Tempering and transshipment tank for processed grains

A technology for reloading boxes and finished grains in a slowing process, which is applied in food preservation, edible seed preservation, food science, etc. It can solve the problems of restricting the shape and height of the goods, occupying the volume of the box, and complicated structure, so as to save slowing time , reduce handling, ensure quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

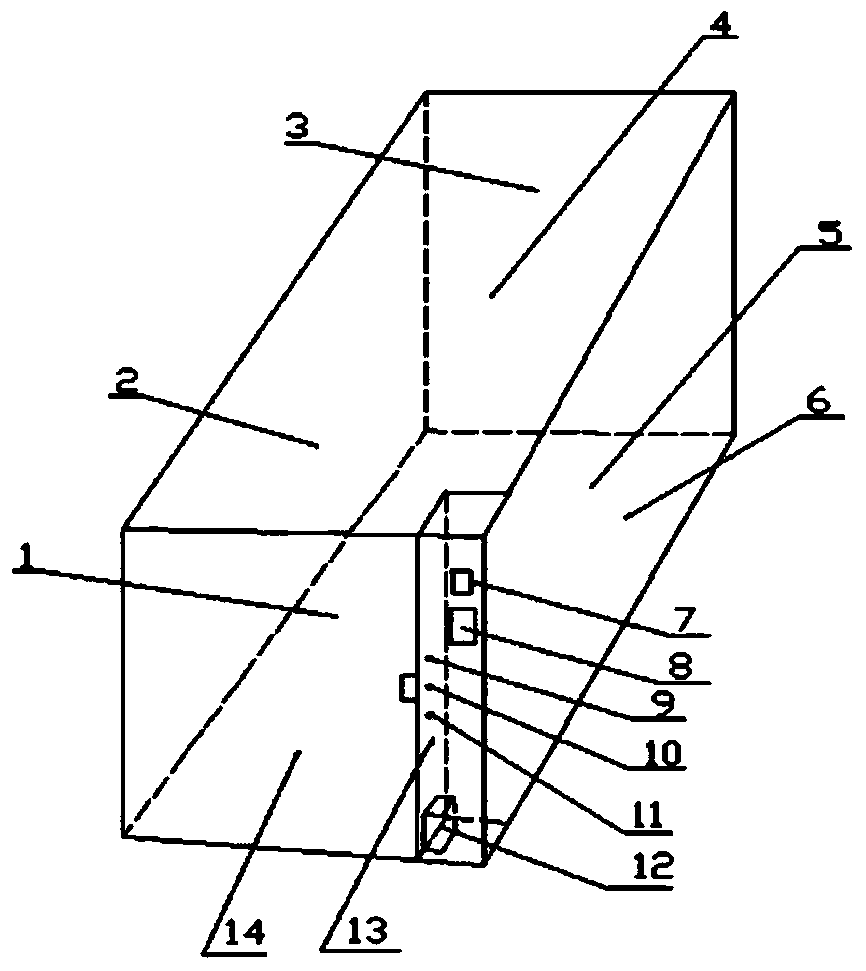

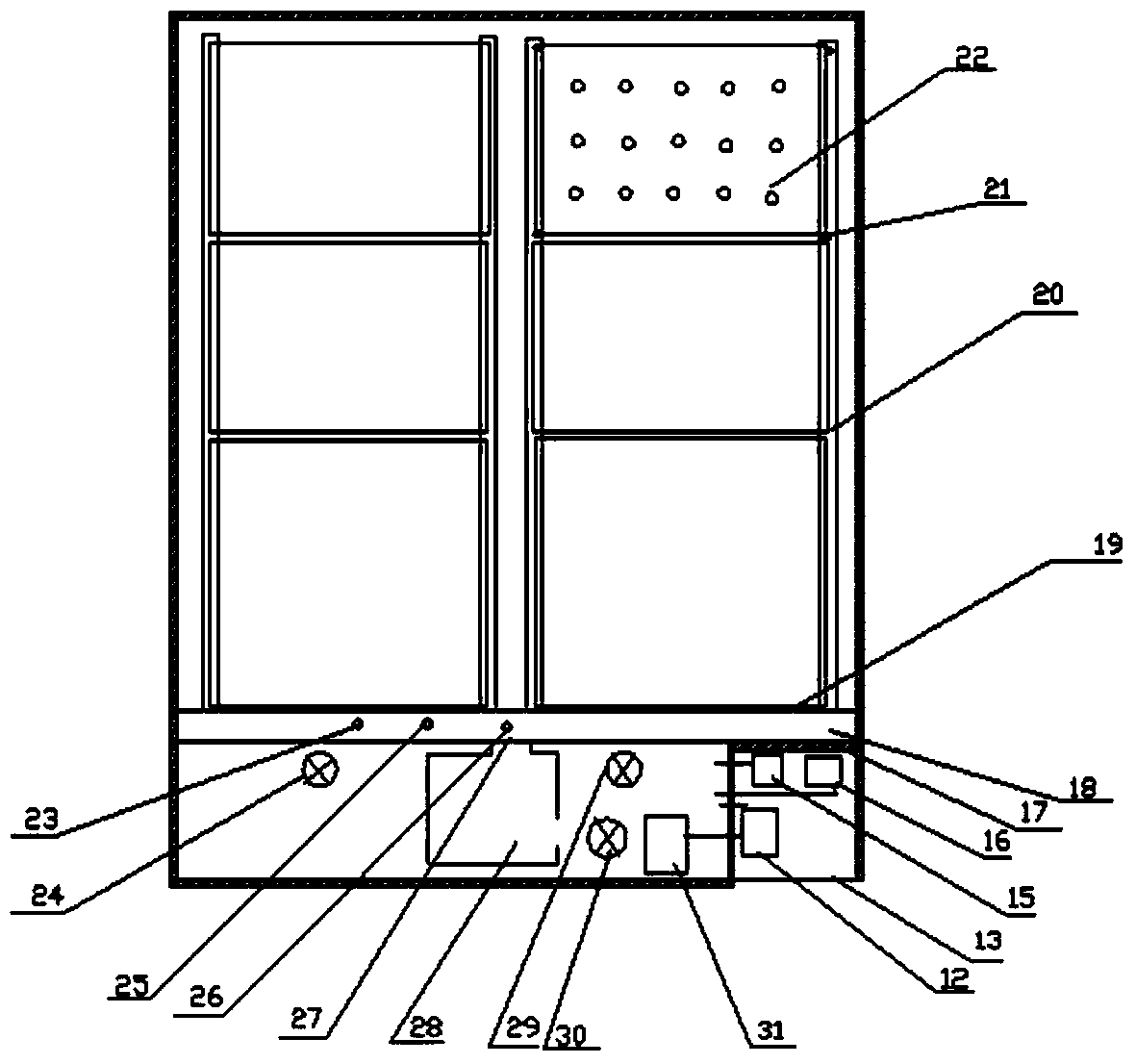

[0078] as attached figure 1 And attached figure 2 As shown, the finished grain suspending box of the present invention includes a box body 1, and the box body 1 includes a base plate 6, a left side plate 2, a rear side plate 3, a right side plate 5, a front side plate 14 and a top plate opposite to the bottom plate 4. The external dimensions of the box body 1 are basically the same as those of general-purpose containers on the market, can be matched, and can be transported on trains or freighters;

[0079] The box body 1 is filled with polystyrene foam plastic or polyurethane foam plastic in the middle of the sandwich steel plate, which has good heat insulation performance, and prevents water droplets from adhering to the inner wall of the box body 1 due to changes in the external environment, and then contacting the grain in the box body 1.

[0080] There is a box door 13 on the front side panel of the box body 1, and there is a partition I at a position opposite to the box...

Embodiment 2

[0112] The difference from Example 1 is that, in the finished grain slow-su transfer box, four grooved steel pipes 20 are arranged at the bottom of the box body 1, and the grooved steel pipes 20 on the left and right sides are respectively 50 mm away from the inner wall of the box body 1. The distance between the two steel pipes 20 is 120 mm; the airflow channel is formed, and at the same time, water droplets are prevented from adhering to the inner wall of the box body 1 due to changes in the external environment, and then contacting the grain in the box body 1. Even if there are local water droplets, they will be quickly carried by the airflow Walk.

Embodiment 3

[0114] The difference from Example 1 is that, in the finished grain slow-su transfer box, four grooved steel pipes 20 are arranged at the bottom of the box body 1, and the grooved steel pipes 20 on the left and right sides are respectively 150 mm away from the inner wall of the box body 1. The distance between the two steel pipes 20 is 160 mm; an airflow channel is formed, and at the same time, water droplets are prevented from adhering to the inner wall of the box body 1 due to changes in the external environment, and then contacting the grain in the box body 1. Even if there are local water droplets, they will be quickly carried by the airflow Walk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com