Patents

Literature

86results about How to "Quality and safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electronic Vapour Inhalers

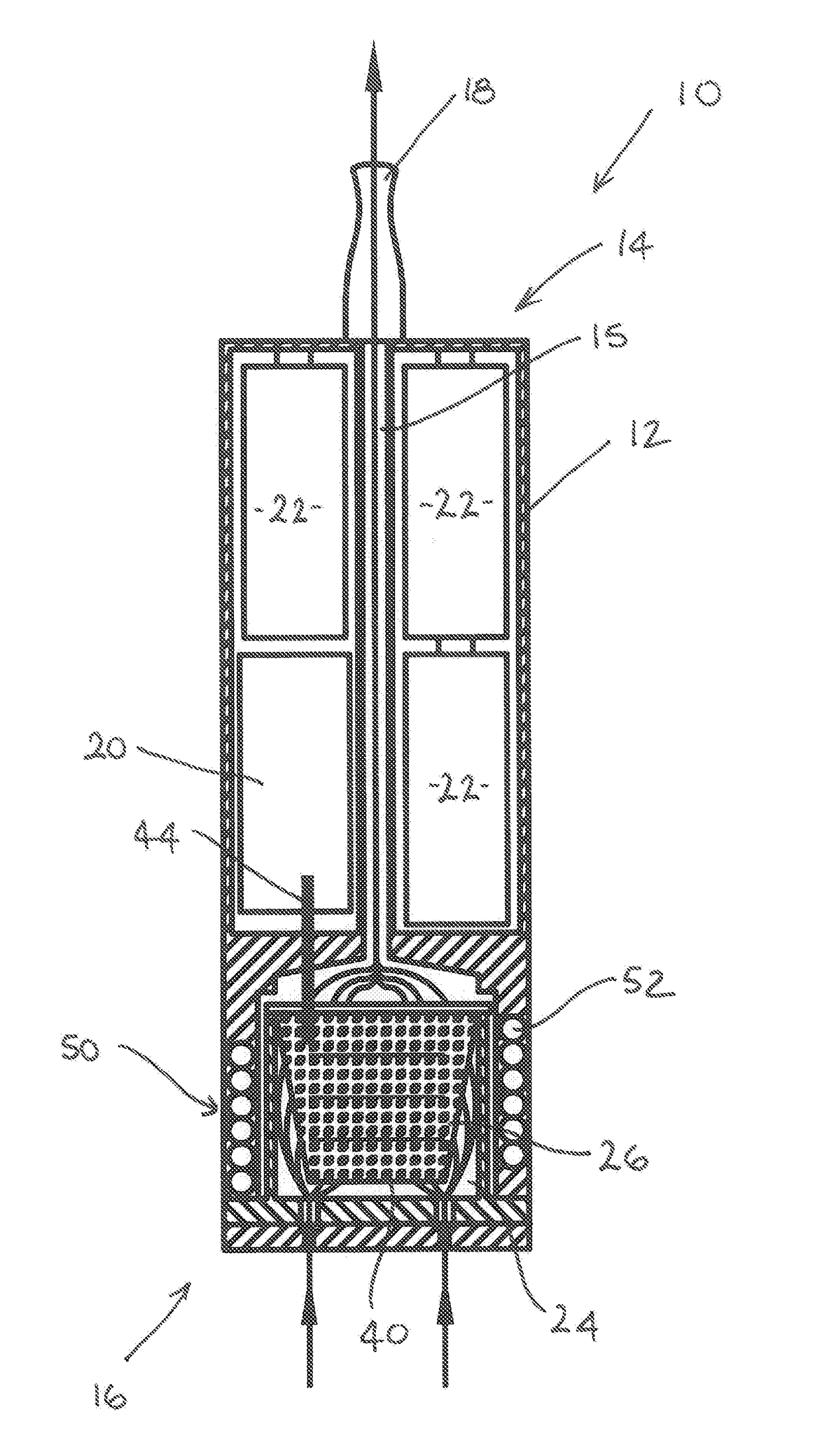

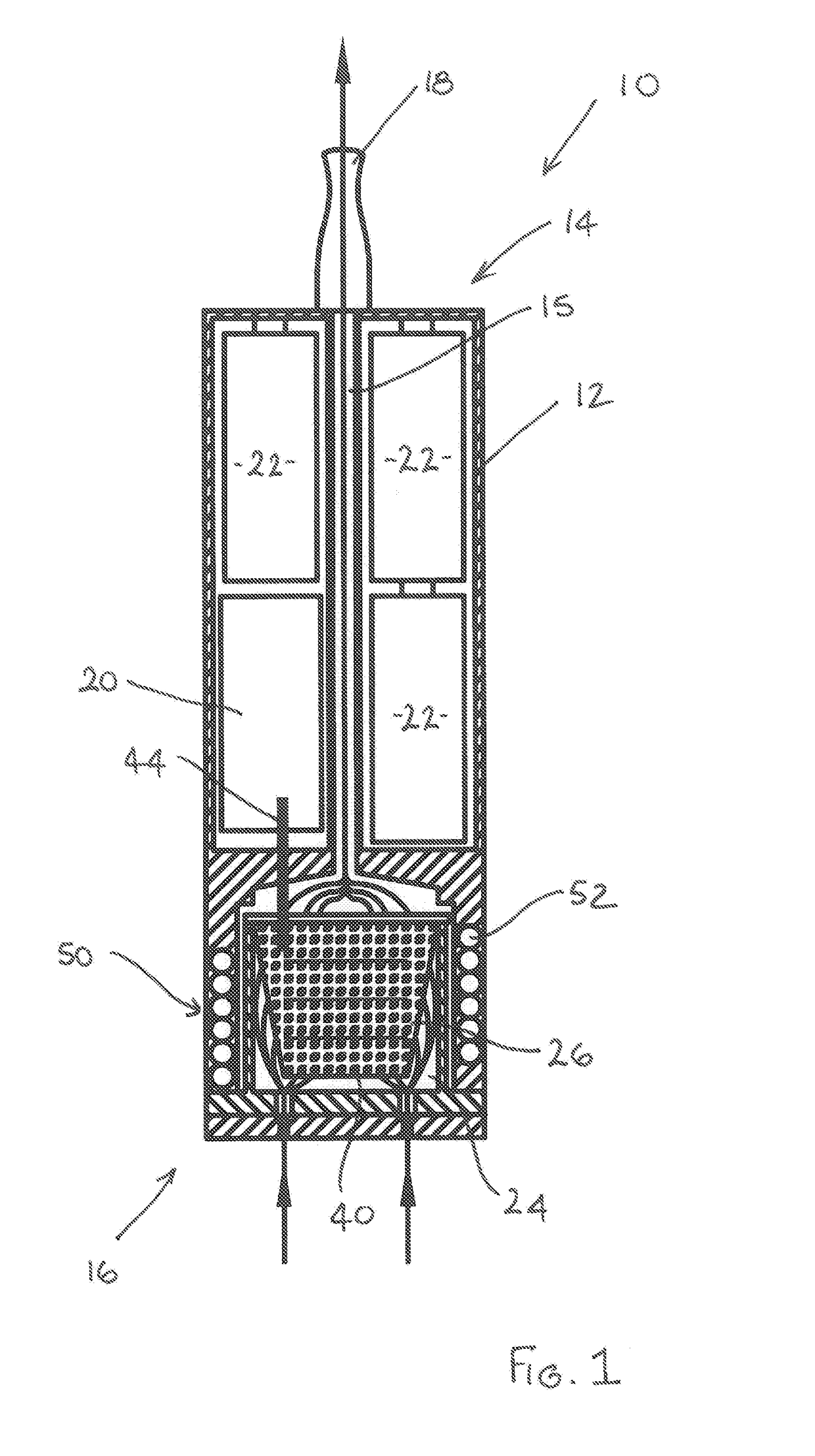

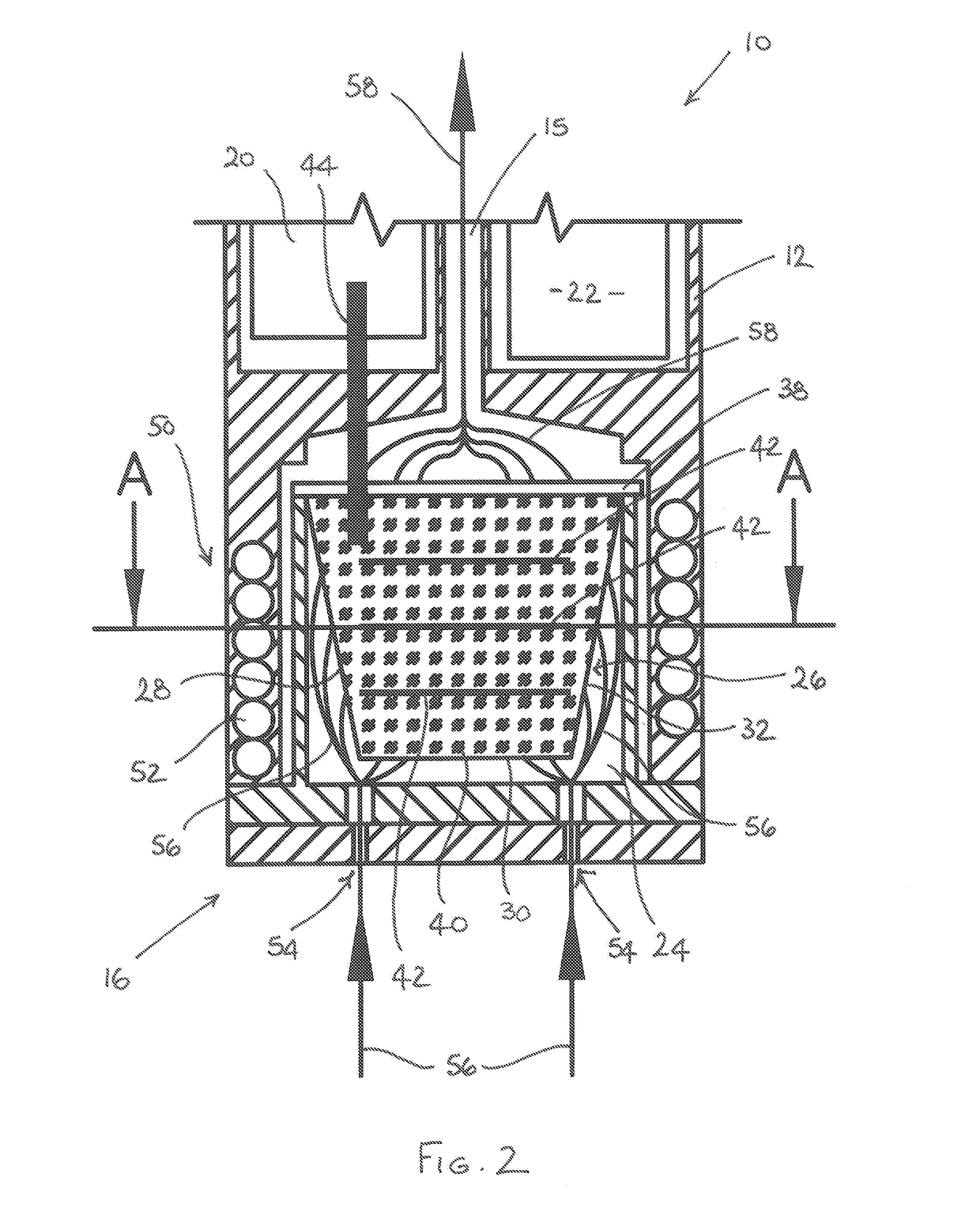

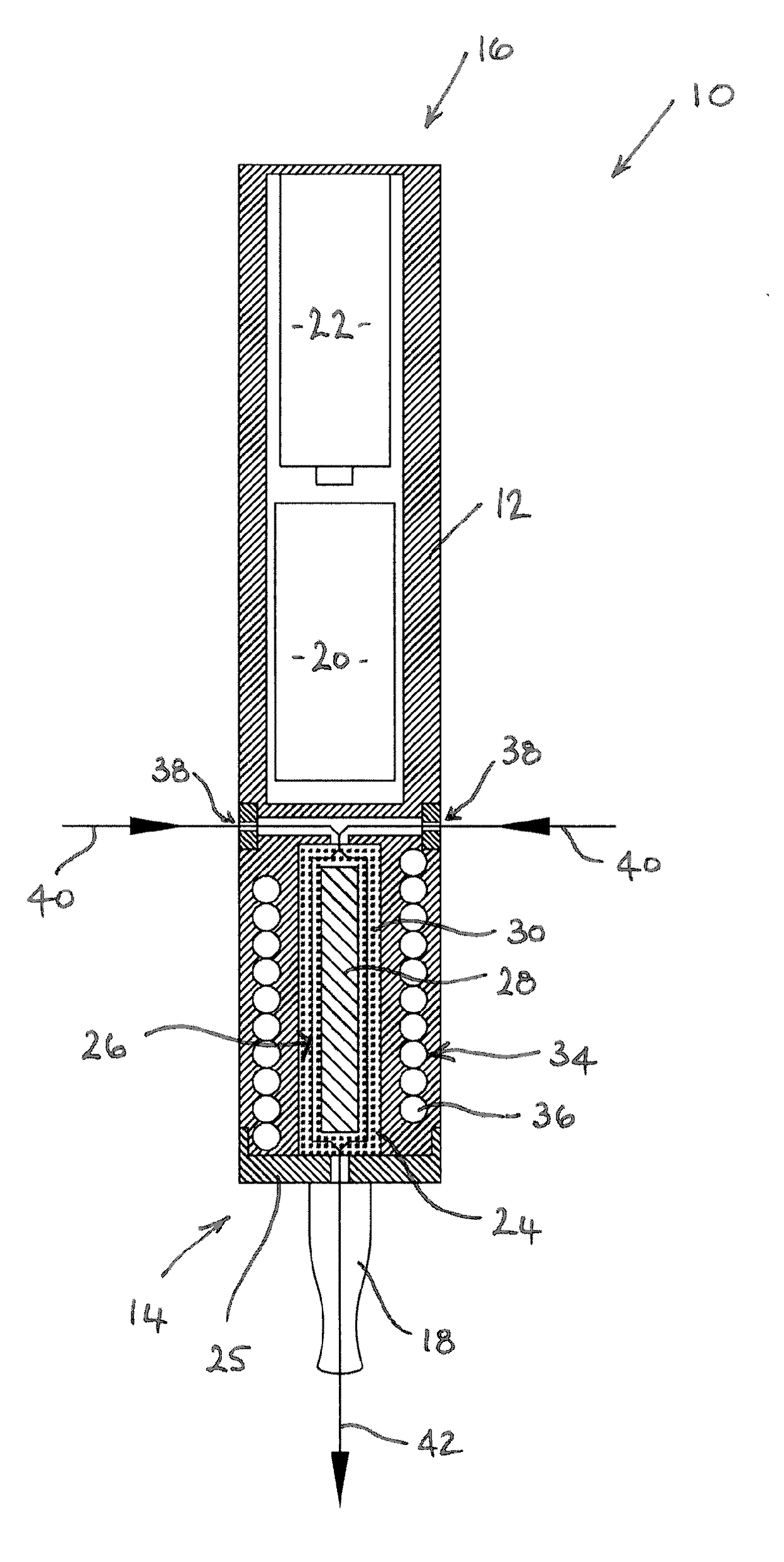

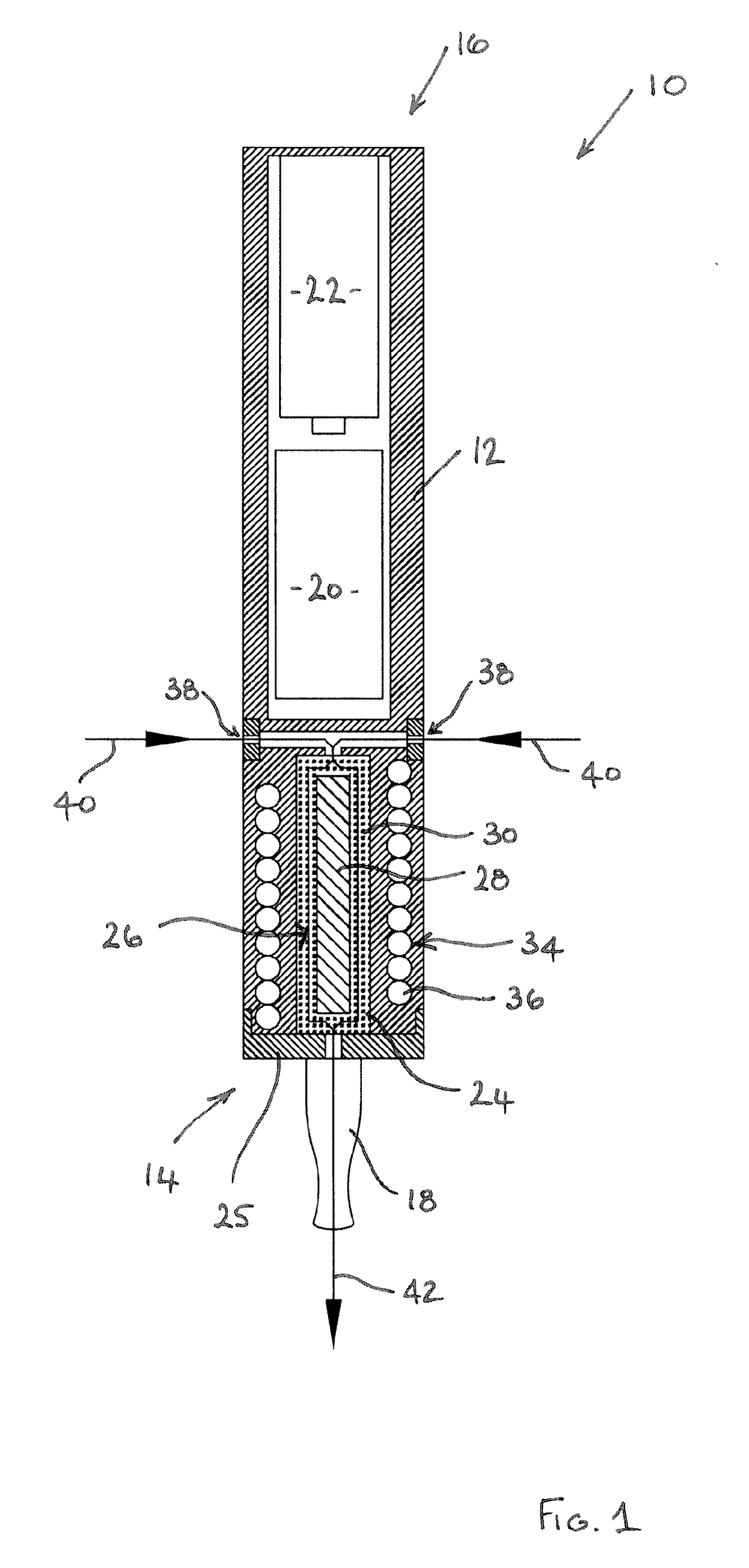

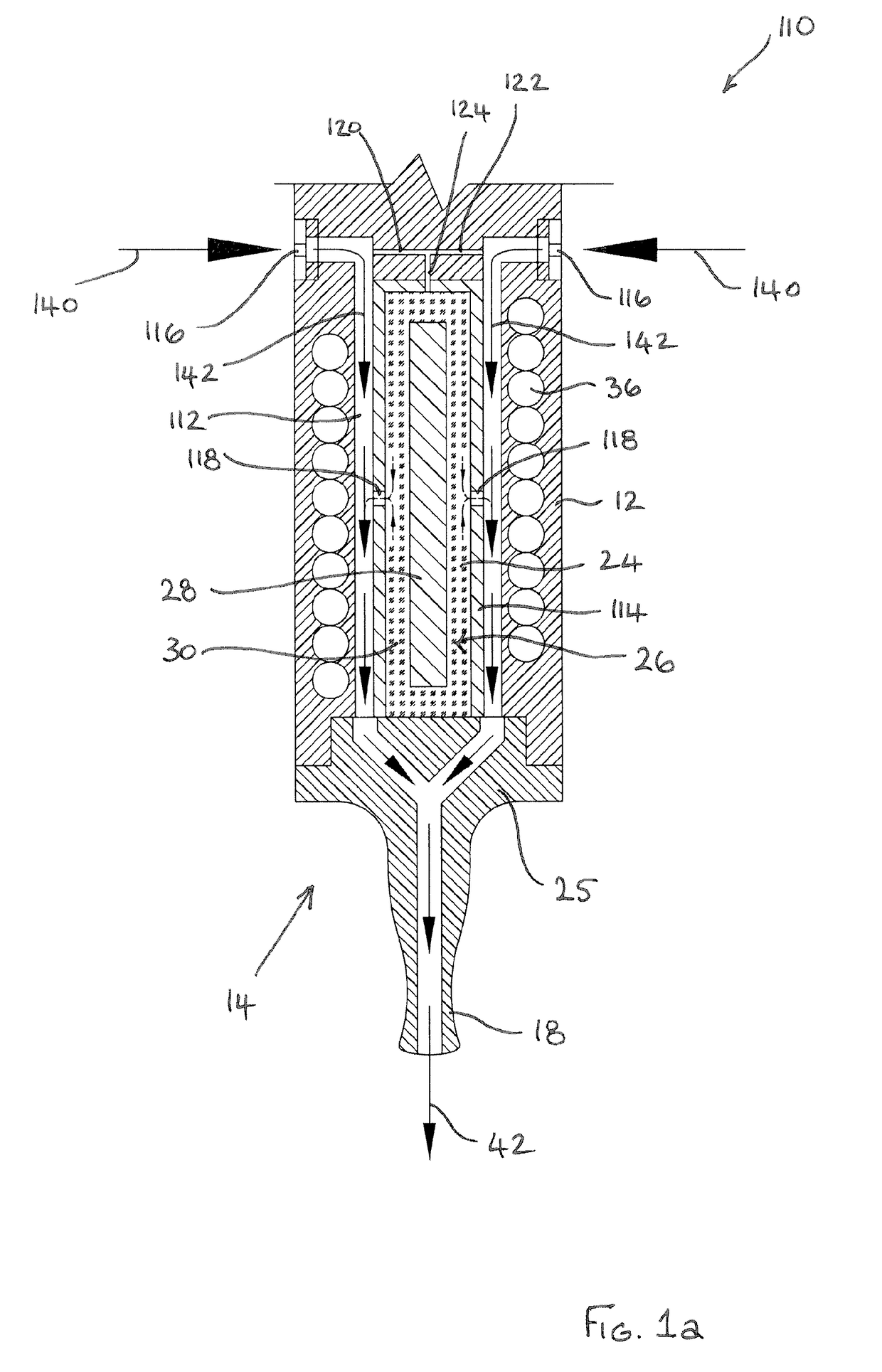

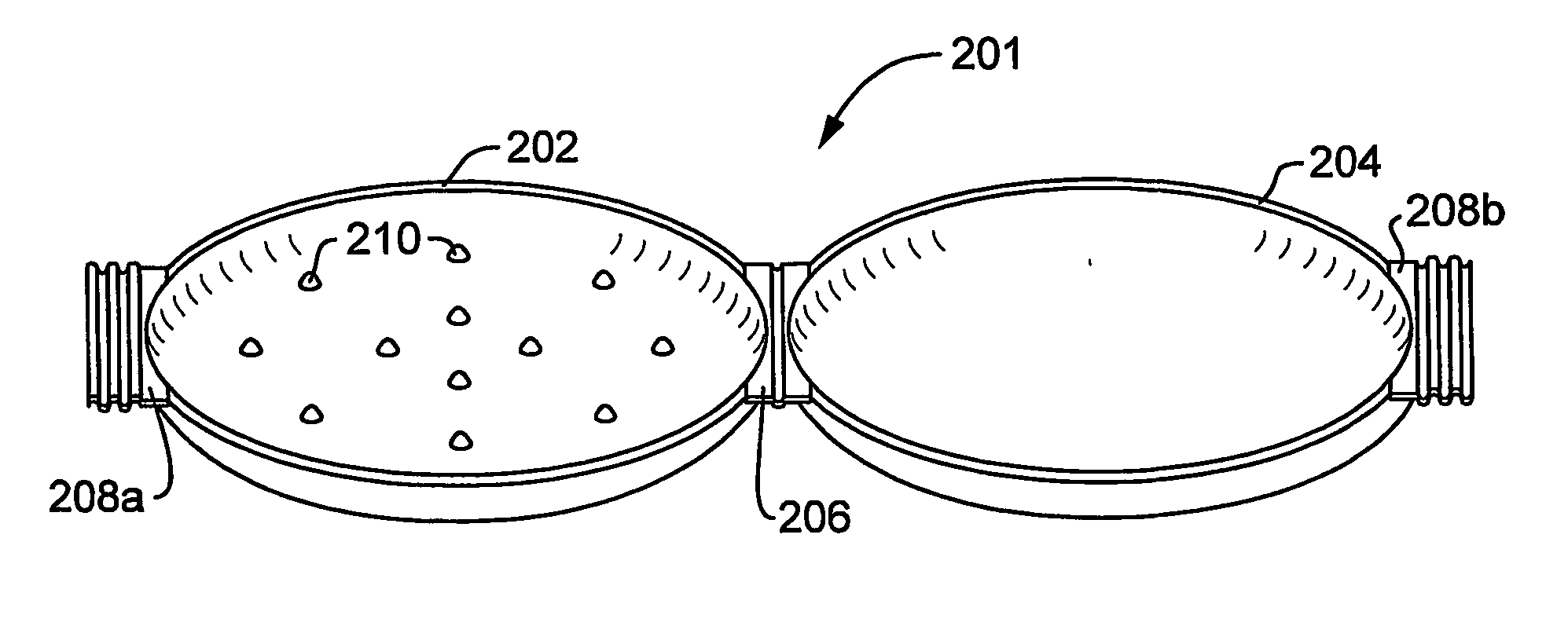

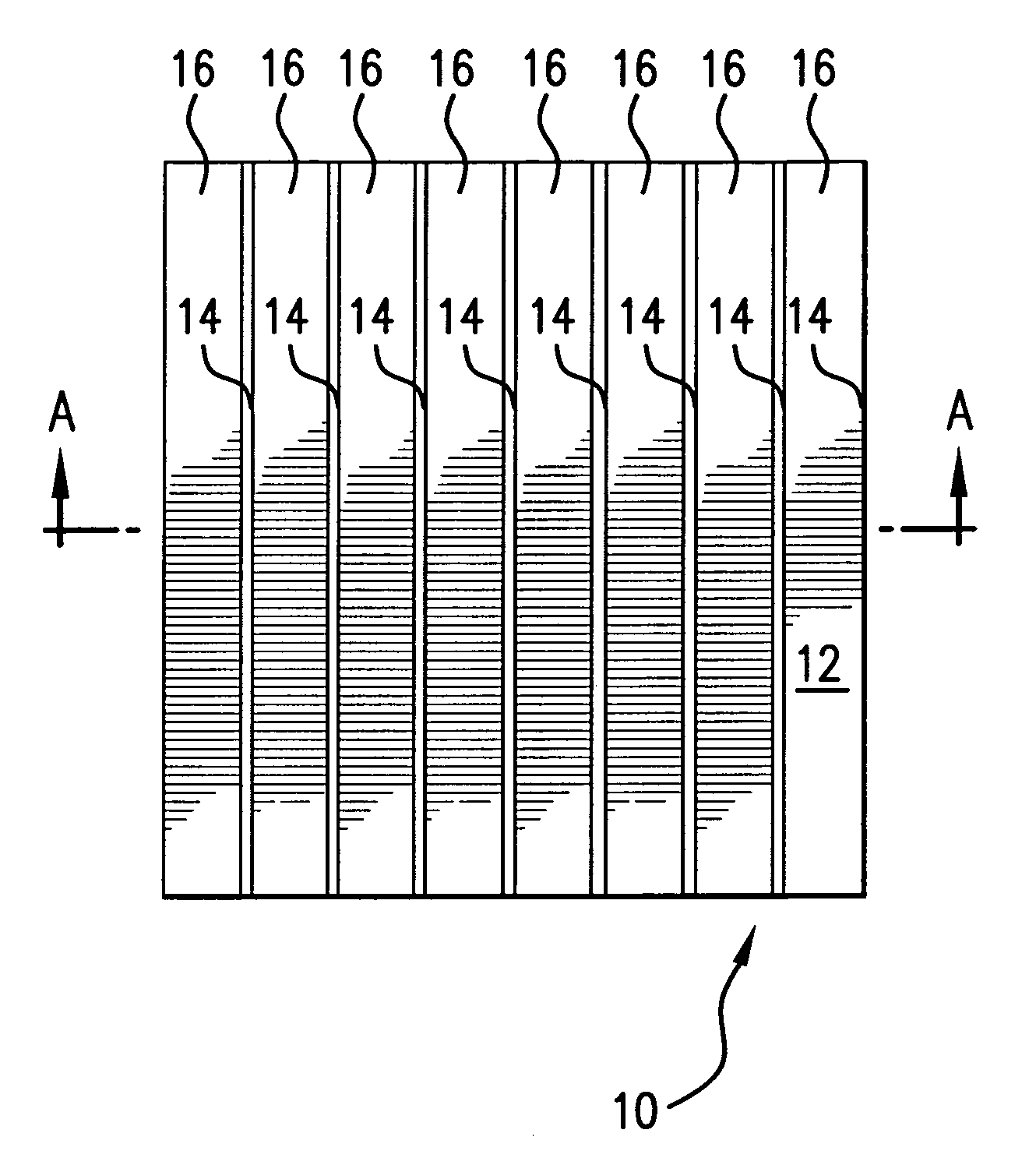

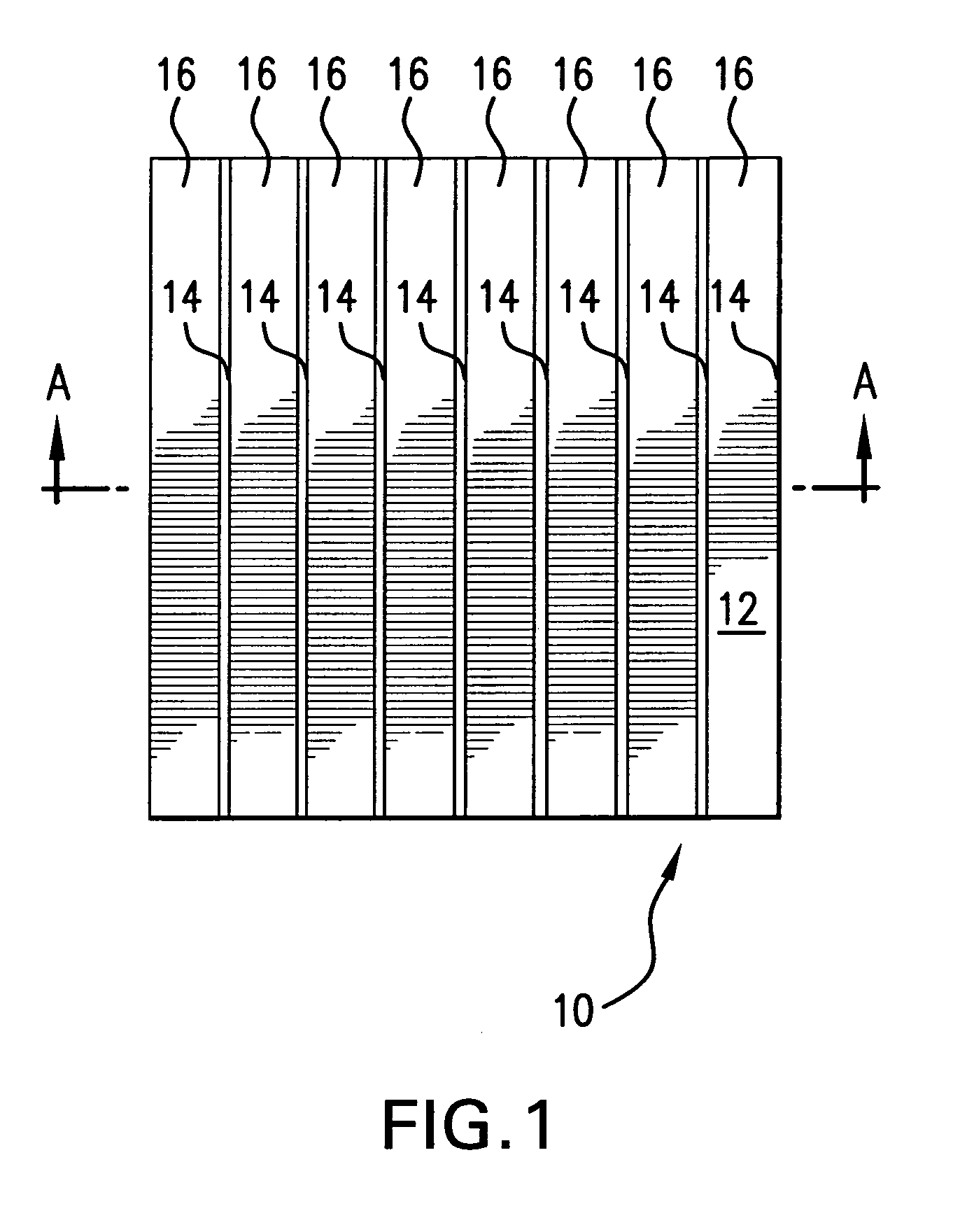

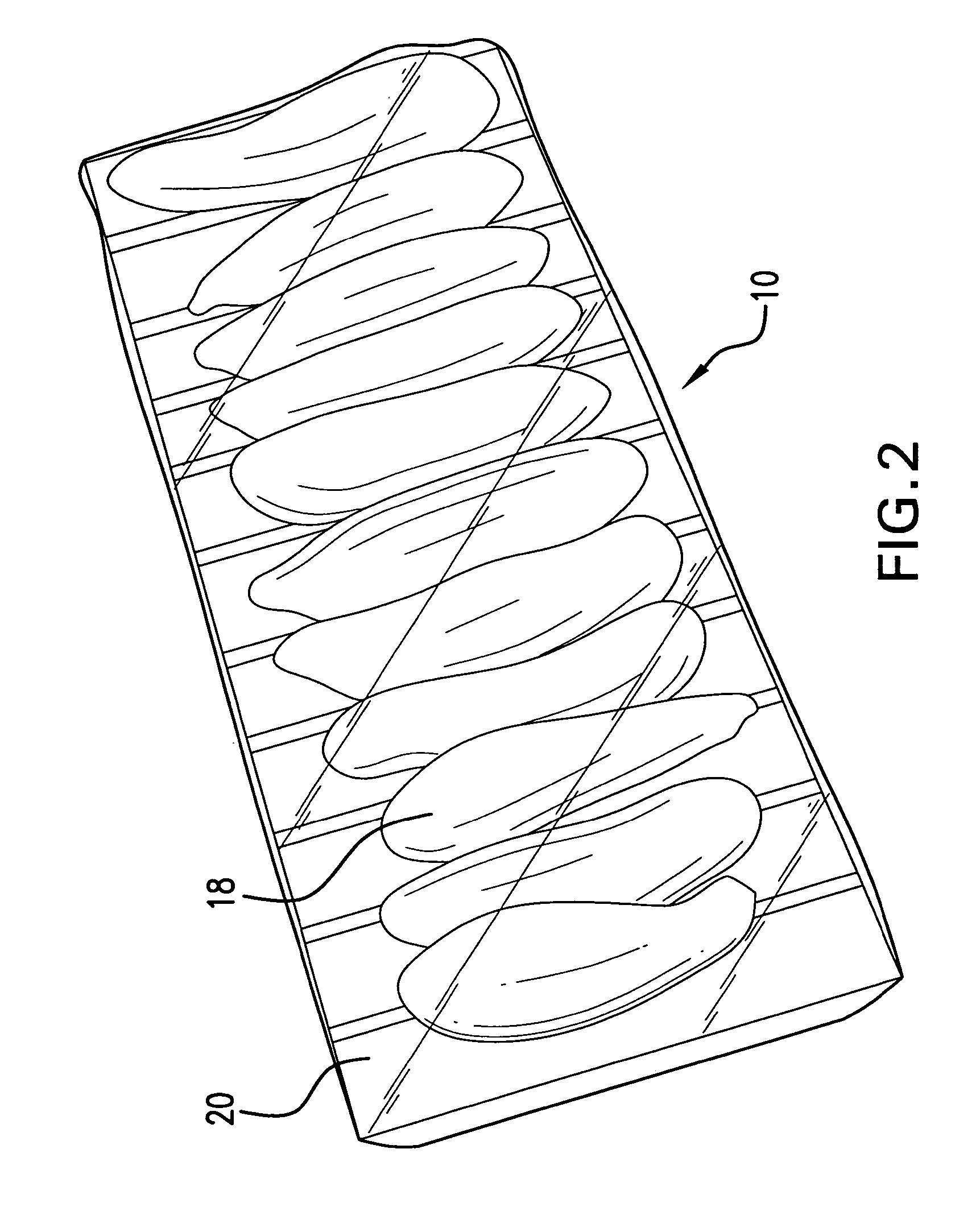

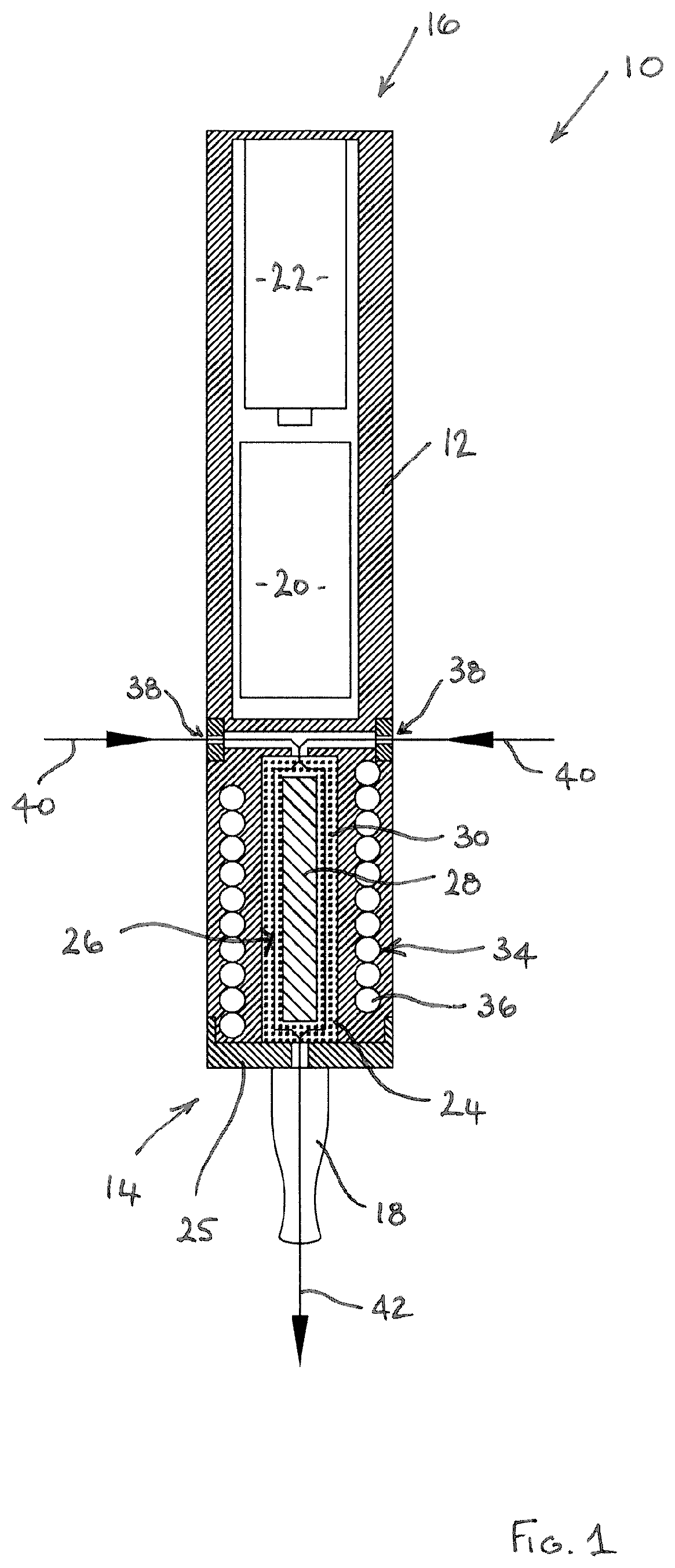

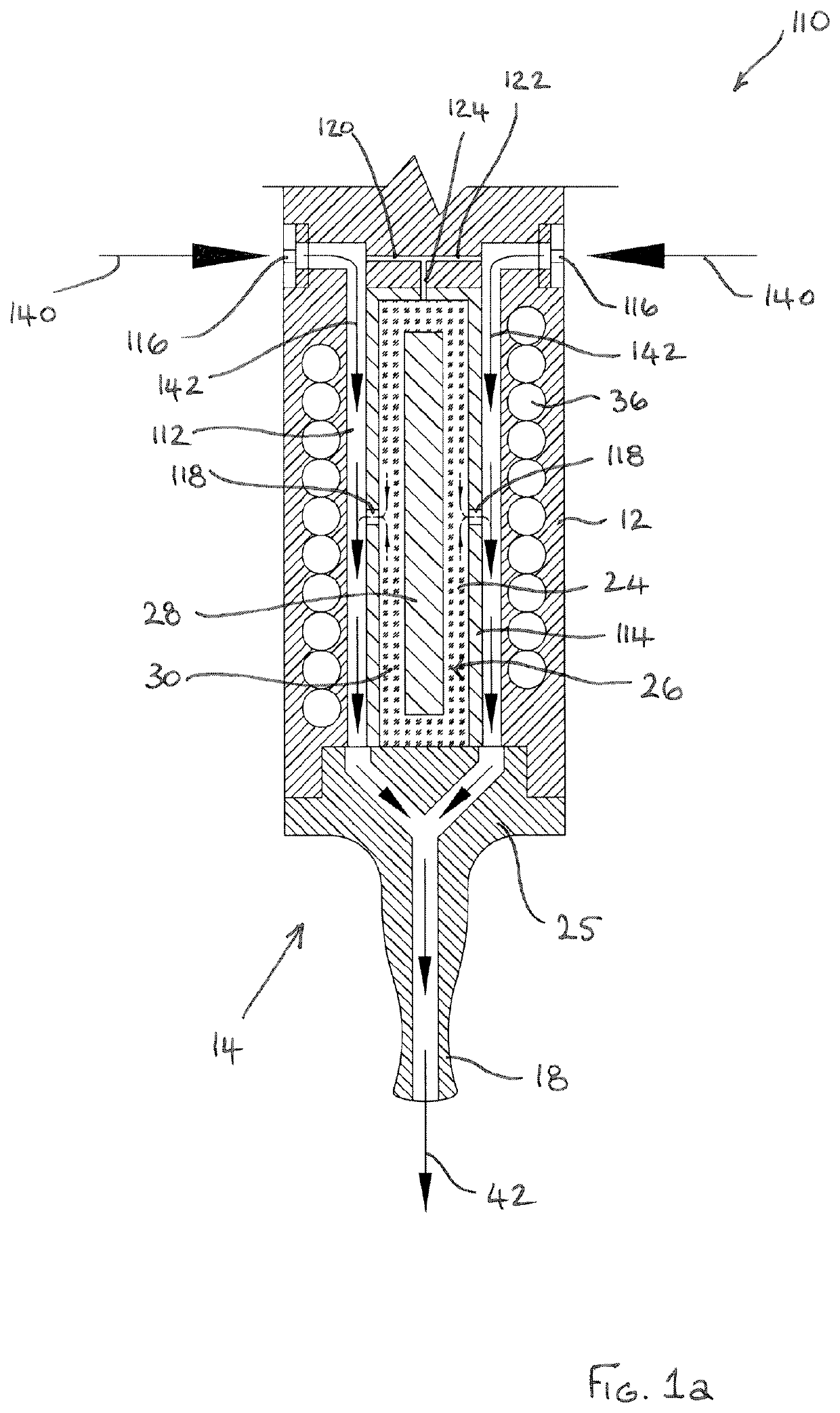

ActiveUS20170156403A1Reduce the possibilityIntegrity safetyTobacco treatmentCoil arrangementsMedicineInhalation

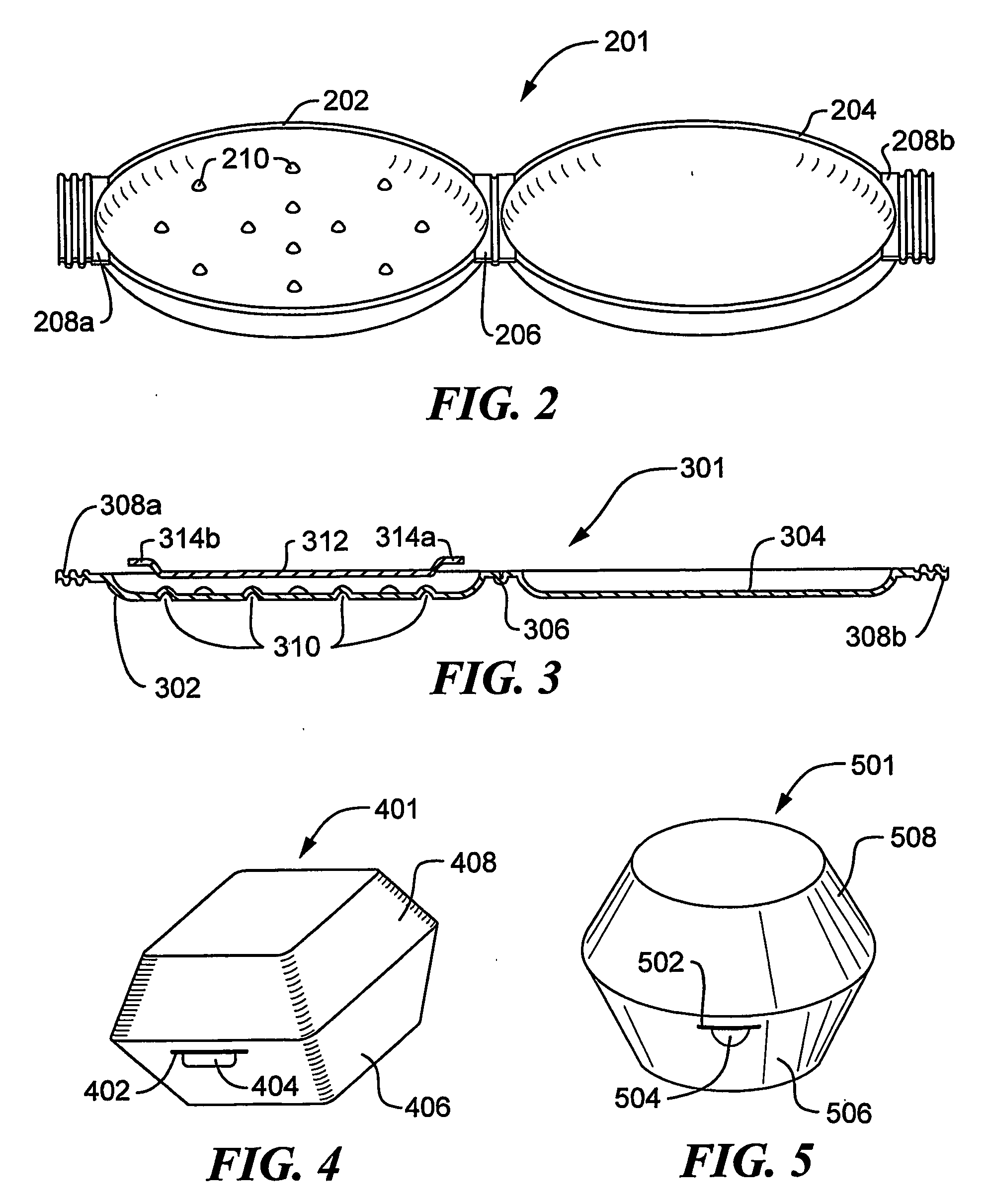

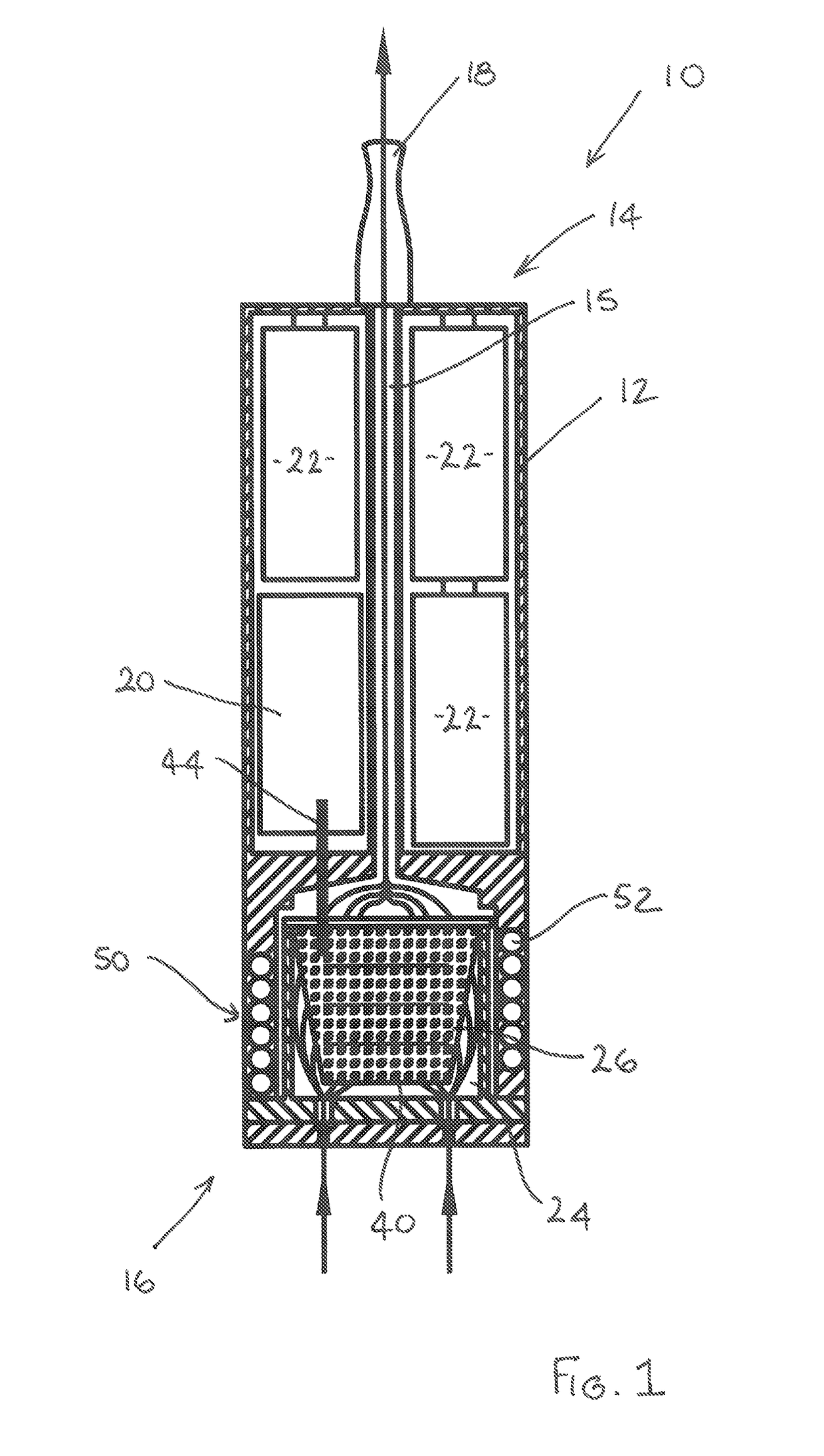

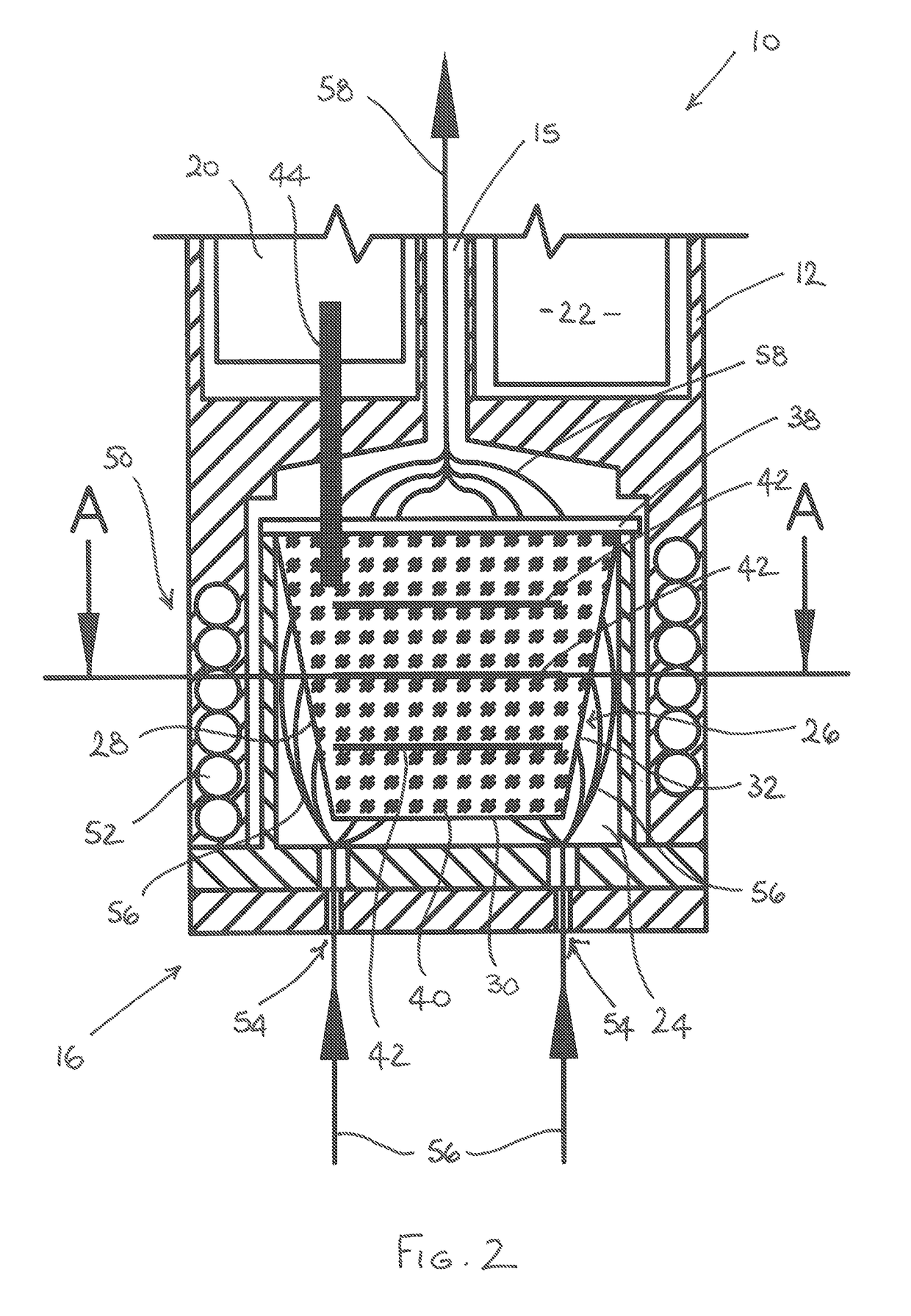

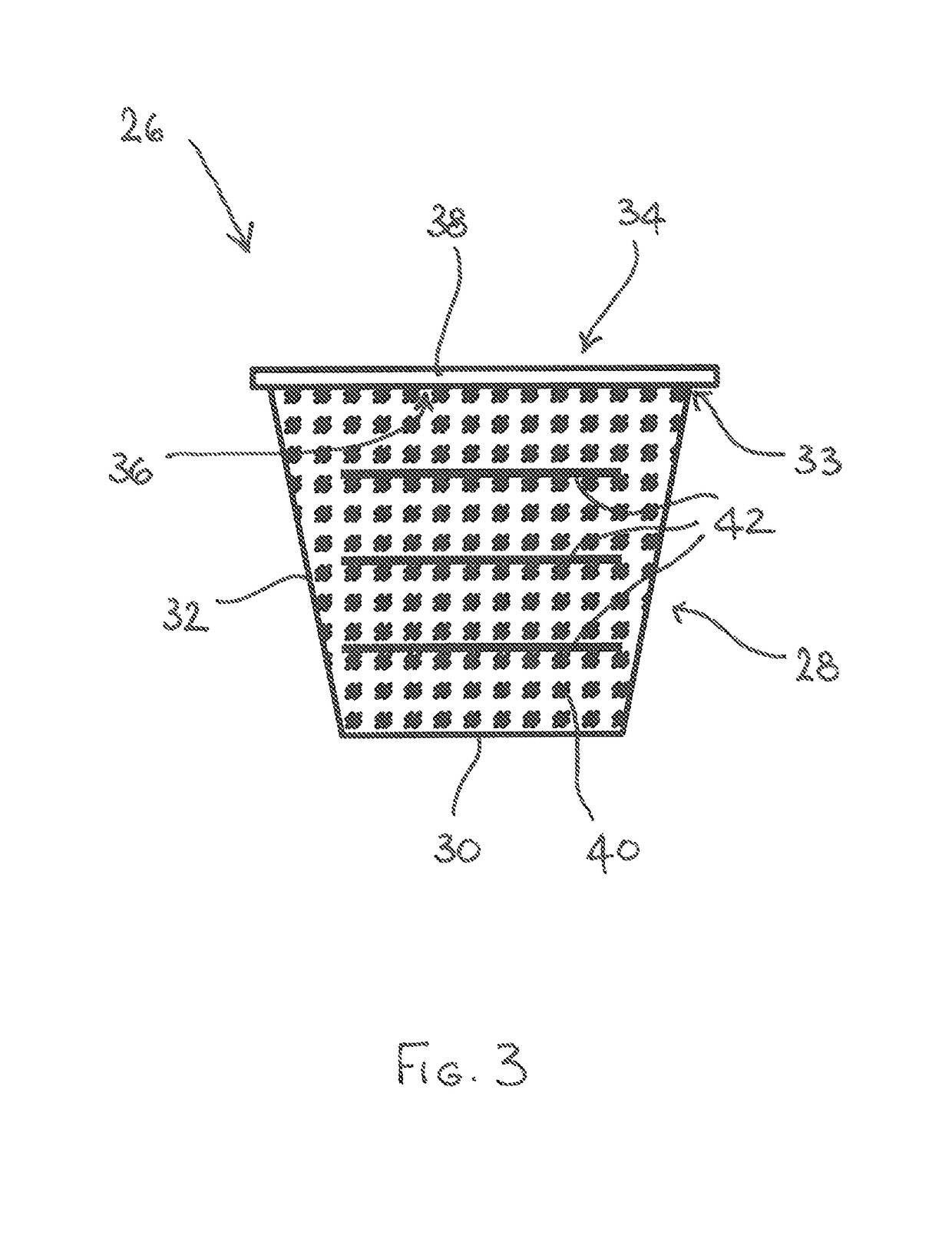

A capsule (26) for an electronic vapour inhaler comprises a shell (28) containing a flavour-release medium (40) and one or more induction heatable elements (42) disposed inside the shell (28) and arranged to heat the flavour-release medium (40) to produce a vapour for inhalation by a user. At least part of the shell (28) is formed of an air permeable material.

Owner:JT INT SA

Electronic Vapour Inhalers

ActiveUS20170311648A1Gradual releaseReduce the possibilityTobacco treatmentTobacco devicesEngineeringInhaler

Owner:JT INT SA

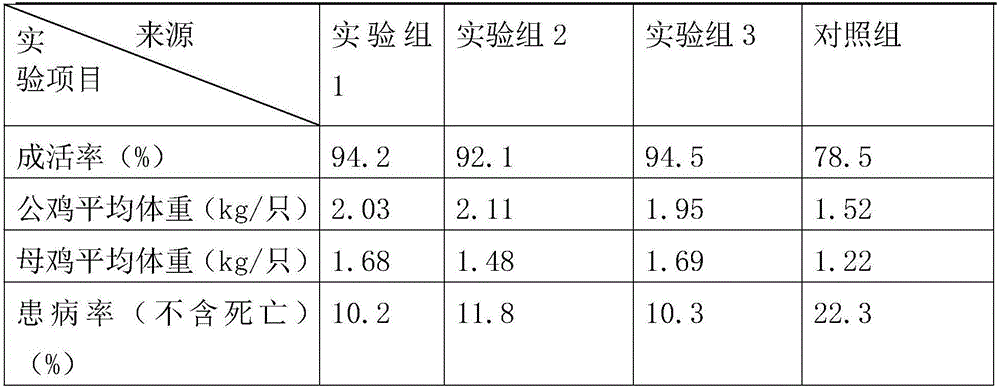

Ecological breeding method of domestic chickens

InactiveCN105660532AImprove stocking viabilityAvoid illnessAnimal feeding stuffAccessory food factorsDiseaseBreeding chicken

The invention discloses an ecological breeding method of domestic chickens. The method comprises the following steps of (1) selecting and arranging a farm; (2) selecting breeding chickens; (3) breeding and managing; (4) preventing diseases. The domestic chickens bred by adopting the ecological breeding method have the advantages of strong autoimmunity, low morbidity, delicious meat and nutrient enrichment and meet the requirements of green food.

Owner:SHILIN LONGJINGSHAN CHICKEN PROFESSIONAL COOP

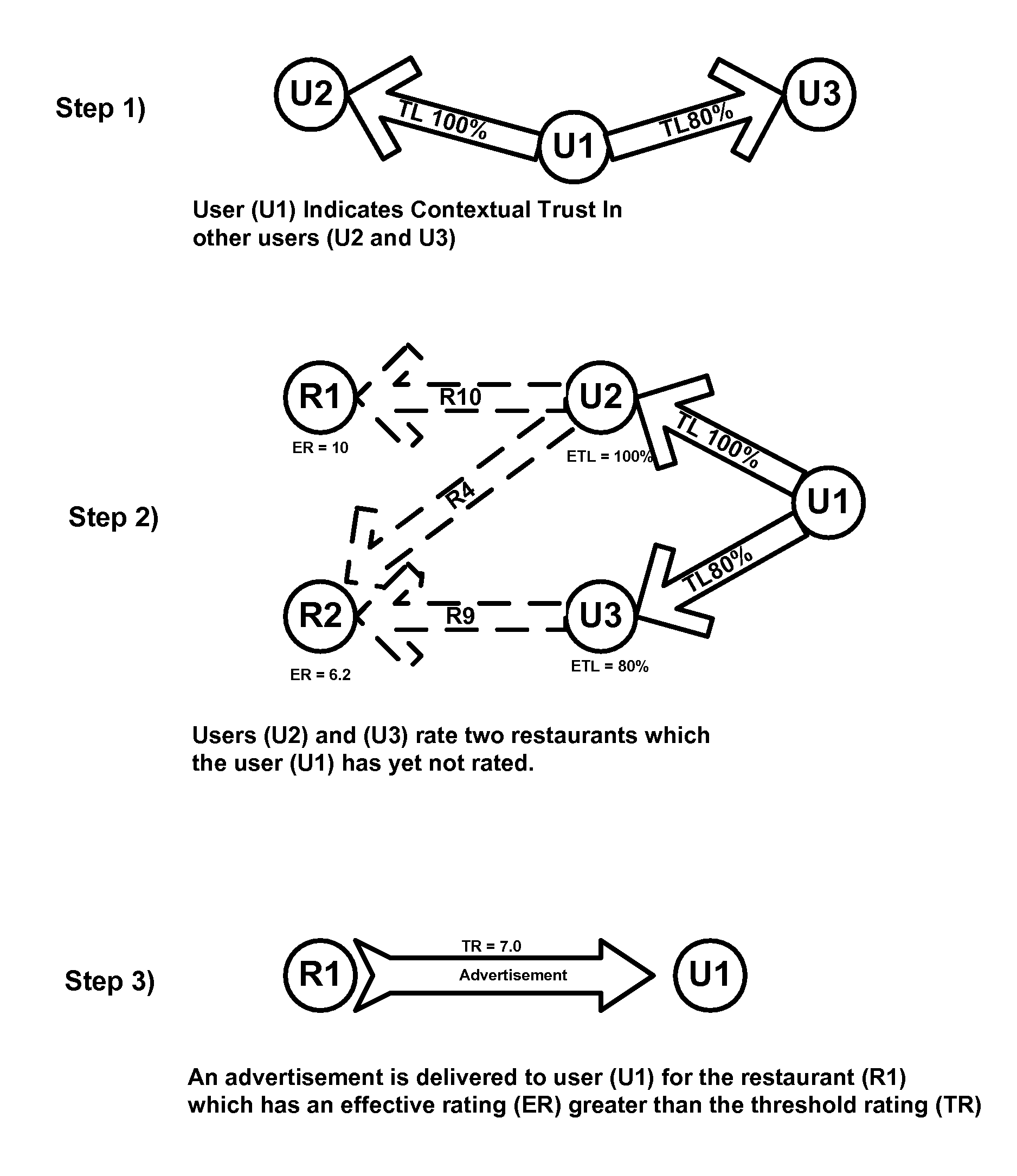

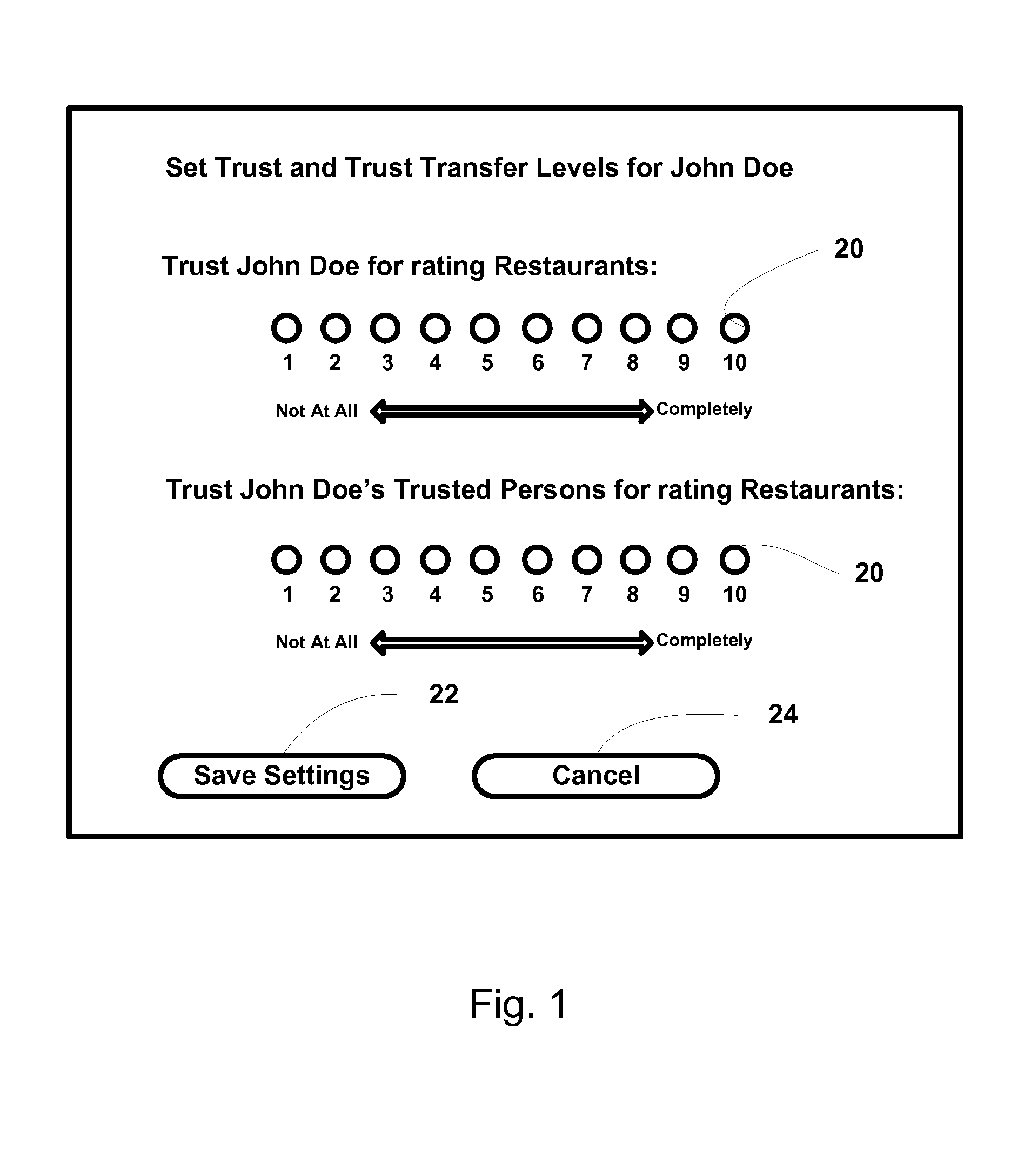

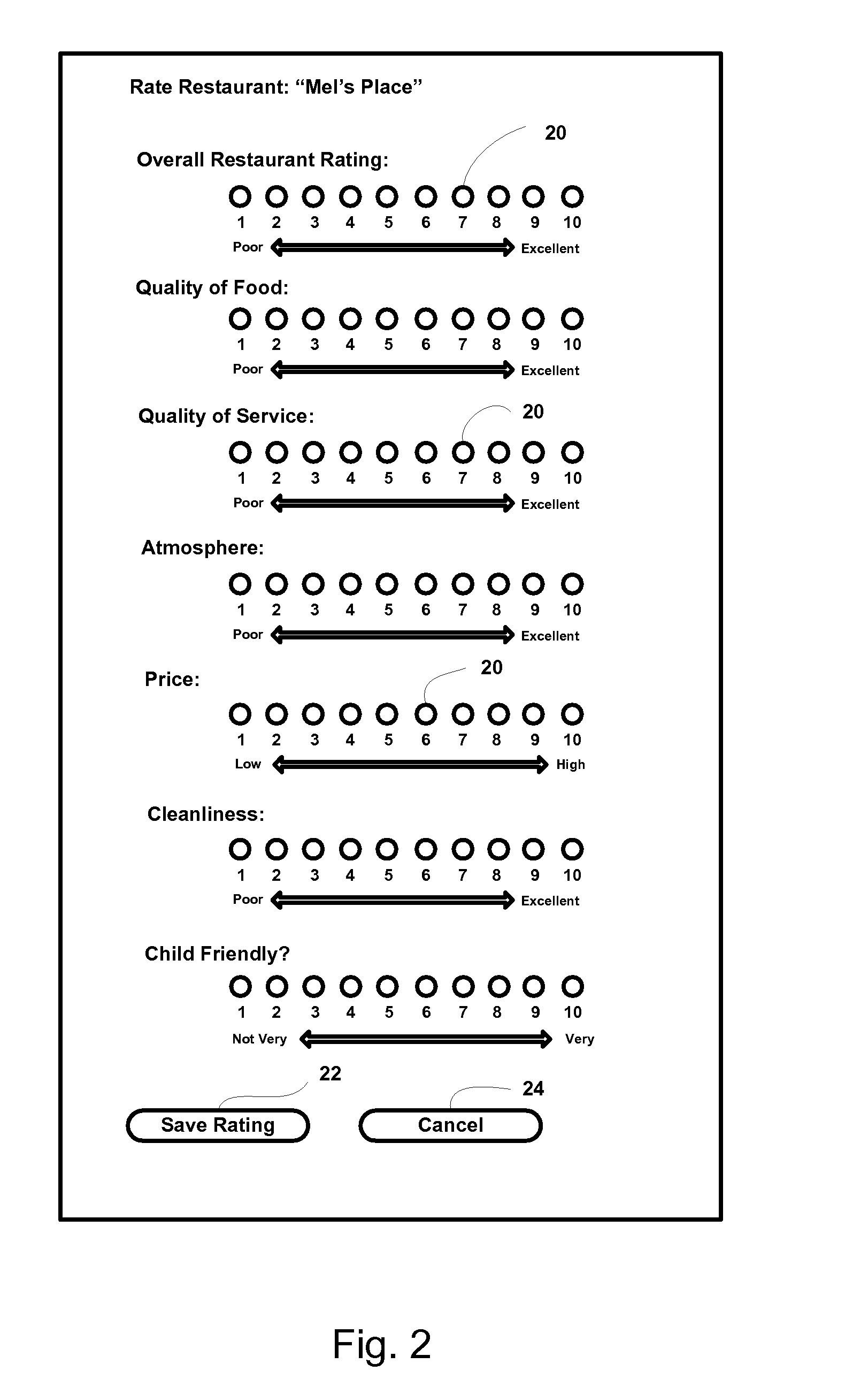

Trust Network Based Advertising System

InactiveUS20100030638A1Preserving safetyPreserving timeAdvertisementsMultiple digital computer combinationsRating systemInternet privacy

The inventive system uses a trust network rating system to target advertisements thereby increasing the effectiveness as well as the palatability of the advertisement. A user of an online system sets up a trust network by indicating criteria whereby the user trusts other users. Ratings made by the other users of goods or services are evaluated according to the particular trust network the user has set up. The user receives advertisements only from those vendors who have met thresholds based on the evaluated ratings. This ensures that the user receives only pertinent and interesting advertisements so that the user is more likely to respond positively to the advertisements.

Owner:DAVIS III JOHN STANNARD +1

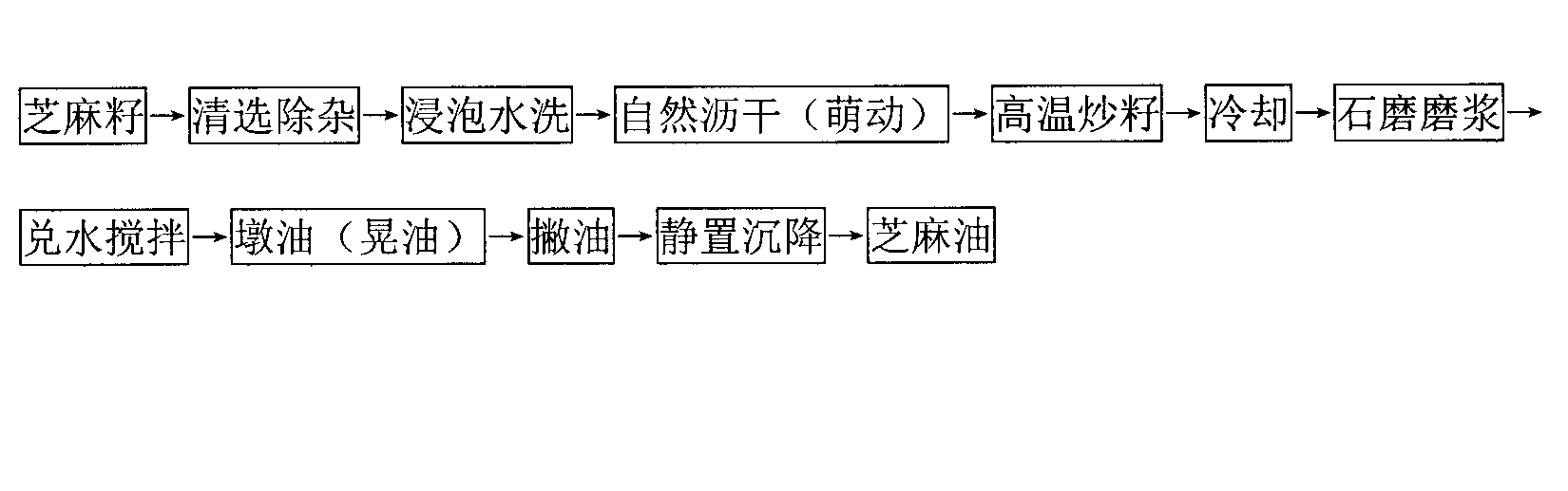

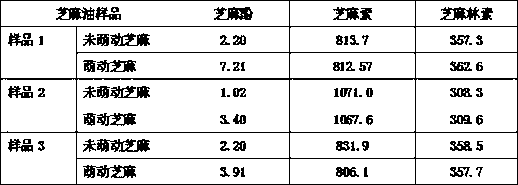

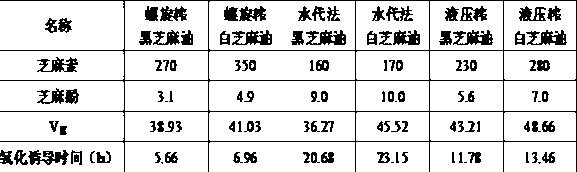

Production process of sesamol-rich fragrant sesame oil

InactiveCN102796609APure fragranceQuality and safetyFatty-oils/fats productionEdible oils/fatsFlavorSesamum

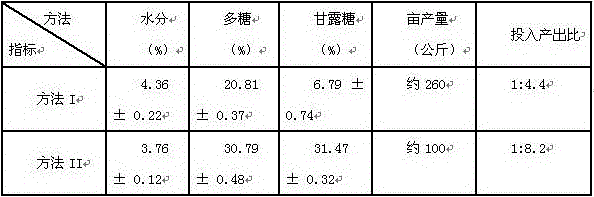

The invention discloses a production process of sesamol-rich fragrant sesame oil. The production process is characterized by comprising the following steps of: cleaning and removing impurities; soaking and washing; naturally draining and germinating; frying seeds at a high temperature; cooling; grinding into pulp with a stone mill; adding water and stirring; turning oil (shaking oil); skimming oil; and standing and settling to obtain a finished product. The production process has the advantages that the defects of high probability of getting burnt during direct roasting of dry sesame and high probability of producing 3,4-benzopyrene after burning are avoided by soaking the sesame with water, draining and then roasting at the high temperature, the sesame seeds are germinated during washing, soaking and drainage of the sesame, the germinated sesame seeds are roasted at the high temperature and then grease is extracted, the sesamol content in the sesame oil is higher than that of the sesame oil extracted from the ungerminated sesame, sesame pulp has high water absorbing speed and high oil yield speed, the obtained sesame oil has better flavor, the content of vitamin E in the sesame oil extracted from the germinated sesame, which is washed and soaked with water and drained, is higher than that of the sesame oil extracted from the ungerminated sesame, and the oil yield is improved by 1-2 percent compared with that in the prior art.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

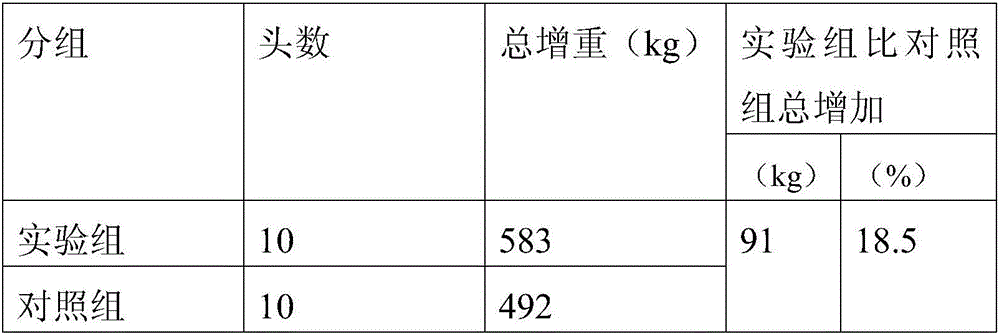

Ecological breeding method of small-ear pigs

InactiveCN106614329AImprove stocking viabilityReduce usageFood processingAnimal feeding stuffNutrientAnimal science

The invention discloses an ecological breeding method of small-ear pigs. The method comprises the following steps: (1) selecting a land and distributing for a cultivating farm; (2) disinfecting a pig farm; (3) performing raising management of piglets; (4) performing raising management of middle pigs; (5) performing raising management of middle and big pigs; (6) performing raising management of growing and fattening pigs; and (7) preventing diseases. Pigs bred by adopting the ecological breeding method of small-ear pigs is strong in self resistance, low in morbidity, delicious in meat, rich in nutrients, and fast to grow; and the bred small ears meet the requirement of green food.

Owner:红河县九冲畜牧业发展有限公司

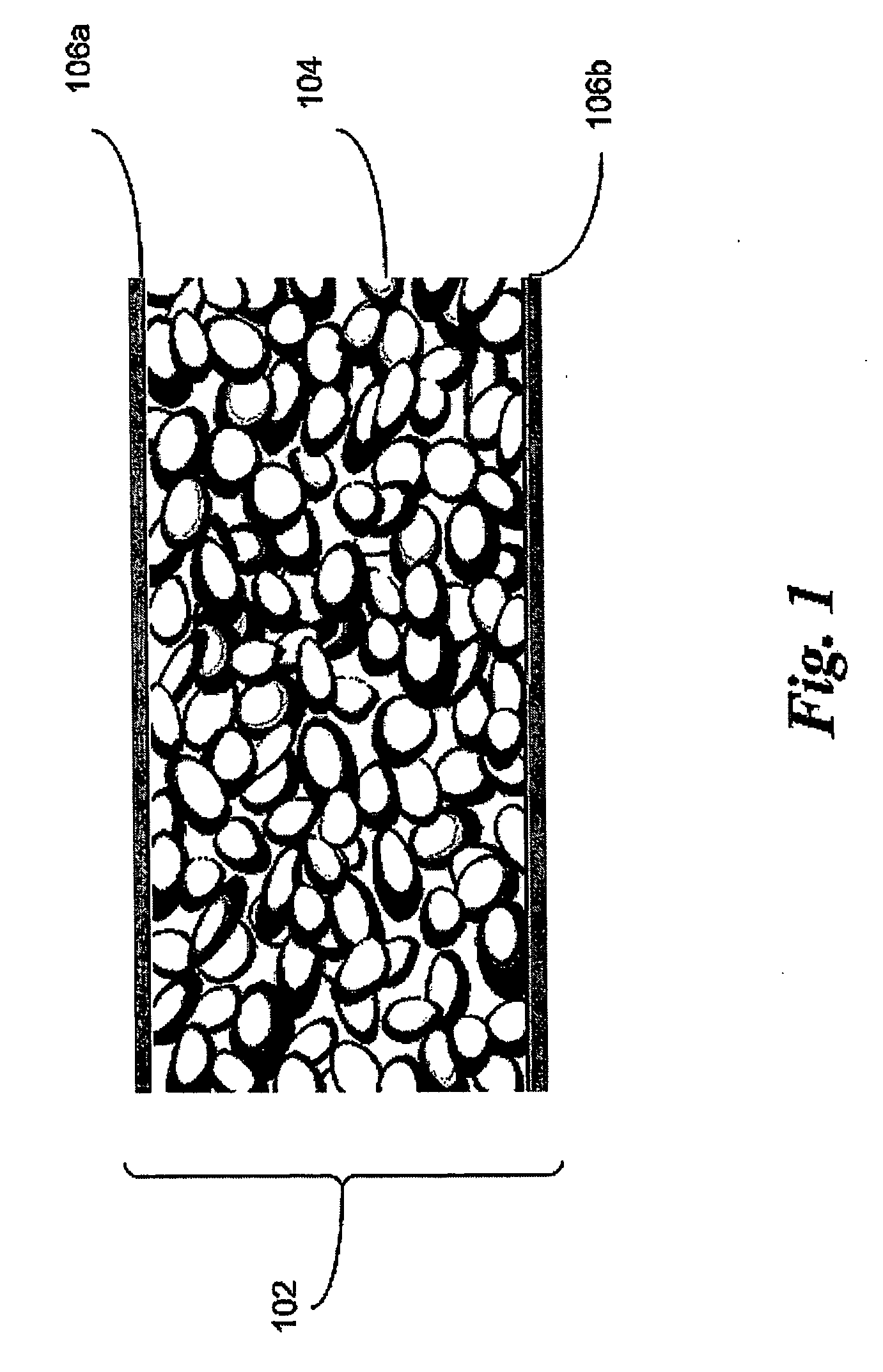

Foamed pet packaging

ActiveUS20060257606A1Quality and safetyHigh temperature resistanceClosure using stoppersSynthetic resin layered productsEngineeringHigh pressure

This invention provides packages and containers produced by a solid state method for the manufacture of foamed polymeric material. The packages are suitable for pre-cooking or sterilization, insulated transport, cooking vessel, reheating, and storage of food. The gas impregnated thermoforming (GIT) process includes interleaving an article of raw polymeric material with a gas channeling means; exposing the article to a non-reacting gas at elevated pressure to achieve a desired concentration of gas within the polymer, thereby forming a partially gas-saturated article, separating it from the gas channeling means, then decompressing, foaming and forming it at a temperature below the material's melt temperature; and finally trimming it to produce a finished foamed polymeric material and recycleable scrap solid state process foamed polymer.

Owner:DART CONTAINER

Ecological chicken raising method

InactiveCN106577486AImprove stocking viabilityImprove the immunityFood processingSpecific water treatment objectivesNutrientBiology

The invention discloses an ecological chicken raising method. The ecological chicken raising method comprises the following steps of (1) selection and layout of a raising farm; (2) selective raising of chicken breeds; (3) raising management of chicks; (4) raising management of young chickens; (5) raising management of medium and large chickens; (6) raising management of fat chickens; and (7) disease prevention. Chickens raised through the ecological chicken raising method are low in self immunity, low in morbidity, delicious in meat, rich in nutrient and high in growing speed, and native chickens raised through the method meet the requirement for green food.

Owner:昆明建羽牧业有限公司

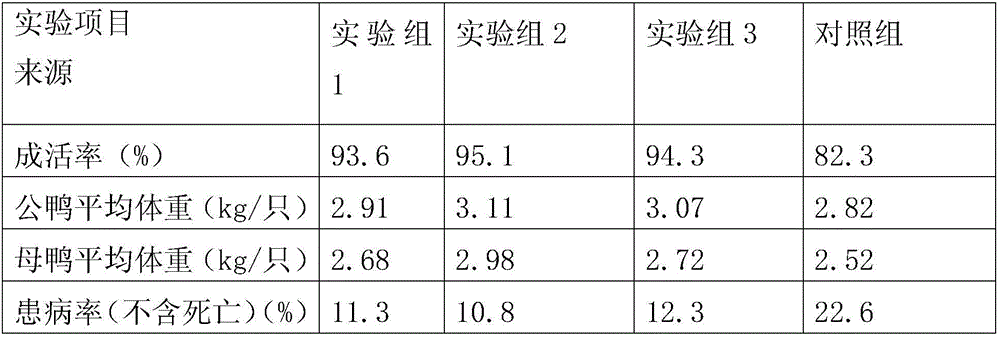

Ecological breeding method of native duck

InactiveCN106106358AImprove stocking viabilityPromote sportsFood processingAnimal feeding stuffDiseasePaddy field

The invention discloses an ecological breeding method of a native duck. The ecological breeding method of the native duck comprises the following steps: (1) selecting and arranging a farm; (2) selecting a duck variety; (3) performing feeding management on a duckling; (4) breeding a young duck in a paddy field; (5) performing feeding management on a medium-sized duck; (6) performing paddy field management on a medium-sized or large-sized duck; (7) performing feeding management on a fattening duck; (8) preventing diseases. The duck bred by the ecological breeding method of the native duck is strong in body resistance, low in disease incidence, delicious in meat and rich in nutrition, and meets requirements on green food.

Owner:禄丰顺鑫农业科技有限公司

Electronic vapour inhalers

ActiveUS10219543B2Reduce the possibilityIntegrity safetyTobacco treatmentCoil arrangementsFlavorMedicine

Owner:JT INT SA

Duck ecological breeding method

InactiveCN106135128AImprove stocking viabilityPromote sportsFood processingAnimal feeding stuffNutrientDisease prevention

The invention discloses a duck ecological breeding method. The method comprises the following steps: (1) farm land selection and layout; (2) duck species breeding; (3) duckling feeding and management; (4) mid-term duck feeding and management; (5) fattening duck feeding and management; (6) disease prevention. The ducks bred by adopting the duck ecological breeding method have strong resistance, low morbidity, delicious meat and abundant nutrients and meet the requirements of green food.

Owner:禄丰顺鑫农业科技有限公司

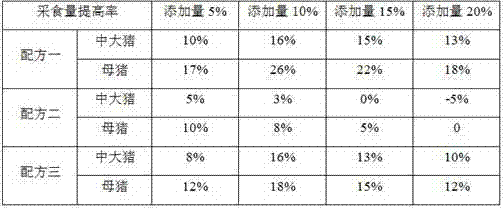

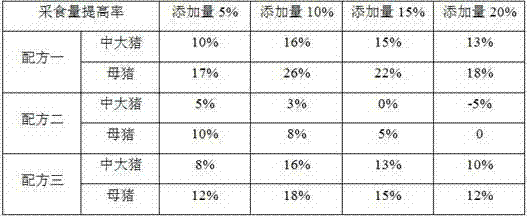

Phagostimulant fermented feed using bean pulp and bran as protein raw materials and preparation method thereof

InactiveCN103027191AGood treatment effectQuality and safetyAnimal feeding stuffAccessory food factorsBiotechnologyNeutral proteinase

The invention relates to a feed additive, particularly a phagostimulant fermented feed using bean pulp and bran as protein raw materials and a preparation method thereof. The phagostimulant fermented feed using bean pulp and bran as protein raw materials is prepared by fermenting the following components in percentage by weight: 8-15% of bean pulp, 55-70% of bran, 1.0-2.0% of Bacillus subtilis, 1.0-2.0% of Lactobacillus acidophilus, 1.0-2.0% of Enterococcus faecalis, 1.0-2.0% of microzyme, 0.1-0.5% of brown sugar, 0.02-0.08% of yeast extract, 0.02-0.08% of potassium dihydrogen phosphate, 0.02-0.08% of neutral proteinase, 0.02-0.08% of acid protease and 15-30% of water. The invention has the advantages of environmental protection, healthiness, favorable phagostimulant effect, strong capacity for killing pathogenic bacteria, and favorable therapeutic effect for porcine anorexia.

Owner:浙江德清博诚生物科技有限公司

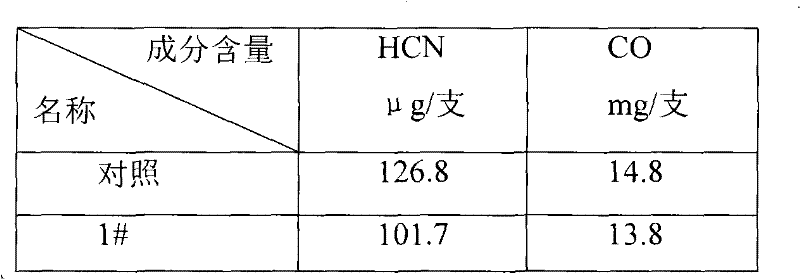

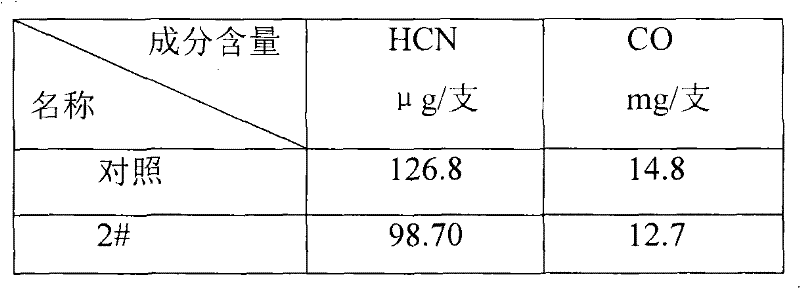

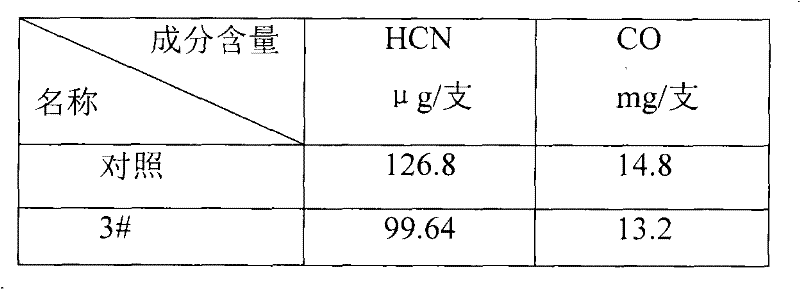

Preparation and adding methods of additive capable of reducing HCN and CO content of cigarettes

ActiveCN102125300AImprove qualityQuality and safetyTobacco treatmentBULK ACTIVE INGREDIENTActive ingredient

The invention discloses preparation and adding methods of an additive capable of reducing HCN and CO content of cigarettes. The additive for cigarette is prepared by a stage extraction or direct water extraction method, wherein thamnolia vermicularis asahina serves as a raw material. The adding method comprises the following steps of: fully stirring and uniformly dissolving one or more of the prepared first additive, the prepared second additive and the prepared third additive in 95 percent ethanol of which the weight is 5 to 20 times that of the additive; freezing the mixture for 5 to 15 hours at the temperature of between -5 and -20 DEG C; taking out and suction-filtering the mixture to obtain a filtrate; taking the filtrate of which the weight is 0.01 to 0.05 percent of that of tobaccoshreds, and adding the 95 percent ethanol until the total weight of the ethanol and the filtrate is 2 percent of the weight of the tobacco shreds; uniformly mixing the ethanol and the filtrate; uniformly spraying the mixture onto the tobacco shreds; and balancing the tobacco shreds for 48 hours under the conditions that the temperature is 22 DEG C and the humidity is 60 percent. An active ingredient is extracted from the thamnolia vermicularis asahina with excellent effects and serves as the additive. The additive is applied to the production of cigarettes to reduce the content of harmful components, namely HCN and CO, of the cigarettes.

Owner:云南瑞升香料技术有限公司

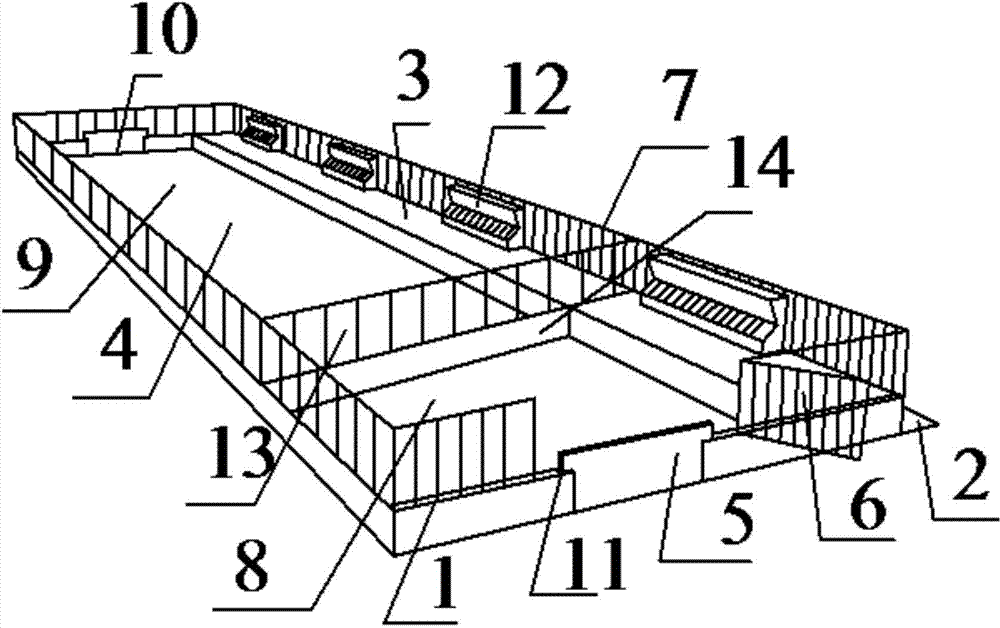

Pig house and method for resource utilization of straw as fermentation bed padding for pigs

InactiveCN104719170AEasy to useSolve the problem of incinerationAnimal housingButt jointResource utilization

The invention provides a pig house for resource utilization of straw as fermentation bed padding for pigs. The pig house comprises a fermentation bed pigpen, a fence is arranged at the edge of the fermentation bed pigpen, a padding pool is arranged on one side of the fermentation bed pigpen in the long side direction, a sleeping table is arranged on the other side of the fermentation bed pigpen, an automatic feeding trough is formed in the portion, close to the aisle side, of the sleeping table, and an aisle is arranged on the outer side of the fermentation bed pigpen and close to the sleeping table. The invention further provides a method for resource utilization of the straw as the fermentation bed padding for the pigs. The pig house for resource utilization of the straw as the fermentation bed padding for the pigs is adopted. The method specifically includes the steps that the straw is collected, utilized and treated, the padding is raked, accumulated, fermented, transformed to manure and treated after the commercial pigs are delivered out of the pigpen, and seamless butt joint treatment between the fermentation bed colony house use period and the straw centralized generation period is conducted.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

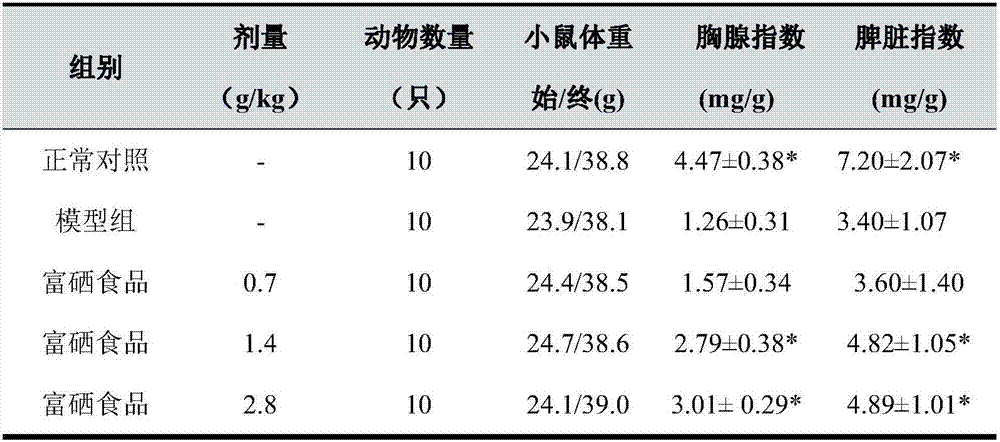

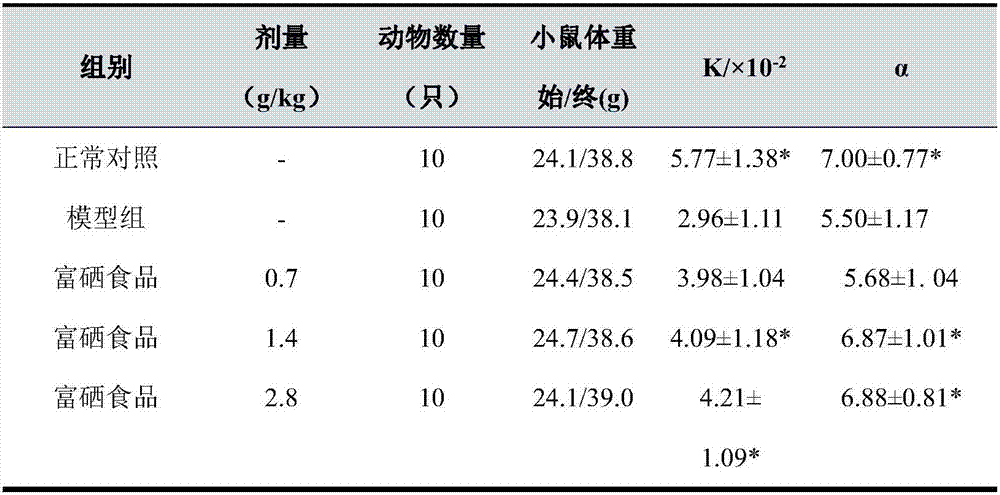

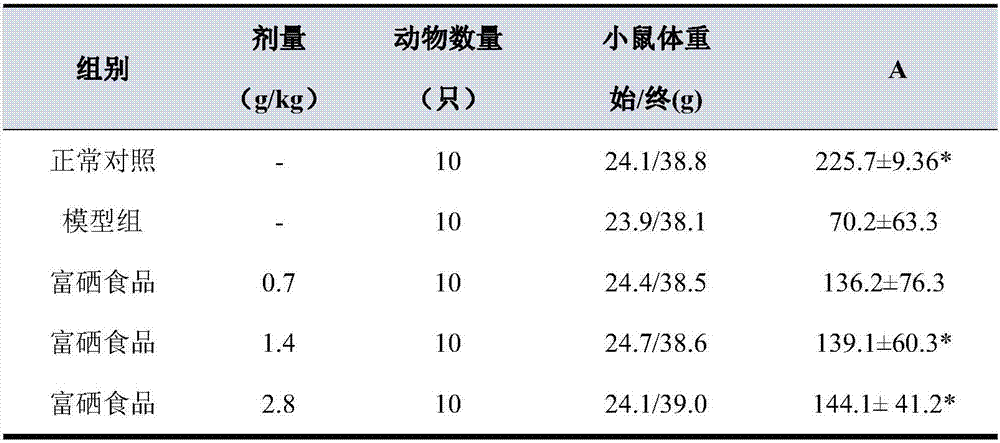

High-selenium nutritive supplement for enhancing immunity and assisting in tumor recovery

ActiveCN107114783AImprove immunityAid in tumor recoveryNatural extract food ingredientsFood ingredient functionsSocial benefitsMANNITOL/SORBITOL

The invention discloses a high-selenium nutritive supplement for enhancing immunity and assisting in tumor recovery. The high-selenium nutritive supplement is characterized by being prepared from the following raw materials in percentage by weight: 10-30% of selenium-enriched plants or extracts thereof, 60-80% of functional ingredients or extracts thereof and 5-20% of auxiliary materials, wherein the selenium-enriched plants include selenium-enriched broccoli, selenium-enriched wild cabbages, selenium-enriched shepherd's purse and the like, the functional ingredients include yacon, konjak, bitter gourds, poria cocos, dandelions, purslane herbs and the like, and the auxiliary materials include sorbitol, mannitol, erythritol and the like. The high-selenium nutritive supplement is prepared through a powder direct tabletting technology or a powder direct mixing and bagging technology. The high-selenium nutritive supplement disclosed by the invention is safe and purely natural; and selenium-enriched raw materials and other functional ingredients are in a scientific compounding ratio, so that the immune functions of organisms are effectively improved, and the high-selenium nutritive supplement contributes to assisting in tumor recovery and has considerable economic benefits and social benefits.

Owner:恩施德源硒材料工程科技有限公司

Feeding attracting type fermented feed and preparation method thereof

The invention relates to a feeding attracting type fermented feed and a preparation method thereof. The feeding attracting type fermented feed is prepared by fermenting the following constituents by weight percent: 8%-40% of one substance or a mixture of two substances selected from bean pulp and corn gluten meal, 30%-70% of bran, 1.0%-2.0% of bacillus subtilis, 1.0%-2.0% of lactobacillus acidophilus, 1.0%-2.0% of enterococcus faecalis, 1.0%-2.0% of saccharomycetes, 0.1%-0.5% of brown sugar, 0.02%-0.08% of yeast extract, 0.02%-0.08% of monopotassium phosphate, 0.02%-0.08% of neutral protease, 0.02%-0.08% of acid proteinase and 15%-30% of water. The feeding attracting type fermented feed has the advantages of nontoxicity, harmlessness, environment friendliness and healthiness, is rich in a lot of lactic acid, excellent in feeding attracting effect and strong in sterilization capability, and has better treatment effect on anorexia of pigs.

Owner:浙江德清博诚生物科技有限公司

Organic black peanut cultivation method

The invention relates to an organic black peanut cultivation method and belongs to the technical field of crop cultivation. The organic black peanut cultivation method particularly includes the steps of cultivation land selection, soil preparation, seed treatment, seeding, membrane rupture and seedling promotion, seedling checking and supplementing, proper intertillage weeding, growth controlling, water management strengthening, harvesting and the like. The organic black peanut cultivation method has the advantages that rural land with no industry and no pollution is selected for planting, pesticides are avoided to be used in seed treatment, pest control and prevention and fertilization, a complete organic cultivation technology is adopted, and black peanuts planted are guaranteed to be pure natural without pollution, are safe in quality and rest assured to eat; since the steps of sufficient basal dressing, plastic film mulching, water management strengthening and the like are adopted, output of the black peanuts in increased by 10%-15%, the grain plumpness reaches 95%, and the organic black peanut cultivation method is simple in process and easy to operate.

Owner:黄振忠

Phagostimulant fermented feed using bean pulp, corn protein powder and bran as protein raw materials and a preparation method thereof

InactiveCN103027184ANatural flavorQuality and safetyAnimal feeding stuffAccessory food factorsBiotechnologyNeutral proteinase

The invention relates to a phagostimulant fermented feed using bean pulp, corn protein powder and bran as protein raw materials and a preparation method thereof. The phagostimulant fermented feed using bean pulp, corn protein powder and bran as protein raw materials is prepared by fermenting the following components in percentage by weight:8-15% of bean pulp, 2-10% of corn protein, 40-60% of bran, 1.0-2.0% of Bacillus subtilis, 1.0-2.0% of Lactobacillus acidophilus, 1.0-2.0% of Enterococcus faecalis, 1.0-2.0% of microzyme, 0.1-0.5% part of brown sugar, 0.02-0.08% of yeast extract, 0.02-0.08% of potassium dihydrogen phosphate, 0.02-0.08% of neutral proteinase, 0.02-0.08% of acid protease and 20-30% of water. The invention has the advantages of environmental protection, healthiness, favorable phagostimulant effect, strong capacity for killing pathogenic bacteria, and favorable therapeutic effect for porcine anorexia.

Owner:浙江德清博诚生物科技有限公司

Method for controlling ethyl carbamate in baijiu by means of lysinibacillus sphaericus

ActiveCN106318893AImprove qualityDecrease EC concentrationBacteriaAlcoholic beverage preparationLysinibacillus sphaericusEthyl ester

The invention discloses a method for controlling ethyl carbamate in baijiu by means of lysinibacillus sphaericus, and belongs to the field of wine brewing and foot safety. The lysinibacillus sphaericus CGMCC NO.13046 with the function of degrading EC and precursor urea thereof is applied to baijiu brewing, the content of EC and the precursor urea thereof in baijiu production can be significantly inhibited, then the content of EC in baijiu is finally decreased, and the method belongs to the technical field of food microbiology. The lysinibacillus sphaericus CGMCC NO.13046 comes from the baijiu brewing process, can resist to high temperature, acid and ethyl alcohol, generates volatile substances such as alcohol and acid simultaneously and can effectively control the content of EC in baijiu, fundamentally control the content of EC in baijiu with different fragrances and improve the quality of baijiu by being applied to baijiu production.

Owner:JIANGNAN UNIV

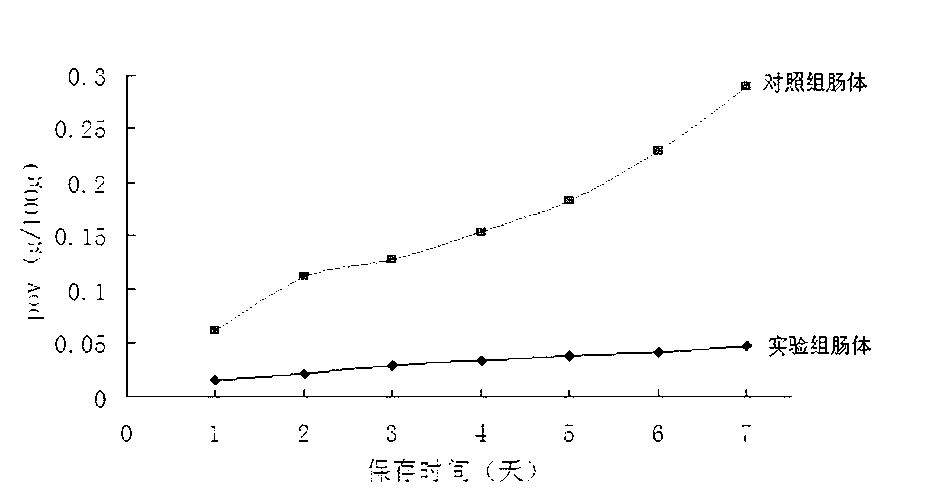

Composite antioxidant for sausage products and preparation method thereof

ActiveCN103211000AReasonable ratioSynergisticMeat/fish preservation using chemicalsFood additiveMaterial type

The invention belongs to the field of food additives, and in particular relates to a composite antioxidant for sausage products and a preparation method thereof. The antioxidant comprises the following materials: a glycyrrhiza antioxidant, sodium phytate, a rosemary extract, D-sodium isoascorbate, tea polyphenols and an emulsifier. The materials are reasonable in proportion, contain various antioxidant compounds, have synergy effect, and are good in antioxidant effect; the shelf-life of sausage products can be prolonged under the precondition of hardly increasing the cost; the composite antioxidant is wide in application range, and is suitable for processing sausage products under the conditions of high temperature and low temperature; the composite antioxidant is simple in formula, convenient to use, high in applicability, simple and convenient to prepare; the quality of material type and using amount is safe and efficient; and the composite antioxidant has an important meaning for solving fat and grease oxidation problem in cooked meat products.

Owner:北京美添阳光科技有限公司

Method for preparing collagen polypeptides by using larimichthys crocea leftovers

ActiveCN103725738AHigh nutritional valueIncrease health functionMicroorganism based processesFermentationAmmoniaLarimichthys crocea

The invention discloses a method for preparing collagen polypeptides by using larimichthys crocea leftovers. The larimichthys crocea leftovers are fermented by condensed bacillus to obtain collagen polypeptide fermented substances, and the molecular weight of a product is 1,000-3,000 daltons; the larimichthys crocea leftovers comprise fish scales, fish skins and viscera mixtures; the preservation number of the condensed bacillus is CCTCC No:M2013193. According to the method, main nutritional substances produced by fermenting the larimichthys crocea leftovers by the condensed bacillus are free calcium and the collagen polypeptides; acidic products and the calcium which are produced in a fermenting process can be converted into soluble calcium; furthermore, extracellaluar proteases can be used for hydrolyzing proteins in the larimichthys crocea leftovers to supply the collagen polypeptides, ammonia acid, phosphorus and the like which assist in calcium absorption.

Owner:浙江东杰生物科技有限公司

Micro-ecological compound microbial agent and method for processing solid crop culture medium through micro-ecological compound microbial agent

ActiveCN105199963ADoes not affect growth and developmentAbsolute reductionFungiBacteriaDiseaseContinuous cropping

The invention belongs to the technical field of microbial fermentation, and provides a micro-ecological compound microbial agent and a method for processing a solid crop culture medium through the micro-ecological compound microbial agent for solving the problems that an existing culture medium cannot be reused, and if the culture medium is reused, continuous cropping obstacles are prone to being caused, and the culture medium becomes a carrier of soil-borne disease pollution and concentrated spread. The micro-ecological compound microbial agent is prepared by mixing bacillus amyloliquefaciens LH-1, bacillus licheniformis, pseudomonas cichorii, propionigenium modestum, thermotoga aritime, bacillus stearothermophilus, candida tropicalis, trichoderma harzianum, streptomycete, actinomyces meyeri and frankiaceae according to a certain ratio. According to the micro-ecological compound microbial agent and the method for processing the solid crop culture medium through the micro-ecological compound microbial agent, pathogenic bacteria can be effectively killed, and the continuous cropping obstacles are overcome; the mode that biological and physical measures are combined is scientifically applied to solve the problems existing in reuse of the matrix, the fruit and vegetable quality safety and zero pollution to the environment are guaranteed, the production cost of farmers is lowered, the agricultural product quality safety is guaranteed, and the ecological environment is protected; the culture medium can be reused for many times, and the growth and development of crops cannot be influenced.

Owner:AGRI BIOTECH RES CENT OF SHANXI PROVINCE

Phagostimulant fermented feed using corn protein powder and bran as protein raw materials and preparation method thereof

InactiveCN103027185ANatural flavorGood treatment effectAnimal feeding stuffAccessory food factorsBiotechnologyNeutral proteinase

The invention relates to a phagostimulant fermented feed using corn protein powder and bran as protein raw materials and a preparation method thereof. The phagostimulant fermented feed using corn protein powder and bran as protein raw materials is prepared by fermenting the following components in percentage by weight: 20-40% of corn protein powder, 20-40% of bran, 1.0-2.0% of Bacillus subtilis, 1.0-2.0% of Lactobacillus acidophilus, 1.0-2.0% of Enterococcus faecalis, 1.0-2.0% of microzyme, 0.1-0.5% of brown sugar, 0.02-0.08% of yeast extract, 0.02-0.08% of potassium dihydrogen phosphate, 0.02-0.08% of neutral proteinase, 0.02-0.08% of acid protease and 20-40% of water. The invention has the advantages of no toxicity, no harm, environmental protection, healthiness, favorable phagostimulant effect, and strong capacity for killing pathogenic bacteria, and thus, has favorable therapeutic effects on porcine anorexia.

Owner:浙江德清博诚生物科技有限公司

Rock wall cultivation method for Dendrobium officinale

InactiveCN106035025AImprove securityGuarantee quality and safetyCultivating equipmentsSoilless cultivationRoot systemMetaldehyde

The invention discloses a rock wall cultivation method for Dendrobium officinale. The rock wall cultivation method includes the following steps: (1) rock wall selection and preparation: selecting a rock wall having an appropriate slope, and using a tool to dig holes in a surface of the rock wall, wherein the depth of the holes is 4-6 cm, the diameter of the holes is 4-6 cm, and the distance between two holes is 8-12 cm; (2) rock wall disinfection, spraying the rock wall with Metaldehyde wettable powder to kill snails; (3) specie source selection, selecting plants which has been domesticated for 2 years, have well developed root systems, and have no pest and diseases as specie strains; and (4) planting and cultivation.

Owner:YUEQING DONGYA DENDROBIUM DEV +1

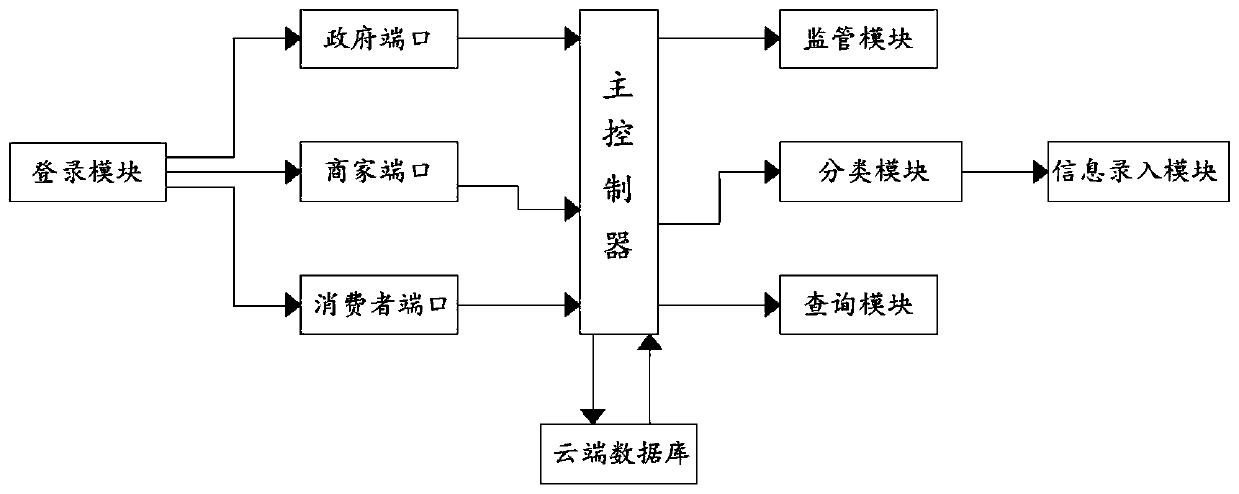

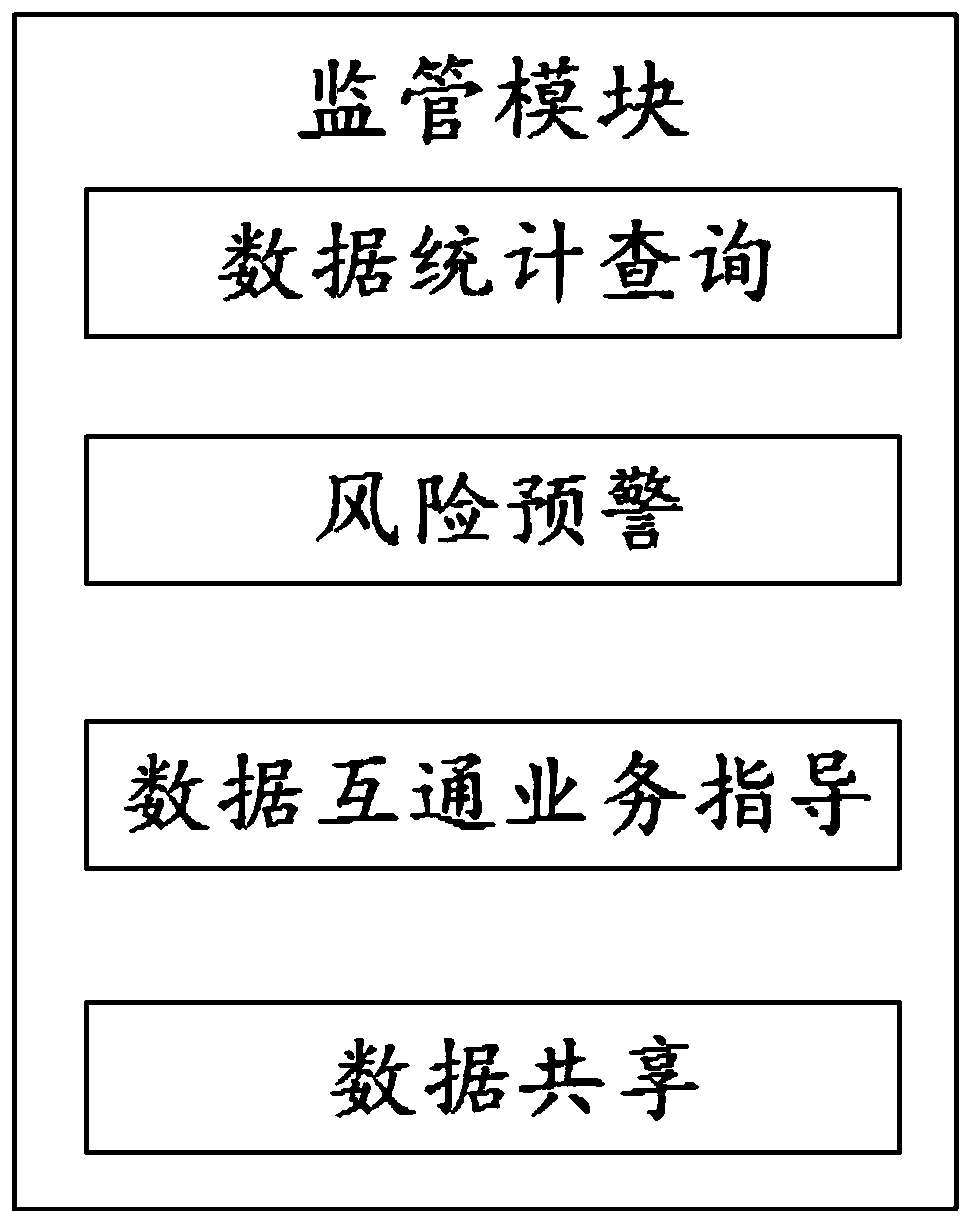

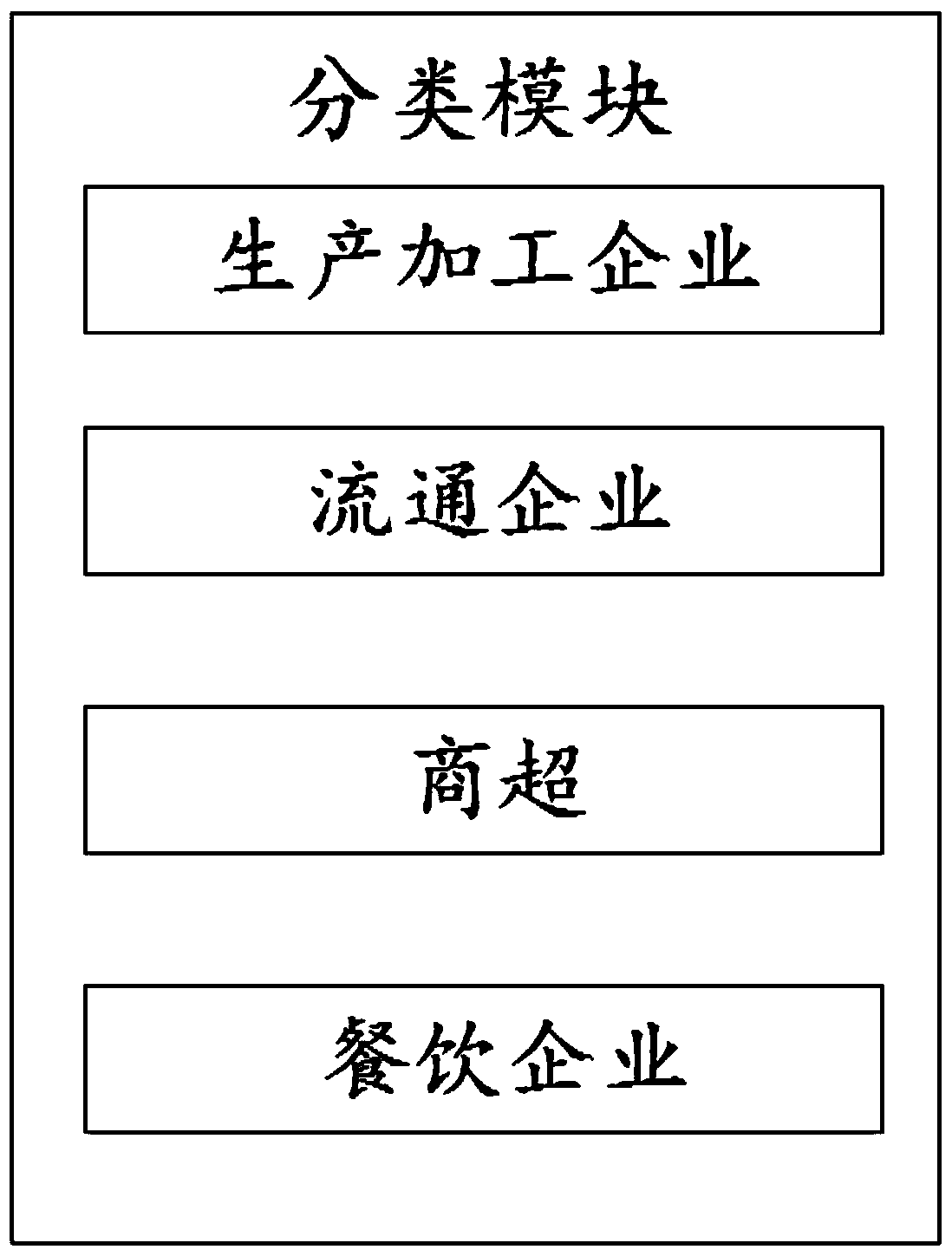

White spirit tracing and quality safety protection system based on social co-governance

PendingCN111325471AEffective and healthy developmentRealize data sharingCo-operative working arrangementsResourcesBusiness enterpriseData profiling

The invention relates to the technical field of white spirit production safety protection management, and discloses a white spirit tracing and quality safety protection system based on social co-governance, which comprises a login module, the output end of the login module is electrically connected with the input end of a government port, the output end of the government port is electrically connected with the input end of a main controller, and the output end of the login module is electrically connected with the input end of a merchant port. The invention discloses a white spirit tracing andquality safety protection system based on social co-governance. A supervision module is arranged and comprises a data statistics query module, a risk early warning module, a data intercommunication service guidance module and a data sharing module. A government can sort out source data and analyze corresponding results, products can be recalled and dispatched and commanded when a quality safety problem occurs, white spirit quality safety and long-term effective and healthy development of the industry are guaranteed, meanwhile, data sharing can provide data such as enterprises, products and detection for the outside, and data exchange and service sharing with a provincial market supervision bureau are achieved.

Owner:GUIZHOU ACADEMY OF TESTING & ANALYSIS +1

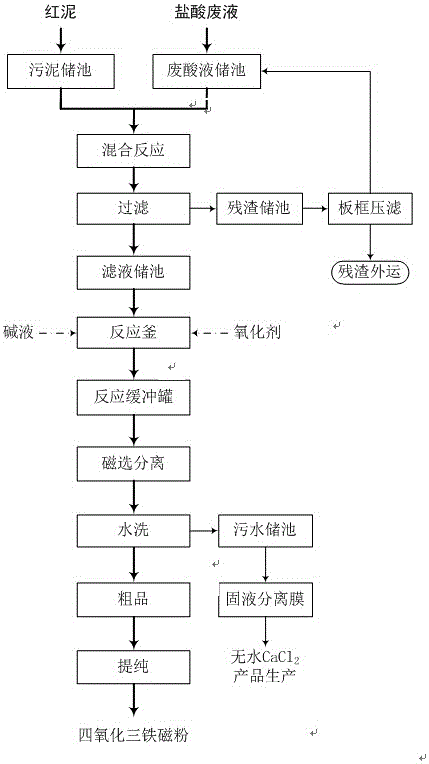

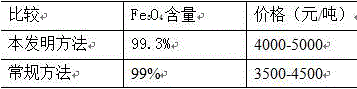

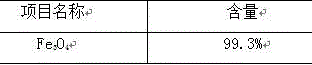

Method for producing ferroferric oxide magnetic powder by recycling industrial waste acid and red mud

The invention discloses a method for producing ferroferric oxide magnetic powder by recycling industrial waste acid and red mud. The method comprises the steps of: mixing hydrochloric acid waste liquid with the red mud according to a ratio of (3-5):1; lifting a mixed solution of an initial reaction to a mixed solution filter through a pump, wherein a filtrate flows into a filtrate storage tank, filter residues are subjected to pressure filtration reduction through a plate-and-frame filter press, then the treated filter residues are transported outwards for disposal, and a plate-and-frame pressure filtration solution is returned back into a waste acid solution storage tank for recycling; lifting a mixed suspension after filtration into a reaction kettle by a pump, heating the reaction kettle to 80-90 DEG C, adding an oxidant and an alkaline solution into the mixed solution at the same time, wherein a stirring system is arranged in the reaction kettle to ensure uniformity and high efficiency of the reaction, and allowing the mixed solution to react in the reaction kettle to generate hydrous ferroferric oxide magnetic powder; performing magnetic separation on wet ferroferric oxide, and performing water washing to obtain a ferroferric oxide magnetic powder crude product, and drying the crude product and purifying the dried crude product to form high-purity ferroferric oxide magnetic powder. The method disclosed by the invention reduces the treatment cost for hazardous wastes and waste acid liquid, and the obtained product is stable in quality and performance and is safe. An environmental and economic benefit win-win effect is achieved.

Owner:天津市国润永泰环保科技有限公司

Chicken feed added with orange peel

InactiveCN101984847AReduce feed costsFast growthFood processingAnimal feeding stuffChemistryAntioxidant

The invention discloses a chicken feed added with orange peel, which comprises the following components in percentage by weight: 60 to 72 percent of corn, 7 to 23 percent of bean pulp, 4 to 5 percent of rice protein powder, 5 to 8 percent of wheat, 1.5 to 3 percent of rapeseed meal, 0.5 to 2.5 percent of oil, 2 to 3 percent of orange peel and 1.5 to 4.5 percent of meat meal. The chicken feed has the advantages that: 1, after the orange peel is added into the feed, artificially synthesized flavoring agent, pigment, mildewproof agent and antioxidant are not needed to be added, so the toxic and side effects of the chemically synthesized antioxidant and mildewproof agent are eliminated, the feed and the chicken meat are environment-friendly and safe, and the feed cost is further reduced; and 2, after the novel feed is used, the growth speed of the chicken is high, the feed / meat ratio is reduced, and the feeding gain is improved.

Owner:HUNAN XIANGJIA ANIMAL HUSBANDRY CO LTD

Produce packaging system and method of use

InactiveUS20060263492A1Reduce riskMinimize damageFruit and vegetables preservationPackagingEngineering

Owner:PHASELOCD

Cartridge for an electronic vapour inhaler

ActiveUS10856575B2Reduce the possibilityIntegrity safetyTobacco treatmentTobacco pipesInhalation DevicesMechanical engineering

Owner:JT INT SA

Method for fermenting aquatic product leftovers by mixed culture bacteria

InactiveCN104591808APromote growthSolve pollutionAnimal corpse fertilisersNitrogenous fertilisersBiotechnologyMixed culture

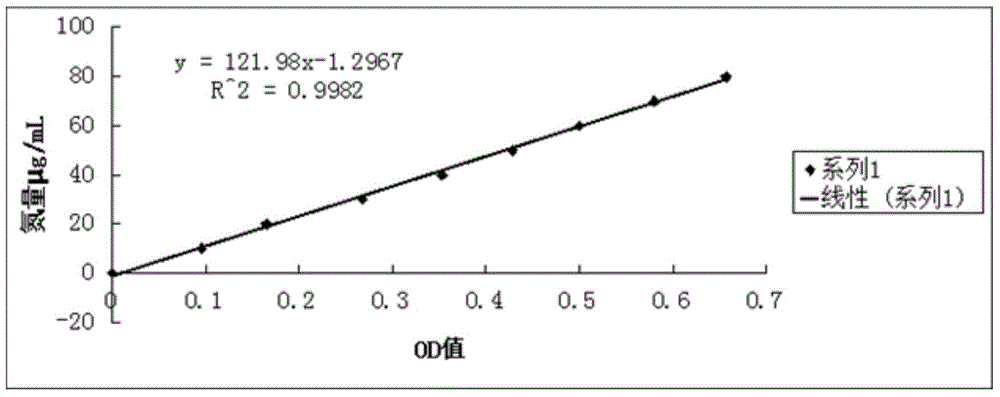

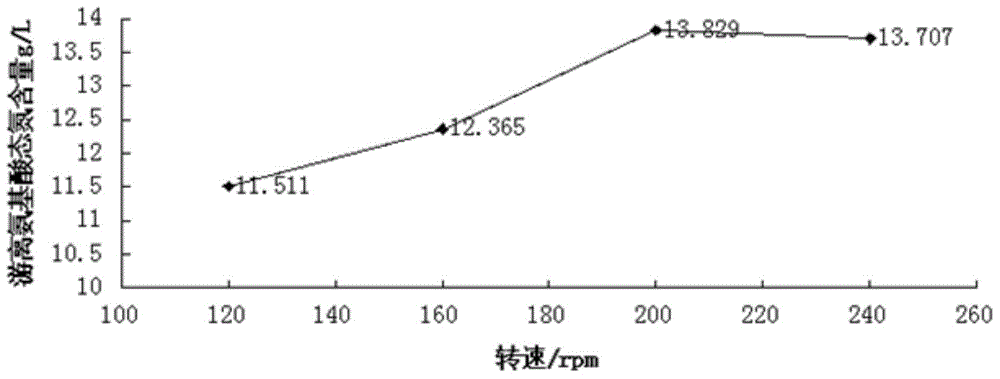

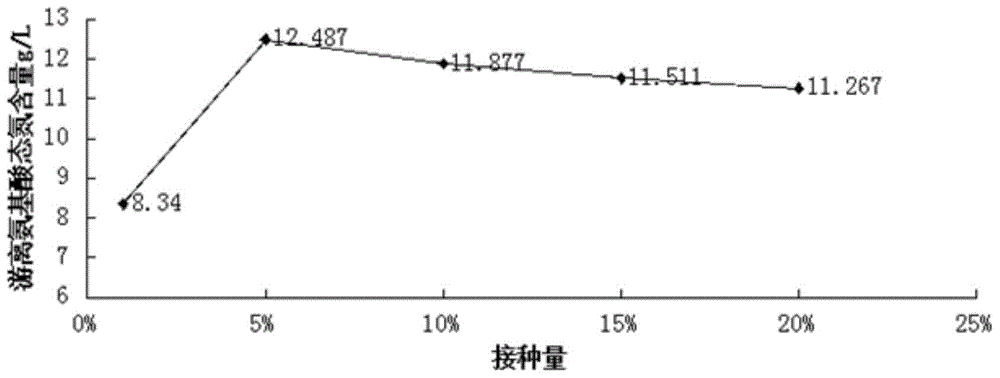

The invention discloses a method for fermenting aquatic product leftovers by mixed culture bacteria. The method is characterized by comprising the following step: fermenting the aquatic product leftovers by a combined bacterial strain, wherein the process parameters are as follows: rotation speed of 203 rpm, an inoculum size of 5% and a temperature of 30 DEG C. Under the condition, the content of nitrogen in free amino acid of the fermented liquor is up to 13.865g / L which is increased by 12.13% in comparison with the content (12.365g / L) before optimization, so that the water-soluble amino acid fertilization standards are met. The method is also suitable for preparing a microbial fertilizer.

Owner:ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com