Method for producing ferroferric oxide magnetic powder by recycling industrial waste acid and red mud

A technology of ferromagnetic tetroxide and industrial waste acid, applied in the directions of iron oxide/iron hydroxide, ferrous oxide, etc., can solve the problems of secondary pollution of waste acid and red mud, etc., to achieve environmental and economic The effect of win-win benefits, low technical level of workers, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

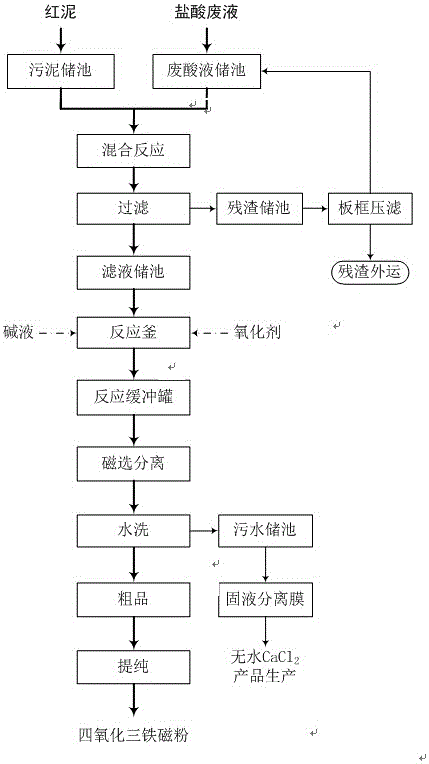

[0033] (1) Mixed reaction: pre-neutralize the hydrochloric acid waste liquid and the red mud raw material according to the mass ratio of 3:1;

[0034] (2) Filtration: The mixed liquid of the preliminary reaction is lifted to the mixed liquid filter by the pump, and the filtrate enters the reactor of the next process, and the filtered residue flows into the filter residue storage tank;

[0035] (3) Reactor: The filtered mixed suspension is lifted into the reactor by a pump, and the reactor is heated to 80°C. At the same time, an oxidant and an alkali solution as a precipitant are added to the mixed solution, and a stirring system is installed in the reactor to ensure The reaction is uniform and efficient, the pH value of the filtrate reaches 9, and the reaction time is more than 2 hours; the alkaline solution is calcium hydroxide, and the oxidant is hydrogen peroxide, wherein the amount of hydrogen peroxide is based on the mass ratio of total iron: hydrogen peroxide = 1:25 dosi...

Embodiment 2

[0039] (1) Mixed reaction: pre-neutralize the hydrochloric acid waste liquid and the red mud raw material according to the mass ratio of 5:1;

[0040] (2) Filtration: The mixed liquid of the preliminary reaction is lifted to the mixed liquid filter by the pump, and the filtrate enters the reactor of the next process, and the filtered residue flows into the filter residue storage tank;

[0041] (3) Reactor: The filtered mixed suspension is lifted into the reactor by a pump, and the reactor is heated to 90°C. At the same time, an oxidant and an alkali solution as a precipitating agent are added to the mixed solution, and a stirring system is installed in the reactor to ensure The reaction is uniform and efficient, the pH value of the filtrate reaches 11, and the reaction time is 4 hours; the alkaline solution is calcium hydroxide, and the oxidant is hydrogen peroxide; the amount of hydrogen peroxide is based on the mass ratio of total iron: hydrogen peroxide=1 :90 dosing;

[00...

Embodiment 3

[0045] Select the red mud from iron and steel industry to produce and the hydrochloric acid waste liquid recycling example that produces in mechanical processing, in conjunction with accompanying drawing, the implementation process of the present invention is described in detail:

[0046] The hydrochloric acid waste liquid is lifted by the pump and mixed with the red mud. The hydrochloric acid waste liquid and the red mud undergo a preliminary neutralization reaction. The mixing ratio of the hydrochloric acid waste liquid and the red mud is 3:1 (mass ratio). The pump is lifted to the mixed liquid filter for filtration, and the filtrate flows into the filtrate storage tank. The filter residue is filtered and reduced by the plate and frame filter press and then transported out for disposal. The filtrate produced during the plate and frame filter press process is returned to the waste acid liquid storage tank. After filtering, the reaction solution is pumped into the reactor, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com