Patents

Literature

335results about How to "Improve flavor quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quality Enhancement of Coffee Beans by Acid and Enzyme Treatment

The subject invention provides methods for treating unroasted or green coffee beans to improve their quality of flavor to the palate, including reduced bitterness, better tasting, and improved aroma. In one embodiment, the invention pertains to the treatment of either green and un-dried, or green and dried, coffee beans with enzymes in a pH adjusted environment. According to the subject invention, the enzymes to be used, the pH of the treatment medium, and the times of treatment are parameters that are optimized based on different desired flavor and / or aroma outcomes.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

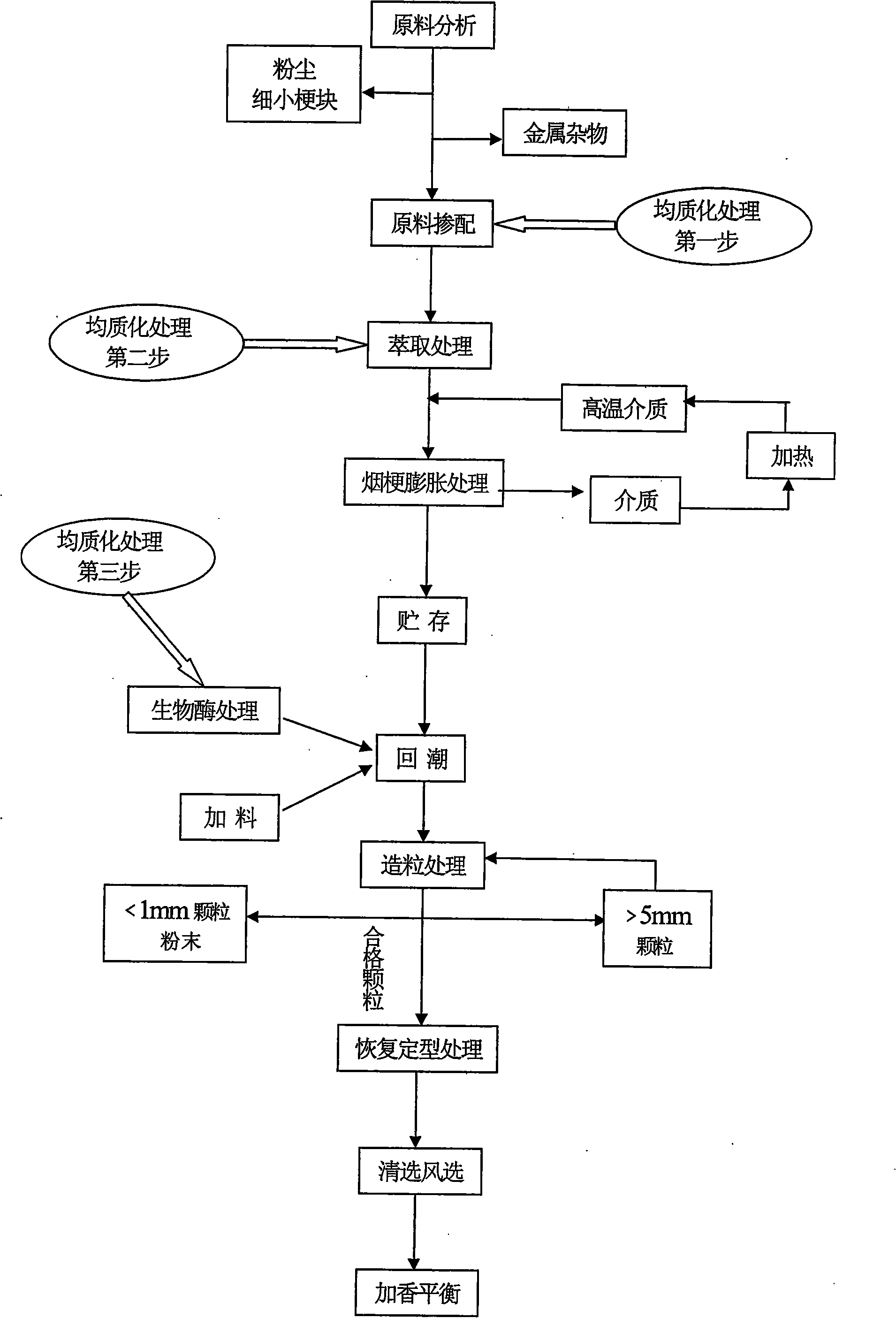

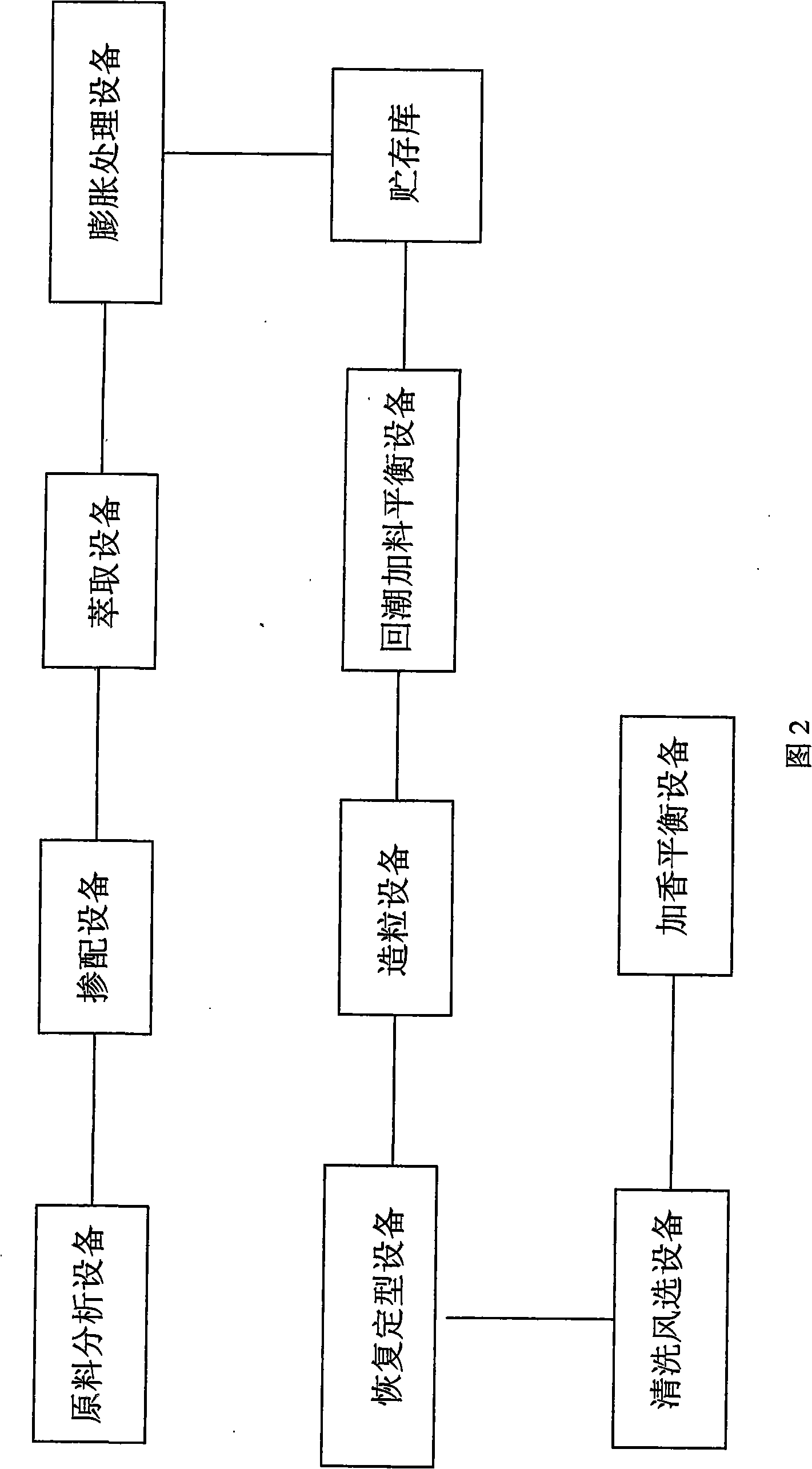

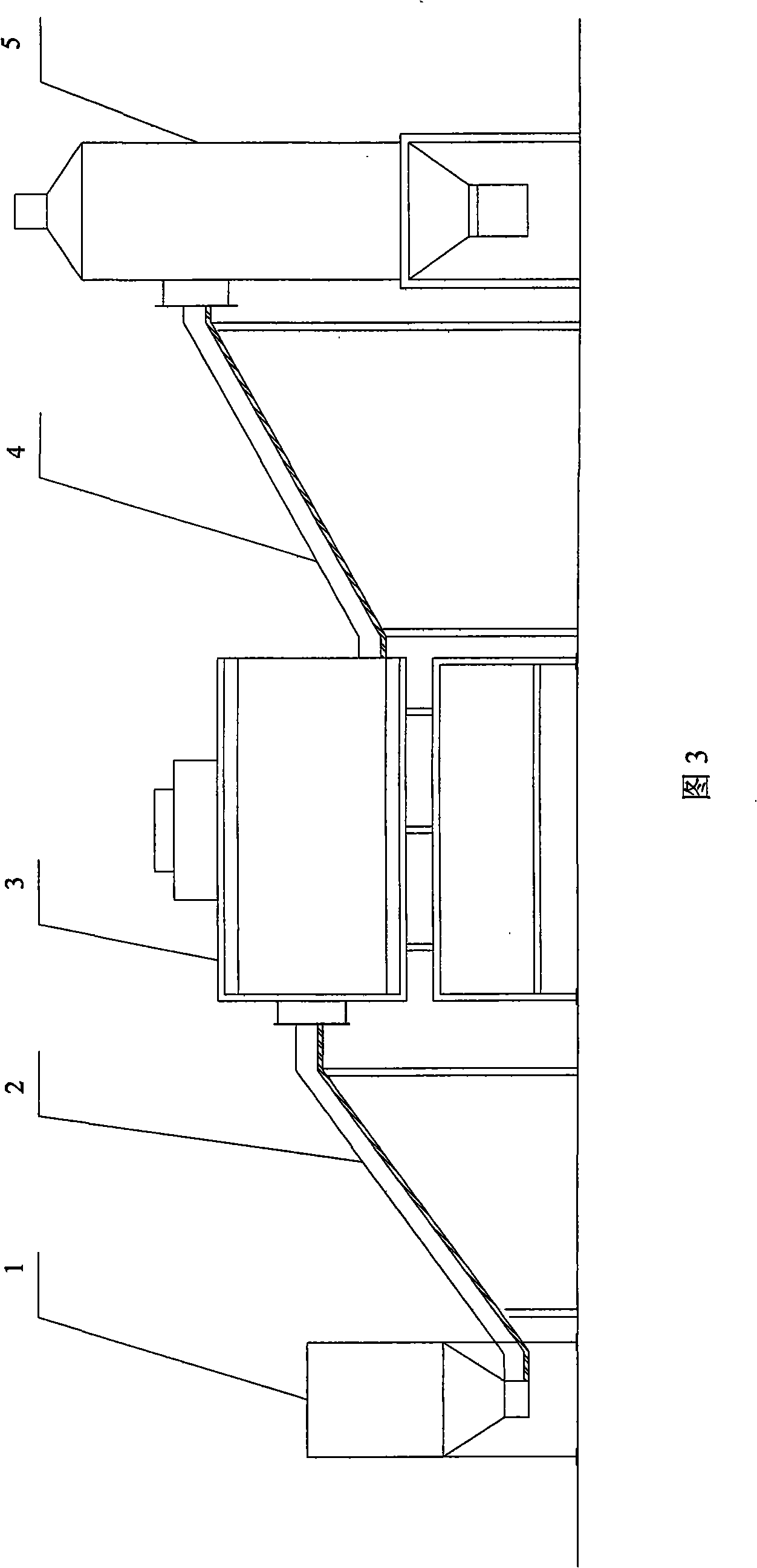

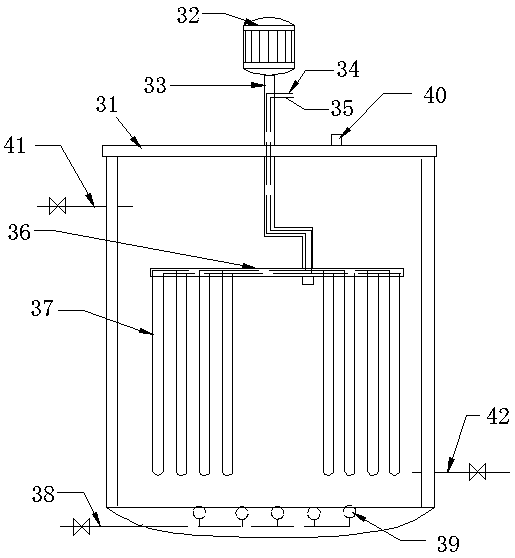

Method and device for preparing expanded stem granule

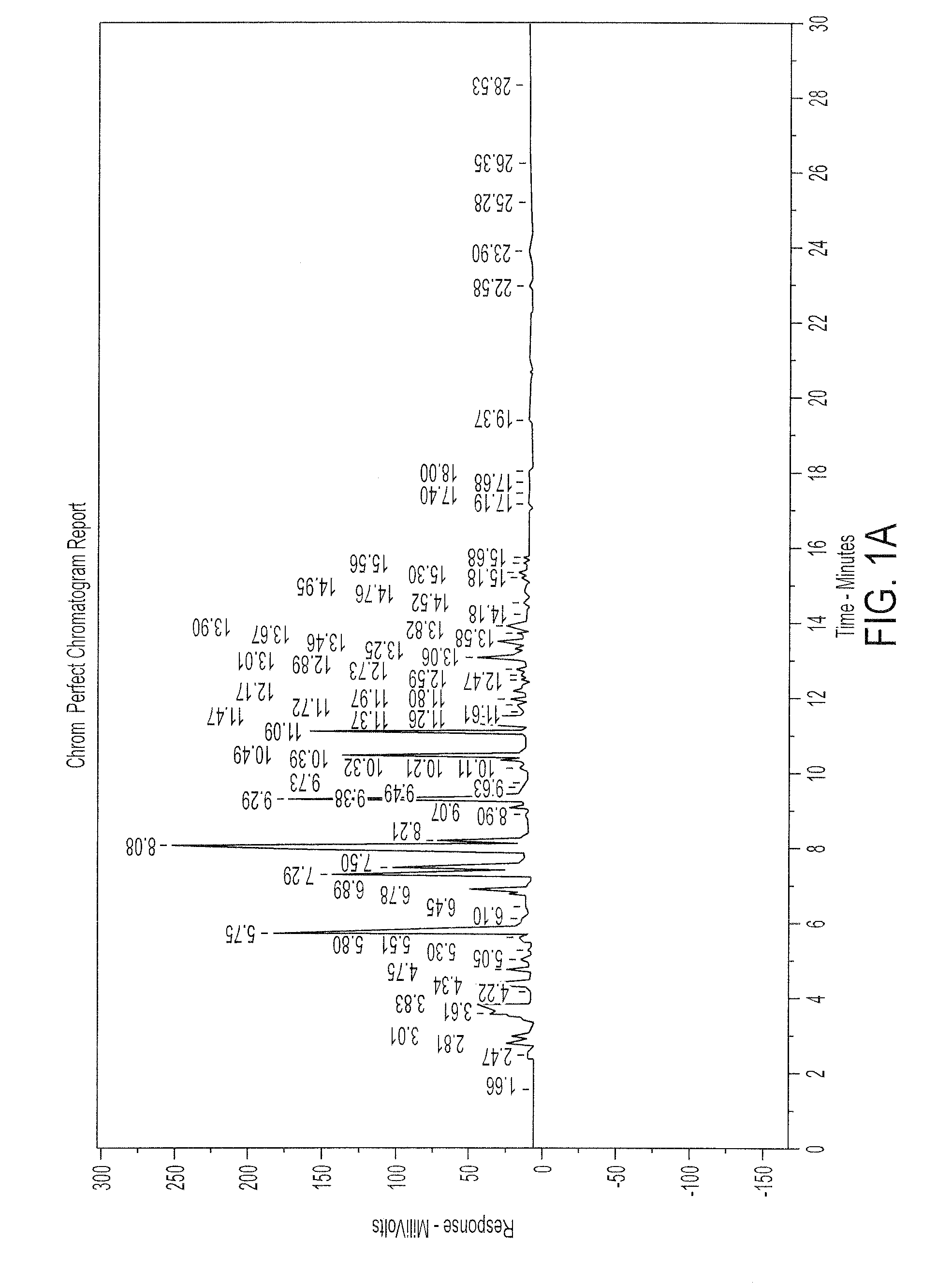

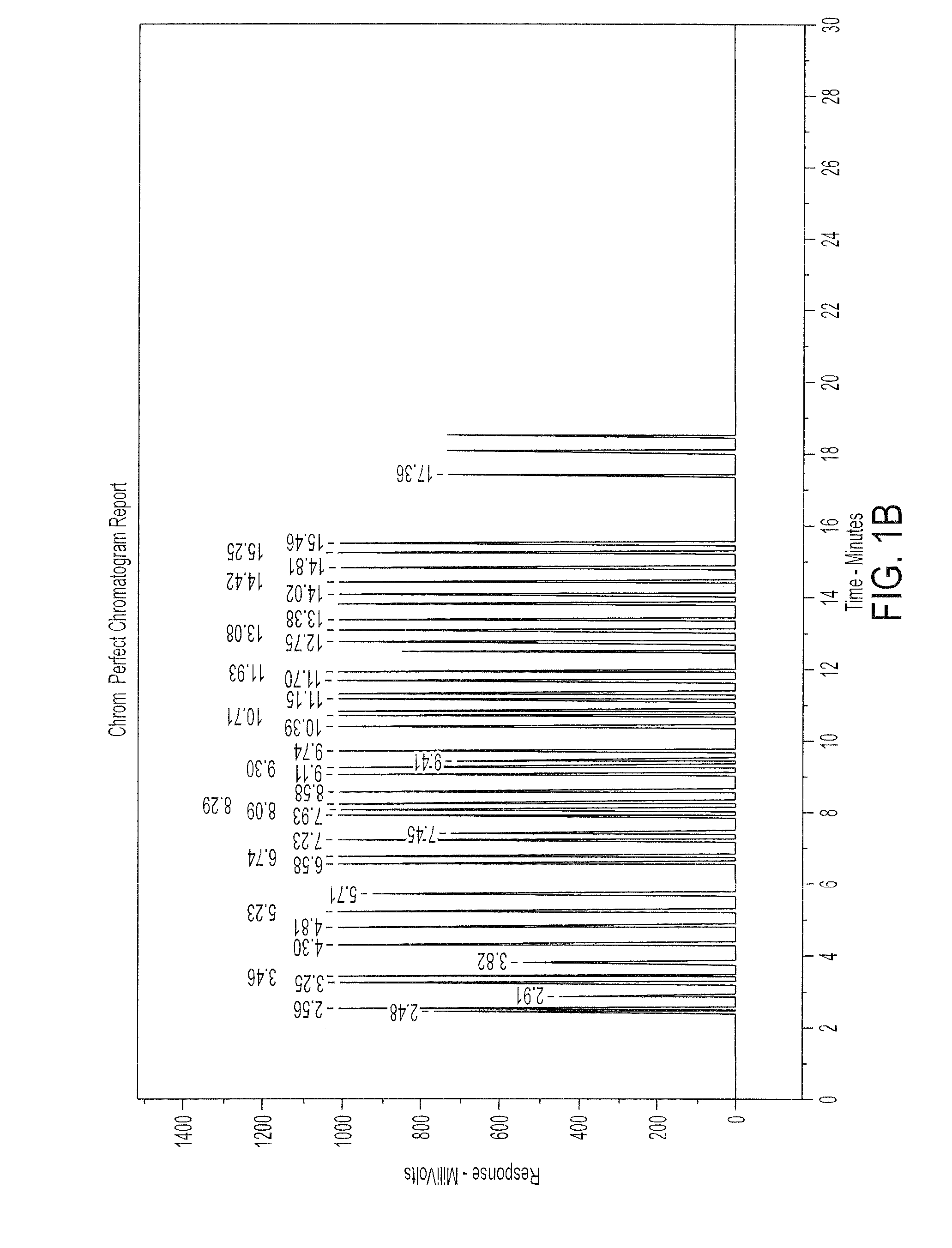

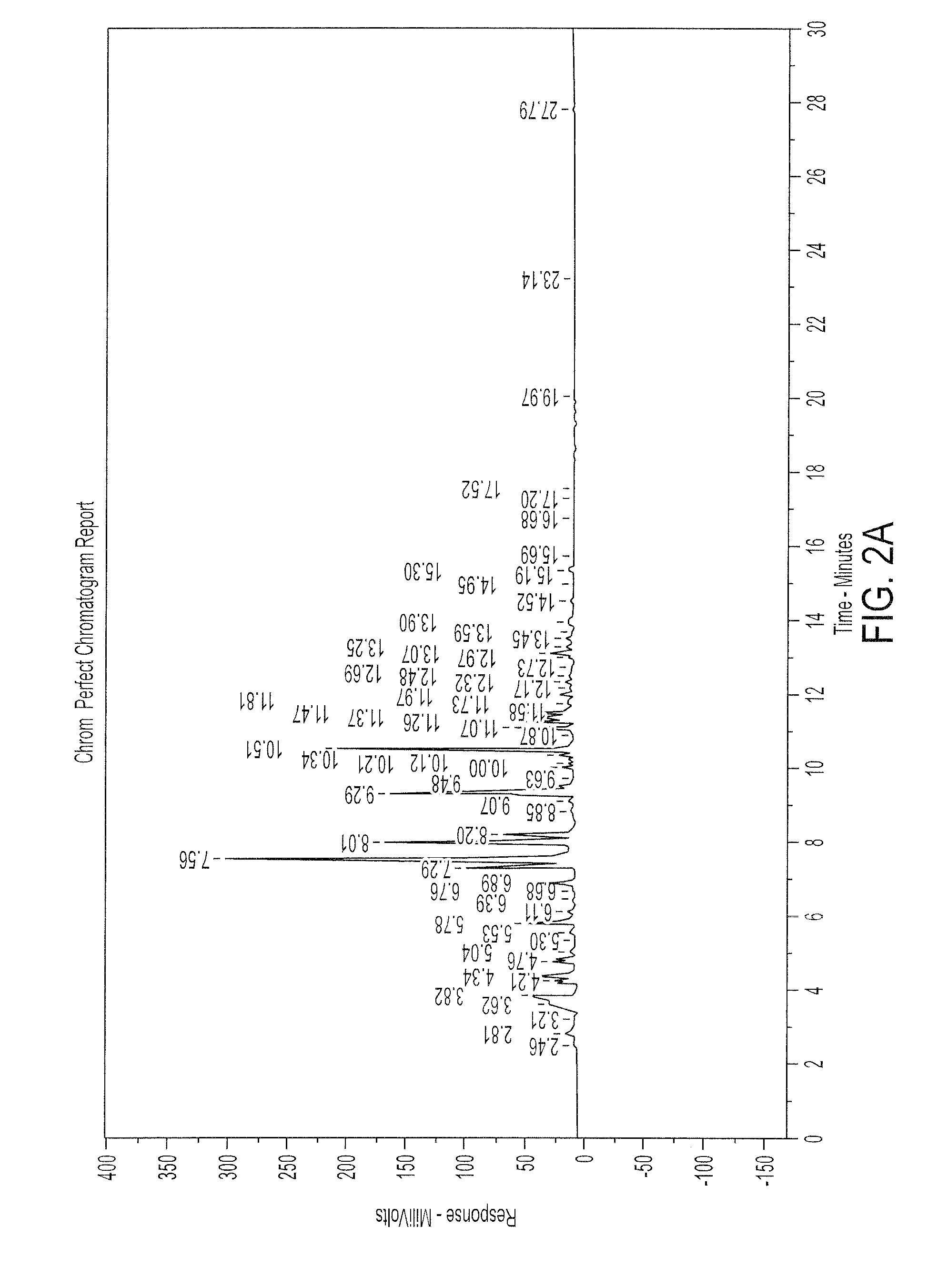

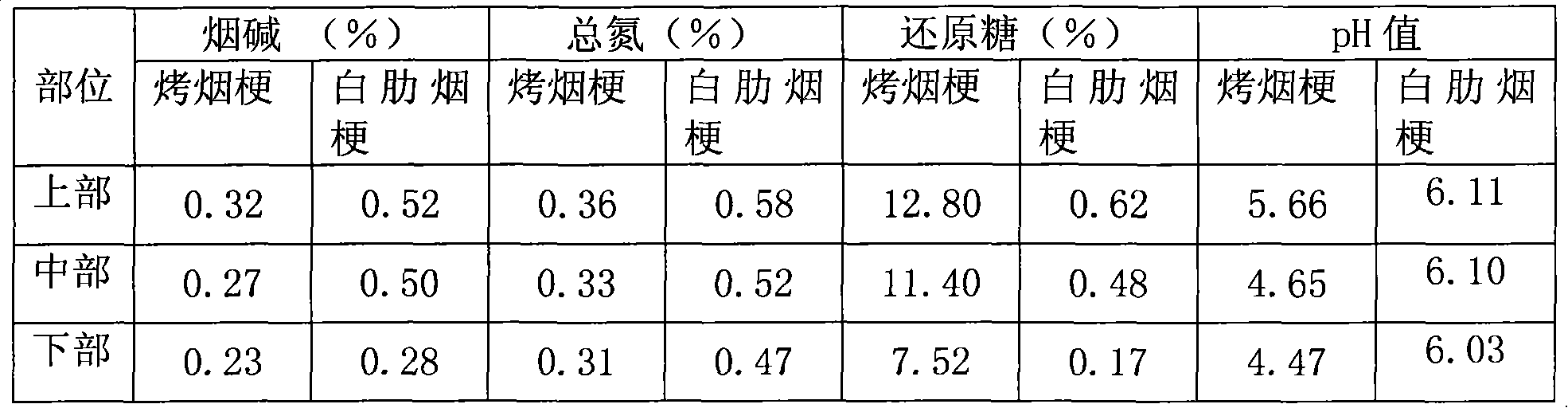

ActiveCN101305836AWide variety of sourcesAchieve expansionTobacco preparationTobacco treatmentTotal nitrogenSugar

The invention discloses a method for preparing expanded tobacco stem particles and the equipment thereof. The method is characterized in that the method can control the mixed ratio of tobacco stems on the basis of raw material analysis. The method comprises the following steps: mixing materials to obtain tobacco stem containing 10 to 18%of total sugar, 8 to 16% of reduced sugar, 0.3 to 1.5% of nicotine, and 1.0 to 2.0% of total nitrogen, extracting, expanding, storing, regaining moisture, granulating, recovering, shaping, cleaning and air-sorting, flavoring, and balancing to obtain the required expanded tobacco stem particles. The invention eliminates the influences of material difference on the quality of the expanded tobacco stem particles to ensure the stability and the uniformity of the product quality, thus improving the utilization rate of the tobacco stem and further improving the production process of the expanded tobacco stem particles. The method has the advantages of simple, reasonable and easy process flow, stable equipment operation, high efficiency, low energy loss, and good application prospect.

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

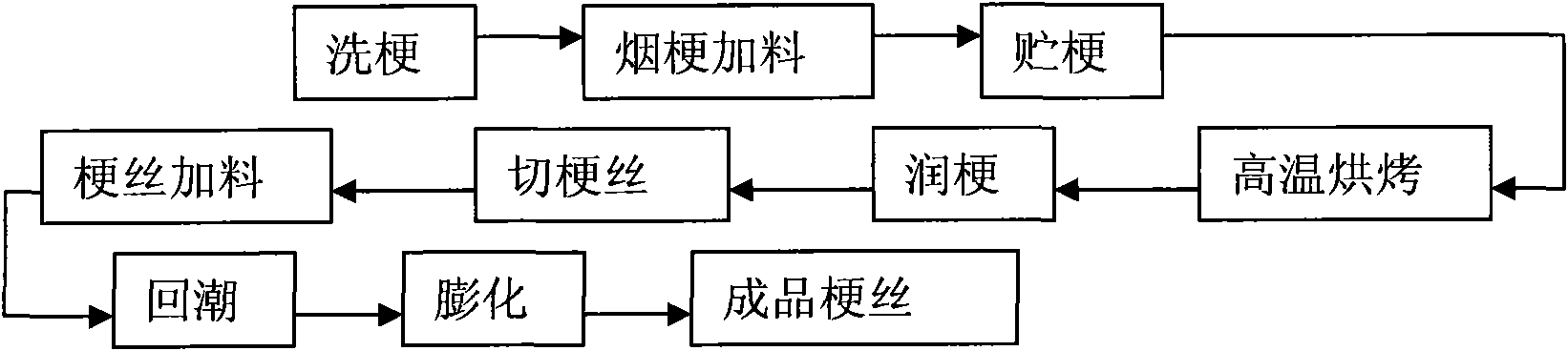

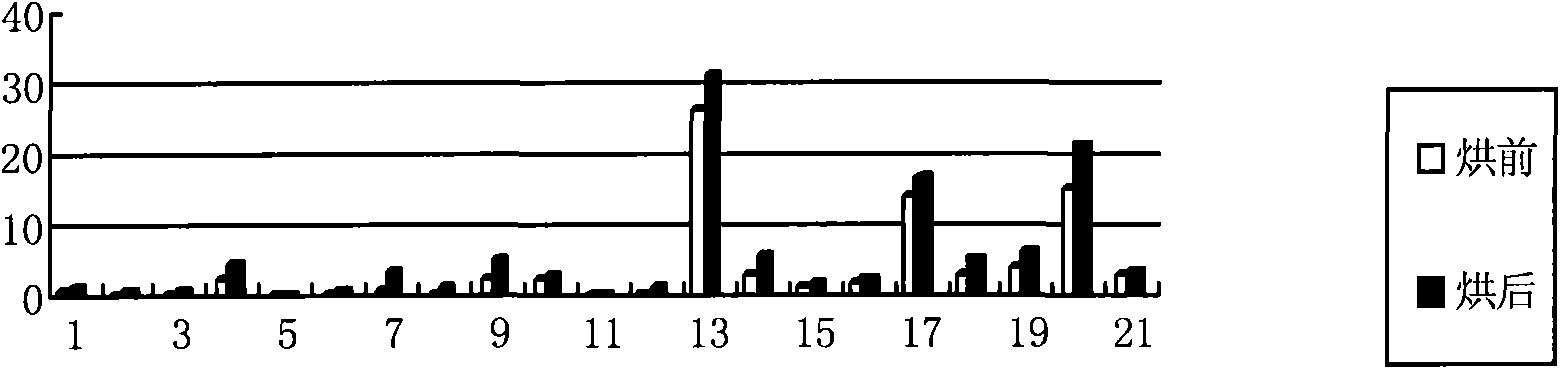

Method for processing burley stems into expanded cut stems

InactiveCN101611923AImprove flavor qualityDevelop raw materialsTobacco preparationTobacco treatmentNitrogenNicotine

The invention discloses a method for processing burley stems into expanded cut stems, which belongs to the technical field of cigarette processing. The method is implemented according to the steps in a sequence as follows: (1) washing burley stems; (2) adding materials to the burley stems for the first time; (3) keeping the burley stems added with the materials in storage; (4) baking the burley stems at high temperature; (5) moistening and cutting the stems; (6) adding the material to the cut burley stems for the second time; (7) moistening again; and (8) expanding, wherein the expanded burley stems are finished cut stems. The method has the advantages of improving the quality of the smoking smell of the burley stems, transforming too high nicotine and various nitrogen-containing compounds in the burley stems into various aroma components, processing a large number of burley stems into the usable expanded cut stems, saving resources and developing a novel usable raw tobacco materials, along with scientificity, reasonability, simple operation and remarkable technical results.

Owner:HUBEI CHINA TOBACCO IND

A kind of processing method of tea drink with low bitterness and astringency and high catechin

ActiveCN102265953AAntioxidantAntioxidant delayTea extractionTea alkaloid content reductionCyclodextrinBitter tastes

The invention provides a processing method of high catechin beverage with low biter taste and belongs to the processing field of food. The processing method comprises the following steps of: 1) taking green broken tea, extracting three times continuously with water so as to obtain an extract liquid I, an extract liquid II and an extract liquid III; 2) coarsely filtering the extract liquid I, the extract liquid II and the liquid III so as to remove tea leaves; 3) respectively processing the extract liquid II and the extract liquid III by use of tannase so as to obtain the corresponding enzymolysis liquid I and enzymolysis liquid II; 4) mixing the extract liquid I, the enzymolysis liquid I and the enzymolysis liquid II to obtain a tea mixed liquid; 5) performing film separation process on the tea mixed liquid so as to obtain clarified tea water; 6) adding VcNa and cyclodextrin into the clarified tea water for mixing so as to obtain the tea beverage; and 7) filtering, sterilizing and bulking the tea beverage to obtain finished products. The tea beverage obtained by the processing method is a green-yellow tea beverage, wherein the content of catechin is more than or equal to 800mg / l; and the tea beverage belongs to a functional tea beverage with pure taste and crisp mouth feel and without obvious bitter taste.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Brewing method of fruit-flavored dry red wine

ActiveCN105219574AOutstanding FeaturesHighlight significant progressMicroorganism based processesWine preparationHarvest timeSteeping

The invention discloses a brewing method of fruit-flavored dry red wine. The brewing method comprises such processing steps as determining a harvest time and harvesting, removing stems, sorting, crushing, extracting juice, cold-steeping, undergoing alcoholic fermentation with peels, separating peels and dregs, undergoing alcoholic fermentation with clear juice, storing, stabilizing, blending, freezing, sterilizing, filling and the like, so that produced dry red wine is intense, elegant and exquisite in fruit flavor, smooth and soft in taste, and is balanced and coordinated in wine body.

Owner:YANTAI CHANGYU PIONEER WINE CO LTD

Brewing method for ice grape wine

ActiveCN101144054AQuality assuranceGuaranteed continuityMicroorganism based processesWine preparationGrape wineFood flavor

The present invention discloses a brewing method of ice grape wine, and the method comprises the process steps of grape harvesting, pressing, ice grape juice storage, fermenting, ice grape wine storage, stabilization, refrigeration, degerming, filtering, and pouring, etc. The ice grape wine can be produced manually, the juice rate is high, the flavor quality is stable, the ice grape wine can not be fermented when being stored, and the quantity of the sulfur dioxide is lower.

Owner:YANTAI CHANGYU PIONEER WINE CO LTD

Shaddock vinegar preparation method

InactiveCN103173343AImprove flavor qualityFree laborMicroorganism based processesVinegar preparationFlavorEnzymatic hydrolysis

The invention discloses a shaddock vinegar preparation method. The method comprises the following steps: 1, washing fresh shaddocks, airing, mechanically peeling, and mechanically beating to obtain a fruit paste; 2, carrying out enzymatic hydrolysis of the fruit paste obtained in step 1, carrying out bitter removal clarification, and adjusting the sugar degree; 3, adding lactic acid bacteria for fermentation, and adjusting the acidity after fermentation ending; 4, adding microzyme for fermentation, and carrying out mash separation after fermentation ending; 5, adding acetic acid bacteria for fermentation to obtain raw vinegar; and 6, carrying out blending, fining clarification treatment, centrifuge and pulse electric-field low-temperature disinfection of the raw vinegar, and carrying out aseptic loading. In the invention, the characteristics of flavor substances comprising the lactic acid bacteria generating lactic acid and the like are fully utilized, and a suitable fermentation condition of the microzyme is created as possible, so the flavor quality of a product is enhanced; a mechanical fresh fruit pretreatment technology is adopted, so the labor force is avoided, the industrial application compatibility is strong, and the health condition and the cost are well controlled; and pulse electric-field low-temperature disinfection of a finished fruit vinegar is adopted, so the flavor loss is greatly reduced.

Owner:SOUTH CHINA UNIV OF TECH

Processing method of alcohol taste tea concentrated solution

The invention discloses a processing method of an alcohol taste tea concentrated solution. The processing method comprises the following steps: 1), crushing and screening tea; 2), extracting effective components in the tea by using a countercurrent extraction column to obtain extract liquid A and extract liquid B; 3), centrifuging the extract liquid A and the extract liquid B at high speeds to obtain supernatant liquid A and supernatant liquid B; 4), concentrating the supernatant liquid B through a reverse osmosis membrane to obtain concentrated liquid B; 5), hydrolyzing the concentrated liquid B by using complex enzyme to obtain an enzymatic hydrolysate B; 6), mixing the enzymatic hydrolysate B with the supernatant liquid A, and seasoning to obtain tea concentrated liquid; 7), sterilizing and filling the tea concentrated liquid to obtain alcohol taste tea concentrated liquid or further spray drying or freeze drying the tea concentrated liquid to obtain instant tea powder. The tea concentrated liquid processed by the method has the characteristics of fresh and mellow taste, light in bitter taste and good flavor quality.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

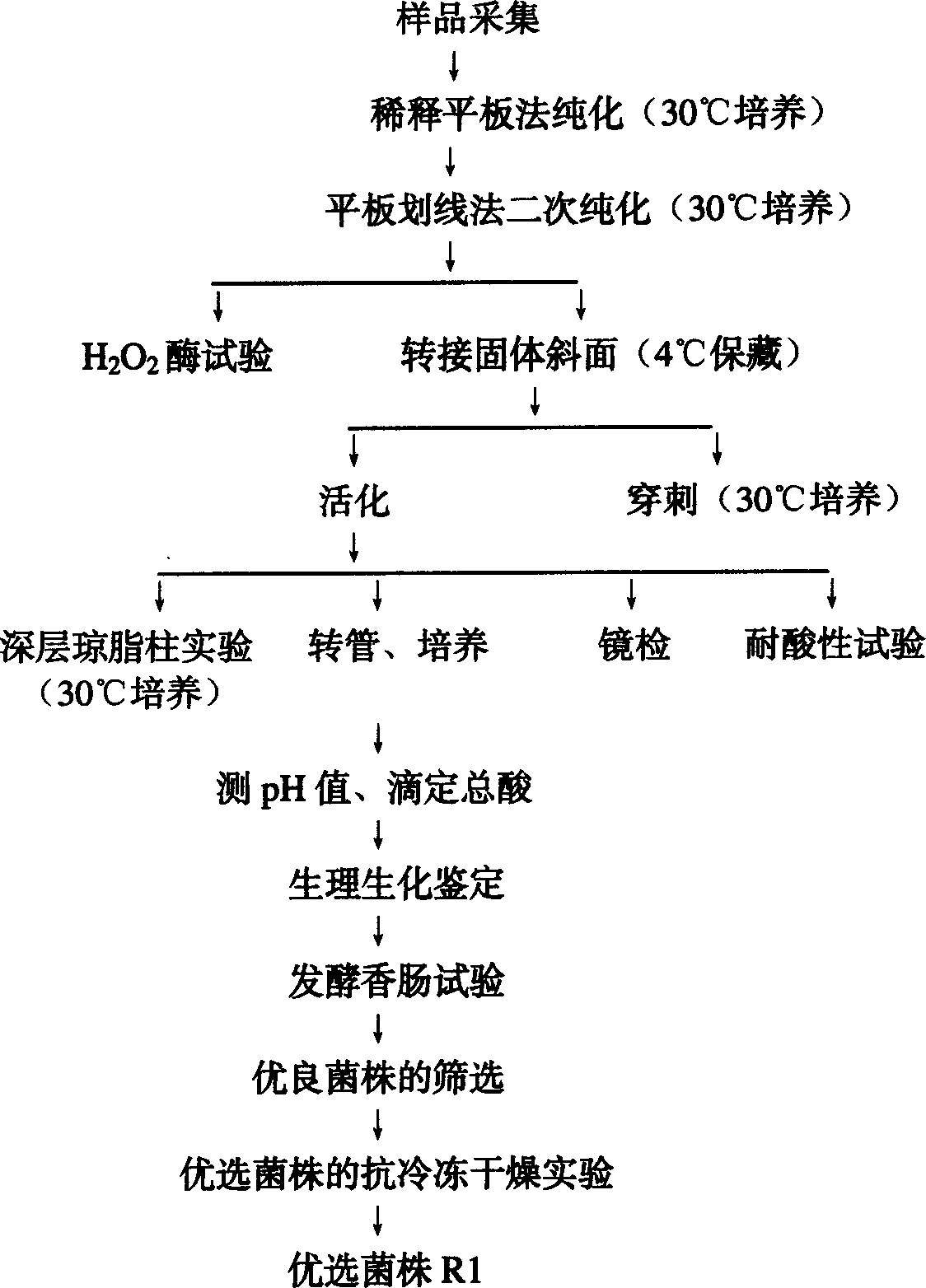

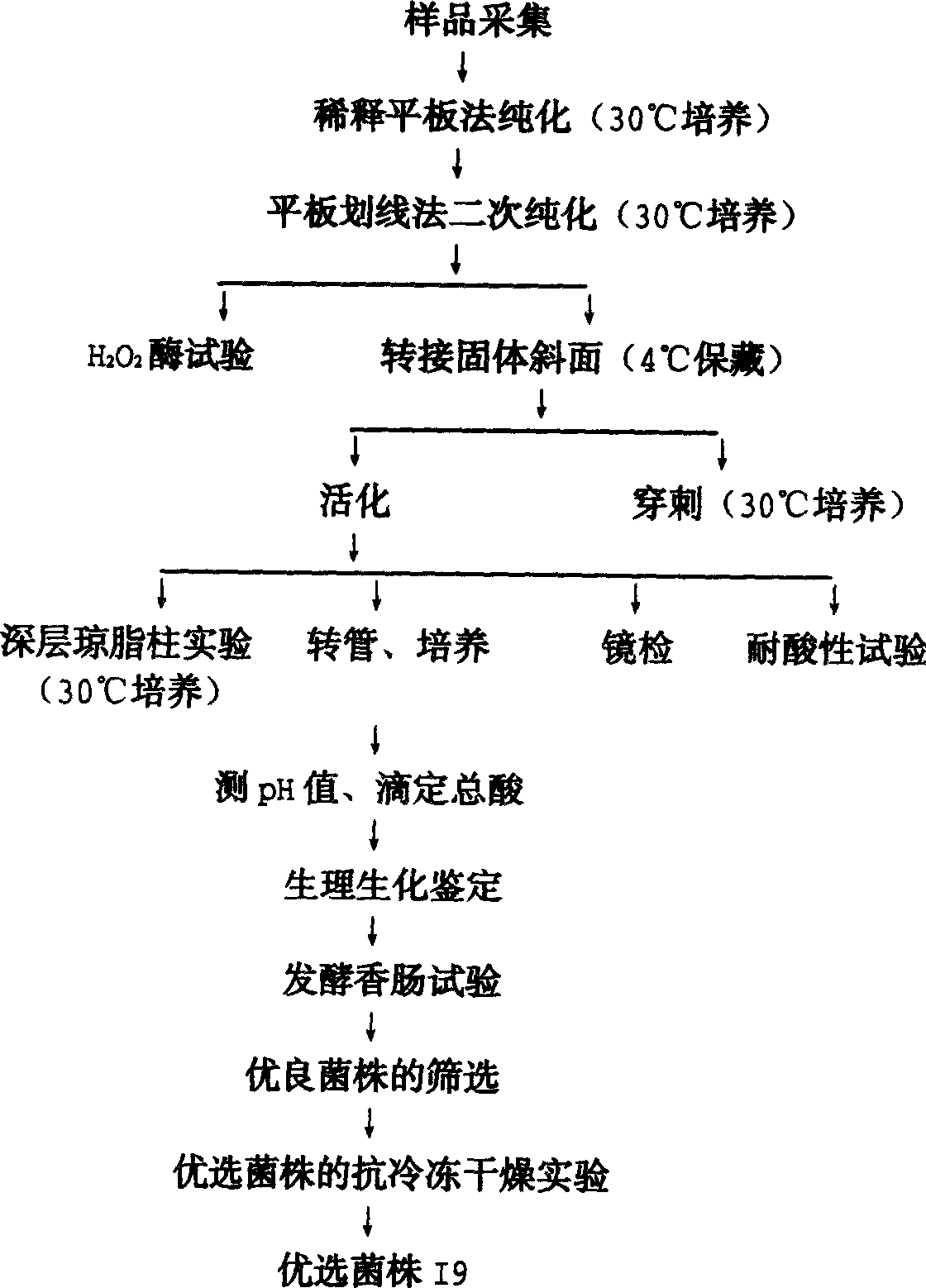

Lactobacillus pentosus strain, ferment produced thereby and the use of ferment in meat ware

The invention discloses a lactobacillus pentosus strain and ferment produced thereby, wherein the docket number of the R1(Lactobacillus pentosus R1) strain in the Chinese Microbiological Culture Preservation Administration Commission Common Microbiological Center is CGMCC No.0917. The pentose lactobacillus R1 strain of the invention can endure 4.0% salt solution and nitrite solution whose concentration is 80-100mg / L. The leaven prepared from the bacterial can be applied into the fermentation production of meat food.

Owner:河南双汇投资发展股份有限公司

Method for preparing pineapple peel residue fruit vinegar

InactiveCN101531965ASmooth and thick tasteSoft and refreshingMicroorganism based processesVinegar preparationCelluloseLactarius

The invention relates to a method for preparing pineapple peel residue fruit vinegar, which comprises the following steps: crushing pineapple peel residues to obtain a pineapple serum with granule diameters smaller than 5 millimeters; using 15 to 18 percent of sticky rice syrup to replace white sugar to adjust the mixed residue fermentation liquor sugar degree to 14 degrees Bx; adopting a mixed culture fermentation method of alcohol microzymes, flavor enhancing microzymes, lactobacilli, and the like to carry out alcoholic fermentation and acetic fermentation, and obtaining raw vinegar by aging; and blending the raw vinegar into a fruit vinegar drink by diluting and fermenting. The vinegar drink has smooth and dense mouth feelings, soft and tasty sourness and special faint scent taste of the pineapples and the sticky rice, and has no green odor and harsh taste of the conventional method, so the taste and the quality are obviously improved. In the period of the alcoholic fermentation, fermentation requirements can be achieved within only two days, and the fermentation cycle is obviously shortened. In addition, after the alcoholic fermentation, most celluloses of the pineapple peel residues are utilized, deposited residues are few, and the utilization rate of the peel residues is high. The method has the advantages of simple process, short production cycle and low energy consumption, and opens a novel technical approach to the high-value integrated processing and utilization of the pineapple peel residues.

Owner:GUANGDONG OCEAN UNIVERSITY

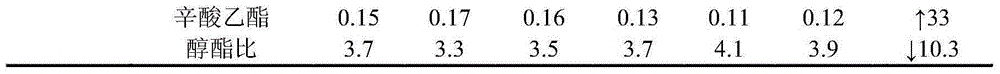

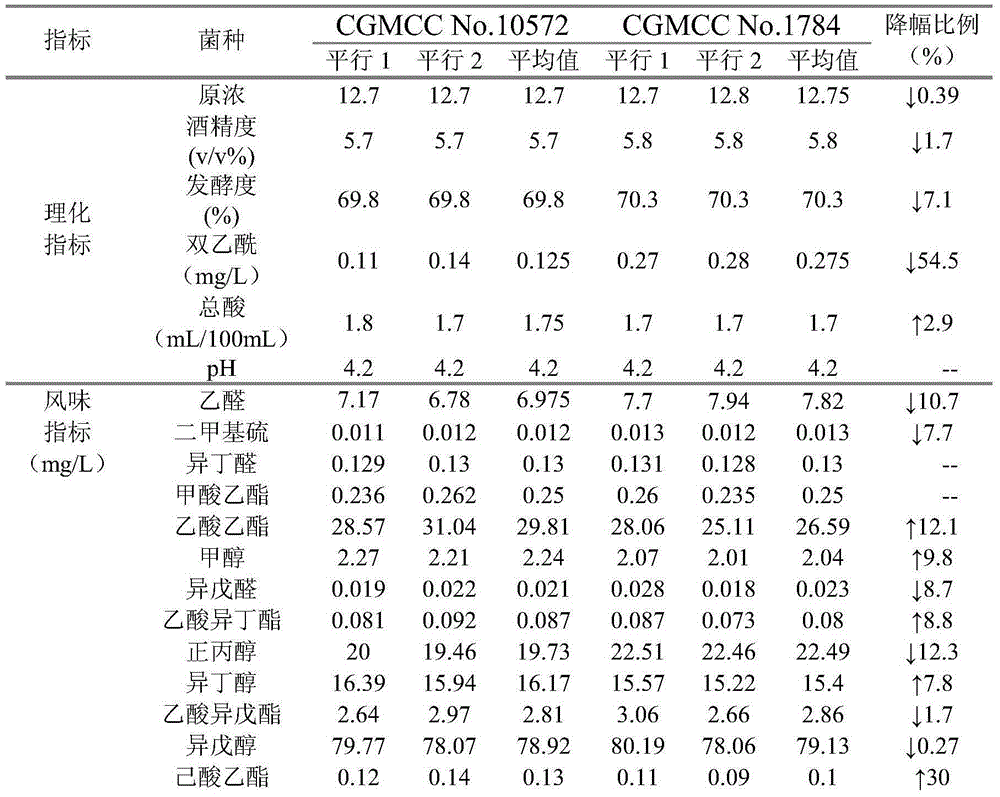

Saccharomyces cerevisiae mutant strain and application thereof

ActiveCN105018360AImprove reducibilityHigh substance contentFungiBeer fermentationMutant strainFlavor

The invention discloses a saccharomyces cerevisiae mutant strain and application thereof. The preservation number of the saccharomyces cerevisiae mutant strain is CGMCC 10572. Experiments show that the saccharomyces cerevisiae CGMCC NO.10572 can evidently enhance the reducing capacity of diacetyl, increase volatile ester content, lower higher alcohol content and increase beer flavor quality. The saccharomyces cerevisiae mutant strain has the advantages that a new method for applying space mutation to saccharomyces cerevisiae breeding is explored, and a precedent for applying space mutation breeding to beer production is set.

Owner:BEIJING YANJING BREWERY

Pediococcus pentosaceus strain, ferment produced thereby and the use of ferment in meat ware

The invention discloses a pediococcus pentosaceus strain, ferment produced thereby and the use of ferment in meat product, wherein the docket number of the R9(Pediiococcus Pentosaceus I9) strain in the Chinese Microbiological Culture Preservation Administration Commission Common Microbiological Center is CGMCC No.0918. The leaven prepared from the bacterial can be applied into the fermentation production of meat food.

Owner:河南双汇投资发展股份有限公司

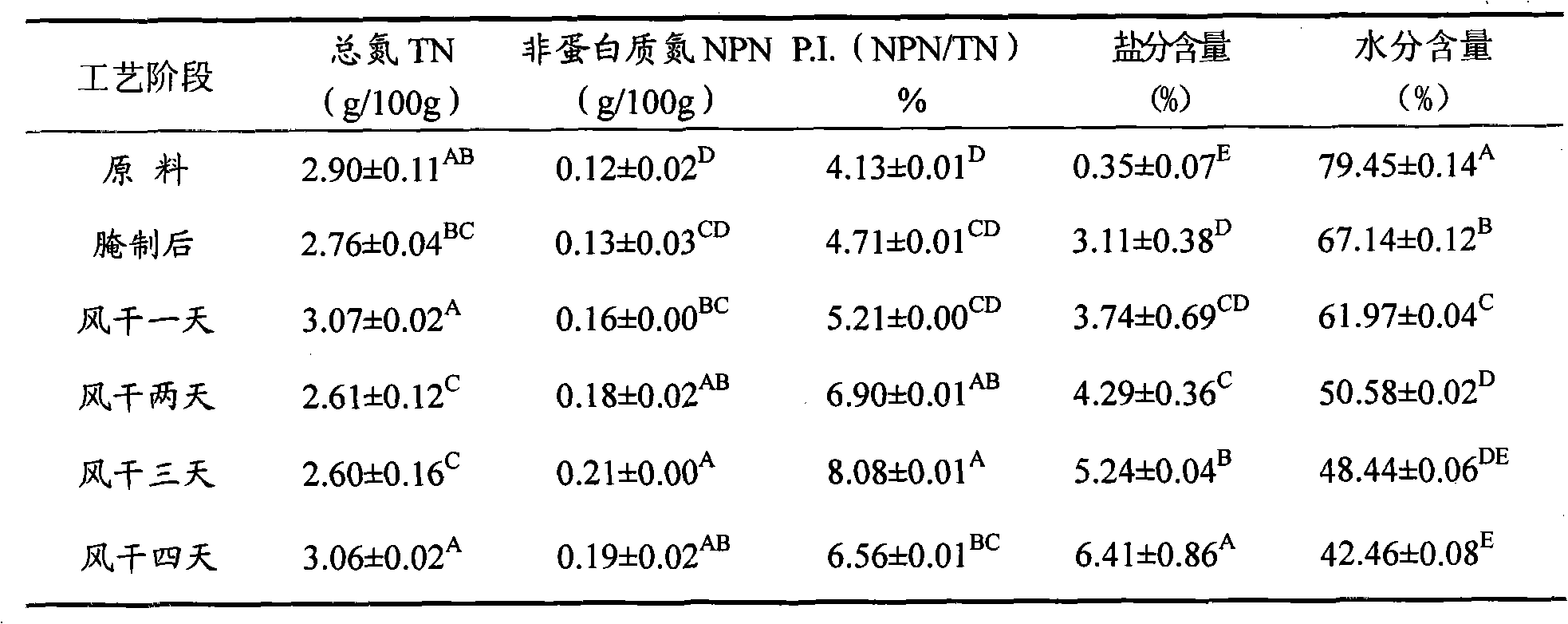

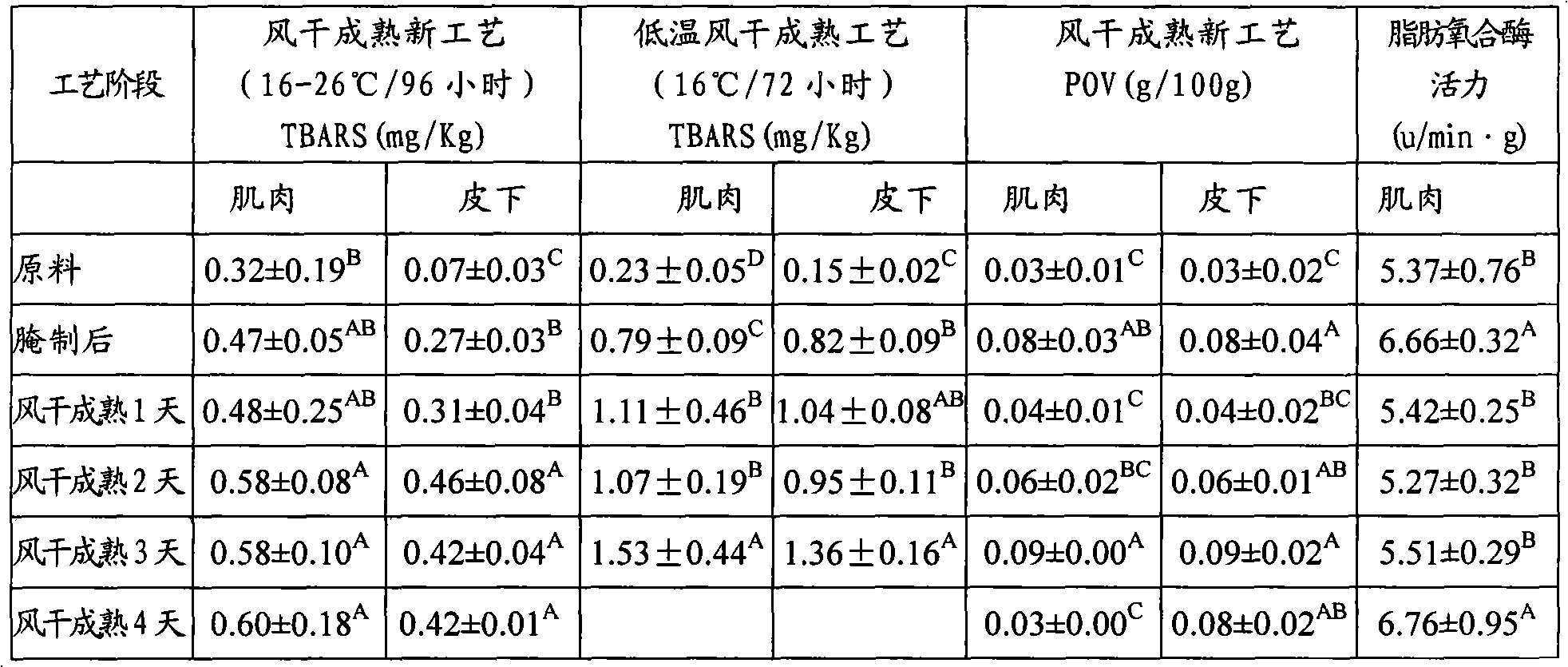

Air drying duck high-temperature maturation process

InactiveCN101254001AHigh activityImprove flavor qualityMeat/fish preservation using acidsFood preparationAdditive ingredientPeroxidase

The invention relates to a novel mature high-temperature air drying process of a dry duck, and belongs to the further processing technology field of animal products. The process includes the steps as follows: a raw ingredient duck is processed with the wet salting (in 3 to 8 DEG C for 18 to 24 hours) in salting liquor (that is NaCl of 10 to 13 percent); then the raw ingredient duck is air-dried to maturity for 3 to 4 days in a gradient temperature elevation way, wherein, the humidity is 55 to 63 percent RH, and the temperature is 13 to 28 DEG C, so that the finished product of the dry duck is obtained. The air drying maturing temperature adopted by the invention is obviously higher than the maturing temperature that is 8 to 10 DEG C in the industrial production of the dry duck at present; the endogenous peroxidase activity and the microbial growth in dry duck muscles can be adjusted through regulating the temperature and the humidity during the air drying maturing process; the decomposition and oxidation of the protein and the lipid in the product and the speed of flavor formation can be accelerated; the fat oxidation index is effectively lowered; based on retaining traditional characteristic flavor of the dry duck, the flavor quality of the dry duck product is effectively increased.

Owner:JIANGSU ZHONGNONG BIOTECH CO LTD

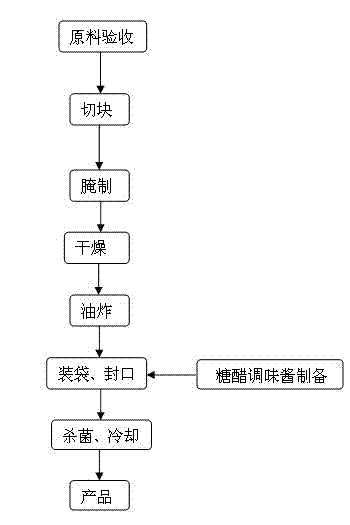

Processing method of instant sweet and sour fish capable of being preserved at normal temperature

The invention provides a processing method of instant sweet and sour fish capable of being preserved at normal temperature and relates to the technical field of food processing and preservation. Fresh and alive freshwater fish is used as a raw material, stripped and sliced, cured, dried, fried, packed, sealed in vacuum mode, sterilized and cooled to be manufactured into an instant sweet and sour fish food. The contemporary food drying and sterilizing processing technology is combined on the basis of a traditional sweet and sour fish manufacturing process to obtain the sweet and sour fish food capable of being preserved at the normal temperature, no chemical preservative is added in a machining process, the produced sweet and sour fish food can well maintain specific flavor, texture, color and nutritional quality of the traditional sweet and sour fish and is convenient and safe to eat, shelf life of the sweet and sour fish food at the normal temperature can reach above 12 months, requirements of consumers for safety, delicacy and convenience of contemporary food are met, industrial production is easy to achieve, and market prospect is wide.

Owner:劲仔食品集团股份有限公司

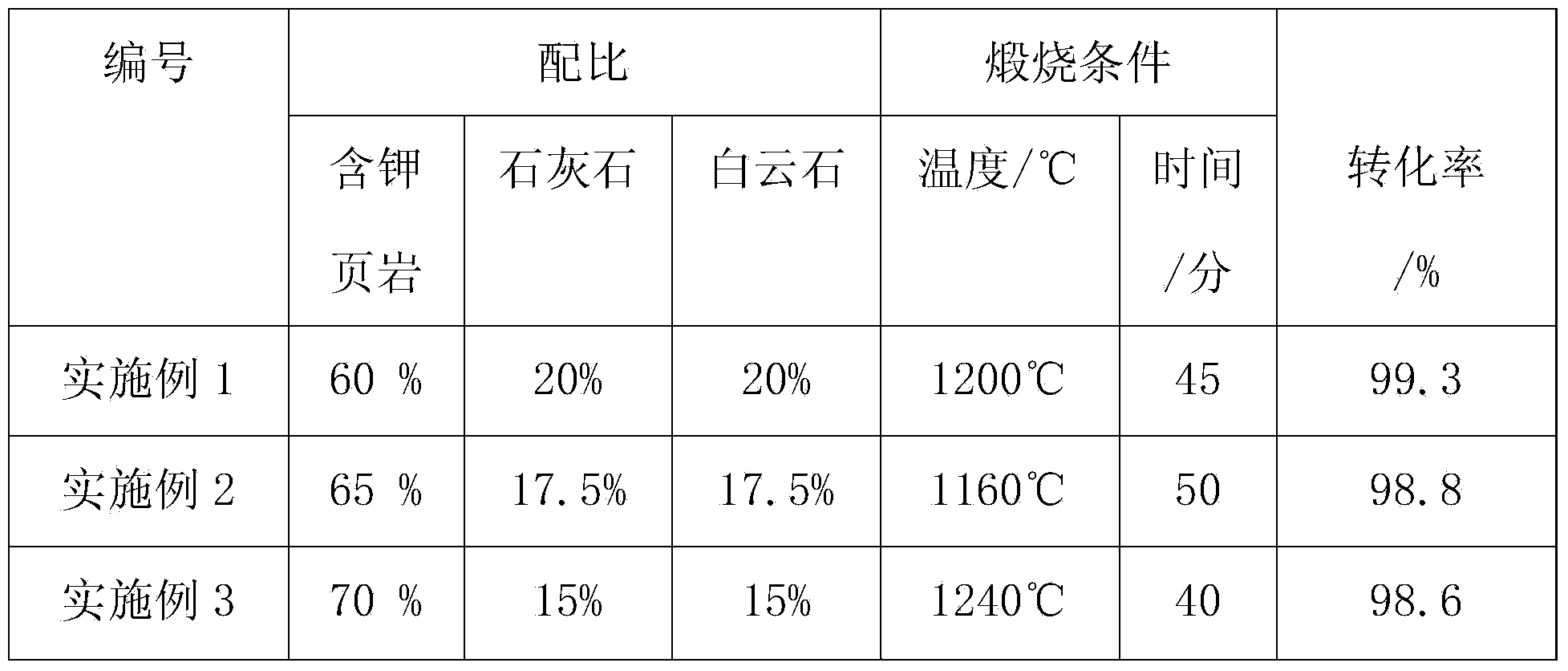

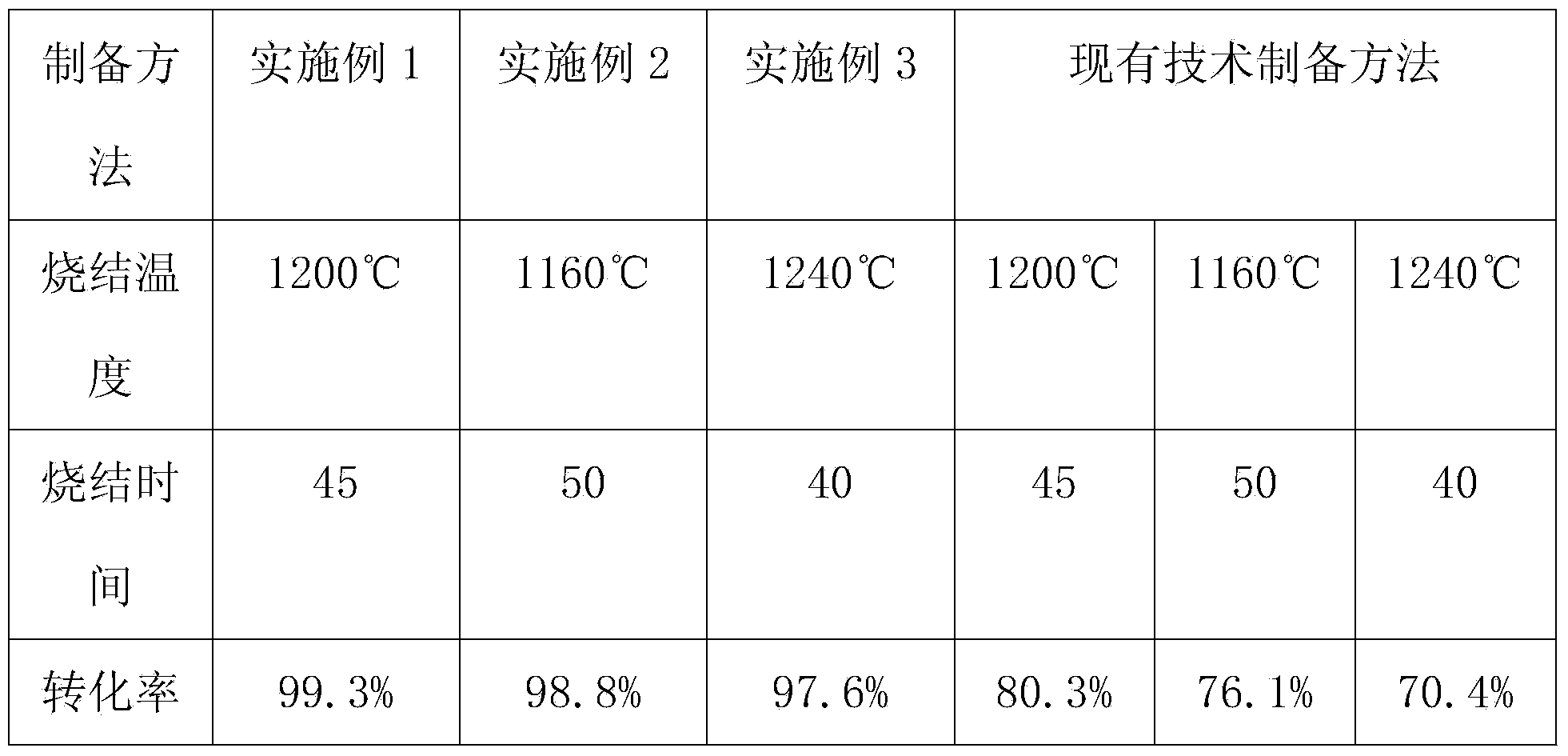

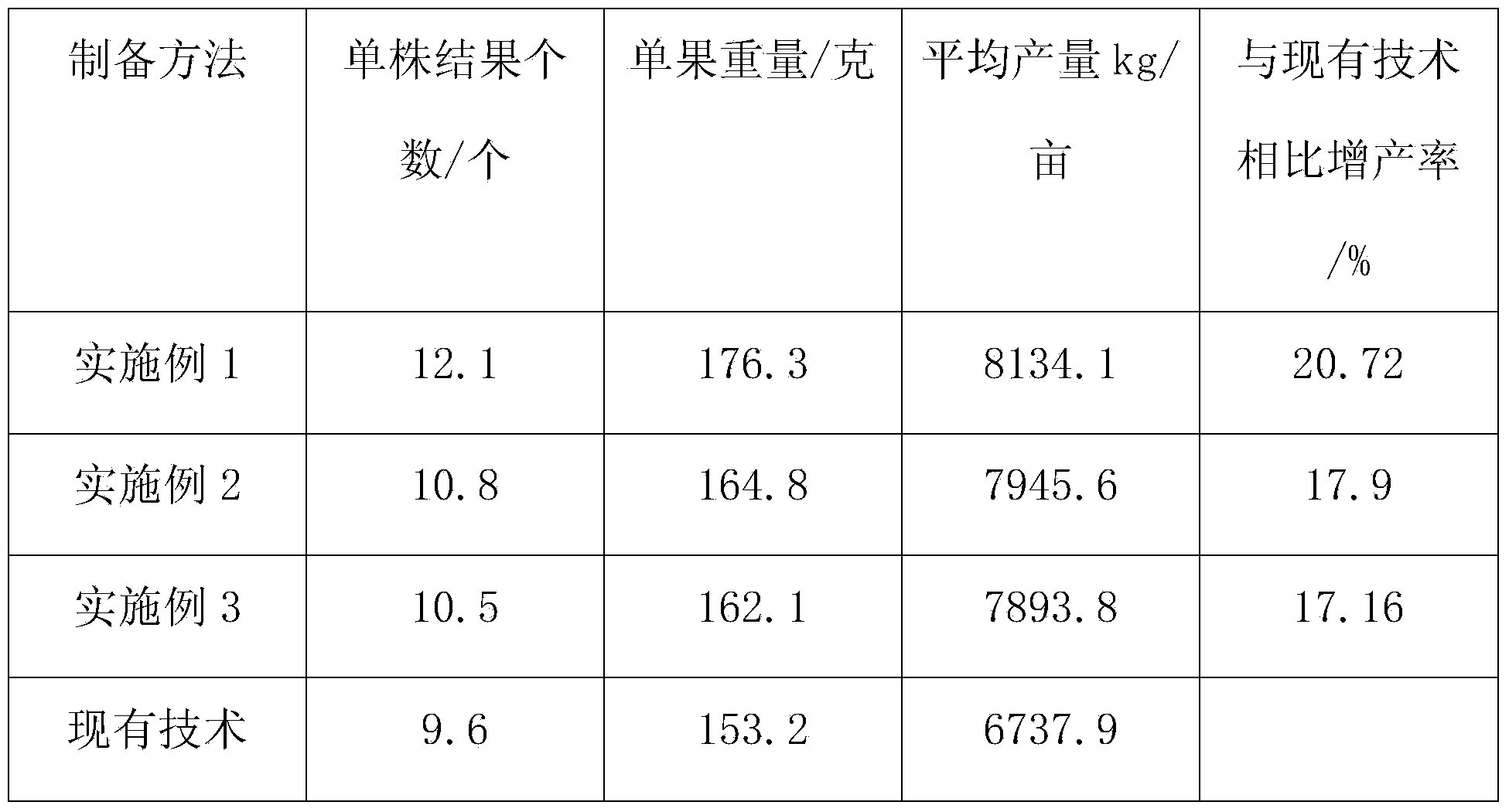

Method for preparing calcium-silicon-potassium-magnesium soil conditioner

ActiveCN104387206AImprove conversion rateImprove heat resistanceCalcareous fertilisersFertilizer mixturesPotassiumSilicon oxide

The invention provides a method for preparing a calcium-silicon-potassium-magnesium soil conditioner. The method comprises the following steps: A, preparing raw materials; B, grinding; C, calcining; D, water quenching; E, crushing; F, granulating; and G, drying. According to the preparation method, potassium-containing shale is utilized to prepare calcium-silicon-potassium fertilizer, so that potassium in the calcium-silicon-potassium fertilizer is sufficiently utilized as potassium fertilizer, and silicon oxide in the calcium-silicon-potassium fertilizer is sufficiently utilized to produce excellent silicon fertilizer; limestone and dolomite added into production are sufficiently utilized to produce calcium fertilizer and excellent soil conditioners; the raw materials are sufficiently utilized and converted into fertilizer, and the fertilizer cannot cause soil acidification, alkalization and hardening after being applied, the commodity quality and product quality of crops can be remarkably improved, and the crops have higher nutritional value.

Owner:HEBEI ZHONGRUI AGRI SCI & TECH

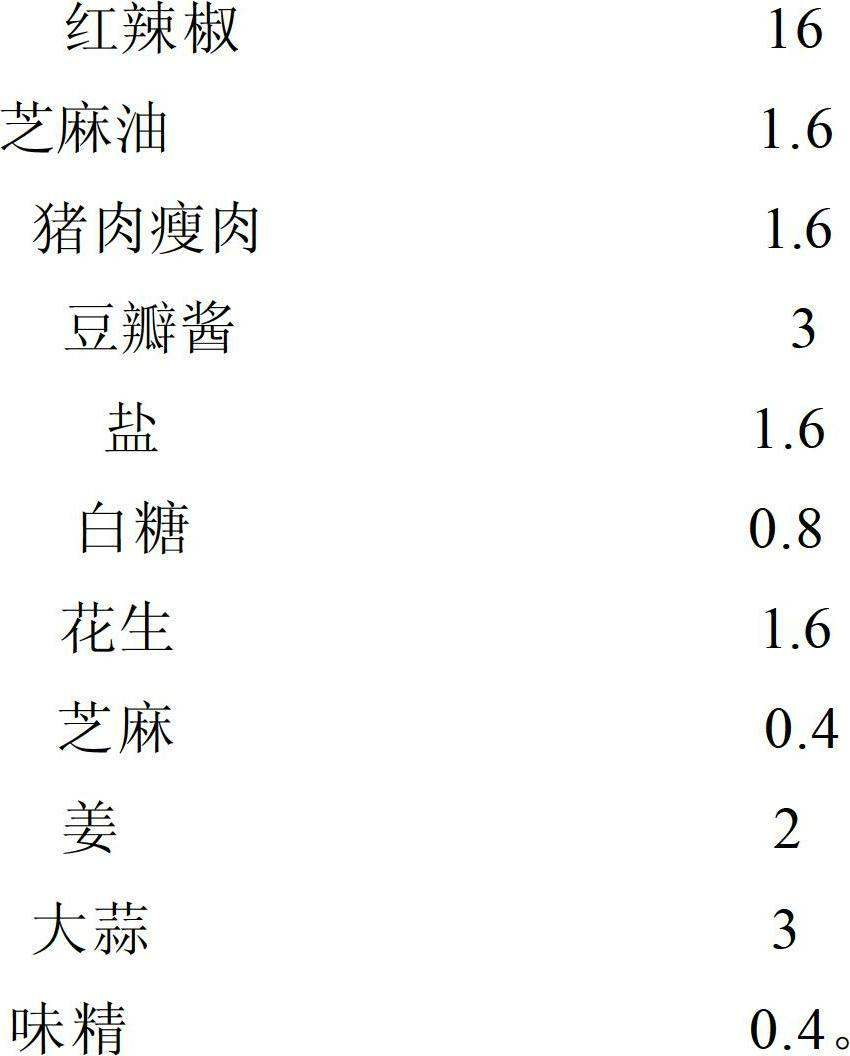

Chilli sauce and preparation method thereof

The invention relates to chilli sauce and a preparation method thereof, wherein the preparation method comprises the following steps of: heating sesame oil to 50-60 DEG C, adding pork lean meat, thick broad-bean sauce, water, red chilli, salt, white sugar, peanuts, sesame, ginger, garlic and monosodium glutamate, and stirring to be uniform so as to prepare the chilli sauce. The chilli sauce provided by the invention is mild in piquancy and has attractive rich color, meanwhile, the flavor is tasty because cooked peanuts and sesame are added, and the chilli sauce is good in color, fragrance andflavor; ginger and garlic enable the chilli sauce to be fresh and tasty, and the flavor is fragrant; the sesame oil enables the chilli sauce to be more rich in nutrition value, no non-natural component is contained, the chilli sauce is safe and healthy in eating, does not go bad after being preserved for around one year, not only is suitable for families, but also is suitable for enterprise production; and compared with the chilli sauce sold in the market, the chilli sauce has a qualitative leap in the aspects of color, fragrance and flavor, safety and controllability and the like. In the rawmaterials provided by the invention, garlic and ginger are natural preservatives, not only can realize effective corrosion resistance, guarantees the food safety, and increases the flavor quality, but also has the efficacies of oxidation resistance and cancer resistance and the like.

Owner:DALIAN NATIONALITIES UNIVERSITY

Processing method of Dendrobium officinalis leaf tea beverage

The invention discloses a processing method of a Dendrobium officinalis leaf tea beverage and belongs to the technical field of Dendrobium officinalis leaf tea beverage processing methods. The processing method includes following process steps: spreading Dendrobium officinalis leaves; dewatering spread leaves by using hot air; twisting dewatered leaves; drying twisted leaves; crushing and separately sieving Dendrobium officinalis leaves; extracting dried leaves of Dendrobium officinalis; extracting green tea; performing tannase treatment on tea juice; compounding and blending Dendrobium officinalis leaf extract and the tea juice; after-treating the composite tea juice. By using the processing method, the Dendrobium officinalis leaf tea beverage which is good in flavor and high in quality and has various healthcare effects can be obtained.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

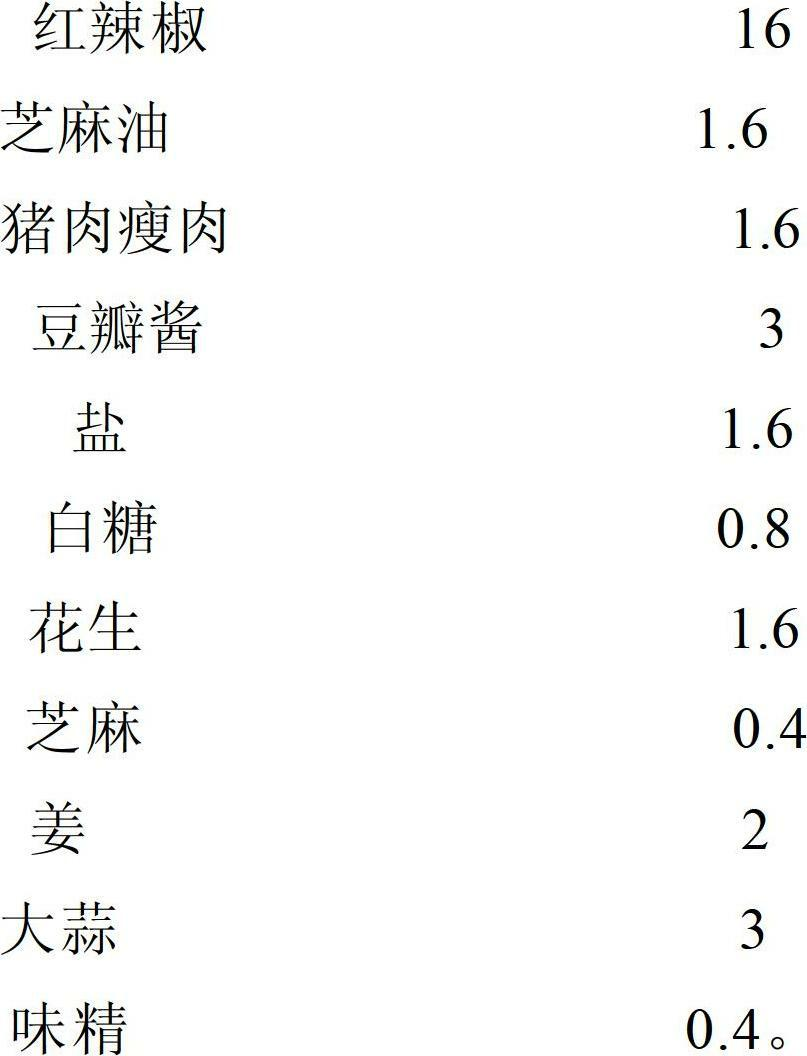

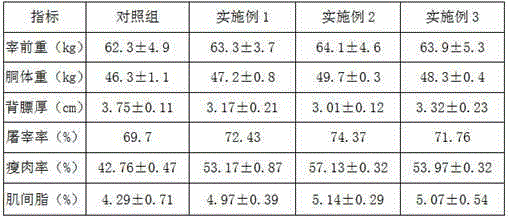

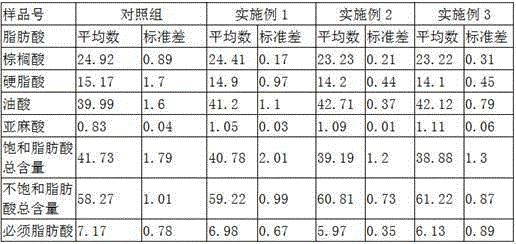

Additive for increasing lean meat rate and flavor of pork

The invention discloses a green additive for increasing the lean meat rate and flavor of pork. The green additive is prepared from, by mass, 95-98% of natural plant compound and 2-5% of microorganism complex microbial inoculants. The natural plant compounds are prepared from, by mass, 45-55% of pine needle meal, 15-20% of paper mulberry leaf powder, 10-15% of perilla leaf powder, 5-10% of mulberry leaf powder, 5-10% of Chinese arborvitae twig powder and 5-10% of tea leaf powder. The microorganism complex microbial inoculants are obtained by evenly mixing streptococcus faecium ferment, lactobacillus plantarum ferment and bifidobacterium bifidum ferment and carrying out low-temperature freezing and drying. By the adoption of the green additive, the backfat thickness of pork can be decreased, the lean meat rate can be increased, the fat percentage can be decreased, the muscle unsaturated fattyacid content and flavor amino acid content can be significantly improved, the purposes of improving the meat quality and improving flavor are achieved, and economic benefits are considerable.

Owner:KUNMING UNIV OF SCI & TECH

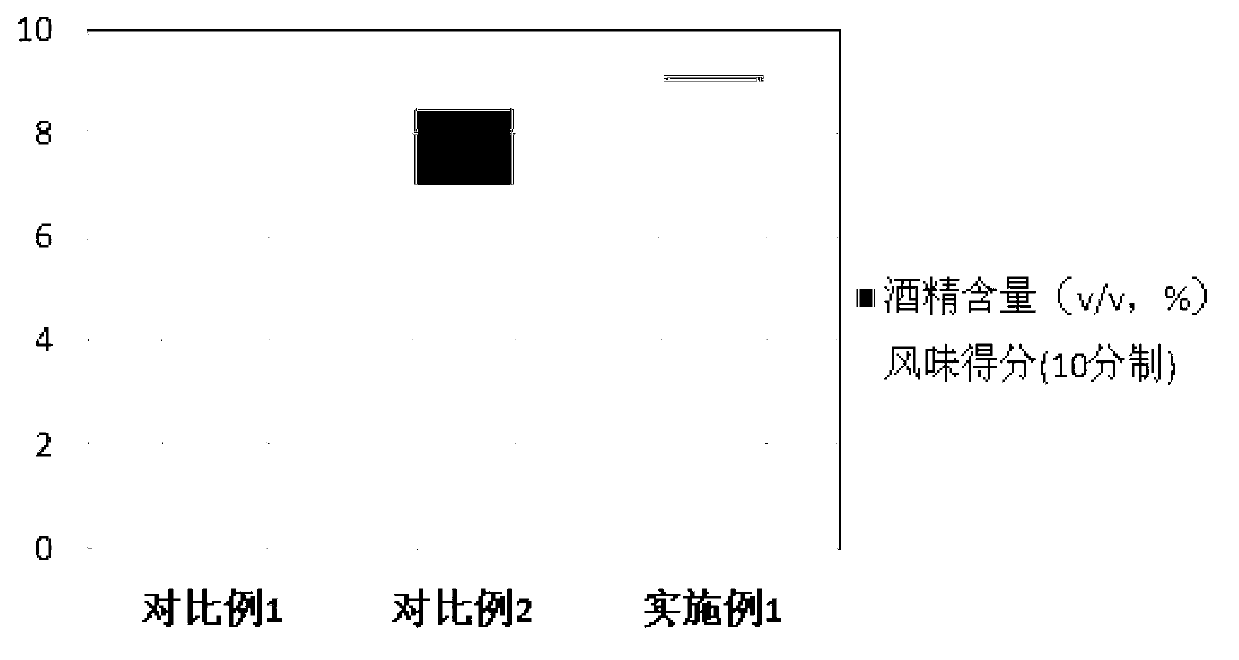

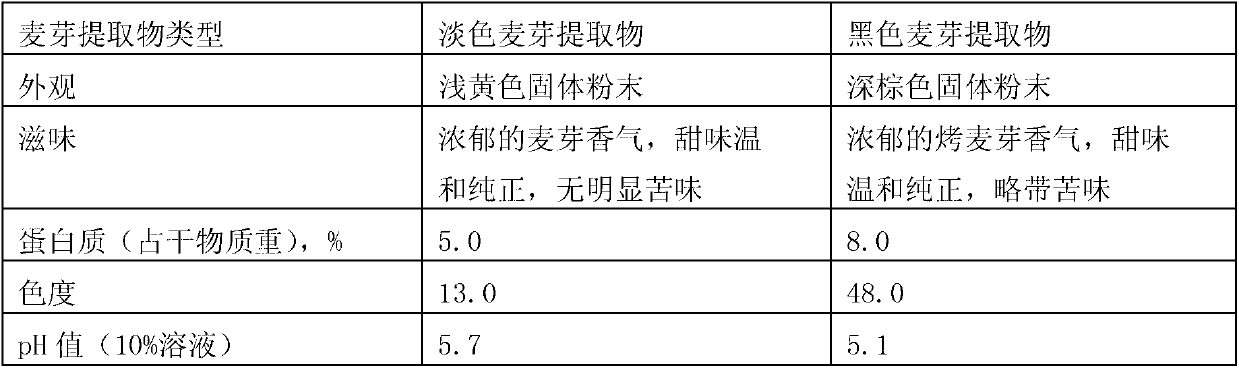

Kbac drink prepared by asynchronous fermentation technology and preparation method thereof

The invention relates to Kbac drink prepared by asynchronous fermentation technology and a preparation method thereof. The Kbac drink is prepared from the following raw materials: malt extract, lupulus, yeast, xylitol, white granulated sugar, citric acid, sodium citrate and pure water. The preparation method comprises the following steps of: adding alpha-amylase into the malt extract for saccharification; performing lactobacillus fermentation, and adding the lupulus; performing lactobacillus fermentation, adding white granulated sugar, xylitol, citric acid and sodium citrate, and mixing with pure water; and filtering and sterilizing to obtain the Kbac drink. Through the invention, the prepared Kbac drink has the advantages of pure mouthfeel, moderate sour and sweet taste, puckery taste and rich nutrition, prevents foreign smell and facilitates control on quality and mouthfeel.

Owner:山东朝能福瑞达生物科技有限公司

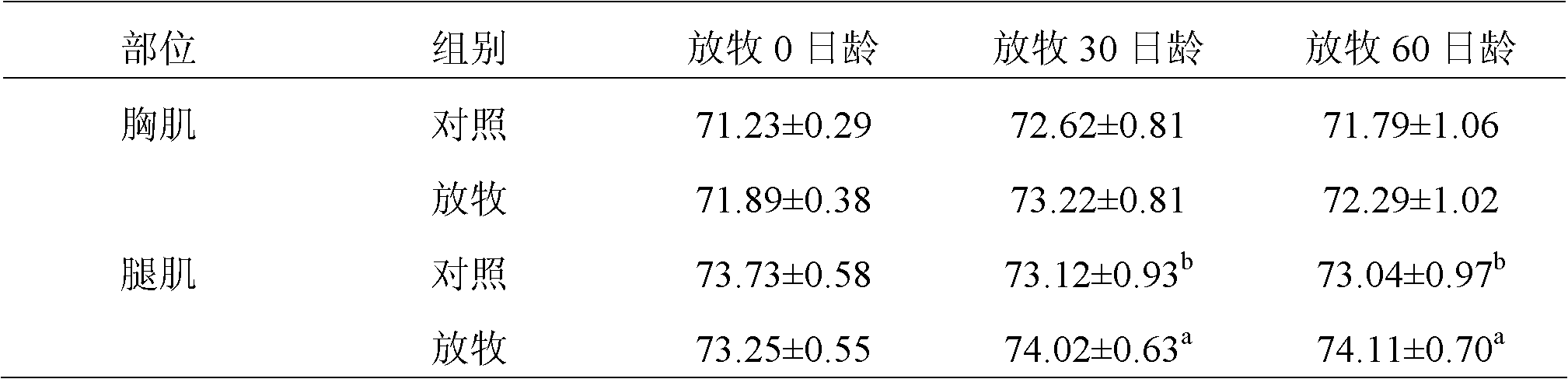

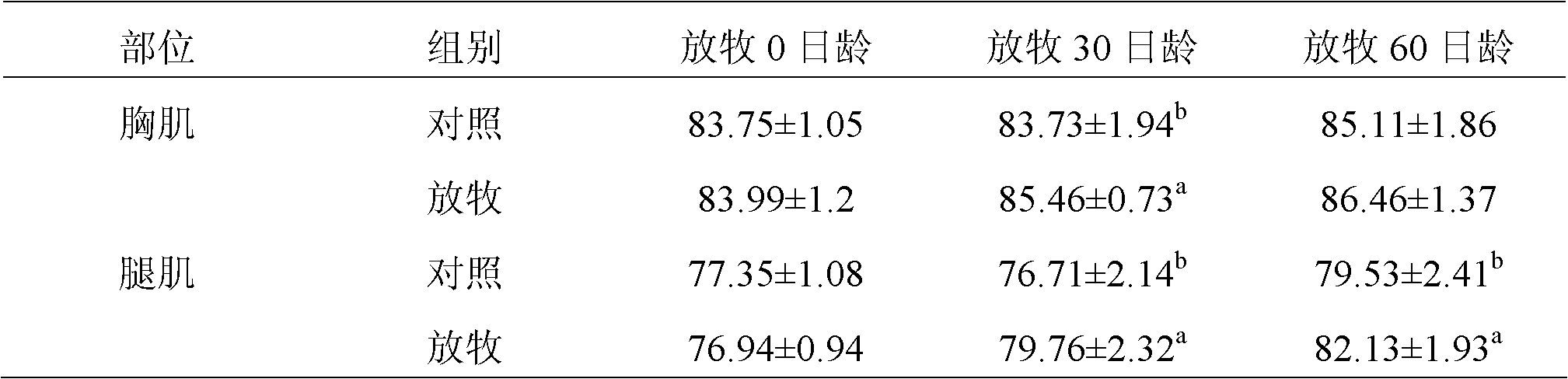

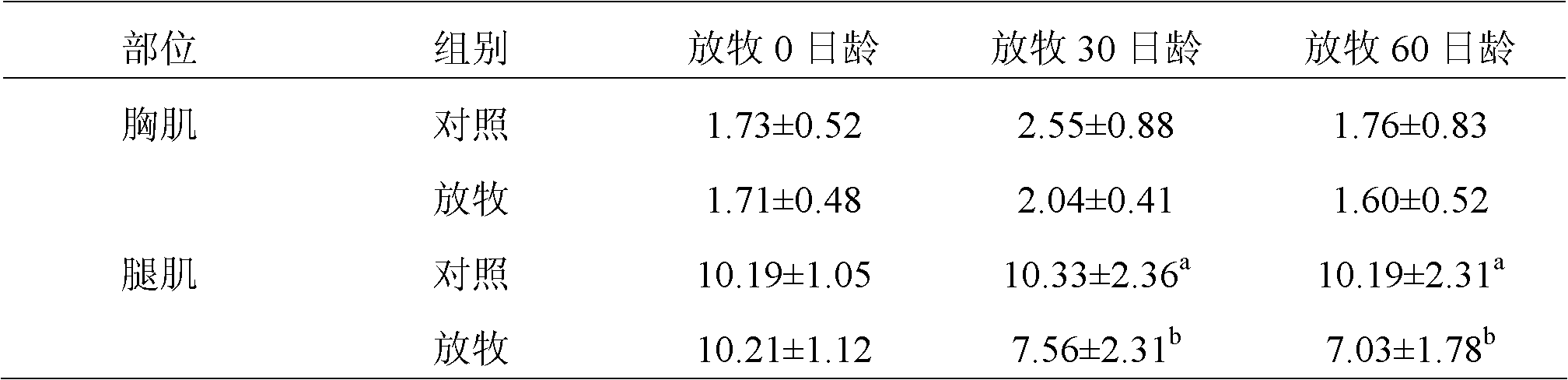

Cultivation method capable of improving flavor and quality of chicken meat

InactiveCN101971789AImprove survival rateImprove farming efficiencyAnimal feeding stuffGrazingFlavor

The invention discloses a cultivation method capable of improving the flavor and the quality of chicken meat and belongs to the field of animal husbandry in agriculture. In the method, a feeding process is divided into two stages: in the first stage, a high-density intensification cultivation mode is adopted, wherein chicken are fed in a plastic tent hen house during a period from the first day of age to the day when the weight of the chicken reaches market weight, the feeding density is 10-30 / m<2>, free choice feeding is adopted and the chicken drink freely throughout the day; and in the second stage, a low-density grazing cultivation mode is adopted, wherein when the weight of the chicken reaches the market weight, a grazing and supplementary feeding method is adopted, and the chicken are fed for 30-60 days, with the feeding density of 30-50 / mu. The two-stage broiler feeding method provided by the invention is favorable to the solving of the problems that chicken meat quality is decreased due to intensification cultivation at present, the survival rate is low, the cultivation cost is higher under a free broiler raising state, and the like, the improvement of the quality and flavor of the chicken meat and the increase of cultivation benefits.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Processing method for improving aftertaste sweet of tea drink

ActiveCN104351402AImprove the aftertasteSimple compositionTea extractionTea alkaloid content reductionAlcoholTannase

A processing method for improving the aftertaste sweet of a tea drink belongs to the technical field of processing methods of tea drinks. The method comprises the following processing steps: tea breaking, extraction, filtering, enzymolysis treatment, ultrasonic treatment, clearing, blending, sterilization and filling. According to the method, extraction is conducted for a short time at a low temperature, and then an extract is subjected to treatment with a compound enzyme consisting of tannase, esterase and glycosidase and ultrasonic treatment; the tea drink processed by the method has the characteristics of fresh, mellow and refreshing taste, good aftertaste sweet and the like.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Production method of capsule tea

InactiveCN103583741APreserve the flavorAvoid the Hassle of Traditional Brewing TeaPre-extraction tea treatmentTea extractionFreeze thawingMicrowave

The invention relates to a production method of capsule tea, and belongs to the field of tea processing technology. The method comprises the following steps: (1) classifying fresh tea leaves, removing non-tea impurities, stalling to green and withering; (2) processing the fresh tea leaves by low-temperature freezing and puffing or freezing-thawing microwave fragmentation; (3) then processing the tea leaves by high-temperature gas heating treatment or microwave fixation, rolling and cutting to obtain fixed rolling-cutting leaves; (4) squeezing 10% to 15% of the fixed rolling-cutting leaves to obtain tea juice; (5) drying the rest of the fixed rolling-cutting leaves primarily, embedding the dried leaves with the atomized tea juice obtained in step (4), drying secondarily, and far infrared heating to improve aroma; (6) alternatively blending with herbaceous plants, and carrying out far infrared heating to improve aroma; (7) packaging the products obtained by step (5) or (6) with plastic capsules to obtain capsule tea. The capsule tea produced by the invention is more stable in quality, convenient, healthy and professional, and adapts to the rhythm of modern life.

Owner:杭州抟翼科技有限公司

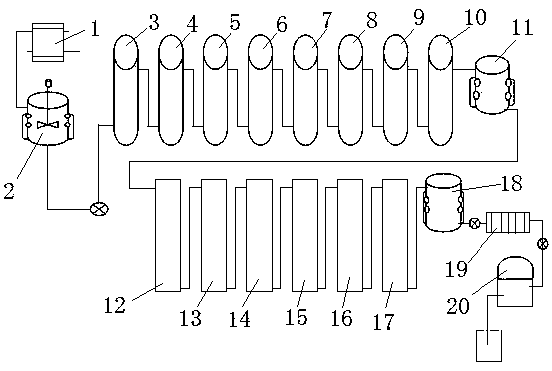

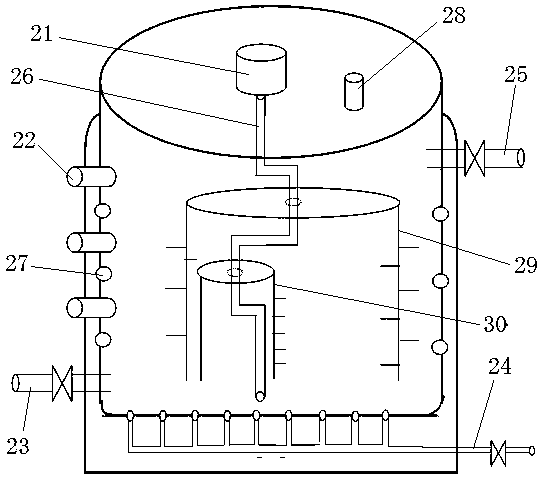

Method and equipment for improving quality of vegetable oil through continuous crystallization, crystal growing, and dewaxing refining

ActiveCN107746746ALess destructiveDestructiveFatty-oils/fats refiningFatty-oils/fats separationOil and greaseVegetable oil

A method and equipment for improving quality of vegetable oil through continuous crystallization, crystal growing, and dewaxing refining are disclosed. Oil and grease dewaxing is performed through eight-stage staged cooling crystallization, six-stage constant-temperature crystal growing, and two-stage low-temperature filtration. Special crystallization and crystal growing devices are adopted, interferences of transmission on crystallization and crystal growing processes are effectively solved as a whole, the heat conduction efficiency is higher, crystal damage caused by a transmission device and relative movement in an oil and grease system is less, energy consumption is lower, crystal dispersibility is significantly improved, and aggregation effects of wax, esters and high-melting-point fat are better. The method and the equipment can further improve dewaxing, winterization and dewaxing effects in crystallization and crystal growing processes of wax-containing vegetable oil, prolong oil product refrigeration time to 60 h or above, improve flavor and quality of oil and make oil palatability good. The method and the equipment are suitable for corn oil, sunflower seed oil, soybean oil, rice bran oil, and the like, and are particularly suitable for corn oil, sunflower seed oil, and the like.

Owner:SHANDONG XIWANG FOOD

Liquor mash preparation method based on multi-enzyme system and application of method in vinegar brewing

ActiveCN107034087AAlcohol conversion rate is highImprove conversion rateMicroorganism based processesAlcoholic beverage preparationCellulosePullulanase

The invention discloses a liquor mash preparation method based on a multi-enzyme system and application of the method in vinegar brewing. Sticky rice powder paste combines with a traditional yeast phase by utilizing multiple biological enzyme preparations such as alpha-amylase, pullulanase, saccharifying enzyme, cellulose enzyme, protease and lipase and a traditional yeast, enzymolysis is performed by adopting step-by-step adding method, and then liquor mash is prepared through alcohol fermentation. By adopting the method, raw and auxiliary material utilization rate is further improved based on liquid saccharification, the alcohol conversion rate is improved, the production cost is reduced, and meanwhile a product flavor obtained by adopting a traditional process is retained.

Owner:JIANGSU HENGSHUN VINEGAR IND

Method for preserving and ripening bananas

InactiveCN103503976AMature controlControl agingFruits/vegetable preservation by coatingFruits/vegetable preservation by freezing/coolingEconomic benefitsPre treatment

The invention relates to a method for preserving and ripening bananas. The method comprises the following steps: (1), harvesting raw materials which meet the harvest standards; (2), performing pretreatment before preservation by soaking fruits in a pretreatment agent; (3), treating with an edible coating agent; (4), treating the fruits with an ethylene absorbent; (5), packing the fruits with antifogging preservation bags; (6) preserving at an appropriate low temperature; (7), performing preservation-stage management; and (8), ripening before sale. The method provided by the invention prolongs the fresh-keeping period of banana fruit preservation to the greatest extent, greatly improves the commercial quality of bananas by the scientific and reasonable ripening technology, and increases the economic benefits.

Owner:HAINAN UNIVERSITY

Staphylococcus xylosus I2 strain, composite ferment produced thereby and the use of ferment in meat ware

The invention relates to an xylose staphylococcus I2 strain, whose docket number in the Chinese Microbiological Culture Preservation Administration Commission Common Microbiological Center is CGMCC No.0919, the leaven can be applied into the production process for meat product e.g. fermentation sausage.

Owner:河南双汇投资发展股份有限公司

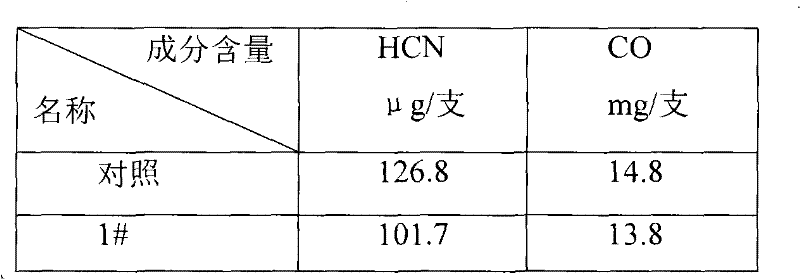

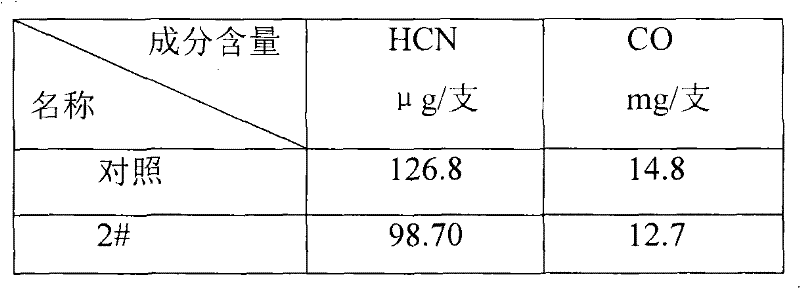

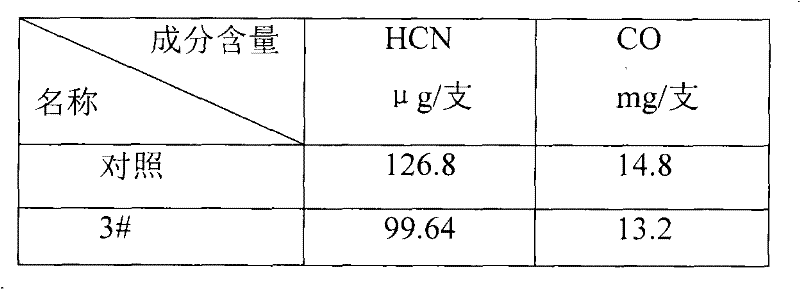

Preparation and adding methods of additive capable of reducing HCN and CO content of cigarettes

ActiveCN102125300AImprove qualityQuality and safetyTobacco treatmentBULK ACTIVE INGREDIENTActive ingredient

The invention discloses preparation and adding methods of an additive capable of reducing HCN and CO content of cigarettes. The additive for cigarette is prepared by a stage extraction or direct water extraction method, wherein thamnolia vermicularis asahina serves as a raw material. The adding method comprises the following steps of: fully stirring and uniformly dissolving one or more of the prepared first additive, the prepared second additive and the prepared third additive in 95 percent ethanol of which the weight is 5 to 20 times that of the additive; freezing the mixture for 5 to 15 hours at the temperature of between -5 and -20 DEG C; taking out and suction-filtering the mixture to obtain a filtrate; taking the filtrate of which the weight is 0.01 to 0.05 percent of that of tobaccoshreds, and adding the 95 percent ethanol until the total weight of the ethanol and the filtrate is 2 percent of the weight of the tobacco shreds; uniformly mixing the ethanol and the filtrate; uniformly spraying the mixture onto the tobacco shreds; and balancing the tobacco shreds for 48 hours under the conditions that the temperature is 22 DEG C and the humidity is 60 percent. An active ingredient is extracted from the thamnolia vermicularis asahina with excellent effects and serves as the additive. The additive is applied to the production of cigarettes to reduce the content of harmful components, namely HCN and CO, of the cigarettes.

Owner:云南瑞升香料技术有限公司

Enzymolysis method for processing tobacco stems

ActiveCN103070469ATotal production time reductionImprove efficiencyTobacco treatmentBiotechnologyAmylase

The invention relates to the field of cigarette processing, and discloses a tobacco-stem processing method for extracting fragrance by utilizing tobacco stems. The method comprises the following steps of: (1) stem-cleaning enzymolysis treatment: in stem cleaning, the tobacco stems and the stem cleaning water flow relatively; the mass ratio of the tobacco stems and the stem cleaning water is 1:10-100; stem-cleaning compound enzyme with the mass being 0.01-0.5% of that of the tobacco stems is added into the stem cleaning water, and the compound enzyme comprises pectinase with the mass fraction being 30-70% and xylanase with the mass fraction being 70-30%; (2) the stems are pressed and cut into stem silks; and (3) secondary enzymolysis treatment: hydrolyzed compound enzyme with the weight being 0.01-0.5% of that of the stem silks is added in the stem silks, and reaction is carried out for 0.5-2h; the hydrolyzed compound enzyme comprises protease, amylase, cellulose and hemicellulase with the weight ratio being 5-1:1:2:1. The method provided by the invention has the advantages that a part of cell wall materials can be effectively removed, the coordination of chemical components is achieved, the loss of aroma components in the soaking and enzymolysis process also can be avoided and the odor-absorbing effect is effectively improved.

Owner:CHINA TOBACCO GUANGDONG IND

Miracle fruit juice liquor and preparation method thereof

The invention relates to a Miracle fruit juice liquor and a preparation method thereof. The Miracle fruit juice liquor which is prepared through alcoholizing a Miracle fruit juice by a liquor, clarifying, filtering, and blending the obtained liquid with the liquor, sugar and softening water comprises, by weight, 15-30% of the Miracle fruit juice, 40-50% of the liquor, 6-10% of sugar, and the balance softening water. The Miracle fruit juice liquor of the invention, which has the advantages of stable flavor and quality, heavy unique fruit fragrance of the Miracle fruit and liquor fragrance, soft and pure taste, no addition of artificial chemical additives of antiseptics, pigments and the like, environmental protection, health, and complete reservation of original nutritive components of theMiracle fruit, is a nutrition health drink, and the production and the processing of the Miracle fruit juice liquor are no longer limited by the raw material seasonality, so the commercial value of the Miracle fruit is improved.

Owner:佛山市顺德区观圣生物技术有限公司 +1

Fine dried millet noodle

The invention discloses a fine dried millet noodle which comprises the following raw materials in parts by mass: 70-85 parts of millets, 3-10 parts of cowpea powder, 2-10 parts of soybean powder, 8-12 parts of wheat gluten, 1-3 parts of edible salt, 0.5-2 parts of edible alkali and 30-36 parts of water. The processing method of the fine dried millet noodle comprises the following steps of: (1) preparing and mixing the raw materials; (2) stirring flour; (3) curing the flour; (4) tabletting; (5) cutting the facets into strips, and drying the strips; and (6) packaging a certain quantity of strips to obtain the finished product. In the invention, millets with abundant nutrition are used as a main raw material, soybeans, cowpeas, wheat gluten and the like are used as auxiliary materials, and all the materials are processed into the fine dried noodle. Not only is a good approach provided for the eating of millets, but also the variety of fine dried noodle is enriched. Compared with the traditional fine dried noodle prepared from wheat as a main raw material, the fine dried millet noodle improves the flavor and nutrition quality of fine dried noodle. People's daily increasing demand for healthy, nutritive and diversified diets is satisfied to certain extent.

Owner:山西省农业科学院谷子研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com