Air drying duck high-temperature maturation process

A mature, high-temperature technology, applied in drying preservation of meat/fish, acid preservation of meat/fish, food preparation, etc., can solve the problems of low air-drying and ripening temperature, affecting product flavor and quality, poor equipment, etc., and achieve the target of reducing fat oxidation. , Speed up lipid decomposition and oxidation, improve the effect of flavor quality and safety quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

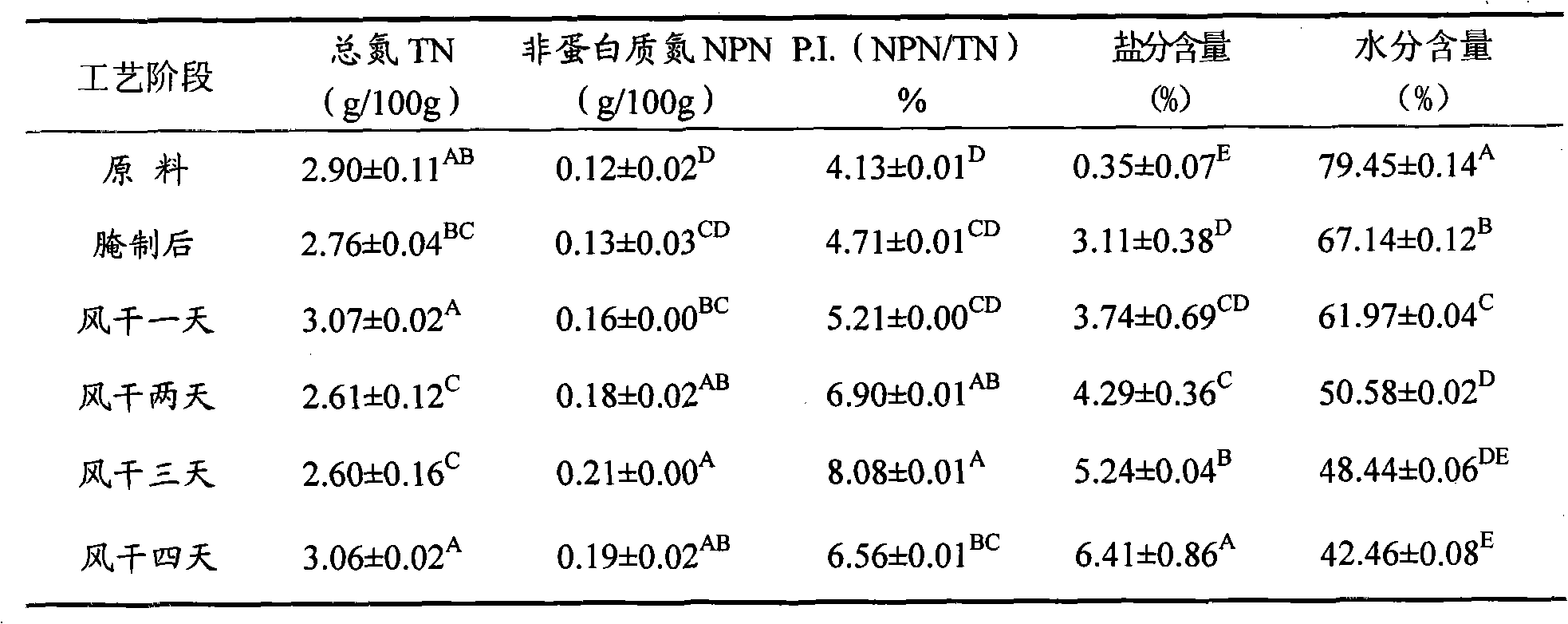

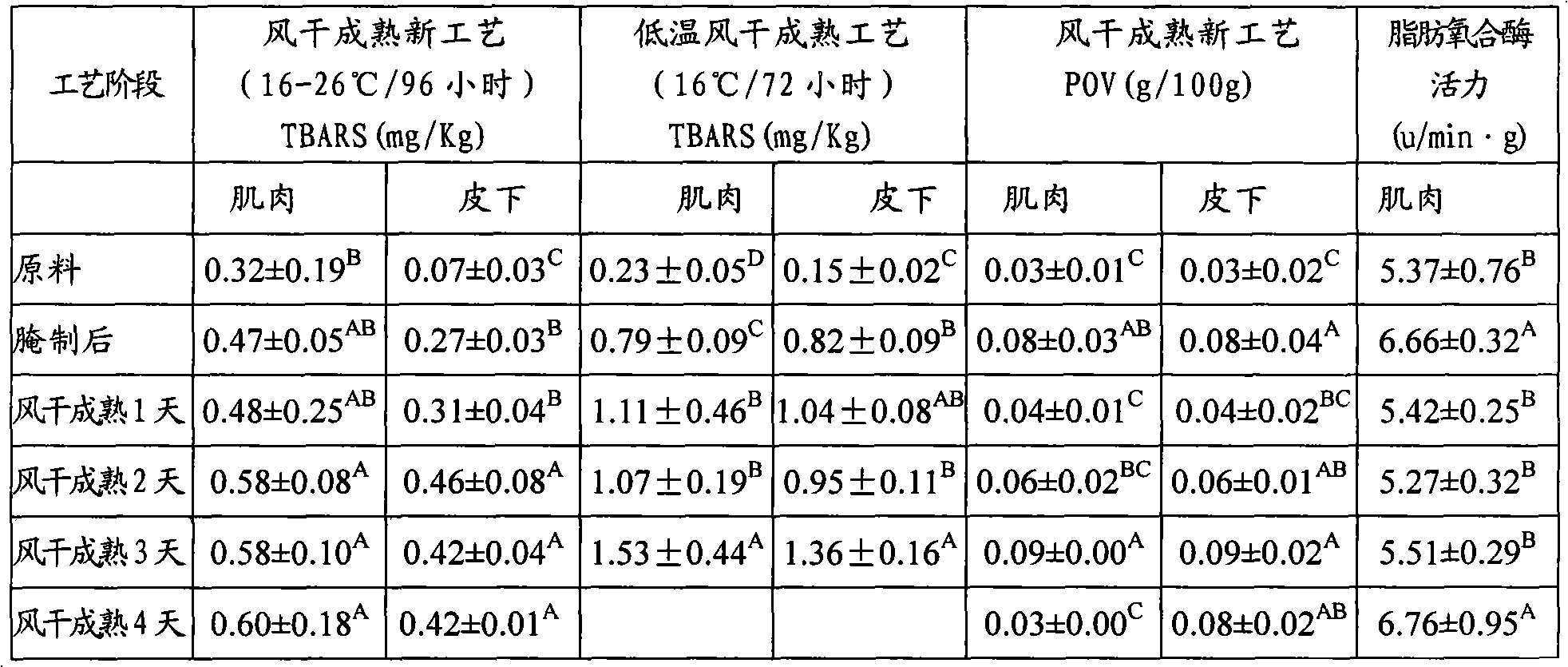

[0012] The new air-dried and mature process of air-dried ducks of the present invention: clean the thawed or slaughtered pre-cooled ducks, wet-cure them in a pickling solution with a NaCl content of 12% for 24 hours, and control the pickling temperature at 3-8°C; Drain the surface moisture of the whole duck in a ventilated place, put it into the modern air-drying maturation process equipment or air-drying maturation room with temperature and humidity control, and carry out low-temperature dehydration at a wind speed of 4 m / s, temperature control at 18°C, and humidity control at 58% RH 24 hours; then ferment for 24 hours at a wind speed of 3 m / s, a temperature of 21°C, and a humidity control of 58% RH for 24 hours; then mature at a wind speed of 3 m / s, a temperature of 24°C, and a humidity control of 58% RH for 24 hours, and then The wind speed is 2 m / s, the temperature is 26°C, and the humidity is controlled at 58% RH and matured for 24 hours at high temperature to become a "wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com