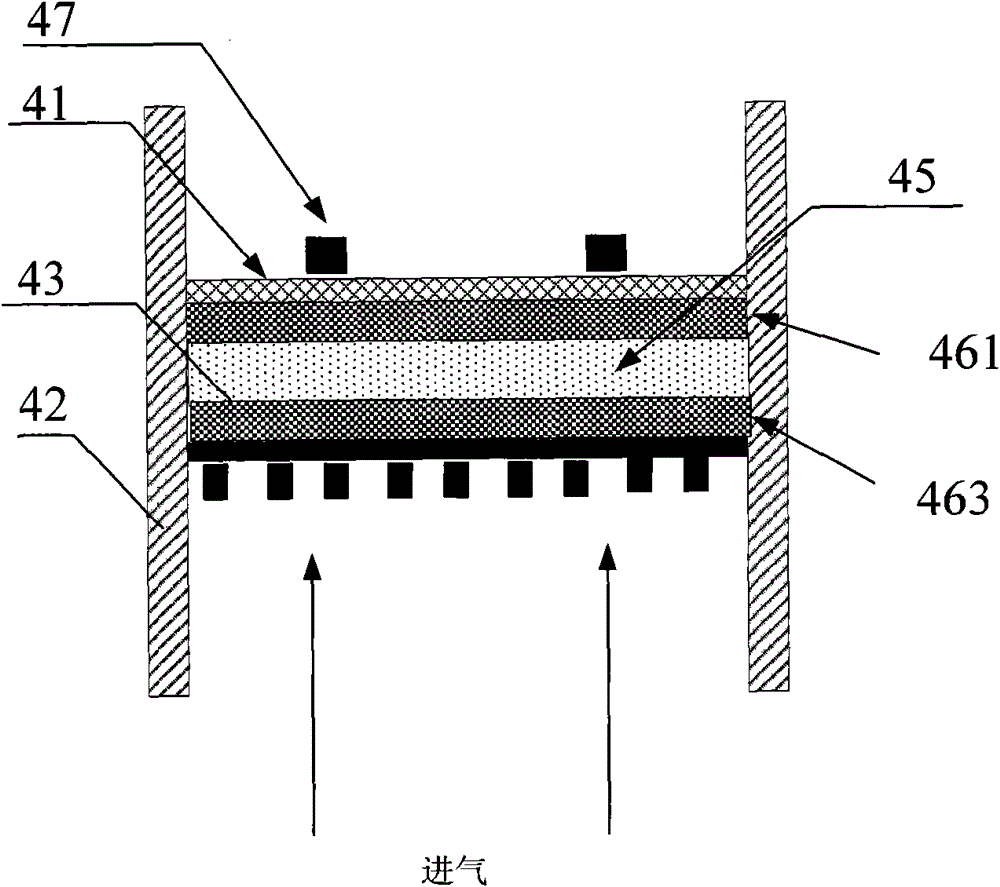

Optimized device for forming catalyst hydro-thermal treatment and fixed fluidized bed catalyst evaluation

ActiveCN101943689BReduce the number of loading and unloadingLess investmentChemical analysis using catalysisComponent separationFluidized bedProduct analysis

The invention provides a device for forming catalyst hydro-thermal treatment and fixed fluidized bed catalyst evaluation. The device comprises an air inlet system, a preheater, a feed system, a fluidized bed reactor and a product analysis system, wherein the preheater is connected with the air inlet system, the feed system is connected with the preheater; the fluidized bed reactor is connected with the outlet of the preheater and is connected with the air inlet system; and the product analysis system is connected with the air outlet of the fluidized bed reactor. The device has the prominent advantages of stable operation, reasonable structure, various functions and contribution to improving the development efficiency of catalysts.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Container molten iron multimodal transport train ship direct-taking mode operation method based on railway loop line

ActiveCN110422649AOvercome limitationsReduce the changeover processLoading/unloadingQuay craneTransportation Facility

The invention provides a container molten iron multimodal transport train ship direct-taking mode operation method based on a railway loop line. A quay crane is arranged on a wharf apron, an annular railway loading and unloading line which is led out from an adjacent railway station is arranged beside the quay crane, a locomotive waiting line connected with the railway loading and unloading line is arranged besides the quay crane, and a special shunting locomotive stays on the locomotive waiting line. The method comprises a port entering operation method, and specifically comprises the steps that 1), a container transport ship arrives at a designated port quay berth; 2), a railway container empty train set is dragged to the railway loading and unloading line to move forwards and backwardsafter being coupled by the special shunting locomotive on the locomotive waiting track; 3), the quay crane grabs and dismounts multimodal transport containers from the ship to a designated position ofthe railway container train set according to the transportation destination of each container; and 4), the special shunting locomotive drags a railway container heavy train set to move out of a wharfapron loading and unloading operation area to the loop line, and then drives out of the loop line. According to the container molten iron multimodal transport vehicle ship direct-taking mode operation method based on the railway loop line, the horizontal transportation facility is reduced, the railway loading and unloading line is arranged in a loop line, the cost is reduced, the loading and unloading time is shortened, and the efficiency is improved.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

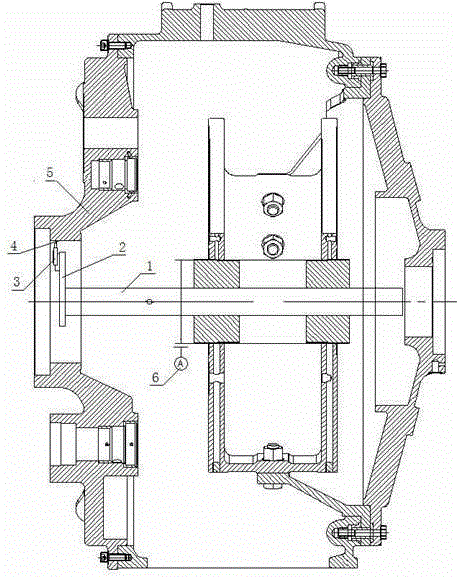

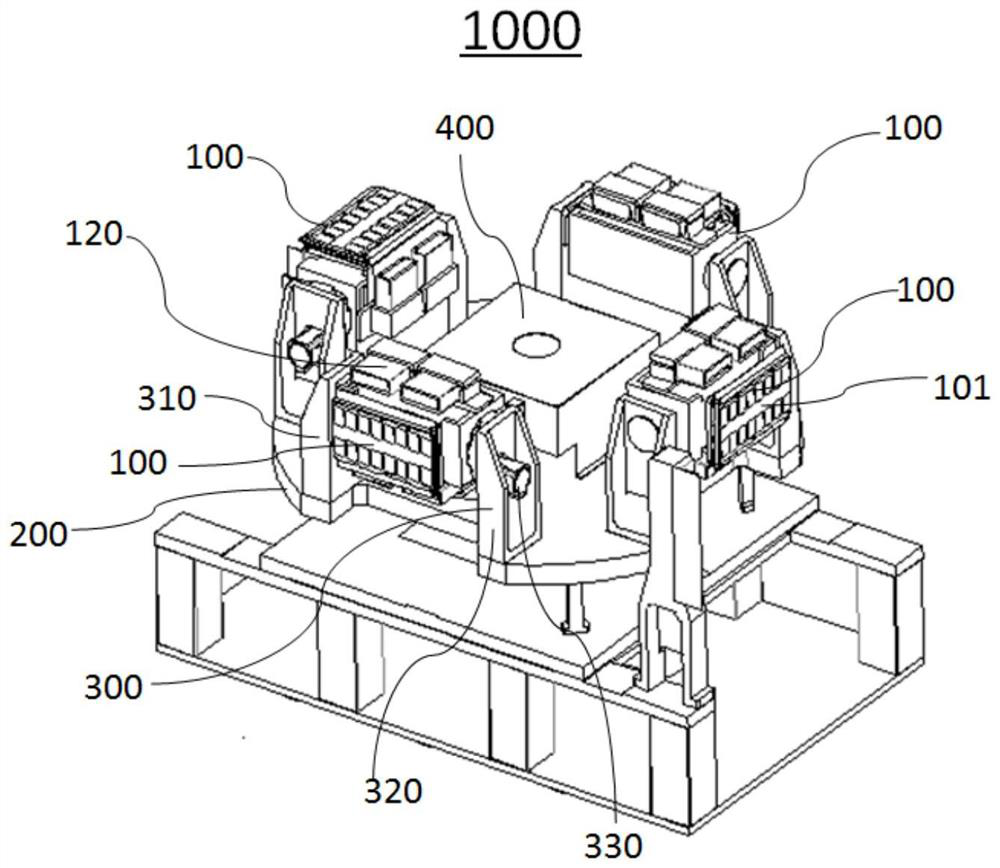

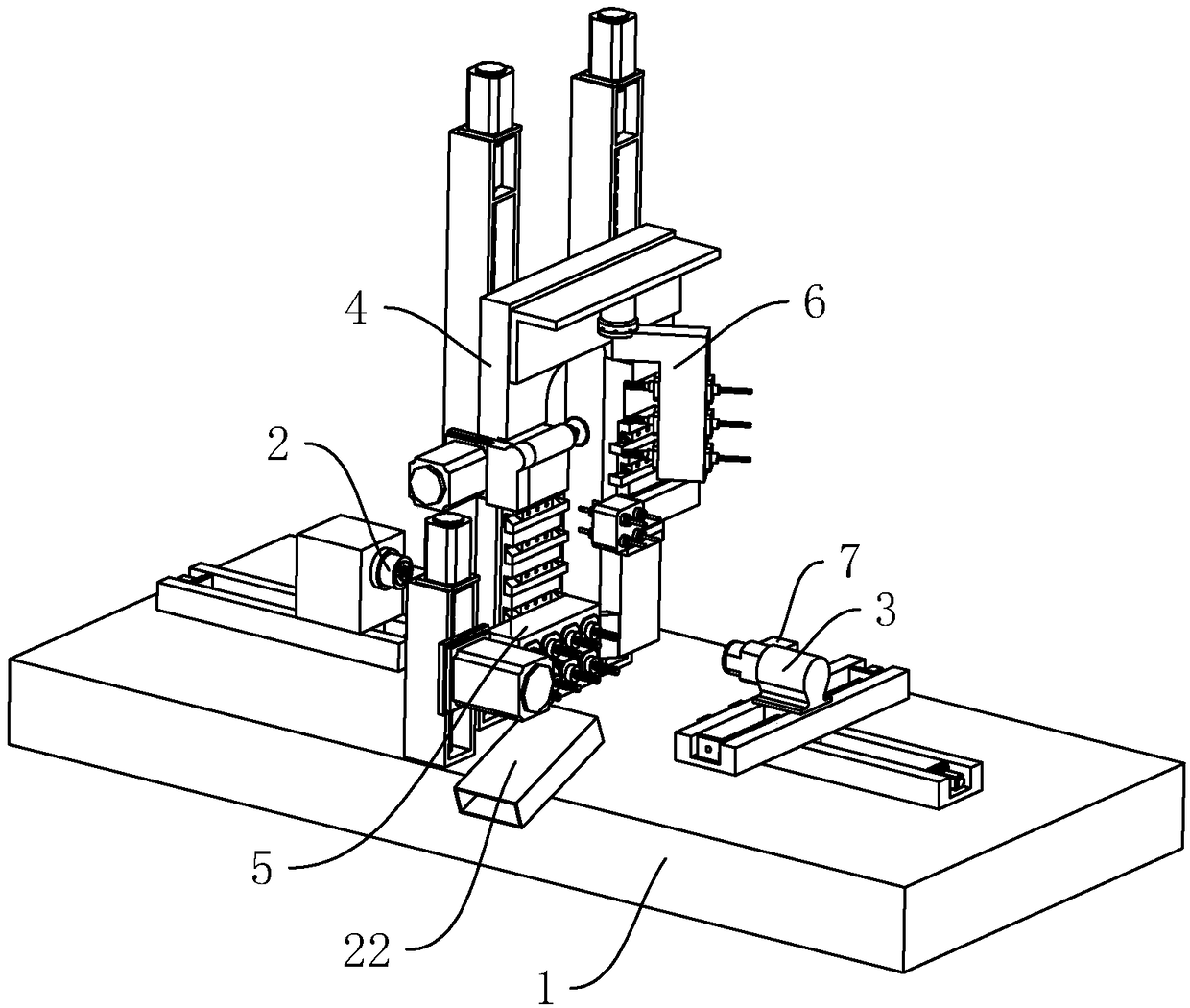

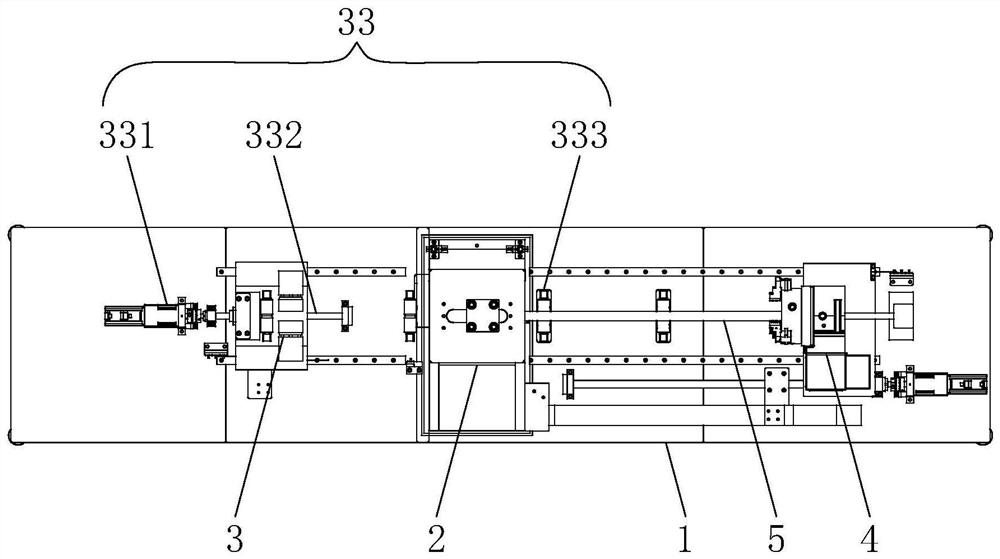

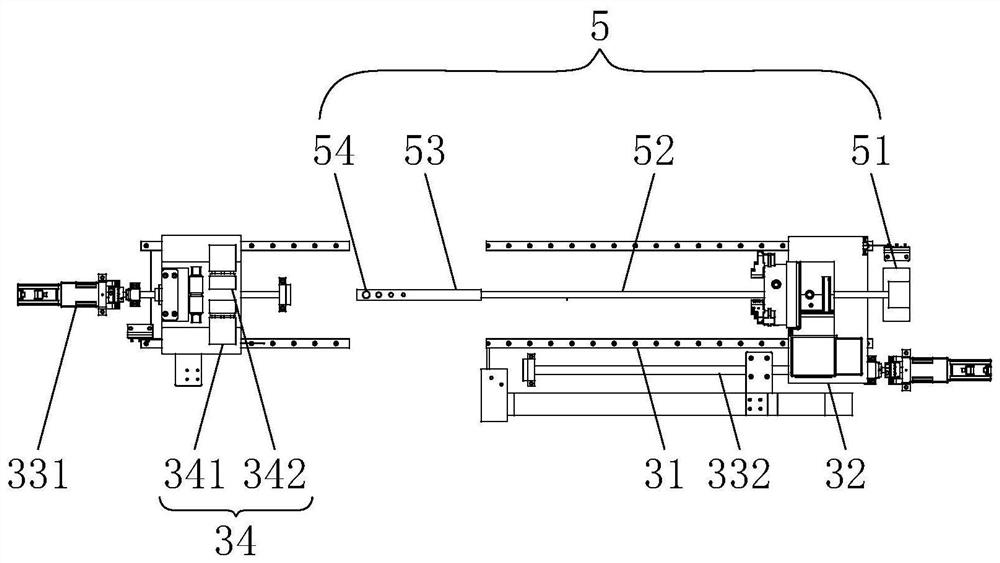

An automatic machine tool with b-axis control

ActiveCN109176052BReduce the number of loading and unloadingVarious processing anglesPrecision positioning equipmentFeeding apparatusMachineAutomaton

The invention discloses an automatic machine tool with B-axis control, and relates to the technical field of machine tools. The automatic machine tool aims to solve the problems that a traditional machine tool cannot realize continuous machining when workpieces are obliquely machined, and time and labor are consumed when the angle is adjusted. According to the key points of the technical scheme, the automatic machine tool with the B-axis control comprises a lathe bed, a main shaft slidably arranged on the lathe bed along the Z axis, secondary shafts slidably arranged on the lathe bed along theZ axis and the X axis, a tool rest which is arranged on the lathe bed and can move along the X axis and the Y axis and a back tool platform which is arranged on the lathe bed and can move up and downalong the Y axis, wherein the tool rest is provided with a B-axis mechanism for obliquely machining a workpiece, and the secondary shafts are provided with deep hole assemblies for drilling deep holes in the end surface of the workpiece. The automatic machine tool with the B-axis control has the advantages of being capable of performing multi-angle oblique machining on the workpiece, realizing continuous machining of the workpiece, improving machining efficiency and reducing cost.

Owner:津上精密机床(浙江)有限公司

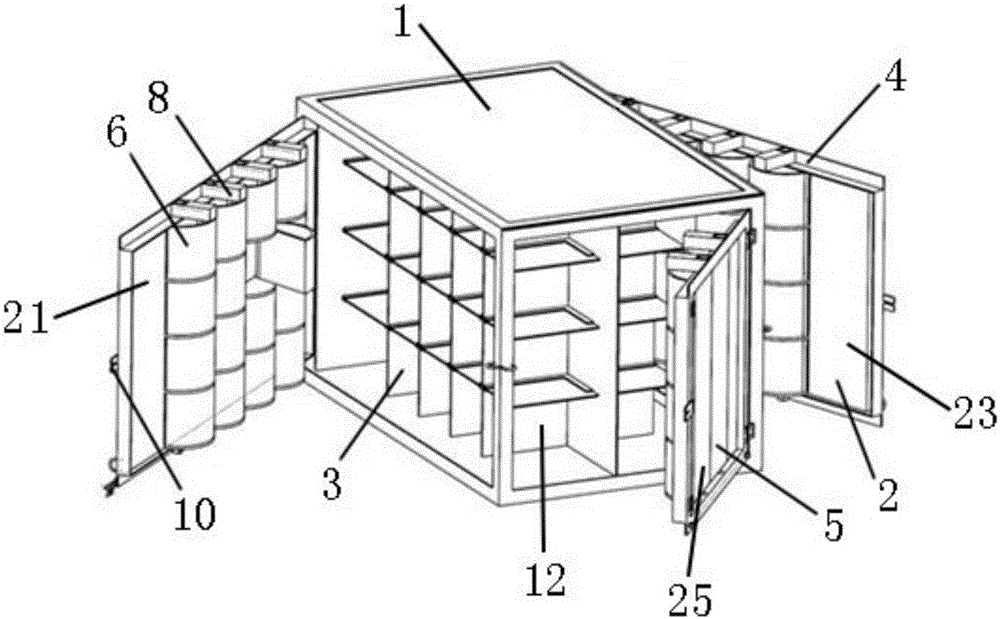

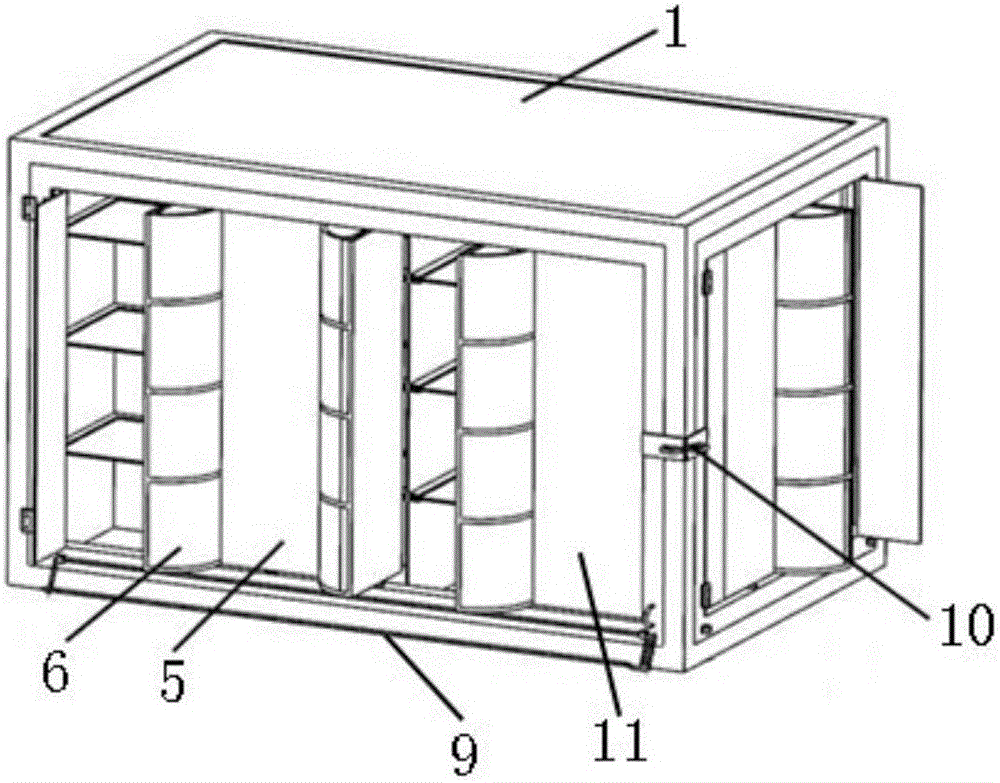

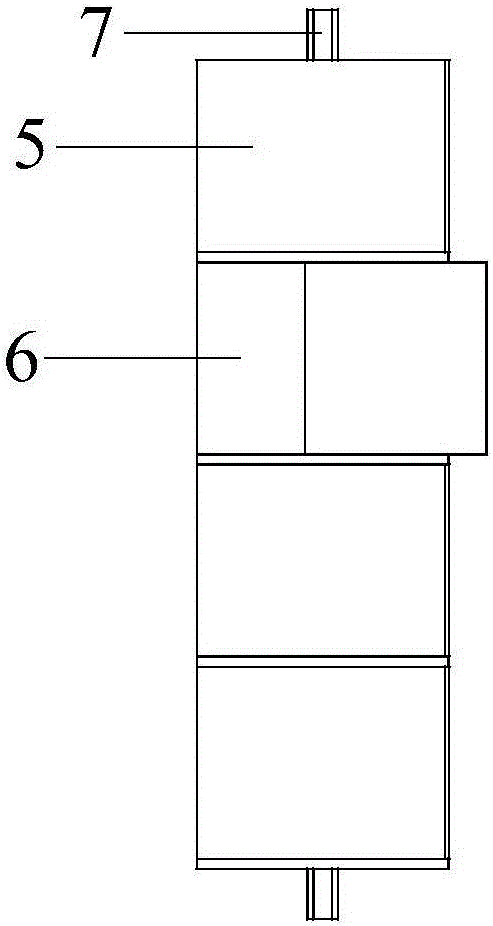

Convenient and fast express delivery compartment

ActiveCN106005055AReduce loading and unloading timesEasy to transportLoading-carrying vehicle superstructuresEngineering

Owner:GUANGXI UNIV

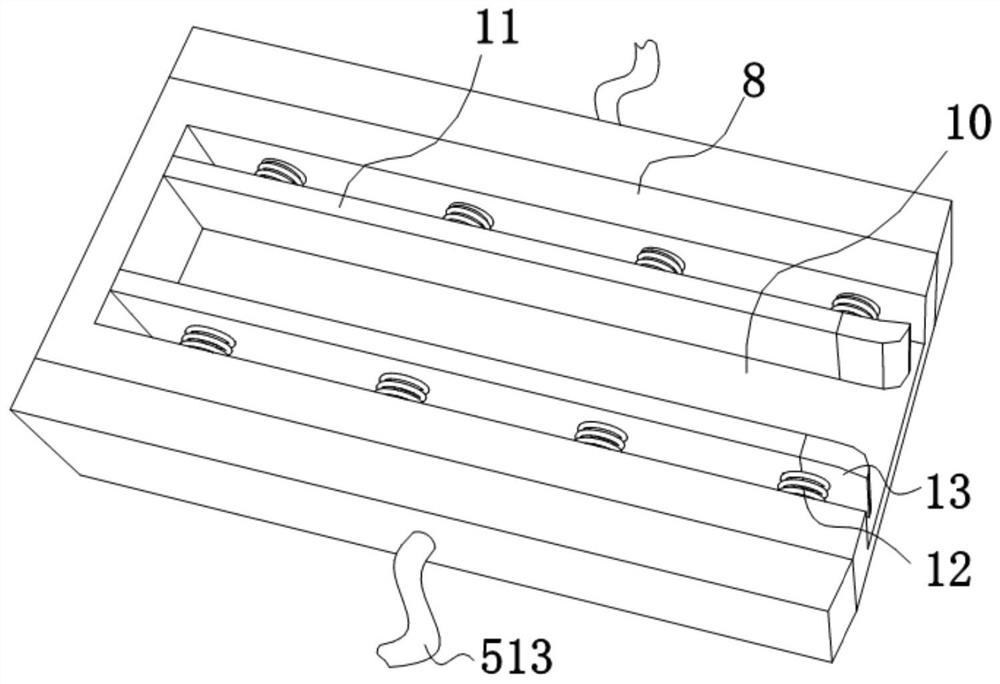

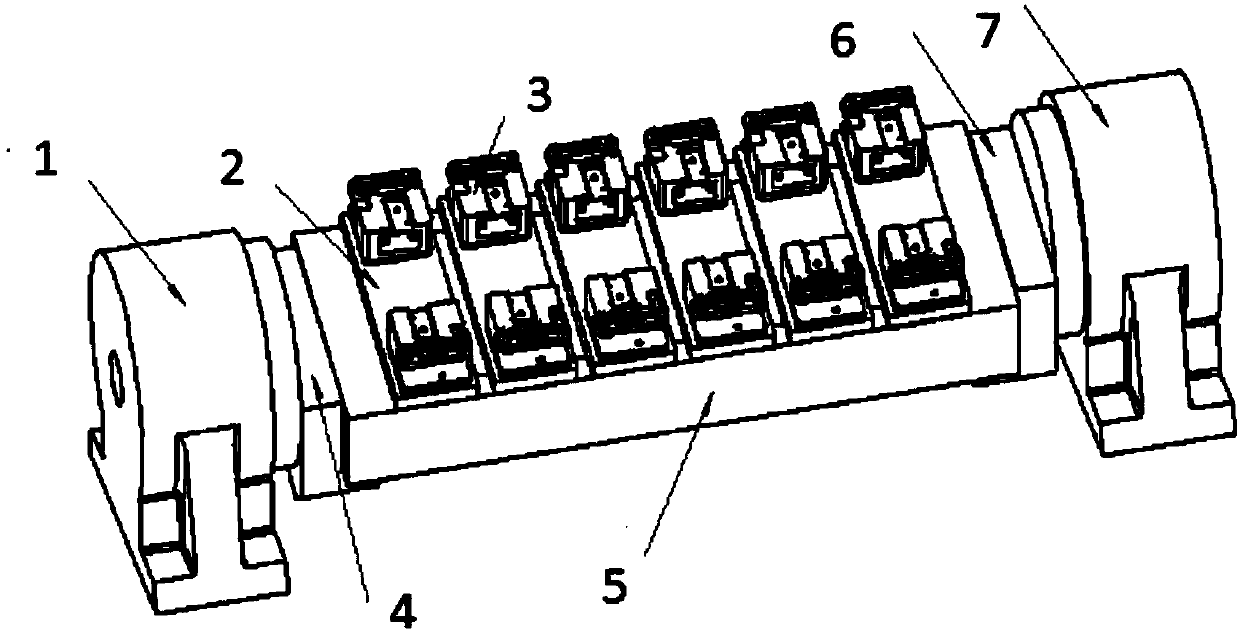

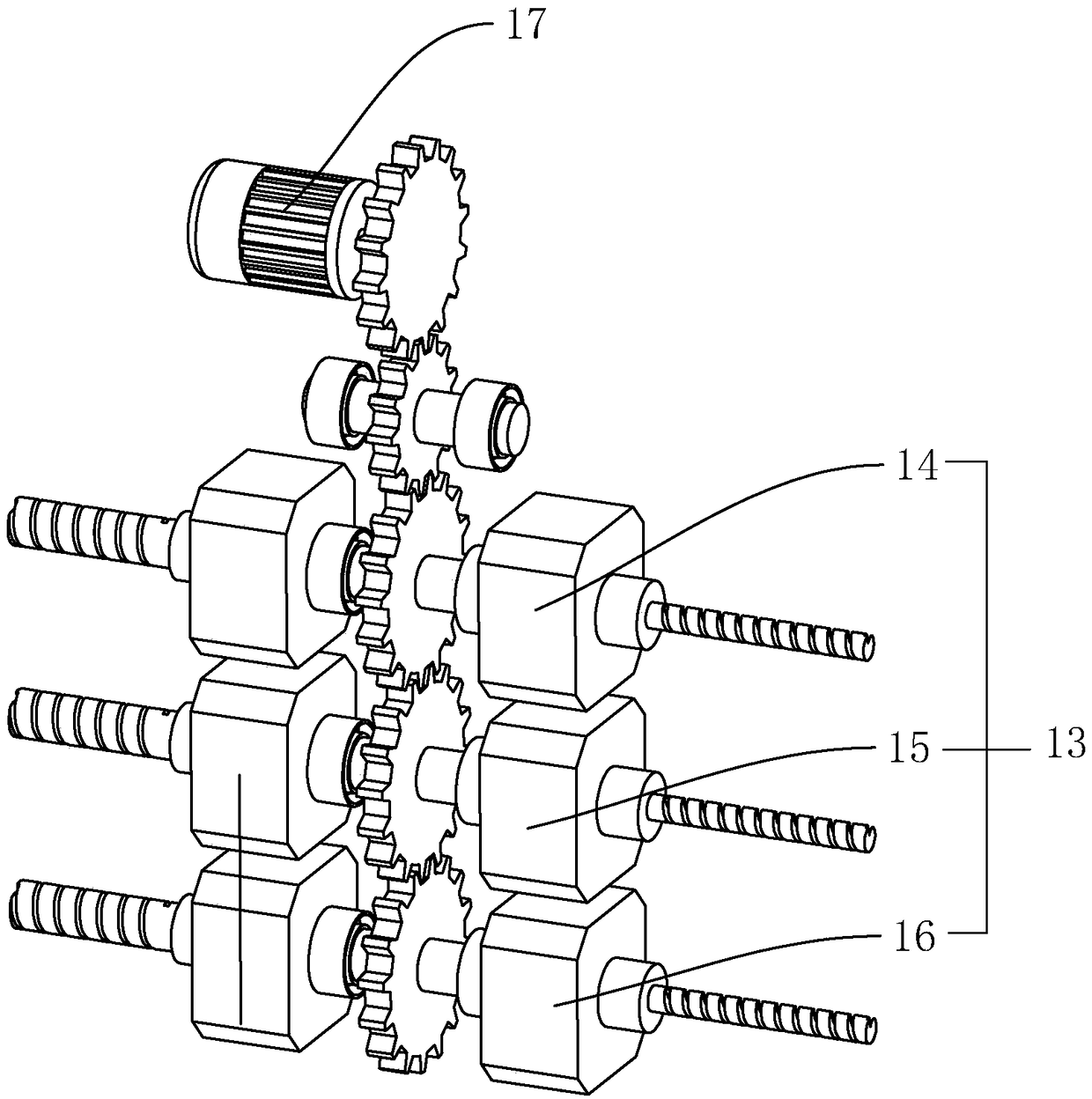

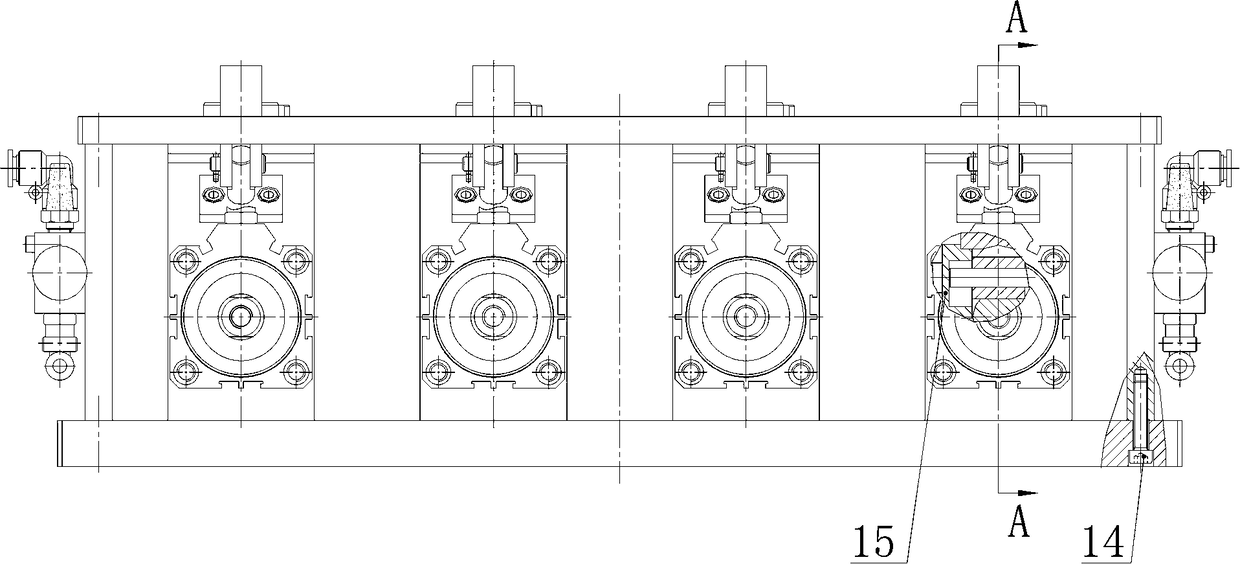

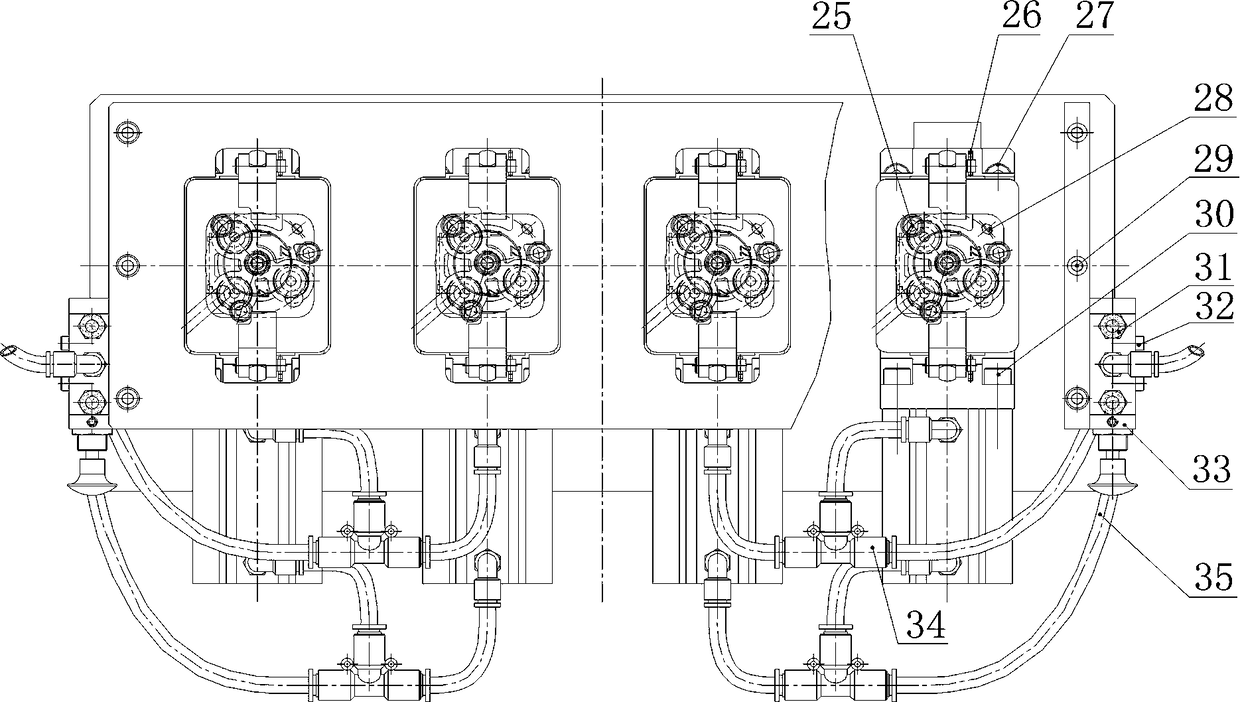

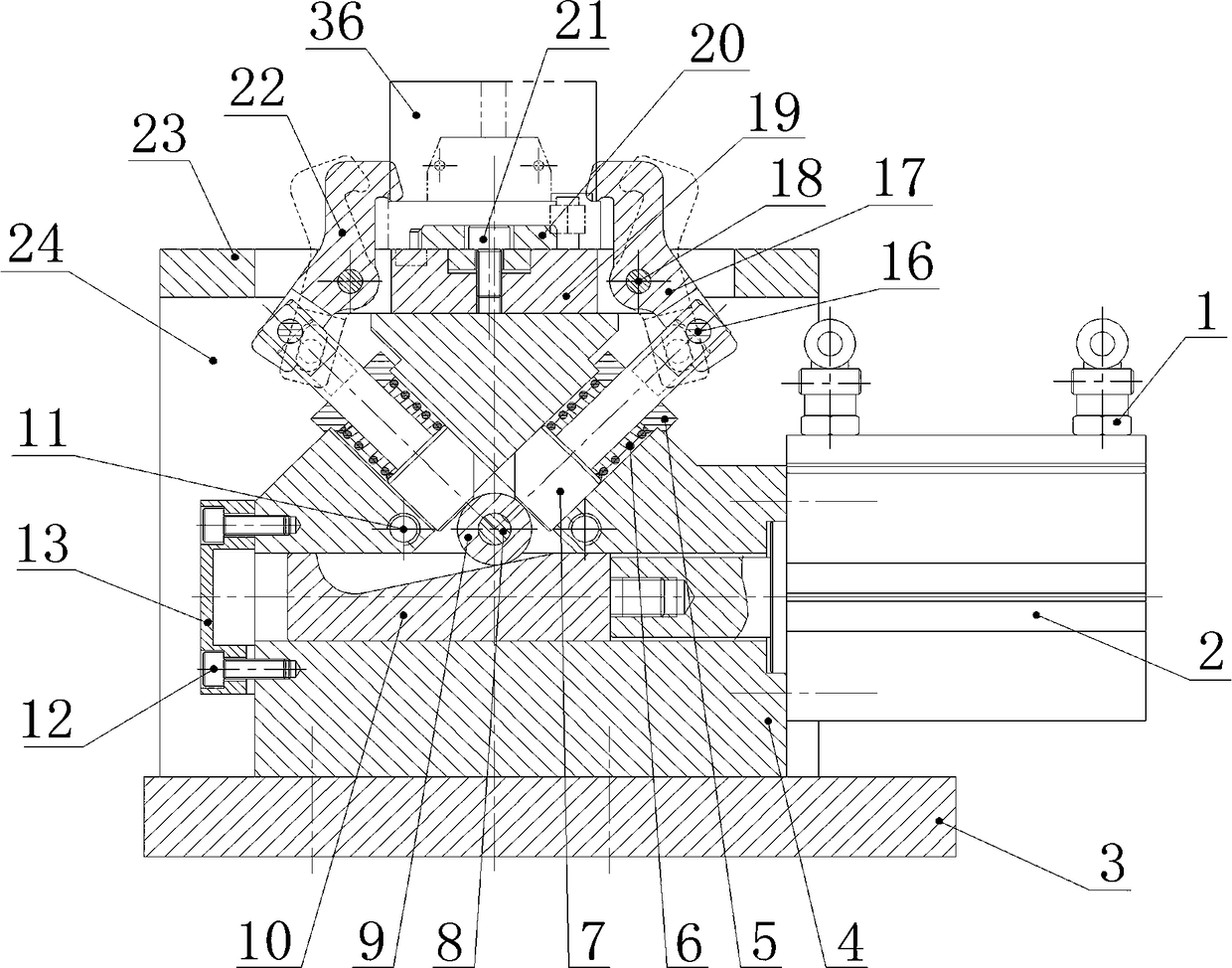

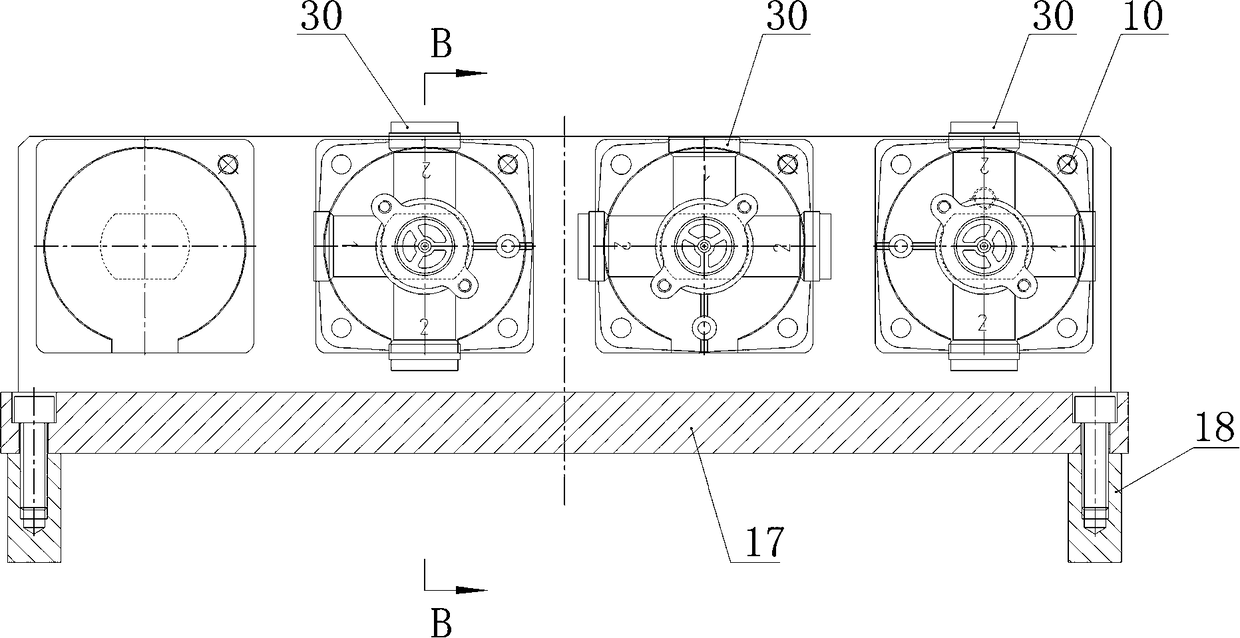

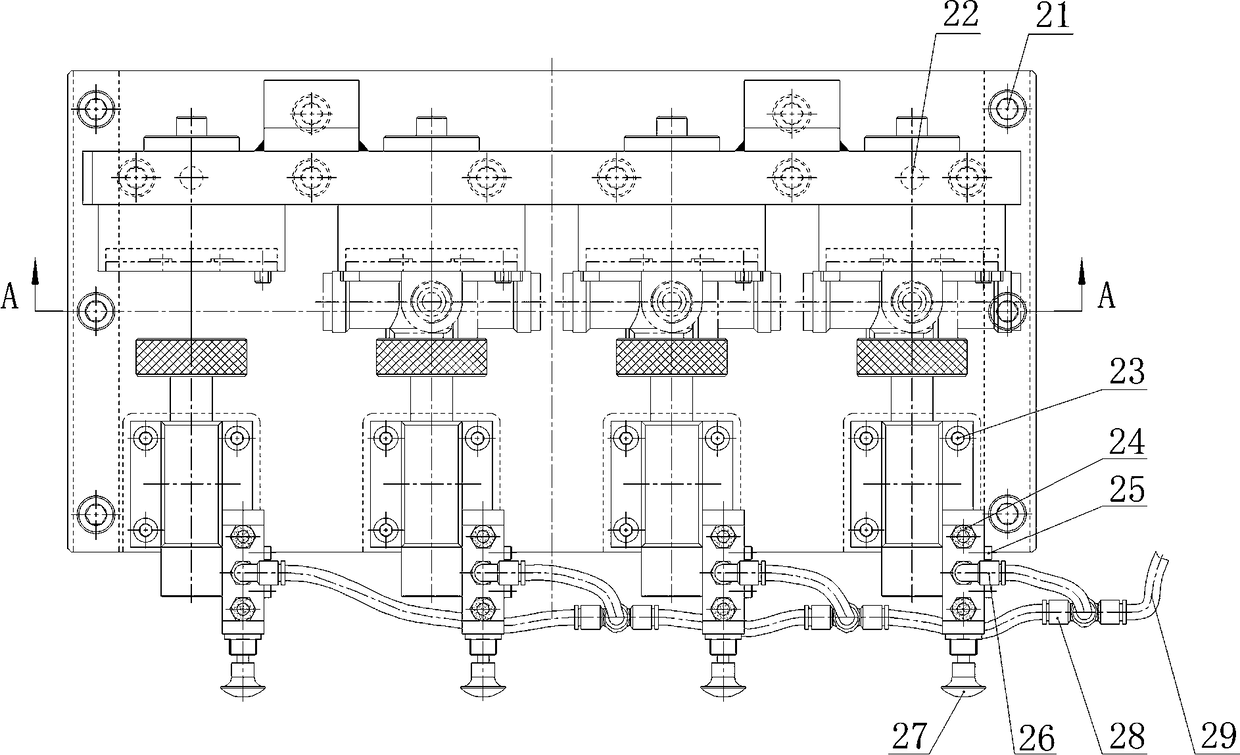

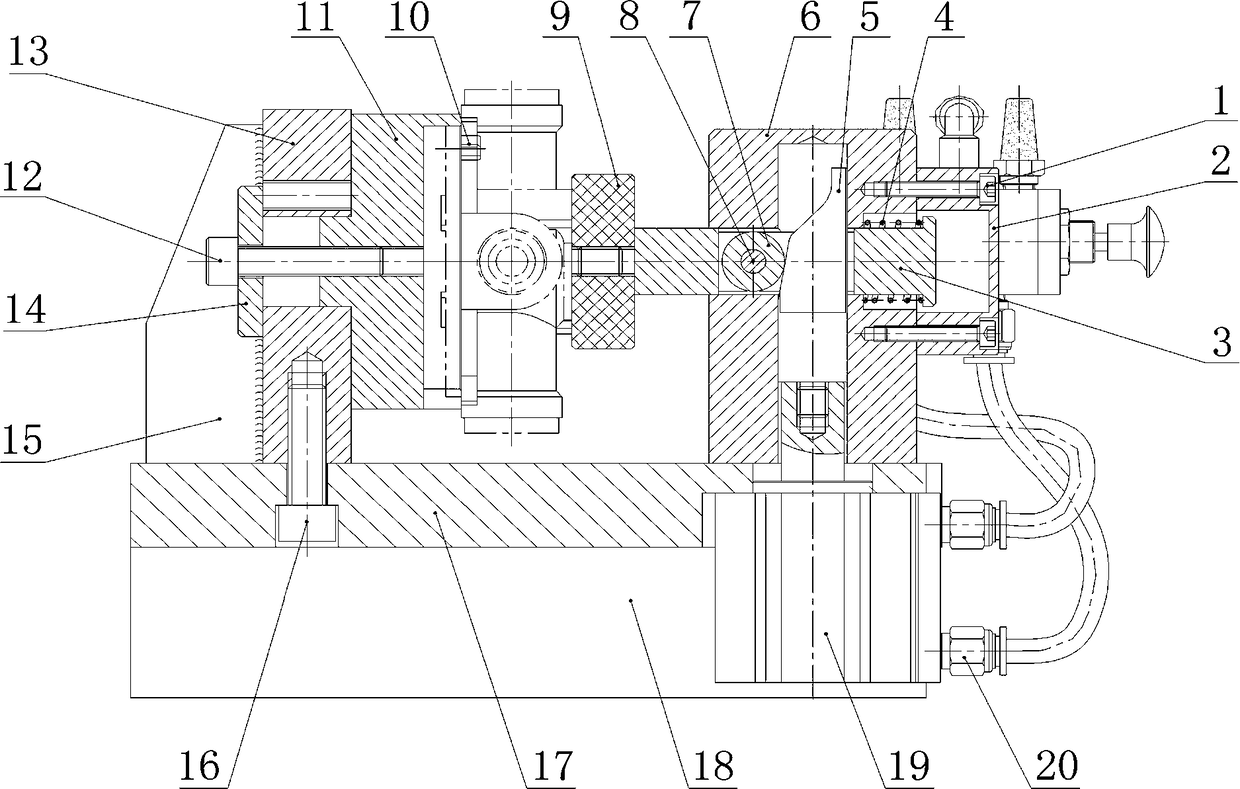

Four-axis magnetic suction cup tool

InactiveCN109531221AUniform and stable forceIncrease the number of pieces processed at a timePositioning apparatusMetal-working holdersEngineeringWorkstation

The invention discloses a four-axis magnetic suction cup tool, which comprises a tail seat, a turntable and a suction cup. A first positioning plate is rotatably mounted on the tail seat, and a secondpositioning plate is rotatably mounted on the turntable. The first positioning plate and the second positioning plate are arranged opposite to each other, and the rotation axes of the first positioning plate and the second positioning plate are collinear. The suction cup is fixedly installed between the first positioning plate and the second positioning plate, wherein the first end of the suctioncup is detachably connected with the first positioning plate, and the second end of the suction cup is detachably connected with the second positioning plate. A plurality of templates are magnetically adsorbed and fixed on the suction cup, and the templates are provided with workstations for installing the machined parts. The invention changes the traditional disassembling and assembling processing mode of a single workpiece, a detachable suction cup is arranged instead, and a plurality of templates on which workpieces can be installed are arranged on the suction cup, so that the number of workpieces processed in a single time is increased, the loading and unloading times of each shift are reduced, and the efficiency is improved. The suction cup not only firmly fixes the templates by utilizing the adsorption capacity of the magnetic disk, but also ensures that each workpiece is subjected to uniform and stable force.

Owner:BENGBU JIXIN COMM MACHINERY

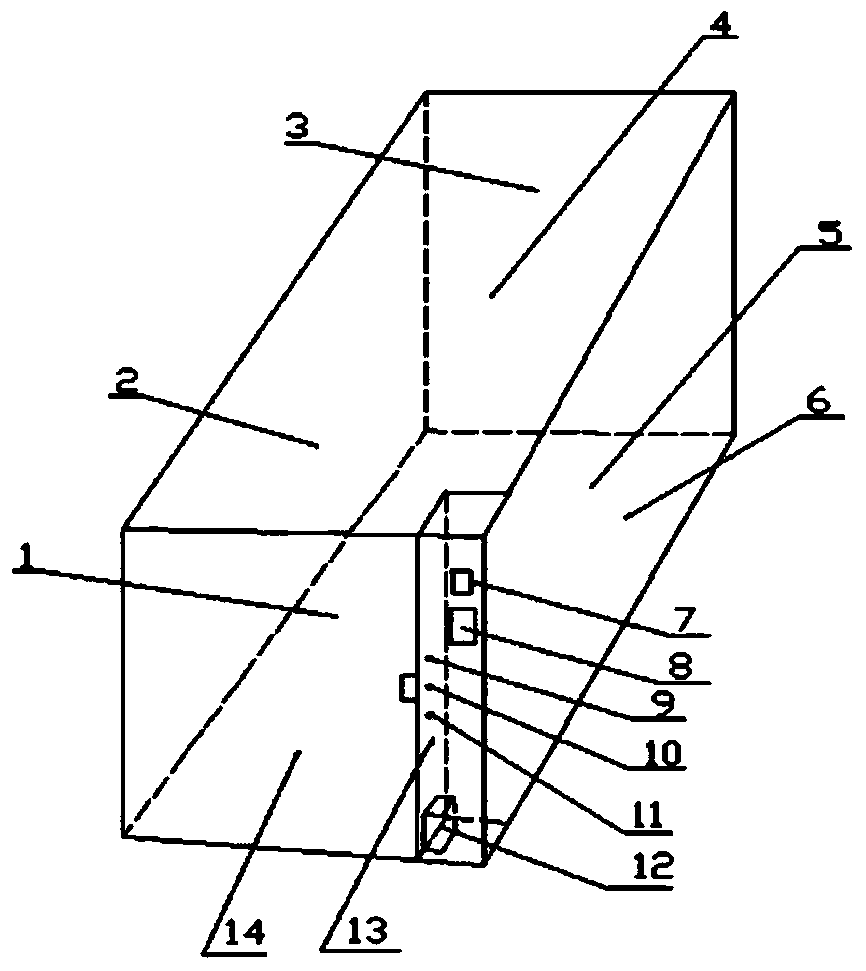

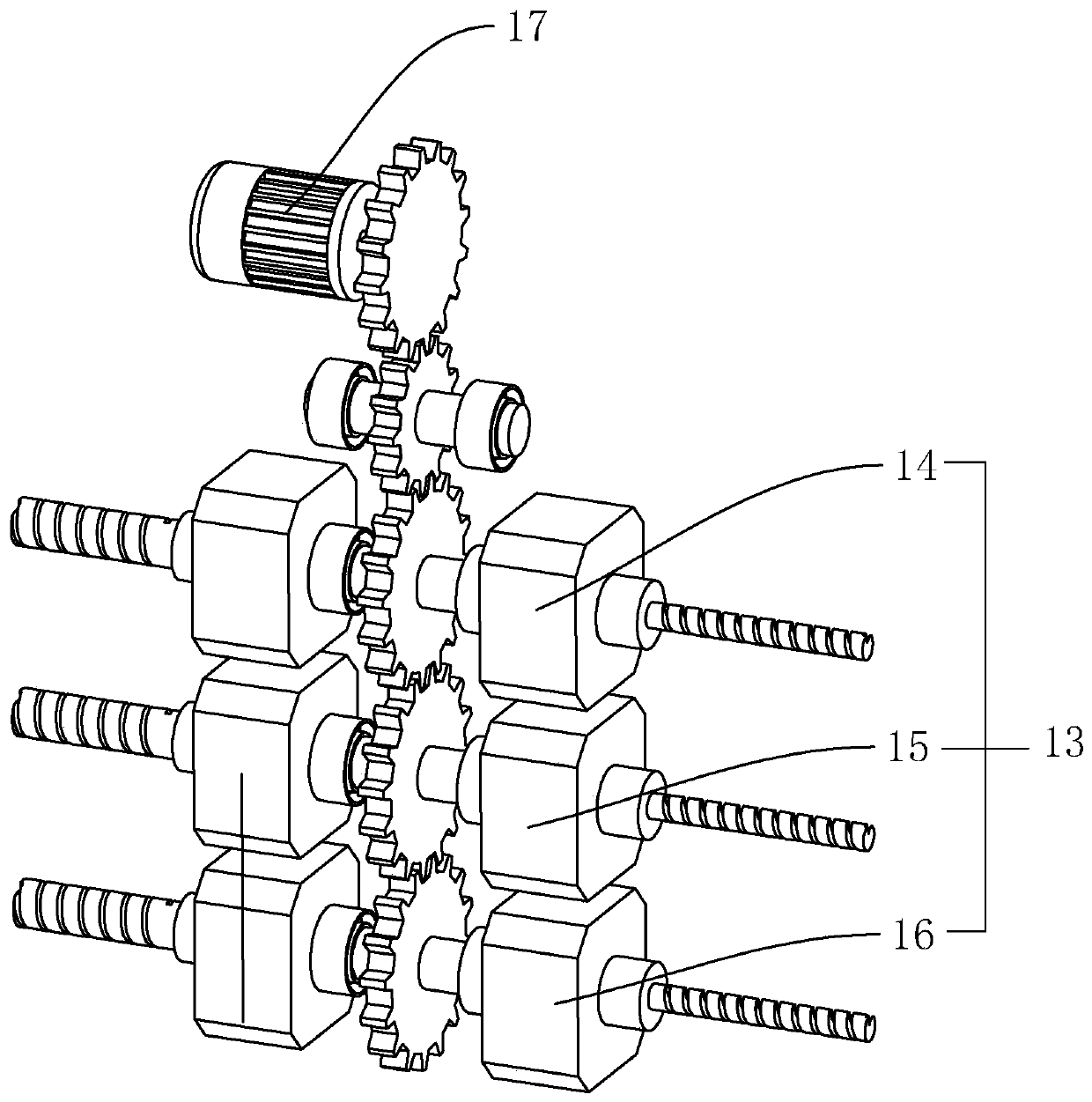

Multi-directional rotating tooling

ActiveCN107745270BRealize processingReduce the number of loading and unloadingWork benchesPositioning apparatusMechanical engineeringMulti directional

The invention discloses a multi-directional rotating tool, and relates to the technical field of machining equipment. The multi-directional rotating tool comprises a base; a rotating block capable ofrotating around the z axis is mounted on the base; a y axis rotating mechanism is fixed on the rotating block, and comprises a support cylinder capable of rotating around the y axis; an x axis rotating mechanism is mounted on the support cylinder, and comprises a rotating cylinder rotationally mounted in the support cylinder; two ends of the rotating cylinder both penetrate through the support cylinder; a holding cylinder for fixing products is mounted at one end of the rotating cylinder; a buckle module capable of rotating and stopping the rotating cylinder is mounted at the other end of therotating cylinder; a support rod capable of inserting in and withdrawing from the holding cylinder is mounted in the rotating holding cylinder; and when the support rod is inserted in the supporting cylinder, the holding cylinder can be expanded to fix the products. The multi-directional rotating tool can realize rotation in multiple directions, and improves the production efficiency and the product quality.

Owner:GEER TECH CO LTD

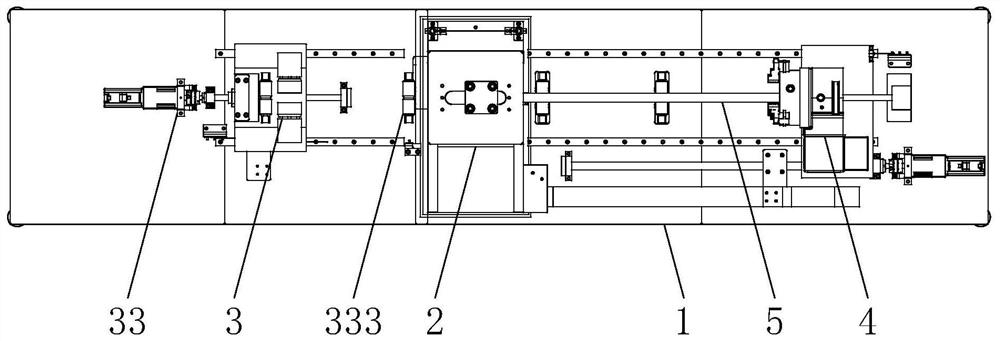

Multi-angle punching device for round holes of collecting pipe

PendingCN113102611AReduce the number of loading and unloadingReduce labor intensityMetal-working feeding devicesPositioning devicesTransfer mechanismStructural engineering

A multi-angle punching device for round holes of a collecting pipe comprises a rack. A punching mechanism used for positioning the collecting pipe and conducting round hole punching on the collecting pipe is arranged on the rack, an axial transferring mechanism used for adjusting the axial position of the collecting pipe to achieve round hole punching at different stations is further arranged at the positions, at the two ends of the punching mechanism, of the rack, and a three-jaw chuck used for rotating the collecting pipe to achieve round hole punching at different angles is further arranged on the axial transferring mechanism. Through cooperation of the punching mechanism and the transferring mechanism, the collecting pipe can move in the axial direction, then the axial punching station is changed, and it is unnecessary to use different punching devices for punching. The collecting pipe can be rotated through the three-jaw chuck, so that the radial punching station of the collecting pipe is adjustable, and it is unnecessary to use different punching devices for punching. The number of feeding and discharging times is reduced, the labor intensity of workers is reduced, and the production efficiency is improved.

Owner:湖南东立智能科技有限公司

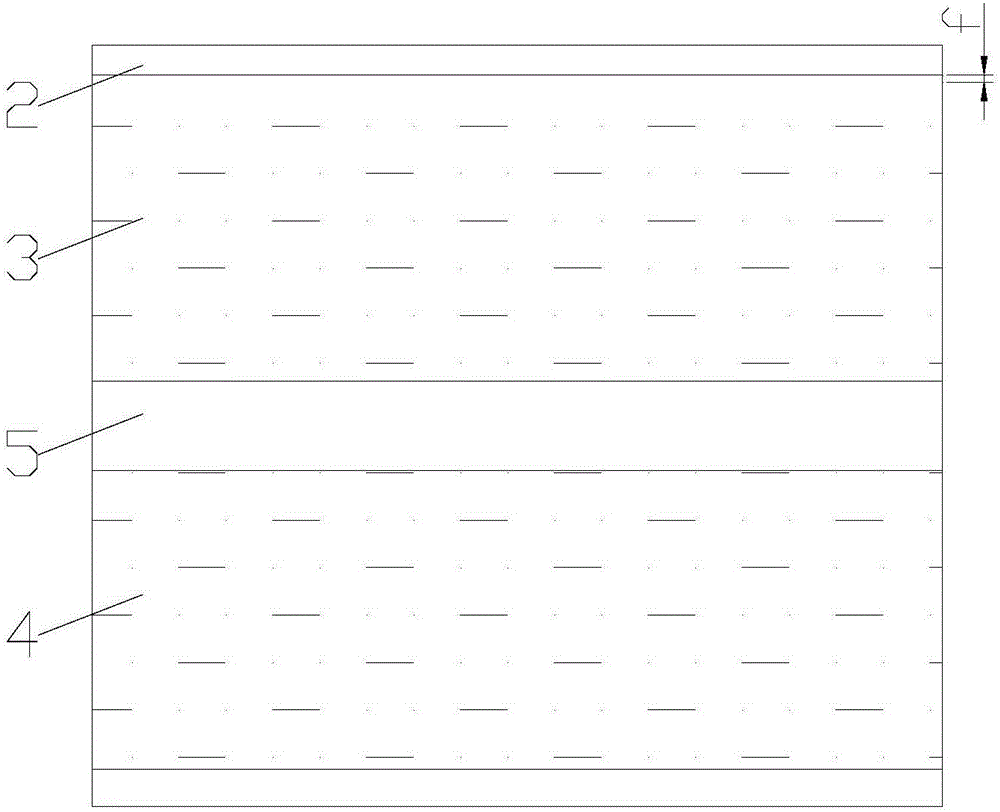

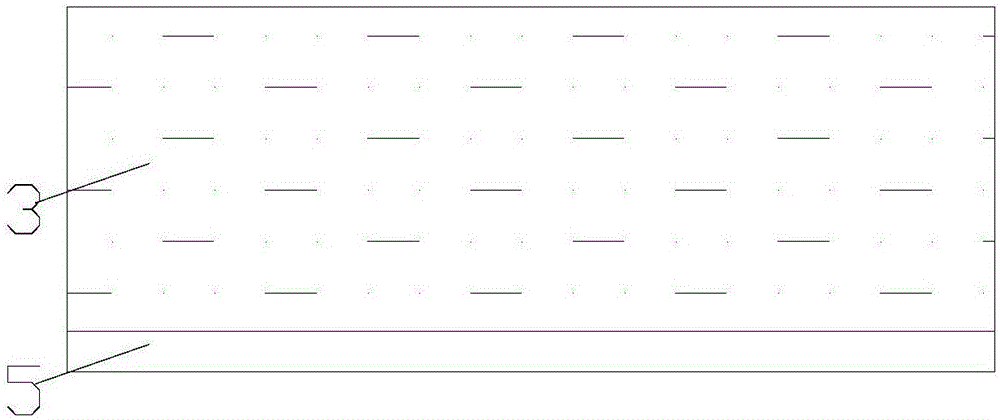

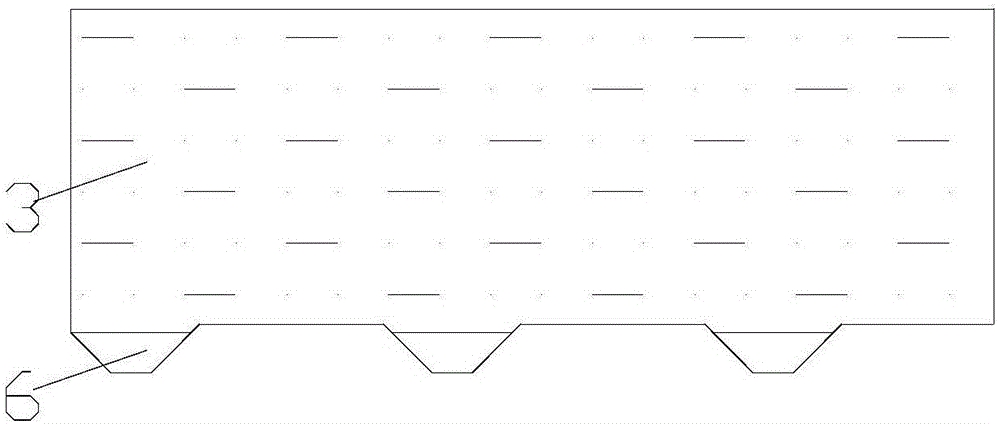

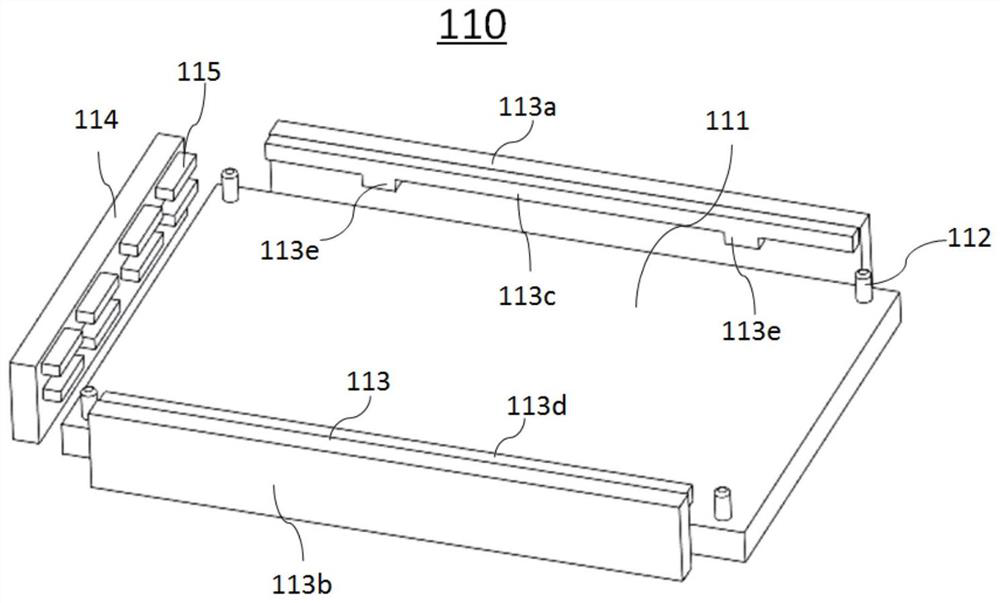

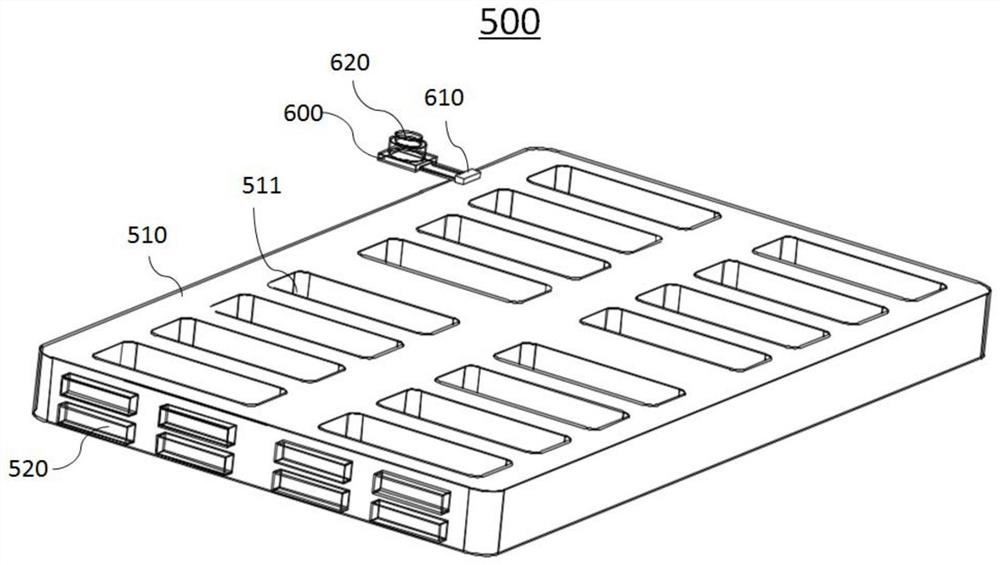

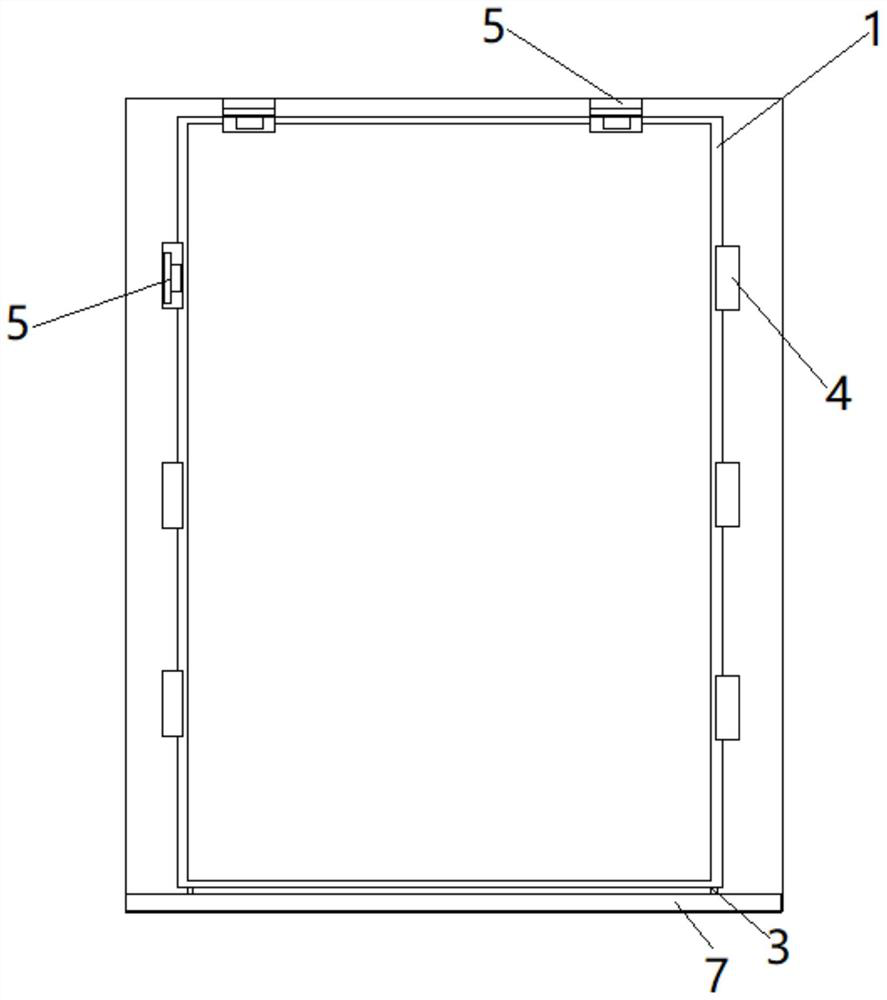

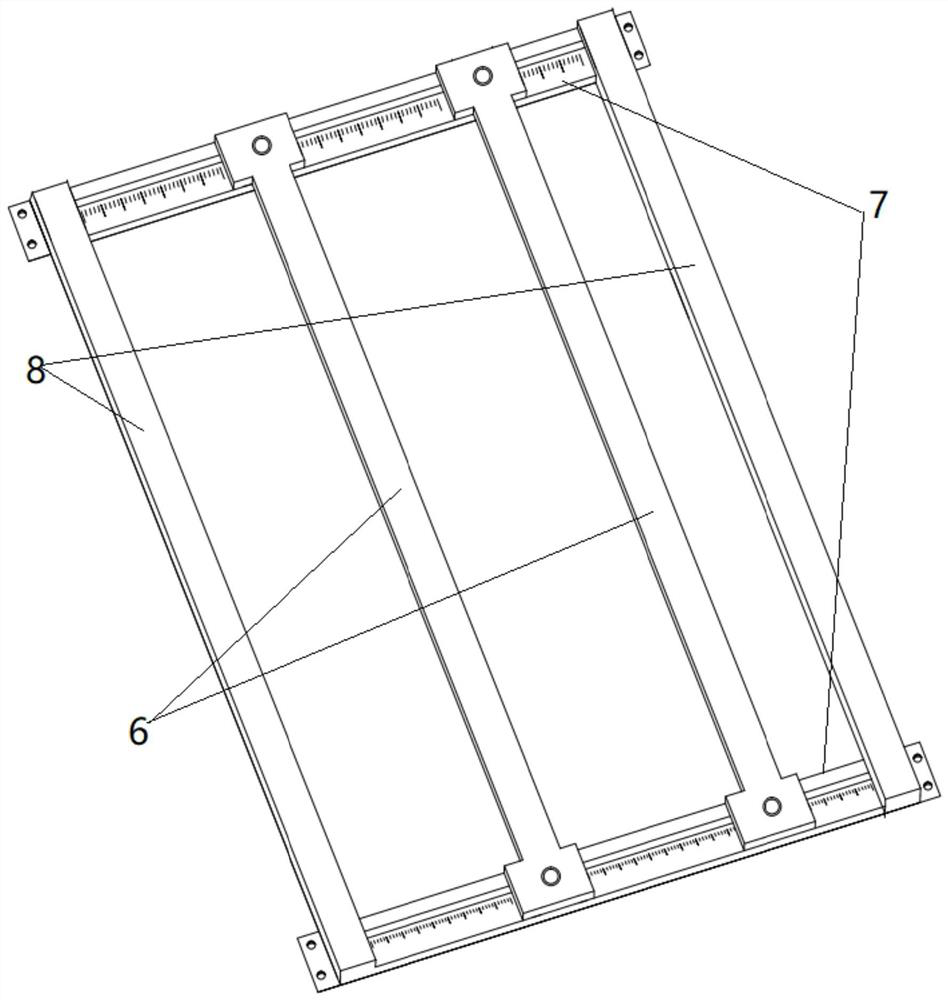

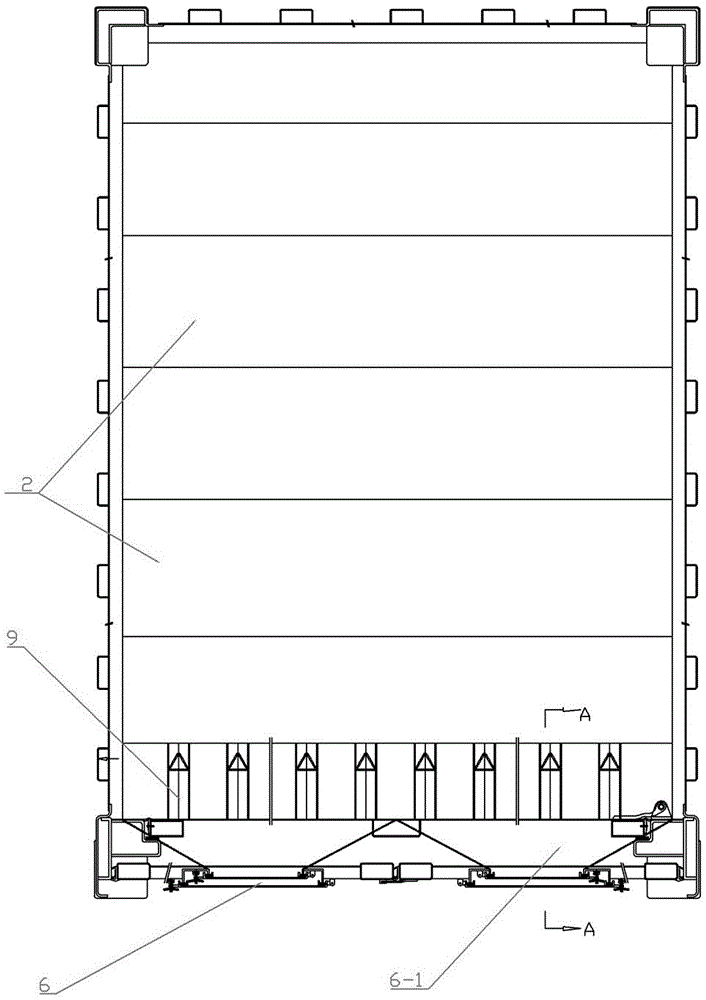

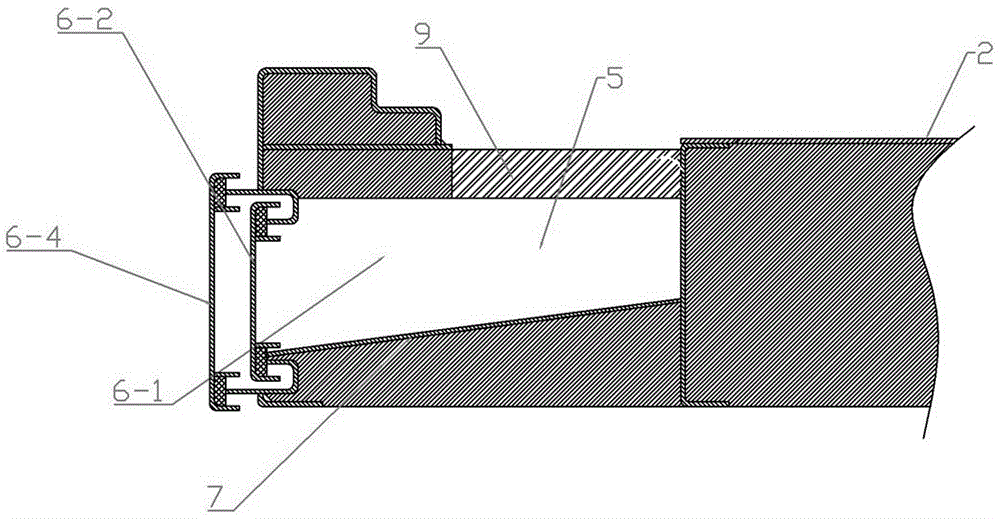

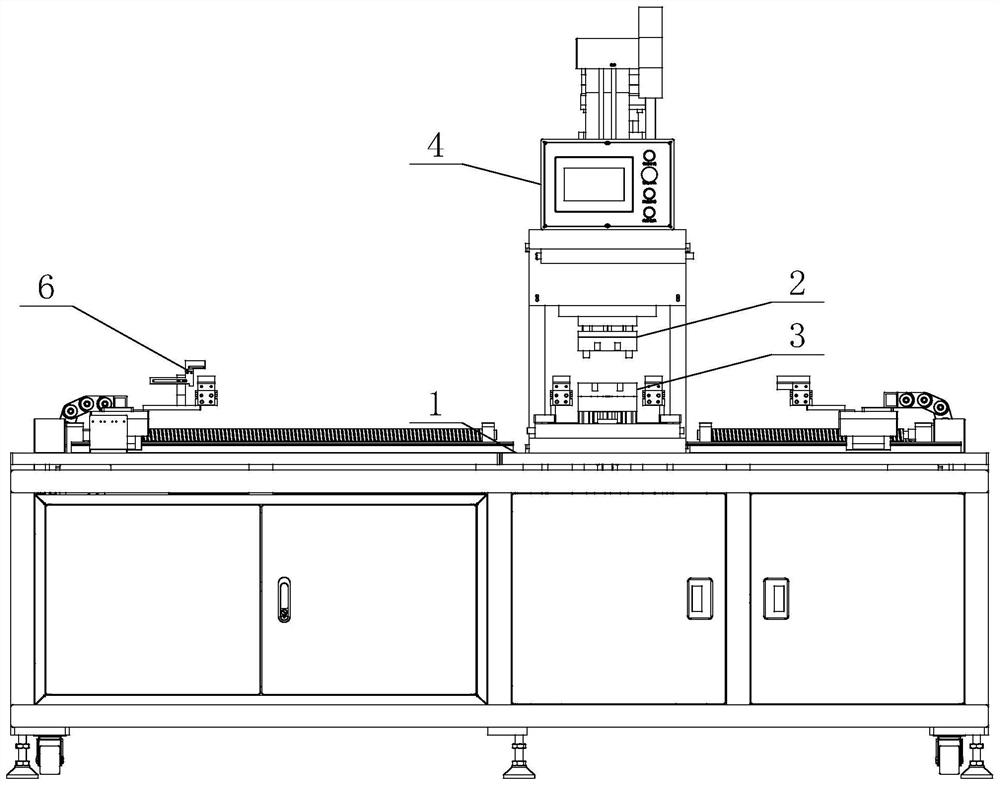

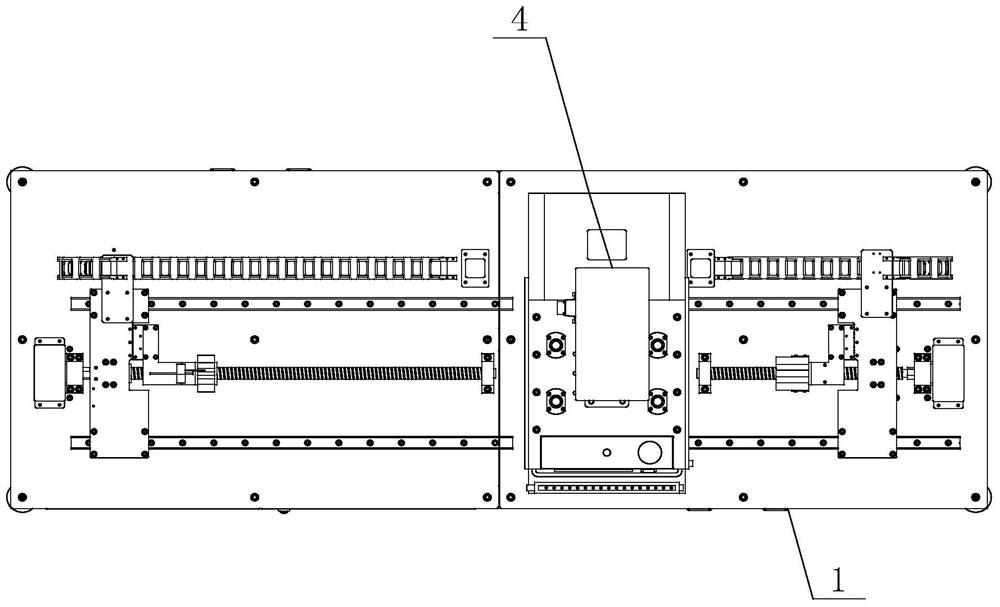

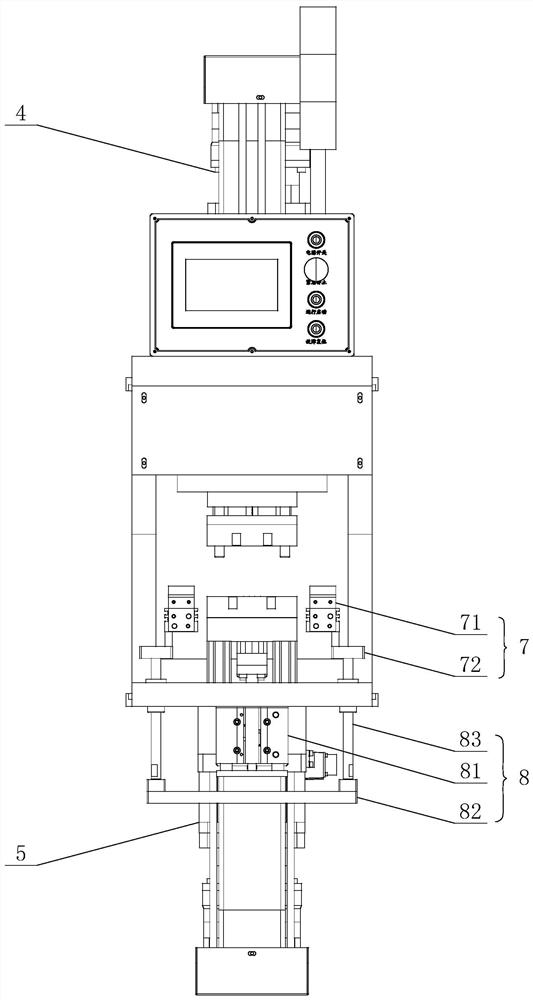

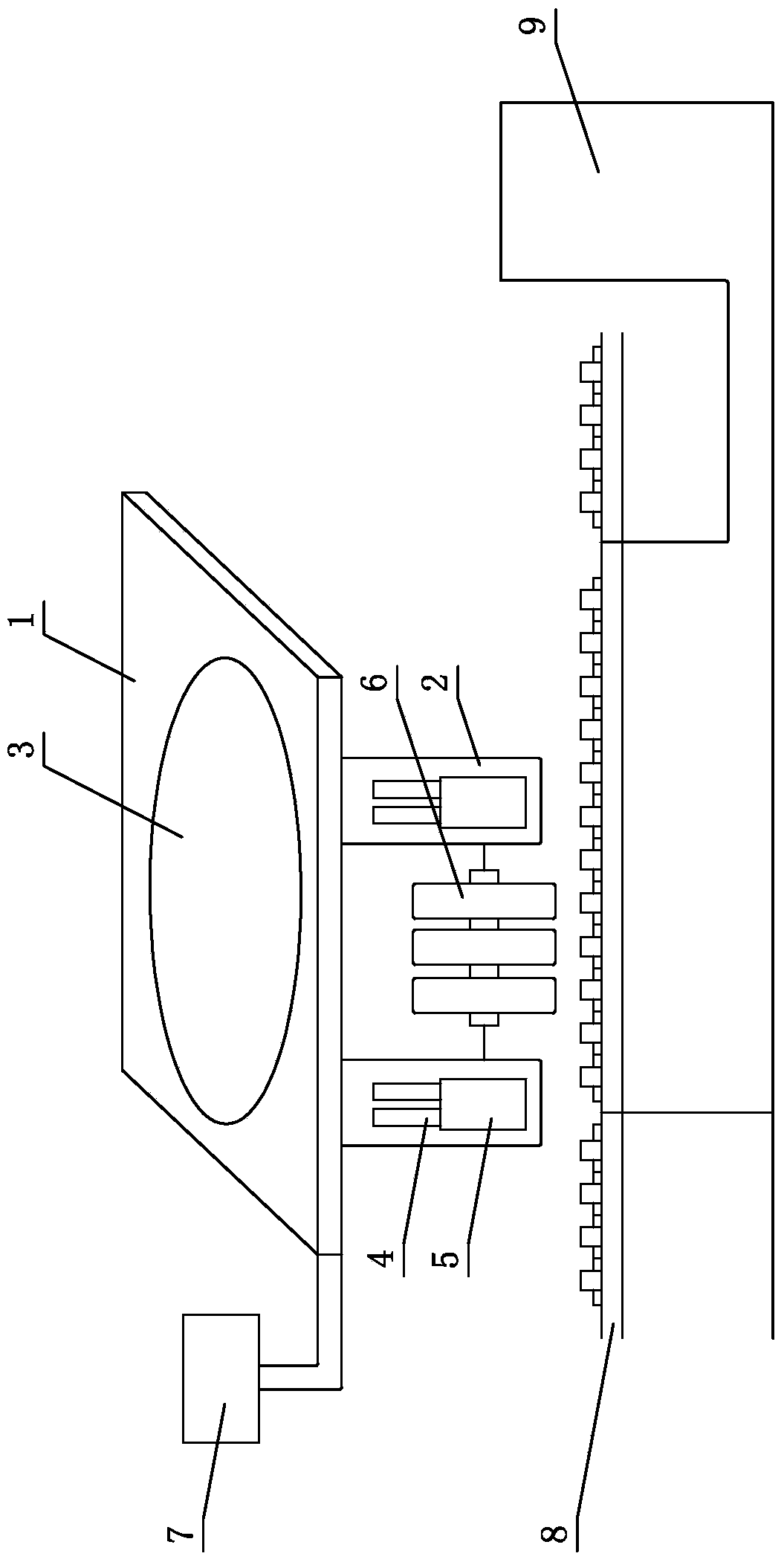

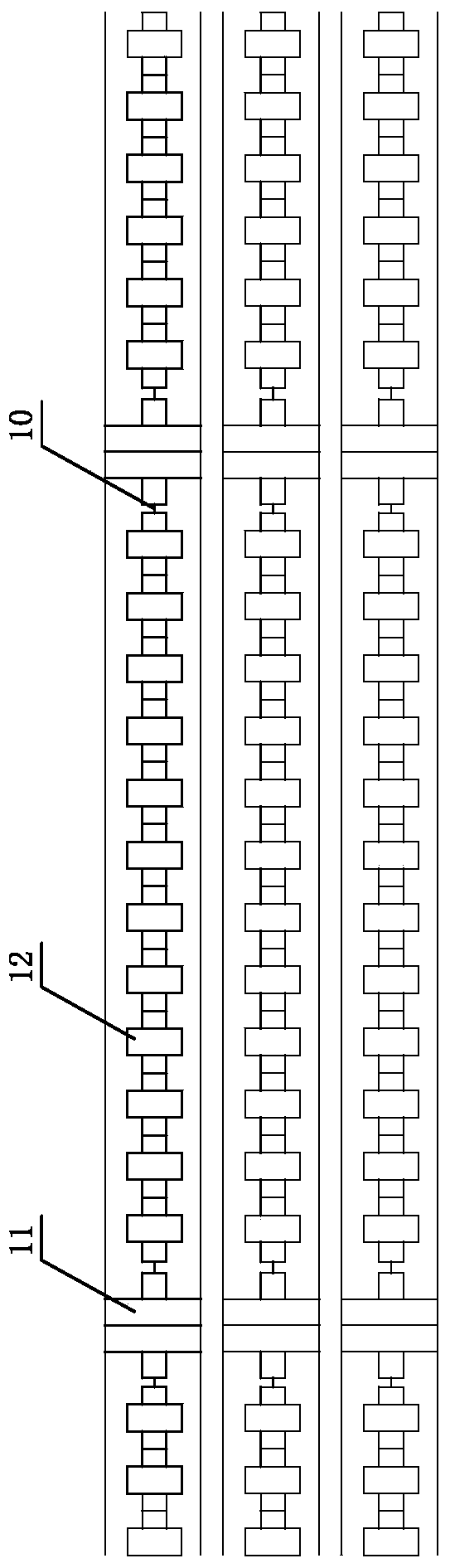

Module detection equipment and jointed board for carrying module array

ActiveCN112752089AAvoid failureLow failure rateEnergy industryTelevision systemsStructural engineeringTest light

The invention relates to module automatic detection equipment. The module automatic detection equipment comprises a detection module and a target plate module, wherein the detection module comprises a material carrying table, the material carrying table is provided with a bearing face and a lateral insertion mechanism, the bearing face is suitable for bearing against the back face of the jointed board, and the lateral insertion mechanism can laterally move relative to the bearing face and is suitable for being in insertion connection with an electrical interface formed in the side face of the jointed board; the jointed board is suitable for carrying a plurality of modules, and the modules are electronic equipment function modules; and the target plate module is suitable for providing a test light source and a target object for the jointed board. The invention also provides a corresponding jointed board for carrying the module array. By reducing extrusion on the two sides of the jointed board in the feeding and discharging process of the jointed board, faults caused by bending or unevenness of the surface of the jointed board can be avoided, and therefore the equipment fault rate is reduced; working efficiency of the detection equipment can be improved; and maintenance and repair are easy.

Owner:NINGBO SUNNY OPOTECH CO LTD

Automatic machine tool with B-axis control

ActiveCN109176052AReduce the number of loading and unloadingVarious processing anglesPrecision positioning equipmentFeeding apparatusMachine toolMachining

The invention discloses an automatic machine tool with B-axis control, and relates to the technical field of machine tools. The automatic machine tool aims to solve the problems that a traditional machine tool cannot realize continuous machining when workpieces are obliquely machined, and time and labor are consumed when the angle is adjusted. According to the key points of the technical scheme, the automatic machine tool with the B-axis control comprises a lathe bed, a main shaft slidably arranged on the lathe bed along the Z axis, secondary shafts slidably arranged on the lathe bed along theZ axis and the X axis, a tool rest which is arranged on the lathe bed and can move along the X axis and the Y axis and a back tool platform which is arranged on the lathe bed and can move up and downalong the Y axis, wherein the tool rest is provided with a B-axis mechanism for obliquely machining a workpiece, and the secondary shafts are provided with deep hole assemblies for drilling deep holes in the end surface of the workpiece. The automatic machine tool with the B-axis control has the advantages of being capable of performing multi-angle oblique machining on the workpiece, realizing continuous machining of the workpiece, improving machining efficiency and reducing cost.

Owner:津上精密机床(浙江)有限公司

Method for recovering coin protein sugar dregs and preparing protein nitrogen sources and nitrogen-containing syrup

ActiveCN101787382BFully denatured and dehydratedHeat condenses wellFermentationProtein nitrogenWastewater

The invention discloses a method for recovering coin protein sugar dregs and preparing protein nitrogen sources and nitrogen-containing syrup in the production of enzymatic corn starch sugar, comprising the steps of size mixing, liquefying, saccharifying, standing separation, centrifugal separation, proteolysis, concentration, drying, compounding, and the like. In the invention, protein is condensed under the heat flash of liquefying, the protein sugar dregs concentrate and float upwards in saccharifying, the sugar dregs are recovered through the steps of standing separation and centrifugal separation, the sugar dregs are dried into protein, or the sugar dregs are hydrolyzed to prepare protein nitrogen sources, and the nitrogen sources can be compounded with syrup to form nitrogen-containing starch syrup for fermenting. Clarified saccharification liquid after centrifugal separation is decolored, filtered, refined and concentrated, and starch syrup products are obtained. The majority of lentous sugar dregs in the saccharification liquid are removed before the treatment of decoloring and filtering, and the decoloring and filtering performance of the material is better. The use level of active carbon, and the like can be properly reduced, the production capability of filtering equipment is improved, and the frequency of the loading and unloading of filters as well as the consumption of washing waste water and various kinds of loss are greatly reduced.

Owner:广州双桥(重庆)有限公司

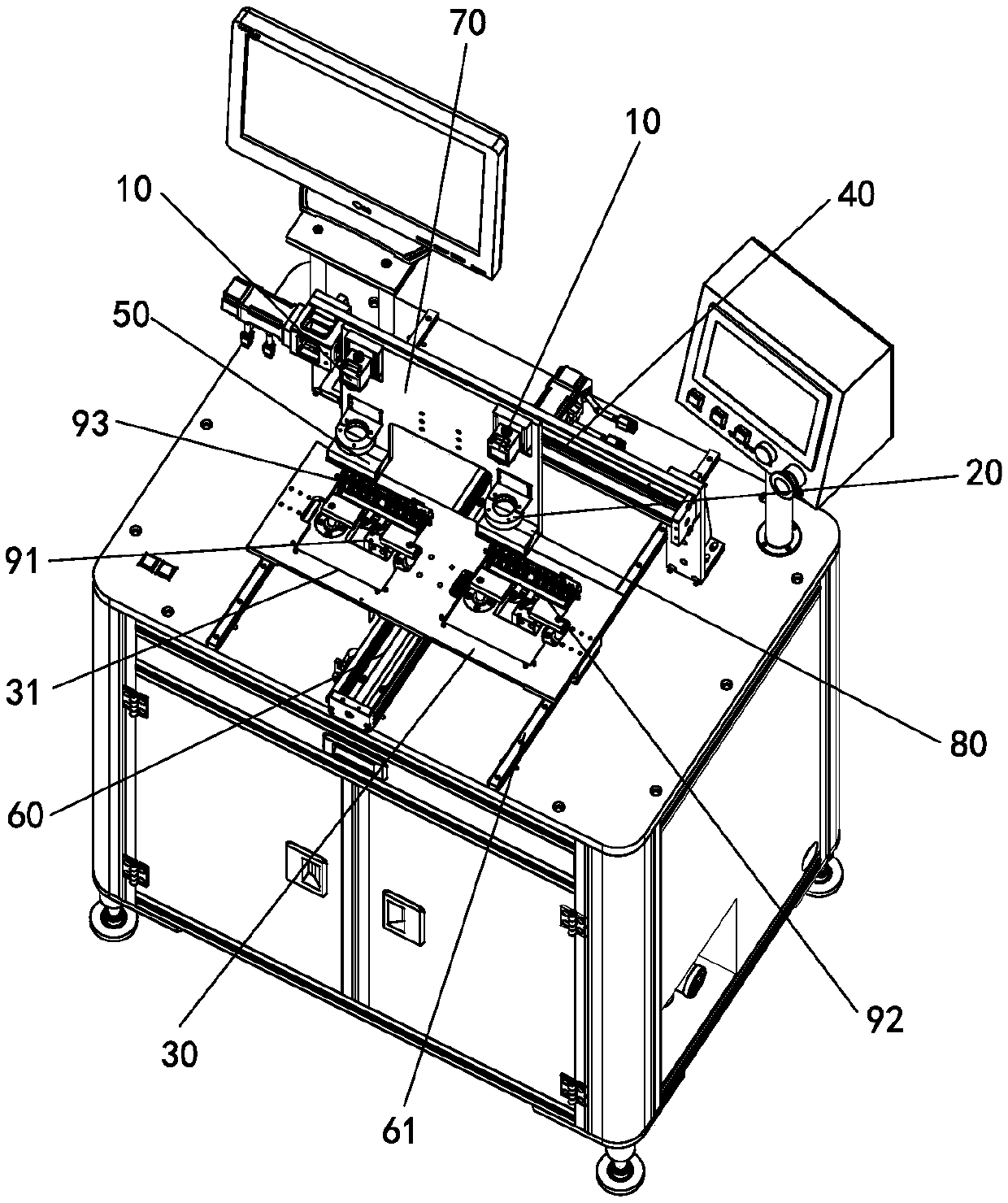

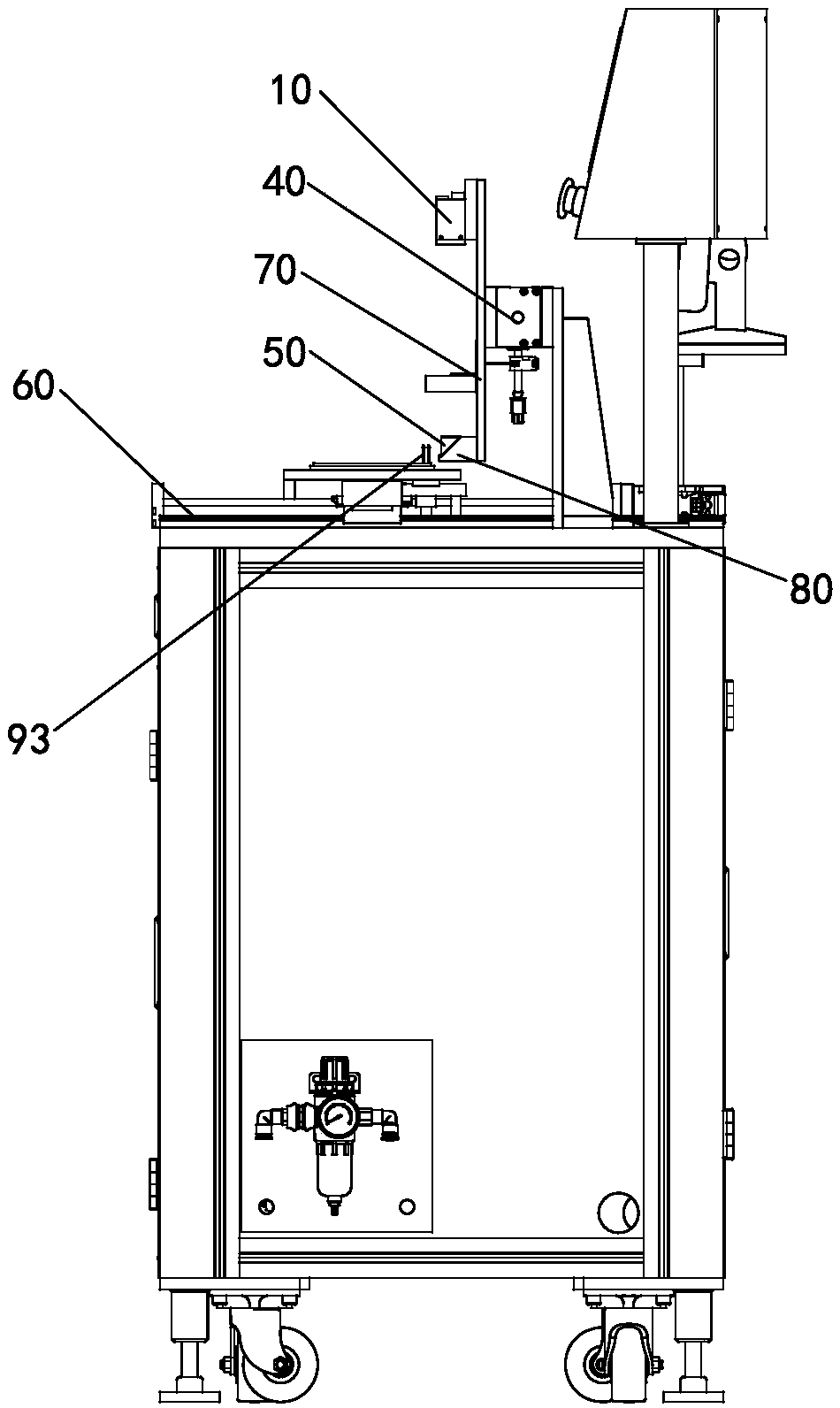

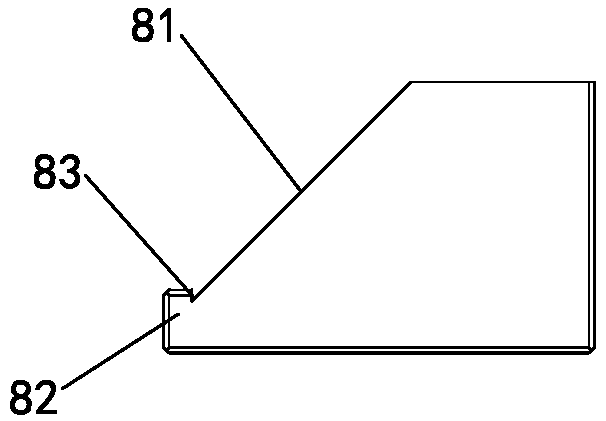

PIN height automatic detecting equipment

PendingCN109579714ARealize continuous detectionImprove detection efficiencyUsing optical meansEngineeringCcd camera

The invention provides PIN height automatic detecting equipment in order to solve the technical problem of low detecting efficiency of PIN detecting equipment in the prior art. The PIN height automatic detecting equipment is provided with a machine vision system, a carrying table and a first displacement mechanism, wherein the machine vision system includes CCD cameras and light sources, the firstdisplacement mechanism drives the CCD cameras to move in a stepping mode, the CCD cameras and the light sources are located over the carrying table and fixed to the side faces of a sliding block of the first displacement mechanism; triangular prisms with the cross sections being in isosceles triangle shapes are arranged below the CCD cameras, one of the straight faces of each triangular prism directly faces the corresponding CCD camera, the other straight face of each triangular prism directly faces PINs; and the carrying table is driven by a second displacement mechanism and operates in thedirection perpendicular to the first displacement mechanism. The total reflection phenomenon of the isosceles right-angle triangular prisms is utilized for light path turning, the CCD cameras collectimages of the side faces of the PINs from the position above the PINs, the carrying table can move in a stepping mode without blocking of the CCD cameras, after detection of one row of PINs is completed by the CCD cameras, the carrying table moves to enable the next row of camera shooting modules to arrive at the positions below the CCD cameras, and in this way, continuous detection of the multiple rows of camera shooting modules is realized.

Owner:昆山东卓精密电子科技有限公司

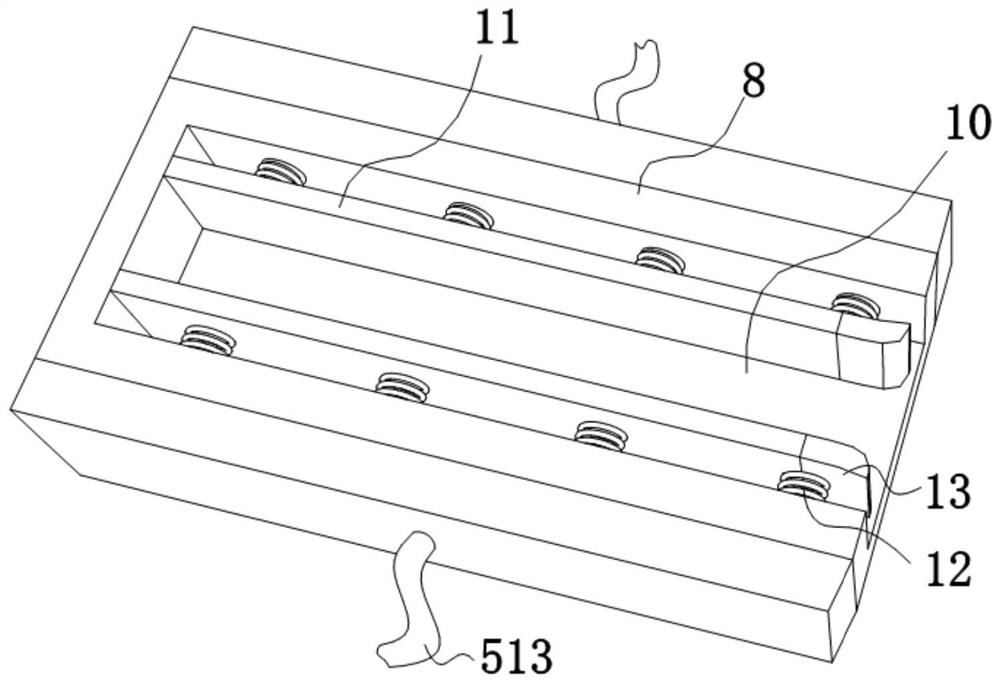

Pneumatic self-locking clamping fixture

ActiveCN105855959BSelf-locking firmly and quicklyFast self-lockingPositioning apparatusMetal-working holdersEconomic benefitsEngineering

The invention relates to a pneumatic self-locking clamping fixture. The fixture comprises a clamping device, wherein the clamping device adopts a wedge clamping mechanism, the wedge clamping mechanism comprises a wedge column (10) and a roller (9), a piston rod mounting double-screw bolt is arranged at one end of the wedge column (10), and the roller (9) is arranged on an inclined working surface of the wedge column (10). Compared with the prior art, the fixture has the beneficial effects as follows: clamping self-locking is controlled by the aid of a double-acting air cylinder, convenient and quick mounting and dismounting are realized, automatic and synchronous clamping is realized by the aid of a double-pressing-plate clamping structure, and the fixture can clamp a to-be-machined part firmly and realize quick self-locking in an instant and can also release the to-be-machined part in an instant after machining is completed, so that the mounting and dismounting efficiency is substantially improved; two guiding columns are arranged to form a cross structure, and thus relatively small workpieces can be clamped to be machined; the fixture has an oblong appearance, and multiple machining stations can be arranged according to sizes of workpieces, accordingly, the multiple workpieces can be machined simultaneously, the machining cost is saved, and the economic benefit is substantially increased.

Owner:杭州杭城摩擦材料有限公司

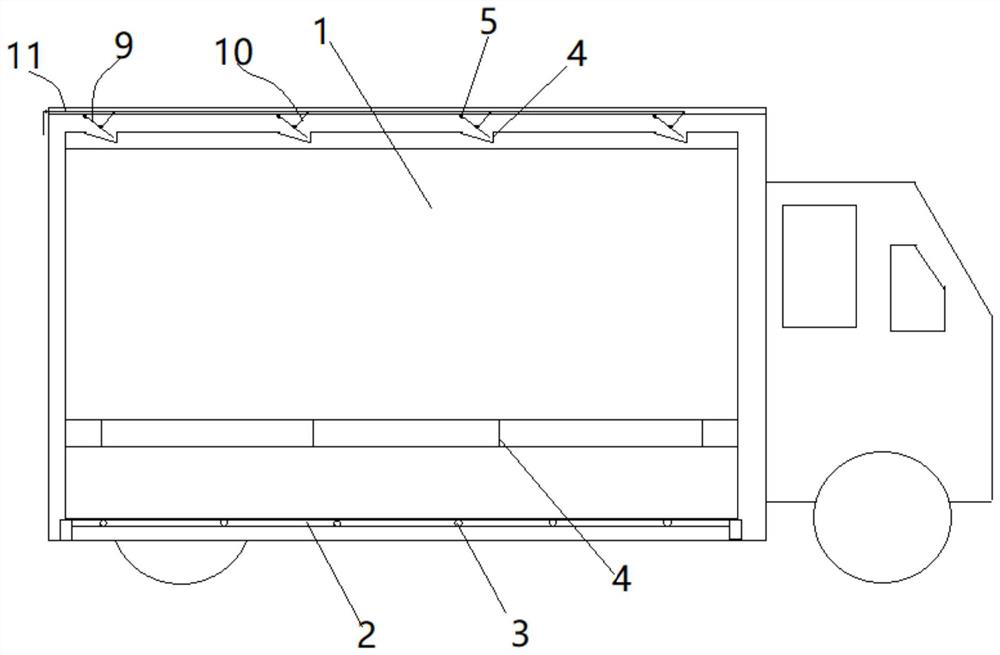

An integrated unit assembly structure for vans

ActiveCN111251969BAvoid shakingSolve the problem of low space utilizationVehicle with rollersVehicle with removable loadingTruckCarriage

The invention discloses an integrated unit assembly structure for a van, comprising a cargo grid unit and a track fixed in the carriage of the truck, and in the form of the cargo grid unit, a bottom moving roller is used to cooperate with the track in the carriage to slide. It is convenient for the loading and unloading of the cargo unit. The whole process of loading and unloading adopts rolling loading and unloading, which is fast and convenient. The cargo unit is used as the cargo carrier unit, which solves the mixed loading of multi-category commodities of different specifications, and the problem of low utilization of compartment space caused by irregular cargo. The cargo compartment unit is provided with a locking and positioning groove, and a locking portion is arranged in the truck compartment. The locking and positioning grooves on the upper are matched and locked to prevent the cargo compartment unit from shaking during transportation. The present invention adopts the cargo compartment unit to prepare the goods to be loaded in the form of the cargo compartment unit in advance, which reduces the number of loading and unloading, and improves the loading and unloading speed. Waiting in line for vehicles saves time and effort.

Owner:CHANGAN UNIV

General container for powder and liquid transportation

The invention relates to a universal container for powder and liquid transportation. The universal container comprises a container body, at least one feeding port is formed in the top side of the container body, a feeding sealing cover is arranged on the feeding port in a sealing mode, a discharge port is formed in the bottom side of the container body, a discharging device corresponding to the discharge port is arranged on the bottom side of the container body, the discharging device comprises a discharging mechanism fixedly connected with the bottom side of the container body and a discharging cavity communicated with the discharging mechanism, the discharging cavity is communicated with the discharge port, the discharging mechanism comprises a discharging supporting beam and a material containing cavity, the material containing cavity is communicated with the discharging cavity, the bottom face, from the material containing cavity to the discharge port, of the discharging cavity is in a slope shape, and a discharge sealing device is arranged on the discharge port. The universal container is easy to manufacture and high in universality, the loading and unloading frequency can be reduced, cargo packing is reduced, the field and the warehouse are saved, operating benefits are improved, operating cost is greatly lowered, and market competitiveness is improved.

Owner:姚平

A grinding and polishing device for aluminum alloy metal parts

ActiveCN112775777BEffectively fixedEasy to polishGrinding carriagesGrinding drivesEngineeringMaterials science

The invention belongs to the technical field of aluminum alloy processing equipment, and discloses a grinding and polishing device for aluminum alloy metal parts, which includes a grinding table and an aluminum alloy plate. Two sets of symmetrically distributed fixing assemblies are arranged on the top of the grinding table. It includes a first hydraulic rod, the installation end of the first hydraulic rod is set on the top of the grinding table, and the output end of the first hydraulic rod is provided with a fixed plate, and a first electric telescopic rod is provided on one side of the fixed plate. The output end of an electric telescopic rod is provided with a first moving plate, and the surrounding end faces of the first moving plate are provided with a second electric telescopic rod, and the other end of the second electric telescopic rod is provided with a second moving plate, so One end of the second moving plate is provided with a first air guide tube, and the other end of the first air guide tube is provided with a suction cup. The present invention can grind and polish both sides of the aluminum alloy plate at one time by arranging a grinding component, a fixing component and a placement plate. The side, and the aluminum alloy plate can be polished and pre-cleaned to control the grinding accuracy.

Owner:JIANGXI DONGYANG ALUMINUM CO LTD

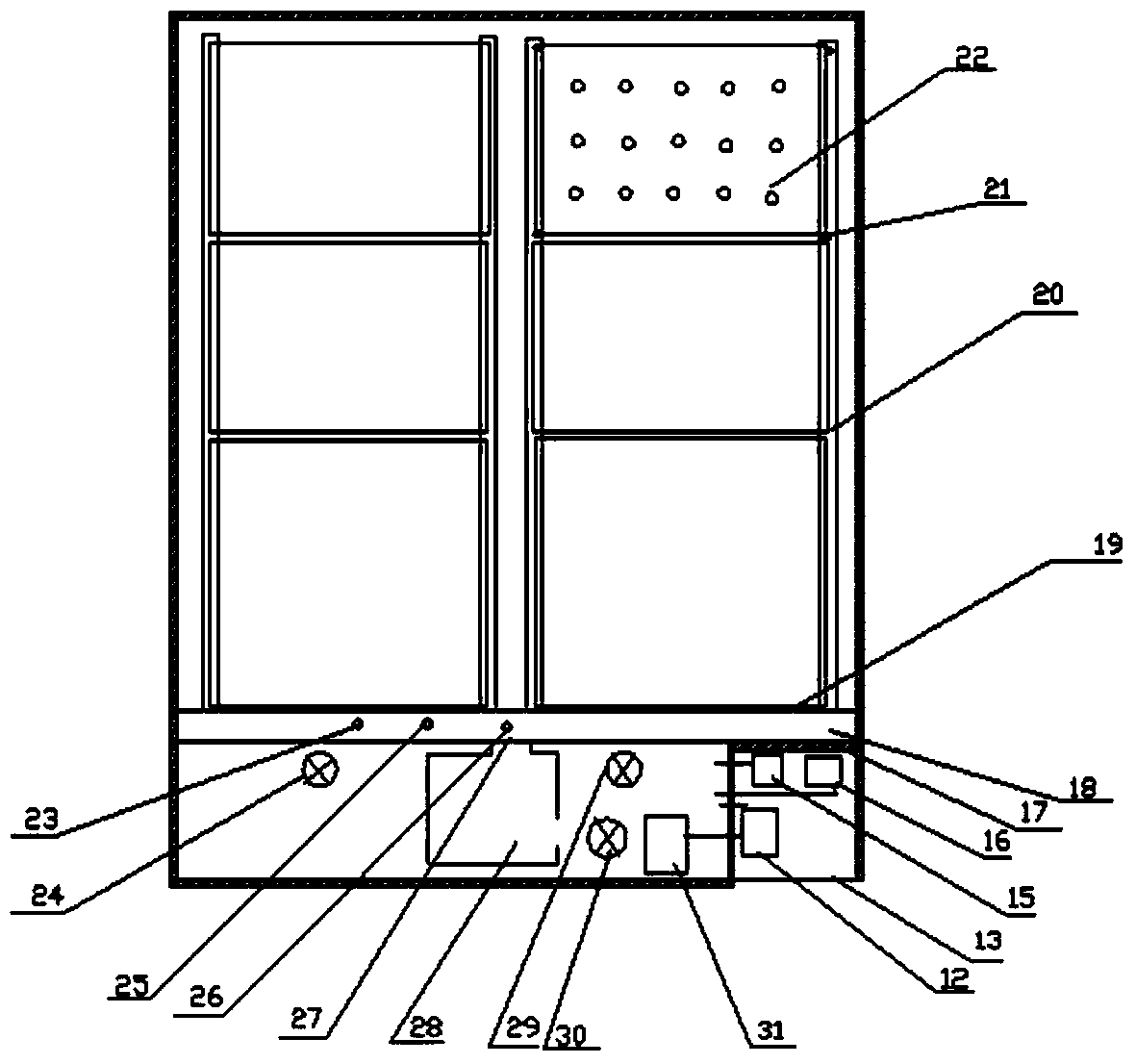

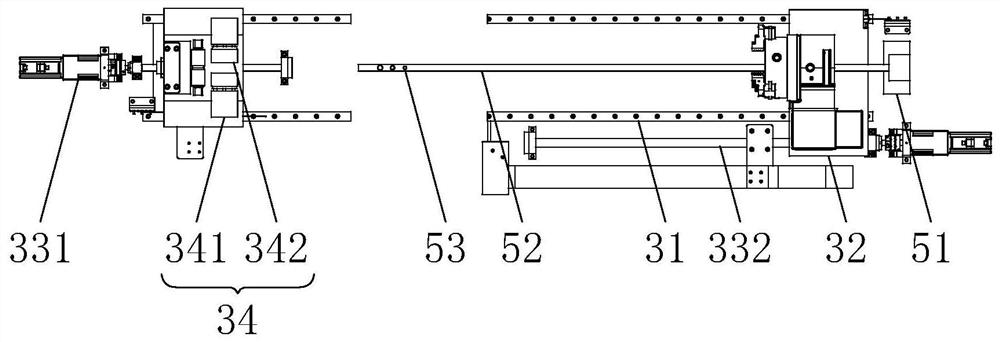

Automatic blanking mechanism for partition plate groove on collecting pipe

PendingCN112935063AReduce the number of loading and unloadingIncrease productivityMetal-working feeding devicesPositioning devicesStructural engineeringIndustrial engineering

The invention discloses an automatic blanking mechanism for a partition plate groove on a collecting pipe. The automatic blanking mechanism comprises a rack, wherein an upper die assembly and a lower die assembly which are used for blanking the upper and lower opposite positions of the collecting pipe are arranged on the rack, an upper die driving part used for driving the upper die assembly to ascend and descend is arranged at the position, on the top of the upper die assembly, of the rack, a lower die driving part used for driving the lower die assembly to ascend and descend is arranged at the position, at the bottom of the lower die assembly, of the rack, and the rack is provided with displacement mechanisms which are arranged at the two ends of the upper die assembly and the two ends of the lower die assembly and drive the collecting pipe to move axially so as to change blanking stations. One-time blanking can be carried out on the relative positions of the collecting pipe on the same machine to form the penetrating type partition plate groove, blanking can be carried out on the different axial positions of the collecting pipe through the displacement mechanisms, the feeding and discharging frequency can be reduced, and then the production efficiency is improved.

Owner:湖南东立智能科技有限公司

Grinding machines for superhard material products

ActiveCN105479291BReduce the number of loading and unloadingReduce pollutionEdge grinding machinesOther manufacturing equipments/toolsSuperhard materialMetallurgy

Owner:广东奔朗新材料股份有限公司

The operation method of the container rail-water intermodal transport vehicle-ship direct fetching mode based on the railway loop

ActiveCN110422649BOvercome limitationsReduce the changeover processLoading/unloadingMechanical engineeringTransportation Facility

Owner:CHINA MAJOR BRIDGE ENERGINEERING

Universal pneumatic self-locking clamping fixture

ActiveCN105855958BReduce the number of loading and unloadingReduce investmentPositioning apparatusMetal-working holdersMachine partsSelf locking

The invention relates to a universal type pneumatic self-locking clamping fixture. The fixture comprises a clamping device, wherein the clamping device adopts a wedge clamping mechanism, the wedge clamping mechanism comprises a wedge column (5) and a roller (7), a piston rod mounting double-screw bolt is arranged at one end of the wedge column (5), and the roller (7) is arranged on an inclined working surface of the wedge column (5). Compared with the prior art, the fixture has the beneficial effects as follows: clamping self-locking is controlled by the aid of a double-acting air cylinder, convenient and quick mounting and dismounting are realized, and the fixture is high in flexibility, can clamp a to-be-machined part firmly and realize quick self-locking in an instant and can also release the to-be-machined part in an instant after machining is completed, so that the mounting and dismounting efficiency is substantially improved; multiple clamping fixtures can be mounted on one working platform simultaneously, and thus multi-process or multi-station machining can be conducted at a time; the fixture is high in universality, particularly, the to-be-machined part is very convenient and quick to change, all that is required is to directly change a positioning base 11 and a rhombic pin 10, and accordingly, universal clamping and machining of different types of workpieces are realized.

Owner:宁波瑞立机械有限公司

Blanking device for round hole of collecting pipe

PendingCN113145730AReduce the number of loading and unloadingReduce labor intensityMetal-working feeding devicesPositioning devicesTransfer mechanismEngineering

The invention relates to a blanking device for a round hole of a collecting pipe. The blanking device for the round hole of the collecting pipe comprises a rack, wherein a blanking mechanism used for positioning the collecting pipe and blanking the round hole of the collecting pipe is arranged on the rack; axial transferring mechanisms used for adjusting the axial position of the collecting pipe to achieve round hole blanking at different stations are further arranged at the positions, at the two ends of the blanking mechanism, of the rack; a positioning chuck is also arranged on each axial transferring mechanism; a core rod mechanism which is arranged in each positioning chuck in a penetrating manner and is used for fixing collecting pipes with different diameters is also arranged on the rack; through cooperation between the blanking mechanism and the transferring mechanisms, the collecting pipe can move in the axis direction, and the axial blanking station is changed; the collecting pipe can be rotated through the positioning chucks, so that the radial blanking station of the collecting pipe is adjustable; and the collecting pipes with different diameters can be fixed through the core rod mechanisms, and different blanking devices do not need to be used for blanking, so that the feeding and discharging frequency is reduced, the labor intensity of workers is relieved, and the production efficiency is improved.

Owner:湖南东立智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com